Effects of Different Natural Additives Alternative to Chemical Ones on Artisanal Bologna-Type Sausages Shelf Life

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation and Characterization of the Tested Powders

2.2.2. The Manufacturing Process of the Mortadellas

2.2.3. Packaging and Storage

2.2.4. Sample Collection

2.2.5. pH and aw Measurements

2.2.6. Lipid Oxidation

2.2.7. Texture Profile Analysis

2.2.8. Color Analysis

2.2.9. Microbiological Analyses

2.2.10. MALDI-TOF MS Identification

2.2.11. Sensory Analyses

2.2.12. Statistical Analyses

3. Results

3.1. Physicochemical Analysis

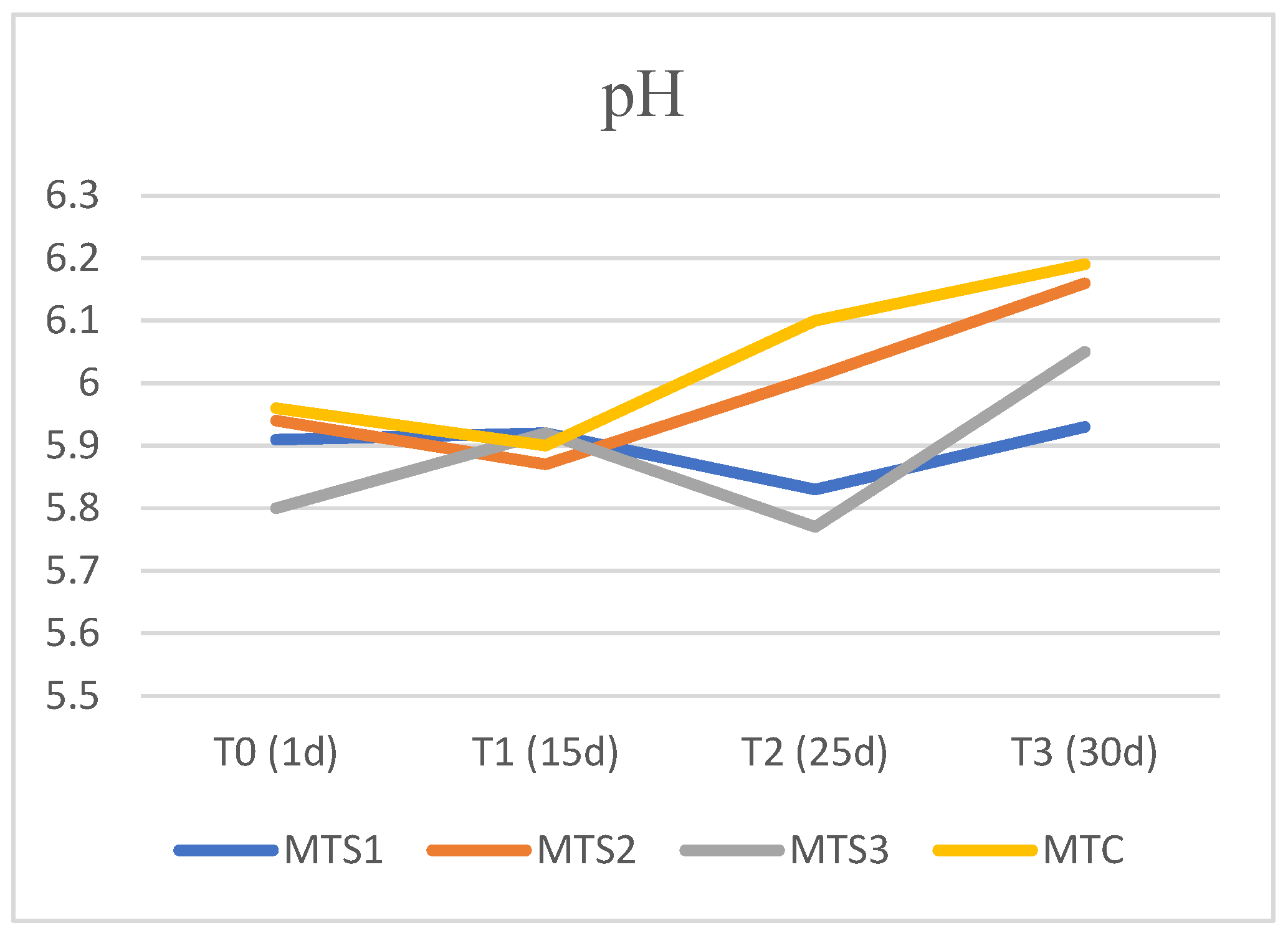

3.1.1. Effects of the Three Tested Plant Powders on the pH and Water Activity (aw) Values of the Mortadellas

3.1.2. Instrumental Color Parameters

3.1.3. Texture Profile Analysis

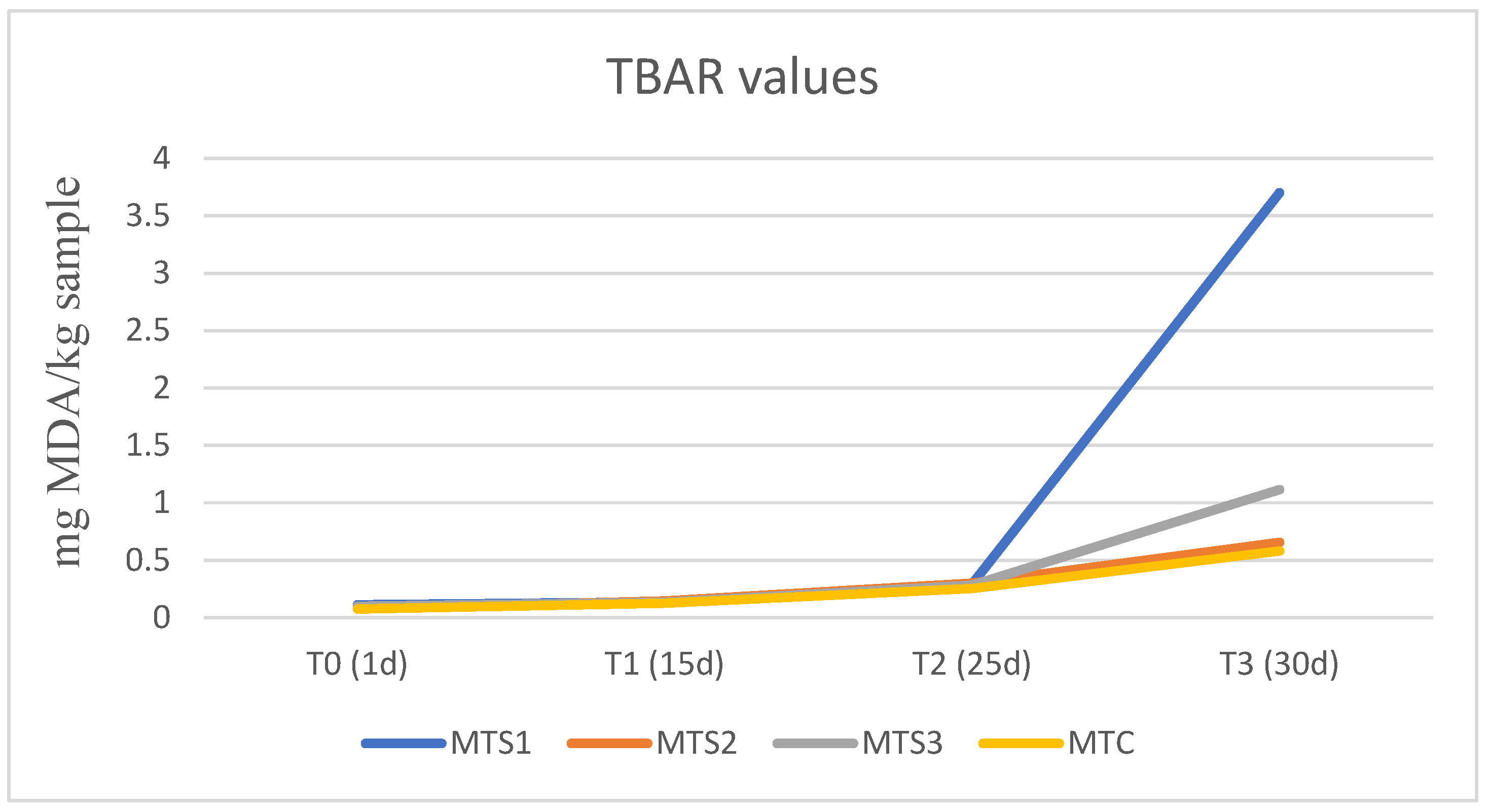

3.1.4. Lipid Oxidation Measurements

3.2. Microbiological Analyses

3.3. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Troy, D.J.; Kerry, J.P. Consumer Perception and the Role of Science in the Meat Industry. Meat Sci. 2010, 86, 214–226. [Google Scholar] [PubMed]

