Experimental Design and Performance Evaluation of a Friction and Wear Testing Apparatus for the Bushing of the Variable Stator Vane

Featured Application

Abstract

1. Introduction

2. Materials and Methods

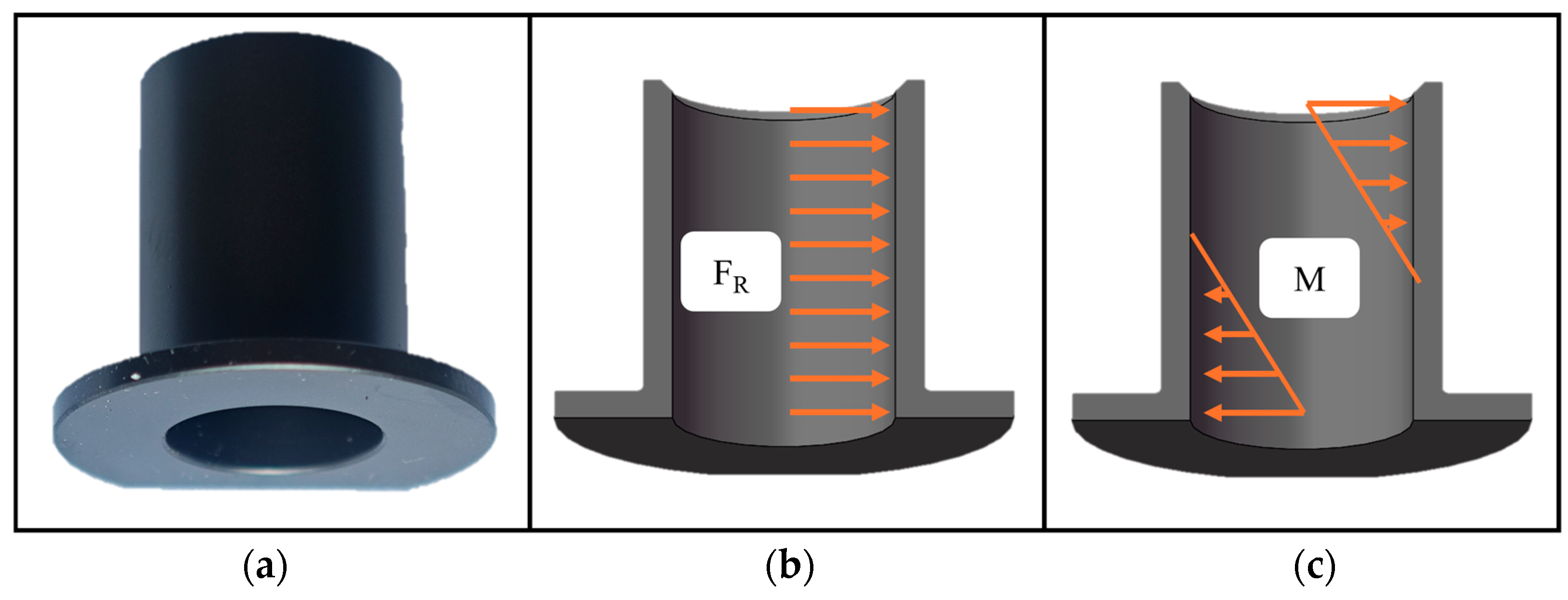

