Abstract

The food industry mostly utilises thermal processing technologies to enhance the food safety and shelf life by inactivating enzymes, pathogens, and spores. However, there is a shift towards consumer preference for minimally processed foods due to health concerns and the limitations of the conventional thermal processing methods. Thus, the food industry has recently increased the utilisation of non-thermal technologies for food processing and preservation in the production of foods while maintaining the nutritional and sensory qualities of the food. Non-thermal approaches including a Pulsed Electric Field (PEF), High-Pressure Processing (HPP), Ionising Radiation (IOR), Ultraviolet (UV) light, Pulsed Light (PL), and Cold plasma (CP) are increasingly being employed for food preservation, especially for heat-sensitive foods, as they enable microbial inactivation with minimal or no thermal application and less degradation of bioactive constituents of foods. As opposed to conventional thermal technologies that may compromise the food quality, non-thermal preservation processes retain the texture, taste, and rheological properties, therefore presenting an invaluable option in the food chain system. Moreover, non-thermal food processing approaches are becoming well-established within the food sector as they can be utilised for a wide range of food items. This paper provides a critical review of the industrial applications, mechanisms of action, and efficiency of major non-thermal food processing technologies. In addition, it also addresses their impact on the food quality, microstructure, and rheology, while exploring their limitations. Although these technologies are of great value in preserving the shelf life and food integrity, high upfront investment costs continue to discourage large-scale adoption. However, with the growing demand for fresh and minimally processed foods, the operational costs for these technologies are expected to become more accessible, promoting their widespread adoption in the industry.

1. Introduction

There is rapid development in the food processing industries globally. This is spurred by the need to improve food processing technologies for an extended shelf life of food and the elimination of spoilage and food-poisoning pathogens [1]. These developments within the agro-sector have improved the safety of foods and are geared towards meeting the demands of consumers for fresh and minimally processed healthy foods with a prolonged shelf life [2,3,4,5]. To fulfil these new consumer requirements, old thermal processes will be phased out in the near future [6]. Generally, high-temperature heating systems utilised in food preservation negatively affect the nutritional value and sensory properties of foods, such as the degradation of heat-sensitive vitamins (e.g., vitamin C), a loss of essential amino acids, and alterations in the texture, colour, and flavour [7]. The main purpose of heat processing technology is to reduce the multiplication of microorganisms and the deterioration of food [8]. New technologies are designed to inactivate microorganisms and maintain other sensory aspects and nutritional values of foods without the application of extreme heat [5,9]. For example, the most common and straightforward method for preserving liquid foods is to use an ultra-high temperature (UHT) or high-temperature short-time (HTST). However, the drawback of this method is that it results in enzyme inactivation, useful proteins are denatured, and vital vitamins are lost [10]. Also, a large amount of energy is consumed by heating, which is not cost-effective, especially in large-scale food production [11]. Recent research in food processing and preservation is targeted at the development of non-heating methods to produce safe processed foods while inactivating microorganisms and being energy efficient, with the overall drive to produce an environmentally friendly product [12,13].

Several non-thermal approaches are available currently and with applications in the food industry. These technologies, that can replace traditional thermal food processing techniques, are becoming very common as they emerge [5,14]. These include physical processes such as a Pulsed Electric Field (PEF), High-Pressure Processing (HPP), Ionising Radiation (IOR), Ultraviolet and Pulsed White Light, as well as chemical treatments such as ozone treatment and cold plasma [6,15,16,17,18,19]. These technologies limit the physical and chemical changes that occur during high-temperature processing, which also affects the bioactive components of foods [20,21,22,23]. The main gain of using such non-thermal processes is to supply superior-quality food with characteristics of fresh food and improved qualities. Furthermore, they are environmentally friendly and economical, finding application in various foods with different rheologies, including juices [20,24,25,26]. The global market for non-thermal food processing technologies has also continued to grow over the years, fueled by increasing consumer demand for minimally processed foods and industry efforts to enhance the food safety and quality [27]. For example, research, development, and manufacturing advances in HPP equipment have increased the production efficiency and operational stability. Geographic regions such as North America, Europe, and Asia have increased large-scale HPP capabilities because of this, with the value of the market standing at approximately USD 9.8 billion in 2015 and projected to grow to USD 54.77 billion by 2025, driven by an average production growth of 500,000 tons annually [27]. However, HPP food is still higher in its processing cost compared to traditional thermal pasteurisation, at 10.7 US¢/L for orange juice compared to 1.5 US¢/L for thermal pasteurisation [5].

The evaluation of the efficiency of certain non-thermal processing technologies to deactivate a range of spore-forming microbes and spores in various food products indicates that a combination of methods is needed [27]. For instance, it has been found that the complete inactivation of microbial spores such as Bacillus pumilus and food safety can be achieved using a combination of supercritical carbon oxide and a co-solvent or an antimicrobial peptide [28]. However, the literature on the effects of thermal and non-thermal food-processing technologies on food properties is only just being explored in full, with limited studies such as the impact on the pectin structure and functionality in fruit- and vegetable-based products being published [29]. In 2021, a review on the impact of non-thermal processing on the structural changes of food components at the micro- and macroscopic levels was published [30]. The review focused on cold plasma treatment, high-pressure processing, irradiation, ultrasonication, a high-voltage electric field, pulsed light technology, and pulsed electric field technologies. Their impact on the structure of food such as protein structure modification was elucidated. Recently, an overview that focused on the impact of non-thermal processing techniques on the functional and physicochemical characteristics of food macromolecules has also been reported [31]. However, how the rheological properties of food products are influenced by non-thermal processing technologies is limited in the literature. Thus, an in-depth understanding of the effects of non-thermal food processing technologies on the food quality and rheology are critical for their application and design.

From a functional perspective, the effectiveness of non-thermal processing depends on its interaction with the microstructure of the food products. Considering that the rheological properties of foods are a function of their microstructure [32], this microstructure is dictated by the complex physicochemical interactions and inter/intramolecular bonds between the food components. This contributes to a food’s mixing attributes, mass and heat transport, and handling during processing. Hence, there is a correlation between the microstructure, rheology, and food processing. Furthermore, during non-thermal processing techniques, the rheological properties of the food determine the flowability, deformation behaviour, and texture under physical forces. This can determine the choice of processing method because of its influence on the processability and stability of food products, mouthfeel attributes, digestion, and absorption of food [33]. Overall, the changes in rheological properties during non-thermal processing are crucial in determining the quality characteristics of the food products [34]. Thus, there is a correlation between non-thermal processing and changes in the rheological properties and quality of different foods including fruit/vegetable products (juice, nectar, and puree) and starchy food products.

Studies on food rheology are important because of the complex nature and interaction of food components. There is a broad spectrum of rheological behaviours and textural features, from low-viscosity fluids like milk or honey to hard solids. (e.g., saltine crackers or raw carrots) [35]. The ability of the food products to deform and flow under shear force defines the rheology, which can be characterised via viscosity, plasticity, and elasticity. The rheological properties can be influenced by changes in the processing temperature, pressure, and external forces. As a result, the flow behaviour of liquid food products such as juice, nectar, puree, honey, mayonnaise, dough, chocolate, etc., can be modified to either Newtonian or non-Newtonian. Overall, in most cases, the complex microstructure of the food products confer mostly non-Newtonian behaviour, in which their apparent viscosity might increase or decrease with a shear rate or both [36]. Other important rheological properties include the yield stress, shear response, and recovery time. For certain foods, the rheological behaviours during processing can be modelled as Newtonian and non-Newtonian (e.g., pseudoplastic, dilatant, Bingham, Herschel–Bulkley, and thixotropic), with the viscoelasticity properties of these food products (which describe the viscosity and elasticity state) signifying the exhibition of both liquid-like (viscous) and solid-like (elastic) behaviours. In food processing systems, these rheological models can be used to predict the texture of food products and shelf life as a function of processing conditions [37]. Hence, an in-depth understanding of food rheology in various non-thermal food processing technologies can be of benefit to the process design, optimisation of processing conditions, product development, and quality control, as the rheological properties of food products can influence their mass transport during non-thermal processing such as drying, thus providing food scientists with quantitative and qualitative data on foods’ mechanical properties and approximate texture [38]. Similarly, for food ingredient analysis and processing, rheological measurements of ingredients and mathematical modelling can be undertaken to ensure appropriate mixing ratios. This reduces production and testing costs and allows for more fine input control using sensitive methods [36].

A variety of factors affect food rheology. For example, temperature fluctuations during the processing and storage of milk may affect yoghurt’s rheology. The numerous iterations of the Arrhenius equation may show how temperature influences the food fluid viscosity [38,39]. Therefore, food companies test the rheological properties of the fluid, thus reducing production loss and improving the product quality, as exemplified in mashed fruits or ground meat, which are characterised as semisolid foods and would exhibit Non-Newtonian behaviour [36,40,41]. The challenge associated with the processing of foods with a complex rheology is the utilisation of an adequate processing technology that does not destroy the food’s properties or is insufficient to ensure food safety [42,43]. Non-thermal processes can be employed for these foods as there is an established correlation between high-temperature treatment and the flow behaviour of foods, which may not be desirable. Furthermore, the non-thermal treatment of foods does not affect the structures and dynamics of the structural development of foods such as pastries and other sugary and sugar-free foods, making them a viable option in the growing trend within the food industry to reduce the presence of sugar and other sweeteners in food [44,45,46,47,48,49]. They will be beneficial in closely matching the rheological behaviour and phase transitions that occur during baking and other processing that new food formulations receive [45].

In addition to utilising non-thermal technologies for foods with a complex rheology and improving the food quality, non-thermal processing technologies inactivate microorganisms that lead to the spoilage of enzymes and extend the shelf life of foods while maintaining their organoleptic, nutritional, and quality characteristics. Despite these developments, there are still some research gaps concerning the extent to which various non-thermal technologies affect the rheological characteristics of food matrices. The effects of each non-thermal method on complex food structures and their potential as substitutes for traditional thermal treatments without compromising the quality, especially in structured and semi-solid foods, are not well understood. Furthermore, while specific non-thermal technologies have been studied, how well they work in various foods have not yet been thoroughly compared, especially when it comes to microbial inactivation, texture preservation, and rheological attributes. Hence, this study intends to thoroughly review and compare various non-thermal technologies with respect to their impact on food rheology, assess their efficacy in microbial inactivation and quality retention across a range of food matrices, and identify major technological and industrial barriers that prevent their widespread use.