- Tarawneh, H.; Obeidat, H.; Sawalha, B. Application of Hazard Analysis Critical Control Point (Haccp) Principles to Beef Mortadella Production. Afr. J. Food Agric. Nutr. Dev. 2024, 24, 24337–24363. [Google Scholar] [CrossRef]

- Auriema, B.E.; Braz Corrêa, F.J.; Guimarães, J.d.T.; Soares, P.T.d.S.; Rosenthal, A.; Zonta, E.; Rosa, R.C.C.; Luchese, R.H.; Esmerino, E.A.; Mathias, S.P. Green Banana Biomass: Physicochemical and Functional Properties and Its Potential as a Fat Replacer in a Chicken Mortadella. LWT 2021, 140, 110686. [Google Scholar] [CrossRef]

- Henrique, J.T.; Biason, M.V.; dos Santos Mendes, P.; Cardoso, F.A.R.; Leimann, F.V.; Gonçalves, O.H.; Bona, E.; de Oliveira, A.; Marques, L.L.M.; Fuchs, R.H.B.; et al. Enhancing Mortadella Formulations: Exploring the Impact of Curcumin Microcrystals, Cochineal Carmine, and Annatto Dyes on Sensory Preferences, Stability, and Antioxidant Potential. Food Chem. X 2024, 23, 101627. [Google Scholar] [CrossRef]

