Abstract

Coal and gas outburst accident is a significant risk in high-gas outburst coal seams, and effective pressure relief gas extraction plays a crucial role in mitigating these hazards. The core challenge lies in understanding the seepage behavior of the coal rock body in the three zones of the overburden during multiple protective layer mining. This study employed a damaged coal rock body seepage test system to conduct repeated loading and unloading seepage tests on coal rock samples from these zones. The results show that the permeability of the broken coal rock body in the caving zone decreases with increasing stress, while it increases with (a) larger particle sizes of the broken coal rock body and (b) with a higher proportion of rock in the sample. The permeability distribution in the goaf follows an “O”-shaped circle pattern and gradually increases from the center outward. Additionally, When the protected layer is located within the fracture zone of the protective layer mining, and the first protective layer mining has already resulted in significant stress relief and permeability improvement, the effect of stress release and permeability enhancement from the second protective layer mining becomes less pronounced. In contrast, if the first protective layer mining does not sufficiently relieve stress or enhance permeability, the second protective layer mining has a more substantial effect. These findings are significant for analyzing the effects of pressure relief enhancement in multi-protective layer mining of high-gas outburst coal seams and for optimizing gas extraction.

1. Introduction

Coal and gas outbursts are common gas hazards in underground coal mining and have garnered significant attention worldwide [1,2]. Since the first recorded outburst at the Issac coal mine in France in March 1834, over 30,000 outbursts have been reported globally [3,4]. The outburst process involves the violent ejection of broken coal and rock mixed with high-pressure gas [5,6,7,8]. This generates a high-velocity stream of pulverized coal and gas that can damage shaft facilities, disrupt the ventilation system, and potentially trigger secondary hazards such as gas explosions, asphyxiation, and combustion, ultimately resulting in severe economic losses and human casualties [9,10,11,12]. Coal and gas outbursts are particularly prevalent in high-gas outburst coal seam groups. To prevent such accidents, efficient gas extraction through pressure relief from the multiple protected seams of these high-gas outburst coal seam groups is essential [13,14,15]. The key to this process lies in understanding the seepage behavior of coal rock bodies in the three zones of the overburden in multi-protection mining. Therefore, experimental research on the seepage law of coal rock bodies in these three overburden zones is critical for preventing coal and gas outburst accidents in the multi-protection mining of high-gas outburst coal seam groups.

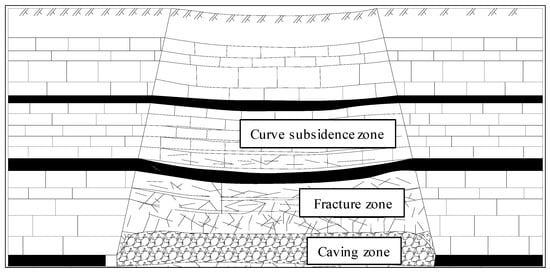

After mining the protective layer of the coal seam group, the overlying rock layers are divided into the caving zone, fracture zone, and curve subsidence zone, collectively referred to as the three zones of overburden [16,17,18], and the distribution characteristics of the three zones of the overlying rock layers are shown in Figure 1. The caving zone consists of broken coal and rock bodies. As the working face advances, the overlying rock layer sinks and compacts the mining airspace, gradually restoring stress in the mining airspace. As a result, parameters such as porosity and permeability continuously change [19,20]. It has been observed that the permeability of broken coal seams decreases significantly after each cycle, with a greater impact during the loading stage. The highest irreversible permeability loss occurs at a coal-to-rock ratio of 50% [21,22]. In a study of the stress–permeability relationship of broken coal, rock, and coal–rock combinations in a caving zone, it was found that permeability stress sensitivity and loss are significantly higher in the first loading–unloading cycle. Re-crushing and re-arrangement were identified as key factors contributing to porosity reduction and permeability decrease [23,24]. The compaction and permeability evolution of broken coal masses in the goaf were also analyzed. This study showed that, under isotropic loading, smaller particle sizes led to greater crushing in mixed particle samples. Additionally, the stress sensitivity of permeability decreased with increasing elastic modulus, effective stress, and Poisson’s ratio [25]. Furthermore, the permeability characteristics of broken coal masses under cyclic loading and unloading conditions revealed that permeability is primarily determined by porosity and follows the cubic law. Stress sensitivity and permeability loss were observed to decrease as the number of loading cycles increased [26].

Figure 1.

Distribution characteristics of the three zones within the overlying strata after coal seam extraction.

