Integrating Cork Biochar as a Green Filler via Photopolymerization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cork Pyrolysis to Obtain Biochar

2.3. Sample Preparation of Cork Biochar Photopolymer Composites

2.4. Material Characterization

2.4.1. Characterization by Scanning Electron Microscopy

2.4.2. Tensile Testing

2.4.3. Thermal Characterization

2.4.4. Electrical Conductivity Testing

3. Results and Discussion

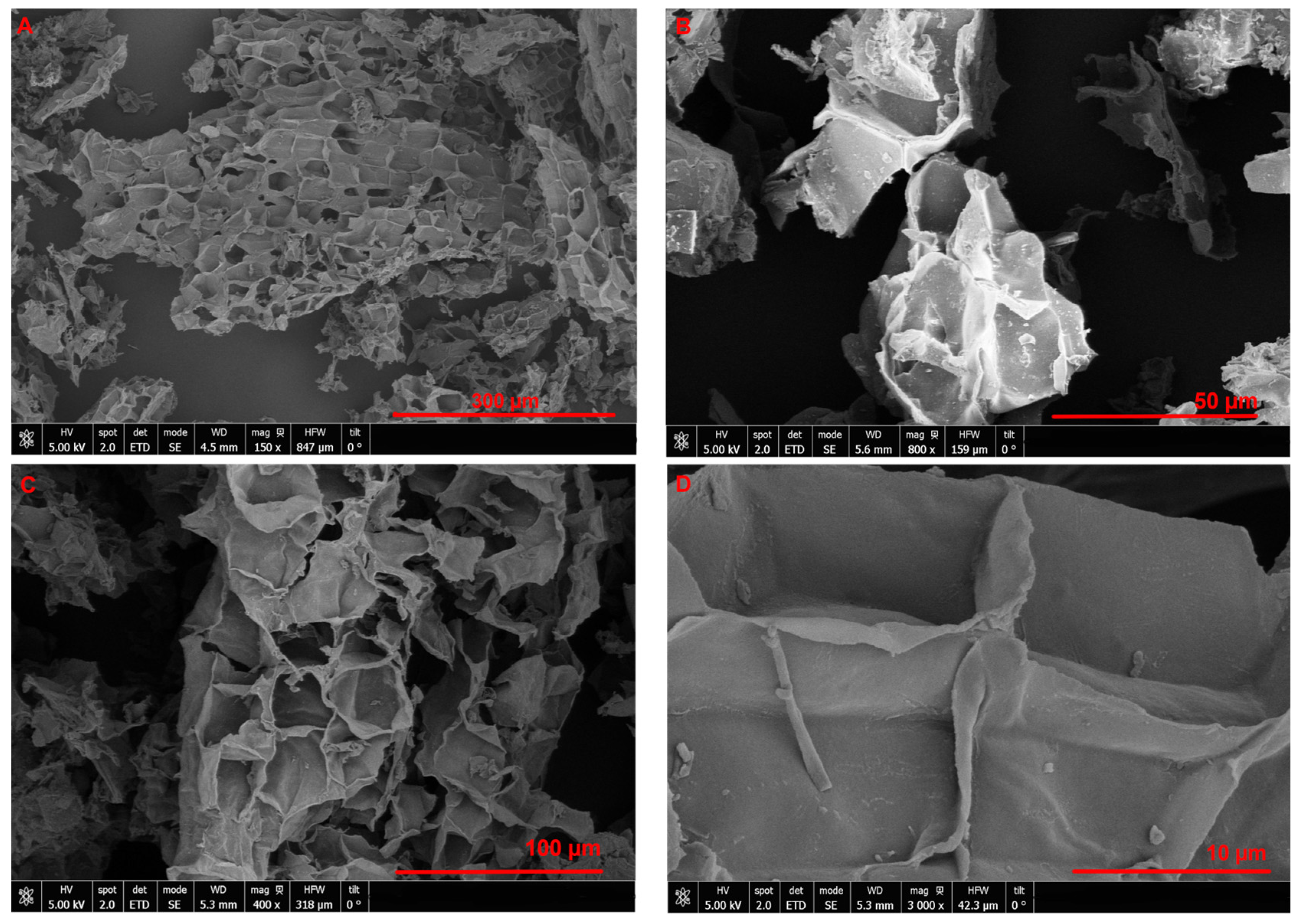

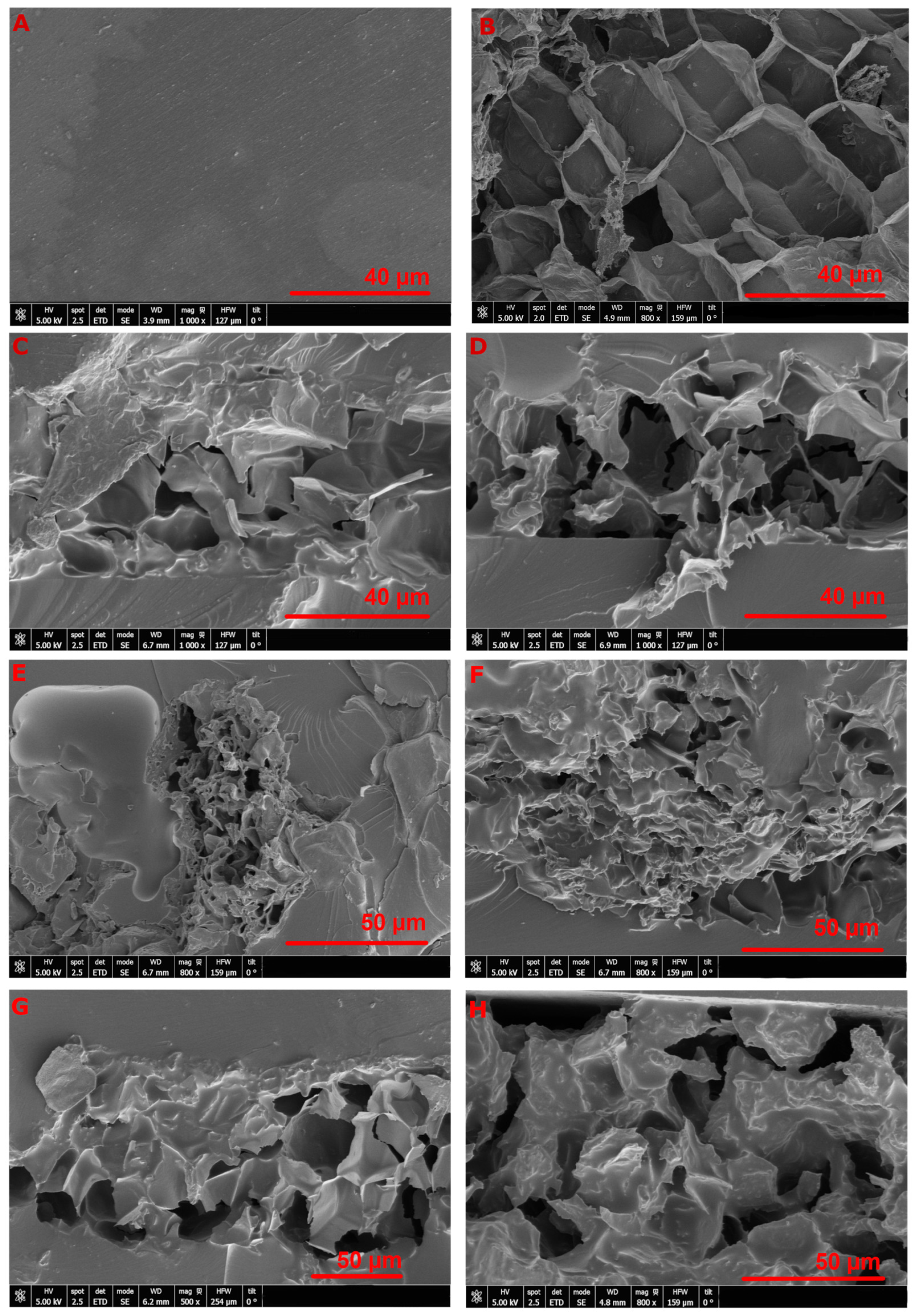

3.1. Morphological Structure Analysis of Cork Biochar and Cork Biochar Polymer Composites

3.2. Thermal Analysis of Cork Biochar-Based Composites

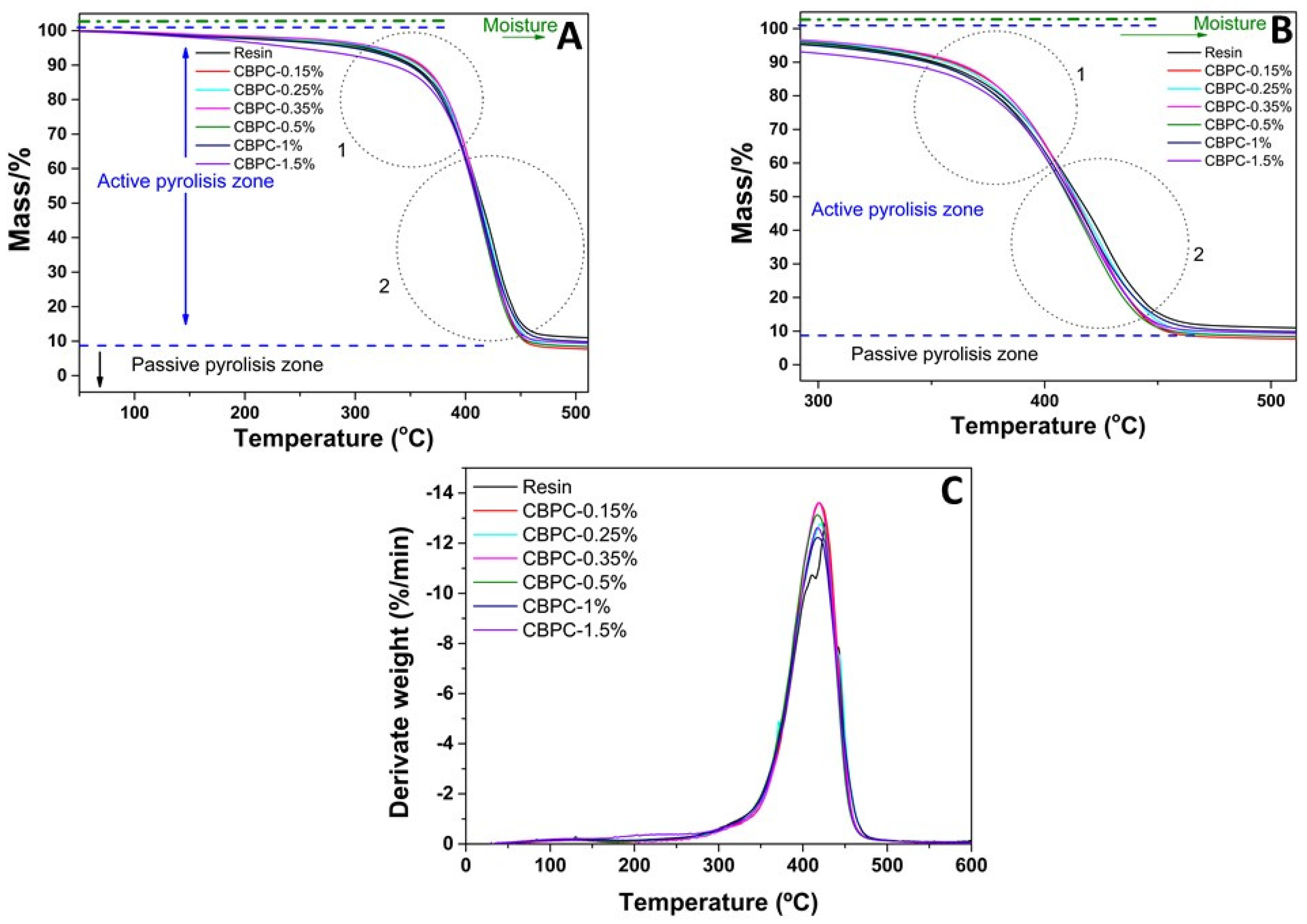

