Evaluation of UV-Curable Solid Rocket Propellants’ Properties for Advanced 3D Printing Technologies

Abstract

1. Introduction

2. Materials and Devices

2.1. Materials

2.2. Isothermal Test Bench

- The type of viscometer;

- The used rotor;

- The rotation speed of the spindle;

- The sample temperature;

- The measurement time;

- The dimensions of the beaker and the presence or absence of a clamp;

- The production process history.

- On the left, the connections for the proper functioning of the DS18B20 thermometers are shown;

- In the central part of the circuit, the Arduino Uno board receives the input signal from the thermometers and processes an output signal consistent with PID logic;

- The low-power signal generated by the Arduino Uno is amplified and transmitted to the motor via an IRF520 MOSFET and an external power supply.

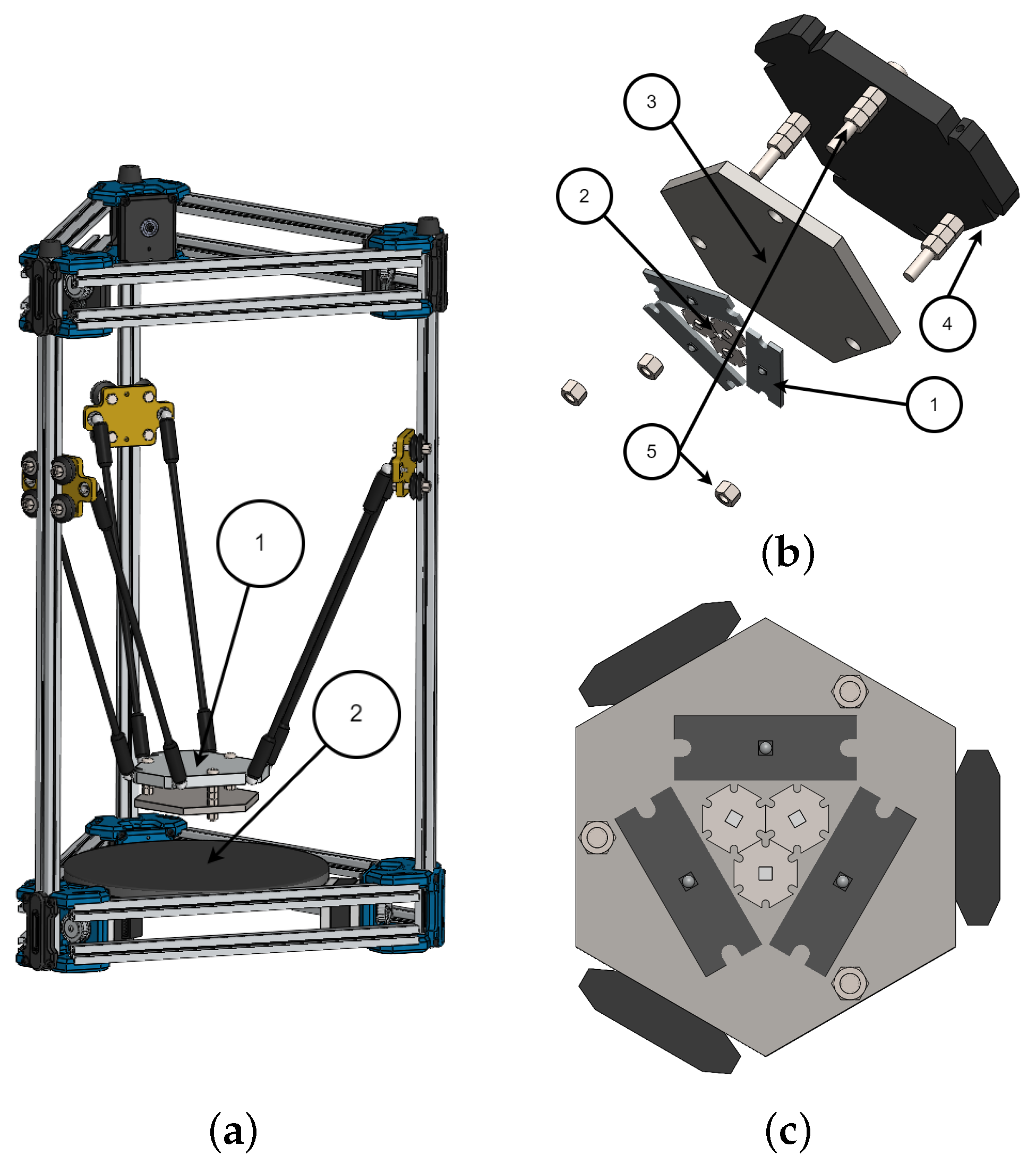

2.3. Delta UV Curing System