The fractured zone above the caving regions exhibits complex permeability characteristics influenced by the evolution of structural damage. Quantitative studies show that fracture network geometry significantly affects gas migration efficiency, with fractal dimension values (D = 1.62–1.78) strongly correlating (R² = 0.86) with permeability enhancement rates [27,28]. Stress-path dependency has been identified as a key control factor, where mining-induced stress redistribution can alter fracture aperture by 0.15–0.38 mm, resulting in 3–8 times variations in permeability across different zones [29,30]. Multi-physics coupling mechanisms further complicate permeability evolution. Recent modeling advances that incorporate fracture–pore interactions reveal that adsorption-induced matrix shrinkage contributes 25–40% of the total permeability improvement in protected seams [31].

The bending subsidence zone exhibits distinct permeability characteristics controlled by elastic deformation mechanisms. Coal permeability in this zone shows stress-path dependency, decreasing with effective stress during loading phases and partially recovering during unloading. Optimal gas drainage efficiency is achieved when boreholes are oriented perpendicular to bedding planes [32]. Experimental investigations reveal that permeability evolution under coupled dynamic–static loading conditions follows a cyclic enhancement pattern, with a 15–28% increase per loading cycle. The permeability remains highly sensitive to static stress variations and gas adsorption effects [33]. Additionally, field studies in protected seams show that axial unloading-induced permeability changes strongly correlate with coal damage accumulation. Acoustic emission event counts (3500–5200 counts/min) serve as quantitative indicators of fracture network development [34]. These findings systematically validate the critical role of protective layer mining in improving gas drainage and mitigating outburst risks.

In summary, although many scholars both domestically and internationally have conducted numerous studies on the seepage characteristics of coal rock bodies in the three overburden zones after protective layer mining and have obtained valuable results, the seepage process in the fracture zone and curved subsidence zone during protective layer mining has not been fully restored due to limitations in testing equipment and other factors. Additionally, there has been limited research on the seepage characteristics of coal rock bodies within the three overburden zones of coal seam groups with multi-protective layer mining [35]. Therefore, this paper conducts a repetitive loading and unloading seepage test on coal rock samples from the three overburden zones using a damaged coal rock seepage test system. This study reveals the seepage characteristics of coal rock in these zones during multi-protection mining of high-gas coal seam groups. The findings are significant for analyzing the effects of pressure relief enhancement in multi-protection mining of high-gas outburst coal seams and for pressure relief gas extraction.

2. Methodology

2.1. Specimen Preparation

Due to limitations in the test equipment, it is impossible to fully restore the seepage process from intact coal rock samples to broken ones in the caving zone during the multi-protection mining process of the coal seam group. Therefore, a seepage test was conducted on broken coal rock bodies from the formed mining goaf using multiple cycles of loading and unloading. Since broken coal rock bodies with varying mixing ratios are found at different locations in the goaf, three coal rock samples with particle sizes of 6.8–10.2 mm and mixing ratios of 1:1, 1:2, and 1:4 were selected for the seepage test in this study. The specimen preparation process is shown in Figure 2. The specific process is as follows: First, collect the large raw coal and gangue from the working face. Next, crush the raw coal and gangue using an artificial crushing method to create a mixed crushed coal rock body with varying particle sizes. Then, screen the crushed coal rock body to obtain particles ranging from 6.8 to 10.2 mm. Finally, prepare various proportions of the crushed coal rock samples with different volume mixing ratios according to the test requirements. The basic information of the specimens is shown in Table 1.

Figure 2.

Sample preparation procedure for coal rock bodies within the three overburdened zones.

Table 1.

Basic information on coal rock samples from the caving zone.

Since the test device can fully restore the seepage process of the coal body in the fracture and curve subsidence zones during the multi-protection mining process of the coal seam group, a seepage test was conducted on the original coal specimen in these zones. The test follows cyclic real stress loading and unloading paths, with a specimen size of 50 mm × 100 mm. The process is as follows: First, collect the large raw coal from the working face. Then, use the ZS 100 core drilling machine to drill 50 mm × 100 mm standard coal plugs. The basic information of the specimen is shown in Table 2.

Table 2.

Basic information on coal samples from fracture and curve subsidence zones.