3.2.1. Thermogravimetric Analysis

3.2.2. Differential Scanning Calorimetry Analysis

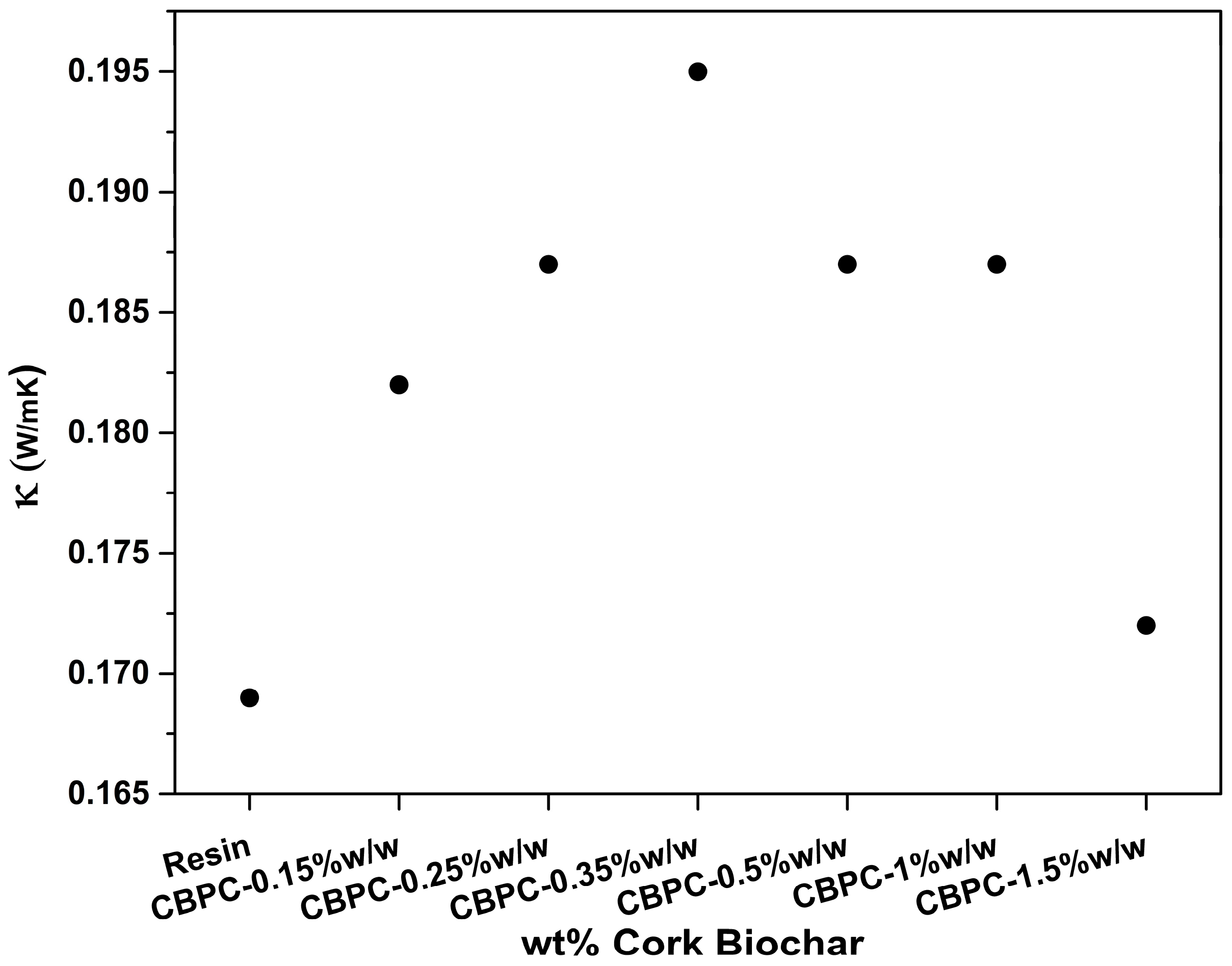

3.2.3. Thermal Conductivity (TC)

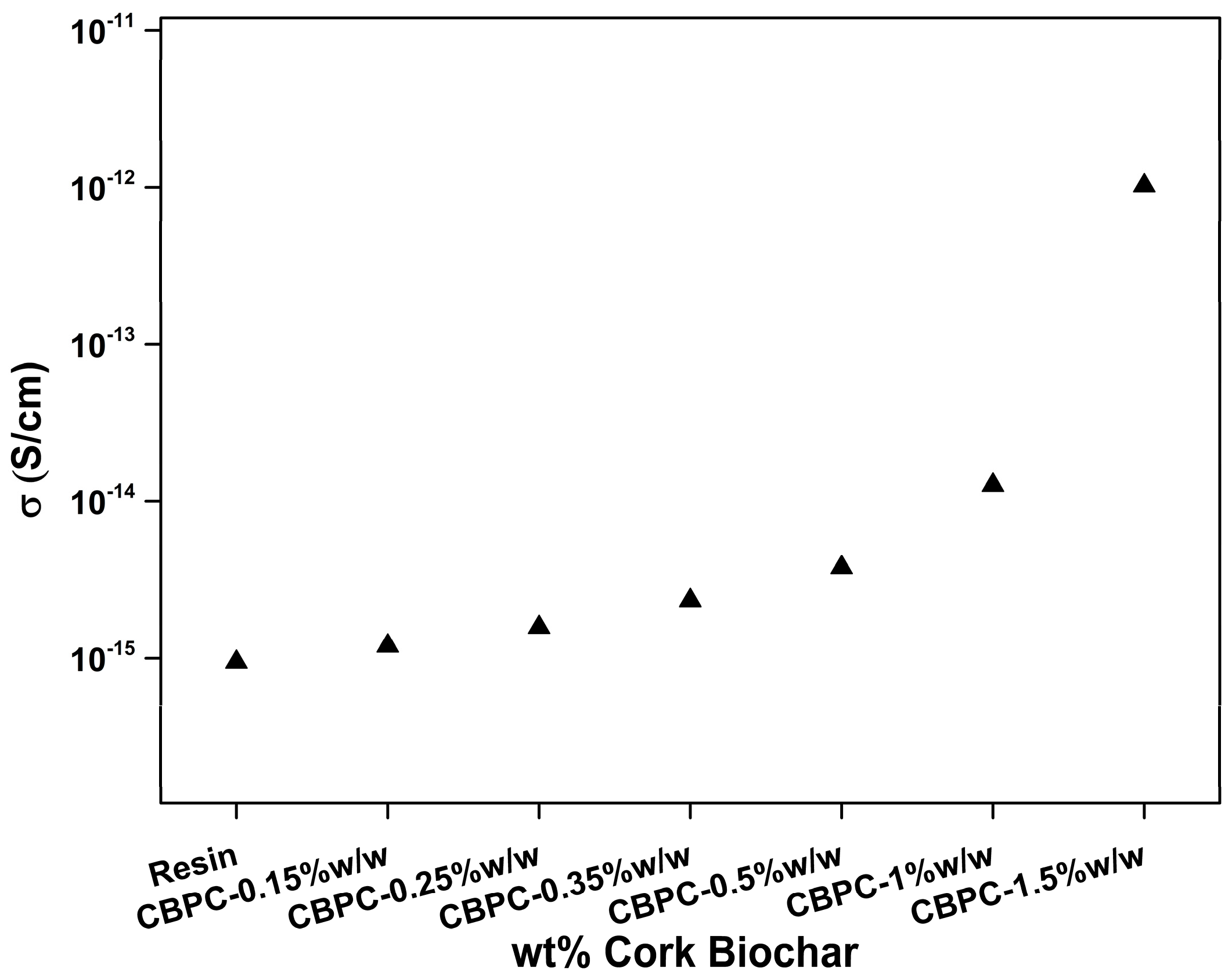

3.3. Electrical Conductivity of Cork Biochar Polymer Composites (CBPCs)

3.4. Mechanical Properties of Cork Biochar Polymer Composites (CBPCs)

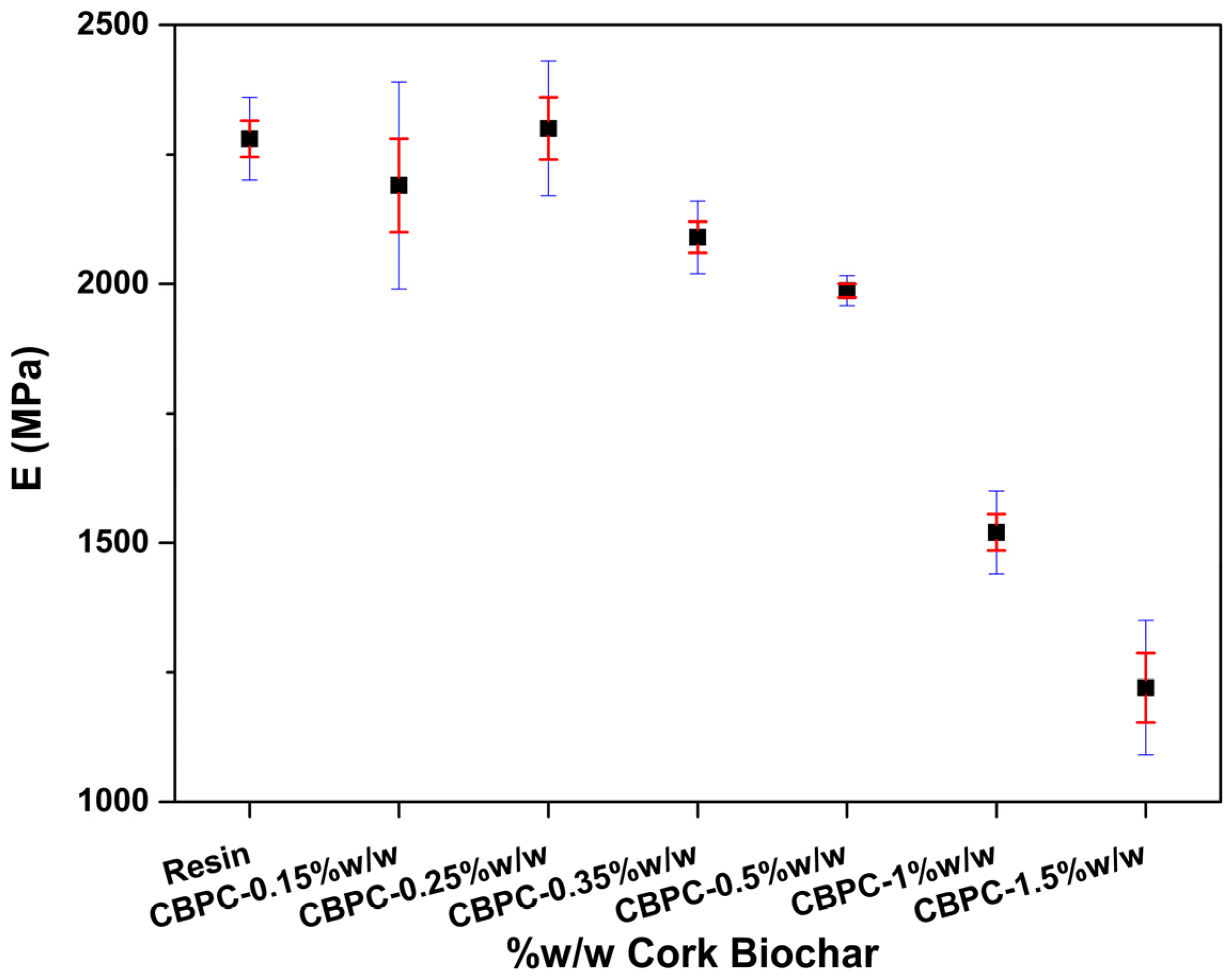

3.4.1. Young’s Modulus of CBPCs

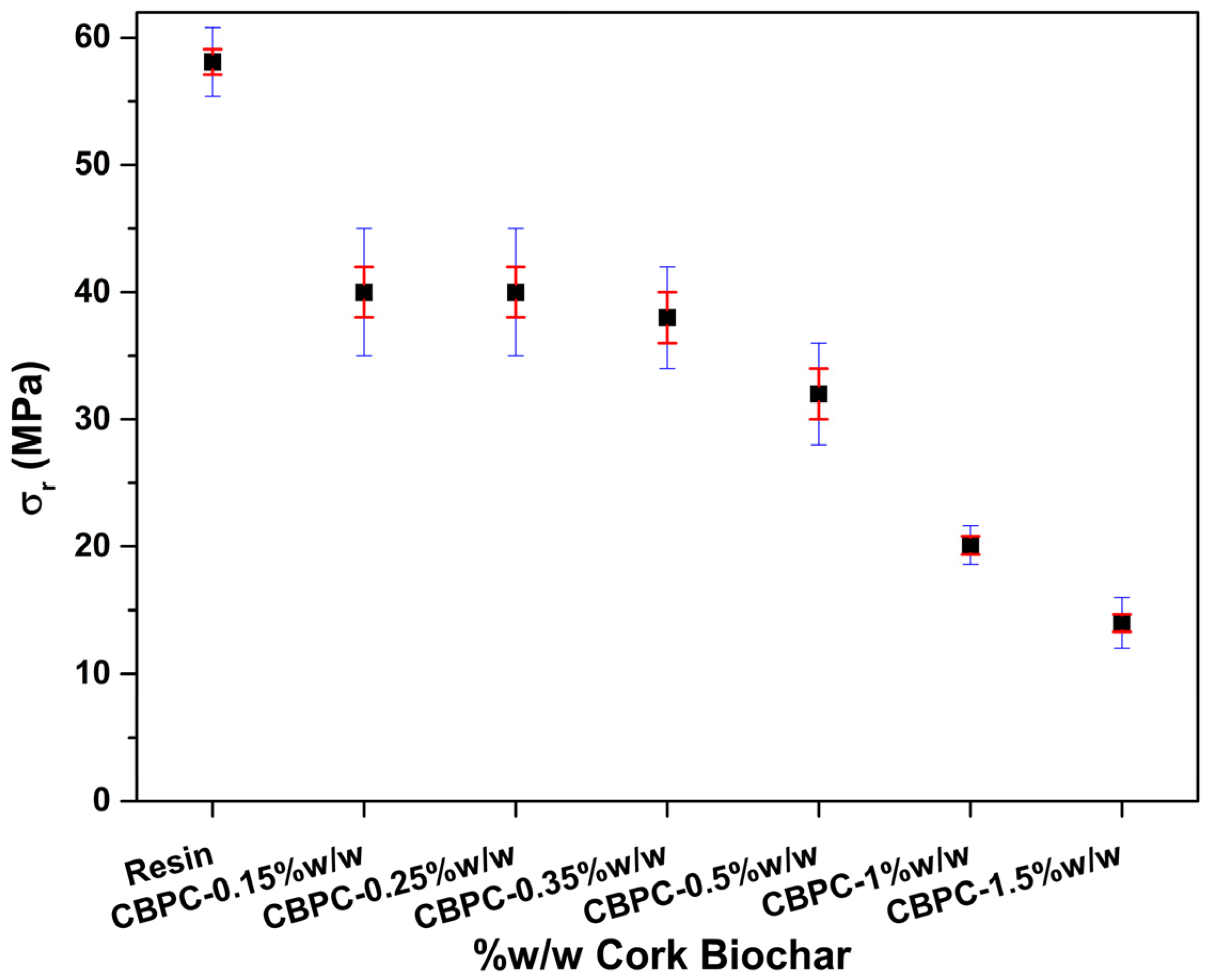

3.4.2. Tensile Strength of CBPCs

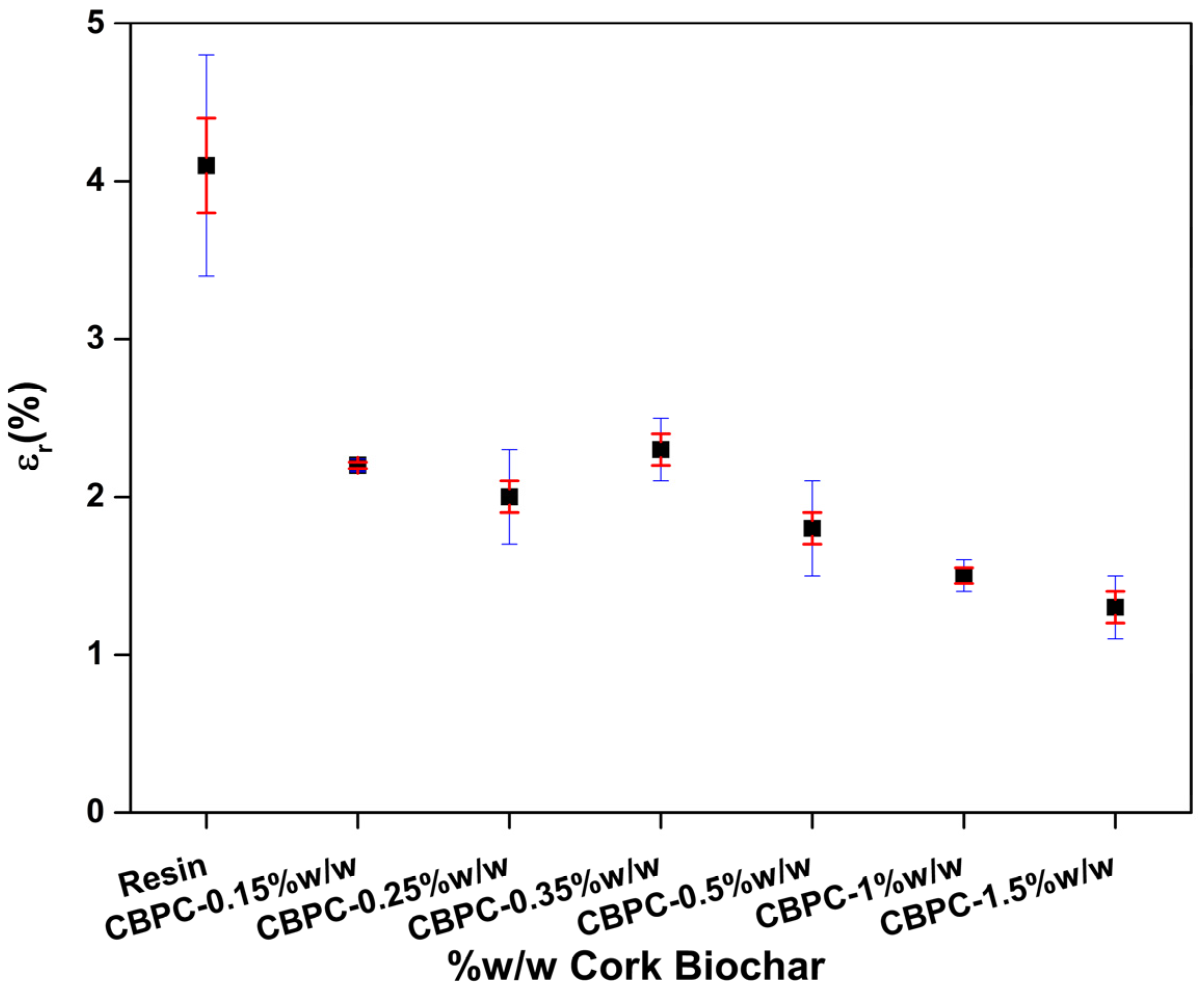

3.4.3. Percentage Elongation at Break of CBPCs

