Structural Optimization and Airflow Uniformity Evaluation of Bag Filter Based on Different Diversion Schemes

Abstract

Featured Application

Abstract

1. Introduction

2. Method and Materials

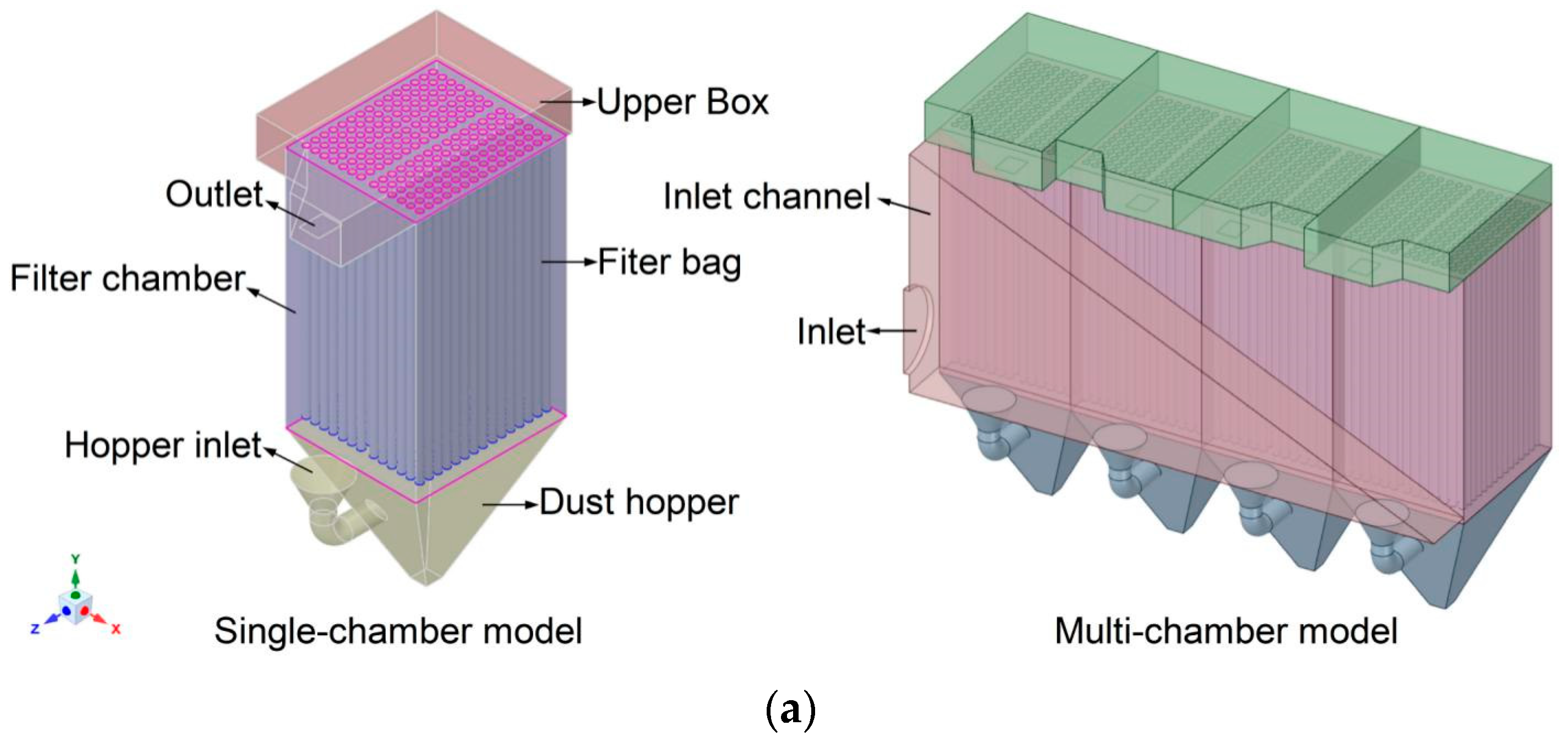

2.1. Case Study and Modelling

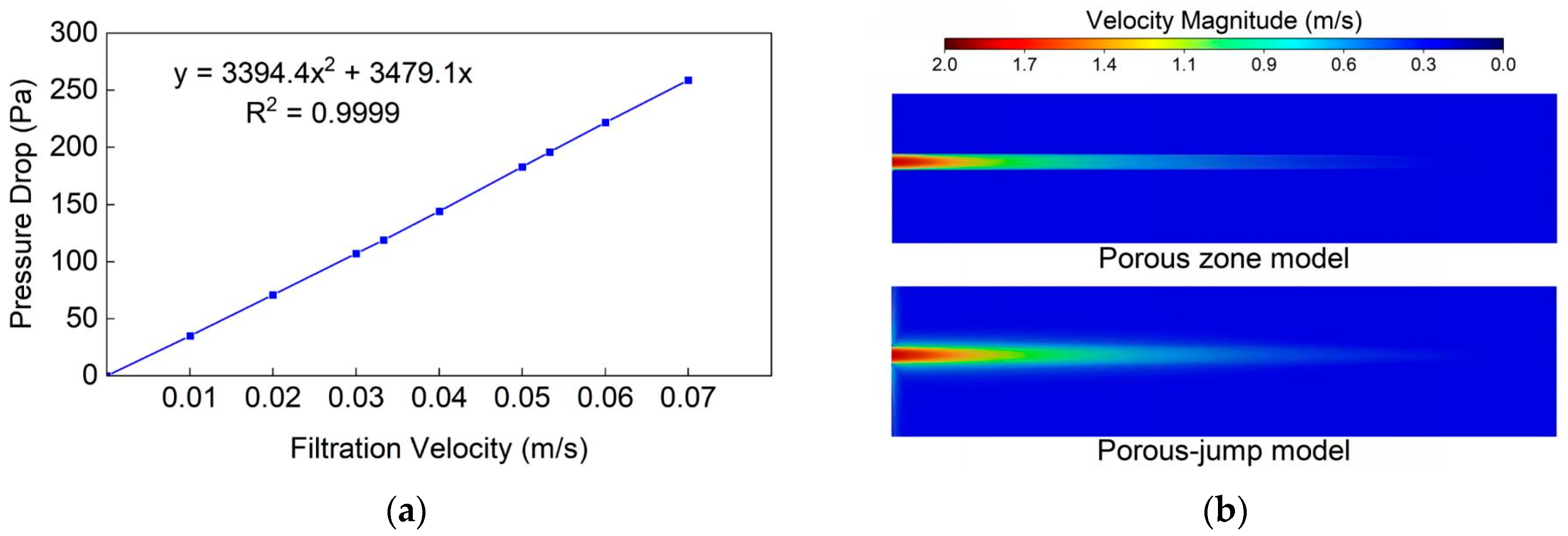