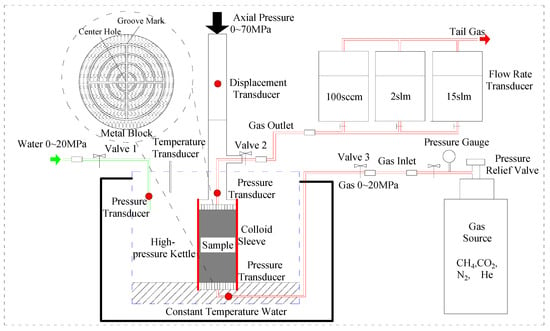

2.2. Test Equipment

This test uses the damaged coal rock body seepage test system shown in the schematic diagram in Figure 3, as described according to Li, B. et al. (2019) [26]. The system can perform seepage tests on intact, fractured, and broken coal rock bodies under different stress paths. The seepage tests in this study were conducted following standard procedures to ensure the accuracy and reliability of the results.

Figure 3.

Schematic diagram of the seepage test system for damaged coal rock body.

2.3. Test Scheme

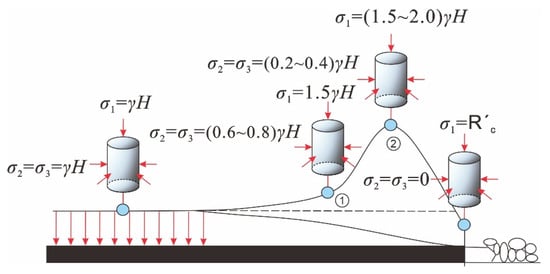

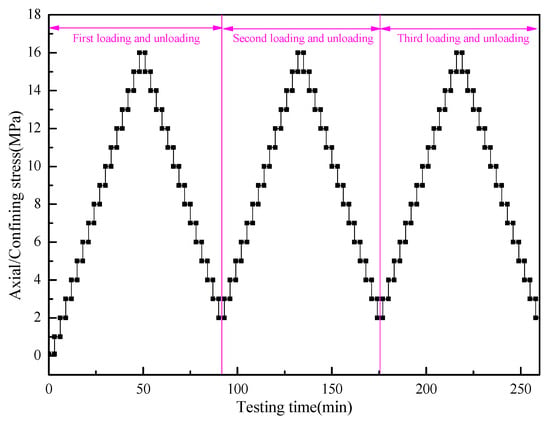

Xie et al. [36] pointed out that the horizontal and vertical stresses in the protected layer vary during the mining process of the coal seam group. The horizontal stress gradually decreases from the initial hydrostatic stress to a relatively low level, remaining in an unloading state. In contrast, the vertical stress in the protected layer gradually increases from the hydrostatic stress state to peak damage and then decreases to a lower level, undergoing a loading and unloading process. Subsequently, the horizontal and vertical stresses are gradually restored to a certain level in the back-mining area by the compaction of the overlying rock layer. The changes in horizontal and vertical stresses in the protected layer after mining are shown in Figure 4. When the coal seam group undergoes multiple protection mining, mining of the back protective layer subjects the protected layer to the stress path shown in Figure 4. The intensity of this stress path depends on factors such as the mining thickness of the protective layer, the layer spacing, and the lithology of the layers. As discussed in Section 2.1, the coal rock body test in the caving zone was conducted using broken coal rock bodies from the formed mining goaf for multiple cycles of isobaric pressure plus unloading seepage tests. The test scheme is shown in Figure 5. The repeated loading and unloading seepage test under the real stress path was conducted for the coal rock body within the fracture and curve subsidence zones, as outlined in Table 3.

Figure 4.

Schematic diagram of the variation in horizontal and vertical stresses of the protected layer in the protective layer mining (modified from Xie et al. [36]).

Figure 5.

Stress loading and unloading paths of coal rock samples in the caving zone.

Table 3.

Repeated loading and unloading seepage test program under real stress paths for coal samples in fracture and curve subsidence zones.

3. Test Results and Analysis

3.1. Characterization of Seepage in a Coal Rock Body Within the Caving Zone of Multiple Protected Mining in the Coal Seam Group

