Study on the Long-Term Influence of Proppant Optimization on the Production of Deep Shale Gas Fractured Horizontal Well

Abstract

1. Introduction

2. Methodology

2.1. Governing Equations of the Solid–Fluid–Heat Coupling Process

2.2. The Influence of Shale Creep and Proppant Embedment on Fracture Closure

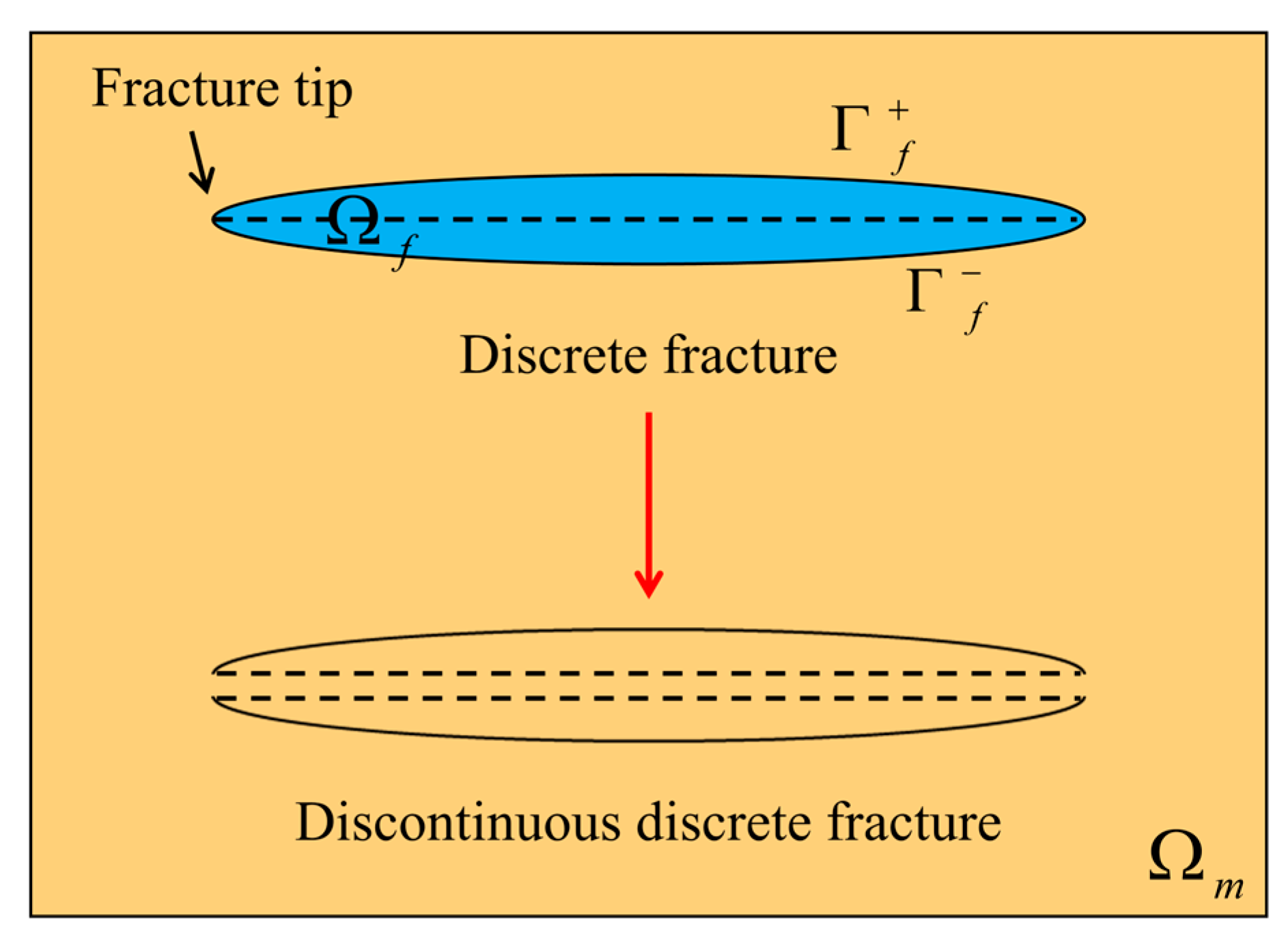

3. Discontinuous Discrete Element Method

3.1. Numerical Description of Fracture–Matrix Coupled Flow

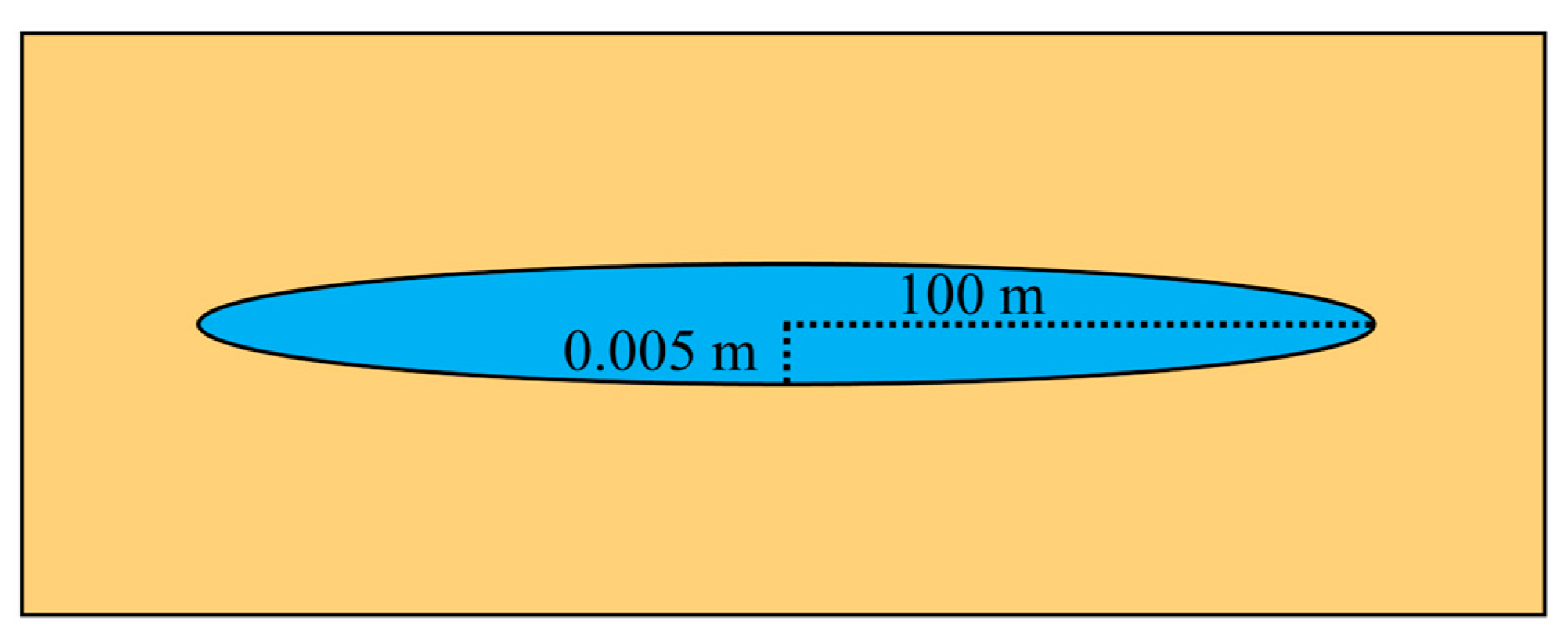

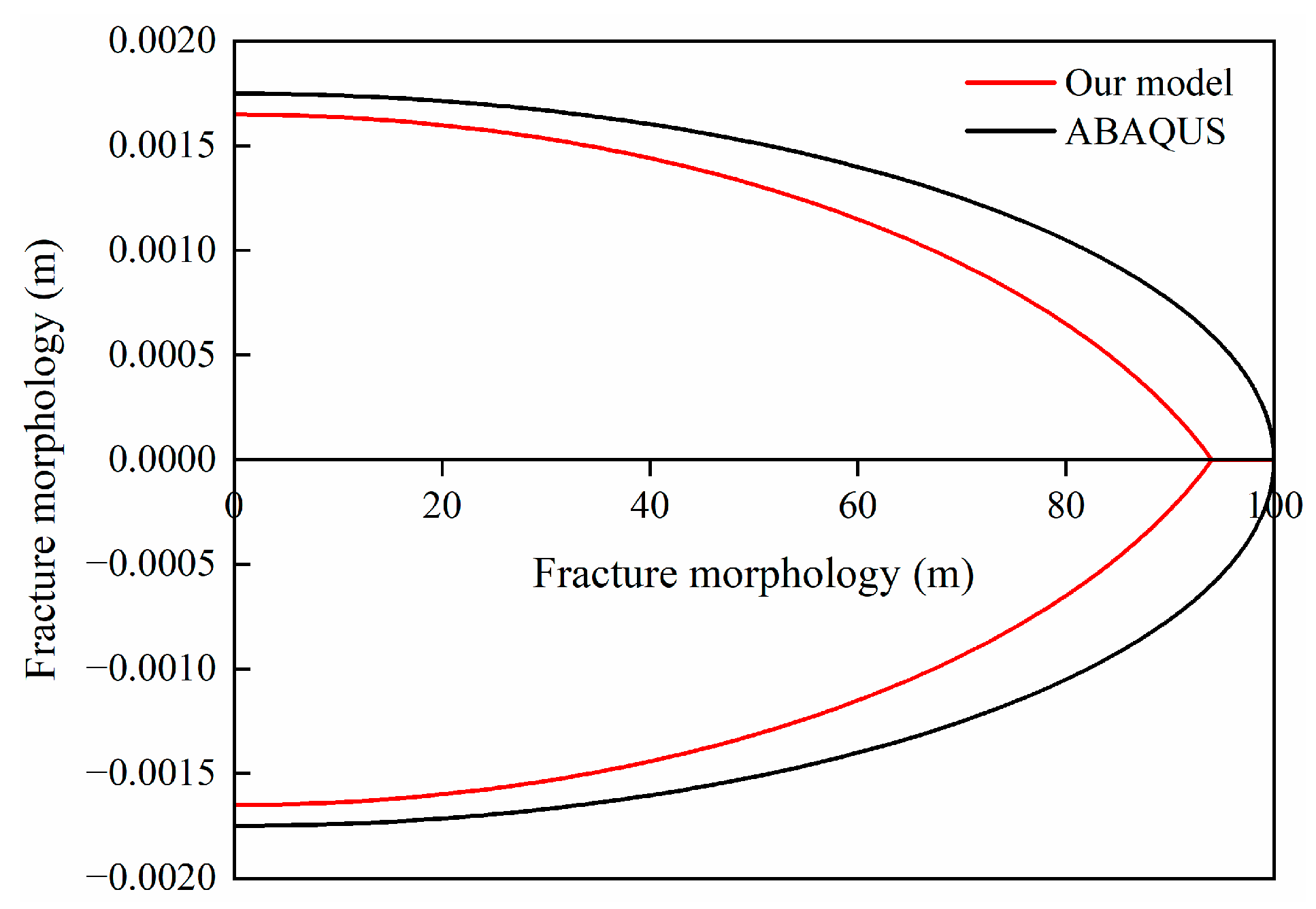

3.2. Model Validation

4. Results

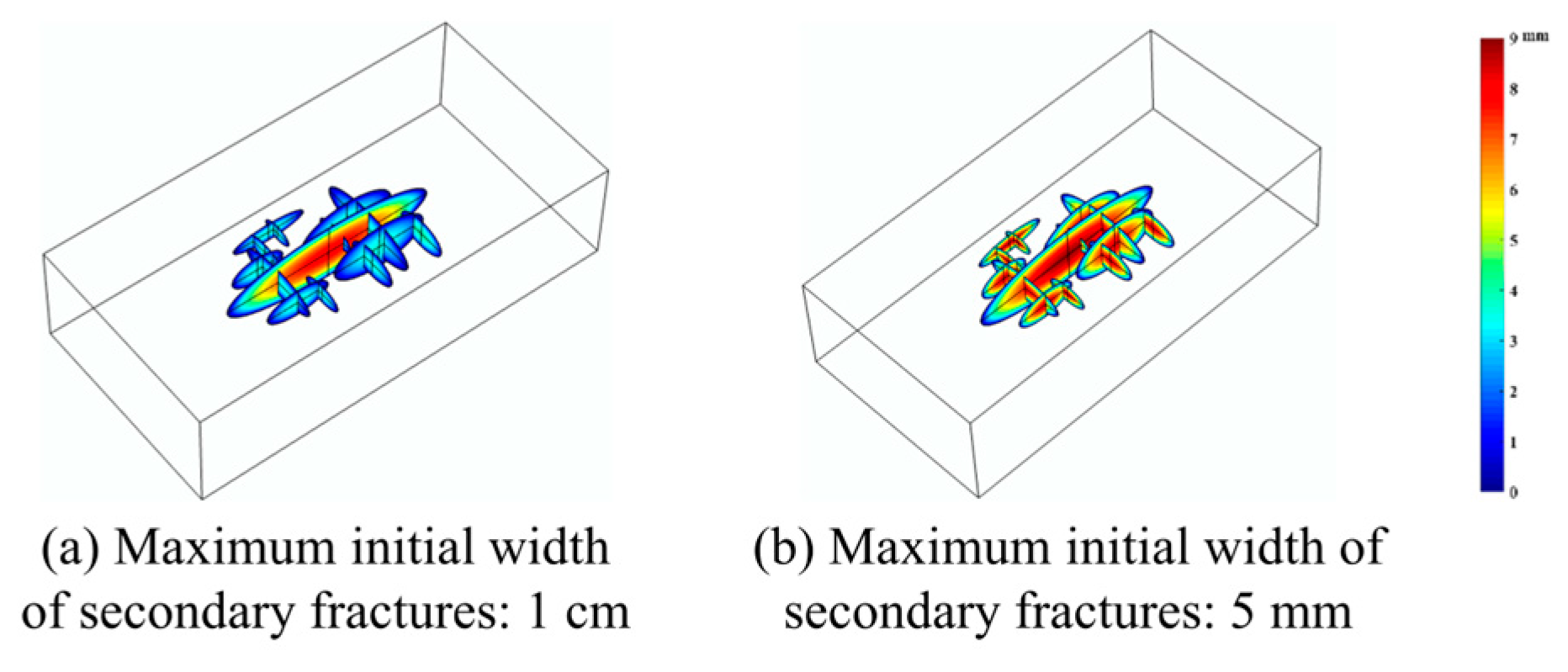

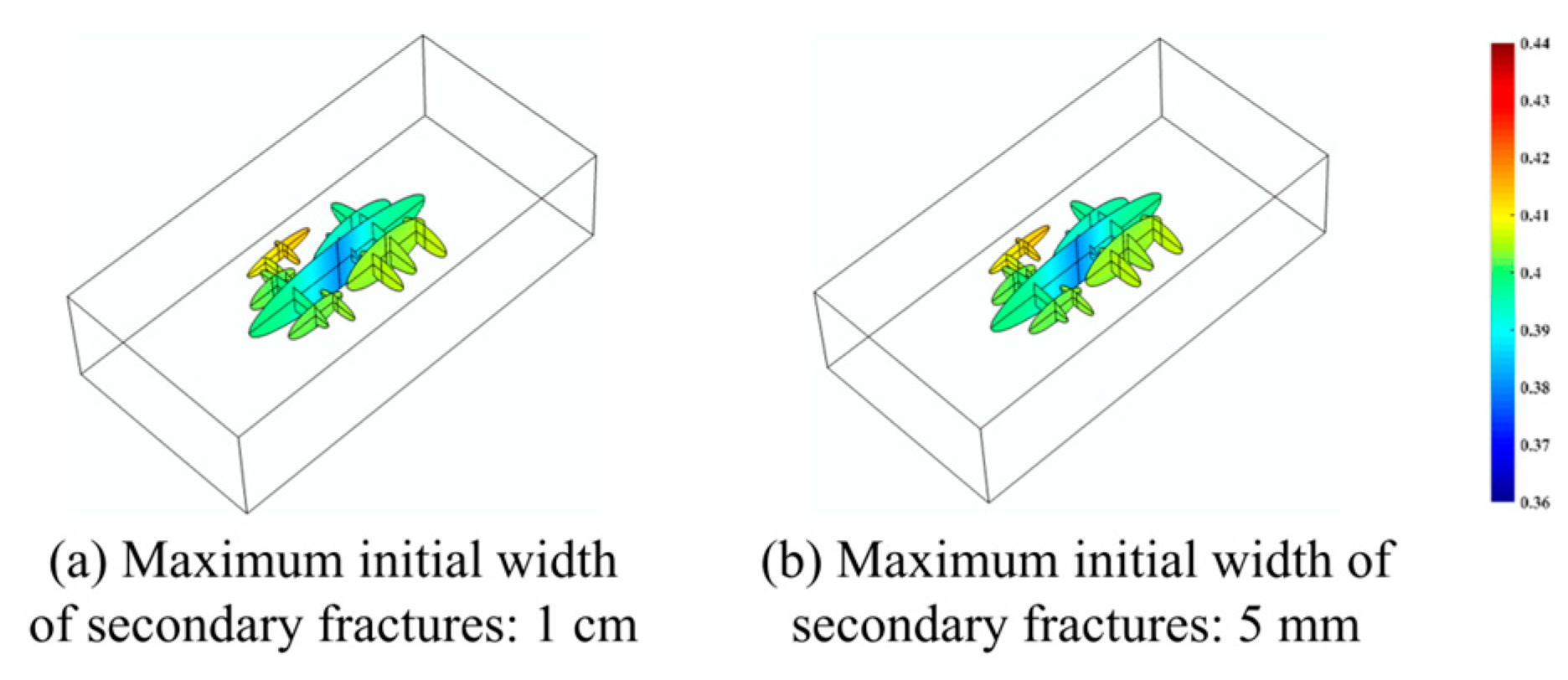

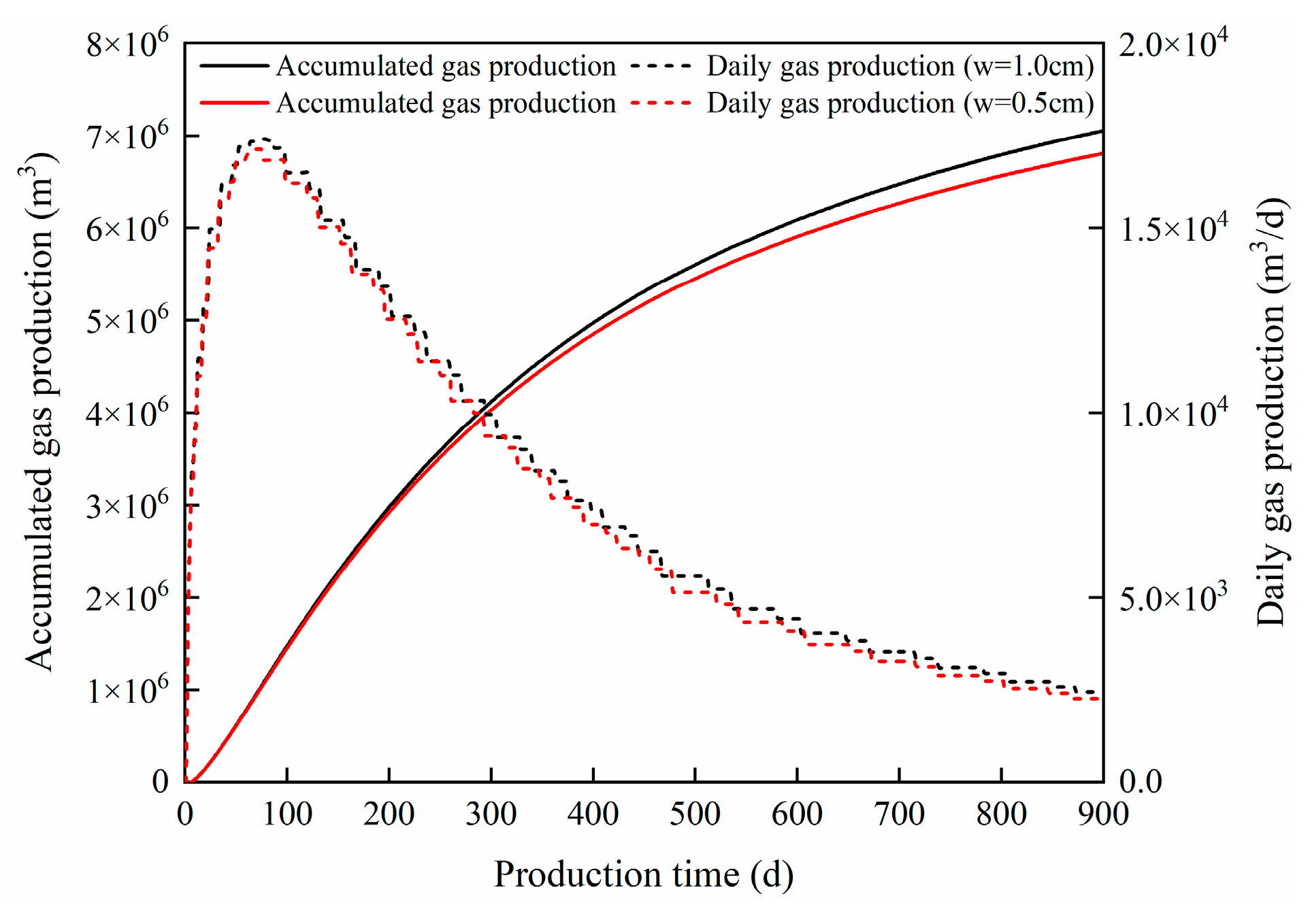

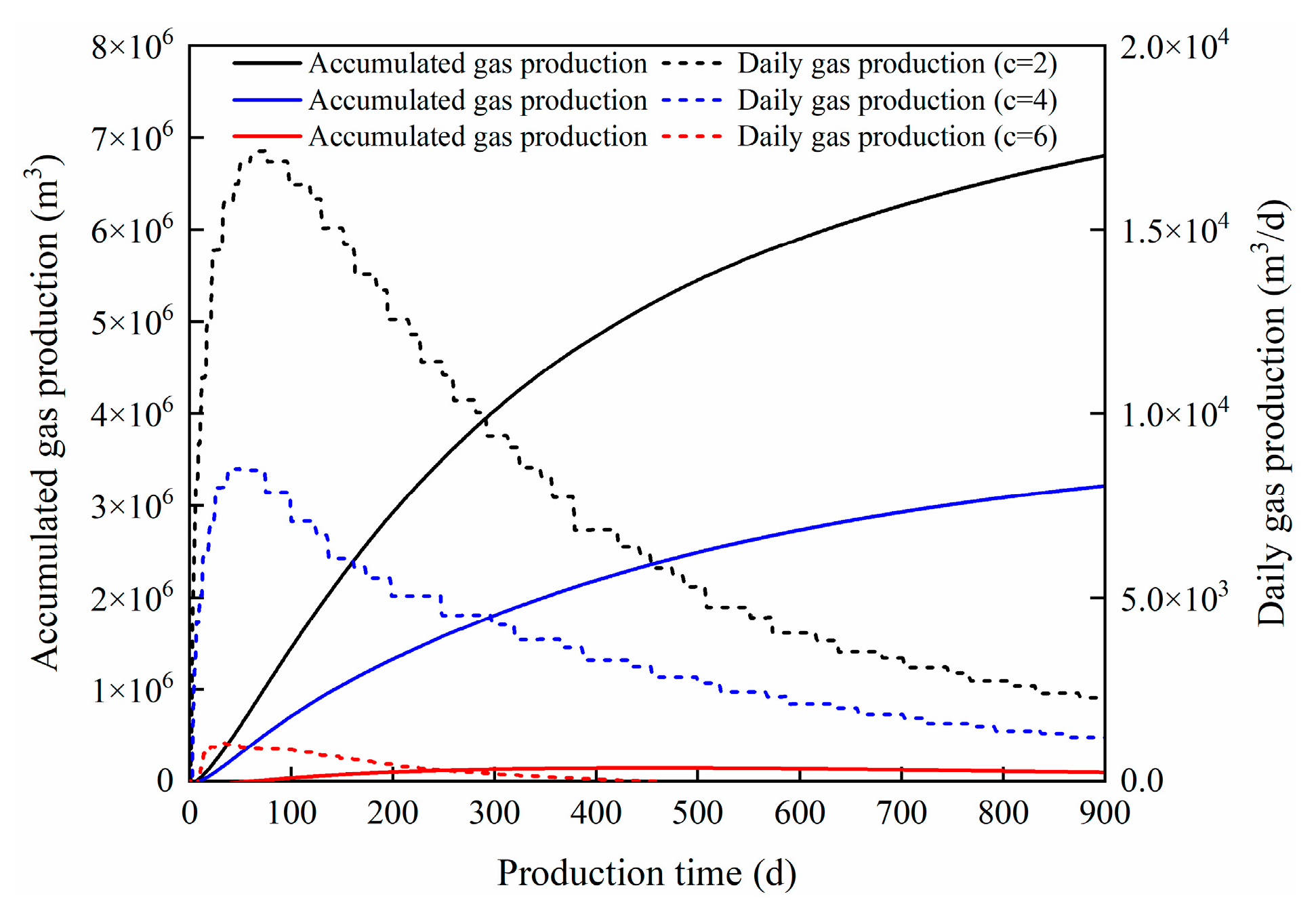

4.1. The Effect of the Proppant Concentration

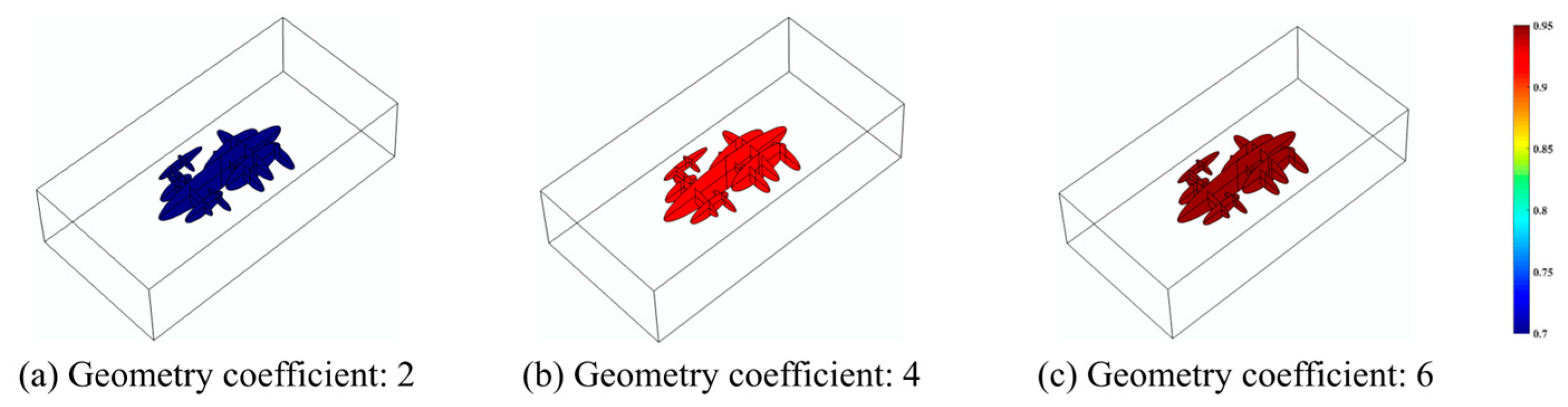