2.2. Establishment of the Numerical Simulation Models

2.2.1. Mathematical Models

2.2.2. Boundary Conditions and Solution Setup

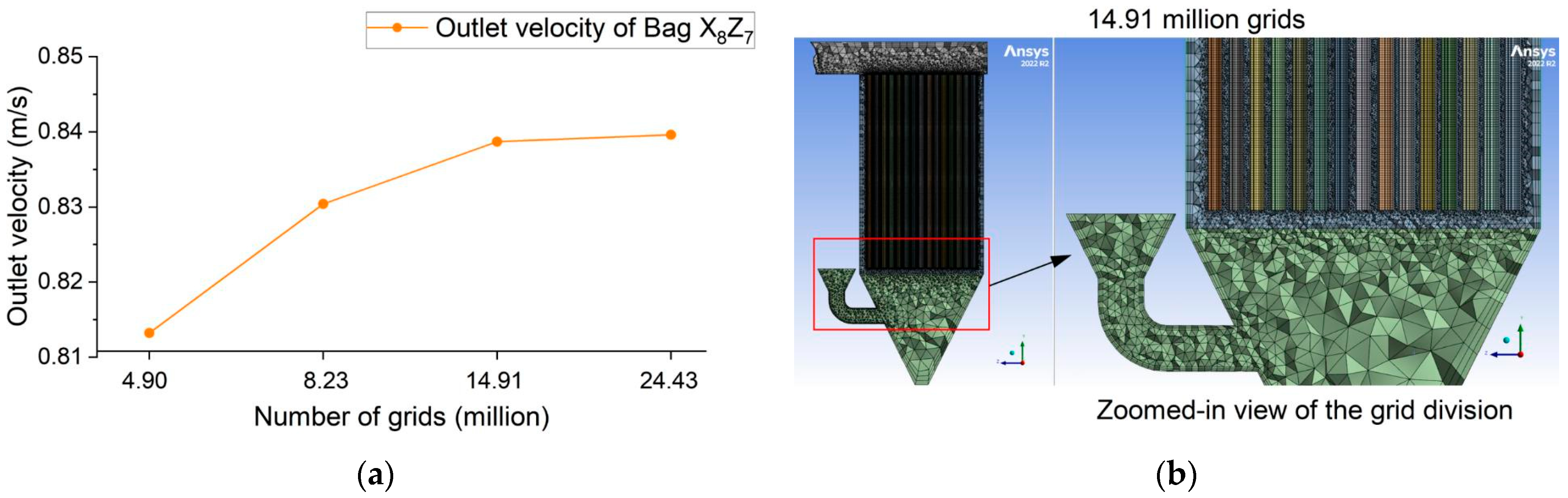

2.2.3. Meshing and Grid Validation

2.3. Evaluation Indices

- Flow distribution coefficient

- 2.

- Integrated flow uneven amplitude

- 3.

- Relative root mean square values (RMS)

- 4.

