Experimental Study on the Effects of Environmentally Friendly Composite Dust Suppressant on Soil Properties

Abstract

1. Introduction

- Focus on suppressants alone: While dust suppressants play a crucial role in controlling dust emissions and improving air quality, most studies have primarily focused on the suppressants themselves, neglecting their impact on soil.

- Insufficient research on soil wind erosion resistance in varied environments: There is a relative lack of research on the changes in soil wind erosion resistance under different environmental conditions when using environmentally friendly composite dust suppressants. This limitation restricts the assessment of the suppressants’ application effectiveness in complex environments. Since the impact of composite dust suppressants on soil strength and wind erosion resistance partially reflects their dust suppression efficacy, experimental research on these aspects is indispensable.

- The discrepancy between laboratory-determined and actual concentrations: Dust suppressants developed in the laboratory, targeting dust suppression mechanisms and effects, theoretically exhibit excellent performance. However, in practical applications, the concentration’s impact on soil strength and other aspects must also be considered. As a result, there is often a difference between the actual spraying concentration and the laboratory-determined concentration.

2. Materials and Methods

2.1. Experiment on the Effect of Composite Dust Suppressant on Soil Strength

2.2. Experiment on the Effect of Composite Dust Suppressant Concentration and Curing Time on the Bearing Capacity of Stabilized Soil