3.4.4. Discussion of the Mechanical Properties of the Cork Biochar-Integrated Materials and Interpretation of the Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Alami, A.H.; Ghani Olabi, A.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Xiao, B. A market assessment of additive manufacturing potential for the aerospace industry. J. Manuf. Process. 2021, 68, 728–738. [Google Scholar] [CrossRef]

- Culmone, C.; Smit, G.; Breedveld, P. Additive manufacturing of medical instruments: A state-of-the-art review. Addit. Manuf. 2019, 27, 461–473. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Islam, M.d.A.; Hossain, N.; Al Mahmud, M.Z.; Rayhan, M.T.; Nishi, N.J.; Chowdhury, M.A. Recent advances of additive manufacturing in implant fabrication—A review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, M.; Chohan, J.S. The role of additive manufacturing for biomedical applications: A critical review. J. Manuf. Process. 2021, 64, 828–850. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Koç, M. Life cycle assessment on fabrication and characterization techniques for additively manufactured polymers and polymer composites. Clean. Environ. Syst. 2024, 12, 100159. [Google Scholar] [CrossRef]

- Abad-Segura, E.; Cortés-García, F.J.; Belmonte-Ureña, L.J. The Sustainable Approach to Corporate Social Responsibility: A Global Analysis and Future Trends. Sustainability 2019, 11, 5382. [Google Scholar] [CrossRef]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D