2.1. Test Specimens and Performance Specifications of the Testing Apparatus

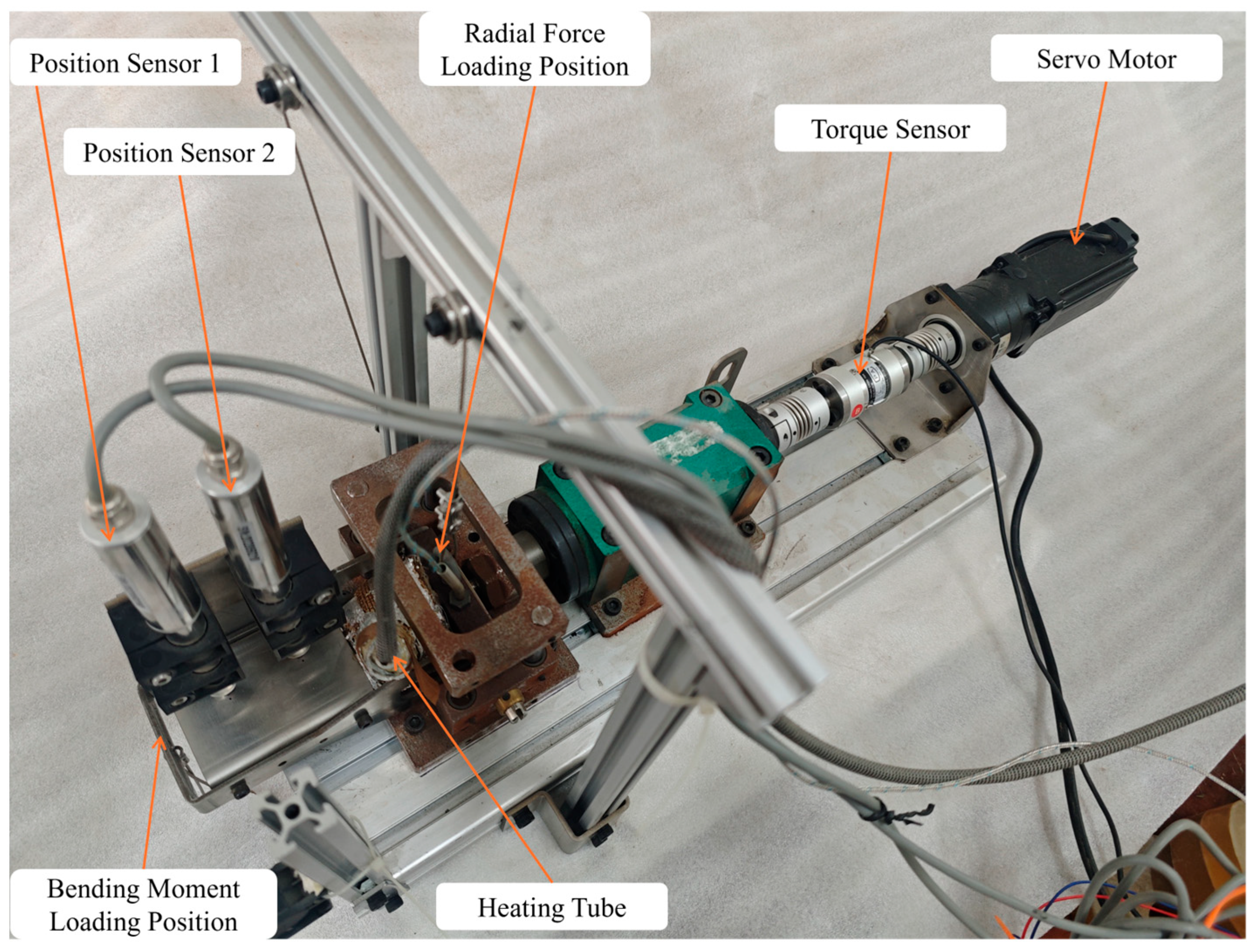

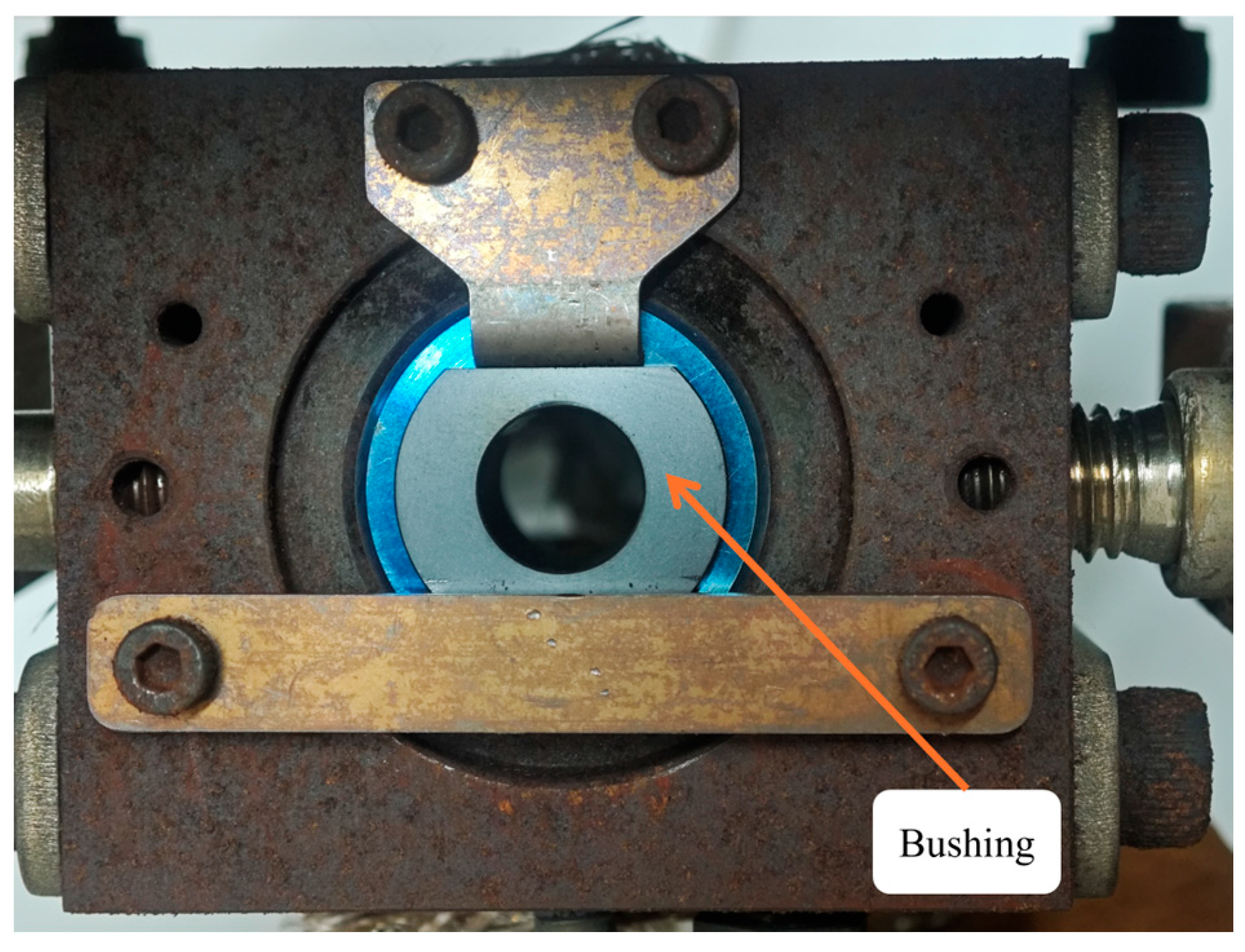

2.2. Testing Apparatus

2.3. Experimental Procedure

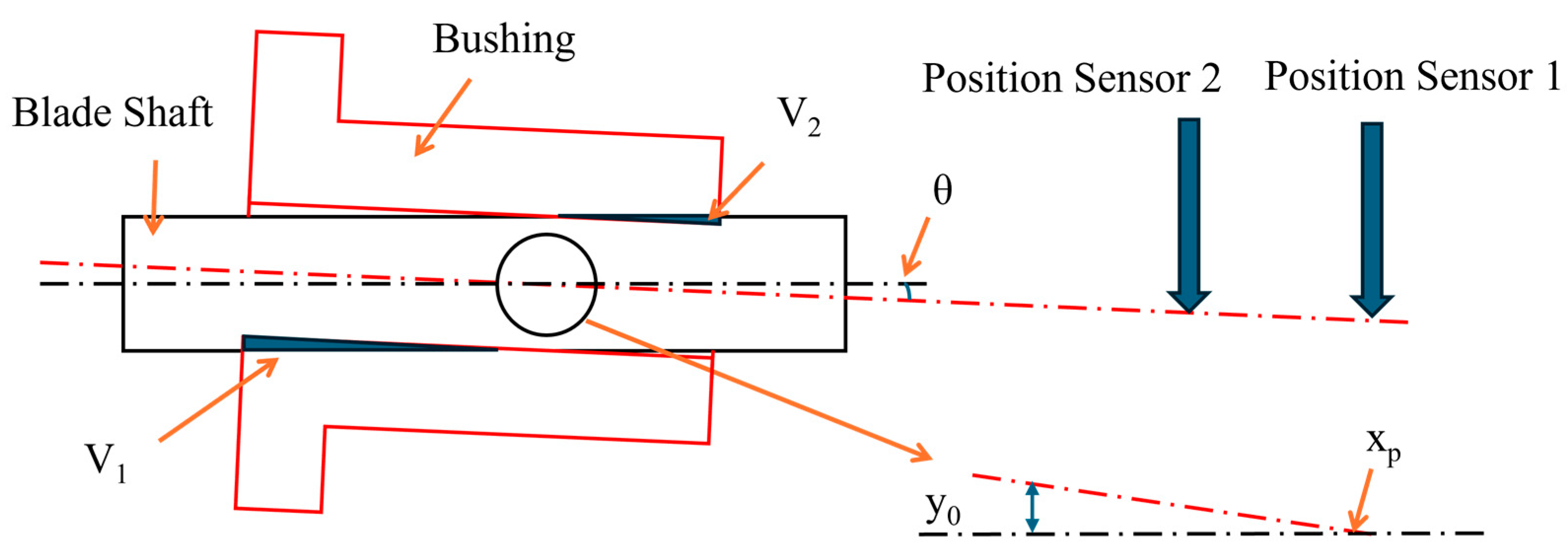