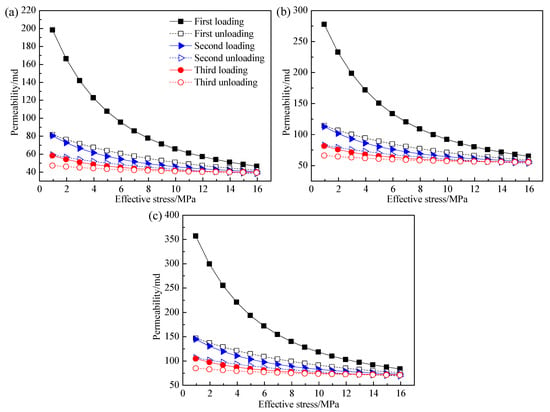

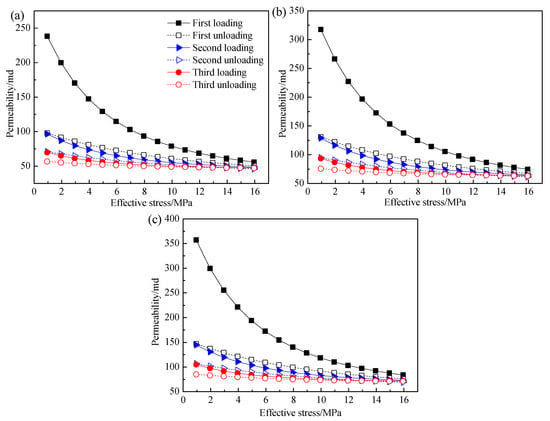

Three cycle loading and unloading seepage tests were conducted on coal rock samples with different mixing ratios, following the test scheme in Figure 5. The test results are shown in Figure 6.

Figure 6.

Plot of permeability versus effective stress for cyclic loading and unloading of broken coal rock samples with different mixing ratios: (a) specimen P1, (b) specimen P2, and (c) specimen P3.

Figure 6 shows that the permeability of broken coal rock samples with different mixing ratios decreases as the effective stress increases. Even under high-stress conditions (16 MPa effective stress), the permeability remains above 40 md, indicating that the porosity between the broken coal rock particles in the protective layer working face goaf remains relatively high. This suggests that the permeability of the broken coal rock body in the goaf stays relatively high, even with compaction. Additionally, samples with a higher proportion of rock bodies exhibit greater permeability under the same stress and show higher stress sensitivity in terms of permeability during the loading and unloading cycles.

Additionally, the permeability change trend in the three loading and unloading processes of the broken coal rock samples is consistent. The permeability during the first loading seepage process is much higher than in the last two loading processes. In each cycle, the permeability during the loading stage is always higher than during the unloading stage. As the number of cyclic loading and unloading increases, the decrease in permeability after each unloading cycle gradually diminishes. The obtained regularity is the same as that reported in [26].

3.2. Seepage Characterization of Coal in Multiple Protected Mining Fracture Zones of the Coal Seam Group

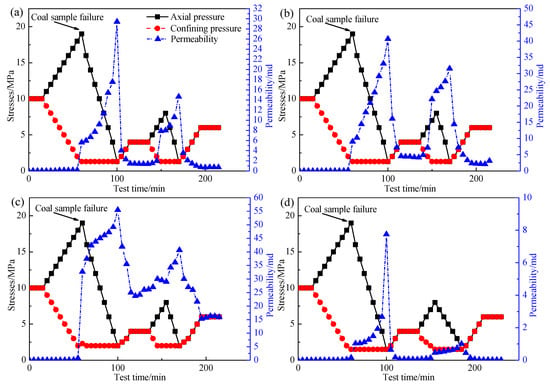

Seven sets of repeated loading and unloading seepage tests were conducted on the coal body of the protected seam in the fracture zone, following the test scheme in Figure 4 and Table 3. The test results are shown in Figure 7 and Figure 8.

Figure 7.

Characterization of permeability under repeated loading and unloading under the real stress path of the coal body in the fracture zone (initial hydrostatic pressure 10 MPa): (a) L1 coal sample, (b) L2 coal sample, (c) L3 coal sample, and (d) L4 coal sample.

Figure 8.

Characterization of permeability under repeated loading and unloading under the real stress path of the coal body in the fracture zone (initial hydrostatic pressure 5 MPa): (a) L5 coal sample, (b) L6 coal sample, and (c) L7 coal sample.

(1) Permeability characteristics of repeated loading and unloading under the real stress path of the coal body within the rift zone (initial hydrostatic pressure 10 MPa).

As shown in Figure 7, when the coal body in the fracture zone is not affected by protective layer mining, the permeability is extremely low under the initial rock stress. When the protected seam is affected by the first protective mining, the axial pressure and confining pressure change. Before the coal body is destroyed, the permeability increases very slowly and remains almost unchanged. Once the coal body is destroyed, the permeability rises sharply. Afterward, during the axial pressure unloading stage, the confining pressure remains constant, and the permeability of the coal samples gradually increases. Finally, as the axial and confining pressures gradually recover to a certain stress level due to the overlying rock strata, the permeability of the coal body decreases sharply.