2. Pulsed Electric Field (PEF)

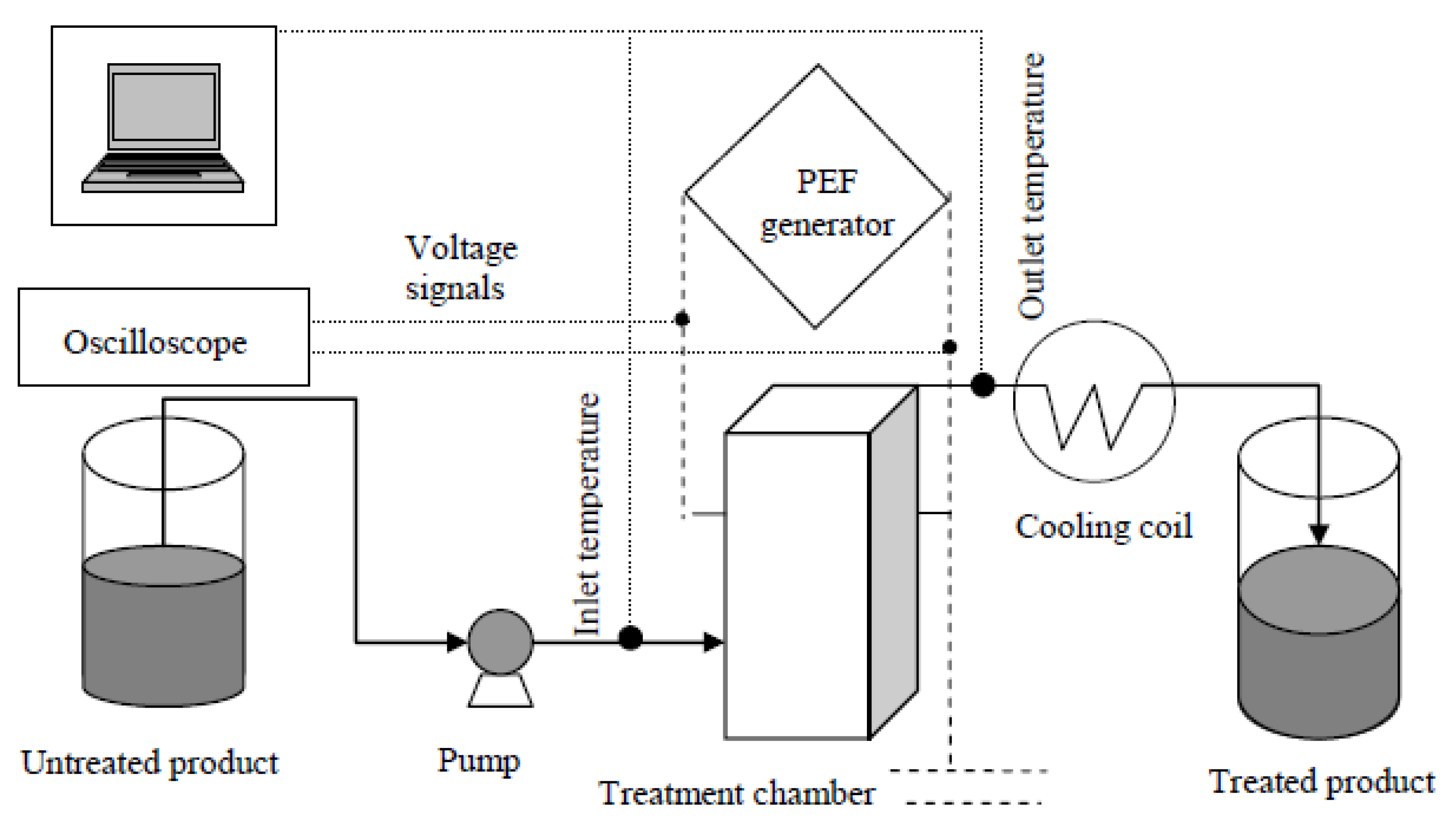

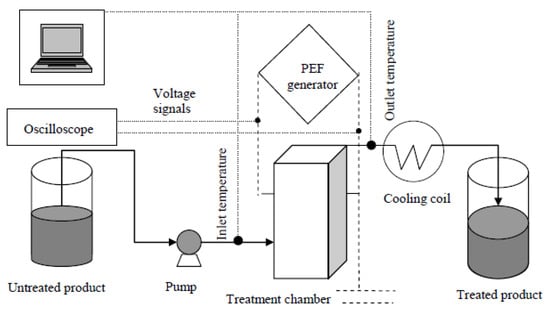

PEF is a modern food processing method which employs an electric field instead of heat for food processing. Varying voltage pulses, from 10 to 80 kV/cm, are applied to foods for a few seconds using two (2) electrodes inserted in the food products [19,50,51]. As demonstrated in Figure 1, a typical PEF system consists of a control and monitoring system along with an electric power source, pulse initiator, assembly room, and cooling systems. These ensure the optimum control of the unit. PEF systems generate a minimum amount of heat (40 °C) [6,52,53,54]. The main mechanism of action of the PEF is an electrical breakdown and electroporation within the food matrix and any microbial agent present [55,56,57,58,59]. Electric energy is passed through the food with the aid of an electric charge. Electroporation produces holes in the cell wall and inner cell of microbes, which inactivate the microorganism. After electroporation, the electrical breakdown processes weaken the pathogen’s cell membrane. As a result, the cell cytoplasmic contents tend to leak and the death of microorganism cells occurs [3]. The efficiency of PEF treatment depends on the rate of conductivity, field strength, PH, nature of food to be preserved, time, temperature, and pulse energy. In preserving apple, orange, pea soup, eggs, milk, and milk products, the PEF is mostly used as this process helps improve the rheological and antioxidant aspects of juices [6,52,53,58,59,60,61,62].

Figure 1.

A schematic illustration of a typical Pulsed Electric Field (PEF) operation [20].

Food pasteurisation using conventional thermal processes has been employed for a long time to achieve food safety. Nowadays, the Pulsed Electric Field (PEF) technology has increasingly been adopted as an alternative to thermal processes in the food industry, particularly in the production of fruit juices, dairy products, and liquid egg processing [63,64]. The main advantage of the pulsed electric field method is that it can increase the shelf life of liquid foods. During this process, organoleptic properties remain the same, as in the original liquid. In the last 50 years, the PEF method has been used on a large scale for pasteurisation in various industries including the diary and fruit juice industries, using large chambers and power supply equipment [24]. However, the application of PEF in solid foods is still emerging, unlike in liquid food processing, due to challenges related to uniform electric field distribution and the efficacy of microbial inactivation [65]. Researchers have reported that high-intensity pulsed electric field processing successfully achieves long-life fresh fruit juices and beverages [20,66]. However, since low-intensity PEF treatment is not very effective against most microbial species, the direct application of PEF for the preservation of solid foods is still not feasible [67]. Nevertheless, the electroporation effect induced by PEF enhances the mass and energy transfer, and thereby makes it highly appropriate for application as a pretreatment prior to drying, cooking, and freezing operations [65].

PEF technology significantly impacts food rheology by maintaining food components’ structural integrity and functional properties during processing. It ensures minimal alteration to the viscosity of liquid foods such as juices while preserving essential bioactive compounds. The process enables effective pasteurisation without thermal damage, retaining the sensory attributes and nutritional value of products such as milk and beverages. The PEF has been associated with the better retention of colour in plant-based products, such as orange juice, due to its mild effect on pigments like carotenoids and chlorophyll, hence yielding more stability and homogeneity [68]. Elez-Martínez et al. [69] made a comparison of high-intensity pulsed electric field (HIPEF) processing and traditional heat pasteurisation in terms of their effects on the microbial shelf life and quality of orange juice at 4 °C and 22 °C. They reported that the HIPEF treatment (35 kV/cm for 1000 μs) was microbiologically stable for 56 days when under refrigeration, whereas spoilage occurred within 30 days at room temperature. Under both storage conditions, the HIPEF-treated orange juice had better colour retention compared to heat pasteurisation (90 °C for 1 min). Notably, HIPEF-treated juice had significantly higher amounts of vitamin C, meeting daily needs for 56 days of cold storage, whereas heat treatment led to a drastic loss of vitamin C after 14 days (25.2–42.8%) [69]. In addition, PEF has been shown to improve the extraction of bioactive compounds such as polyphenols from fruits and vegetables, which enhance the nutritional and functional properties of the treated foods [70]. Parniakov et al. [71] reported that the PEF-assisted extraction of the nutritionally valuable and antioxidant components from papaya peels at 4 kV/cm and 400 pulses yielded total polyphenols (85%) compared to the raw peel sample (75%). Likewise, Hossain et al. [72] found that PEF treatment at a field strength of 0.75 kV/cm and 600 μs, resulted in the maximum yield of total steroidal alkaloids (1856.2 μg/g dried potato peels) which was 99.9% higher than that of the untreated peels. Notably, while the PEF enables the extraction of bioactive compounds, it does not cause a major change in the texture or structural integrity of liquid foods [66]. In solid foods, though, electroporation due to PEF may lead to softening due to cell membrane breakdown, which can be beneficial for the subsequent processing steps such as drying [65]. This controlled modification does not impact the overall rheological stability, but rather optimises the food matrix for an enhanced bioavailability of nutrients. This results in increased stability and homogeneity, which is crucial for improved quality and consumer acceptance. Using the PEF for processing ensures that bioactive compounds, including vitamins and antioxidants, remain largely intact, thus enhancing the nutritional profile of the treated products. For example, the antioxidant activity in fruit juices treated with PEF is higher than in products processed with conventional thermal treatments, which assures a better taste and health benefits [6,52,70]. In addition, a PEF can inactivate spoilage enzymes such as polyphenol oxidase in juices, thus extending the shelf life and improving product stability [2]. These advantages make a PEF suitable for producing high-quality, fresh-like foods with an extended shelf life [61,64].

The effect of PEF on the rheological properties of the dough and bread quality have also been reported. In the study by Pankiewicz et al. [73], yeasts that were treated with a PEF under optimal conditions exhibited a higher magnesium content, and this led to a 50% increase in the level of magnesium in bread compared to the control samples. Notably, the PEF-treated yeasts did not alter the overall chemical composition of the bread, but significantly affected its technological properties. Treated samples had a greater moisture content (54.03 ± 0.29%), which contributed to lowering the total baking loss, thus improving the overall baking efficiency and product quality. These findings indicate the capability of PEF not only in microbial inactivation, but also in functional ingredient enrichment in bakery products, widening its application scope in the food industry [73]. Another study by Grgić et al. [74] demonstrated that the use of PEF at 12 kV/cm for 162 ms significantly inhibited the activity of β-glucanase by up to 76.5%, increasing the content of total β-glucans (33.5%) and water-extractable arabinoxylans (36–41%). The resulting structural improvements enhanced the functional qualities of flour, evidenced through the higher level of gluten aggregation energy (19–29%) and dough viscosity (18–43%) upon blending wheat flour with PEF-treated oat or barley flour. However, PEF treatment also induced a reduction in the specific volume (11–24%) of the final bread product. Scanning electron microscopy (SEM) demonstrated the pronounced microstructural alteration of barley proteins, further validating the PEF’s impact on the flour structure, which affirms PEF’s efficacy to modulate the enzymatic activity and manipulate the polysaccharide structures [74].