2.4. Cartesian 3D Printer

3. Methodology and Procedures

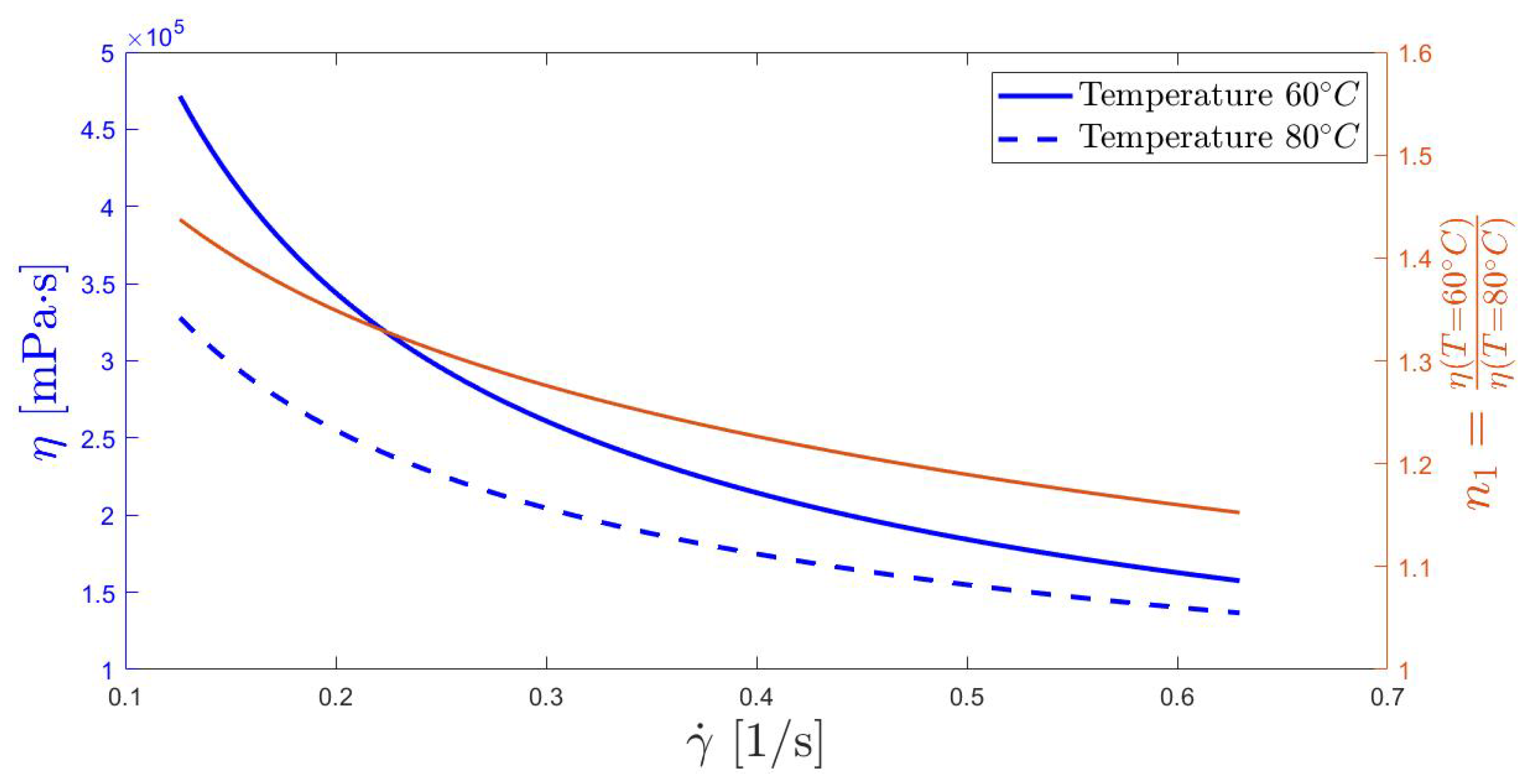

3.1. Pseudoplasticity Test

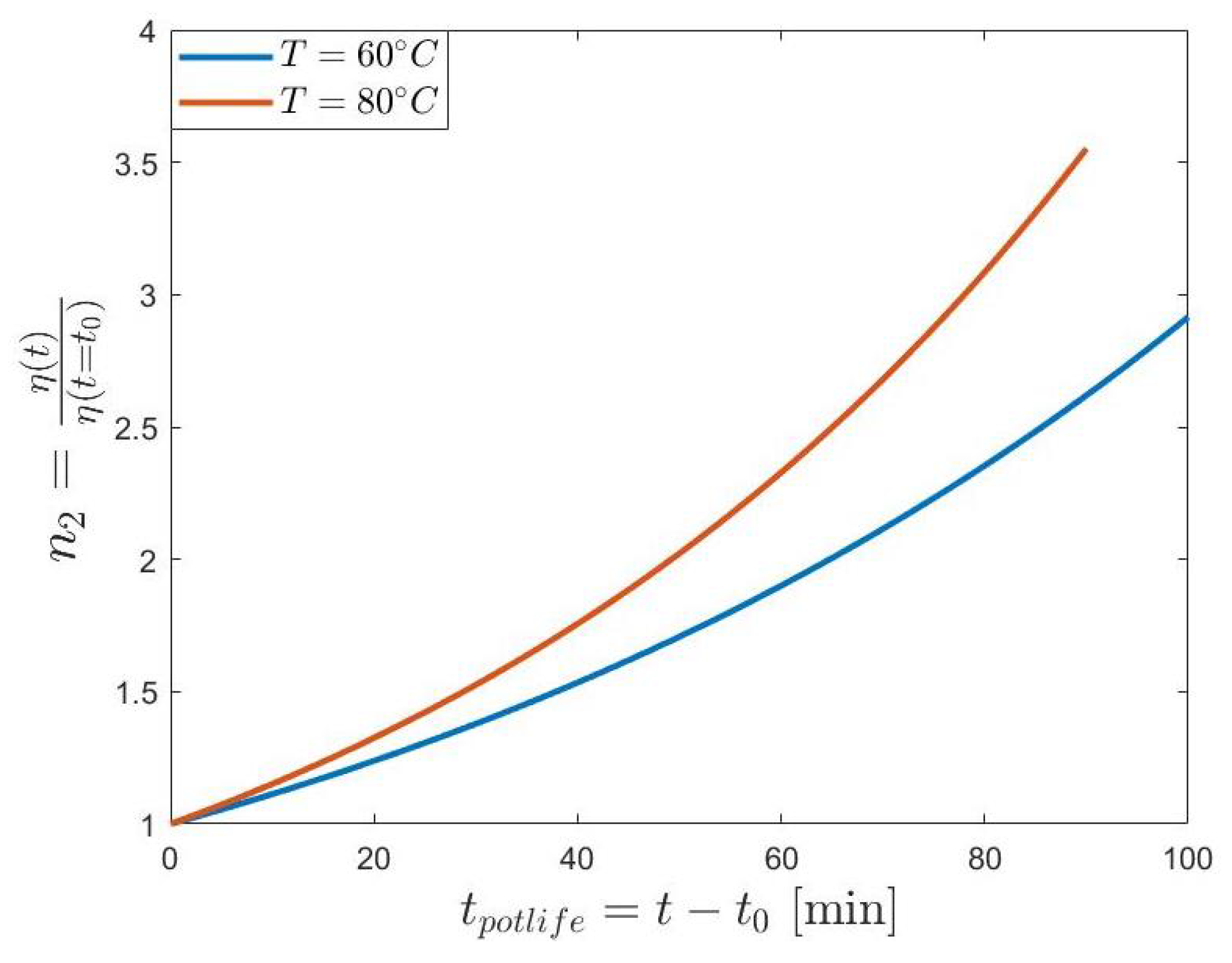

3.2. Pot-Life Test

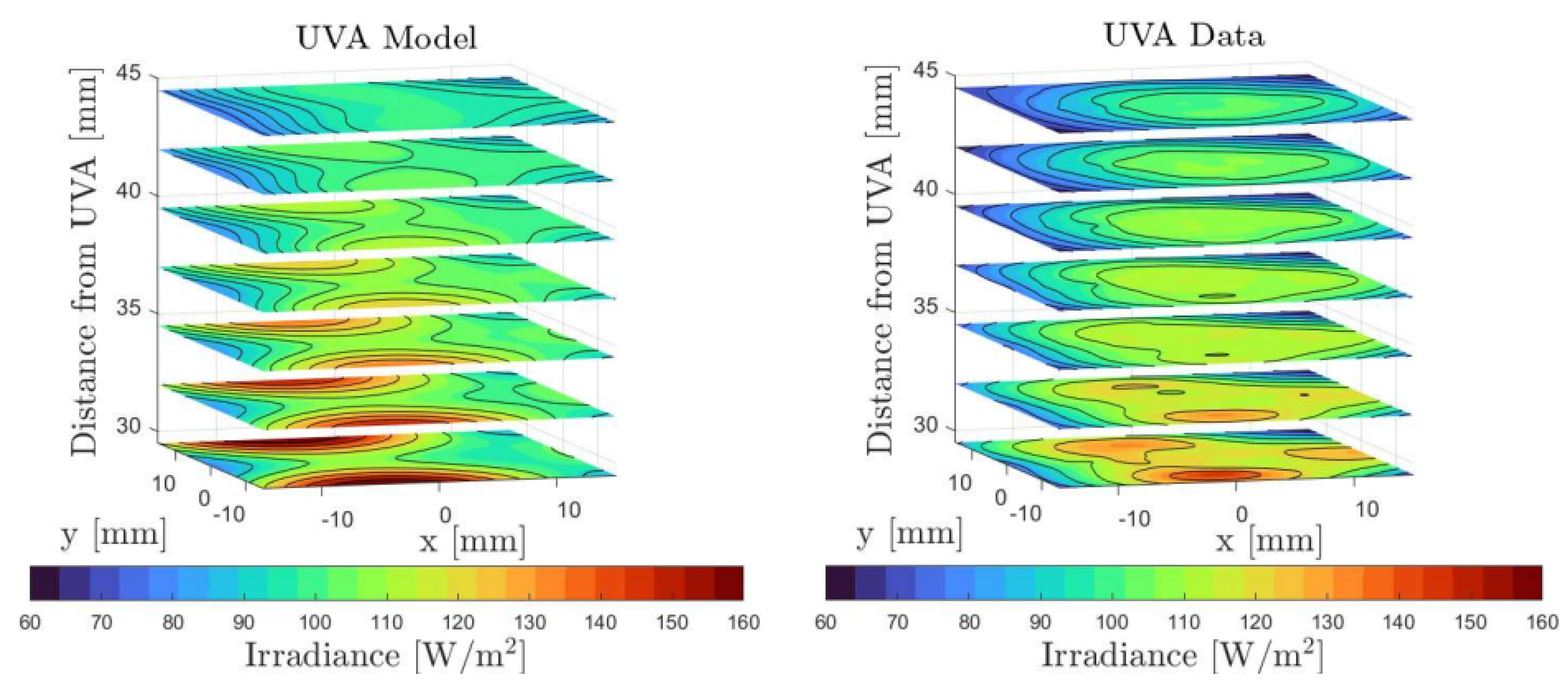

3.3. Uva and UVC Curing Test

4. Results

4.1. Pseudoplasticity Test

4.2. Pot-Life Test

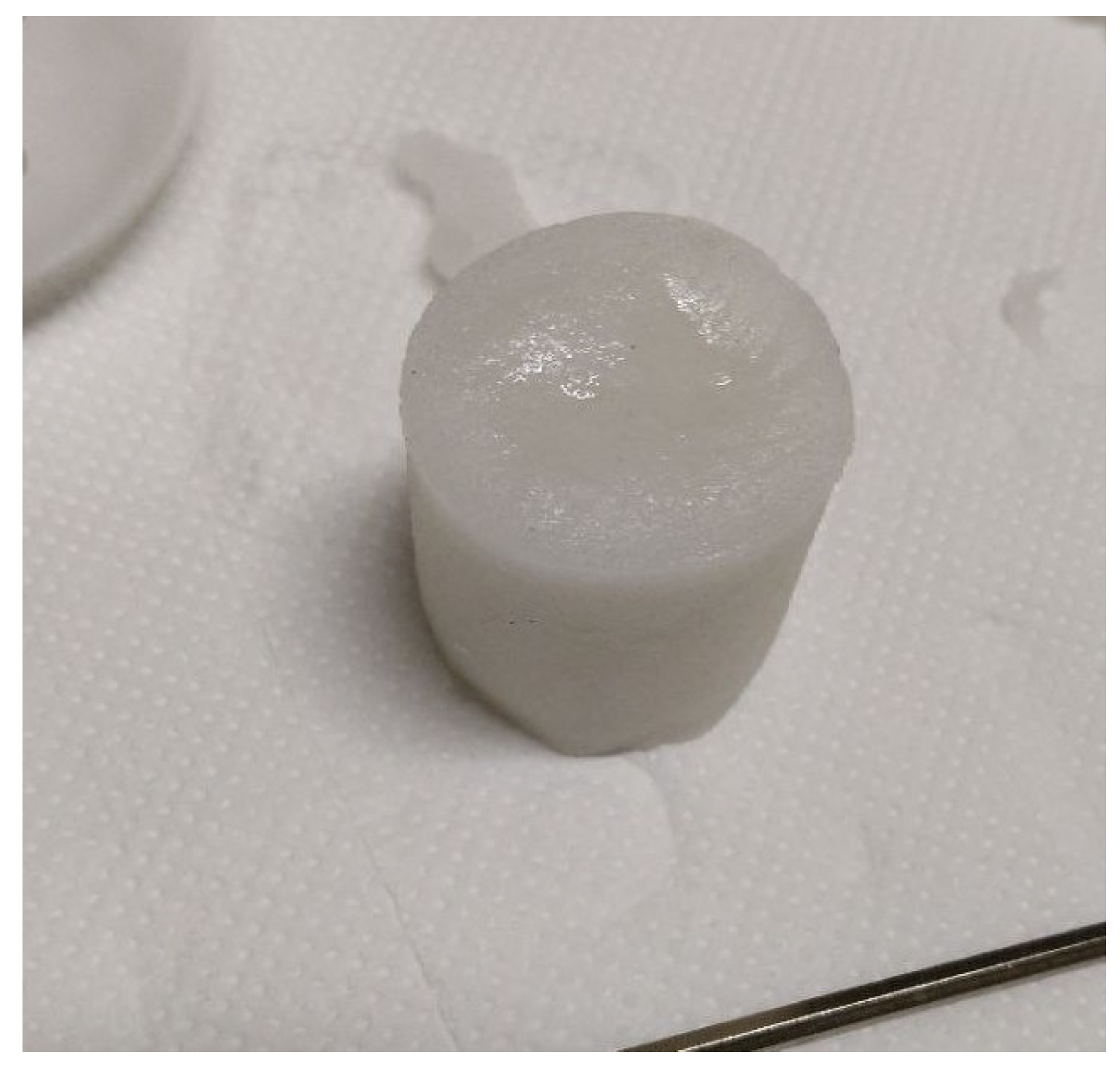

4.3. Uva and UVC Curing Tests

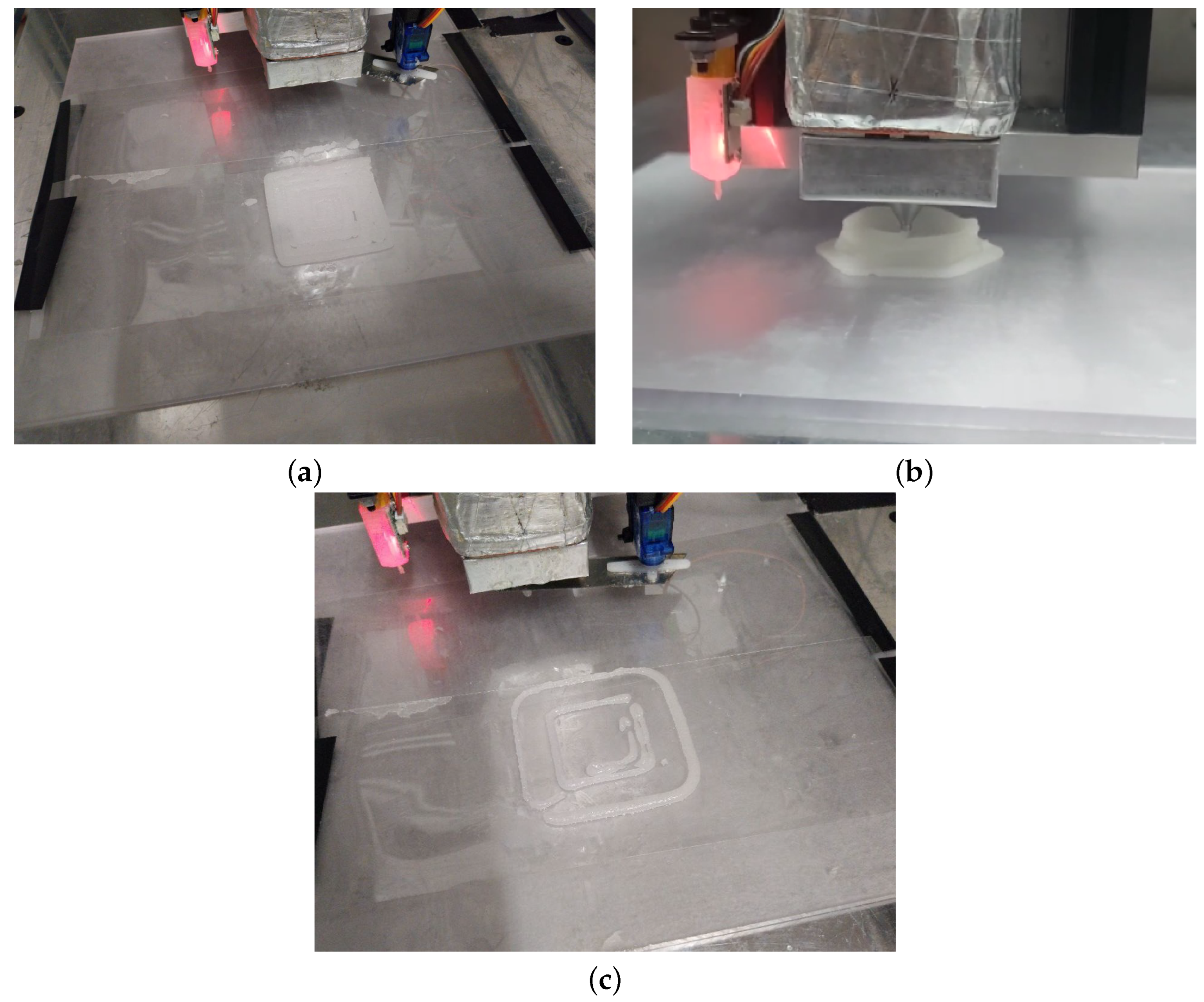

4.4. 3d Printing Test

- Viscosity: An increase in its value results in a non-linear reduction in the extrudable flow rate. The increase in temperature must be carefully evaluated to achieve a reduction in the viscosity of the slurry without drastically compromising the mechanical properties.

- Nozzle diameter: An excessive value makes it impossible to form objects with a defined shape, while an insufficient value leads to nozzle clogging. The average flow velocity in relation to the nozzle diameter shows a complex trend in the case of biphasic materials such as solid propellants.