- Fraqueza, M.J.; Laranjo, M.; Elias, M.; Patarata, L. Microbiological Hazards Associated with Salt and Nitrite Reduction in Cured Meat Products: Control Strategies Based on Antimicrobial Effect of Natural Ingredients and Protective Microbiota. Curr. Opin. Food Sci. 2021, 38, 32–39. [Google Scholar]

- Mohammed, A.M.; Moneim, A.; Sulieman, E.; Salih, Z.A.; Mahgoub, A. Quality Characteristics of Laboratory-Made Mortadella Meat Product. Int. J. Food Sci. Nutr. Eng. 2015, 5, 96–100. [Google Scholar] [CrossRef]

- Giosuè, C.; Maniaci, G.; Gannuscio, R.; Ponte, M.; Pipi, M.; Di Grigoli, A.; Bonanno, A.; Alabiso, M. Traits of Mortadella from Meat of Different Commercial Categories of Indigenous Dairy Cattle. Animals 2024, 14, 1980. [Google Scholar] [CrossRef]

- Bolívar-Monsalve, J.; Ramírez-Toro, C.; Bolívar, G.; Ceballos-González, C. Mechanisms of Action of Novel Ingredients Used in Edible Films to Preserve Microbial Quality and Oxidative Stability in Sausages—A Review. Trends Food Sci. Technol. 2019, 89, 100–109. [Google Scholar]

- Campagnol, P.C.B.; dos Santos, B.A.; Wagner, R.; Terra, N.N.; Pollonio, M.A.R. The Effect of Yeast Extract Addition on Quality of Fermented Sausages at Low NaCl Content. Meat Sci. 2011, 87, 290–298. [Google Scholar] [CrossRef]

- Verlindo, R.; Bernardi, J.L.; Puton, B.M.S.; Ostrowski, G.M.; do Nascimento, L.H.; Duarte, P.F.; Zeni, J.; Backes, G.T.; Valduga, E.; Schwert, R.; et al. Influence of Sodium Nitrite Microcapsules on the Physicochemical Properties, Microbiological Stability, and Mathematical Modeling during the Shelf Life of Mortadella. J. Fur Verbraucherschutz Und Leb. 2024, 19, 59–69. [Google Scholar] [CrossRef]

- Honorato, T.C.; Batista, E.; do Nascimento, K.d.O.; Pires, T. Food Additives: Applications and Toxicology. Rev. Verde De Agroecol. E Desenvolv. Sustentável 2013, 8. No. 5. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20153272415 (accessed on 15 March 2025).

- Silva, M.M.; Lidon, F.C. Food Preservatives—An Overview on Applications and Side Effects. Emir. J. Food Agric. 2016, 28, 366–373. [Google Scholar]

- Nikolova, A.S.; Belichovska, D. The Effect of Nitrite Use in Meat Products on Human Health. Knowl.-Int. J. 2024, 63, 271–276. [Google Scholar]

- Dissanayake, K. Impact of Curing Salt (Nitrites) on the Processed Meat Products and Its Alternatives: A Review. New Mater. Compd. Appl. 2024, 8, 254–264. [Google Scholar] [CrossRef]

- Kunrath, C.A.; Savoldi, D.C.; Mileski, J.P.F.; Novello, C.R.; Da Trindade Alfaro, A.; Marchi, J.F.; Tonial, I.B. Application and Evaluation of Propolis, the Natural Antioxidant in Italian-Type Salami. Braz. J. Food Technol. 2017, 20, 2. [Google Scholar] [CrossRef][Green Version]

- Alahakoon, A.U.; Jayasena, D.D.; Ramachandra, S.; Jo, C. Alternatives to Nitrite in Processed Meat: Up to Date. Trends Food Sci. Technol. 2015, 45, 37–49. [Google Scholar]

- De Oliveira, V.S.; do Nascimento, R.M.; Cuambe, S.L.; Rosa, V.H.C.; Saldanha, T.; Barbosa Júnior, J.L.; Barbosa, M.I.M.J. Green Banana Biomass (Musa spp.): A Promising Natural Ingredient to Improve Technological and Nutritional Properties of Food Products. Food Biosci. 2024, 60, 104342. [Google Scholar]

- Riel, G.; Boulaaba, A.; Popp, J.; Klein, G. Effects of Parsley Extract Powder as an Alternative for the Direct Addition of Sodium Nitrite in the Production of Mortadella-Type Sausages—Impact on Microbiological, Physicochemical and Sensory Aspects. Meat Sci. 2017, 131, 166–175. [Google Scholar] [CrossRef]

- Aminzare, M.; Hashemi, M.; Ansarian, E.; Bimkar, M.; Azar, H.H.; Mehrasbi, M.R.; Daneshamooz, S.; Raeisi, M.; Jannat, B.; Afshari, A. Using Natural Antioxidants in Meat and Meat Products as Preservatives: A Review. Adv. Anim. Vet. Sci. 2019, 7, 417–426. [Google Scholar]