Furthermore, it is well known that consumers generally enjoy liquid/pastry food products based on their rheological and colour characteristics. Using a controlled stress rheometer with shear rates ranging from 0 to 200 s−1, the evaluation of the effects of pulsed electric field (PEF) treatments with an electric field intensity of 18, 20, and 22 kV cm−1 and number of pulses of 25, 50, 75, and 100 on the colour and rheological characteristics of soy milk was carried out [75]. In this study, the flow behaviour, viscosity, and rheological parameters of PEF-treated soy milk were observed. The results showed that the apparent viscosity of soy milk increased from 6.62 to 7.46 (10−3 Pa s), with an increase in the electric field intensity from 18 to 22 kV cm−1 and increase in the number of pulses from 0 to 100. Shear-thinning behaviour and an increase in the apparent viscosity with the increasing electric field intensity and number of pulses are the results of PEF’s effects on the flow behaviour and viscosity of reconstituted skim milk treated with electric field intensities of 15, 18, and 20 kV cm−1 and numbers of pulses of 20, 40, or 60 [76]. In another study, the impact of PEF on the functional, rheological, and structural properties of vital wheat gluten were evaluated [77]. It was found that the elastic modulus, viscous modulus, tan δ of the wet gluten protein, and the apparent viscosity of the vital wheat gluten changed significantly (p < 0.05) with the increase in the electric field intensity. Consequently, the PEF treatment showed a significant impact on the gluten protein properties to various extents. This implies that PEF processing affected the rheological properties of soy milk. Hence, depending on the electric field intensity and number of pulses, PEFs, a non-thermal alternative technology, have the potential to affect the quality, sensory, and nutritional qualities of food products while also inactivating spore-forming bacteria and extending their shelf life. The PEF’s effects on the rheological, structural, and physicochemical characteristics of almond milk showed that, following PEF treatments, the viscosity and nonenzymatic browning significantly decreased while the electrical conductivity, cloud value, and cloud stability significantly increased [78]. The changes in the nutritional qualities and rheological properties of red raspberry (Rubus strigosus) and blueberry (Vaccinium corymbosum) purees were studied based on treatment with a PEF in continuous, ultrasonication (US), and combined methods [79]. The results prove that only US and combined methods were capable of inactivating polyphenol oxidase (PPO) at a significant level (p < 0.01). However, ultrasonication (US) caused a significant change in the rheology of the purees, especially in blueberry, revealing a gradual shift from a non-Newtonian to Newtonian model, complemented with a decline in the apparent viscosity. Hence, microstructure development, quality control, sensory analysis, and process equipment design all benefit greatly from the evolution of rheological properties in relation to food processing conditions. Nonetheless, non-thermal technologies are appropriate for treating berries due to their improved nutritional quality; however, the process design should consider changes in rheological properties [79].

3. High-Pressure Processing (HPP)

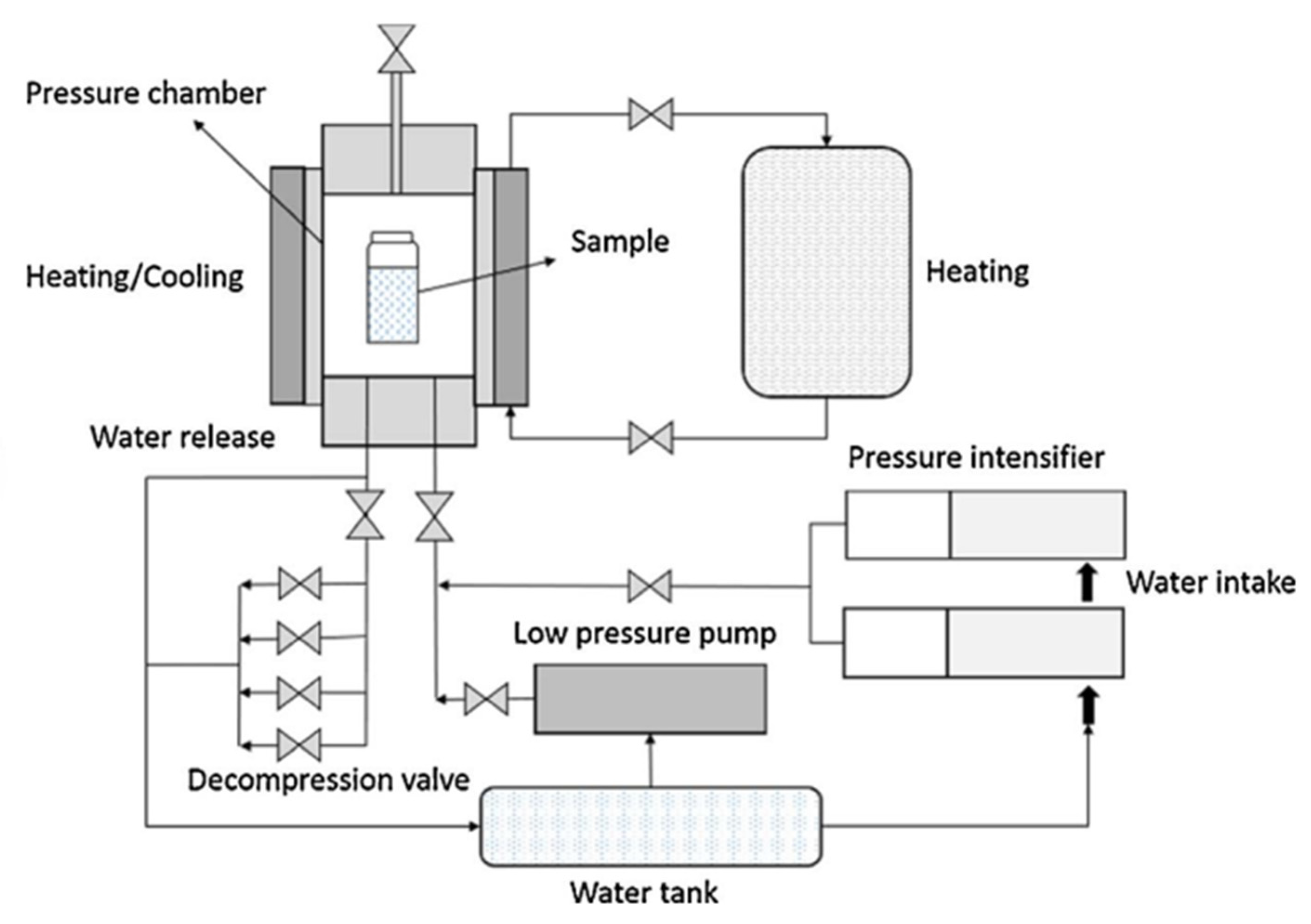

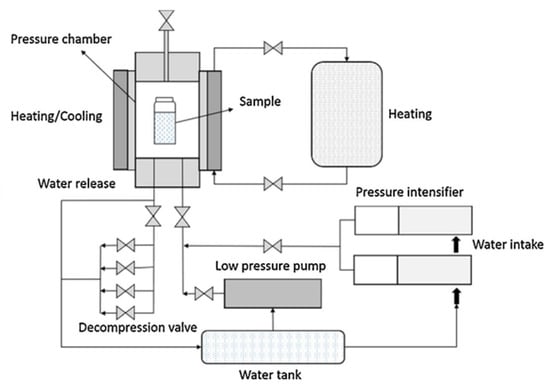

High-pressure processing (HPP), also known as ultra-high and high-hydrostatic-pressure processing, is a processing technology that applies a controlled high pressure to food to extract key bioactive components and inactivate possible microbial contaminants without applying heat. The beauty of this process is that it maintains the flavour, colour, texture, and nutrients of foods. Although, its effect on colour can vary depending on the food matrix and specific processing conditions [80]. This cold pasteurisation process reduces the quantity of microbes and enhances the shelf life of foods. HPP is based on two thermodynamic principles, both of which account for microbial inactivation: Le Chatelier’s principle, where a high pressure decreases the volume and affects molecular interactions, and the isostatic principle, which enables consistent pressure applications independent of the food geometry [81]. HPP inactivates microorganisms by breaking down non-covalent bonds and damaging microbial cell membranes [3,6]. The treatment parameters usually vary depending on the food type, with exposure times ranging from 1 to 20 min at temperatures of 0–110 °C and pressures of 100–1000 MPa [80,82], although pressures up to 1000 MPa are rarely used routinely. A high pressure also disrupts the tertiary and secondary micro-molecule structure and proteins within foods. In this process, the breakdown of non-covalent bonds alters the cells’ cellular function, leading to their inactivation. For liquid foods like juices and milk, lower pressures (100–400 MPa) and moderate temperatures (20–50 °C) are typically used to inactivate microbes while preserving the sensory and nutritional quality [51,80]. The study by Hiremath and Ramaswamy [83] demonstrated that to obtain the optimum conditions for the treatment of the food product, the most resistant microorganism can be selected as the target microorganism. In their study, a 5 min treatment at 400 MPa was sufficient to inhibit Leuconostoc mesenteroides, which was determined to be the most resistant spoilage bacteria. Also, at 400 MPa, a six log decrease in E. coli O157:H7 was seen after 10 min of treatment; at 500 and 550 MPa, no survivors were found following the 1 min treatment. Counts were recorded during treatment and throughout subsequent storage for 28 days. Since E. coli O157:H7 was the most resistant pathogenic bacterial strain, the HPP was built based on it. Hence, when there was no growth of E. coli O157:H7 during the whole storage period, the results demonstrated that these procedures were satisfactory [83]. Pilavtepe-Çelik et al. [84] also reported that E. coli O157:H7 and Staphylococcus aureus were inactivated by high-pressure treatment (200–400 MPa/0–40 min/40 °C) in carrot juice and peptone water, demonstrating the potential of HPP in the development of safe processed foods. In contrast, solid foods such as meats, meat products, and seafoods, require higher pressures (400–1000 MPa) and, in some cases, elevated temperatures (above 50 °C) to ensure microbial inactivation [80,82]. Indeed, it has been noted that bacteria show the greatest resilience to pressure at temperatures ranging from 20 to 30 °C [85]. The study by Patterson and Kilpatrick [86] revealed a 1 log decimal reduction of E. coli O157:H7 in poultry meat after 15 min of treatment at 400 MPa and 20 °C. However, a six log reduction was attained when 400 MPa treatments were coupled with 50 °C temperatures within 15 min. Pérez-Baltar et al. [87] investigated the impact of high-pressure processing on deboned dry-cured hams. They discovered that after 60 days of storage at 4 and 12 °C, a high pressure of 600 MPa for 5 min inactivated L. monocytogenes at the surface. On the other hand, variations in the dry-cured ham’s interior and exterior salt and nitrate contents, moisture content, and water activity demonstrated variations in pathogen inactivation. During HPP treatment, dry-cured hams achieved a surface reduction of around 2 logs and an internal reduction of about 3 logs. Their study demonstrated that HPP treatment at 600 MPa/5 min could provide food safety against L. monocytogenes according to the United States Department of Agriculture (USDA) and European standards [87]. The high-pressure treatment of milk has been found to only disrupt the ionic and hydrophobic interactions of macromolecules (proteins), without denaturing the beneficial proteins it contains [80]. Along with successful microbial inactivation, very little to no impact on the tiny molecules of milk components (vitamins, flavour, and amino acids), colour, and other nutritional components have been reported [88] at pressures of around 100–500 MPa and a moderate temperature (10–50 °C). Yang et al. [89] investigated the use of HPP treatment to inactivate foodborne pathogens in milk. The results from their study demonstrated that 300 MPa of pressure for 30 min at 25 °C was the optimal condition for the inactivation of foodborne pathogens such as Salmonella, E. coli, Shigella, and S. aureus in milk. Therefore, different food products may be subjected to temperatures of 0–110 °C and pressures up to 100–1000 MPa at a suitable time range, depending on the desired balance between the microbial inactivation and product [80,82]. The high-pressure processor used in the study by Zhao et al. [90] used a mixture of distilled water and propylene glycol with 7:3 as the pressure transmitting fluid. The pressure was increased at the rate of 300 MPa/min and depressurised at 25 MPa/s, while the temperature increased 3 °C per 100 MPa. The HPP was assisted by carbon dioxide (CO2) in the study and was shown to inactivate Escherichia coli and Staphylococcus aureus in liquid samples, demonstrating the potential application of this process in the food industry. As shown in Figure 2, the processor had a two-litre pressure chamber, one heating system, one low-pressure pump, four decompression valves, one water tank, and two pressure intensifiers.