- To estimate the volumetric flow of the propellant, a simplified model can be used, which assumes a constant fluid density during the extrusion process, a steady flow within the nozzle, and that the nozzle exit diameter is significantly smaller than the syringe diameter. According to these assumptions, the pressure difference in the nozzle is defined bywhere (p) is the pressure applied by the syringe piston, while () is the ambient pressure. If the slurry exhibits behavior describable by Equation (4), the theoretical flow rate can be obtained by [51]where (), (), (), and () represent the characteristic angle of the extruder nozzle, the inner inlet diameter of the nozzle, the outlet diameter, and the length between the two sections, respectively. Assuming a constant volumetric flow rate based on the design printing speeds, to reduce (), it is necessary to increase the geometry of the nozzle’s outlet diameter or reduce the viscosity by increasing the temperature (reducing the K factor) or vary the nozzle angle (). Consequently, three standard nozzles were used, 0.6 mm, 1.5 mm, and 3 mm, respectively, with an angle, (), of 60°, applying preheating up to 80 °C.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AP | Ammonium perchlorate |

| AS | Ammonium sulfate |

| BAPO | Bis-(2,4,6-trimethylbenzoyl) phenylphosphine oxide |

| FDM | Fused Deposition Modeling |

| HTPB | Hydroxyl-Terminated Polybutadiene |

| PB | Polybutadiene |

| PID | Proportional–Integral–Derivative controller |

| PLA | Polylactic acid |

| PPCF | Polypropylene-reinforced carbon fiber |

| PTTM | Pentaerythritol tetrakis(3-mercaptopropionate) |

| PCP | Polymer Conversion Percentage |

| RPM | Revolutions per minute |

| SD | Standard deviation |

| SF | Swelling factor |

| UV | Ultraviolet radiation |

Mathematical and Experimental Variables

| A | Area, mm2 |

| Extruder nozzle inlet diameter, m | |

| Extruder nozzle outlet diameter, m | |

| F | Applied force, N |

| K | Flow consistency index, Pa |

| Gauge length, m | |

| Outlet diameter, m | |

| ln | Natural logarithm |

| n | Flow behavior index |

| Ratio between 60 °C and 80 °C for pseudoplastic curves | |

| Adimensional viscosity in pot-life test | |

| p | Pressure, Pa |

| Ambient pressure | |

| Volumetric flow of propellant, m3/s | |

| Coefficient of determination | |

| T | Temperature, °C or K |

| Time for PID transient to reach temperature | |

| Shear stress, Pa | |

| Extruder nozzle angle, rad | |

| Shear rate, 1/s | |

| Viscosity, Pa·s | |

| Diameter, cm | |

| Rotor speed, [1/s] |

References

- Barrère, M. Rocket Propulsion; Elsevier: Amsterdam, The Netherlands, 1960. [Google Scholar]