When the second protective layer mining affects the protected layer, the permeability characteristics are similar to those of the first mining event. However, the permeability of the coal body in the second mining is lower than that in the first mining throughout the process. This is because, during the first protective layer mining, the permeability of the coal samples increased by hundreds to thousands of times when they were fractured, indicating severe damage and the formation of many large fractures. After the loading stage, due to the compaction of the overlying rock layer, two things occurred: first, the internal penetrating fractures were closed by external forces, leading to a substantial reduction in fracture openings; second, the coal fragments on the rough fracture surfaces were prone to breaking off and blocking the fracture channels during the loading process, further reducing the fracture openings. This resulted in a significant reduction in permeability, as shown in Figure 7.

Therefore, during the second unloading, the permeability of the coal samples is lower than during the first unloading, as it is difficult to reopen the closed fractures, and coal dust continues to accumulate and block the fracture channels. It can also be concluded that the permeability improvement and stress release effects from the first protective layer mining are more pronounced. The first mining event has a greater impact on the coal body, causing more significant damage, while the second mining event has a less noticeable effect on stress release and permeability improvement.

(2) Permeability characteristics of repeated loading and unloading under the real stress path of the coal body in the fracture zone (initial hydrostatic pressure 5 MPa).

As shown in Figure 8, the permeability characteristics of the coal body in the fracture zone with an initial hydrostatic pressure of 5 MPa under the real stress path of repeated loading and unloading are similar to those of the coal body in the rift zone with an initial hydrostatic pressure of 10 MPa. However, the overall permeability after the first unloading is smaller than after the second unloading in the coal body with an initial hydrostatic pressure of 5 MPa. This is the opposite of what is observed in the coal body with an initial hydrostatic pressure of 10 MPa. The main reasons for this are as follows: during the first unloading stage, the permeability of coal samples with an initial hydrostatic pressure of 5 MPa increased only a few dozen times during the crushing stage, indicating that the crushing was not severe and only a few penetrating cracks were formed. When the coal samples underwent the second unloading, they were damaged again, and more penetrating fractures were created. This led to the overall permeability of the coal samples during the second unloading being higher than during the first unloading. From this, it can be concluded that when the first protective layer mining has an insufficient effect on unloading and penetration of the protected layer, meaning the mining does not significantly affect the coal body and the damage is minimal, the stress release and permeability improvement from the second protective layer mining are more pronounced. These effects are significantly greater than those from the first unloading of the protective layer.

3.3. Seepage Characterization of Coal in a Curve Subsidence Zone of the Coal Seam Group with Multiple Protection Mining

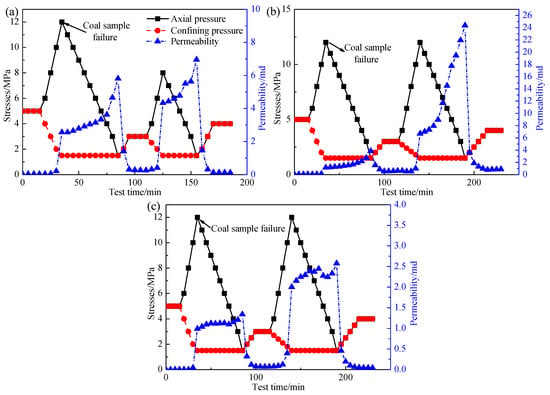

Three sets of repetitive loading and unloading seepage tests were conducted on the coal body of the protected seam in the curve subsidence zone with an initial hydrostatic pressure of 10 MPa, following the test scheme in Figure 4 and Table 3. The test results are shown in Figure 9.

Figure 9.

Changing pattern of permeability under repeated loading and unloading under the true stress path of the coal body within the curve subsidence (initial hydrostatic pressure of 10 MPa): (a) W1 coal sample, (b) W2 coal sample, and (c) W3 coal sample.

In Figure 9, the permeability characteristics of the coal body in the curve subsidence zone with an initial hydrostatic pressure of 10 MPa are consistent with those of the coal body in the fracture zone with the same initial hydrostatic pressure under repeated loading and unloading along the real stress path. Since the coal body in the curve subsidence zone is not damaged during the two loading and unloading processes, the change in permeability is very small, increasing only a few times. Therefore, the permeability of the coal samples during both the loading and unloading processes remains very low, with minimal changes. This suggests that when the protected layer is in the curve subsidence zone during protective layer mining, the effect of mining on unloading and increasing permeability is very limited, even after multiple mining cycles. Additionally, the overall permeability of the coal samples during the second unloading is slightly smaller than during the first unloading. This is mainly because the coal samples were not damaged during the unloading processes and remained in the elastic stage throughout. The small cracks that were closed during the first unloading were not reopened in the second unloading, resulting in a slightly lower overall permeability during the second unloading.