printing in upcycling plastic and biomass waste to sustainable polymer blends and composites: A review. Mater. Des. 2024, 237, 112558. [Google Scholar] [CrossRef]

- Ganguly, A.; Shankar, S.; Das, A.; Shukla, M.; Swaroop, C.; Bhardwaj, T. Natural fibre reinforced composites: A review based on additive manufacturing routes and biodegradability perspective. Mater. Today Proc. 2022, 62, 131–135. [Google Scholar] [CrossRef]

- Rigotti, D.; Pegoretti, A. 23—Additive manufacturing with biodegradable polymers. In Biodegradable Polymers, Blends and Composites; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ramesh, M., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2022; pp. 611–679. [Google Scholar] [CrossRef]

- Mukherjee, C.; Varghese, D.; Krishna, J.S.; Boominathan, T.; Rakeshkumar, R.; Dineshkumar, S.; Rao, C.B.; Sivaramakrishna, A. Recent advances in biodegradable polymers—Properties, applications and future prospects. Eur. Polym. J. 2023, 192, 112068. [Google Scholar] [CrossRef]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci. Total Environ. 2023, 882, 163446. [Google Scholar] [CrossRef] [PubMed]

- Ji, A.; Zhang, S.; Bhagia, S.; Yoo, C.G.; Ragauskas, A.J. 3D printing of biomass-derived composites: Application and characterization approaches. RSC Adv. 2020, 10, 21698–21723. [Google Scholar] [CrossRef]