- Miller, W.H. Solid Rocket Motor Performance Analysis and Prediction; Technical Report NASA SP-8039; National Aeronautics and Space Administration: Washington, DC, USA, 1971.

- Sutton, G.P.; Biblarz, O. Rocket Propulsion Elements; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- McClain, M.S.; Afriat, A.; Rhoads, J.F.; Gunduz, I.E.; Son, S.F. Development and characterization of a photopolymeric binder for additively manufactured composite solid propellant using vibration assisted printing. Propellants Explos. Pyrotech. 2020, 45, 853–863. [Google Scholar] [CrossRef]

- Bogue, R. 3D printing: The dawn of a new era in manufacturing? Assem. Autom. 2013, 33, 307–311. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Song, S.; Shi, J.; Ren, Q.; Miao, K.; Tang, M.; Shi, H. Comparative Study on Extrusion 3D Printing of Solid Propellant Based on Plunger and Screw. Materials 2025, 18, 777. [Google Scholar] [CrossRef]

- Muthiah, R.; Krishnamurthy, V.; Gupta, B. Rheology of HTPB propellant. I. Effect of solid loading, oxidizer particle size, and aluminum content. J. Appl. Polym. Sci. 1992, 44, 2043–2052. [Google Scholar] [CrossRef]

- Osgood, A. Rheological characterization of non-Newtonian propellants for casting optimization. In 5th Propulsion Joint Specialist; AIAA: Reston, VA, USA, 1969; p. 518. [Google Scholar]

- Mahanta, A.; Dharmsaktu, I.; Pattnayak, P. Rheological behaviour of HTPB-based composite propellant: Effect of temperature and pot life on casting rate. Def. Sci. J. 2007, 57, 435–442. [Google Scholar] [CrossRef]

- Mahanta Abhay, K.; Monika, G.; Pathak Devendra, D. Empirical modeling of chemoviscosity of hydroxy terminated polybutadiene based solid composite propellant slurry. Malays. Polym. J. 2010, 5, 1–16. [Google Scholar]

- McClain, M.; Gunduz, I.; Son, S. Additive manufacturing of ammonium perchlorate composite propellant with high solids loadings. Proc. Combust. Inst. 2019, 37, 3135–3142. [Google Scholar] [CrossRef]

- McClain, M.; Afriat, A.; Montano, B.J.; Ray, S.; Rhoads, J.; Gunduz, I.E.; Son, S.F. Investigation of Additively Manufactured Layered Composite Solid Propellant. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. AIAA Paper 2020-1427. [Google Scholar] [CrossRef]

- McClain, M. Additive Manufacturing of Viscous Materials: Development and Characterization of 3d Printed Energetic Structures. Ph.D. Thesis, Purdue University, Wlest Lafayette, IN, USA, 2020. [Google Scholar] [CrossRef]

- Plotzke, J.; Torgerson, N.R.; Seaberg, S.D.; McClain, M. Mechanical Properties of 3D-Printed Multi-Material Polymeric Composites. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar] [CrossRef]

- Tkachev, D.; Dubkova, Y.; Zhukov, A.; Verkhoshanskiy, Y.; Vorozhtsov, A.; Zhukov, I. Photocurable high-energy polymer-based materials for 3d printing. Polymers 2023, 15, 4252. [Google Scholar] [CrossRef]

- Tan, B.; Dou, J.; Wen, Y.; Duan, B.; Mo, H.; Wei, Z.; Zhang, J.; Pan, Y.; Ding, X.; Liu, N. 3D printing for explosive and propellant applications. Addit. Manuf. Front. 2024, 3, 200151. [Google Scholar] [CrossRef]

- Garino, S.; Antonaci, P.; Pastrone, D.; Sangermano, M.; Maggi, F. Photo-polymerization for additive manufacturing of composite solid propellants. Acta Astronaut. 2021, 182, 58–65. [Google Scholar] [CrossRef]

- Galavotti, A.; Noè, C.; Polizzi, G.; Antonaci, P.; Maggi, F.; Masseni, F.; Pastrone, D. Solid Rocket Propellant Photo-Polymerization with an In-House LED-UV Prototype. Polymers 2023, 15, 1633. [Google Scholar] [CrossRef] [PubMed]

- Zumbo, A.; Stumpo, L.; Antonaci, P.; Ferrero, A.; Masseni, F.; Polizzi, G.; Tetti, G.; Pastrone, D. Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry. Polymers 2024, 16, 576. [Google Scholar] [CrossRef] [PubMed]