4. Engineering Guidance of This Study

4.1. Guidance on the Selection of Protective Layers for Coal Seam Group Mining

From the results of the tests in Section 3.2 and Section 3.3, it is clear that when the protected seam is in the fracture zone during protective seam mining, the stress release and permeability improvement effects are significant. In contrast, when the protected seam is in the curve subsidence zone, these effects are minimal. Therefore, in practical protective layer mining, it is advisable to position the protected layer in the fracture zone and avoid the curve subsidence zone to achieve optimal stress release and permeability improvement.

4.2. Guidance on the Location of Gas Extraction Drill Holes in the Goaf

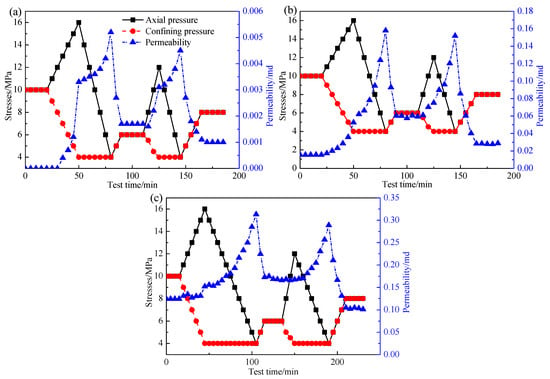

The goaf primarily consists of broken coal rock bodies, with varying mixing ratios and grain sizes across different areas. To explore the permeability variations in these areas, it is essential to analyze the seepage characteristics of broken coal rock bodies with different grain sizes. Therefore, this study conducted cyclic loading and unloading seepage tests on three types of broken rock samples with particle sizes of 2.8–4.6 mm, 4.6–6.8 mm, and 6.8–10.2 mm. The test program is shown in Figure 5, and the results are presented in Figure 10.

Figure 10.

Plot of permeability versus effective stress for three cycle unloading tests of broken rock samples with different grain sizes: (a) 2.8 to 4.6 mm, (b) 4.6 to 6.8 mm, and (c) 6.8 to 10.2 mm.

As can be seen in Figure 10, the permeability of broken rock samples is proportional to the particle size, i.e., the permeability of broken rock samples increases with the increase in the particle size of samples.

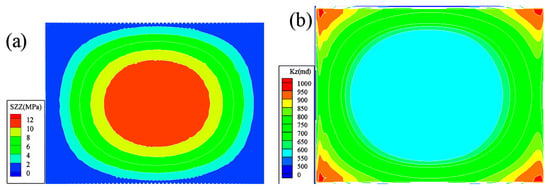

In summary, the permeability of broken coal rock bodies decreases with increasing stress, increases with larger particle sizes, and rises with a higher proportion of rock in the broken coal rock body samples. The vertical stress in the mining area generally forms an “O”-shaped distribution, as shown in Figure 11a. The broken coal rock body in the goaf is compacted by vertical pressure, with larger vertical stresses resulting in smaller particle sizes. Consequently, the particle size distribution also follows an “O”-shaped pattern, with sizes increasing from the center to the outer edges. Based on the relationships between permeability, stress, and particle size, the permeability distribution in the goaf also follows an “O”-shaped pattern, gradually increasing from the center to the outer areas, as shown in Figure 11b. Therefore, gas extraction drill holes should be positioned along the outer rim of the goaf, particularly in the four corners of it, to enhance drilling efficiency.

Figure 11.

Vertical stress and permeability distribution in the goaf: (a) vertical stress distribution in the goaf and (b) permeability distribution in the goaf.

5. Conclusions

This paper utilized a damaged coal rock body seepage test system to conduct repeated loading and unloading seepage tests on coal rock body samples from three overburden zones. The tests revealed the seepage characteristics of coal rock bodies in these zones under multi-protection layer mining in high-gas coal seam groups. The main conclusions are as follows:

- (1)

- The permeability of the broken coal sample during the first loading seepage process is significantly higher than during the subsequent loading processes. Permeability during the loading stage is consistently greater than during the unloading stage in each cycle. As the number of loading and unloading cycles increases, the permeability decreases as each cycle gradually diminishes.

- (2)

- The permeability of broken coal rock bodies decreases with stress, increases with larger particle sizes, and rises with a higher proportion of rock in the coal rock samples. The permeability distribution in the mining area follows an “O”-shaped pattern, gradually increasing from the center to the outer areas.

- (3)

- When the protected layer is located within the fracture zone of protective layer mining, and the first mining stage has already resulted in significant stress relief and permeability improvement, the effect of the second protective layer mining on stress release and permeability enhancement becomes less pronounced. In contrast, if the first mining stage did not sufficiently relieve stress or enhance permeability, the second mining stage has a more substantial effect.