4.2. The Effect of Proppant Placement

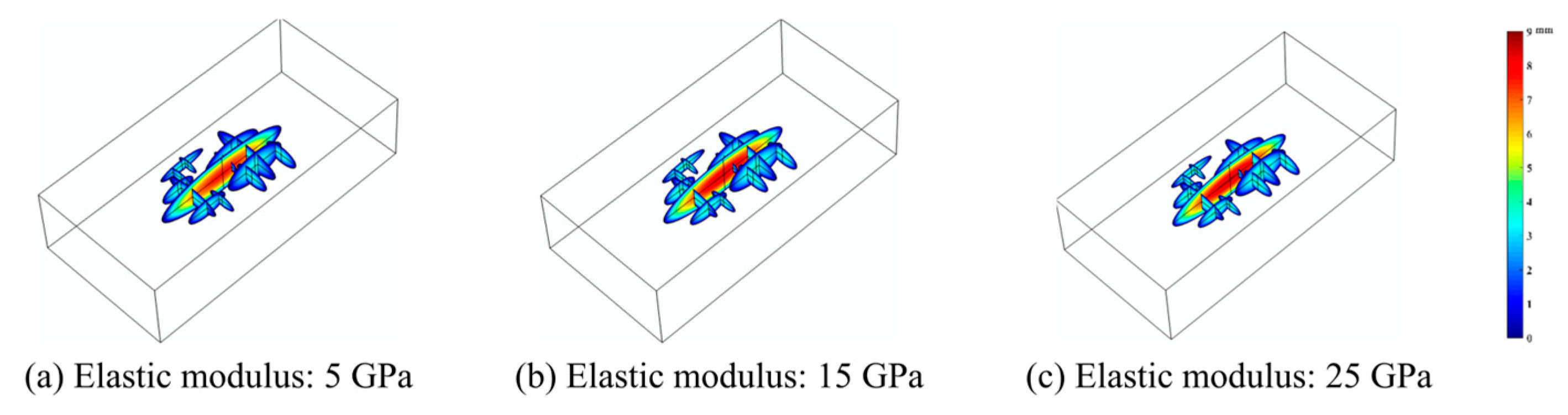

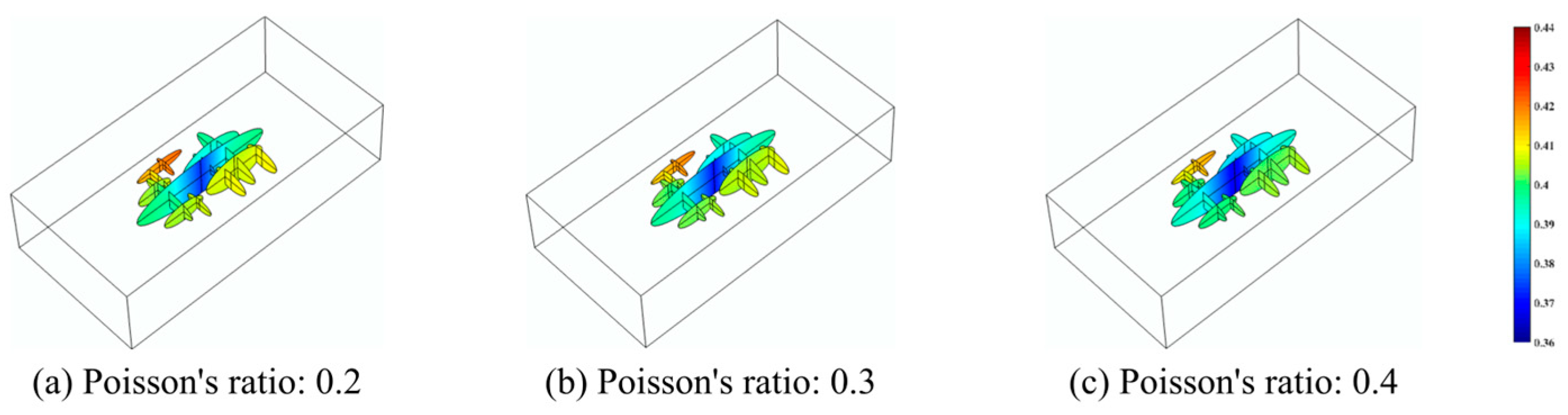

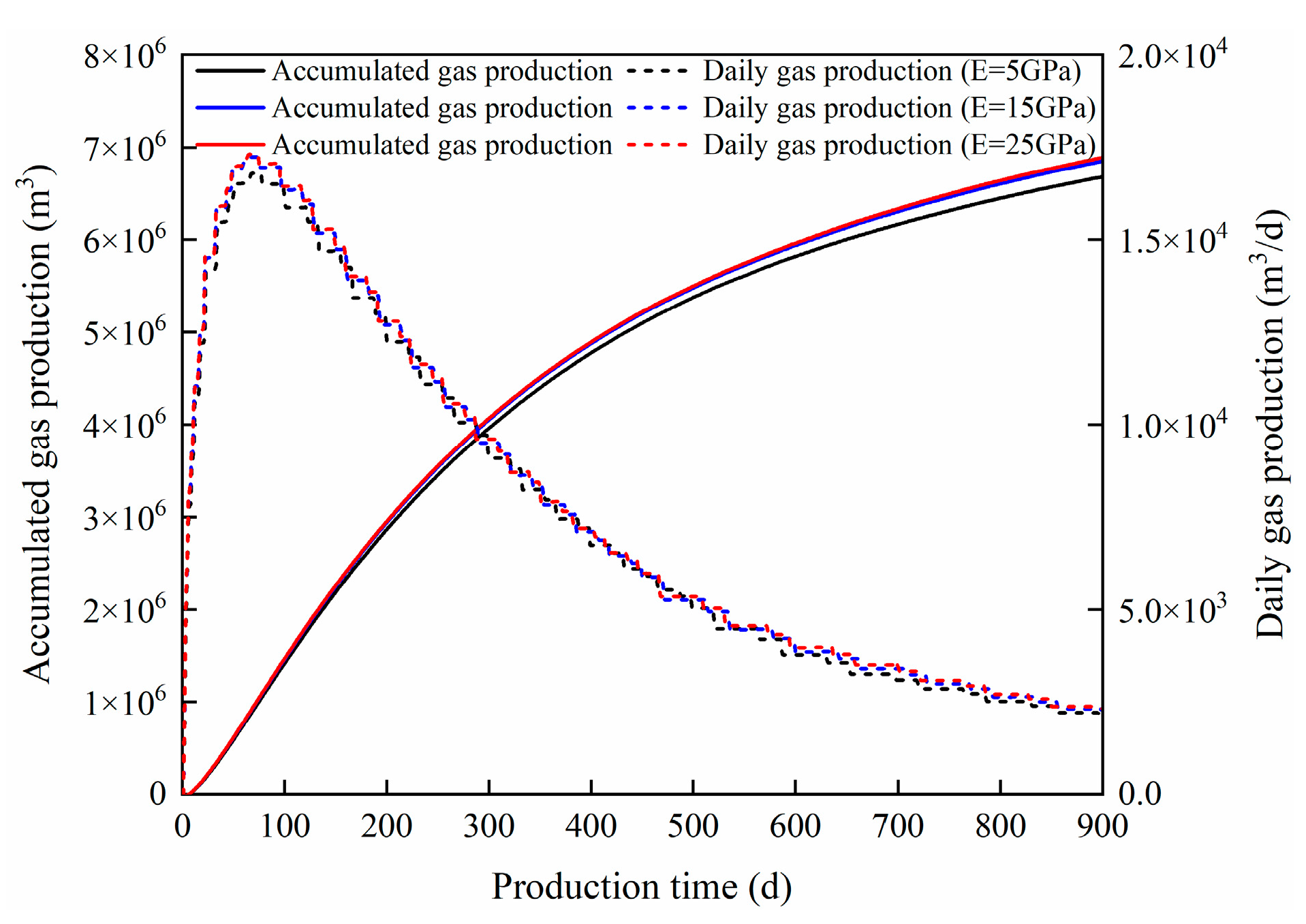

4.3. The Effect of Proppant Mechanical Properties

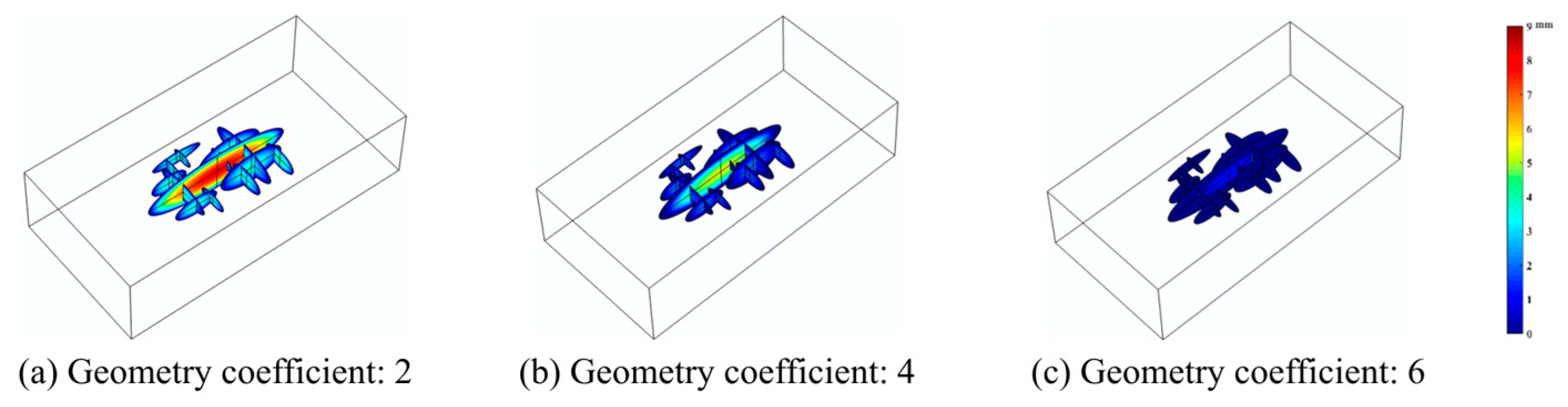

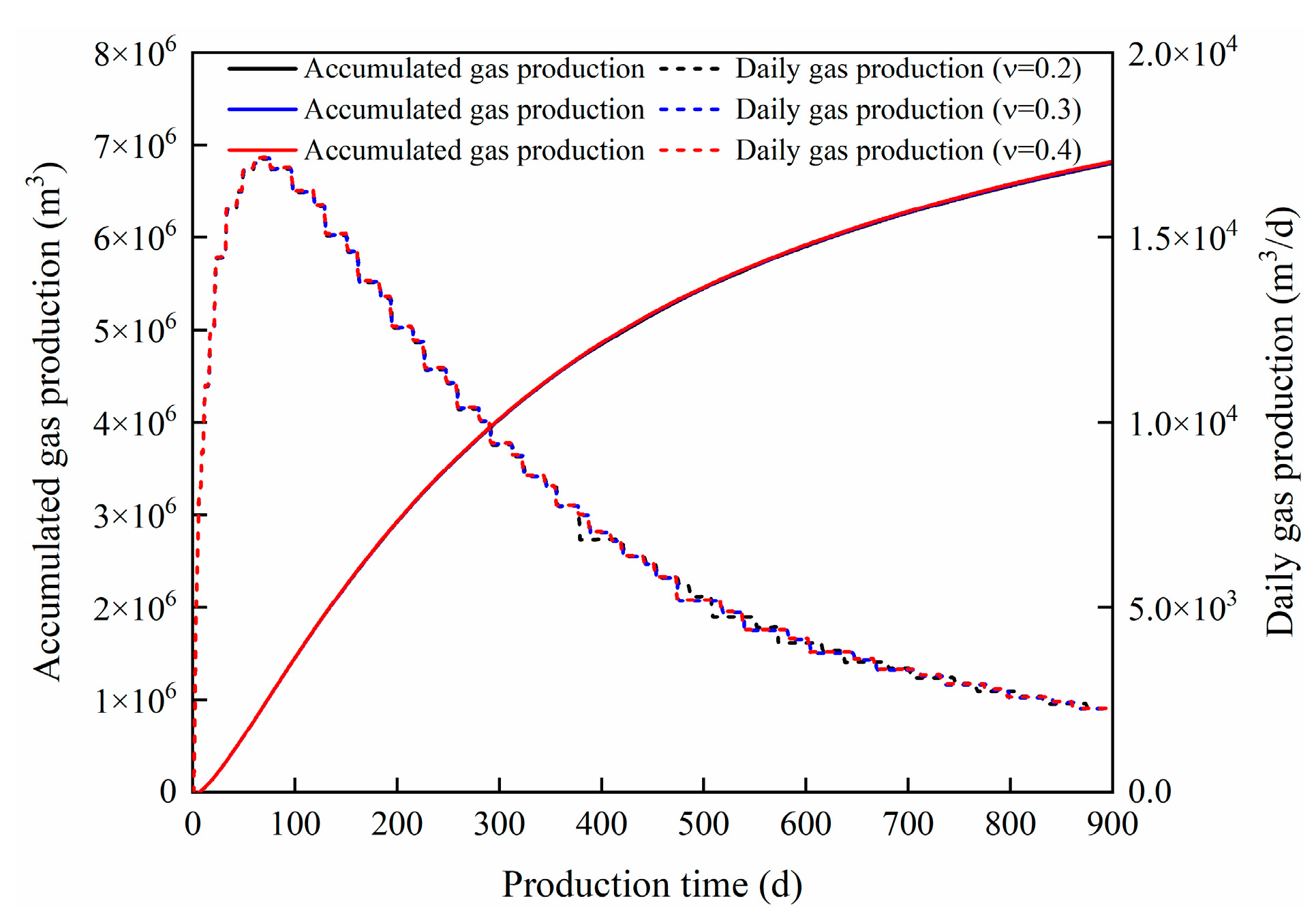

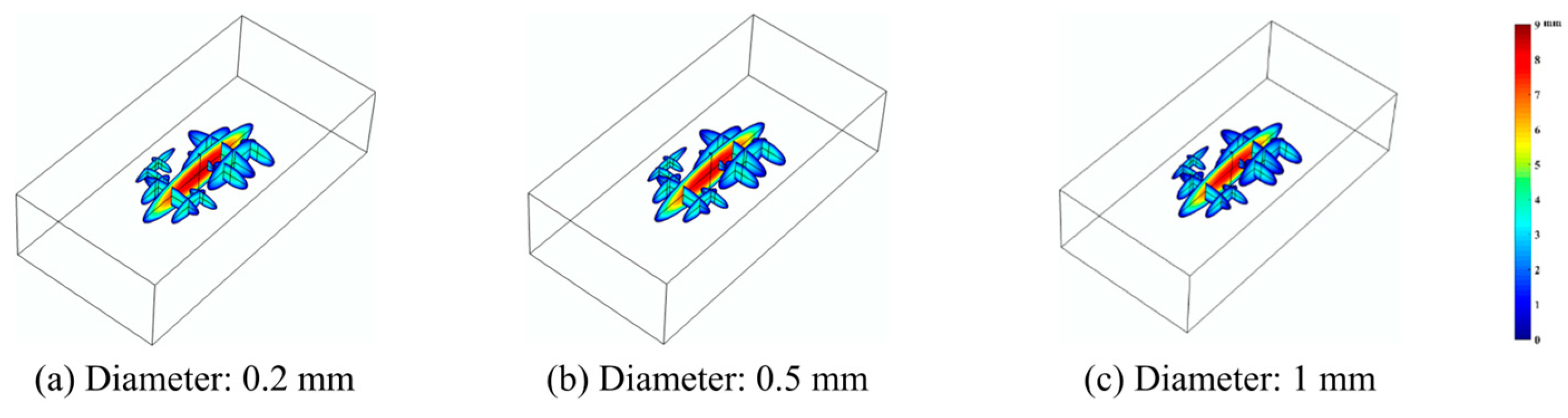

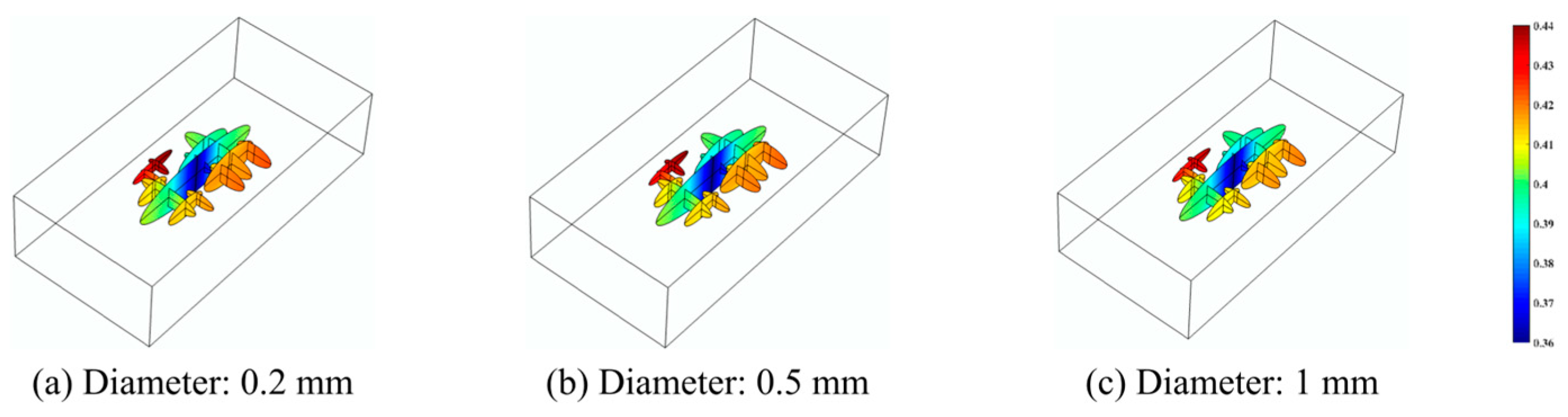

4.4. The Effect of the Proppant Diameter

5. Conclusions

- (1)

- The fracture closure width calculated by the real fracture model is smaller than that of the discontinuous discrete fracture model. However, the applicability of the model to ultra-deep shale gas reservoirs needs further verification, and the impact of extreme geological conditions (such as high-stress anisotropy) is not considered.

- (2)

