1. Introduction

With the rapid development of highway networks worldwide, asphalt pavements in many countries have entered the maintenance phase [

1,

2,

3]. As an emerging green maintenance technology, hot-in-place asphalt pavement recycling enables 100% reuse of existing pavement materials while addressing road distresses, effectively achieving energy conservation, emission reduction, and cost efficiency in road maintenance projects [

4,

5,

6]. This technology has consequently garnered extensive research and application. A critical feature of hot-in-place recycling is its high reclaimed asphalt pavement (RAP) content, leading to a substantial proportion of aged asphalt in the total binder system. To restore the rheological properties of aged asphalt and ensure effective integration with new asphalt, the addition of reclaiming agents becomes essential. As the core material determining recycled pavement quality, reclaiming agent performance has thus become a research frontier in the field.

Current research categorizes reclaiming agents by their base oil sources: petrochemical oils, vegetable oils, and waste extract oils. Petrochemical oils (including aromatic, paraffinic, and naphthenic oils) dominate traditional regenerants. While studies demonstrate their effectiveness in reducing asphalt stiffness and enhancing low-temperature cracking resistance [

7,

8], their fatigue resistance performance remains controversial. Moreover, these oils exhibit significant volatility at temperatures exceeding 180 °C, limiting the RAP content to ≤30% [

9,

10]. Vegetable oils, composed of unsaturated fatty acid–glycerol compounds, have been developed from soybean, corn, and rapeseed oils [

11,

12,

13,

14], with optimal dosages around 5–6%. These bio-based agents demonstrate superior low-temperature crack resistance, fatigue resistance, and high boiling points. Waste extract oils encompass waste engine oil and waste vegetable oil. Although waste engine oil requires additives to improve viscosity, stability, and cleanliness due to compositional complexity [

15,

16], waste vegetable oils (primarily from fast-food fryers) effectively restore aged asphalt’s rheology through their small molecular weights [

17,

18,

19]. Plant-derived waste oils, rich in fatty acid methyl esters, exhibit strong lipophilicity and permeability [

20,

21,

22], presenting substantial market potential.

Existing studies suggest that while petrochemical-based regenerants show good asphalt compatibility, their high cost and poor high-temperature stability limit applications. In contrast, vegetable-oil-based agents attract growing attention due to abundant resources, cost effectiveness, and high-temperature stability during construction. However, regeneration efficacy varies significantly across vegetable oil types, necessitating further exploration in agent formulation.

To address these gaps, this study develops a novel vegetable oil regenerant through the dehydration and filtration of waste palm oil blended with plasticizers and anti-aging agents, using petrochemical-based regenerants as benchmarks. The research methodology involves three phases: (1) determining optimal dosage via dynamic shear rheometer and bending beam rheological tests on aged asphalt; (2) analyzing viscoelastic effects on asphalt mixtures through uniaxial dynamic modulus tests and trabecular bending creep tests; (3) evaluating road performance via rutting resistance, trabecular bending, freeze–thaw splitting, and immersion Marshall stability tests. The findings provide theoretical guidance for expanding the selection and application of asphalt reclaiming agents.

2. Raw Materials and Test Methods

2.1. Raw Materials

2.1.1. Reclaimed Asphalt Pavement (RAP)

The reclaimed asphalt pavement (RAP) was milled and recovered from a highway maintenance section and its related indicators were tested. The results are shown in

Table 1. It can be seen that the asphalt penetration and ductility of the original pavement material are low, indicating that the pavement has a high degree of asphalt aging under long-term traffic loads and environmental effects, so it is necessary to add a rejuvenating agent to restore its road performance.

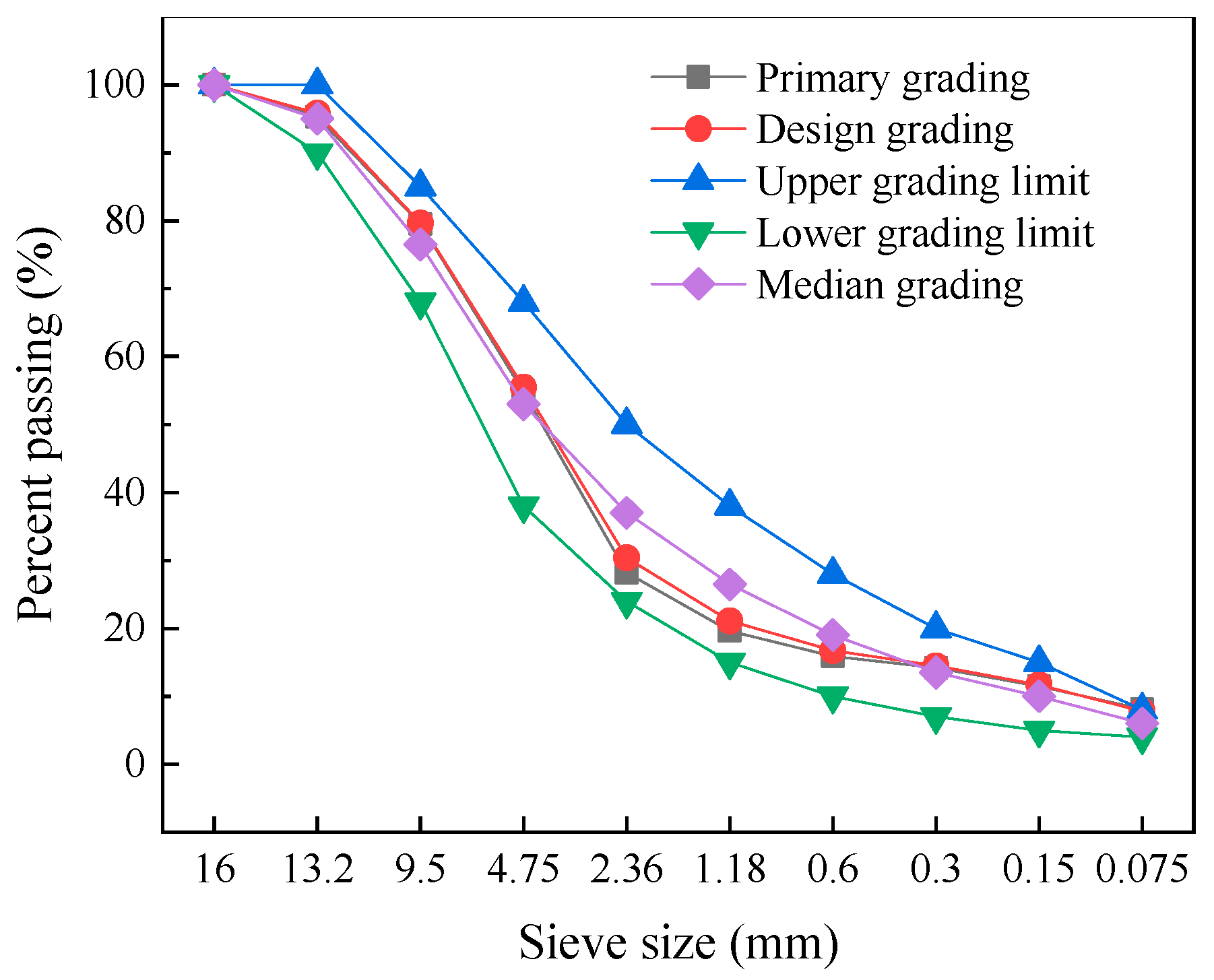

In addition, the long-term operation of asphalt pavement and the process of in situ hot raking inevitably lead to the refinement of aggregate gradation. Therefore, some coarse aggregate usually needs to be added to a recycled asphalt mixture to optimize the gradation. According to the screening results of the RAP, the synthetic gradation of the hot-in-place recycled mixture used in this study is 85% RAP + 15% new material, and the design gradation is shown in

Figure 1 below.