2.3. Shear Strength Test

2.4. Effect of Dust Suppressant on Soil Surface Hardness

2.5. Effect of Dust Suppressant on Soil Wind Erosion Resistance

3. Results and Discussion

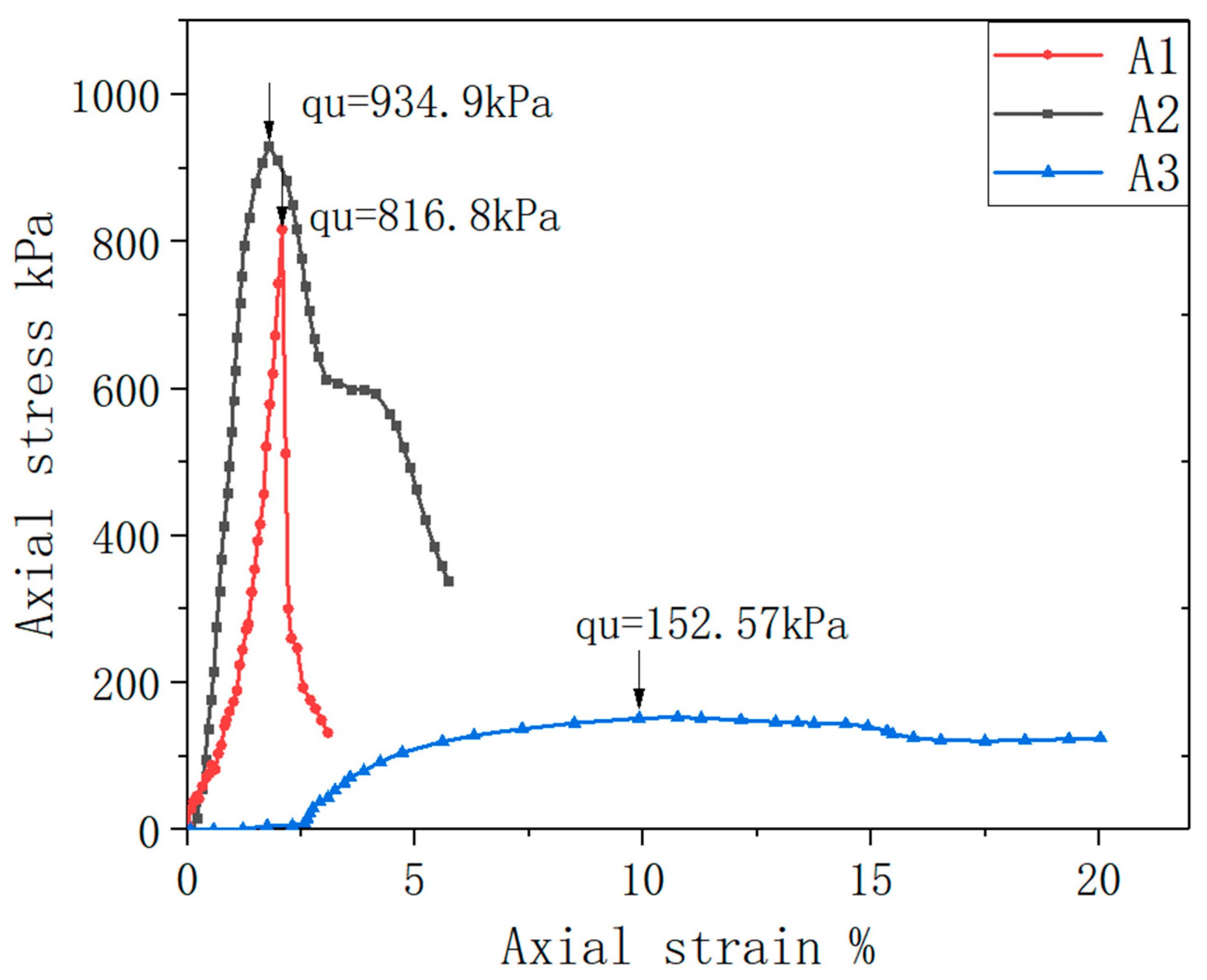

3.1. Effect of Composite Dust Suppressant Concentration on the Bearing Capacity of Solidified Soil

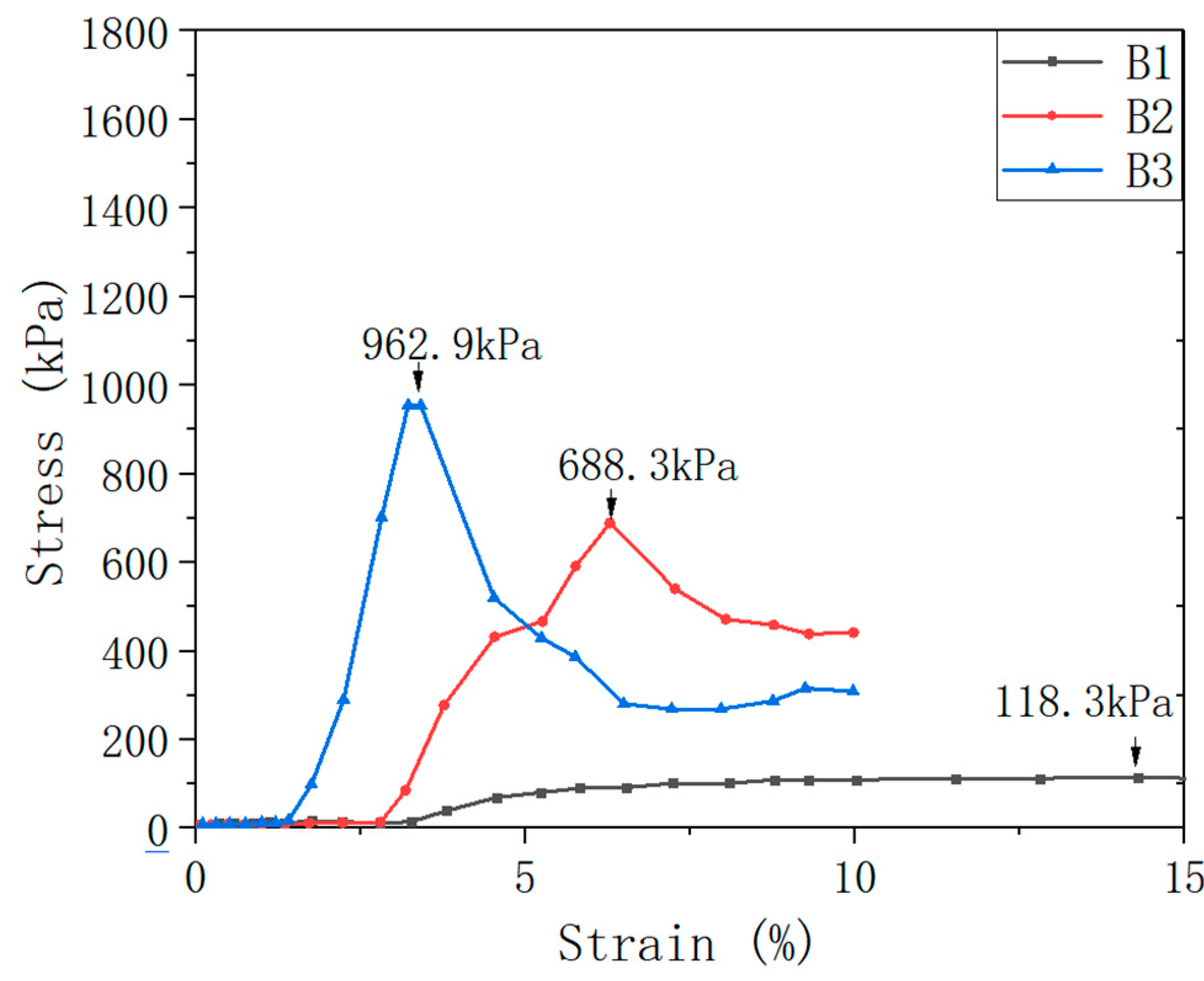

3.2. Effect of Curing Time on the Bearing Capacity of Solidified Soil

3.3. Results of Shear Resistance Tests

3.4. Experimental Investigation on the Effect of Dust Suppressant on Soil Surface Hardness

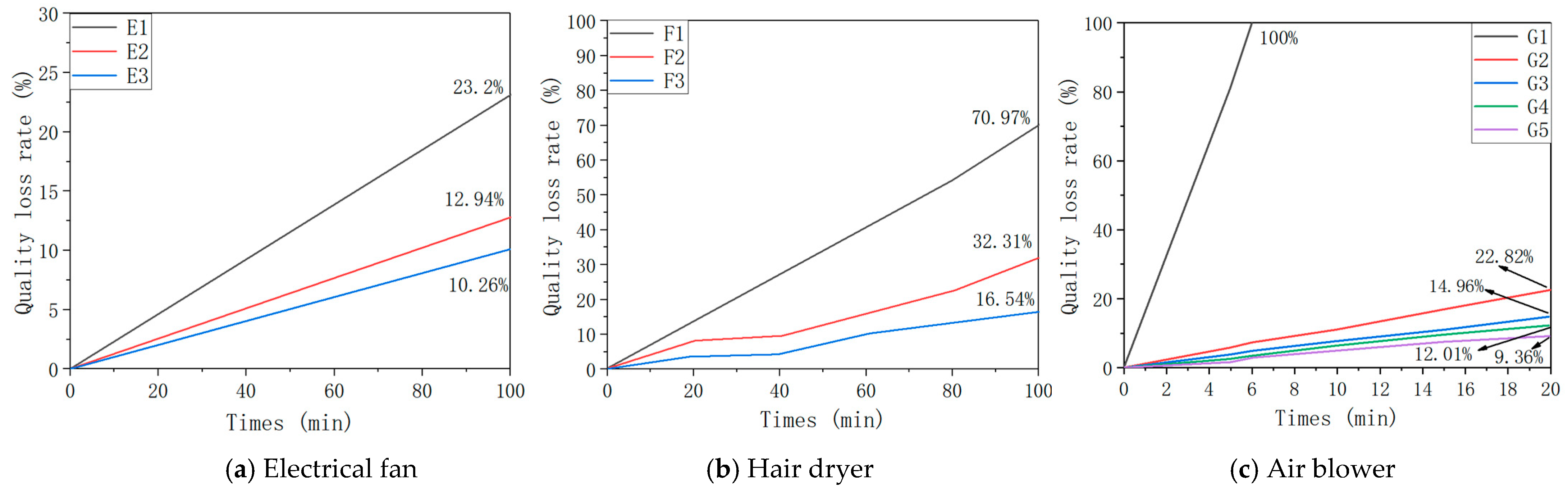