2.4. Sensor Data Processing Method

3. Result and Discussion

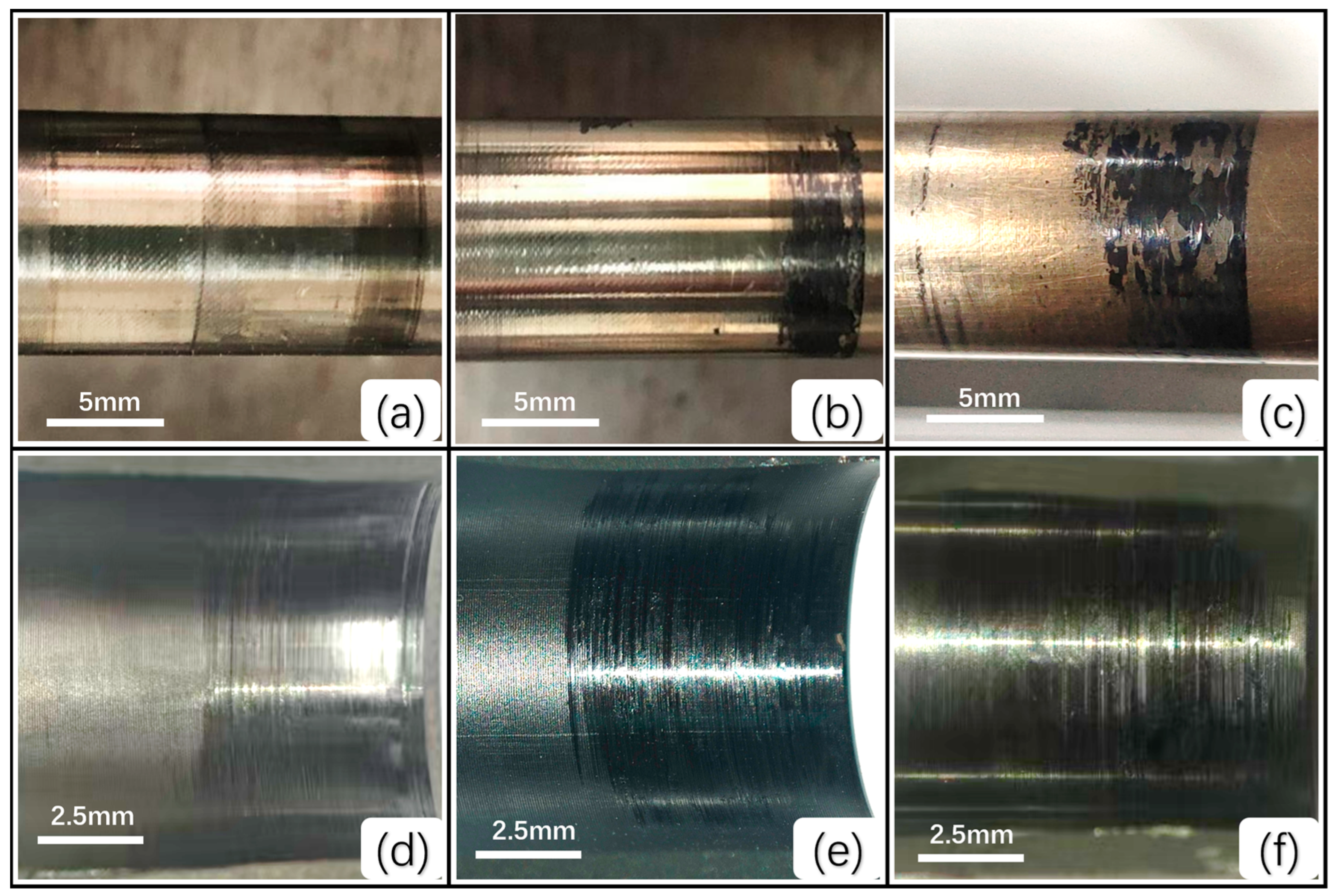

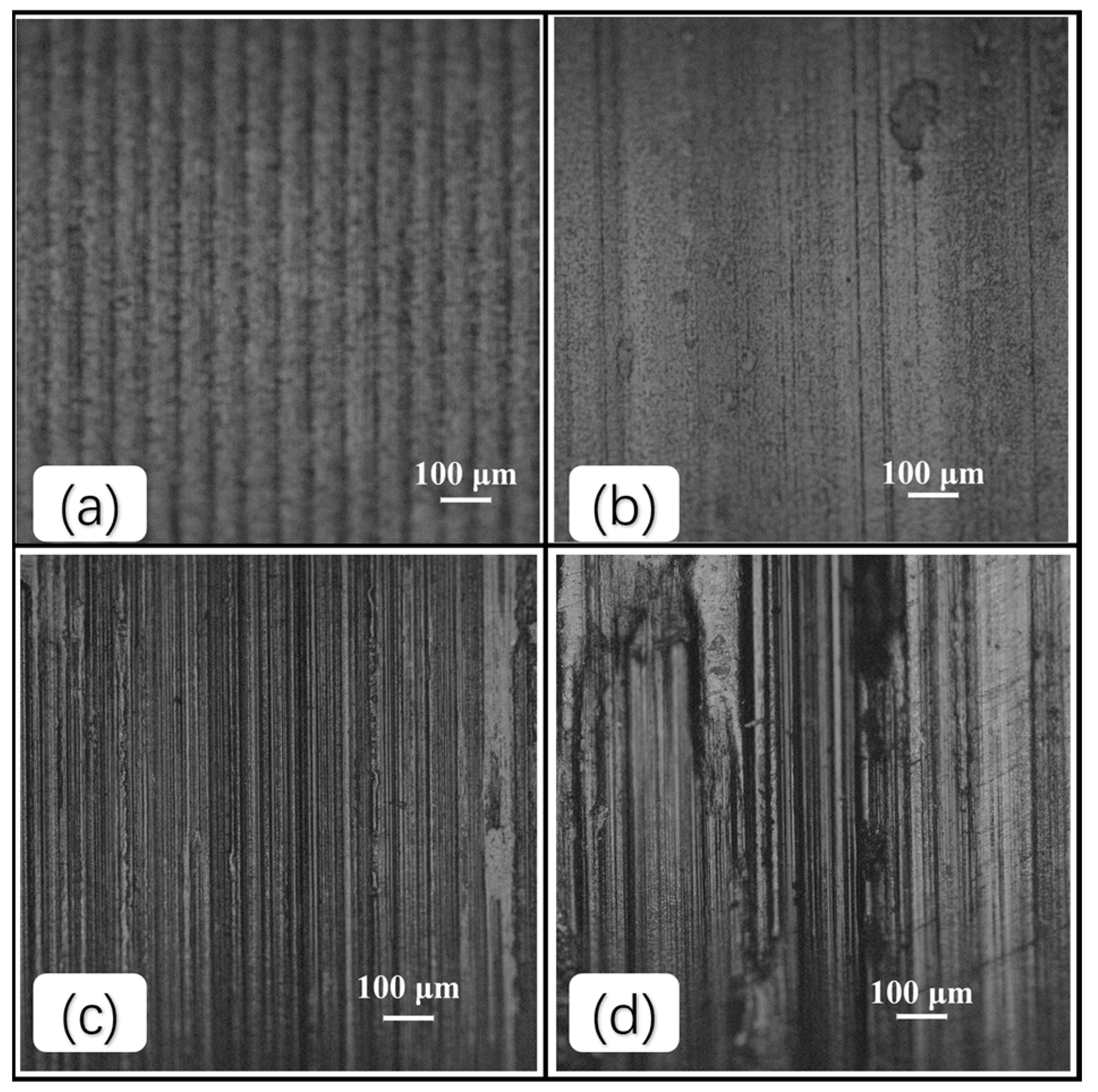

3.1. Surface Morphology Analysis

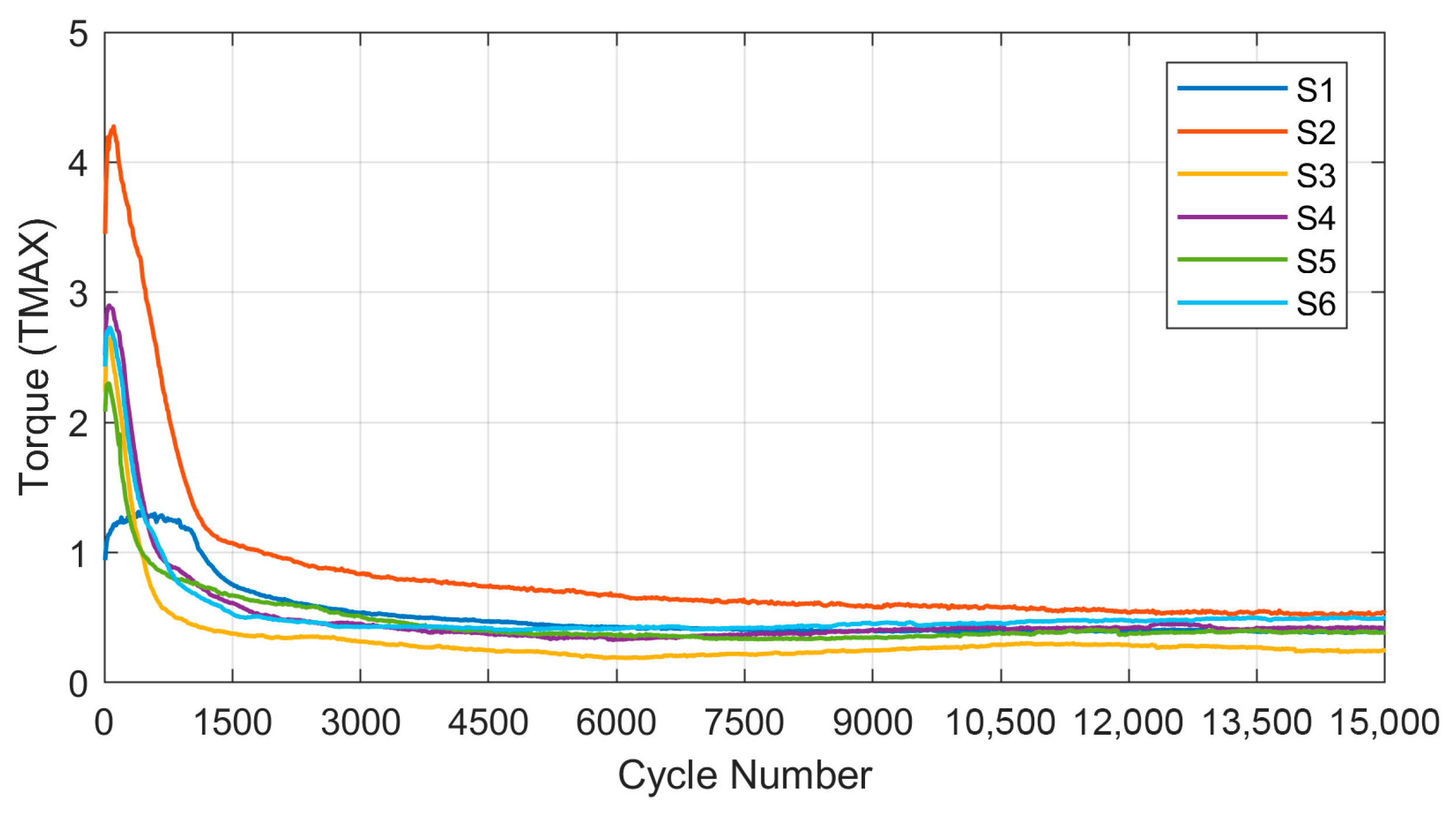

3.2. Evolution of Friction Torque

3.3. Evolution of Equivalent Wear Volume

4. Conclusions and Outlook

4.1. Conclusions

4.2. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Janssen, J.; Pohl, D.; Jeschke, P.; Halcoussis, A.; Hain, R.; Fuchs, T. Effect of an Axially Tilted Variable Stator Vane Platform on Penny Cavity and Main Flow. J. Turbomach 2022, 144, 021010. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, M.; Zeng, H.; Luo, Z.; Han, Q. Dynamics of Variable Stator Vane Adjustment Mechanism Considering the Flexibility of Linkage. Int. J. Aerosp. Eng. 2025, 2025, 7302080. [Google Scholar] [CrossRef]

- Fan, J.; Xu, H.; Meng, Q.; Xu, S. A Multi-Layer Kriging Surrogate Model for the Reliability Analysis of Variable Stator Vanes in Aero Engines. Aeronaut. J. 2025, 129, 123–143. [Google Scholar] [CrossRef]