2.1.2. Reclaiming Agent

There are two types of reclaiming agents used in this study: one is a market-purchased reclaiming agent based on petrochemical oil (denoted as PCO) and the other is a waste palm oil reclaiming agent (denoted as WPO) independently developed by our team. The WPO preparation process is as follows: the waste palm oil is filtered and dehydrated, heated to 100 °C, and proportions of 8% plasticizer (epoxy fatty acid methyl ester) and 2% anti-aging agent (pentaerythritol phenylpropionate) are added with uniform stirring; then, the vegetable oil regenerating agent is obtained by maintaining the temperature and stirring for 30 min to form a uniform liquid. The two reclaiming agents were tested for their relevant indicators, and the results are listed in

Table 2.

2.1.3. SBS Modified Asphalt

The newly added asphalt in this study adopted SBS modified asphalt, and its technical indicators are listed in

Table 3.

2.2. Test Methods

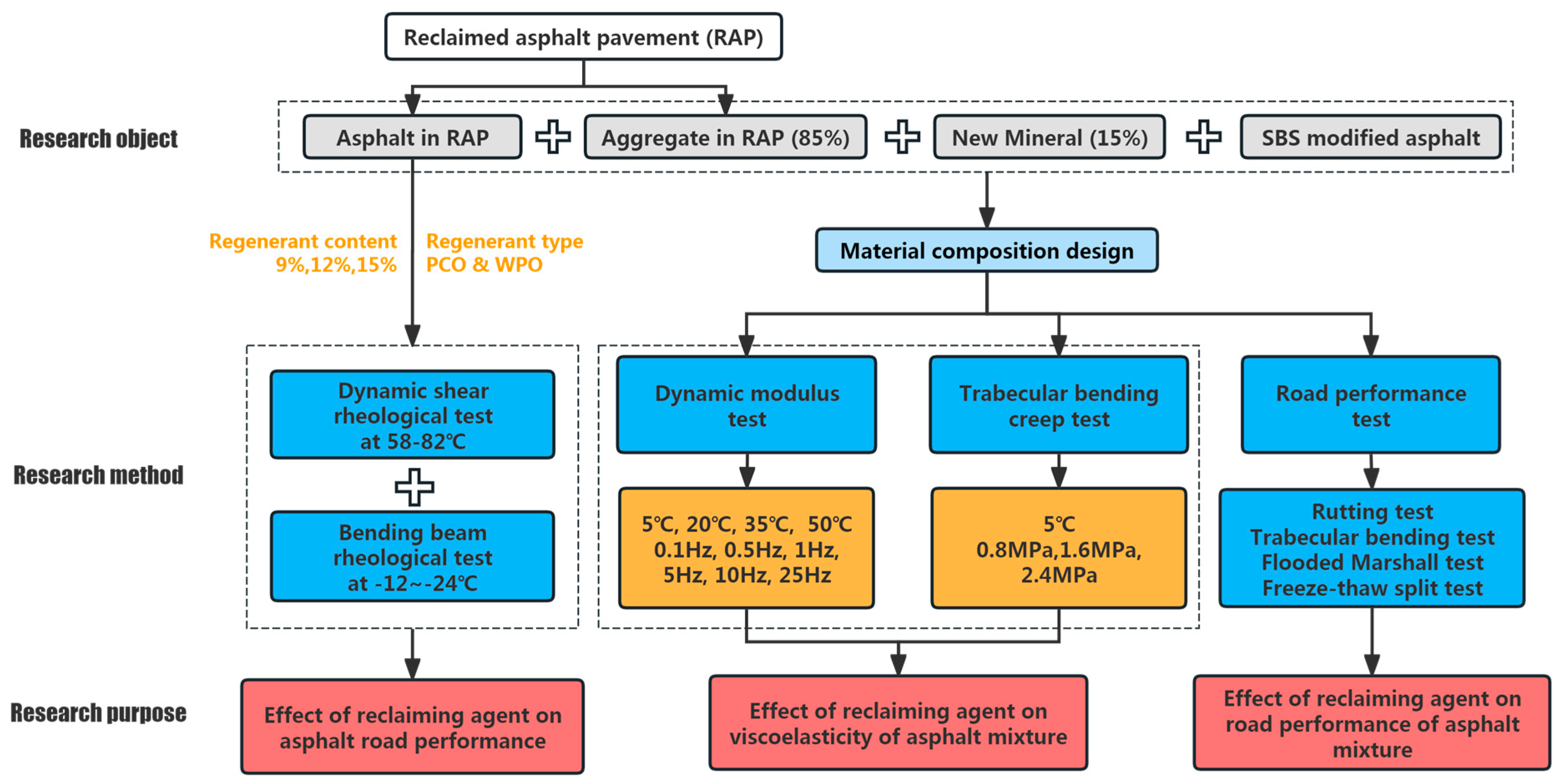

The technical route studied in this paper is shown in

Figure 2.

2.2.1. Preparation of Recycled Asphalt

The RAP and the reclaiming agent were heated to 120 °C and 100 °C, respectively, to make them in a molten state. The reclaiming agent was added to the RAP asphalt at 9%, 12%, and 15%, respectively, and a high-speed shear JRJ300-D-1 was used to stir the mixtures at 1000 r/min for 5 min to obtain the recycled asphalt. The reclaimed asphalt was prepared with the PCO and WPO, respectively.

2.2.2. DSR Test

A dynamic shear rheometer can apply a sinusoidal shear load to asphalt through torque to reflect the shear resistance of the asphalt. This paper used this equipment to perform a temperature sweep test the recycled asphalt. The temperature sweep test conditions were a test temperature of 58–82 °C (interval 6 °C) and a sweep frequency of 10 rad/s.

2.2.3. BBR Test

A bend beam rheometer can apply a constant load to a rectangular parallelepiped asphalt sample at the mid-span position to reflect the typical phenomenon of asphalt as a viscoelastic material: creep. In this paper, this equipment was used to conduct a bending creep test on the asphalt. The test conditions were a test temperature of −12~−24 °C (interval −6 °C), 980 mN loading for 240 s, and unloading for 10 s [

23].

2.2.4. Preparation of Recycled Asphalt Mixture

According to the RAP grading and screening results, 85% RAP + 15% new material was used as the new ore grading. The RAP heating temperature was 120 °C, the new aggregate heating temperature was 180 °C, the SBS-modified asphalt heating temperature was 170 °C, and the regenerating agent heating temperature was 100 °C. The mixing temperature and molding temperature of the mixture were controlled at 175 °C. The following tests were carried out.

2.2.5. Uniaxial Compression Dynamic Modulus Test

The dynamic modulus is an important parameter in asphalt pavement design, which is related to loading temperature and frequency. Using a rotary compactor (SGC) to form a 150 × 100 (mm) test piece, an asphalt mixture performance testing machine (AMPT) was used for experimental research. According to the actual operating environment of asphalt pavement, this paper adopted 5 °C, 20 °C, 35 °C, and 50 °C as the test temperatures and used 0.1 Hz, 0.5 Hz, 1 Hz, 5 Hz, 10 Hz, and 25 Hz for the experimental research. The test was carried out according to the temperature from low to high and the frequency from high to low.

2.2.6. Trabecular Bending Creep Test

First, 300 × 300 × 50 (mm) rut plates were formed, and after 48 h of cooling, they were cut into 250 × 30 × 35 (mm) trabecular specimens. UTM-130 equipment was used to conduct small beam bending creep tests on the asphalt mixtures. The test temperature was 5 °C under 0.8 MPa, 1.6 MPa and 2.4 MPa load levels, and the test loading time was 1800 s, which was recorded by the supporting computer.