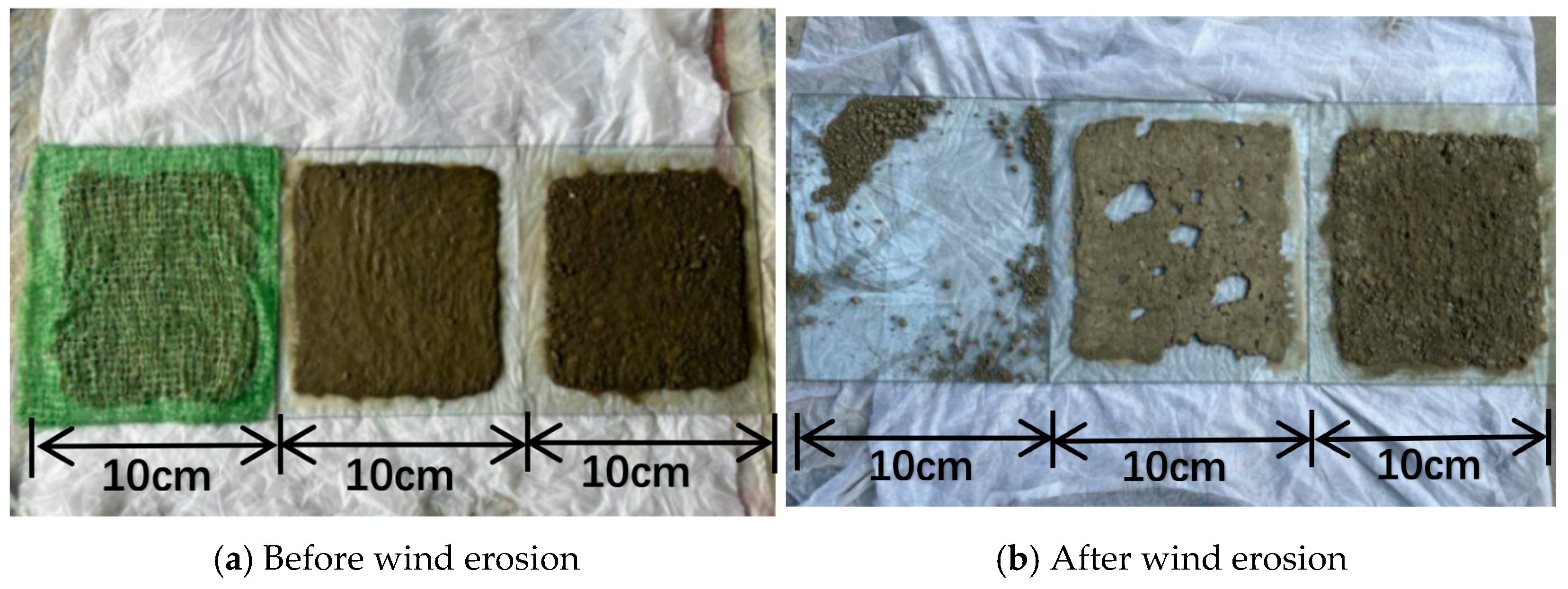

3.5. Experimental Results on the Effect of Dust Suppressant on Soil Wind Erosion Resistance

4. Conclusions

- A 10-times dilution significantly enhances compressive strength, soil stability, and smoothness while reducing friction and application costs, making it an economical and effective dust suppression solution.

- The binding effect strengthens over time, with ultimate compressive strength increasing by 570 kPa and 844.6 kPa after 14 and 28 days, respectively. At 28 days, soil strength reaches its peak as the binder–soil interaction is optimized.

- Shear strength increases with vertical load, rising from 35 kPa to 203 kPa as load increases from 100 kPa to 400 kPa. Compared to water-treated soil, suppressant-treated samples exhibit greater cohesion and internal friction, improving stability.

- The binder significantly strengthens the soil, increasing hardness from 25.0 HA (without binder) to 57.3 HA, optimizing soil structure, and reducing deformation.

- The suppressant outperforms water and dustproof nets in wind erosion tests. Under level 11 wind, suppressant-treated soil showed the lowest mass loss (9.36%) within 20 min, while the dustproof net failed entirely within 6 min.