- Oh, Y.-N.; Choi, H.-Y.; Kim, Y.-B.; Hong, S.-G.; Kim, H.-Y. Effect of Paprika Powder on the Antioxidant Capacity of Emulsion-Type Sausages. Food Sci. Anim. Resour. 2024, 44, 1126–1141. [Google Scholar] [CrossRef]

- Bambeni, T.; Tayengwa, T.; Chikwanha, O.C.; Manley, M.; Gouws, P.A.; Marais, J.; Fawole, O.A.; Mapiye, C. Biopreservative Efficacy of Grape (Vitis vinifera) and Clementine Mandarin Orange (Citrus reticulata) by-Product Extracts in Raw Ground Beef Patties. Meat Sci. 2021, 181, 108609. [Google Scholar] [CrossRef]

- Egidio, M.; Casalino, L.; De Biasio, F.; Di Paolo, M.; Gómez-García, R.; Pintado, M.; Sardo, A.; Marrone, R. Antimicrobial Properties of Fennel By-Product Extracts and Their Potential Applications in Meat Products. Antibiotics 2024, 13, 932. [Google Scholar] [CrossRef]

- Porto-Fett, A.C.S.; Campano, S.G.; Rieker, M.; Stahler, L.J.; McGeary, L.; Shane, L.E.; Shoyer, B.A.; Osoria, M.; Luchansky, J.B. Behavior of Listeria Monocytogenes on Mortadella Formulated Using a Natural, Clean-Label Antimicrobial Agent during Extended Storage at 4 or 12 °C. J. Food Prot. 2018, 81, 769–775. [Google Scholar] [CrossRef]

- Lastra-Vargas, L.; Hernández-Nava, R.; Ruíz-González, N.; Jiménez-Munguía, M.T.; López-Malo, A.; Palou, E. Oregano Essential Oil as an Alternative Antimicrobial for the Control of Listeria Monocytogenes and Salmonella in Turkey Mortadella during Refrigerated Storage. Food Chem. Adv. 2023, 2, 100314. [Google Scholar] [CrossRef]

- Michalea-Dimoulea, N.A.; Karageorgou, A.; Goliomytis, M.; Tzoutzou, M.; Ilias-Dimopoulos, V.; Simitzis, P. The Effects of a Natural Citrus Phenolic Extract on the Quality Attributes and Oxidative Stability of Pariza-Type Meat Emulsion Product. Appl. Sci. 2024, 14, 6030. [Google Scholar] [CrossRef]

- Gwak, S.H.; Bae, S.M.; Jeong, J.Y. Evaluating the Potential of vegetable powders as Nitrite Replacements in Cured Pork Sausages: Effects of Different Processing Methods to Produce Chinese Cabbage and Radish Powders. Food Sci. Anim. Resour. 2024, 44, 1028–1039. [Google Scholar] [CrossRef] [PubMed]

- Ambrosio, R.L.; Smaldone, G.; Di Paolo, M.; Vollano, L.; Ceruso, M.; Anastasio, A.; Marrone, R. Effects of Different Levels of Inclusion of Apulo-calabrese Pig Meat on Microbiological, Physicochemical and Rheological Parameters of Salami during Ripening. Animals 2021, 11, 3060. [Google Scholar] [CrossRef]

- Xiong, Z.; Sun, D.W.; Pu, H.; Xie, A.; Han, Z.; Luo, M. Non-Destructive Prediction of Thiobarbituric Acid Reactive Substances (TBARS) Value for Freshness Evaluation of Chicken Meat Using Hyperspectral Imaging. Food Chem. 2015, 179, 175–181. [Google Scholar] [CrossRef]

- Di Paolo, M.; Ambrosio, R.L.; Lambiase, C.; Vuoso, V.; Salzano, A.; Bifulco, G.; Barone, C.M.A.; Marrone, R. Effects of the Aging Period and Method on the Physicochemical, Microbiological and Rheological Characteristics of Two Cuts of Charolais Beef. Foods 2023, 12, 531. [Google Scholar] [CrossRef]

- Marrone, R.; Smaldone, G.; Ambrosio, R.L.; Festa, R.; Ceruso, M.; Chianese, A.; Anastasio, A. Effect of Beetroot (Beta vulgaris) Extract on Black Angus Burgers Shelf Life. Ital. J. Food Saf. 2021, 10, 9031. [Google Scholar]

- ISO 18593: 2018; Microbiology of the Food Chain—Horizontal Methods for Surface Sampling. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms. Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 21528-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteri-aceae. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 6888-1:2003; Microbiology of Food and Animal Feeding Stuffs—Horizontal Methods for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species). International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 4831:2006; Microbiology of Food and Animal Feeding STUFFS—Horizontal Method for the Detection and Enumeration of Coliforms—Most Probable Number Technique. International Organization for Standardization: Geneva, Switzerland, 2006.

- UNI EN ISO 7932: 2020; Microbiology of Food and Animal Feeding STUFFS—Horizontal Method for the Enumeration of Presumptive Bacillus cereus. International Organization for Standardization: Geneva, Switzerland, 2020.