2.2.7. Road Performance Test

This paper used a rutting test to evaluate high-temperature stability, a trabecular bending test to evaluate low-temperature crack resistance, and a freeze–thaw splitting test and flooded Marshall test to evaluate water stability.

3. Results

3.1. Analysis of Rheological Test Results

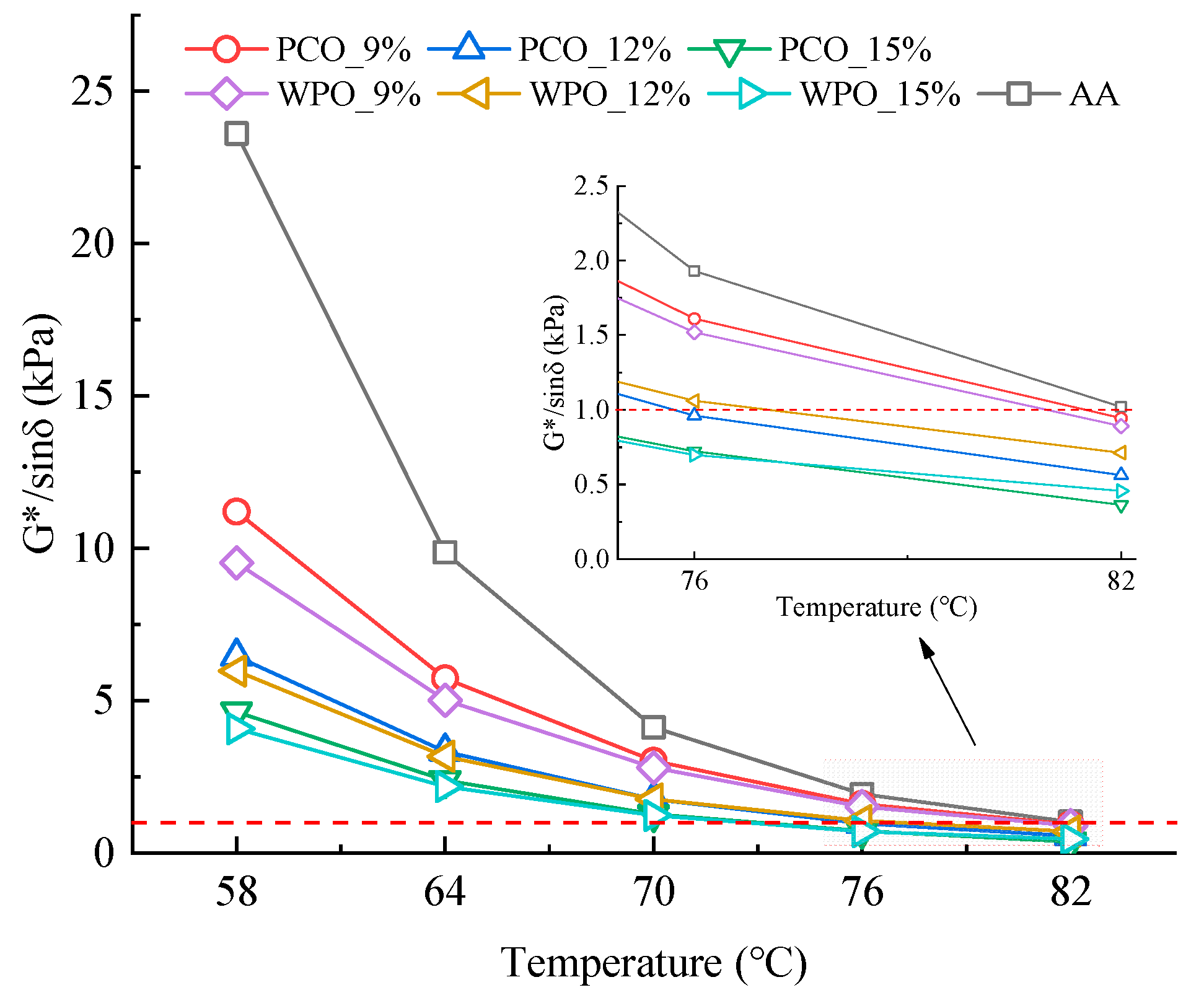

3.1.1. High-Temperature Rheology of Recycled Asphalt

The DSR test results can be calculated to obtain two viscoelastic parameters, including the complex shear modulus

G* and the phase angle

δ, where the

G* represents the total asphalt resistance of repeated shear deformation and the δ reflects the relative ratio of asphalt’s elasticity and viscosity [

24]. The SHRP specification adopts the rutting factor

G*/sin

δ to evaluate the asphalt performance graded (PG) and requires

G*/sin

δ not to be less than 1.0 kPa [

25]. The DSR test results of asphalt under different types and dosages of rejuvenating agents are shown in

Figure 3.

It can be seen from

Figure 3 that the effects of regenerant and temperature on the high-temperature performance of asphalt are consistent; that is, with the increase in temperature and the increase in the content of regenerant, the rutting factor of the asphalt decreases. According to the SHRP grading standard, the high-temperature grade of the original aged asphalt is PG82; when the content of the reclaiming agent is increased from 9% to 15%, the high-temperature grade of the recycled asphalt is reduced from PG76 to PG70, and the high-temperature performance of the asphalt becomes worse. This is because the main components of the regenerants are aromatic hydrocarbons and saturates, which have a small molecular weight and can penetrate and soften the aged asphalt. On the other hand, it can be found that the effects of the two regenerants on the high-temperature performance of the aged asphalt are not exactly the same, which is manifested in the difference in the rutting factor under the same dosage and temperature conditions. In order to further analyze the difference in the influence of the two regenerants on the high-temperature performance of asphalt, Δ

G was used. The Δ

G expression is defined as follows:

It can be seen from

Figure 4 that Δ

G has a significant relationship with the regenerator content and temperature. It can also be observed that the Δ

G of the rutting factors of the two recycled asphalts decreases with the increase in temperature, and the decrease is more significant with the increase in the regenerant dosage. Relatively speaking, the rutting factor of the recycled asphalt WPO is lower at a low temperature and higher at high temperature than the PCO, which means that recycled asphalt WPO has better temperature sensing performance.

3.1.2. Low-Temperature Rheology of Recycled Asphalt

In the SHRP specification, the stiffness modulus

S and creep rate change rate

m at 60 s are used as the evaluation index of the low-temperature grade of asphalt, and it is required that

S ≤ 300 MPa and

m ≥ 0.3 [

25].

Figure 5 is the calculated curve of the change in the asphalt S and m with temperature under different regenerant contents. It can be seen that S has an exponential function relationship with temperature, and m has a good linear relationship with temperature. The low-temperature grades of the recycled asphalt are PG-6, PG-18, PG-18, and PG-18 when the regenerant content is at 0%, 9%, 12%, and 15%, respectively. The incorporation of a regenerant greatly improves the low-temperature crack-resistance performance of the asphalt. Considering the high- and low-temperature properties of the recycled asphalt, the recommended waste palm oil reclaiming agent content is 12%.