- The higher the proppant concentration, the wider the fractures formed, but it did not have a significant impact on shale gas production. When the initial fracture width increased from 5 mm to 1 cm, the cumulative gas production over 900 days increased by only 3.65%.

- (3)

- Poor proppant placement means that the proppant is unevenly placed in the fracture. At this time, the proppant cannot effectively support the fracture surface, resulting in a decrease in conductivity and effective drainage area and a significant decrease in shale gas production.

- (4)

- When the elastic modulus of the proppant increases, the fracture width and cumulative gas production increase accordingly, but the proppant with a larger elastic modulus increases the embedding amount, resulting in a poor fracture transformation effect. Although the increase in the Poisson’s ratio of the proppant increases the leakage area, it reduces the crossflow capacity, so the Poisson’s ratio of the proppant has little effect on shale gas production.

- (5)

- Small-sized proppants have a lower proppant laying concentration, which brings lower construction costs. Small-sized proppants are easier to pump to the far end of the fracture network, and the actual construction effect will be better than large-sized proppants. Therefore, small-sized proppants are more suitable for deep shale gas hydraulic fracturing construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, C.; Nie, H.; Dang, W.; Chen, Q.; Zhang, G.; Li, W.; Lu, Z. Shale gas exploration and development in China: Current status, geological challenges, and future directions. Energy Fuels 2021, 35, 6359–6379. [Google Scholar] [CrossRef]