- UNI EN 10272:2006; Microbiology of Food and Animal Feedings Stuffs—Horizontal Method for the Detection and Enumeration of Campylobacter Growing at 41.5 °C. Part 1. Detection Method. ISO 10272-1. International Organization for Standardization: Geneva, Switzerland, 2006.

- UNI EN ISO 14189:2016; Water Quality—Enumeration of Clostridium Perfringens—Method Using Membrane Filtration. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. ISO: Geneva, Switzerland, 2017.

- ISO 6579-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp. ISO: Geneva, Switzerland, 2017.

- Jeong, S.; Hong, J.S.; Kim, J.O.; Kim, K.H.; Lee, W.; Bae, I.K.; Lee, K.; Jeong, S.H. Identification of Acinetobacter Species Using Matrix-Assisted Laser Desorption Ionization-Time of Flight Mass Spectrometry. Ann. Lab. Med. 2016, 36, 325–334. [Google Scholar] [CrossRef]

- Jaspal, M.H.; Badar, I.H.; Amjad, O.B.; Yar, M.K.; Ijaz, M.; Manzoor, A.; Nasir, J.; Asghar, B.; Ali, S.; Nauman, K.; et al. Effect of Wet Aging on Color Stability, Tenderness, and Sensory Attributes of Longissimus Lumborum and Gluteus Medius Muscles from Water Buffalo Bulls. Animals 2021, 11, 2248. [Google Scholar] [CrossRef] [PubMed]

- Júnior, M.M.; de Oliveira, T.P.; Gonçalves, O.H.; Leimann, F.V.; Medeiros Marques, L.L.; Fuchs, R.H.B.; Cardoso, F.A.R.; Droval, A.A. Substitution of Synthetic Antioxidant by Curcumin Microcrystals in Mortadella Formulations. Food Chem. 2019, 300, 125231. [Google Scholar] [CrossRef] [PubMed]

- Biasi, V.; Huber, E.; Goldoni, T.S.H.; de Melo, A.P.Z.; Hoff, R.B.; Verruck, S.; Barreto, P.L.M. Goldenberry Flour as a Natural Antioxidant in Bologna-Type Mortadella during Refrigerated Storage and in Vitro Digestion. Meat Sci. 2023, 196, 109041. [Google Scholar] [CrossRef] [PubMed]

- Lúcia Fernandes Pereira, A.; Fontoura Vidal, T.; Costa Teixeira, M.; Freitas de Oliveira, P.; Cláudio Fernandes Franco Pompeu, R.; Maria Martins Vieira, M.; Fernando Fuentes Zapata, J. Antioxidant Effect of Mango Seed Extract and Butylated Hydroxytoluene in Bologna-Type Mortadella during Storage. Ciência E Tecnol. Aliment. 2011, 31, 135–140. [Google Scholar]

- Orsolin, D.; Steffens, C.; Rosa, C.D.; Steffens, J. Redução Do Tempo No Processo de Cozimento de Mortadela e Avaliação Da Qualidade Final Do Produto. Cienc. Anim. Bras. 2015, 16, 589–597. [Google Scholar] [CrossRef]

- Baldin, J.C.; Michelin, E.C.; Polizer, Y.J.; Rodrigues, I.; de Godoy, S.H.S.; Fregonesi, R.P.; Pires, M.A.; Carvalho, L.T.; Fávaro-Trindade, C.S.; de Lima, C.G.; et al. Microencapsulated Jabuticaba (Myrciaria cauliflora) Extract Added to Fresh Sausage as Natural Dye with Antioxidant and Antimicrobial Activity. Meat Sci. 2016, 118, 15–21. [Google Scholar] [CrossRef]

- de Almeida, P.L.; de Lima, S.N.; Costa, L.L.; de Oliveira, C.C.; Damasceno, K.A.; dos Santos, B.A.; Campagnol, P.C.B. Effect of Jabuticaba Peel Extract on Lipid Oxidation, Microbial Stability and Sensory Properties of Bologna-Type Sausages during Refrigerated Storage. Meat Sci. 2015, 110, 9–14. [Google Scholar] [CrossRef]

- Nuñez de Gonzalez, M.T.; Hafley, B.S.; Boleman, R.M.; Miller, R.K.; Rhee, K.S.; Keeton, J.T. Antioxidant Properties of Plum Concentrates and Powder in Precooked Roast Beef to Reduce Lipid Oxidation. Meat Sci. 2008, 80, 997–1004. [Google Scholar] [CrossRef]

- Bekhit, A.E.D.; Geesink, G.H.; Ilian, M.A.; Morton, J.D.; Bickerstaffe, R. The Effects of Natural Antioxidants on Oxidative Processes and Metmyoglobin Reducing Activity in Beef Patties. Food Chem. 2003, 81, 175–187. [Google Scholar]

- Ghiretti, G.P.; Zanardi, E.; Novelli, E.; Campanini, G.; Dazzi, G.; Madarena, G.; Chizzolini, R. Comparative evaluation of some antioxidants in salame Milano and mortadella production. Meat Sci. 1997, 47, 167–176. [Google Scholar]