- Relative standard deviation

2.4. Experimental Verification of the Model

3. Results and Discussion

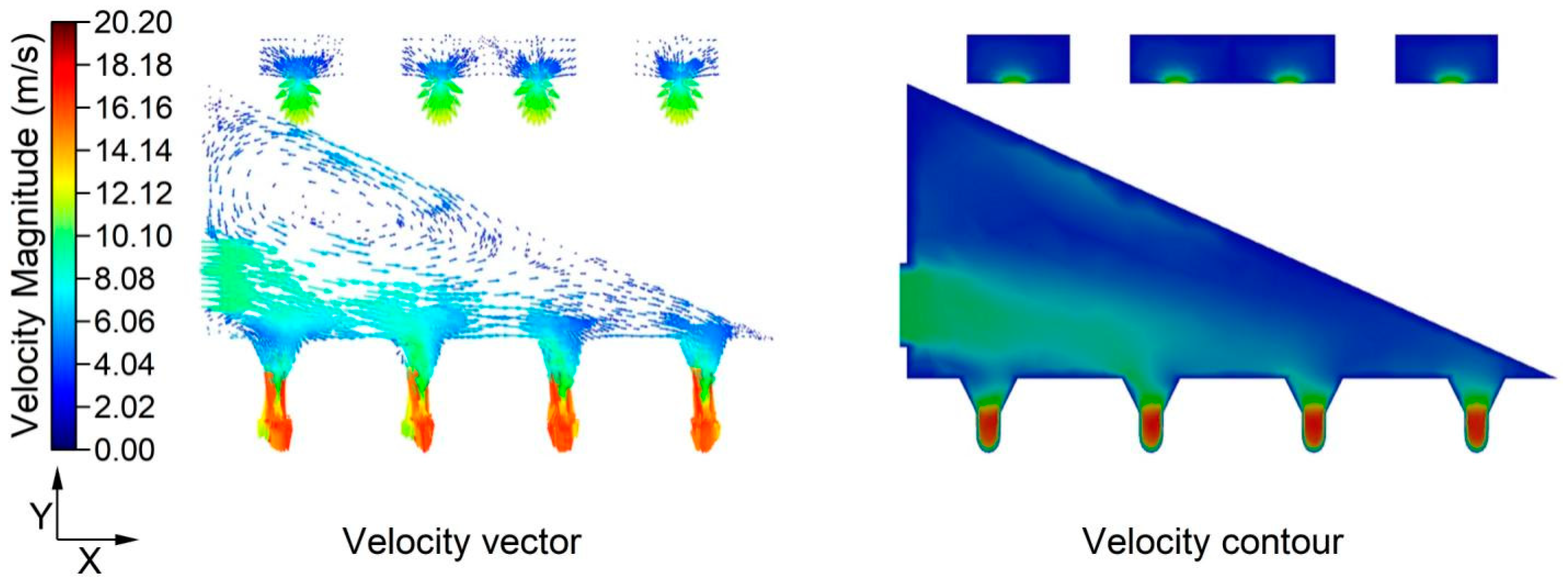

3.1. Flow Field Analysis for Multi-Chamber Model

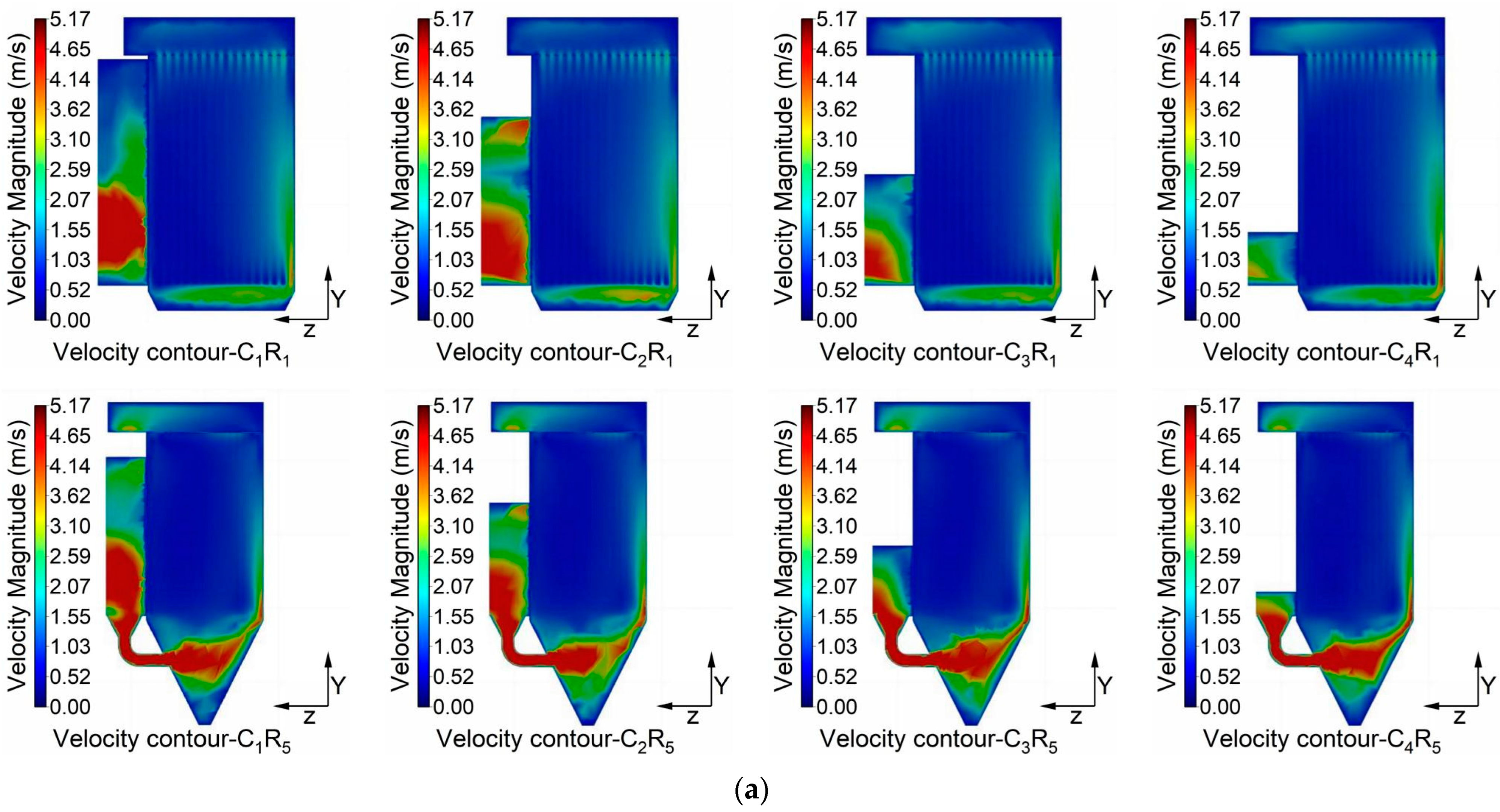

3.1.1. Overall Flow Field Distribution

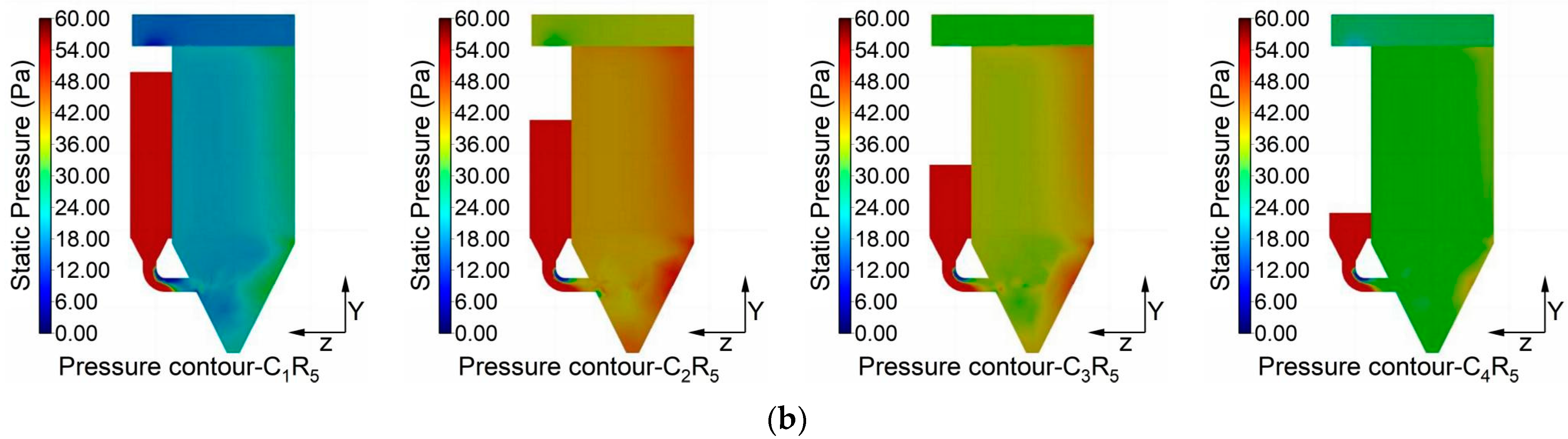

3.1.2. Filtration Flow Distribution of Filter Bags

3.2. Optimization Design of the Bag Filter