3.2. Analysis of Recycled Asphalt Mixture

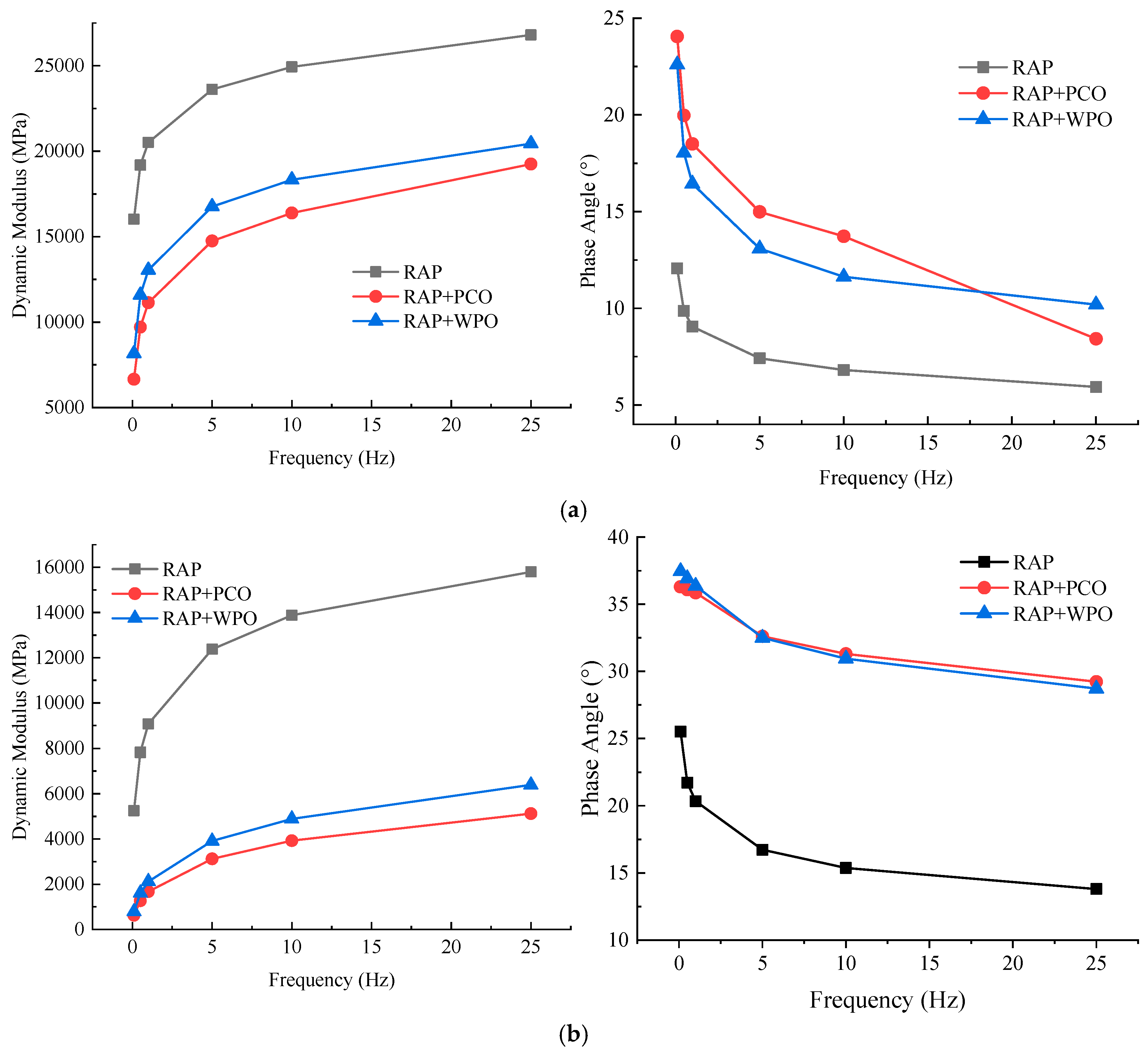

3.2.1. Dynamic Mechanical Characteristics

The uniaxial compression dynamic modulus test results of the RAP, petrochemical-oil-based recycled asphalt mixture (RAP + PCO), and waste-palm-oil-based recycled asphalt mixture (RAP + WPO) under different frequency and temperature conditions are shown in

Figure 6a–d.

It can be seen that the dynamic modulus of the three asphalt mixtures shows consistency with changes in temperature and frequency. As the temperature decreases and the frequency increases, the dynamic modulus of the asphalt mixtures increases, and the incorporation of the reclaiming agents does not change the temperature and frequency dependence of the mixture. The dynamic modulus of the asphalt mixture is significantly reduced, and the phase angle of the asphalt mixture is increased by the PCO or WPO. However, the performance of the two bitumen under the same test conditions is not consistent. The specific differences are as follows: the dynamic modulus of the WPO recycled asphalt mixture is lower than that of the PCO recycled asphalt mixture at a low temperature and high frequency, and the opposite is true at a high temperature and low frequency.

The phase angle development trends of the three asphalt mixtures at different temperatures and frequencies are not consistent. The temperature turning points of the RAP, RAP + PCO, and RAP + WPO are 38 °C, 21 °C, and 21 °C, respectively. When the temperature is lower than this turning temperature, the phase angle of the asphalt mixture decreases with the increase in frequency. At the transition temperature, the phase angle of the asphalt mixture increases with increasing frequency. The reason is that under the condition of low temperature or high frequency, the modulus of asphalt increases significantly, and the asphalt and its mixture exhibit greater elastic properties, while at high temperatures and low frequencies, asphalt mixtures transform into viscoelastic bodies. At this time, the ratio of elasticity of the mixture decreases and the ratio of viscosity increases, and its viscous properties are mainly affected by the asphalt binder. The incorporation of a regenerant changes the temperature sensitivity of the asphalt, which in turn affects the viscoelastic properties of the asphalt mixture.