Figure 2.

Schematic diagram of high-pressure processing [90].

During HPP processing, baskets of packaged food are introduced in steel vessels full of water, and a piston is used to apply a high pressure. This way, incompressible water is passed through the food uniformly from all surfaces. This results in the reduction of the size of micelles in dairy protein, leading to the denaturation of proteins, increased solubility, and, in some instances, a colour change. In other applications, the ripening of cheese is accelerated by the process of HPP. This is possibly due to changes in the microstructure of fresh curd due to the applied pressure. In liquids, including whole eggs and tomato juices, a 3–5 log reduction in microbiological counts by HPP has been reported [91]. The viscosity of juices is unchanged by the HPP process compared to thermal treatment and untreated juices. This improves the rheology of foods including mango pulp and tomato purees, where viscosity is reduced with or without heating, but the water binding capacity is increased [32,91,92,93].

In the HPP process, protein denaturation takes place in the food; this process is irreversible and the extent depends upon the type of protein and treatment conditions. These changes are responsible for improving the food quality and preservation. The processing of milk using HPP results in changes to the milk’s protein structure such as the destabilisation of casein micelles, bringing about coagulation and an improved texture. This can improve the stringiness and meltability of different cheeses and related products [32,94]. The study by Cadesky et al. [95] investigated the impact of HPP at 150–450 MPa for 15 min on the structural change of milk proteins. The results showed that the pressure treatment led to the dissociation of calcium phosphate and, therefore, the destabilisation of the casein micelles. The soluble calcium and phosphorus levels increased at pressures up to 350 MPa, but decreased at 450 MPa. Additionally, treatment at 450 MPa formed soft protein gels containing casein substructures (15–20 nm diameter) homogeneously dispersed. Serum proteins were significantly denatured at pressures greater than 250 MPa, highlighting the influence of HPP on the stability and texture of milk proteins. Other researchers have reported that the treatment of milk by HPP denatured the whey protein in it, and because of the milk fat globule membrane interaction with protein, a reduction in cream of 70% is achieved [32,96]. Other foods in which HPP is used include salsas, guacamole, chilled entrees, and smoothies. It is also famous within the seafood industry to preserve oysters and seafood [91]. Overall, HPP can enhance the food shelf life and save food from detrimental changes in their sensory aspects and nutritional values. The study by Ribeiro et al. [97] examined the effects of HPP on cheese made from ultrafiltered milk (UF-cheese) using recombinant chymosin (RC) or bovine rennet (BR). The results showed that HPP treatment at 600 MPa for 5 min at 25 °C extended the shelf life of UF-cheese by reducing proteolysis and microbial counts while maintaining colour stability. The treated cheeses exhibited increased syneresis over time and had a firmer texture compared to the untreated samples. Proteolysis was significantly reduced by 42.8% in RC cheese and 52.5% in BR cheese after one day of storage, indicating the potential of HPP in enhancing whey protein solubility, influencing the cheese texture and moisture retention [97]. It is worth noting that the HPP process cannot be applied to low-acidic foods. This is because HPP can cause a change in the pH of the food and affects the enzymatic reactions by altering the kinetic constants or by causing conformational changes in the food structure. At pH ≥ 4.6, it has limited effectiveness in inactivating spores of pathogenic bacteria such as Clostridium botulinum. Thus, HPP is primarily used for acidic foods (pH ≤ 4.6), where the acidic conditions naturally inhibit spore-forming bacteria. However, it is possible to simultaneously raise the temperature (90–120 °C) during HPP to boost the effectiveness of inactivating spores and pressure-resistant microorganisms. Synergistic effects against spores on several food commodities have been observed when heat (90–120 °C) and pressure are applied either sequentially or concurrently [98]. In a similar vein, the successive use of other methods such as irradiation and preservatives in conjunction with HPP has demonstrated additive and synergistic effects against spores and pathogens to ensure the safety of food commodities [99,100]. Additionally, HPP can cause pH shifts in food matrices, influencing enzymatic reactions by altering kinetic constants and inducing conformational changes in enzyme structures. Under a high pressure (100–1000 MPa), enzymes such as polyphenol oxidase and pectin methylesterase may exhibit increased or decreased activity depending on pressure-induced unfolding or aggregation [101]. For example, the pressure denaturation of pectin methylesterase can increase its activity and thereby modify the fruit texture, while the inactivation of polyphenol oxidase prevents enzymatic browning in juices [82]. These changes affect the food stability, texture, and sensory attributes, making the precise control of pressure conditions essential for maintaining quality.

HPP enhances the rheological characteristics of foods by modifying their microstructure and increasing their water-binding capacities. This leads to improved solubility and alters the textural properties, such as the firmness of cheese or the viscosity of purees. The process preserves the natural sensory qualities of foods, including the flavour, colour, and nutrients, making them a sustainable and versatile choice for liquid and solid foods. For this reason, food processing using HPP can become a sustainable and flexible solution for liquid and solid foods. HPP-treated mango pulp, for instance, retains its natural viscosity, while protein denaturation during HPP processing can improve the meltability of cheeses and related products [92,96]. Studies have shown that pressures between 400 and 600 MPa can induce up to 30–50% denaturation of whey proteins, which contributes to a smoother texture in dairy products [102]. For example, the study by Liu et al. [103] found that HPP (600 MPa for 5 min) led to a significant denaturation of β-lactoglobulin (about 41–59%) and a slight denaturation of α-lactalbumin (6%) in milk, leading to the disruption of casein micelle disruption. Apart from contributing to a smoother texture in dairy products, the HPP-induced disruption of casein micelles has been found to alter the optical characteristics of milk, including its turbidity and lightness [96]. Additionally, the cold gelation induced by HPP on some protein systems allows for creating new textures in foods such as high-protein gels or low-fat spreads [104]. This is useful in the reduction of the fat content in meat products while maintaining or even enhancing their functional and textural properties. The relationship between these structural modifications and rheological behaviour is important. Higher viscosity in liquid and semi-solid foods, such as fruit purees and dairy products, is a result of the increased water-binding capacity brought on by pressure-induced protein unfolding and polysaccharide interactions [105]. Improved gelation from HPP-induced denaturation improves the firmness, elasticity, and cohesiveness of foods high in protein, such as meat and cheese. For example, regulated protein denaturation in dairy products enhances the meltability and spreadability, thereby improving the mouthfeel [80]. The high-pressure treatment promotes the formation of a stronger gel structure, which reduces the fat content without compromising the sensory qualities. This is usually achieved by the structural modification of proteins, which induces changes in myofibrillar protein gelation, one of the most important factors affecting the final texture and mouthfeel of products such as sausages [106]. Through these interrelated adjustments, HPP balances viscosity, firmness, and spreadability to maximise the product quality while also altering the microstructure and regulating the final rheological characteristics. The new microstructure developed after HPP treatment enhances the water-binding capacity of these products, improving the juiciness, firmness, and overall acceptability. Through these changes, the manufacturers are enabled to design low-fat meat products possessing the required texture and sensorial quality to meet the growing consumer demand for healthier alternatives without compromising the product quality [106].

In several food products, the presence of proteins and or polysaccharides can affect the texture, microstructure, shelf life, thickening, and stability because of gelling. The rheology of these components can be affected by the pressure level during HPP. In a pioneering study, the rheological characterisation of a selected allergenic protein after HHP processing was investigated via the modelling of the rheological behaviour [107]. The results showed that viscosity is increased as the processing pressure levels increase (600, 700, and 800 MPa) and the treatment time increases (15 and 25 min). Based on the Ostwald de Waele rheological model, the flow consistency index (K) of a Bovine Serum Albumin solution increases with the increasing pressure levels, treatment times, and protein concentration, whereas the protein solution processed at pressure levels above 600 MPa demonstrated a characteristic behaviour of a pseudoplastic fluid. A study of the effect of pH and HPP on the rheological properties of egg white albumin and basil seed gum (EWA-BSG) mixtures has been reported for pressure levels of 0, 200, and 400 MPa [108]. The flow behaviour of the EWA-BSG solution was adequately described by Herschel–Bulkley and Carreau models. The results showed that the viscoelastic parameters of the storage modulus, loss modulus, tan (δ), and low-point stress implied a stronger microstructure at the highest pressure (400 MPa). Furthermore, the effect of high-pressure processing (HPP) on the protein conformation analysis, the microstructure, strength of the pea protein gel, and gel rheology and dissolution were studied based on the high-pressure level, treatment time, protein concentration, and pH [109]. The microstructure study based on scanning electron microscopy (SEM) revealed denser networks with a greater degree of crosslinking for pea protein gels at the higher-pressure level when comparing treatments at 600 MPa vs. 300 MPa at the same pH. The changes in the storage modulus (G′) and loss modulus (G″) of a gel system were observed depending on the HPP conditions (pressure level). This indicates the sensitivity of proteins to a pressure variation depending on their types. In a comparative study of 0.8% xanthan gum (XG) or 600 MPa/5 min high-pressure processing (HPP) for the texture modification of lentil protein vegetable purees (10% zucchini, 10% carrots, 2.5% extra virgin olive oil, and 21.8% lentil protein concentrate), it was found that HPP-treated purees showed the highest stiffness (storage modulus), the lowest deformability capacity (yield strain), and the lowest structural stability (yield stress) [110]. In other words, gels obtained by HPP techniques are stronger, while those with hydrocolloids (xanthan gum) are more elastic. However, proteins and polysaccharides are two groups of macromolecules that govern the structure–function properties of foods. In such food systems, gel fabrication by HPP could create microstructures and textures with specific properties depending on the pressure and treatment time. After HPP at a pressure of 300 MPa, the viscosity of milk–gelatin mixtures increased with high milk solid concentrations (15% and 20% w/w), whereas the viscosity decreased following a further increase in the pressure level to 600 MPa [111]. Based on confocal laser scanning microscopy, ruptured aggregates and phase separation were observed at a higher pressure level.