- Lee, M.A.; Han, D.J.; Jeong, J.Y.; Choi, J.H.; Choi, Y.S.; Kim, H.Y.; Paik, H.D.; Kim, C.J. Effect of Kimchi Powder Level and Drying Methods on Quality Characteristics of Breakfast Sausage. Meat Sci. 2008, 80, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Commission Regulation (EC). Commission Regulation (EC) No 1441/2007 of 5 December 2007 Amending Regulation (EC) No 2073/2005 on Microbiological Criteria for Foodstuffs. Off. J. Eur. Communities 2007, L322, 12–29. [Google Scholar]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Fernández-López, J.; Pérez-Álvarez, J.A. Effect of Added Citrus Fibre and Spice Essential Oils on Quality Characteristics and Shelf-Life of Mortadella. Meat Sci. 2010, 85, 568–576. [Google Scholar] [CrossRef] [PubMed]

- Fernández-López, J.; Lucas-González, R.; Roldán-Verdú, A.; Viuda-Martos, M.; Sayas-Barberá, E.; Ballester-Sánchez, J.; Haros, C.M.; Pérez-Álvarez, J.A. Effects of Black Quinoa Wet-Milling Coproducts on the Quality Properties of Bologna-Type Sausages during Cold Storage. Foods 2020, 9, 274. [Google Scholar] [CrossRef]

- Ranucci, D.; Miraglia, D.; Branciari, R.; Morganti, G.; Roila, R.; Zhou, K.; Jiang, H.; Braconi, P. Frankfurters Made with Pork Meat, Emmer Wheat (Triticum dicoccum Schübler) and Almonds Nut (Prunus dulcis Mill.): Evaluation during Storage of a Novel Food from an Ancient Recipe. Meat Sci. 2018, 145, 440–446. [Google Scholar] [CrossRef]

- dos Santos, B.A.; da Fontoura, A.M.; Correa, L.P.; Pinton, M.B.; Padilha, M.; Fracari, P.R.; Ribeiro, S.R.; Wagner, R.; Cichoski, A.J.; Barin, J.S.; et al. Jabuticaba Peel Extract and Nisin: A Promising Combination for Reducing Sodium Nitrite in Bologna-Type Sausages. Meat Sci. 2023, 204, 109273. [Google Scholar] [CrossRef]

| Parameter | Sample | T0 (Day 1) | T1 (Day 15) | T2 (Day 25) | T3 (Day 30) |

|---|---|---|---|---|---|

| Lightness, L* | MTS1 | 55.08 ± 3.23 | 56.70 ± 0.51 | 57.27 ± 1.15 | 56.73 ± 0.27 |

| MTS2 | 57.36 ± 0.77 | 57.27 ± 1.15 | 57.88 ± 0.80 | 55.82 ± 0.49 | |

| MTS3 | 57.55 ± 0.76 | 57.50 ± 0.69 | 56.87 ± 1.15 | 54.99 ± 3.68 | |

| MTC | 57.59 ± 0.76 | 57.63 ± 0.69 | 57.94 ± 1.15 | 56.91 ± 3.68 | |

| Redness, a* | MTS1 | 9.81 ± 0.46 A | 11.09 ± 0.78 y | 9.10 ± 0.75 B,X | 9.89 ± 0.24 A,X |

| MTS2 | 8.74 ± 1.14 A | 9.10 ± 0.75 x,a | 9.75 ± 0.60 Y | 11.04 ± 0.34 B,b,Y | |

| MTS3 | 9.14 ± 0.70 | 10.11 ± 0.51 a | 9.59 ± 0.23 Y | 8.22 ± 0.38 X,b | |

| MTC | 10.09 ± 0.70 | 10.98 ± 0.51 y | 11.06 ± 0.23 | 11.20 ± 0.38 Y | |

| Yellowness, b* | MTS1 | 13.23 ± 0.71 a,A,X,x | 10.52 ± 1.73 b | 10.59 ± 0.35 x,B | 11.59 ± 0.50 |

| MTS2 | 9.64 ± 0.38 Y | 10.59 ± 0.35 | 11.30 ± 0.36 | 11.65 ± 0.66 | |

| MTS3 | 10.78 ± 1.01 y | 10.43 ± 1.13 | 10 ± 0.82 x | 11.44 ± 1.07 | |

| MTC | 11.80 ± 1.01 | 11.84 ± 1.13 | 12.58 ± 0.82 y | 12.72 ± 1.07 |

| Parameter | Sample | T0 (Day 1) | T1 (Day 15) | T2 (Day 25) | T3 (Day 30) |

|---|---|---|---|---|---|

| Hardness, N | MTS1 | 7.09 ± 0.67 X | 7.49 ± 0.31 X | 8.06 ± 0.63 X,a | 6.90 ± 0.79 X,b |

| MTS2 | 4.61 ± 0.67 Y,a | 5.19 ± 0.99 Y | 5.88 ± 0.74 Y,b | 4.79 ± 0.88 Y | |

| MTS3 | 4.25 ± 0.28 Y,A | 3.93 ± 0.61 Y,D | 5.84 ± 0.14 Y,B | 4.48 ± 0.52 Z,C | |

| MTC | 4.06 ± 0.28 a,Y | 4.53 ± 0.61 Y | 5.36 ± 0.14 b,Y | 4.62 ± 0.52 Y | |

| Adhesiveness | MTS1 | −15.77 ± 4.43 X | −9.45 ± 4.61 X | −7.34 ± 2.41 | −6.07 ± 1.57 Y |