- Romani, A.; Suriano, R.; Levi, M. Biomass waste materials through extrusion-based additive manufacturing: A systematic literature review. J. Clean. Prod. 2023, 386, 135779. [Google Scholar] [CrossRef]

- Rahman, A.M.; Rahman, T.T.; Pei, Z.; Ufodike, C.O.; Lee, J.; Elwany, A. Additive Manufacturing Using Agriculturally Derived Biowastes: A Systematic Literature Review. Bioengineering 2023, 10, 845. [Google Scholar] [CrossRef]

- Chang, B.P.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. A comprehensive review of renewable and sustainable biosourced carbon through pyrolysis in biocomposites uses: Current development and future opportunity. Renew. Sustain. Energy Rev. 2021, 152, 111666. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste derived biochar as an alternative filler in biocomposites—Mechanical, thermal and morphological properties of biochar added biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of Biochar to Improve Mechanical, Thermal and Electrical Properties of Polymer Composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef] [PubMed]

- Minugu, O.P.; Gujjala, R.; Shakuntala, O.; Manoj, P.; Chowdary, M.S. Effect of biomass derived biochar materials on mechanical properties of biochar epoxy composites. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2021, 235, 5626–5638. [Google Scholar] [CrossRef]

- Hernandez-Charpak, Y.D.; Trabold, T.A.; Lewis, C.L.; Diaz, C.A. Biochar-filled plastics: Effect of feedstock on thermal and mechanical properties. Biomass Convers. Biorefinery 2022, 12, 4349–4360. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Gurav, R.; Choi, T.R.; Kim, H.J.; Yang, S.Y.; Song, H.S.; Park, J.Y.; Park, Y.L.; Han, Y.H.; Choi, Y.K.; et al. Conversion of waste cooking oil into biodiesel using heterogenous catalyst derived from cork biochar. Bioresour. Technol. 2020, 302, 122872. [Google Scholar] [CrossRef]

- Quarta, A.; Novais, R.M.; Bettini, S.; Iafisco, M.; Pullar, R.C.; Piccirillo, C. A sustainable multi-function biomorphic material for pollution remediation or UV absorption: Aerosol assisted preparation of highly porous ZnO-based materials from cork templates. J. Environ. Chem. Eng. 2019, 7, 102936. [Google Scholar] [CrossRef]

- Stephanie, H.; Mlsna, T.E.; Wipf, D.O. Functionalized biochar electrodes for asymmetrical capacitive deionization. Desalination 2021, 516, 115240. [Google Scholar] [CrossRef]

- Pullar, R.C.; Gil, L.; Oliveira, F.A.C. Biomimetic cork-based CeO2 ecoceramics for hydrogen generation using concentrated solar energy. Cienc. Tecnol. Dos Mater. 2016, 28, 23–28. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Wang, Q.; Chu, D.; Luo, C.; Lai, Z.; Shang, S.; Rahimi, S.; Mu, J. Transformation mechanism from cork into honeycomb–like biochar with rich hierarchical pore structure during slow pyrolysis. Ind. Crops. Prod. 2022, 181, 114827. [Google Scholar] [CrossRef]

- Zhai, W.; Zhong, Y.; Xu, M.; Wei, X.; Cai, L.; Xia, C. Transforming wastes into functional materials: Natural cork-based physical structural components and polymers. Green Chem. 2024, 26, 8615–8641. [Google Scholar] [CrossRef]

- Wang, Q.H.; Lai, Z.Y.; Mu, J.; Chu, D.M.; Zang, X.R. Converting industrial waste cork to biochar as Cu (II) adsorbent via slow pyrolysis. Waste Manag. 2020, 105, 102–109. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, L.; Li, Z.; Wang, S.; Shi, J.; Tang, W.; Li, N.; Yang, J. The recent development of vat photopolymerization: A review. Addit. Manuf. 2021, 48, 102423. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Oliveira, J.; Etxebarria, I.; Luis Vilas-Vilela, J.; Lanceros-Mendez, S. State-of-the-Art and Future Challenges of UV Curable Polymer-Based Smart Materials for Printing Technologies. Adv. Mater. Technol. 2019, 4, 1800618. [Google Scholar] [CrossRef]

- D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- E1350-23; Standard Guide for Testing Sheathed Thermocouples, Thermocouple Assemblies, and Connecting Wires Prior to, and After Installation or Service. ASTM International: West Conshohocken, PA, USA, 2023.

- D257-21; Standard Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- E1530-25; Standard Test Method for Evaluating the Resistance to Thermal Transmission by the Guarded Heat Flow Meter Technique. ASTM International: West Conshohocken, PA, USA, 2025.

- Jankovic, B.; Manic, N.; Stojiljkovic, D. The gaseous products characterization of the pyrolysis process of various agricultural residues using TGA-DSC-MS techniques. J. Therm. Anal. Calorim. 2020, 139, 3091–3106. [Google Scholar] [CrossRef]

- Zhao, S.H.; Luo, Y.H.; Zhang, Y.L.; Long, Y.F. Experimental Investigation of Rice Straw and Model Compound Oxidative Pyrolysis by in Situ Diffuse Reflectance Infrared Fourier Transform and Coupled Thermogravimetry-Differential Scanning Calorimetry/Mass Spectrometry Method. Energy Fuels 2015, 29, 4361–4372. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Jiang, F.; Drummer, D. Curing Kinetic Analysis of Acrylate Photopolymer for Additive Manufacturing by Photo-DSC. Polymers 2020, 12, 1080. [Google Scholar] [CrossRef]

- De Leon, A.S.; Molina, I.S. Influence of the Degree of Cure in the Bulk Properties of Graphite Nanoplatelets Nanocomposites Printed via Stereolithography. Polymers 2020, 12, 1103. [Google Scholar] [CrossRef]