- Masseni, F.; Zumbo, A.; Stumpo, L.; Polizzi, G.; Tetti, G.; Lusetti, T.; Noé, C.; Antonaci, P.; Ferrero, A.; Pastrone, D.; et al. Advancements in Photocurable Solid Propellants for Additive Manufacturing. In Proceedings of the AIAA SCITECH 2025 Forum, Orlando, FL, USA, 6–10 January 2025. [Google Scholar] [CrossRef]

- Bisbee, W.; Flanagan, J.; Grant, L.; Hamermesh, C.; Hilzinger, J.; Fujikawa, C.; Lawton, E.; Beck, C. Study to Find Simulants for Fuels for Use in Structures Fatigue Testing; Technical Report ASD-TRD-63-405; Air Force Flight Dynamics Laboratory, Research and Technology Division, Air Force Systems Command: Air Force Base, OH, USA, 1963. [Google Scholar]

- Sohn, H.; Moreland, C. The effect of particle size distribution on packing density. Can. J. Chem. Eng. 1968, 46, 162–167. [Google Scholar] [CrossRef]

- Esiyok, H.; Candarli, M.E. Theoretical and Experimental Packing Density Study of Hydroxyl Terminated Polybutadiene-Ammonium Perchlorate Based Propellant and Its Influence on Burning Rate. Int. J. Energetic Mater. Chem. Propuls. 2014, 13, 455–469. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook; Vincentz Network: Hannover, Germany, 2012; Volume 10. [Google Scholar] [CrossRef]

- Mischenko, S.; Mordasov, M.; Savenkov, A.; Sychev, V. Analysis of the influence of sizes of a vessel with a liquid on the readings of Brookfield viscometer. Meas. Tech. 2020, 63, 288–294. [Google Scholar] [CrossRef]

- SAMA Tools. SAVISC152-2, 2010.

- ISO 2555; Plastics—Resins in the Liquid State or as Emulsions or Dispersions—Determination of Apparent Viscosity Using a Single Cylinder Type Rotational Viscometer Method. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/70023.html (accessed on 5 March 2025).

- ASTM D1084-B; Standard Test Methods for Viscosity of Adhesives. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/d1084-16r21.html (accessed on 5 March 2025).

- ASTM D2196; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d2196-20.html (accessed on 5 March 2025).

- Aznarte, E.; Ayranci, C.; Qureshi, A. Digital light processing (DLP): Anisotropic tensile considerations. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Saed, A.; Behravesh, A.; Hasannia, S.; Ardebili, S.; Akhoundi, B.; Pourghayoumi, M. Functionalized poly l-lactic acid synthesis and optimization of process parameters for 3D printing of porous scaffolds via digital light processing (DLP) method. J. Manuf. Process. 2020, 56, 550–561. [Google Scholar] [CrossRef]

- Nielsen, L.E. Cross-linking–effect on physical properties of polymers. J. Macromol. Sci. Part 1969, 3, 69–103. [Google Scholar] [CrossRef]

- Lajoie, J.; Blocker, J.; Sippel, T. Rheological, Ballistic and Mechanical Properties of 3D Printed, Photocured Composite Propellants. J. Propuls. Power 2023, 39, 1–9. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, Y.; Zhang, Y.; Song, D.; Huang, H.; Zhong, C.; Ye, G. Hydrogen abstraction of carbon/phosphorus-containing radicals in photoassisted polymerization. RSC Adv. 2016, 6, 68952–68959. [Google Scholar] [CrossRef]

- Stiles, A.; Tison, T.A.; Pruitt, L.; Vaidya, U. Photoinitiator selection and concentration in photopolymer formulations towards large-format additive manufacturing. Polymers 2022, 14, 2708. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Sakovich, G. Design principles of advanced solid propellants. J. Propuls. Power 1995, 11, 830–837. [Google Scholar] [CrossRef]

- Wang, H.; Ji, Y.; Jiang, X.; Li, Z. Study on Rheological Properties and Pouring Process of Hydroxyl-Terminated Polybutadiene (HTPB) Propellants. Polymers 2023, 15, 4707. [Google Scholar] [CrossRef]

- Singh, H.; Shekhar, H. Solid Rocket Propellants: Science and Technology Challenges; Royal Society of Chemistry: London, UK, 2016. [Google Scholar]

- Herrada-Manchón, H.; Fernández, M.A.; Aguilar, E. Essential Guide to Hydrogel Rheology in Extrusion 3D Printing: How to Measure It and Why It Matters? Gels 2023, 9, 517. [Google Scholar] [CrossRef]

- Chen, N.; He, C.; Pang, S. Additive manufacturing of energetic materials: Tailoring energetic performance via printing. J. Mater. Sci. Technol. 2022, 127, 29–47. [Google Scholar] [CrossRef]

- Douglass, H.; Collins, J.J.; Carlton, L.; Madison, E.; Keller, R.J. Solid Propellant Processing Factors in Rocket Motor Design; Technical Report NASA SP-8075; National Aeronautics and Space Administration: Washington, DC, USA, 1973.

- Herder, G.; Weterings, F.P.; De Klerk, W. Mechanical analysis on rocket propellants. J. Therm. Anal. Calorim. 2003, 72, 921–929. [Google Scholar] [CrossRef]

- Wang, H.; Zou, J.; Yang, B.; Shi, M.; Li, Y.; Guo, C.; Hu, R.; Li, Y. Effect of Transient and Steady-State Current on the Photothermal Performance of a UVC-LED. J. Electron. Mater. 2022, 51, 119–125. [Google Scholar] [CrossRef]

- ASTM D2765-16; Standard Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics. ASTM International: West Conshohocken, PA, USA, 2016. Available online: https://www.astm.org/d2765-16.html (accessed on 5 March 2025).