| MTS2 | −5.55 ± 2.62 Y | −6.03 ± 3.53 | −5.86 ± 3.04 | −4.45 ± 4.30 Y | |

| MTS3 | −3.66 ± 1.18 Y,A | −3.34 ± 0.43 Y,A | −3.65 ± 1.88 A | −3.53 ± 1.28 X,B | |

| MTC | −3.84 ± 1.18 Y | −3.49 ± 0.43 | −3.75 ± 1.88 | −4.63 ± 1.28 Y | |

| Elasticity | MTS1 | 0.92 ± 0.33 | 1.04 ± 0.29 x,X | 1.01 ± 0.21 x | 0.90 ± 0.12 Y |

| MTS2 | 0.89 ± 0.02 | 0.77 ± 0.09 Y | 0.81 ± 0.03 | 0.72 ± 0.21 Y | |

| MTS3 | 0.85 ± 0.09 A | 0.82 ± 0.12 y,A | 0.76 ± 0.10 y,A | 0.36 ± 0.07 X,B | |

| MTC | 0.88 ± 0.09 | 0.81 ± 0.12 y | 0.89 ± 0.10 | 0.84 ± 0.07 Y | |

| Chewiness, N × mm | MTS1 | 2.88 ± 0.18 X,A,a | 3.93 ± 0.22 X,B | 3.54 ± 0.50 X,b | 2.30 ± 0.30 |

| MTS2 | 1.74 ± 0.60 Y | 2.01 ± 0.22 | 1.99 ± 0.98 | 1.30 ± 0.47 | |

| MTS3 | 1.62 ± 0.38 | 1.97 ± 0.34 | 1.88 ± 0.32 | 1.76 ± 0.35 | |

| MTC | 1.70 ± 0.38 Y | 1.84 ± 0.34 Y | 1.95 ± 0.32 Y | 1.68 ± 0.35 | |

| Cohesiveness | MTS1 | 0.50 ± 0.04 | 0.51 ± 0.03 x | 0.40 ± 0.03 | 0.42 ± 0.06 Y |

| MTS2 | 0.45 ± 0.03 | 0.43 ± 0.05 | 0.38 ± 0.05 | 0.43 ± 0.03 Y | |

| MTS3 | 0.43 ± 0.02 A | 0.30 ± 0.04 y,A | 0.46 ± 0.05 A | 1.63 ± 0.34 Z,B | |

| MTC | 0.42 ± 0.02 A | 0.44 ± 0.04 A | 0.35 ± 0.05 A | 0.67 ± 0.34 B,X | |

| Gumminess, N | MTS1 | 3.48 ± 0.45 x,A,X | 3.76 ± 0.21 Y,A | 3.15 ± 0.50 B,X | 2.88 ± 0.46 B,X |