The HPP process is, overall, an excellent process for food preservation and minor undesirable changes in food products are minimal, thus positioning it to be a method of choice in various food matrices [91,112,113]. However, certain problems must be considered for the mass application of HPP. Specialty packaging is usually required because HPP must be conducted using flexible, pressure-resistant materials [5]. High energy consumption and high operational costs associated with the special equipment used in HPP also pose financial barriers, thereby creating limitations on implementing it on a large scale in the food industry [114]. Nevertheless, the ongoing advancement of HPP technology means that these operations are more and more optimised for cost and scalability.

4. Ionising Radiation (IOR)

Gamma electron beam/X ray is used in the ionising radiation process to reduce microbial action and decrease enzymatic activities in agro-food products [6,115]. Ionising radiation is a pasteurisation process, and no heat is added in this method. Microorganisms are inactivated due to the breakdown of their cellular structure and fragmentation process. However, the efficacy and impact of ionising radiation are dependent on the food composition, radiation dose, and oxygen availability [116]. Lipid-containing foods can become rancid by lipid oxidation, whereas pigment degradation due to excessive doses of radiation can lead to discolouration in fruit, vegetables, and meat products [117]. The study by Zhao et al. [118] on the effects of gamma irradiation on Ponkan fruit revealed severe damage induced by excessive doses (>1 kGy), including accelerated aging and browning. Small doses (0.25–1.0 kGy) were attempted to assess their action on Penicillium digitatum inhibition and on the fruit quality. The study showed a reverse association between the gamma dose and the growth of fungi, and concluded that gamma radiation induces damage in the fungal membranes and leakage of intracellular material. However, while 1.0 kGy effectively inhibited fungal growth, it also led to the accelerated aging of fruit, a loss in weight, and browning. Hence, 0.5 kGy was found to be optimal for inhibiting the rot of fruit while conserving the maximum amount of nutrients and weight. Of all the dosages, the fruit samples subjected to 0.5 kGy contained maximum levels of total soluble solids (10.5%) and vitamin C (17.5 mg/100 g), as well as a minimal loss of titratable acidity (0.68%), even after storage. Browning was observed in all the irradiated samples, which increased with the dose and storage time. Therefore, while ionising radiation can enhance the shelf life, it can potentially cause undesirable sensory changes, depending on the dose [118]. Hence, the ionising radiation process is not valid for all types of food, such as milk and protein, as their respective food colour, odour, and flavour can be altered. Some foods soften and lose their original colour at high-level doses [91]. The irradiation of food has been extensively studied due to its efficiency as a tool for preserving food. Several studies investigated the potential changes in the structures of food due to irradiation, with most of them focusing on alterations in terms of the texture of solid foods. Studies examining fluids have mainly explored the depolymerisation of biopolymers [32].

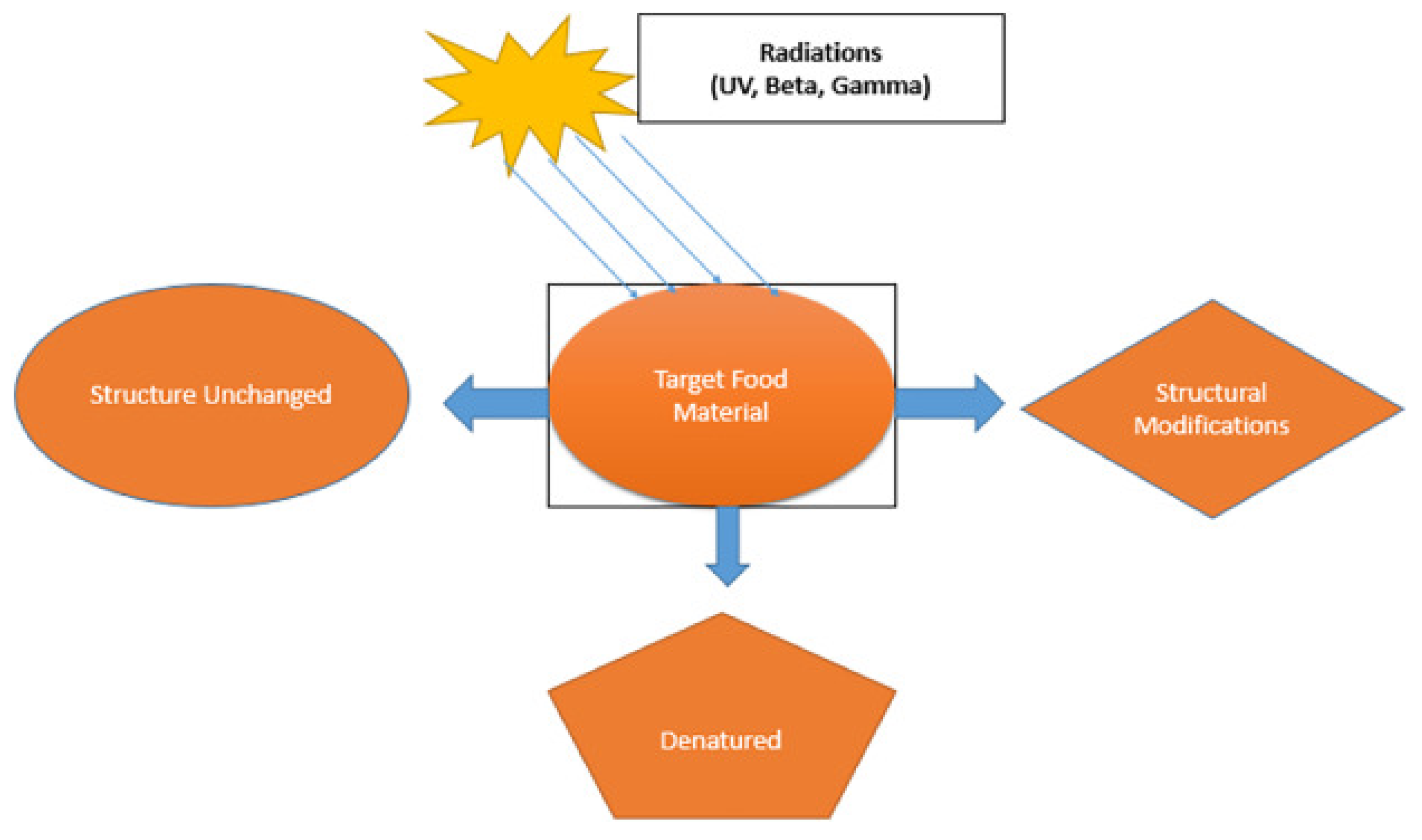

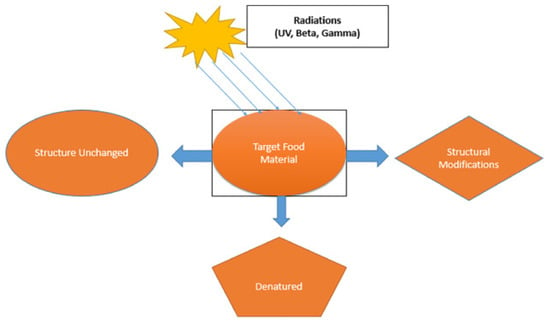

When photons interact with food molecules, charged ions are formed, and super-reactive free radicals react among themselves [6]. There are several steps towards utilising and applying ionising radiation in food preservation. The first process is the generation of gamma rays via cobalt-60 or Cesium-137. This is followed by the application of X-ray beams that are passed at 5 MeV. Finally, a generated high-electron beam is emitted via accelerators, and an energy level of 10 MeV or less is maintained [6,119]. This is illustrated in Figure 3.

Figure 3.

Pictorial representation of the ionising radiation process in a typical food system [120].

The effect of ionising radiation on food rheology is mostly dependent upon the dose. It has been reported that the viscosity of honey is not impaired up to doses of 5 and 10 kGy, as shown in the study by Migdał et al. [121] where ionising radiation at the dose of about 10 kGy effectively decreased the number of microorganisms and its antibiotic activity and stability (5-HMF), without influencing the organoleptic value of honey. In contrast, the viscosity and consistency of hydrocolloid solutions decrease with increased radiation [64,122,123]. In the study by Singh and Sharma [124], the gum solution’s apparent viscosity initially increased as the radiation dose rose from 0 to approximately 8.17 ± 0.2 kGy, indicating an improvement in the emulsion stability. However, as the total absorbed dose increased beyond this threshold, the viscosity steadily declined due to the degradation of the polymer structure, ultimately affecting the gel-forming and thickening properties of the gum sample.

The irradiation process has been shown to be safe. The World Health Organisation (WHO), the Scientific Committee on Food, which provided scientific advice to the European Commission (EC) on food safety, the Food and Agriculture Organisation (FAO) of the United Nations, and the International Atomic Energy Agency (IAEA) have all agreed that food irradiation up to doses of 10 kGy is accepted internationally for foods destined for human and animal consumption and does not make food radioactive, nor pose any health risks to consumers [125]. The FAO, IAEA, and WHO conducted a group study in 1997 that examined the effects of exposing food to radiation above the recommended dose of 10 kGy [126]. The study found that few food samples could withstand such high doses without losing their sensory qualities, but that irradiating animal feed with radiation doses higher than 70 kGy showed no health issues in the test subjects. Therefore, it was determined that it is safe to expose food to ionising radiation of any dose as long as it is carried out to accomplish a technological goal, does not cause nutritional deficiencies, and does not affect the food’s safety, such as the decontamination of spices, dried herbs, and vegetable seasonings, which may require doses up to 30 kGy to ensure microbial safety [125,127].