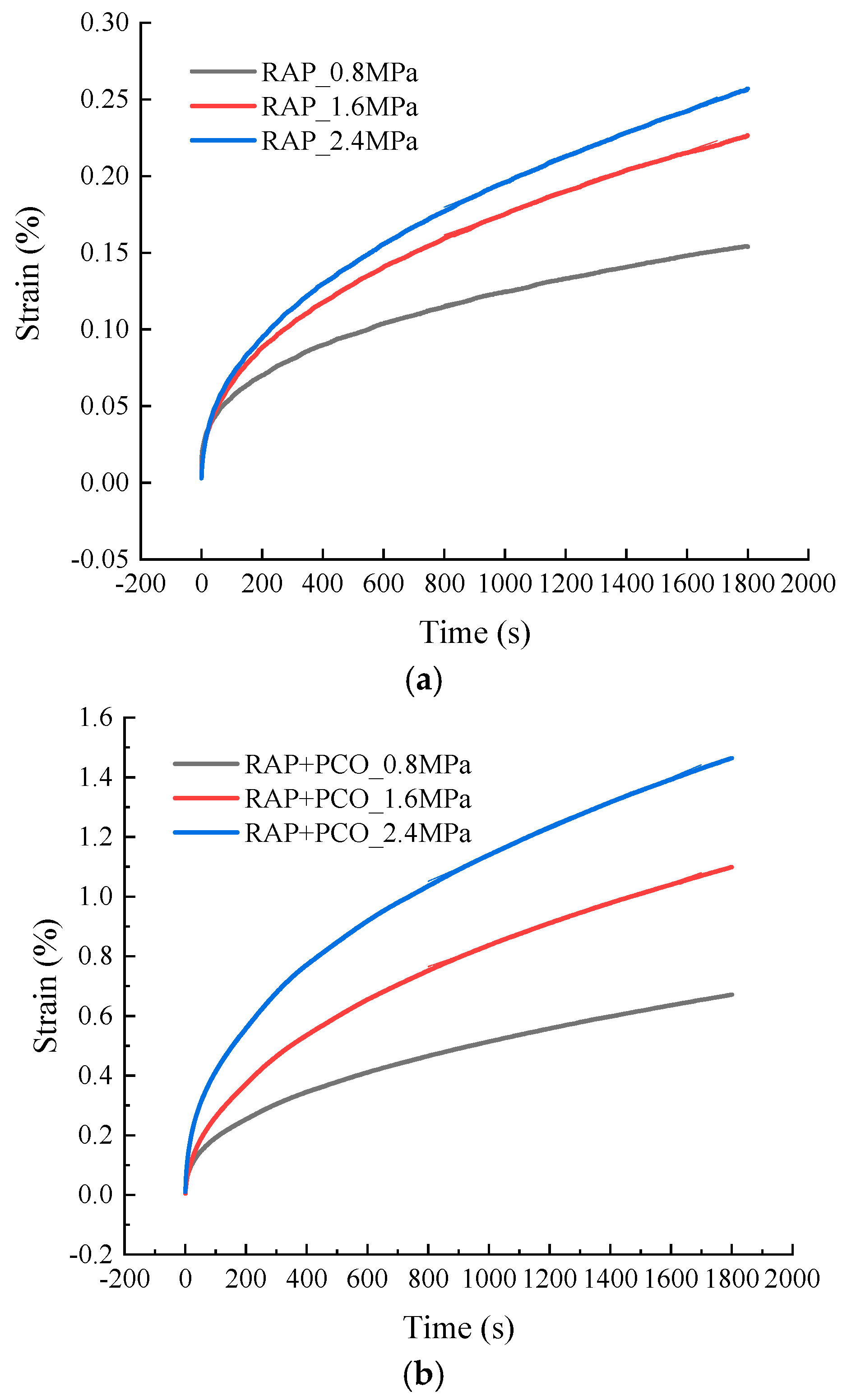

3.2.2. Creep Mechanical Characteristics

The creep curves of the three asphalt mixtures under different loads are shown in

Figure 7a–c. According to the relationship of creep rate with time, the creep of the asphalt mixtures generally includes three stages. The first stage is the deceleration stage, where the creep rate shows a downward trend with time. The second stage is the stable stage, where the creep rate basically remains unchanged. The third stage is the creep acceleration stage, where the creep rate increases with time. It can be found by observing the loading curve that the creep deformations of the three asphalt mixtures all increase significantly with the increase in the load. The RAP and RAP + PCO only have a creep migration period during the loading time. In the stable period, the RAP + WPO has a creep failure period under the stress condition of 2.4 MPa.

Among them, the creep rate in the second stage remains constant and can reflect the permanent deformation characteristics of the asphalt mixture. The larger the value under the same stress level, the greater the strain produced at the same time and the better the low-temperature performance [

26]. The stable creep rate of the three asphalt mixtures, RAP, RAR + PCO, and RAP + WPO, under different load levels are listed in

Table 4.

It can be seen from the above chart that the steady-state creep rate and strain of the three asphalt mixtures are RAP + WPO > RAP + PCO > >RAP under the same stress level, indicating that the incorporation of the reclaiming agent increases the low temperature of the asphalt mixture deformability. And the anti-cracking effect of the WPO regenerant is better than that of the PCO regenerant at a low temperature. What is more, the steady-state creep rate of the RAP and RAP + PCO decrease approximately linearly with the increase in the stress level. In the second stage, the steady-state creep rate of the RAP + WPO first decreases and then increases, which is mainly due to the premature creep failure stage of the asphalt mixture.

3.3. Road Performance Test Analysis

The comprehensive road performance of the reclaimed asphalt mixtures is listed in

Table 5.

The rutting test was used to evaluate the high-temperature deformation resistance of the asphalt mixtures in reference to the China Technical Standard. The dynamic stability index can be obtained from this test. The greater the dynamic stability, the stronger the high-temperature deformation resistance of an asphalt mixture. As can be seen from

Table 5, the dynamic stability of the three asphalt mixtures is in the order of RAP > RAP + PCO > RAP + WPO. This is because the reclaiming agent supplements the aromatic fraction lost in the aging process of the asphalt, the light oil fraction of the asphalt increases while the asphaltene proportion decreases, and the deformation resistance of the asphalt is weakened to a certain extent. The dynamic stability of the waste-palm-oil-based regenerated mixture is about 85% of that of the petrochemical-oil-based regenerated mixture, but it still reaches more than 3000 times/mm, which fully meets the anti-rutting demand of a heavy traffic road surface.

The low-temperature bending test was used to evaluate the low-temperature cracking resistance of the asphalt mixture. The maximum flexural strain was obtained by the test. The greater the value, the better the low-temperature cracking resistance of the asphalt mixture. At the same time, it was not difficult to find that the low-temperature bending strain of the original pavement did not meet the requirements of the specification. After adding a regenerant, the maximum flexural tensile strain of the asphalt mixture was significantly increased, and the maximum flexural tensile strain of the waste-palm-oil-based regenerated mixture was about 21% higher than that of the petrochemical-oil-based regenerated mixture, which is consistent with the BBR test of the reclaimed asphalt, and again shows that the waste-palm-oil-based regenerator has a prominent advantage in the low-temperature cracking resistance of the aging asphalt.

The water damage resistance of the asphalt mixtures was evaluated by a freeze–thaw splitting test and an immersion Marshall test. The obtained freeze–thaw splitting strength ratio and residual stability index can quantitatively analyze the water stability of the mixture. The higher the value, the stronger the water damage resistance of the mixture. It can be seen from the table that the water stability test of the asphalt mixtures showed that the residual stability and freeze–thaw splitting strength ratio of the original pavement asphalt mixture were the worst, while the waste-palm-oil-based and petrochemical-oil-based recycled asphalt mixtures were basically the same, and both reached more than 90%. The addition of a regenerant increased the residual stability and freeze–thaw splitting strength of asphalt mixture by about 10%.