- Future research will focus on optimizing the formulation of the composite dust suppressant to enhance its performance across different soil types. Additionally, long-term environmental impact assessments will be conducted to evaluate its biodegradability and ecological safety. Further large-scale field trials will also be carried out to validate laboratory findings and assess real-world applicability under various climatic and environmental conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Viitanen, J.; Kingston, R. Smart cities and green growth: Outsourcing democratic and environmental resilience to the global technology sector. Environ. Plan. A 2014, 46, 803–819. [Google Scholar] [CrossRef]

- Zuo, J.; Rameezdeen, R.; Hagger, M.; Zhou, Z.; Ding, Z. Dust pollution control on construction sites: Awareness and self-responsibility of managers. J. Clean. Prod. 2017, 166, 312–320. [Google Scholar] [CrossRef]

- Perini, K.; Castellari, P.; Calbi, M.; Prandi, S.; Roccotiello, E. Fine dust collection capacity of a moss greening system for the building envelope: An experimental approach. Build. Environ. 2025, 267, 112203. [Google Scholar] [CrossRef]

- Jung, S.; Yoon, S. Effects of Creating Street Greenery in Urban Pedestrian Roads on Microclimates and Particulate Matter Concentrations. Sustainability 2022, 14, 7887. [Google Scholar] [CrossRef]

- Lee, Y.; Yuan, C.; Yen, P.; Mutuku, J.; Huang, C.; Wu, C.; Huang, P. Suppression Efficiency for Dust from an Iron Ore Pile Using a Conventional Sprinkler and a Water Mist Generator. Aerosol Air Qual. Res. 2022, 22, 210320. [Google Scholar] [CrossRef]

- Kokkonen, A.; Väänänen, M.; Säämänen, A.; Pasanen, P. The evaluation of short-term water misting of room air in reducing airborne dust after renovation work. Ann. Work Expo. Health 2019, 63, 242–255. [Google Scholar] [CrossRef]

- Liao, Q.; Feng, G.; Fan, Y.; Hu, S.; Shao, H.; Huang, Y. Experimental investigations and field applications of chemical suppressants for dust control in coal mines. Adv. Mater. Sci. Eng. 2018, 2018, 6487459. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, W.; Yang, Z.; Zhang, J.; Gao, Y.; Shao, Z.; Zhang, Y.; Zhang, L.; Wen, S. Preparation and characterization of an environmentally friendly compound chemical agent for road dust suppression in a copper mine. Environ. Prog. Sustain. Energy 2021, 40, e13532. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, G.; Gao, D.; Wei, Z.; Wang, N. Preparation and performance characterization of a composite dust suppressant for preventing secondary dust in underground mine roadways. Chem. Eng. Res. Des. 2020, 156, 195–208. [Google Scholar] [CrossRef]

- Jiang, B.; Liu, Z.; Zhao, Y.; Zhang, X.; Wang, X.; Ji, B.; Zhang, Y.; Huang, J. Development of an eco-friendly dust suppressant based on modified pectin: Experimental and theoretical investigations. Energy 2024, 289, 130018. [Google Scholar] [CrossRef]

- Wu, M.; Hu, X.; Zhang, Q.; Lu, W.; Zhao, Y.; He, Z. Study on preparation and properties of environmentally-friendly dust suppressant with semi-interpenetrating network structure. J. Clean. Prod. 2020, 259, 120870. [Google Scholar]

- Zhu, Y.; Cui, Y.; Shan, Z.; Dai, R.; Shi, L.; Chen, H. Fabrication and characterization of a multi-functional and environmentally-friendly starch/organo-bentonite composite liquid dust suppressant. Powder Technol. 2021, 391, 532–543. [Google Scholar] [CrossRef]

- Niu, W.; Nie, W.; Bao, Q.; Tian, Q.; Li, R.; Zhang, X.; Yan, X.; Lian, J. Development and characterization of a high efficiency bio-based rhamnolipid compound dust suppressant for coal dust pollution control. Environ. Pollut. 2023, 330, 121792. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, Y.; Yang, Z.; Zhang, J.; Zhang, Y.; Gao, Y.; Shao, Z.; Zhang, L. Study on the physicochemical characteristics and dust suppression performance of new type chemical dust suppressant for copper mine pavement. Environ. Sci. Pollut. Res. 2021, 28, 59640–59651. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Liu, J.; Feng, Y.; Zhao, Y.; Wang, X.; Liu, W.; Zhang, M.; Liu, Y. Application of urease-producing microbial community in seawater to dust suppression in desert. Environ. Res. 2023, 219, 115121. [Google Scholar] [CrossRef]

- Kuttner, B.; Thomas, S. Interactive effects of biochar and an organic dust suppressant for revegetation and erosion control with herbaceous seed mixtures and willow cuttings. Restor. Ecol. 2017, 25, 367–375. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Singapore, 2006.