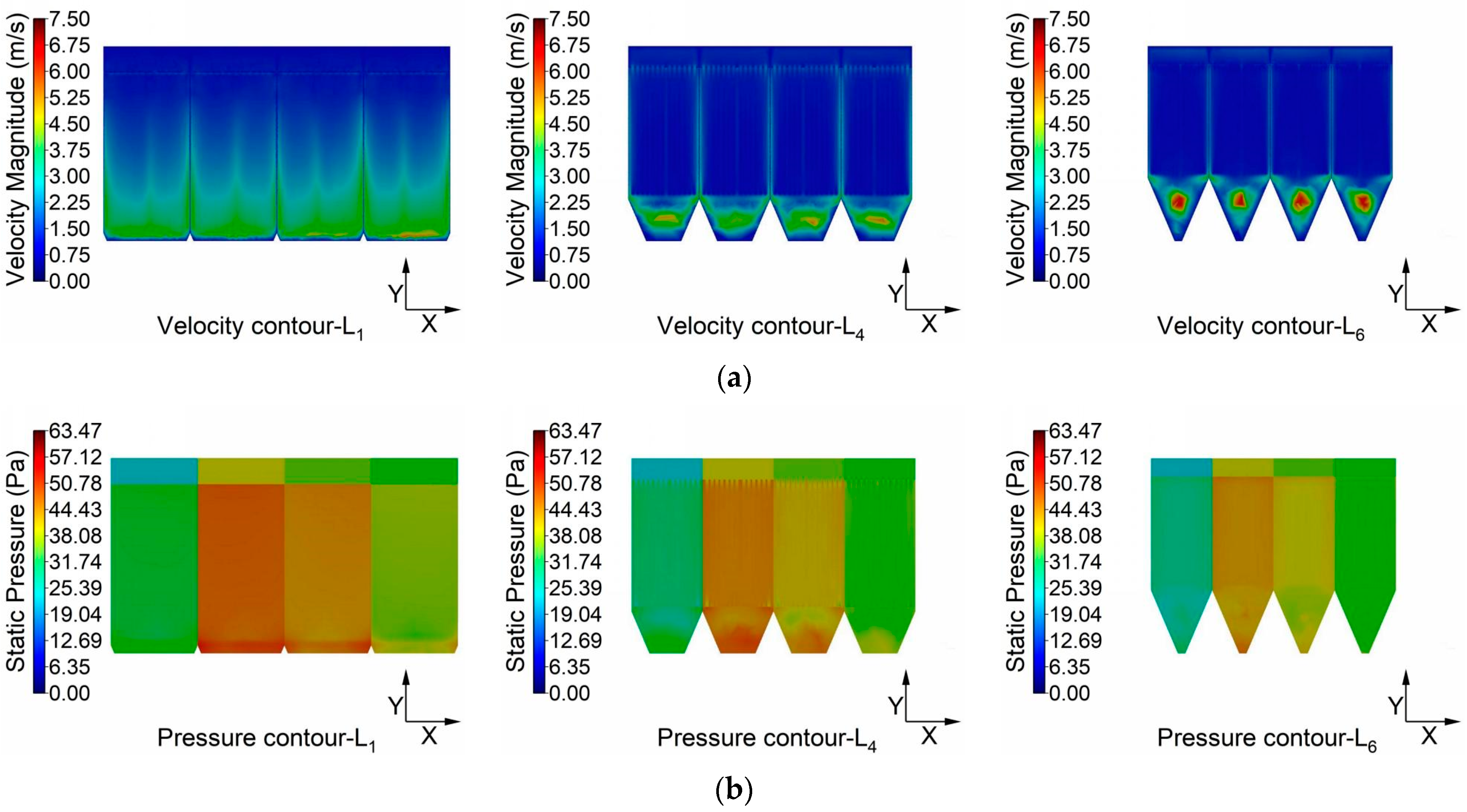

3.2.1. Structural Optimization Design

3.2.2. Validation Based on Scaled-Down Simplified Models

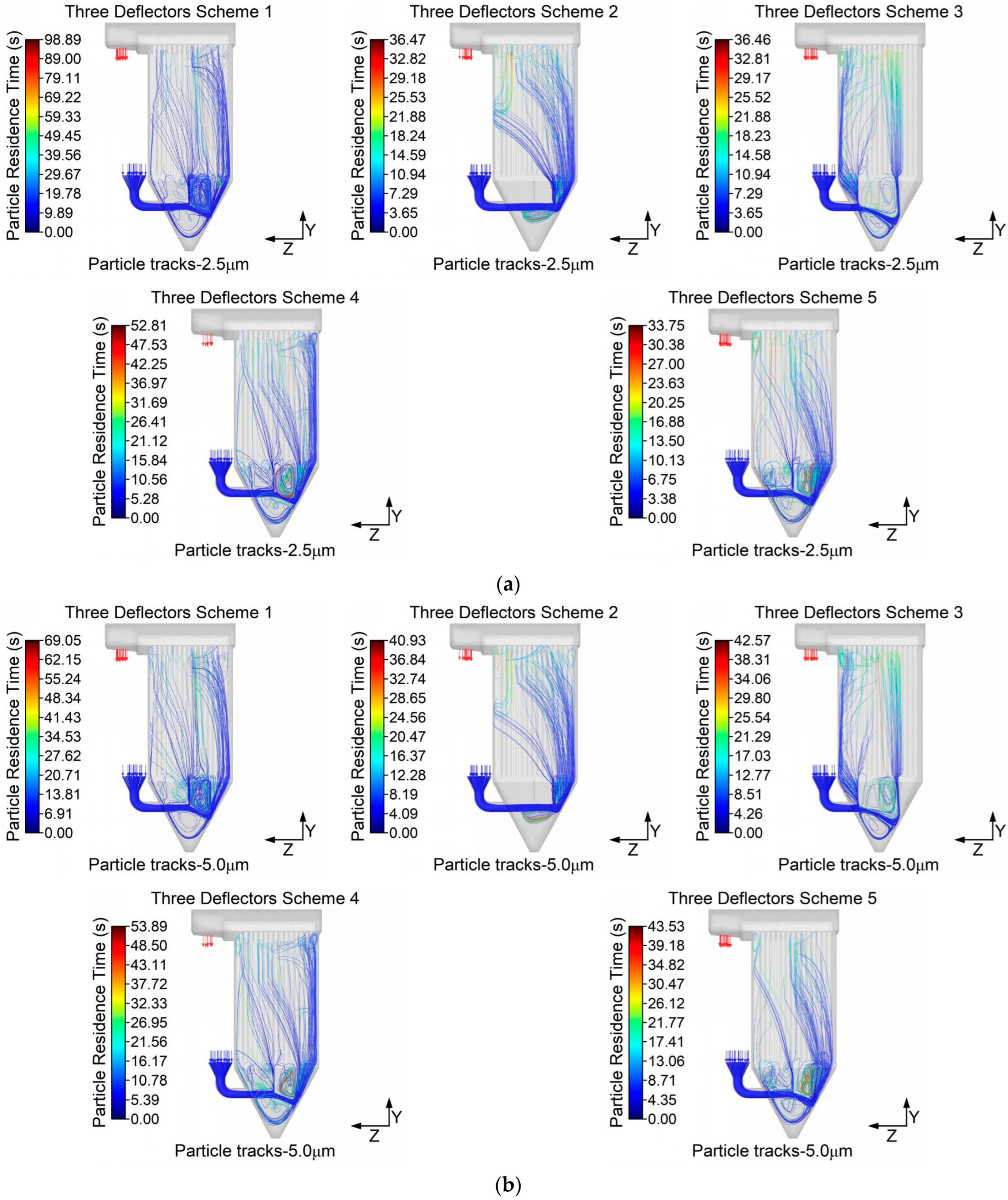

3.2.3. Comparative Analysis of Full-Scale Optimization Models

4. Conclusions

- Although there are numerical differences in airflow velocity and pressure across the chambers of the bag filter, they all share similar distribution characteristics. Uneven airflow distribution, primarily caused by high-velocity inlet airflow colliding with the hopper walls, leads to higher velocities near the bag bottom and sidewalls. This results in inconsistent airflow handling by the filter bags, varying levels of dust scouring due to vortex formation, and significant differences in wear and filter bag lifespan.