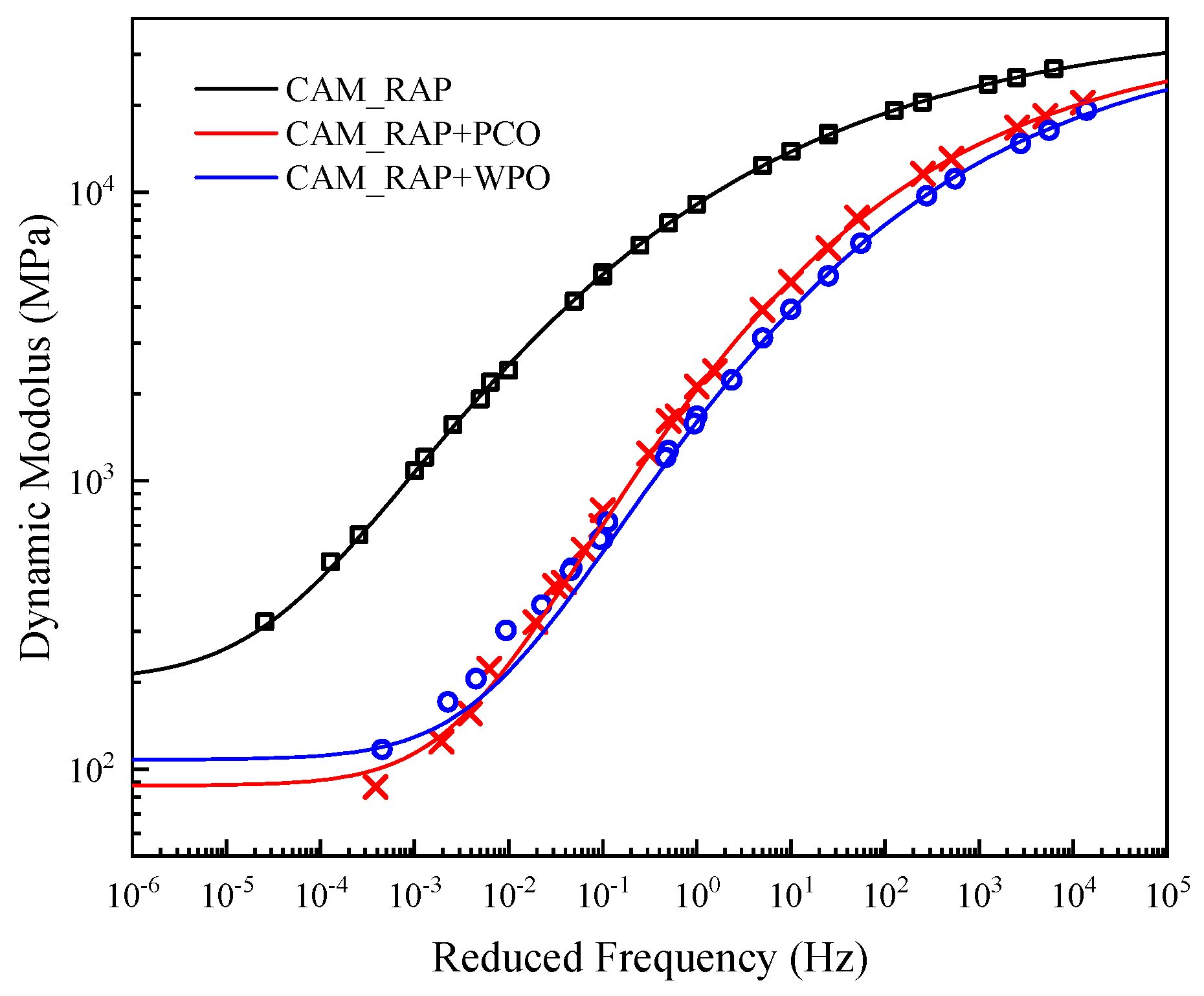

3.4. Analysis of Hot Recycled Mixture Based on CAM Model

3.4.1. Dynamic Characteristics

As a typical viscoelastic material, an asphalt mixture has significant temperature sensitivity. According to the time–temperature superposition principle [

27], the mechanical phenomena of these mixtures at different temperatures can be translated to obtain the mechanical properties at a wider range of temperatures and frequencies. In this paper, the improved CAM model was used to analyze the dynamic viscoelastic characteristics of the reclaimed asphalt mixture [

28], in which the dynamic modulus and phase angle were expressed as follows:

where

is the complex shear modulus of the equilibrium state;

is the glassy complex shear modulus;

fc is the elastic limit threshold; and

k and

me are shape parameters and rheological parameters, respectively.

R is the intercept of

and

on logarithmic coordinates, which can be calculated as follows:

where

δm is the maximum phase angle of the viscous component of the mixture;

fd is the frequency corresponding to the highest point of the phase angle; and

Rd is the shape parameter.

Taking 20 °C as the reference temperature, the least square method was used to plan and solve the problem. After translating the other three temperatures, the improved CAM model was adopted to carry out a fitting analysis on the dynamic moduli of the three mixtures. The main curve of the dynamic moduli of asphalt mixtures was drawn, as shown in

Figure 8.

The dynamic modulus master curve fitting parameters are shown in

Table 6, where it can be seen that when a vehicle’s driving speed is about 60 km/h, the loading frequency is equivalent to 10 Hz. When the loading frequency is greater than 10 Hz, the dynamic modulus of the three asphalt mixtures is RAP > RAP + PCO > RAP + WPO, and high frequency corresponds to low temperature, which indicates that the addition of two regenerators reduces the dynamic modulus of the asphalt mixture at low temperature, so it is easier to produce deformation and release temperature stress. This is also proved by the fitting results of the CAM model, whose fitting parameter fc reflects the frequency of the same viscous and elastic components of the asphalt mixture, and the higher the fc, the better the anti-cracking performance at low temperature. When the loading frequency is less than 0.01 Hz, the dynamic moduli of the three asphalt mixtures are RAP > RAP + WPO > RAP + PCO, and the low frequency corresponds to the high temperature. The addition of the regenerating agent reduces the viscosity of the asphalt binder, thus reducing the high-temperature stability of the asphalt mixture. The

me and

Rd of the fitting parameters reflect the temperature sensitivity of the mixture. The lower

me and

Rd are, the less sensitive the mixture is to temperature. The fitting results of

me and

R are RAP > RAP + PCO > RAP + WPO, which indicates that the temperature sensitivity of the waste-palm-oil-based reclaimed asphalt mixture is better than that of the petrochemical-oil-based reclaimed asphalt mixture, while the RAP has the worst temperature sensitivity.

The phase angle is an important parameter reflecting the viscoelastic properties of asphalt mixtures, which represents the change in the viscoelastic ratio of an asphalt mixture. The higher the phase angle is, the greater the viscous component is. The main curve of the phase angle fitting of the three asphalt mixtures according to the improved CAM model is shown in

Figure 9, and the fitting results are listed in

Table 7, from which it can be seen that the improved CAM model can well fit the main curve of the phase angle of the asphalt mixtures after translation, and the phase angle of the asphalt mixtures at different frequencies can be inferred through the fitted equation. The addition of two regenerating agents both delayed and increased the peak value of phase angle of asphalt mixtures.

The fitting parameter fd was RAP + WPO > RAP + PCO > RAP, and when the loading frequency was higher than 10 Hz, the phase angle of the mixture was RAP + PCO > RAP + WPO, indicating that the waste-palm-oil-based regenerated mixture showed more viscous properties at a low temperature. That is, it is easier to produce flow deformation, which is very favorable for resisting low temperature and cracking. When the loading frequency was less than 0.01 Hz, the phase angle of the mixture was RAP > RAP + PCO > RAP + WPO, which indicates that the elastic ratio of the waste-palm-oil-based reclaimed mixture is higher than that of the petrochemical-oil-based reclaimed asphalt mixture at a high temperature, which has a positive effect on improving the high-temperature performance of the asphalt mixture.