- (4)

- When the protected layer is located within the curved subsidence zone of protective layer mining, the mining process is ineffective in relieving stress and improving permeability, even when multiple layers are mined. Therefore, in protective layer mining practices, it is recommended to select a protected layer within the fracture zone and avoid positioning it in the curved subsidence zone to achieve the best results for stress release and permeability improvement. Additionally, gas extraction drill holes should be positioned along the outer rim of the goaf, particularly at the four corners of it, to enhance drilling efficiency.

Author Contributions

Conceptualization, B.L.; methodology, J.Z. and B.L.; investigation, J.Z. and B.L.; writing—original draft preparation, J.Z. and B.L.; writing—review and editing, J.Z.; funding acquisition, J.Z. and B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is financially supported by the National Natural Science Foundation of China (52204132 and 42304085), the Jiangsu Funding Program for Excellent Postdoctoral Talent (2023ZB154), the Natural Science Foundation of Jiangsu Province (BK20231086), the Hunan Provincial Natural Science Foundation of China (2023JJ40285), and the Scientific Research Foundation of Hunan Provincial Education Department (22B0469).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lei, Y.; Cheng, Y.; Wang, L.; Ren, T.; Tu, Q. Mechanisms of coal and gas outburst experiments: Implications for the energy principle of natural outbursts. Rock Mech. Rock Eng. 2023, 56, 363–377. [Google Scholar] [CrossRef]

- An, F.; Yuan, Y.; Chen, X.; Li, Z.; Li, L. Expansion energy of coal gas for the initiation of coal and gas outbursts. Fuel 2019, 235, 551–557. [Google Scholar] [CrossRef]

- Beamish, B.B.; Crosdale, P.J. Instantaneous outbursts in underground coal mines: An overview and association with coal type. Int. J. Coal Geol. 1998, 35, 27–55. [Google Scholar] [CrossRef]

- Shepherd, J.; Rixon, L.K.; Griffiths, L. Outbursts and geological structures in coal mines: A review. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 267–283. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Lei, Y.; Cheng, Y.; Wang, L.; Ren, T.; Tu, Q. Evidence for universal rupture behavior during coal and gas outbursts. Fuel 2022, 324, 124592. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.; Jiang, H.; Jin, K.; Wang, H.; Wang, L. Role of the rapid gas desorption of coal powders in the development stage of outbursts. J. Nat. Gas Sci. Eng. 2016, 28, 491–501. [Google Scholar] [CrossRef]

- Wold, M.B.; Connell, L.D.; Choi, S.K. The role of spatial variability in coal seam parameters on gas outburst behaviour during coal mining. Int. J. Coal Geol. 2008, 75, 1–14. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Ren, T.; Zhao, W.; Tu, Q.; Dong, J.; Wang, Z.; Hu, B. Experimental investigation on the formation and transport mechanism of outburst coal-gas flow: Implications for the role of gas desorption in the development stage of outburst. Int. J. Coal Geol. 2018, 194, 45–58. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.; Guo, P.; Jin, K.; Tu, Q.; Wang, H. An analysis of the gas-solid plug flow formation: New insights into the coal failure process during coal and gas outbursts. Powder Technol. 2017, 305, 39–47. [Google Scholar] [CrossRef]

- Shu, L.; Wang, K.; Liu, Z.; Zhao, W.; Zhu, N.; Lei, Y. A novel physical model of coal and gas outbursts mechanism: Insights into the process and initiation criterion of outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Kissell, F.N.; Iannacchione, A.T. Gas outbursts in coal seams. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2024; pp. 177–184. [Google Scholar] [CrossRef]

- He, A.; Fu, H.; Huo, B.; Fan, C. Permeability enhancement of coal seam by lower protective layer mining for gas outburst prevention. Shock. Vib. 2020, 2020, 8878873. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, W.; Lin, B.; Si, G.; Zhang, J.; Wang, J. Integration of protective mining and underground backfilling for coal and gas outburst control: A case study. Process Saf. Environ. Prot. 2022, 157, 273–283. [Google Scholar] [CrossRef]

- Aguado, M.B.D.; Nicieza, C.G. Control and prevention of gas outbursts in coal mines, Riosa–Olloniego coalfield, Spain. Int. J. Coal Geol. 2007, 69, 253–266. [Google Scholar] [CrossRef]