- Sekmen, K.; Rehbein, T.; Johlitz, M.; Lion, A.; Constantinescu, A. Thermal analysis and shrinkage characterization of the photopolymers for DLP additive manufacturing processes. Contin. Mech. Thermodyn. 2024, 36, 351–368. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Estaji, S.; Kiaei, H.; Mansourian-Tabaei, M.; Nouranian, S.; Jafari, S.H.; Ruckdäschel, H.; Arjmand, M.; Khonakdar, H.A. A review of electrical and thermal conductivities of epoxy resin systems reinforced with carbon nanotubes and graphene-based nanoparticles. Polym. Test. 2022, 112, 107645. [Google Scholar] [CrossRef]

- Mingo, N.; Esfarjani, K.; Broido, D.; Stewart, D. Cluster scattering effects on phonon conduction in graphene. Phys. Rev. B 2010, 81, 045408. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, K.; Feng, Y.; Liang, L.; Chi, M.; Zhang, Z.; Chen, X. Recent advances in thermal-conductive insulating polymer composites with various fillers. Compos. Part A Appl. Sci. Manuf. 2024, 178, 107998. [Google Scholar] [CrossRef]

- Ali, Z.; Yaqoob, S.; Yu, J.; D’Amore, A. Critical review on the characterization, preparation, and enhanced mechanical, thermal, and electrical properties of carbon nanotubes and their hybrid filler polymer composites for various applications. Compos. Part C Open Access 2024, 13, 100434. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Zhang, B.Y.; Guo, B.H.; Yu, J.; Guo, Z.X. Improved electrical conductivity of polymer/carbon black composites by simultaneous dispersion and interaction-induced network assembly. Compos. Sci. Technol. 2019, 179, 106–114. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X.; Song, W. Effect of various carbon nanofillers and different filler aspect ratios on the thermal conductivity of epoxy matrix nanocomposites. Results Phys. 2019, 15, 102771. [Google Scholar] [CrossRef]

- Tessema, A.; Zhao, D.; Moll, J.; Xu, S.; Yang, R.; Li, C.; Kumar, S.K.; Kidane, A. Effect of filler loading, geometry, dispersion and temperature on thermal conductivity of polymer nanocomposites. Polym. Test. 2017, 57, 101–106. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Mozrall, A.M.; Hernandez-Charpak, Y.D.; Trabold, T.A.; Diaz, C.A. Effect of biochar content and particle size on mechanical properties of biochar-bioplastic composites. Sustain. Chem. Pharm. 2023, 35, 101223. [Google Scholar] [CrossRef]

- Girdthep, S.; Komrapit, N.; Molloy, R.; Lumyong, S.; Punyodom, W.; Worajittiphon, P. Effect of plate-like particles on properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend: A comparative study between modified montmorillonite and graphene nanoplatelets. Compos. Sci. Technol. 2015, 119, 115–123. [Google Scholar] [CrossRef]

- Tavares, L.; Sousa, L.R.; da Silva, S.M.; Lima, P.S.; Oliveira, J.M. Effect of Incorporation of Graphene Nanoplatelets on Physicochemical, Thermal, Rheological, and Mechanical Properties of Biobased and Biodegradable Blends. Polymers 2023, 15, 3622. [Google Scholar] [CrossRef] [PubMed]

| Formulation | %w/w Cork Biochar |

|---|---|

| Resin | 0 |

| CBPC-0.15 | 0.15 |

| CBPC-0.25 | 0.25 |

| CBPC-0.35 | 0.35 |

| CBPC-0.5 | 0.5 |

| CBPC-1 | 1 |

| CBPC-1.5 | 1.5 |

| CBPC | %w/w Cork Biochar | Young’s Modulus (E) (MPa) (±SD) | Tensile Strength (σr) (MPa) (±SD) | Elongation at Break (Ɛr%) (±SD) |

|---|---|---|---|---|

| Resin | 0 | 2280 ± 80 | 58.1 ± 2.7 | 4.1 ± 0.7 |

| CBPC-0.15 | 0.15 | 2190 ± 200 | 40 ± 5 | 2.20 ± 0.04 |

| CBPC-0.25 | 0.25 | 2300 ± 130 | 40 ± 5 | 2.0 ± 0.3 |

| CBPC-0.35 | 0.35 | 2090 ± 70 | 38 ± 4 | 2.3 ± 0.2 |

| CBPC-0.5 | 0.5 | 1987 ± 29 | 32 ± 4 | 1.8 ± 0.3 |

| CBPC-1 | 1 | 1520 ± 80 | 20.1 ± 1.5 | 1.5 ± 0.1 |

| CBPC-1.5 | 1.5 | 1220 ± 130 | 14 ± 2 | 1.3 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Ocaña, I.; Fernández-Delgado, N.; Benito, J.; Molina, S.I. Integrating Cork Biochar as a Green Filler via Photopolymerization. Appl. Sci. 2025, 15, 3207. https://doi.org/10.3390/app15063207

Romero-Ocaña I, Fernández-Delgado N, Benito J, Molina SI. Integrating Cork Biochar as a Green Filler via Photopolymerization. Applied Sciences. 2025; 15(6):3207. https://doi.org/10.3390/app15063207

Chicago/Turabian StyleRomero-Ocaña, Ismael, Natalia Fernández-Delgado, Javier Benito, and Sergio I. Molina. 2025. "Integrating Cork Biochar as a Green Filler via Photopolymerization" Applied Sciences 15, no. 6: 3207. https://doi.org/10.3390/app15063207

APA StyleRomero-Ocaña, I., Fernández-Delgado, N., Benito, J., & Molina, S. I. (2025). Integrating Cork Biochar as a Green Filler via Photopolymerization. Applied Sciences, 15(6), 3207. https://doi.org/10.3390/app15063207