| MTS2 | 2.09 ± 0.39 Y | 2.27 ± 0.62 Z | 2.27 ±0.37 Y | 2.07 ± 0.34 y,Z | |

| MTS3 | 1.83 ± 0.20 Y,A | 1.46 ± 0.21 W,B | 2.69 ± 0.21 C | 2.43 ± 0.30 Y,D | |

| MTC | 2.85 ± 0.20 y,X | 2.96 ± 0.21 X | 3.17 ± 0.21 X | 2.66 ± 0.30 x,X |

| Parameter | Sample | T0 (Day 1) | T1 (Day 15) | T2 (Day 25) | T3 (Day 30) |

|---|---|---|---|---|---|

| TAB 30 °C | MTS1 | 1.96 | 5.49 | 5.70 | 6.46 |

| MTS2 | 1.96 | 4.10 | 3.96 | 5.94 | |

| MTS3 | 3.96 | 2.48 | 4.73 | 5.65 | |

| MTC | 2.83 | 3.31 | 3.89 | 4.02 | |

| Enterobacteriaceae | MTS1 | <1 | <1 | <1 | <1 |

| MTS2 | <1 | <1 | <1 | <1 | |

| MTS3 | <1 | <1 | <1 | <1 | |

| MTC | <1 | <1 | <1 | <1 | |

| β-Glucuronidase-positive E. coli | MTS1 | <1 | <1 | <1 | |

| MTS2 | <1 | <1 | <1 | ||

| MTS3 | <1 | <1 | <1 | ||

| MTC | <1 | <1 | <1 | ||

| Coagulase-positive Staphylococci | MTS1 | <2 | 3.07 | 5.70 | 3.49 |

| MTS2 | <2 | 2.56 | 3.95 | 3.47 | |

| MTS3 | 3.96 | <2 | 2.65 | 4.8 | |

| MTC | <2 | <2 | <2 | <2 | |

| Sulfite-reducing Clostridia | MTS1 | <2 | <2 | <2 | |

| MTS2 | <2 | <2 | <2 | ||

| MTS3 | <2 | <2 | <2 | ||

| MTC | <2 | <2 | <2 | ||

| Campylobacter spp. | MTS1 | <2 | <2 | <2 | |

| MTS2 | <2 | <2 | <2 | ||

| MTS3 | <2 | <2 | <2 | ||

| MTC | <2 | <2 | <2 | ||

| B. cereus | MTS1 | <2 | <2 | 2.91 | |

| MTS2 | <2 | <2 | <2 | ||

| MTS3 | <2 | <2 | <2 | ||

| MTC | <2 | <2 | <2 | ||

| Listeria monocytogenes | MTS1 | <2 | <2 | <2 | 2.25 |

| MTS2 | <2 | <2 | <2 | <2 | |

| MTS3 | <2 | <2 | <2 | <2 | |

| MTC | <2 | <2 | <2 | <2 |

| Attribute | MTS1 | MTS2 | MTS3 | MTC |

|---|---|---|---|---|

| External evaluation | ||||

| Color intensity | 4.1 ± 0.7 | 3.5 ± 0.4 | 3.5 ± 0.9 | 4.2 ± 0.0 |

| Visible seasoning | 4.1 ± 0.6 | 3.2 ± 0.3 | 4.9 ± 0.1 | 2.5 ± 0.1 |

| Homogeneity perception | 4.5 ± 0.7 | 4.1 ± 0.5 | 3.2 ± 0.8 | 4.8 ± 0.0 |

| Presence of holes | 2.1 ± 1.2 | 2.5 ± 0.3 | 2.5 ± 0.1 | 1 ± 0.0 |

| Hole size | 2 ± 0.6 | 1 ± 0.2 | 2 ± 0.2 | 1 ± 0.5 |

| Shine | 3 ± 0.0 | 3.5 ± 0.1 | 3.5 ± 0.0 | 3.6 ± 0.3 |

| Odor | ||||

| Intensity | 4 ± 0.0 | 4 ± 0.5 | 4.5 ± 0.7 | 4.75 ± 0.3 |

| Seasoning smell | 2.75 ± 0.8 | 2.75 ± 0.7 | 3.75 ± 0.9 | 4.1 ± 0.6 |

| Pepper smell | 2.25 ± 0.2 | 2.25 ± 0.9 | 2.5 ± 0.7 | 1 ± 0.2 |

| Unpleasant odors | 1 ± 0.5 | 1 ± 0.0 | 1 ± 0.3 | 1 ± 0.0 |

| Texture | ||||

| Chew resistance | 1.5 ± 0.6 | 1.25 ± 0.0 | 1 ± 0.0 | 1 ± 0.5 |

| Gelatinous texture | 2 ± 0.0 | 1.75 ± 0.2 | 2 ± 0.8 | 2.75 ± 0.4 |

| Juiciness | 3.5 ± 0.3 | 3 ± 0.0 | 3.5 ± 0.1 | 1.5 ± 0.1 |

| Taste | ||||

| Flavor intensity | 3.2 ± 0.6 | 2.5 ± 0.3 | 3.2 ± 0.6 | 4.7 ± 0.5 |

| Seasoning flavor | 3.5 ± 0.3 | 3 ± 0.5 | 3.5 ± 0.2 | 3.25 ± 0.2 |

| Pepper flavor | 2.5 ± 0.0 | 2 ± 0.3 | 2.5 ± 0.8 | 1 ± 0.8 |

| Saltiness | 3.5 ± 0.8 | 3 ± 0.6 | 3.5 ± 0.3 | 3 ± 0.3 |

| Unpleasant taste | 1 ± 0.0 | 1 ± 0.5 | 1 ± 0.0 | 1 ± 0.0 |

| Total score | 50.5 | 45.3 | 51.55 | 46.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Egidio, M.; Di Paolo, M.; Casalino, L.; Vuoso, V.; Alesio, S.; Sardo, A.; Marrone, R. Effects of Different Natural Additives Alternative to Chemical Ones on Artisanal Bologna-Type Sausages Shelf Life. Appl. Sci. 2025, 15, 3571. https://doi.org/10.3390/app15073571

Egidio M, Di Paolo M, Casalino L, Vuoso V, Alesio S, Sardo A, Marrone R. Effects of Different Natural Additives Alternative to Chemical Ones on Artisanal Bologna-Type Sausages Shelf Life. Applied Sciences. 2025; 15(7):3571. https://doi.org/10.3390/app15073571

Chicago/Turabian StyleEgidio, Marica, Marika Di Paolo, Loriana Casalino, Valeria Vuoso, Sophia Alesio, Alma Sardo, and Raffaele Marrone. 2025. "Effects of Different Natural Additives Alternative to Chemical Ones on Artisanal Bologna-Type Sausages Shelf Life" Applied Sciences 15, no. 7: 3571. https://doi.org/10.3390/app15073571

APA StyleEgidio, M., Di Paolo, M., Casalino, L., Vuoso, V., Alesio, S., Sardo, A., & Marrone, R. (2025). Effects of Different Natural Additives Alternative to Chemical Ones on Artisanal Bologna-Type Sausages Shelf Life. Applied Sciences, 15(7), 3571. https://doi.org/10.3390/app15073571