- The addition of deflectors enhances airflow organization by guiding dust-laden air to collide with the deflectors, causing coarse particles to settle more efficiently and reducing excessive velocity, ensuring a more uniform flow into the filtration area. However, potential negative effects, such as increased abrasion and particle adhesion, should be addressed. Future research should focus on deeper investigation into the interactions between particles and deflectors to better understand their impact on filter performance.

- Three Deflectors Scheme 4 demonstrates relatively superior optimization, achieving improvements of 40.3% in ∆Kqi, 47.4% in ∆, 51.8% in RMS σ, and 51.6% in Cv compared to the original model. It also reduced pressure drops by 11.2%, leading to lower energy consumption. This design minimizes channeling, resulting in more uniform airflow and significantly enhanced filtration efficiency. Furthermore, it effectively guides particle movement within the filter chamber, ensuring overall improved system performance.

- The optimization measures have currently only been applied to the single-chamber model, and the results are valid for relatively low levels of fine particulate air pollution. Future research will focus on applying these measures to multi-chamber models and generalizing the results for industrial applications. Additionally, this study derives an optimal condition within a limited range of design structures. More deflector sizes and combinations will be explored, and more accurate experimental validation based on full-scale models will be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ottaviano, G.; Pendolino, A.L.; Marioni, G.; Crivellaro, M.A.; Scarpa, B.; Nardello, E.; Pavone, C.; Trimarchi, M.V.; Alexandre, E.; Genovois, C.; et al. The Impact of Air Pollution and Aeroallergens Levels on Upper Airway Acute Diseases at Urban Scale. Int. J. Environ. Res. 2022, 16, 42. [Google Scholar] [CrossRef]

- Huang, W.; Fang, J.; Song, X.; Xu, H.; Wu, R.; Song, J.; Xie, Y.; Xu, X.; Zeng, Y.; Wang, T. Associations of ultrafine and fine particles with childhood emergency room visits for respiratory diseases in a megacity. Thorax 2022, 77, 391–397. [Google Scholar]

- Di, Q.; Dai, L.; Wang, Y.; Zanobetti, A.; Choirat, C.; Schwartz, J.D.; Dominici, F. Association of Short-term Exposure to Air Pollution with Mortality in Older Adults. JAMA J. Am. Med. Assoc. 2017, 318, 2446. [Google Scholar] [CrossRef]

- Richard, L. Filter media surface modification technology: State of the art. Filtr. Sep. 2004, 41, 20–21. [Google Scholar] [CrossRef]

- Deuschle, T.; Janoske, U.; Piesche, M. A CFD-model describing filtration, regeneration and deposit rearrangement effects in gas filter systems. Chem. Eng. J. 2008, 135, 49–55. [Google Scholar] [CrossRef]

- Liu, M.; Li, Y.; Xu, Y.; Chen, L.; Wang, Q.; Ma, Q.; Yuan, X. A multi-criteria group decision making framework for sustainability evaluation of sintering flue gas treatment technologies in the iron and steel industry. J. Clean. Prod. 2023, 389, 136048. [Google Scholar] [CrossRef]

- Zheng, C.; Kanaoka, C. Recent advances in dust collection technology and ISO standardization in bag filtration. J. Zhejiang Univ.-Sci. A 2018, 19, 21–33. [Google Scholar] [CrossRef]

- Wen, Z.; Di, J.; Liu, S.; Han, J.; Lee, J.C.K. Evaluation of flue-gas treatment technologies for municipal waste incineration: A case study in Changzhou, China. J. Clean. Prod. 2018, 184, 912–920. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, D.; Hu, A.J.; Xu, H.L.; Chen, H.Y. Flow field and pressure characteristics in pulse-jet dust cleaning. Int. J. Environ. Sci. Technol. 2023, 20, 6735–6746. [Google Scholar] [CrossRef]

- Ji, Z.; Shi, M.; Ding, F. Transient flow analysis of pulse-jet generating system in ceramic filter. Powder Technol. 2004, 139, 200–207. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Zhou, F. Effect of cone installation in a pleated filter cartridge during pulse-jet cleaning. Powder Technol. 2015, 284, 245–252. [Google Scholar] [CrossRef]

- Aroussi, A.; Simmons, K.; Pickering, S.J. Particulate deposition on candle filters. Fuel 2001, 80, 335–343. [Google Scholar] [CrossRef]

- Huachang, C.; Liang, Y.; Joo-Hong, C. Optimization of Nozzle Design for Pulse Cleaning of Ceramic Filter. Chin. J. Chem. Eng. 2008, 16, 306–313. [Google Scholar]