- Zhang, H.; Song, L.K.; Bai, G.C.; Li, X.Q. Active Extremum Kriging-Based Multi-Level Linkage Reliability Analysis and Its Application in Aeroengine Mechanism Systems. Aerosp. Sci. Technol. 2022, 131, 107968. [Google Scholar] [CrossRef]

- Chen, S.; Yin, N.; Yu, Q.; Zhang, Z. A Novel Tribometer for Investigating Bushing Wear. Wear 2019, 430–431, 263–271. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Liu, Y.; Wang, S. Numerical Investigation of a Variable Stator Vane with Nonuniform Partial Radial Gaps in an Annular Compressor Cascade. Int. J. Turbo Jet Engines 2024, 40, s315–s324. [Google Scholar] [CrossRef]

- Xie, W.; Liu, C.; Huang, G.; Qin, Z.; Zong, K.; Jiang, D. Trans-Scale Rough Surface Contact Model Based on Molecular Dynamics Method: Simulation, Modeling and Experimental Verification. Eur. J. Mech. A Solids 2023, 100, 105021. [Google Scholar] [CrossRef]

- Yu, X.; Sun, Y.; Wu, S. Multi-Stage Contact Model between Fractal Rough Surfaces Based on Multi-Scale Asperity Deformation. Appl. Math. Model. 2022, 109, 229–250. [Google Scholar] [CrossRef]

- Zong, K.; Qin, Z.; Chu, F. Modeling of Frictional Stick-Slip of Contact Interfaces Considering Normal Fractal Contact. J. Appl. Mech. 2022, 89, 031003. [Google Scholar] [CrossRef]

- Jeng, Y.R.; Lin, Z.W.; Shyu, S.H. Changes of Surface Topography During Running-In Process. J. Tribol. 2004, 126, 620–625. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, X.; Lu, W. Comprehensive Evaluation of Surface Topography in Running-in Wear Process. In Proceedings of the Sixth International Symposium on Precision Mechanical Measurements, Guiyang, China, 8–12 August 2013; Volume 8916, pp. 1112–1117. [Google Scholar]

- Zambrano, O.A.; Muñoz, E.C.; Rodríguez, S.A.; Coronado, J.J. Running-in Period for the Abrasive Wear of Austenitic Steels. Wear 2020, 452–453, 203298. [Google Scholar] [CrossRef]

- Liu, Y.; Li, B.; He, Y.; Dong, Y.; Wang, S. Effect of Silane Coating Surface Treatment on Friction and Wear Properties of Carbon Fiber/PI Composites. Mater. Sci. 2022, 40, 214–222. [Google Scholar] [CrossRef]

- Zheng, F.; Lv, M.; Wang, Q.; Wang, T. Effect of Temperature on Friction and Wear Behaviors of Polyimide (PI)-Based Solid-Liquid Lubricating Materials. Polym. Adv. Technol. 2015, 26, 988–993. [Google Scholar] [CrossRef]

- Milojević, S.; Savić, S.; Mitrović, S.; Marić, D.; Krstić, B.; Stojanović, B.; Popović, V. Solving the Problem of Friction and Wear in Auxiliary Devices of Internal Combustion Engines on the Example of Reciprocating Air Compressor for Vehicles. Tech. Gaz. 2023, 30, 122–130. [Google Scholar] [CrossRef]

- Regis, A.; Linares, J.M.; Arroyave-Tobon, S.; Mermoz, E. Numerical Model to Predict Wear of Dynamically Loaded Plain Bearings. Wear 2022, 508–509, 204467. [Google Scholar] [CrossRef]

- Cheng, S.; Meng, X.; Li, R.; Liu, R.; Zhang, R.; Sun, K.; Ye, W.; Zhao, F. Rough Surface Damping Contact Model and Its Space Mechanism Application. Int. J. Mech. Sci. 2022, 214, 106899. [Google Scholar] [CrossRef]

- Harnafi, M.; Guidault, P.A.; Boucard, P.A.; Paleczny, C. A Simplified Model for the Wear Prediction of Plain Bearings in the Variable Stator Vane System. Tribol. Int. 2024, 196, 109667. [Google Scholar] [CrossRef]

- Schmidt, A.A.; Schmidt, T.; Grabherr, O.; Bartel, D. Transient Wear Simulation Based on Three-Dimensional Finite Element Analysis for a Dry Running Tilted Shaft-Bushing Bearing. Wear 2018, 408–409, 171–179. [Google Scholar] [CrossRef]