- Sieger, J.; Lottermoser, B.; Freer, J. Effectiveness of protein and polysaccharide biopolymers as dust suppressants on mine soils: Results from wind tunnel and penetrometer testing. Appl. Sci. 2023, 13, 4158. [Google Scholar] [CrossRef]

- Wang, J.; Hu, X.; Zhao, Y.; Li, X.; Zhao, P.; Guo, Y. Effects of molasses-based microbial dust suppressant on soil dust and microbial community. Powder Technol. 2024, 441, 119831. [Google Scholar] [CrossRef]

- Beighley, R.; He, Y.; Valdes, J. Characterizing potential water quality impacts from soils treated with dust suppressants. J. Environ. Qual. 2009, 38, 502–512. [Google Scholar] [CrossRef]

- Freer, J.; Bucher, P.; Braun, M.; Lottermoser, B. Food processing by-products and wastes as potential dust suppressants at mine sites: Results from unconfined compressive strength testing. J. Air Waste Manag. Assoc. 2022, 72, 1012–1026. [Google Scholar] [CrossRef]

- GB/T50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Gao, J.; Yang, Y.; Bian, X.; Zhu, G. Study on dynamic shear properties of sulfate saline soil-geotextile interface with different salt content. Soil Dyn. Earthq. Eng. 2024, 183, 108807. [Google Scholar] [CrossRef]

- Mirmehrabi, H.; Ghafoori, M.; Lashkaripour, G. Impact of some geological parameters on soil abrasiveness. Bull. Eng. Geol. Environ. 2016, 75, 1717–1725. [Google Scholar] [CrossRef]

- Qu, J.; Li, G.; Ma, B.; Liu, J.; Zhang, J.; Liu, X.; Zhang, Y. Experimental study on the wind erosion resistance of Aeolian sand solidified by microbially induced calcite precipitation (MICP). Materials 2024, 17, 1270. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhao, Z.; Zhao, Y.; Geng, Z.; Hu, X.; Cheng, W.; Dong, Y. Performance optimization and mechanism analysis of applied Enteromorpha-based composite dust suppressant. Environ. Geochem. Health 2023, 45, 4897–4913. [Google Scholar] [CrossRef]

- Morsali, M.; Shekaari, H.; Golmohammadi, B. Hydration behavior of L-proline in the presence of mono, bis, tris-(2-hydroxyethyl) ammonium acetate protic ionic liquids: Thermophysical properties. Sci. Rep. 2024, 14, 27229. [Google Scholar] [CrossRef]

- Li, X.; Huang, F.; Sun, Q.; Ling, H.; Liu, J.; An, Y.; Liu, L. Analysis of limestone mine dust curing based on microbially induced calcium carbonate precipitation and its mechanism. J. Environ. Chem. Eng. 2024, 12, 114041. [Google Scholar] [CrossRef]

- Yu, X.; Zhao, Y.; Feng, Y.; Hu, X.; Liu, J.; Wang, X.; Wu, M.; Dong, H.; Liang, Y.; Wang, W.; et al. Synthesis and performance characterization of a road coal dust suppressant with excellent consolidation, adhesion, and weather resistance. Colloids Surf. A Physicochem. Eng. Asp. 2022, 639, 128334. [Google Scholar] [CrossRef]

- Wang, G.; Cai, T.; Lu, D.; Ma, C.; Meng, F.; Du, X. Experimental study on cohesion-friction mechanical properties for concrete. Constr. Build. Mater. 2024, 449, 138421. [Google Scholar] [CrossRef]

- To, H.; Torres, S.G.; Scheuermann, A. Primary fabric fraction analysis of granular soils. Acta Geotech. 2015, 10, 375–387. [Google Scholar] [CrossRef]