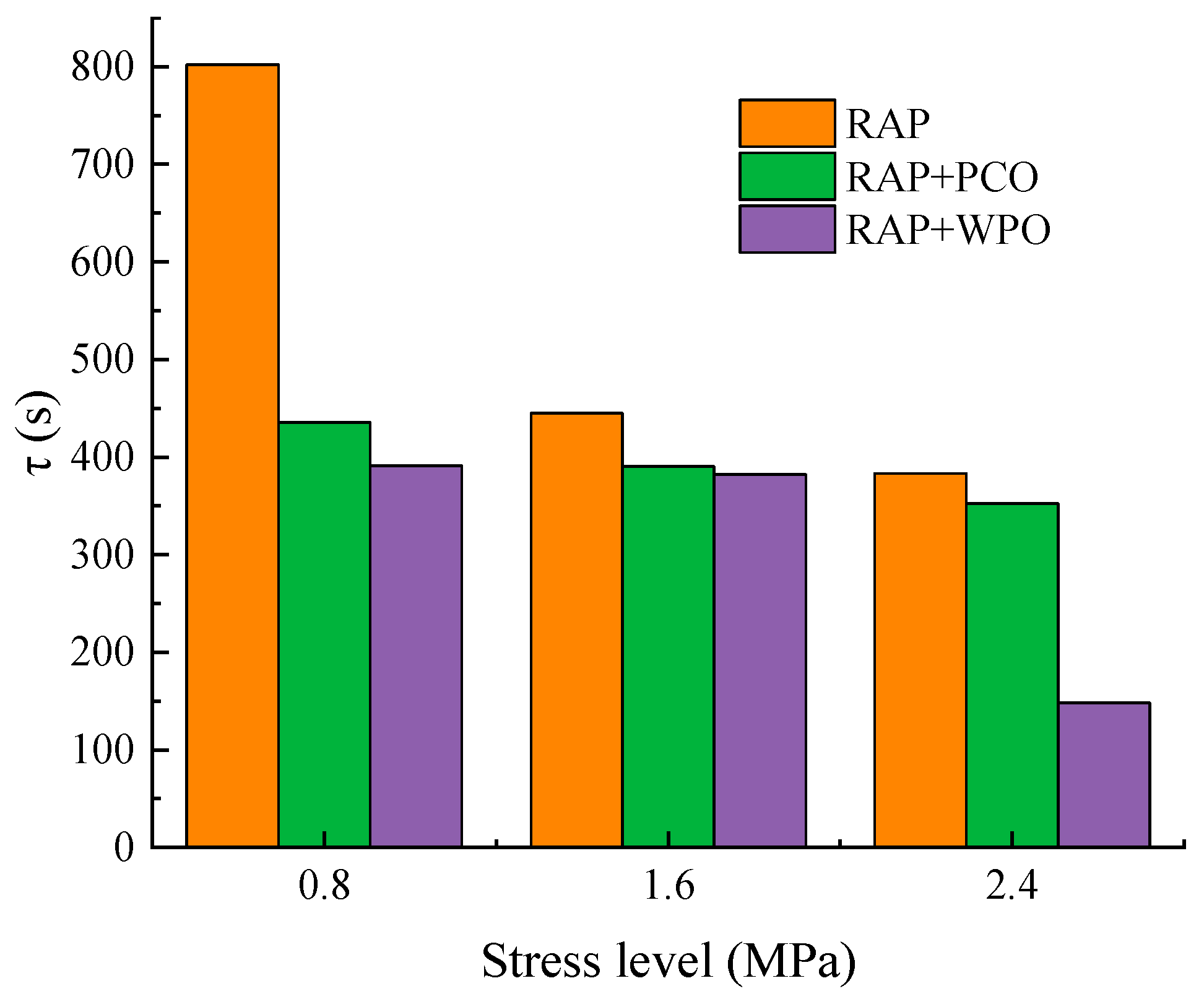

3.4.2. Creep Characteristics

The deformation characteristic of an asphalt mixture is the external manifestation of its internal viscoelasticity. Studying the viscoelastic change in a reclaimed asphalt mixture in the process of low-temperature creep is helpful to understand and explain its low-temperature deformation behavior essentially. The viscoelastic characteristics of an asphalt mixture can be obtained based on the Burgers model, which also reflects the creep and stress relaxation behavior of an asphalt mixture, as shown in Equations (5) and (6) [

29].

where

J(t) is creep compliance;

ε(t) is stress;

σ0 is stress; and

E1,

E2,

η1, and

η2 are the elastic modulus and viscosity coefficient, respectively.

1stOpt software was used to nonlinearly fit the creep behavior of the asphalt mixtures, and the Burgers model parameters

E1,

E2,

η1,

η2 could be obtained. Based on the model parameters, the relaxation time of the asphalt mixtures under different stress levels could be obtained:

τ =

η1/E1 [

30]. The calculation results of relaxation time are shown in

Figure 10.

Relaxation time is an important parameter to characterize the change in internal stress of materials over time. The shorter the relaxation time, the faster the dissipation of the internal stress of materials and the better the cracking resistance at low temperature. As can be seen from

Figure 8, the addition of a regenerant significantly reduces the relaxation time of the asphalt mixtures. Under the stress levels of 0.8 MPa, 1.6 MPa, and 2.4 MPa, the relaxation time of the petrochemical-oil-based reclaimed asphalt mixture is reduced by 45%, 12%, and 8%, and that of the waste-palm-oil-based reclaimed asphalt mixture is reduced by 51%, 14%, and 61%, respectively. At the same time, with the increase in the stress level, the relaxation time of the three asphalt mixtures decreases gradually. According to the study, stress and temperature have equivalent effects; that is, the higher the temperature and the greater the stress, the larger the creep strain of the mixture and the shorter the corresponding relaxation time.

In the Burgers model, a spring and a clay pot are used to represent the storage and consumption capacity of materials, respectively. Johansson et al. established the storage and dissipation energy of materials through the model parameters [

31,

32,

33] shown in Equations (7) and (8).

where W

s is stored energy and W

d is dissipated energy.

The dissipated energy ratio is the ratio of dissipated energy to stored energy, which is also an important index reflecting the stress relaxation ability of materials. The higher the dissipation energy ratio, the better the low-temperature cracking resistance of an asphalt mixture. It can be seen from the formula that the dissipated energy ratio is a function of time. In this paper, the state of the asphalt mixtures in the steady-state creep stage (1000 s in this paper) is selected for comparison so as to analyze the change in the low-temperature performance of the asphalt mixtures before and after adding the regenerator. The calculation results are shown in

Table 8.

As can be seen from

Table 8, the addition of a regenerant improves the dissipated energy ratio of the asphalt mixtures, which means that the addition of regenerant speeds up the energy dissipation in the asphalt mixtures, which is extremely favorable for the timely release of thermal shrinkage stress. With the increase in stress level, the dissipated energy ratio of the asphalt mixtures shows an increasing trend, which indicates that the energy stored in the asphalt mixtures is more easily released. Under the same stress level, the value of W

d/W

s of the three asphalt mixtures is WPO + RAP > PCO + RAP > RAP, which means that the waste palm oil more easily achieves crack resistance by releasing strain energy under low-temperature load conditions.

4. Conclusions

In this study, a waste-palm-oil-based reclaiming agent was developed, and its effects on reclaimed asphalt and mixtures were systematically investigated through experimental analyses. The key conclusions are summarized as follows:

(1) As the content of the waste palm oil reclaiming agent increases, the rutting factor and creep stiffness modulus of asphalt decrease, while the creep rate increases. Considering the balance between the high- and low-temperature performance of the recycled asphalt, the optimal content of the waste palm oil reclaiming agent is recommended to be 12%.

(2) The incorporation of the waste palm oil reclaiming agent alters the dynamic viscoelastic properties of the reclaimed asphalt mixtures, reducing the dynamic modulus of the RAP while increasing the phase angle. The relationship between the dynamic modulus and phase angle in the recycled asphalt mixtures is influenced by both the test temperature and loading frequency. The modified CAM model demonstrates excellent correlation with the frequency-dependent dynamic modulus and phase angle of the recycled asphalt mixtures. Specifically, at loading frequencies above 10 Hz, the palm oil recycled asphalt mixture exhibits a lower dynamic modulus and a higher phase angle. Conversely, at frequencies below 0.01 Hz, the waste palm oil reclaiming agent displays enhanced temperature sensitivity.

(3) The addition of waste palm oil improves the static creep characteristics of asphalt mixtures. Compared with petroleum-based reclaiming agents, the waste palm oil agent produces higher steady-state creep rates and strain magnitudes, along with shorter stress relaxation times and higher dissipation energy ratios under low-temperature conditions. These properties indicate that asphalt mixtures containing waste palm oil are more prone to deformation and energy dissipation, thereby enhancing their low-temperature crack resistance.

(4) Road performance tests confirmed that the asphalt mixtures containing the waste palm oil reclaiming agent exhibited superior high-temperature rutting resistance, low-temperature cracking resistance, and moisture damage resistance, validating the reliability of the analytical results. Furthermore, the waste palm oil reclaiming agent demonstrated significant practical potential due to its wide availability, cost effectiveness, and favorable performance characteristics.

Author Contributions

Conceptualization, X.G.; data curation, X.G.; formal analysis, F.K. and C.X.; investigation, Y.Z. and Z.C.; methodology, X.G.; project administration, X.G.; writing—original draft, X.G. and H.C.; writing—review and editing, X.G. and H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by National Natural Science Foundation of China (52008235); the Shanxi Basic Research Project of China (202203021212514); and the Shanxi Traffic Control Group Technology Project (23-JKKJ-14, 23-JKKJ-15).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We would like to acknowledge the Shanxi Transportation Technology Research & Development Co., Ltd. for technical support in the testing procedure and data processing.