- Zhang, H.; Luo, Z.; Pang, C.; Xu, C.; Yao, S. A New Contact Force Model for Revolute Joints Considering Elastic Layer Characteristics Effects. J. Sound Vib. 2025, 596, 118743. [Google Scholar] [CrossRef]

- Hegadekatte, V.; Kurzenhäuser, S.; Huber, N.; Kraft, O. A Predictive Modeling Scheme for Wear in Tribometers. Tribol. Int. 2008, 41, 1020–1031. [Google Scholar] [CrossRef]

- Colbert, R.S.; Alvarez, L.A.; Hamilton, M.A.; Steffens, J.G.; Ziegert, J.C.; Burris, D.L.; Sawyer, W.G. Edges, Clearances, and Wear: Little Things That Make Big Differences in Bushing Friction. Wear 2010, 268, 41–49. [Google Scholar] [CrossRef]

- He, K.; Ma, Y.; Zhang, Z. Tribo-Informatics Approach to Investigate the Friction and Wear of Bushings in the Variable Stator Vane System. J. Tribol. 2023, 145, 121704. [Google Scholar] [CrossRef]

- Kurdi, A.; Kan, W.H.; Chang, L. Tribological Behaviour of High Performance Polymers and Polymer Composites at Elevated Temperature. Tribol. Int. 2019, 130, 94–105. [Google Scholar] [CrossRef]

- Lv, M.; Zheng, F.; Wang, Q.; Wang, T.; Liang, Y. Friction and Wear Behaviors of Carbon and Aramid Fibers Reinforced Polyimide Composites in Simulated Space Environment. Tribol. Int. 2015, 92, 246–254. [Google Scholar] [CrossRef]

- Chang, J.; Luo, Z.; Wang, Y.; Han, Q.; Han, F.; Zhang, H. Characterization of Joint Contact Model Considering Friction of Variable Stator Vane Mechanism and Application to Principle-Level Mechanism. Int. J. Non-Linear Mech. 2023, 156, 104511. [Google Scholar] [CrossRef]

- Chang, J.; Luo, Z.; Wei, K.; Han, Q.; Han, F. Investigation of Spatial Plane Joint Characteristic for Dynamic Analysis of VSV Mechanism Based on Similarity Scaling Technique. Int. J. Non-Linear Mech. 2023, 148, 104300. [Google Scholar] [CrossRef]

- Wollmann, T.; Nitschke, S.; Klauke, T.; Behnisch, T.; Ebert, C.; Füßel, R.; Modler, N.; Gude, M. Investigating the Friction, Wear and Damage Behaviour of Plain Bearing Bushes of the Variable Stator Vane System. Tribol. Int. 2022, 165, 107280. [Google Scholar] [CrossRef]

| Specification | Value |

|---|---|

| Radial Load Range () | 0–600 N |

| Bending Moment Load Range () | 0–5 Nm |

| Maximum Blade Oscillation Frequency () | 2 Hz |

| Maximum Test Temperature() | 400 °C |

| Sample Number | Temperature/°C | Radial Load/KN | Bending Moment/Nm |

|---|---|---|---|

| 1 | 250 | 30 | 1.5 |

| 2 | 300 | 30 | 3 |

| 3–6 | 350 | 30 | 1.5 |

| Sample Number | Peak Torque/Nm | Cycle |

|---|---|---|

| 3 | 2.65 | 76 |

| 4 | 2.90 | 64 |

| 5 | 2.30 | 55 |

| 6 | 2.73 | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Xie, L. Experimental Design and Performance Evaluation of a Friction and Wear Testing Apparatus for the Bushing of the Variable Stator Vane. Appl. Sci. 2025, 15, 13077. https://doi.org/10.3390/app152413077

Liu S, Xie L. Experimental Design and Performance Evaluation of a Friction and Wear Testing Apparatus for the Bushing of the Variable Stator Vane. Applied Sciences. 2025; 15(24):13077. https://doi.org/10.3390/app152413077

Chicago/Turabian StyleLiu, Shenglei, and Liyang Xie. 2025. "Experimental Design and Performance Evaluation of a Friction and Wear Testing Apparatus for the Bushing of the Variable Stator Vane" Applied Sciences 15, no. 24: 13077. https://doi.org/10.3390/app152413077

APA StyleLiu, S., & Xie, L. (2025). Experimental Design and Performance Evaluation of a Friction and Wear Testing Apparatus for the Bushing of the Variable Stator Vane. Applied Sciences, 15(24), 13077. https://doi.org/10.3390/app152413077