- Ti, Z.; Li, J.; Wang, M.; Li, X.; Jin, Z.; Tai, C.; Wang, K. Fracture characteristics and zoning model of overburden during longwall mining. Shock. Vib. 2021, 2021, 2857750. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Jiang, X.; Zhang, Q.; Wei, Y. Evolution characteristics of overburden instability and failure under deep complex mining conditions. Geofluids 2022, 2022, 6418082. [Google Scholar] [CrossRef]

- Zhu, H.; Fang, S.; Huo, Y.; Guo, J.; Wu, Y.; Hu, L. Study of the dynamic development law of overburden breakage on mining faces. Sci. Rep. 2020, 10, 6555. [Google Scholar] [CrossRef]

- Palchik, V. Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. Environ. Geol. 2002, 42, 92–101. [Google Scholar] [CrossRef]

- Li, S.; Fan, C.; Luo, M.; Yang, Z.; Lan, T.; Zhang, H. Structure and deformation measurements of shallow overburden during top coal caving longwall mining. Int. J. Min. Sci. Technol. 2017, 27, 1081–1085. [Google Scholar] [CrossRef]

- Kan, Z.; Zhang, L.; Li, M.; Yuan, X.; Huang, M. Investigation of seepage law in broken coal and rock mass under different loading and unloading cycles. Geofluids 2021, 2021, 8127250. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Q.; Zhang, C. Stress-path dependent permeability zonation in longwall mining goafs: Field measurements and DEM validation. Int. J. Rock Mech. Min. Sci. 2023, 168, 105402. [Google Scholar]

- Zhang, C.; Zhang, L. Permeability characteristics of broken coal and rock under cyclic loading and unloading. Nat. Resour. Res. 2019, 28, 1055–1069. [Google Scholar] [CrossRef]

- Wang, K.; Xue, Y.; Zhao, Y. Micromechanical analysis of particle reorientation effects on crushed coal compaction behavior. Powder Technol. 2022, 408, 117692. [Google Scholar] [CrossRef]

- Li, B.; Liang, Y.; Zhang, L.; Zou, Q. Experimental investigation on compaction characteristics and permeability evolution of broken coal. Int. J. Rock Mech. Min. Sci. 2019, 118, 63–76. [Google Scholar] [CrossRef]

- Li, B.; Zou, Q.; Liang, Y. Experimental research into the evolution of permeability in a broken coal mass under cyclic loading and unloading conditions. Appl. Sci. 2019, 9, 762. [Google Scholar] [CrossRef]

- Guannan, L.; Dayu, Y.; Boming, Y.; Feng, G.; Peijian, C. A study on gas drainage considering coupling process of fracture-pore microstructure and coal deformation. Fractals 2021, 29, 2150065. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Wang, J. Fractal characterization of mining-induced fracture networks and its impact on coal permeability. Fractals 2023, 31, 2340021. [Google Scholar]

- Xie, H.; Li, X.; Cai, J.; Wang, S.; Feng, C. Evolution of fissures and pressure discharge of gas caused by mining of the upper protective layer of a coal seam. Sci. Rep. 2023, 13, 2561. [Google Scholar] [CrossRef]

- Liu, G.F.; Chen, D.; Wang, H. Stress-aperture-permeability relationships in fractured coal: Experimental and numerical study. Rock Mech. Bull. 2022, 2, 100045. [Google Scholar]

- Wang, Y.B.; Zhang, L.; Zhao, P. Coupled adsorption-stress-permeability model for gas drainage optimization. Energy 2023, 285, 129302. [Google Scholar] [CrossRef]

- Tian, K.; Wei, E. Gas seepage model and experiment based on bedding effect of fractured coal body. Math. Probl. Eng. 2022, 2022, 3863267. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Wang, Z.; Huang, W. Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading. Appl. Sci. 2024, 14, 8373. [Google Scholar] [CrossRef]

- Ding, K.; Wang, L.; Wang, W.; Li, Z.; Jiang, C.; Ren, B.; Wang, S. Experimental study on gas seepage characteristics of axially unloaded coal under different confining pressures and gas pressures. Processes 2022, 10, 1055. [Google Scholar] [CrossRef]

- Lu, S.; Li, M.; Ma, Y.; Wang, S.; Zhao, W. Permeability changes in mining-damaged coal: A review of mathematical models. J. Nat. Gas Sci. Eng. 2022, 106, 104739. [Google Scholar] [CrossRef]

- Xie, H.P.; Zhou, H.W.; Liu, J.F.; Xue, D.J. Mining-induced mechanical behavior in coal seams under different mining layouts. J. China Coal Soc. 2011, 36, 1067–1074. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).