- Wu, G.; Xu, C.; Yang, Y.; Liang, X. Research on Optimized Design, Synthesis Mechanism, and Performance of Composite Dust Suppressant for Laterite in a Plateau. ACS Omega 2024, 9, 38710–38721. [Google Scholar] [CrossRef]

| ID | Test Object | Dilution Ratio | Concentration (L/m2) | Curing Time (day) | Test Plan |

|---|---|---|---|---|---|

| A1 | Cylindrical soil sample treated with dust suppressant | N/A | 2 | 7 | Unconfined compressive strength test to measure compressive strength after curing |

| A2 (B1) | 10 | 0.2 | 7 | ||

| A3 | 20 | 0.1 | 7 | ||

| B2 | 10 | 0.2 | 14 | ||

| B3 | 10 | 0.2 | 28 |

| ID | Test Object | Vertical Load | Constant Strain Rate | Test Plan |

|---|---|---|---|---|

| C1 | Cylindrical soil sample treated with a composite dust suppressant | 100 kPa | 0.8 mm/min | Direct shear apparatus test to measure the shear stress at soil sample failure |

| C2 | 200 kPa | |||

| C3 | 300 kPa | |||

| C4 | 400 kPa |

| ID | Test Object | Composite Dust Suppressant | Test Plan |

|---|---|---|---|

| D1 | Soil contained in an aluminum tray sprayed with dust suppressant | without binder with binder | Measure surface hardness after drying |

| D2 |

| ID | Test Object | Dust Suppression Method | Erosion Method by Blowing |

|---|---|---|---|

| E1 | Dust net | Erosion by electric fan (simulating a Level 3 wind) | |

| E2 | 40 cm × 40 cm square soil sample | Water | |

| E3 | Composite dust suppressant | ||

| F1 | Dust net | Erosion by hair dryer (simulating a Level 5 wind) | |

| F2 | 40 cm × 40 cm square soil sample | Water | |

| F3 | Composite dust suppressant | ||

| G1 | 40 cm × 40 cm square soil sample | Dust net | Erosion by blower (simulating an Level 11 wind) |

| G2 | Water | ||

| G3 | Commercial dust suppressant 1 | ||

| G4 | Commercial dust suppressant 2 | ||

| G5 | Composite dust suppressant |

| Device | Level | Distance (m) | Wind Speed (m/s) | Wind Level | Working Height (cm) |

|---|---|---|---|---|---|

| Electrical fan | Low | 0.3 | 3.3~3.4 | Level 3 | 10 cm |

| Middle | 4.2~4.3 | ||||

| High | 5.4~5.5 | ||||

| Hair dryer | / | 0.1 | 8.4~8.5 | Level 5 | |

| Air blower | / | 0.1 | 28.0~30.0 | Level 11 |

| Aluminum Boxes | Unit | 1 | 2 | 3 | Average |

|---|---|---|---|---|---|

| D1 | HA | 25 | 27 | 23 | 25.0 |

| D2 | HA | 58 | 60 | 54 | 57.3 |

| dust suppressant [32] | HA | / | / | / | 43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Liu, M.; Ma, B.; Zhang, Y.; Liu, Z.; Liu, Z. Experimental Study on the Effects of Environmentally Friendly Composite Dust Suppressant on Soil Properties. Appl. Sci. 2025, 15, 2998. https://doi.org/10.3390/app15062998

Xu Y, Liu M, Ma B, Zhang Y, Liu Z, Liu Z. Experimental Study on the Effects of Environmentally Friendly Composite Dust Suppressant on Soil Properties. Applied Sciences. 2025; 15(6):2998. https://doi.org/10.3390/app15062998

Chicago/Turabian StyleXu, Yong, Min Liu, Ben Ma, Yingda Zhang, Zhuhong Liu, and Zihao Liu. 2025. "Experimental Study on the Effects of Environmentally Friendly Composite Dust Suppressant on Soil Properties" Applied Sciences 15, no. 6: 2998. https://doi.org/10.3390/app15062998

APA StyleXu, Y., Liu, M., Ma, B., Zhang, Y., Liu, Z., & Liu, Z. (2025). Experimental Study on the Effects of Environmentally Friendly Composite Dust Suppressant on Soil Properties. Applied Sciences, 15(6), 2998. https://doi.org/10.3390/app15062998