- Sovetova, M.; Calautit, J.K. Design, calibration and performance evaluation of a small-scale 3D printer for accelerating research in additive manufacturing in construction. Clean. Eng. Technol. 2024, 10, 100786. [Google Scholar] [CrossRef]

- Li, W.; Ghazanfari, A.; Leu, M.C.; Landers, R.G. Extrusion-on-demand methods for high solids loading ceramic paste in freeform extrusion fabrication. Virtual Phys. Prototyp. 2017, 12, 193–205. [Google Scholar] [CrossRef]

- Udofia, E.N.; Zhou, W. Microextrusion based 3d printing—A review. In Proceedings of the 2018 International Solid Freeform Fabrication Symposium. University of Texas at Austin, Austin, TX, USA, 13–15 August 2018. [Google Scholar] [CrossRef]

- Zong, H.; Cong, Q.; Zhang, T.; Hao, Y.; Xiao, L.; Hao, G.; Zhang, G.; Guo, H.; Hu, Y.; Jiang, W. Simulation of printer nozzle for 3d printing tnt/hmx based melt-cast explosive. Int. J. Adv. Manuf. Technol. 2022, 119, 3105–3117. [Google Scholar] [CrossRef]

- Li, M.; Tian, X.; Schreyer, D.J.; Chen, X. Effect of Needle Geometry on Flow Rate and Cell Damage in the Dispensing-Based Biofabrication Process. Biotechnol. Prog. 2011, 27, 1777–1784. [Google Scholar] [CrossRef]

| Temperature [°C] | [RPM] | [1/s] | Viscosity [mPa·s] | Viscosity SD [%] |

|---|---|---|---|---|

| 60 | 0.6 | 0.13 | 477,285 ± 60,199 | 12.61 |

| 1.5 | 0.32 | 227,541 ± 59,829 | 26.29 | |

| 3 | 0.63 | 180,400 ± 22,494 | 12.49 | |

| 80 | 0.6 | 0.13 | 327,667 ± 39,589 | 12.08 |

| 1.5 | 0.32 | 200,564 ± 11,472 | 5.71 | |

| 3 | 0.63 | 135,613 ± 7885 | 5.81 |

| Temperature [°C] | UVA Time [s] | UVC Time [s] | Expected Layer Size [mm] | Mean Layer Size [mm] | PCP [%] |

|---|---|---|---|---|---|

| 25 | 90 | 0 | 1.00 | 1.09 ± 0.06 | 75.1 ± 5.5 |

| 180 | 0 | 91.2 ± 1.4 | |||

| 270 | 0 | 92.1 ± 3.3 | |||

| 25 | 135 | 135 | 1.00 | 1.09 ± 0.08 | 88.3 ± 1.9 |

| 90 | 180 | 81.4 ± 1.9 | |||

| 25 | 180 | 180 | 1.00 | 1.09 ± 0.08 | 90.5 ± 1.2 |

| 270 | 180 | 94.7 ± 1.9 | |||

| 25 | 270 | 0 | 2.00 | 2.02 ± 0.05 | 91.6 ± 0.4 |

| 180 | 90 | 89.2 ± 1.6 | |||

| 25 | 270 | 0 | 3.00 | 2.92 ± 0.11 | 89.7 ± 0.8 |

| 180 | 90 | 80.7 ± 3.4 | |||

| 90 | 90 | 0 | 1.00 | 1.05 ± 0.05 | - |

| 180 | 0 | 80.8 ± 3.2 | |||

| 270 | 0 | 89.3 ± 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masseni, F.; Tetti, G.; Zumbo, A.; Noé, C.; Polizzi, G.; Stumpo, L.; Ferrero, A.; Pastrone, D. Evaluation of UV-Curable Solid Rocket Propellants’ Properties for Advanced 3D Printing Technologies. Appl. Sci. 2025, 15, 2933. https://doi.org/10.3390/app15062933

Masseni F, Tetti G, Zumbo A, Noé C, Polizzi G, Stumpo L, Ferrero A, Pastrone D. Evaluation of UV-Curable Solid Rocket Propellants’ Properties for Advanced 3D Printing Technologies. Applied Sciences. 2025; 15(6):2933. https://doi.org/10.3390/app15062933

Chicago/Turabian StyleMasseni, Filippo, Giacomo Tetti, Alessandra Zumbo, Camilla Noé, Giovanni Polizzi, Leonardo Stumpo, Andrea Ferrero, and Dario Pastrone. 2025. "Evaluation of UV-Curable Solid Rocket Propellants’ Properties for Advanced 3D Printing Technologies" Applied Sciences 15, no. 6: 2933. https://doi.org/10.3390/app15062933

APA StyleMasseni, F., Tetti, G., Zumbo, A., Noé, C., Polizzi, G., Stumpo, L., Ferrero, A., & Pastrone, D. (2025). Evaluation of UV-Curable Solid Rocket Propellants’ Properties for Advanced 3D Printing Technologies. Applied Sciences, 15(6), 2933. https://doi.org/10.3390/app15062933