- Shim, J.; Joe, Y.; Park, H. Influence of air injection nozzles on filter cleaning performance of pulse-jet bag filter. Powder Technol. 2017, 322, 250–257. [Google Scholar] [CrossRef]

- Qian, Y.; Bi, Y.; Zhang, Q.; Chen, H. The optimized relationship between jet distance and nozzle diameter of a pulse-jet cartridge filter. Powder Technol. 2014, 266, 191–195. [Google Scholar] [CrossRef]

- Chen, J.; Wang, B.; Yuan, K.; Kang, Y.; Feng, S.; Han, F.; Wu, H.; Zhou, R.; Zhong, Z.; Fan, Y. One-pot in situ synthesis of Cu-SAPO-34/SiC catalytic membrane with enhanced binding strength and chemical resistance for combined removal of NO and dust. Chem. Eng. J. 2021, 420, 130425. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, Y.; Luo, X.; Wang, W.; Huang, J.; Lai, Y.; Wang, Y.; Zhang, Y.; Cai, W. Integration of dedusting and denitration in V2O5-WO3/TiO2/PTFE-based catalytic bag-filter materials: Lab- and pilot-scale testing and development of SCR models. J. Clean. Prod. 2023, 407, 137122. [Google Scholar] [CrossRef]

- Gao, D.; Zhou, G.; Liu, R.; Li, S.; Kong, Y.; Wang, Y. CFD investigation on gas–solid two-phase flow of dust removal characteristics for cartridge filter: A case study. Environ. Sci. Pollut. Res. 2021, 28, 13243–13263. [Google Scholar] [CrossRef]

- Li, W.; Shen, S.; Li, H. Study and optimization of the filtration performance of multi-fiber filter. Adv. Powder Technol. Int. J. Soc. Powder Technol. Jpn. 2016, 27, 638–645. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, H.; Wang, K.; He, Y.; Zheng, C. Simulation of filtration process for multi-fiber filter using the Lattice-Boltzmann two-phase flow model. J. Aerosol Sci. 2013, 66, 164–178. [Google Scholar] [CrossRef]

- Qian, F.; Huang, N.; Zhu, X.; Lu, J. Numerical study of the gas–solid flow characteristic of fibrous media based on SEM using CFD–DEM. Powder Technol. 2013, 249, 63–70. [Google Scholar] [CrossRef]

- Subrenat, A.; Bellettre, J.; Cloirec, P.L. 3-D numerical simulations of flows in a cylindrical pleated filter packed with activated carbon cloth. Chem. Eng. Sci. 2003, 58, 4965–4973. [Google Scholar] [CrossRef]

- Yu, X.G.; Chen, J. Research on Removal Equipment for Industrial Dust Emissions with the Finite Element Method for the Manner of Filter Board and Filter Bag Layout. Appl. Mech. Mater. 2013, 345, 576–580. [Google Scholar] [CrossRef]

- Fu, H.M.; Zhao, Y.J. Experimental Study on Flow Field Characteristic of Bag Filter. Adv. Mater. Res. 2012, 508, 254–258. [Google Scholar] [CrossRef]

- Lo, L.; Hu, S.; Chen, D.; Pui, D.Y.H. Numerical study of pleated fabric cartridges during pulse-jet cleaning. Powder Technol. 2010, 198, 75–81. [Google Scholar] [CrossRef]

- Long, Z.; Yao, Q. Numerical simulation of the flow and the collection mechanism inside a scale hybrid particulate collector. Powder Technol. 2012, 215, 26–37. [Google Scholar] [CrossRef]

- Baléo, J.L.; Subrenat, A.; Cloirec, P.L. Numerical simulation of flows in air treatment devices using activated carbon cloths filters. Chem. Eng. Sci. 2000, 55, 1807–1816. [Google Scholar] [CrossRef]

- Kaya, F.; Karagoz, I. Numerical investigation of performance characteristics of a cyclone prolonged with a dipleg. Chem. Eng. J. 2009, 151, 39–45. [Google Scholar] [CrossRef]

- Lee, K.; Sohn, J.; Park, Y. Filtration performance characteristics of ceramic candle filter based on inlet structure of high-temperature and high-pressure dust collectors. J. Ind. Eng. Chem. 2015, 21, 101–110. [Google Scholar] [CrossRef]

- Pereira, T.W.C.; Marques, F.B.; Pereira, F.D.A.R.; Ribeiro, D.D.C.; Rocha, S.M.S. The influence of the fabric filter layout of in a flow mass filtrate. J. Clean. Prod. 2016, 111, 117–124. [Google Scholar] [CrossRef]

- Qianpu, W.; Melaaen, M.C.; Silva, S.R.D. A Computational and Experimental Study of Fluid Flow in a De-duster. Model. Identif. Control. 2002, 23, 53–64. [Google Scholar]

- Zhang, F.; Ding, Y.; Low, Z.; Jia, L.; Zhou, G.; Liu, Y.; Zhong, Z.; Xing, W. Effects of flow distributor structures and particle-wall interaction on baghouse gas-solid flow. Sep. Purif. Technol. 2024, 335, 126140. [Google Scholar] [CrossRef]

- Lima, W.F.; Huebner, R. Optimization of Air Distribution in a Baghouse Filter Using Computational Fluid Dynamics. Eng. Technol. Appl. Sci. Res. 2019, 9, 4452–4456. [Google Scholar] [CrossRef]