- Zhao, W.; Jia, A.; Wei, Y.; Wang, J.; Zhu, H. Progress in shale gas exploration in China and prospects for future development. China Pet. Explor. 2020, 25, 31. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.; Zhou, S.; Shi, Z.; Zhang, L. Deep shale gas in China: Geological characteristics and development strategies. Energy Rep. 2021, 7, 1903–1914. [Google Scholar] [CrossRef]

- Jiang, T.; Bian, X.; Wang, H.; Li, S.; Jia, C.; Liu, H.; Sun, H. Volume fracturing of deep shale gas horizontal wells. Nat. Gas Ind. B 2017, 4, 127–133. [Google Scholar] [CrossRef]

- Zhao, J.; Ren, L.; Jiang, T.; Hu, D.; Wu, L.; Wu, J.; Yin, C.; Li, Y.; Hu, Y.; Lin, R.; et al. Ten years of gas shale fracturing in China: Review and prospect. Nat. Gas Ind. B 2022, 9, 158–175. [Google Scholar] [CrossRef]

- Wang, H.; Chen, L.; Qu, Z.; Yin, Y.; Kang, Q.; Yu, B.; Tao, W. Modeling of multi-scale transport phenomena in shale gas production-A critical review. Appl. Energy 2020, 262, 114575. [Google Scholar] [CrossRef]

- Zhang, L.; Shan, B.; Zhao, Y.; Guo, Z. Review of micro seepage mechanisms in shale gas reservoirs. Int. J. Heat Mass Transf. 2019, 139, 144–179. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, S.; Song, H. Flow mechanism and simulation approaches for shale gas reservoirs: A review. Transp. Porous Media 2019, 126, 655–681. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de la Ville de Dijon: Exposition et Aapplication des Principes à Suivre et des Formules à Employer dans les Questions de Distribution D’eau; Victor dalmont: Paris, France, 1856. [Google Scholar]

- Xiong, X.; Devegowda, D.; Michel, G.G.; Sigal, R.F.; Civan, F. A Fully-Coupled Free and Adsorptive Phase Transport Model for Shale Gas Reservoirs Including Non-Darcy Flow Effects. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar] [CrossRef]

- Berkowitz, B.; Ewing, R.P. Percolation theory and network modeling applications in soil physics. Surv. Geophys. 1998, 19, 23–72. [Google Scholar] [CrossRef]

- Javadpour, F.; Fisher, D.; Unsworth, M. Nanoscale gas flow in shale gas sediments. J. Can. Pet. Technol. 2007, 46, PETSOC-07-10-06. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and apparent permeability of gas flow in mudrocks (shales and siltstone). J. Can. Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Fathi, E.; Akkutlu, I.Y. Matrix heterogeneity effects on gas transport and adsorption in coalbed and shale gas reservoirs. Transp. Porous Media 2009, 80, 281–304. [Google Scholar] [CrossRef]