Conflicts of Interest

Authors Xuekai Gao, Fansheng Kong, Yancong Zhang, Zhiqiang Cheng were employed by the company Shanxi Transportation Technology Research & Development Co., Ltd. Author Xuekai Gao was employed by the company Shanxi Intelligent Transportation Laboratory Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RAP | Reclaimed asphalt pavement |

| PCO | Petrochemical oil |

| WPO | Waste palm oil reclaiming agent |

| SBS | Styrene–butadiene–styrene |

| DSR | Dynamic shear rheometer |

| BBR | Bend beam rheometer |

References

- Cheng, H.; Sun, L.; Liu, L.; Li, H. Fatigue characteristics of in-service cold recycling mixture with asphalt emulsion and HMA mixture. Constr. Build. Mater. 2018, 192, 704–714. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; González, Á. Assessment of the sustainability of asphalt pavement maintenance using the microwave heating self-healing technique. J. Clean. Prod. 2022, 365, 132859. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, C.; Qu, J.; Lv, S.; Ju, Z.; Ding, S.; An, H.; Ren, K. Research on pavement performance of recycled asphalt mixture based on separation technology of asphalt and aggregate in RAP. Constr. Build. Mater. 2023, 393, 132103. [Google Scholar] [CrossRef]

- Li, M.; Yuan, J.; Jin, T.; Wang, W.; Sun, Y.; Cheng, H. Investigation of performance evolution in recycled asphalt mixtures: The impact of virgin and RAP binder blending. Constr. Build. Mater. 2025, 469, 140519. [Google Scholar] [CrossRef]

- Musco, A.; Tarsi, G.; Tataranni, P.; Salzano, E.; Sangiorgi, C. Use of bio-based products towards more sustainable road paving binders: A state-of-the-art review. J. Road Eng. 2024, 4, 151. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Mokhtari, A.; David Lee, H.; Williams, R.C.; Guymon, C.A.; Scholte, J.P.; Schram, S. A novel approach to evaluate fracture surfaces of aged and rejuvenator-restored asphalt using cryo-SEM and image analysis techniques. Constr. Build. Mater. 2017, 133, 301–313. [Google Scholar] [CrossRef]

- Orešković, M.; Menegusso Pires, G.; Bressi, S.; Vasconcelos, K.; Lo Presti, D. Quantitative assessment of the parameters linked to the blending between reclaimed asphalt binder and recycling agent: A literature review. Constr. Build. Mater. 2020, 234, 117323. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Suo, Z.; You, Z.; Li, H.; Xu, S.; Sun, L. Effectiveness of Vegetable Oils as Rejuvenators for Aged Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, D4016003. [Google Scholar] [CrossRef]

- Cao, X.; Wang, H.; Cao, X.; Sun, W.; Zhu, H.; Tang, B. Investigation of rheological and chemical properties asphalt binder rejuvenated with waste vegetable oil. Constr. Build. Mater. 2018, 180, 455–463. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, Y.; Chen, L.; Li, F. Diluting or dissolving? The use of relaxation spectrum to assess rejuvenation effects in asphalt recycling. Constr. Build. Mater. 2018, 188, 143–152. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and Fatigue Evaluation of Asphalt Mixtures Containing RAP Treated with a Bio-Agent. Appl. Sci. 2017, 7, 216. [Google Scholar] [CrossRef]

- Lei, Z.; Bahia, H.; Yi-Qiu, T.; Ling, C. Effects of refined waste and bio-based oil modifiers on rheological properties of asphalt binders. Constr. Build. Mater. 2017, 148, 504–511. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Recycled stone mastic asphalt mixtures incorporating high rates of waste materials. Constr. Build. Mater. 2018, 187, 1–13. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Yan, S.; Zhou, C.; Zhang, J.; Li, G. Molecular dynamics simulation on the rejuvenation effects of waste cooking oil on aged asphalt binder. J. Traffic Transp. Eng. 2022, 9, 795–807. [Google Scholar] [CrossRef]

- Hennig Osmari, P.; Aragão, F.T.S.; Leite, L.; Simão, R.; Motta, L.; Kim, Y. Chemical, Microstructural, and Rheological Characterizations of Binders to Evaluate Aging and Rejuvenation. Transp. Res. Rec. J. Transp. Res. Board 2017, 2632, 14–24. [Google Scholar] [CrossRef]

- Luo, H.; Huang, X. Research on Change of Performance and Component of Recycled Oil Regenerated Asphalt During Secondary Aging. China J. Highw. Transp. 2021, 34, 98–110. [Google Scholar]

- Borghi, A.; Jiménez, D.B.C.A.; Lo, P.D.; Giustozzi, F. Effects of Laboratory Aging on Properties of Biorejuvenated Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, 4017149. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory characterization of asphalt binders modified with waste vegetable oil using SuperPave specifications. Int. J. Pavement Res. Technol. 2018, 11, 68–76. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.A.; Al-Zerkani, M.A. Rejuvenation of aged asphalt binder extracted from reclaimed asphalt pavement using waste vegetable and engine oils. Case Stud. Constr. Mater. 2019, 11, e00279. [Google Scholar] [CrossRef]

- Tang, N.; Luo, M.; Xue, C.; Liu, S.; Li, R.; Zhu, H.; Cheng, H. Performance evaluation and mechanism investigation of aged SBS/chemically activated rubberized asphalt. Constr. Build. Mater. 2025, 458, 139497. [Google Scholar] [CrossRef]

- Xue, C.; Tang, N.; Gao, X.; Cheng, H.; Zhang, Y.; Wang, W.; Cheng, Y.; Wei, J. Quantifying emission characteristics and performance evolutions of eco-friendly rubberized asphalt binder. Transp. Res. Part D Transp. Environ. 2025, 140, 104647. [Google Scholar] [CrossRef]

- Kennedy, T.W.; Huber, G.; Harrigan, E.; Cominsky, R.J.; Hughes, C.S.; Quintus, H.L.V.; Moulthrop, J.S. Superior Performing Asphalt Pavements (Superpave): The Product of the SHRP Asphalt Research Program; SHRP: Washington, DC, USA, 1994. [Google Scholar]

- Moon, K.H.; Marasteanu, M.O.; Turos, M. Comparison of Thermal Stresses Calculated from Asphalt Binder and Asphalt Mixture Creep Tests. J. Mater. Civ. Eng. 2013, 25, 1059–1067. [Google Scholar] [CrossRef]

- Tavassoti-Kheiry, P.; Boz, I.; Chen, X.; Solaimanian, M. Application of Ultrasonic Pulse Velocity Testing of Asphalt Concrete Mixtures to Improve the Prediction Accuracy of Dynamic Modulus Master Curve. In Airfield and Highway Pavements; ASCE: Reston, VA, USA, 2017; pp. 152–164. [Google Scholar]

- Ouyang, J.; Zhao, J.; Tan, Y. Modeling Mechanical Properties of Cement Asphalt Emulsion Mortar with Different Asphalt to Cement Ratios and Temperatures. J. Mater. Civ. Eng. 2018, 30, 4018263. [Google Scholar] [CrossRef]

- Saboo, N.; Mudgal, A. Modelling creep and recovery response of asphalt binders using generalized burgers model. Pet. Sci. Technol. 2018, 36, 1627–1634. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Viscosity, relaxation time, and dynamics within a model asphalt of larger molecules. J. Chem. Phys. 2014, 140, 34507. [Google Scholar] [CrossRef]

- Lv, S.; Peng, X.; Liu, C.; Ge, D.; Tang, M.; Zheng, J. Laboratory investigation of fatigue parameters characteristics of aging asphalt mixtures: A dissipated energy approach. Constr. Build. Mater. 2020, 230, 116972. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Chen, X. Analysis of fatigue behaviors of asphalt mixture under actual loading waveforms using pseudo-strain-based approaches. Int. J. Pavement Eng. 2023, 24, 2020269. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Chen, X. Effects of actual loading waveforms on the fatigue behaviours of asphalt mixtures. Int. J. Fatigue 2021, 151, 106386. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).