- Chen, C.; Cheng, M. Effect of flow distributors on uniformity of velocity profile in a baghouse. J. Air Waste Manag. Assoc. 2005, 55, 886–892. [Google Scholar] [CrossRef]

- Chen, C.J. Reducing pressure drop in a baghouse using flow distributors. J. Air Waste Manage. Assoc. 2001, 51, 1471–1475. [Google Scholar] [CrossRef]

- Ansys, Inc. Ansys Fluent User’s Guide, Release 14.0; Ansys, Inc.: Canonsburg, PA, USA, 2011; pp. 260–355. [Google Scholar]

- Park, S.; Joe, Y.H.; Shim, J.; Park, H.; Shin, W.G. Non-uniform filtration velocity of process gas passing through a long bag filter. J. Hazard. Mater. 2019, 365, 440–447. [Google Scholar] [CrossRef]

| Scheme | ∆Kqi | σ | Cv (%) | (m/s) | ||

|---|---|---|---|---|---|---|

| Original model | Simulation | 0.9992 | 0.2169 | 0.2516 | 25.23% | 0.6907 |

| Experiment | 1.1161 | 0.2311 | 0.2701 | 27.08% | 0.6361 | |

| Relative error | 11.70% | 6.56% | 7.33% | 7.33% | 7.89% | |

| Scheme | Length of the Deflectors (mm) | Spacing Between the Deflectors (mm) |

|---|---|---|

| Three Deflectors Scheme 1 | 1054-1304-1554 | 965-965-965-965 |

| Three Deflectors Scheme 2 | 804-1054-1304 | 965-965-965-965 |

| Three Deflectors Scheme 3 | 1304-1554-1804 | 965-965-965-965 |

| Three Deflectors Scheme 4 | 1054-1304-1554 | 905-945-985-1025 |

| Three Deflectors Scheme 5 | 1054-1304-1554 | 1130-800-800-1130 |

| Schemes | σ | Cv (%) | (m/s) | ||

|---|---|---|---|---|---|

| Three Deflectors Scheme 1 | Simulation | 0.1966 | 0.2421 | 24.27 | 0.6902 |

| Experiment | 0.2138 | 0.2558 | 25.6419 | 0.6401 | |

| Relative error | 8.74% | 5.66% | 5.66% | 7.26% | |

| Three Deflectors Scheme 2 | Simulation | 0.1990 | 0.2504 | 25.10 | 0.6907 |

| Experiment | 0.2164 | 0.2633 | 26.4015 | 0.6370 | |

| Relative error | 8.73% | 5.19% | 5.19% | 7.77% | |

| Three Deflectors Scheme 3 | Simulation | 0.1758 | 0.2218 | 22.23 | 0.6906 |

| Experiment | 0.1916 | 0.2309 | 23.1510 | 0.6409 | |

| Relative error | 9.00% | 4.13% | 4.13% | 7.20% | |

| Three Deflectors Scheme 4 | Simulation | 0.1945 | 0.2346 | 23.52 | 0.6907 |

| Experiment | 0.2034 | 0.2471 | 24.7713 | 0.6392 | |

| Relative error | 4.55% | 5.32% | 5.32% | 7.46% | |

| Three Deflectors Scheme 5 | Simulation | 0.1980 | 0.2458 | 24.64 | 0.6905 |

| Experiment | 0.2155 | 0.2579 | 25.8556 | 0.6396 | |

| Relative error | 8.84% | 4.92% | 4.92% | 7.37% | |

| Schemes | ∆Kqi | σ | Cv (%) | ∆P | |

|---|---|---|---|---|---|

| Original Model | 1.181 | 0.190 | 0.253 | 25.334 | 523.67 |

| Three Deflectors Scheme 1 | 0.682 | 0.103 | 0.130 | 13.086 | 535.43 |

| Three Deflectors Scheme 2 | 0.823 | 0.120 | 0.151 | 15.124 | 527.80 |

| Three Deflectors Scheme 3 | 0.526 | 0.097 | 0.119 | 11.882 | 532.31 |

| Three Deflectors Scheme 4 | 0.705 | 0.100 | 0.122 | 12.263 | 465.02 |

| Three Deflectors Scheme 5 | 0.763 | 0.113 | 0.143 | 14.335 | 523.48 |

| Three Deflectors Scheme 6 | 0.564 | 0.110 | 0.132 | 13.244 | 533.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Ma, S.; Wang, Y.; Ma, H. Structural Optimization and Airflow Uniformity Evaluation of Bag Filter Based on Different Diversion Schemes. Appl. Sci. 2025, 15, 4174. https://doi.org/10.3390/app15084174

Hu H, Ma S, Wang Y, Ma H. Structural Optimization and Airflow Uniformity Evaluation of Bag Filter Based on Different Diversion Schemes. Applied Sciences. 2025; 15(8):4174. https://doi.org/10.3390/app15084174

Chicago/Turabian StyleHu, Hongli, Shuo Ma, Yu Wang, and Hongting Ma. 2025. "Structural Optimization and Airflow Uniformity Evaluation of Bag Filter Based on Different Diversion Schemes" Applied Sciences 15, no. 8: 4174. https://doi.org/10.3390/app15084174

APA StyleHu, H., Ma, S., Wang, Y., & Ma, H. (2025). Structural Optimization and Airflow Uniformity Evaluation of Bag Filter Based on Different Diversion Schemes. Applied Sciences, 15(8), 4174. https://doi.org/10.3390/app15084174