Factors that affect the effectiveness of ionising radiations include the presence or absence of oxygen, the composition of the medium, the food density, and thickness [5,6,91,127,128]. IOR technology influences food rheology by inducing structural changes in biopolymers, such as depolymerisation, which can decrease the viscosity of hydrocolloid solutions. Certain foods, such as protein products and milk, are more susceptible to radiation-induced changes due to their complex biochemical composition and sensitivity to oxidative and structural alterations [129]. The irradiation effect on proteins is a function of various factors, including the protein structure (globular or fibrous), state (native or denatured), composition, the presence of other molecules, and environmental conditions such as the dose, dose rate, temperature, and oxygen levels [130,131]. Irradiation causes structural changes that cause proteins to aggregate or unfold through the breakage of the peptide chains, disulfide bonds, and secondary interactions including hydrogen and hydrophobic bonds. Also, irradiation enables the creation of ionic and free radical intermediates, which enhance oxidative reactions. These reactions can result in protein oxidation, creating carbonyl groups, a loss of sulfhydryl groups, and cross-linking, ultimately altering protein functionality. Over time, oxidative modifications cause texture alterations, a reduced water-binding capacity, denaturation, the modification of functional properties, and reduced emulsification properties [131]. Thus, while irradiation is an important preservation technique, its oxidative effects must be properly regulated to maintain food stability, sensory characteristics, and the overall quality. Research shows that the viscosity of honey remains stable at doses up to 10 kGy, while higher doses beyond this threshold may affect sensory and rheological properties, such as the consistency and texture [121]. Similarly, in dairy products, doses above 5 kGy can induce protein denaturation which results in undesirable textural changes [129], while in hydrocolloids, structural breakdown can occur at doses exceeding 8.17 ± 0.2 kGy, leading to a reduced viscosity and gel strength [124]. These findings underscore the importance of optimising the IOR application to balance microbial safety with the retention of the food quality [127,132]. The effect of ionising radiation on the rheology of foods is not confined to viscosity changes alone. The depolymerisation of biopolymers can result in changes in the textural and stability characteristics of foods, influencing properties such as the firmness, chewiness, and general mouthfeel. This becomes relevant in the use of hydrocolloids and gums in processed foods, where the breakdown of chains reduces their thickening ability and changes the final texture [133]. In addition, ionising radiation can enhance the oxidation of some food constituents responsible for the colour, flavour, and even the aroma of the food product. While these chemical modifications are useful in extending the shelf life and microbial safety of food, sometimes they concomitantly may induce off-flavours or off-colour development in food items like fruits, vegetables, and meat products [127,132]. Therefore, radiation dosages have to be optimised with due care in order to strike a proper balance between food safety and the maintenance of high sensory and rheological qualities so that foods remain appealing for consumption while benefiting from the preservative effects of IOR.

Most studies have been focusing on the inactivation of pathogens and spore-forming microbes by treating with ionising radiation to improve food safety and extend the shelf life. However, the physical treatment of food products by ionising radiation can cause radiation-induced changes in the rheological properties, texture, and quality. Changes in the chemical structure of food subjected to ionising radiation might occur because of energy interactions while it is being processed. The changes in the rheological behaviour of gamma-irradiated honey treated at doses of 0, 5, and 10 kGy were studied [134]. The results showed that the gamma radiation interaction with the honey at 5 and 10 kGy doses did not impact the viscosity significantly (p < 0.05) or its Newtonian rheological behaviour. In a study on the influence of gamma irradiation on the texture, colour, and viscosity of potato starch at doses of 0, 5, 10, and 15 kGy, the results obtained demonstrated that while the texture became inversely proportional to the applied radiation dose, increasing doses promoted a slight rise in colour and decreased the viscosity [135]. Thus, unlike honey molecules, starch molecules undergo some degradation under irradiation, which resulted in a decreasing viscosity with increasing IOR doses. Hence, the application of IOR (a gamma or electron beam) in food processing has the capacity to induce molecular changes and degradation depending on the components of the food product such as starch. Consequently, the impact of IOR on rheology revealed that the viscosity decreased with the increasing radiation dose, according to a study that investigated the effects of ionising radiation on the rheological characteristics of degreased seasoned flours (carbohydrate (78.9%), lipids (13.6%), protein (2.1%), and dietary fibres (7.8%)) at doses of 0 (control) and 5 kGy [136]. This can be ascribed to radiation-induced molecular structure degradation. In addition, starch’s gelling properties, as well as the viscosity and structural rheological stability of its gels, seem to be the key elements influencing the potential usage of starch in a variety of food products. In another study on similar food products, the effects of ionising radiation on the rheological and physicochemical properties of bacon and traditional farofa were investigated at doses of 1, 5, and 10 kGy [137]. The findings revealed that at 5 and 10 kGy, irradiation significantly affected the farofa’s viscosity profile and textural properties, including its cohesiveness, hardness, and springiness. Additionally, Co-60 gamma irradiation applied to an industrial powder white, yolk, and whole egg at doses between 0 and 25 kGy, revealed that irradiation with doses up to 5 kGy inactivate microbes to non-detectable levels and no significant variation in the viscosity of irradiated egg white samples was observed [138], whereas the whole egg or egg yolk samples exhibited some changes in rheological properties depending on the dose level. This suggests that irradiation can induce the structural degradation of proteins.

5. Ultraviolet and Pulsed Light

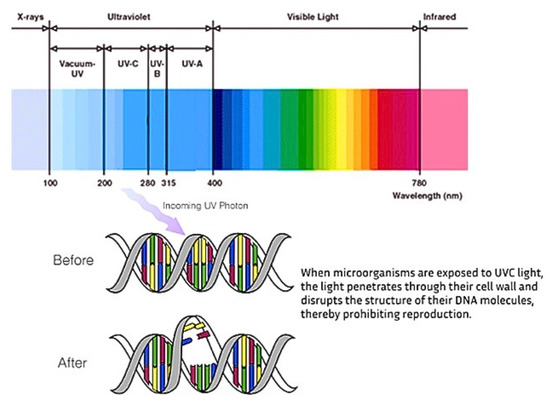

UV light inactivates microorganisms primarily through the induction of damage to their DNA/RNA through the creation of dimers between the pyrimidine nucleotide molecules in the nucleic acid backbone which disrupt replication and transcription and lead to cell death [139]. The synthesis of those dimers (pyrimidine 6–4 pyrimidone photoproducts, or 6–4PPs, and cyclobutane pyrimidine dimers, or CPDs) interferes with the microbes’ regular DNA construction and other biological processes [139]. Similarly, PL treatment destabilises microbial cells with the incorporation of intense energy pulses, which bring about rapid photothermal and photochemical annihilation. Structural havoc on bacterial cell membranes results from the high-energy pulses, yielding intracellular material leakage and oxidative stress [12]. Ultraviolet light (UV) has a low penetrating capacity and is used to disinfect food surfaces or packaging. Originally, UV light was only used in transparent liquid, but with improvements in reactors and optimum hydraulics, the delivery and exposure of target microorganisms in different food matrices and foods with varying rheologies to UV light is now possible. Studies have investigated the effects of UV irradiation on the rheology of fish gelatin. The results from the study by Bhat and Karim [128] demonstrated that the gel strength of fish gelatin increased after the treatment with UV irradiation for 30 and 60 min. The viscosity of the irradiated samples was seen to reduce while the melting enthalpy changed significantly. Like UV, the pulsed light (PL) processing method has gained prominence in the food industry. In PL processing, a highly energised, short array of pulses from the white light broad band are passed through food, and this is more effective for food processing and preservation as normal UV light is 1000 times weaker than pulsed light [140,141]. In recent years, several scientific publications have elaborated on the principles of pulsed light for food processing, including its mechanism for microbial inactivation [142,143,144,145,146]. PL processing is useful for different solid and liquid foods and has been applied in fruits, fish, meat, and vegetables to remove microbes [147,148,149,150].

UV and PL technologies affect the food rheology by modifying treated products’ textural and structural properties. UV treatment has been shown to enhance the gel strength of fish gelatin, resulting in stronger gel networks and reduced viscosity. This is also because of the cross-linking of the UV-induced polypeptides of collagen, leading to higher protein–protein interactions and a firmer gel matrix [151]. UV also leads to partial protein denaturation, exposing reactive amino acid residues to cross-linking, making the gel stronger. The UV light may further lead to the oxidation of sulfhydryl (-SH) groups and, upon forming disulfide (-S-S-) bonds, and so a stable harder gel network is created [152]. Similarly, PL processing effectively maintains fresh produce’s texture, appearance, and microbial safety. In polysaccharide-rich foods, PL treatment breaks hydrogen bonds and induces depolymerisation, reducing viscosity with the concurrent gelation of a structure of reinforced strength in protein-based systems [139]. Transient thermal and photochemical changes induced by the high-energy pulses reorder water–macromolecule interactions influencing the overall rheological behaviour [12]. These methods are highly effective in preserving the food quality, particularly in maintaining the microbial safety, sensory attributes (such as the colour, texture, and flavour), and nutritional composition. However, their application is limited by their penetration capacity and the nature of the food matrix [128,141].