- Fathi, E.; Akkutlu, I.Y. Mass transport of adsorbed-phase in stochastic porous medium with fluctuating porosity field and nonlinear gas adsorption kinetics. Transp. Porous Media 2012, 91, 5–33. [Google Scholar] [CrossRef]

- Zhang, Q.; Su, Y.; Wang, W.; Lu, M.; Sheng, G. Gas transport behaviors in shale nanopores based on multiple mechanisms and macroscale modeling. Int. J. Heat Mass Transf. 2018, 125, 845–857. [Google Scholar] [CrossRef]

- Zhang, L.; Li, D.; Lu, D.; Zhang, T. A new formulation of apparent permeability for gas transport in shale. J. Nat. Gas Sci. Eng. 2015, 23, 221–226. [Google Scholar] [CrossRef]

- Liang, Y.; Cheng, Y.; Han, Z.; Pidho, J.J.; Yan, C. Study on multiscale fluid–solid coupling theoretical model and productivity analysis of horizontal well in shale gas reservoirs. Energy Fuels 2023, 37, 5059–5077. [Google Scholar] [CrossRef]

- Song, F.; Hu, X.; Ji, K.; Huang, X. Effect of fluid-solid coupling on shale mechanics and seepage laws. Nat. Gas Ind. B 2018, 5, 41–47. [Google Scholar] [CrossRef]

- Wu, Y.S.; Pruess, K. A multiple-porosity method for simulation of naturally fractured petroleum reservoirs. SPE Reserv. Eng. 1988, 3, 327–336. [Google Scholar] [CrossRef]

- Kim, J.G.; Deo, M.D. Finite element, discrete-fracture model for multiphase flow in porous media. AIChE J. 2000, 46, 1120–1130. [Google Scholar] [CrossRef]

- Wei, S.; Xia, Y.; Jin, Y.; Chen, M.; Chen, K. Quantitative study in shale gas behaviors using a coupled triple-continuum and discrete fracture model. J. Pet. Sci. Eng. 2019, 174, 49–69. [Google Scholar] [CrossRef]

- Danso, D.K.; Negash, B.M.; Ahmed, T.Y.; Yekeen, N.; Ganat, T.A.O. Recent advances in multifunctional proppant technology and increased well output with micro and nano proppants. J. Pet. Sci. Eng. 2021, 196, 108026. [Google Scholar] [CrossRef]

- Katende, A.; O’Connell, L.; Rich, A.; Rutqvist, J.; Radonjic, M. A comprehensive review of proppant embedment in shale reservoirs: Experimentation, modeling and future prospects. J. Nat. Gas Sci. Eng. 2021, 95, 104143. [Google Scholar] [CrossRef]

- Yan, X.; Huang, Z.; Zhang, Q.; Fan, D.; Yao, J. Numerical investigation of the effect of partially propped fracture closure on gas production in fractured shale reservoirs. Energies 2020, 13, 5339. [Google Scholar] [CrossRef]

- Li, K.; Gao, Y.; Lyu, Y.; Wang, M. New mathematical models for calculating proppant embedment and fracture conductivity. SPE J. 2015, 20, 496–507. [Google Scholar] [CrossRef]

- Kim, J.; Seo, Y.; Wang, J.; Lee, Y. History matching and forecast of shale gas production considering hydraulic fracture closure. Energies 2019, 12, 1634. [Google Scholar] [CrossRef]

- Zheng, S.; Manchanda, R.; Sharma, M.M. Modeling fracture closure with proppant settling and embedment during shut-in and production. SPE Drill. Complet. 2020, 35, 668–683. [Google Scholar] [CrossRef]

- Zhang, F.; Emami-Meybodi, H. Flowback fracture closure of multi-fractured horizontal wells in shale gas reservoirs. J. Pet. Sci. Eng. 2020, 186, 106711. [Google Scholar] [CrossRef]

- Pati, S.; Borah, A.; Boruah, M.P.; Randive, P.R. Critical review on local thermal equilibrium and local thermal non-equilibrium approaches for the analysis of forced convective flow through porous media. Int. Commun. Heat Mass Transf. 2022, 132, 105889. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, S.; Jin, Y.; Chen, K. Self-diffusion flow and heat coupling model applicable to the production simulation and prediction of deep shale gas wells. Nat. Gas Ind. B 2021, 8, 359–366. [Google Scholar] [CrossRef]

- Liang, Z.; Chen, Z.; Rahman, S.S. Experimental investigation of the primary and secondary creep behaviour of shale gas reservoir rocks from deep sections of the Cooper Basin. J. Nat. Gas Sci. Eng. 2020, 73, 103044. [Google Scholar] [CrossRef]

- Findley, W.N.; Davis, F.A. Creep and Relaxation of Nonlinear Viscoelastic Materials; Courier Corporation: New York, NY, USA, 2013; ISBN 0-486-66016-8. [Google Scholar]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Reine Angew. Math. 1882, 1882, 156–171. [Google Scholar] [CrossRef]

- Wei, S. The Thermo-Hydro-Mechanical Couplingmechanism of Fracture Closure During Deepshale Gas Production. Doctoral Dissertation, China University of Petroleum, Beijing, China, 2022. [Google Scholar] [CrossRef]

| Simulation Parameters | Values | Units | Symbols |

|---|---|---|---|

| Maximum horizontal principal stress | 50 | Mpa | |

| Minimum horizontal principal stress | 45 | Mpa | |

| Initial formation temperature | 410 | K | |

| Thermal conductivity | 3 × 10−11 | m2/(s·K) | |

| Interstitial convective heat transfer coefficient | 1000 | W/(m3·K) | |

| Desorption rate of adsorbed gas | 0.8 × 10−5 | 1/s | |

| Adsorption rate of free gas | 0.8 × 10−6 | 1/s | |

| Effective stress coefficient | 0.8 | - | |

| Viscosity coefficient | 1 × 1017 | Pa·s | |

| Proppant geometric coefficient | 2, 4, 6 | - | |

| Proppant elastic modulus | 5, 15, 25 | GPa | |

| Proppant Poisson’s ratio | 0.2, 0.3, 0.4 | - | |

| Proppant diameter | 0.2, 0.5, 1 | mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Wei, S.; Jin, Y.; Xia, Y. Study on the Long-Term Influence of Proppant Optimization on the Production of Deep Shale Gas Fractured Horizontal Well. Appl. Sci. 2025, 15, 2365. https://doi.org/10.3390/app15052365

Chen S, Wei S, Jin Y, Xia Y. Study on the Long-Term Influence of Proppant Optimization on the Production of Deep Shale Gas Fractured Horizontal Well. Applied Sciences. 2025; 15(5):2365. https://doi.org/10.3390/app15052365

Chicago/Turabian StyleChen, Siyuan, Shiming Wei, Yan Jin, and Yang Xia. 2025. "Study on the Long-Term Influence of Proppant Optimization on the Production of Deep Shale Gas Fractured Horizontal Well" Applied Sciences 15, no. 5: 2365. https://doi.org/10.3390/app15052365

APA StyleChen, S., Wei, S., Jin, Y., & Xia, Y. (2025). Study on the Long-Term Influence of Proppant Optimization on the Production of Deep Shale Gas Fractured Horizontal Well. Applied Sciences, 15(5), 2365. https://doi.org/10.3390/app15052365