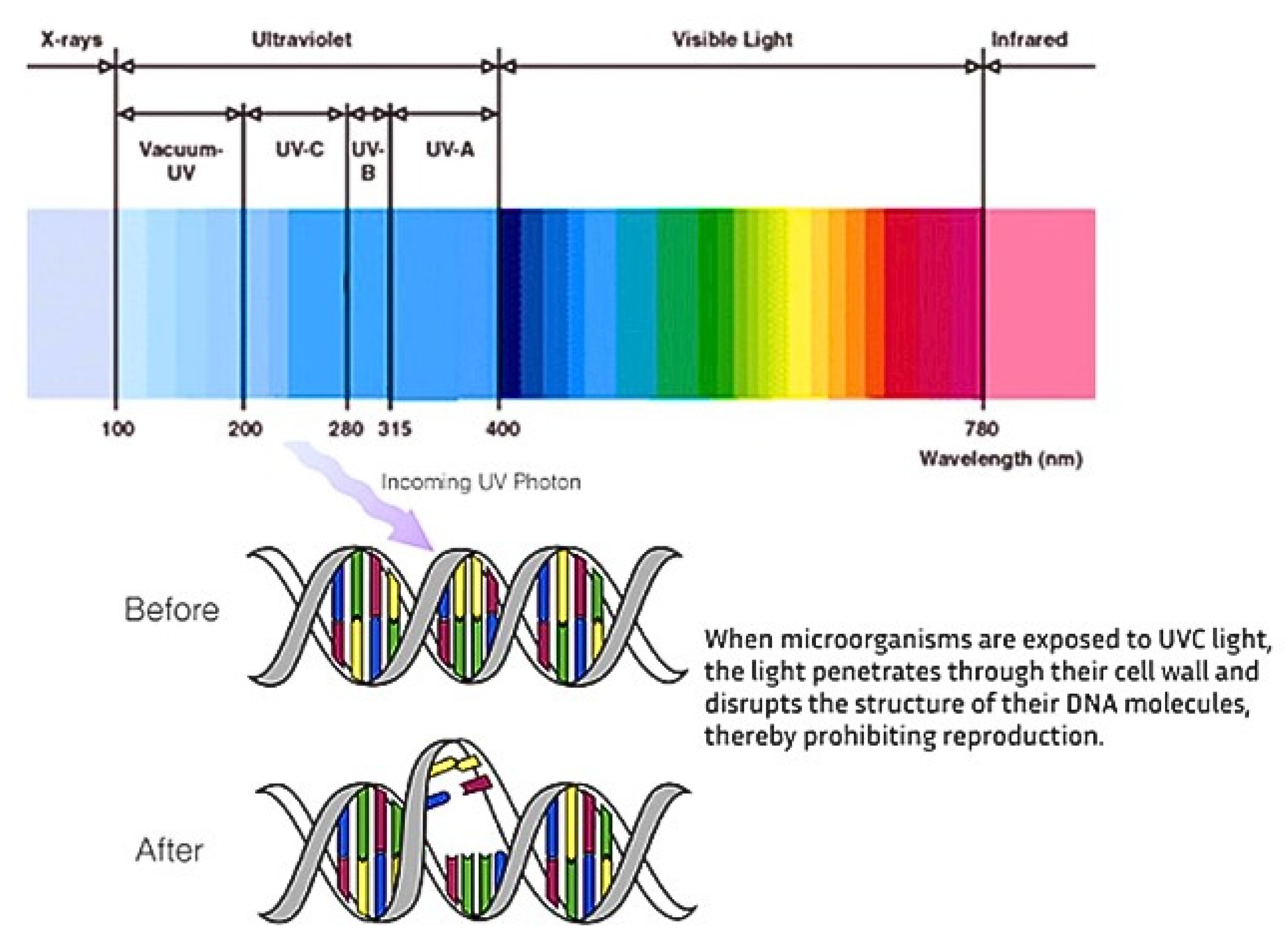

The optimal UV and PL treatment conditions for various food matrices have been determined by different studies. For instance, UVC treatment at the wavelength of 253.7 nm is considered germicidal against microorganisms and has been successfully applied to improve microbial safety and maintain the sensory quality of fresh juice and dairy products with little oxidation [153,154]. As shown in Figure 4, when microorganisms are exposed to UVC light, the light penetrates through their cell wall and disrupts the structure of their DNA molecules, prohibiting reproduction. According to Orlowska et al. [155], apple juice treated with a monochromatic low-pressure (LPM) lamp set at 253.7 nm and 10 mJ/cm2 only had a 1.30% decrease in the vitamin C concentration, demonstrating the potential of UV-C in the treatment of fruit juices without reducing their sensory quality. However, prolonged UV exposure can degrade light-sensitive vitamins, such as vitamin C and certain B-complex vitamins, leading to a decline in their nutritional value. Studies have shown that riboflavin (vitamin B2) is particularly susceptible to UV degradation, which could impact the overall micronutrient composition of treated foods [156]. Furthermore, natural pigments such as carotenoids and anthocyanins are prone to degradation under intense and prolonged light exposure [157]. Similarly, PL treatment at 0.5–9.6 J/cm2 has been reported to inactivate pathogens effectively in fresh-cut fruits and vegetables without affecting their textural quality. The study by Zaharah et al. [158] investigated the effect of different PL fluences (1.5, 4.2, 6.9, 9.6, and 12.3 J/cm2) on the physical and microbiological quality of pennywort (Centella asiatica) stored at 4 °C. The results showed that fluences of 6.9, 9.6, and 12.3 J/cm2 reduced the microbial counts significantly, with the highest inactivation at 9.6 and 12.3 J/cm2. However, PL at 6.9 J/cm2 was determined to be optimum, as it was effective in reducing E. coli contamination without affecting the texture and extending the shelf life by approximately four days. SEM showed that PL disrupted the bacterial cell membrane, which was responsible for its antimicrobial efficacy. Interestingly, the two higher fluences (9.6 and 12.3 J/cm2) altered the colour of the leaves, suggesting the necessity of dose optimisation in PL applications. Additionally, in lipid-rich foods, intensive bursts of PL energy and prolonged UV exposure can lead to lipid oxidation, particularly in unsaturated fatty acids. This can cause the formation of off-flavours and reduce the sensory quality due to the accumulation of lipid peroxidation products and their interference with taste and aroma [12].

Figure 4.

A schematic of the action of UVC light on microorganisms.

Importantly, UV and PL technologies further affect other important rheological properties, including the elasticity, firmness, and flow behaviour. For instance, UV-induced cross-linking in proteins and polysaccharides might build more intensive gel matrices that can enhance the firmness and stability of some food products, such as jellies and dairy-based ones, which provides a longer shelf life for foods [159]. On the other hand, PL technology has been reported to cause microstructural modifications in food tissues due to its high energy pulses, inducing cell wall loosening in fruits and vegetables [141]. These features can lead to improved juice extraction efficiencies and an enhanced water retention capacity, making PL particularly valuable to produce beverages and fruit-based products [6,160]. However, these treatments should not be overused because it could result in undesired effects such as over-softening or a loss of natural texture that may reduce the quality of the products. In addition, UV and PL can initiate oxidative reactions in some food components, which may alter their sensory properties, such as the flavour and colour. For example, UV light, if applied for a longer period, may cause browning in light-sensitive foods like milk or fresh juices due to the decomposition of ascorbic acid and polyphenols [153]. PL treatment, although efficient in microbial reduction, can also bring about oxidative stress in food compounds, which in turn can catalyse pigment degradation in some fruits and vegetables, resulting in discolouration and impacting consumer acceptability [12]. Mitigation strategies include optimising the exposure time, wavelength, and intensity to balance microbial inactivation with minimal oxidative damage [155], using antioxidants such as ascorbic acid or tocopherols to counteract the oxidative effects [161], packaging modifications using oxygen-scavenging films to limit the oxygen exposure for oxygen-sensitive foods [162], and UV-blocking films or opaque containers to protect light-sensitive nutrients and pigments from degradation during storage [163]. The complete realisation of the potential of these technologies will need optimisation studies with respect to the dose, exposure time, and characteristics of the food matrix.

6. Cold Plasma (CP)

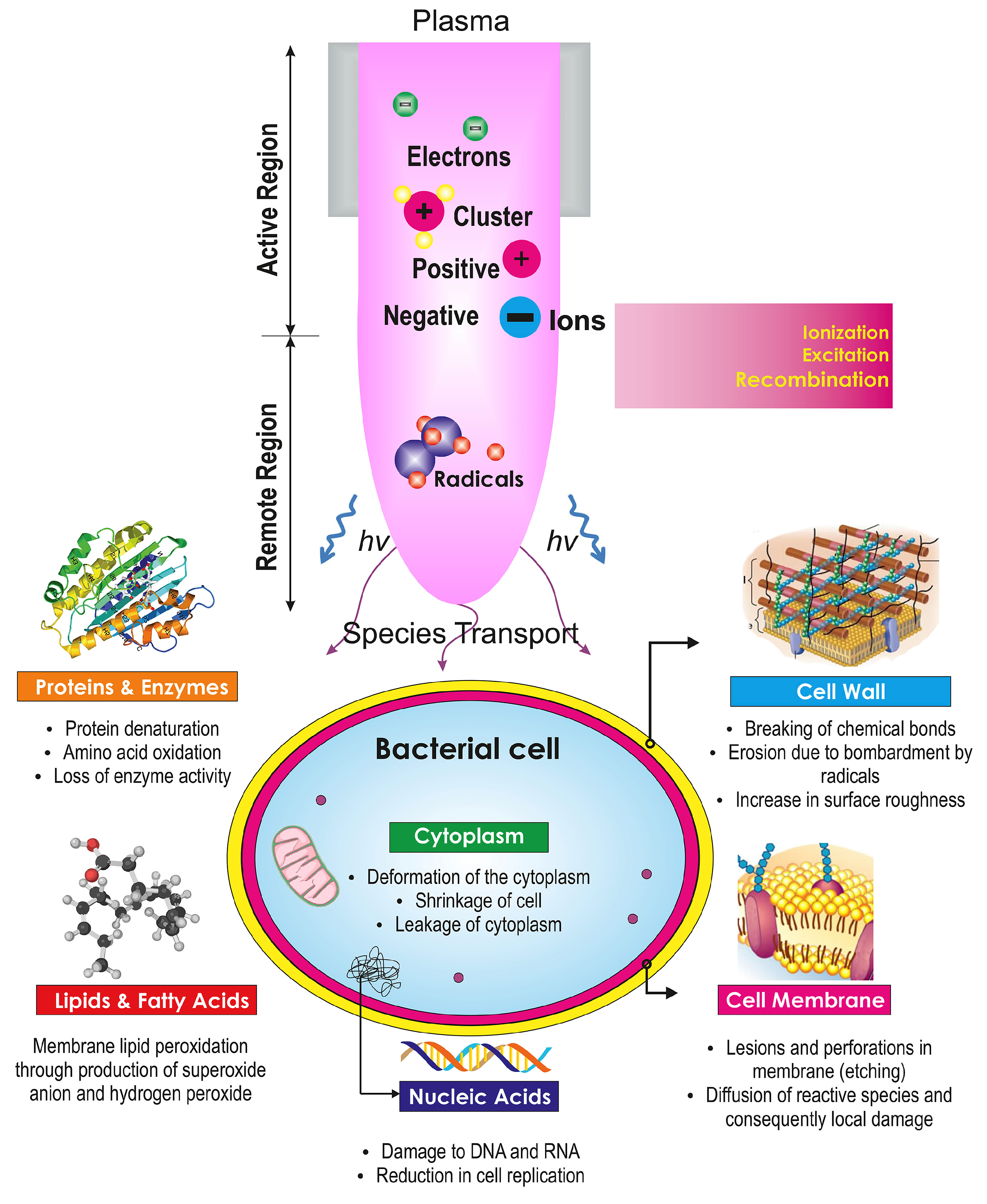

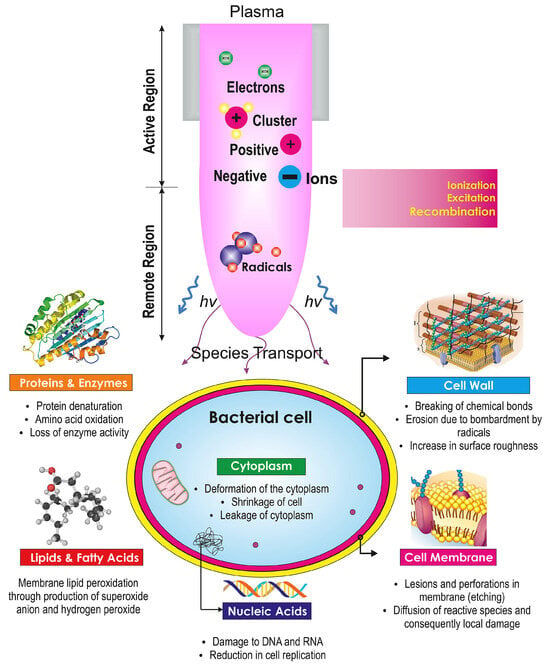

Cold plasma (CP) technology, a type of nonthermal plasma, has drawn a lot of interest in the food processing industry because of its potential for surface cleaning, microbiological inactivation, and shelf life extension while maintaining nutritional quality [164]. Electrons, ions, and radicals are among the active species that make up plasma, the fourth state of matter. According to their thermal equilibrium, the low-temperature plasma can be classified into cold plasma (nonthermal plasma) and quasi-equilibrium plasma (thermal plasma) [165]. Atmospheric cold plasma (ACP) is one of the most widely applied nonthermal plasma technologies that can be generated through various discharge methods, including corona discharge (CD), dielectric barrier discharge (DBD), micro-hollow-cathode discharge (MHCD), a plasma needle (PN), and an atmospheric pressure plasma jet [166,167]. The initiation of CP results in numerous elastic and inelastic collisions between electrons, ions, and molecules [168]. Active components of CP, which are predominantly reactive oxygen species (ROS) and reactive nitrogen species (RNS), include the ozone, hydroxyl radicals, superoxide anions, nitric oxide, nitrogen dioxide, and nitrous oxide, and they play critical roles in food processing [169]. These ROS and RNS have strong oxidative properties and high diffusion coefficients, which enable them to diffuse efficiently and inactivate spoilage microorganisms on the surface of foods [167]. Their transient nature allows them to quickly recombine with molecules that have not reacted, returning the gas mixture to its initial state at the end of the treatment. As a result, CP is a residue-free and environmentally friendly technique that supports “clean label” processing principles [170]. In addition, since it can operate at an ambient temperature and pressure, it is particularly suitable for processing heat-sensitive foods while maintaining their quality and safety. Figure 5 illustrates how CP affects bacterial cell structures, leading to sterilisation and a loss of functionality.

Figure 5.

A schematic of the action of cold plasma on bacterial cell structures resulting in loss of functionality and sterilisation [171].

CP has been shown in recent studies to be successful in lowering bacterial infections in meat and dairy products without appreciably altering their nutritional value or sensory appeal. Gavahian et al. [172] investigated the efficacy of cold plasma against Salmonella enterica that has been injected on the surface of duck eggshells. In this context, arc plasma was applied to Salmonella-contaminated duck eggs for 10, 20, 30, and 40 s. The findings showed that the Salmonella population was considerably reduced by all plasma treatments, and that the bactericidal effects of plasma were strengthened by longer treatment durations. After 40 s of plasma application, a maximum bacterial decrease of a 4.1 log cycle was noted. Additionally, egg quality measures, such as the eggshell strength, eggshell colour, and yolk colour, were unaffected by the plasma treatments [172]. Furthermore, the use of CP technology to inactivate food-borne pathogens in the fresh-cut fruit and vegetable sector has been assessed, considering the several drawbacks to using chlorine and other chemical agents for microbial inactivation in the industry, such as residue retention and inefficiency due to dilution and degradation over time [170]. Mahnot et al. [173] assessed the efficacy of high-voltage ACP in reducing the natural microflora of carrots treated for 1, 2, 3, 4, and 5 min at 60, 80, and 100 kV (60 Hz frequency). Carrot discs treated at 100 kV for 5 min (~250 W power) showed a population reduction of about 2 log10 CFU/g in both yeast and mould and total aerobic mesophiles. Only slight changes in the pH, colour, texture, and total carotenoids were observed in the CP-treated carrots, proving CP to be a better treatment option than chlorine, hydrogen peroxide, and high-pressure carbon treatment. This study concluded that voltages between 80 and 100 kV and treatment durations of 4 to 5 min are recommended for the shelf-life assessment of plasma-treated chopped carrots to maximise the inhibition of spoilage microflora and preserve the quality [173].

Additionally, it has been demonstrated that CP inactivates the enzymes Peroxidase (POD) and Polyphenol Oxidase (PPO), which are typically found in the majority of fruits and vegetables and cause browning reactions by forming o-quinones following a series of reactions that are deemed undesirable because they ultimately result in a deterioration in the flavour and colour [167]. Pankaj et al. [174] investigated the kinetics of the inactivation of tomato peroxidase as a model enzyme at 30, 40, and 50 kV, using atmospheric air dielectric barrier discharge plasma treatments up to 5′. They found that both the treatment time and voltage reduced the POD enzyme activity, with the former having a stronger effect. CP has also been assessed for efficacy in controlling key microbial indicators encountered in the food industry effluent. In the study by Patange et al. [175], it was found that microbial counts in synthetic dairy and meat effluents were significantly reduced within 120 s of ACP treatment and completely annihilated after 300 s. In addition, 20 min of ACP treatment provided a ≥2 Log10 reduction of Bacillus megaterium endospores in the wastewater effluent. For the determination of the potential toxicity, the study used two fish cell lines (PLHC-1 and RTG-2) and a crustacean model (Daphnia magna) for bioassays. While untreated effluents were toxic to the aquatic models, ACP treatment inhibited the toxic effects. However, the observed toxic effects were dependent on the concentration and treatment period of the ACP-treated effluent, with 30% cytotoxicity in Daphnia magna and fish cells seen after 24 h of exposure to the ACP-treated effluent for concentrations up to 5%. This study demonstrates ACP’s potential as a highly effective wastewater treatment agent while emphasising the need to control treatment parameters to prevent environmental toxicity [175].

In the food industry, several unit operations including mixing, shaping, kneading, moulding, pasteurisation, filling, etc., are highly influenced by the rheological properties of food products [176]. It has been reported that the interaction of plasma species with starch causes chemical, enzymatic, and physical modifications through three different plausible mechanisms such as cross linking, depolymerisation, and plasma etching [177]. Hence, the response of the food rheological characteristics to plasma species during treatment would be of interest to the food industry as they determine the design of food processing and handling equipment. Review articles on the application of cold plasma as a potentially useful technology to improve the rheological properties of food and starch modification have been published [176,177,178]. The summarised findings of these reviews showed that cold plasma could be a promising technique for modifying starch to achieve the desired rheological characteristics. In an informative study, the interaction of plasma species with corn starch changed the rheological behaviour from pseudo-plastic to non-Newtonian due to molecular weight degradation [179]. This resulted in the decreased viscosity of the CP-treated starch, affirming that CP can modulate the rheological properties of starchy food products. On the other hand, CP processing has proven to improve the gelling characteristics of plant proteins by modifying their structure through oxidation and crosslinking [180]. Also, from a study on the effect of cold atmospheric-pressure plasma on the rheological properties of gum Arabic, it was shown that CP treatment improved its viscosity and elastic-like behaviour [181]. Similarly, Basak and Annapure [182] investigated and reported the effect of atmospheric-pressure CP on the rheological and gelling properties of high-methoxyl apple pectin using a pin-to-plate plasma reactor at a 1 kHz frequency, 190 V, 210, and 230 V voltages and 3, 6, 9, 12, and 15 min treatment time. The results showed that after CP treatment, the pseudoplastic pectin dispersions transitioned towards a Newtonian-like behaviour, while the decreasing stability and strength of pectin dispersions and gels were observed with the increasing voltage (≥210 V). Though improved rheological properties were observed for low voltage–time combinations (190 V/9 min and 210 V/6 min), prolonged exposure at higher voltage processing (210 and 230 V) negatively impacted both the rheological and gelling properties. In another study, the changes in the structural morphology and rheological properties of pectin fractions isolated from okra pods under CP treatment were studied at a plasma flow of 3 L/min, pulse frequency of 20 kHz, power consumption of 750 W, and treatment time of 5 to 30 s [183]. A slight change in the rheological behaviour of the fluid from dilatant towards Newtonian was observed for chelator-soluble pectin and diluted alkali-soluble pectin, and pseudoplastic behaviour for water-soluble pectin. In the investigation of the effect of atmospheric CP (N2-O2/N2 plasma species) treatment on the acid gelation properties of skim milk, it was found that the viscosity increased as the treatment time increased from 0 to 5 min and there was a significant impact on the storage/elastic modulus [180]. Similarly, the study of the impact of CP processing on the rheological properties of pearl millet flour at different power levels (20–30 kV) for 10–20 min, found that CP-treated samples exhibited a higher storage modulus (G′), demonstrating an elastic behaviour [184]. Consequently, the CP-processed pearl millet flours possess higher values of flow behaviour indices than those observed in the control, suggesting higher shear-thinning behaviour. A similar increase in the shear-thinning behaviour was observed for CP-treated gum Arabic dispersions [181]. In general, it is obvious from the review of the literature that CP processing can strengthen the elastic (storage modulus) features of food products as a result of increased intermolecular interactions. This will also aid in determining the possible applications of CP in the food industry.

The industrial application of CP technology requires further studies on process optimisation and the effect on food components. This study by Coutinho et al. [185] investigated the effect of different process times (5, 10, and 15 min) and flow rates (10, 20, and 30 mL/min) of CP treatment on the physicochemical properties, bioactive compounds, fatty acid composition, and volatile profile of chocolate milk drinks. The findings showed that mild (a lower flow rate and shorter duration) and severe (a higher flow rate and longer duration) plasma conditions led to the reduction of bioactive compounds such as the total phenolic content and ACE-inhibitory activity. In addition, these conditions altered the fatty acid composition, increasing the amount of saturated fatty acids and decreasing the amount of monounsaturated and polyunsaturated fatty acids, resulting in less favourable health indices (increased atherogenic, thrombogenic, and hypercholesterolemic fatty acids). A decrease in volatile compounds was also observed. On the other hand, intermediate cold-plasma conditions maintained an optimal balance of bioactive compounds, preserved a desirable fatty acid profile, and improved the volatile profile by increasing the ketones, esters, and lactones. These results suggest that cold plasma technology could be a promising processing method for chocolate milk drinks, but the optimisation of the treatment parameters is necessary to preserve nutritional and sensory properties [185].

7. Utilisation of Non-Thermal Food Processing Technologies

There is now an increased acceptance of non-thermal food-processing technologies compared to the previous decade due to their various advantages over conventional methods, such as improved energy efficiency, a better retention of nutrients, reduced reliance on preservatives, and less threat to the environment. Numerous phases are involved in food processing, including raw material storage, washing, heating, chilling, emulsification, and drying. During thermal food processing, waste steam is released into the environment by the equipment, and this can contain the proteins, lipids, carbohydrates, and cleaning agent residues used in these procedures [167]. The environment may be negatively impacted by the waste items produced. Therefore, using greener and cleaner technologies that use raw materials without posing much environmental harm is crucial. The food industry has traditionally employed thermal technologies which include cooking, drying, pasteurisation, and sterilisation, all of which require the combustion of fossil fuels while electricity is utilised for power generation and refrigeration [80,167]. With benefits including shorter cooking times, the preservation of quality characteristics, and increased product safety, non-thermal technologies offer a substitute for these thermal technologies [5]. Furthermore, they have found wide applications in foods with complex rheologies in which the conventional heat-based methods of processing or preserving may not be feasible. Importantly, these technologies can be utilised in different food matrices such as liquid foods, solid, and semi-solid foods.

7.1. Non-Thermal Technologies in Liquid Foods