Influence of Blasting Approaches in In-Pit Haul Road Construction on Emission Levels and Resource Management: A Case Study from the Holcim “Dubie” Open-Pit Mine

Abstract

1. Introduction

2. Materials and Methods

2.1. Open-Pit Mine

2.2. Methods

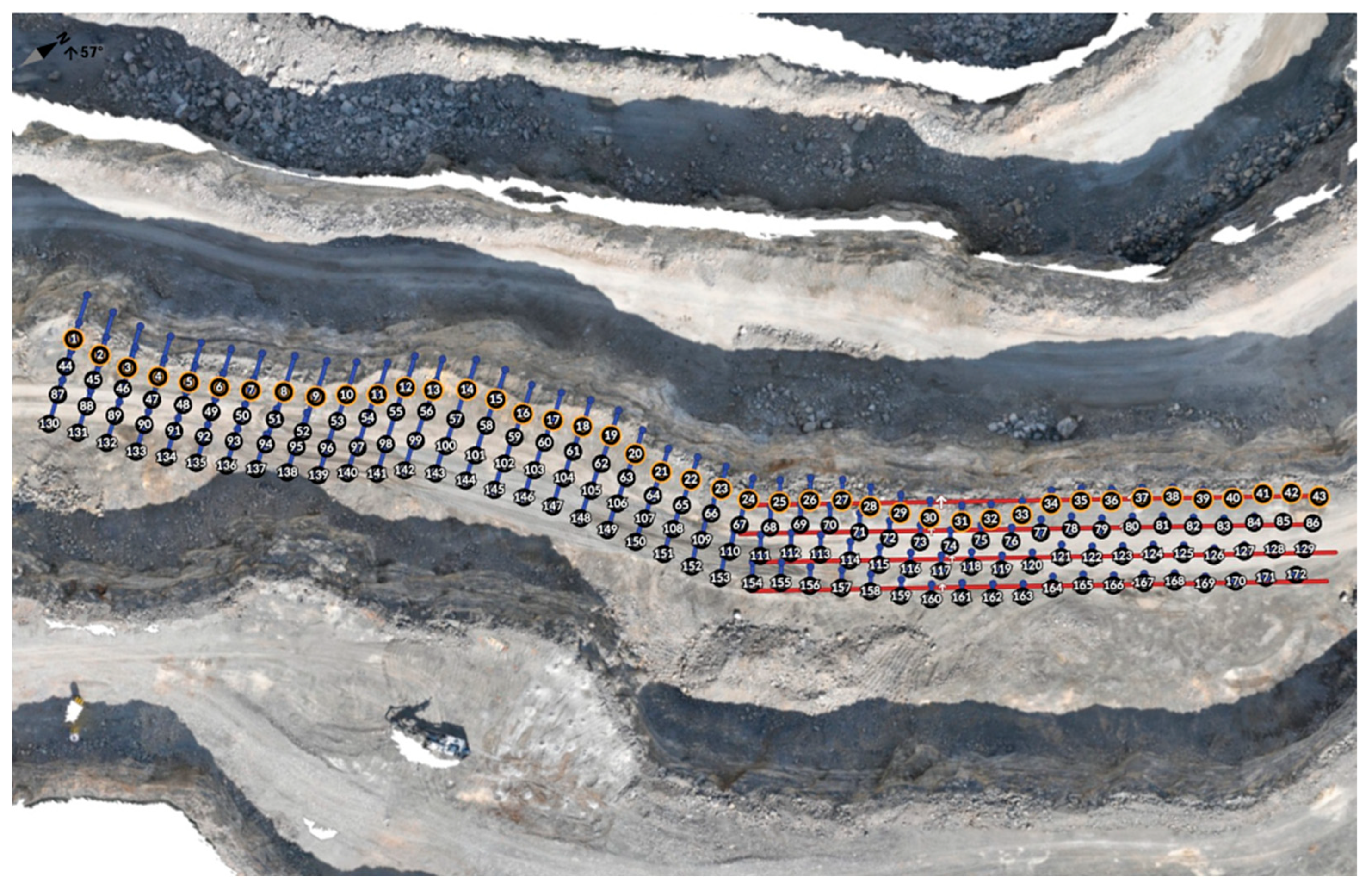

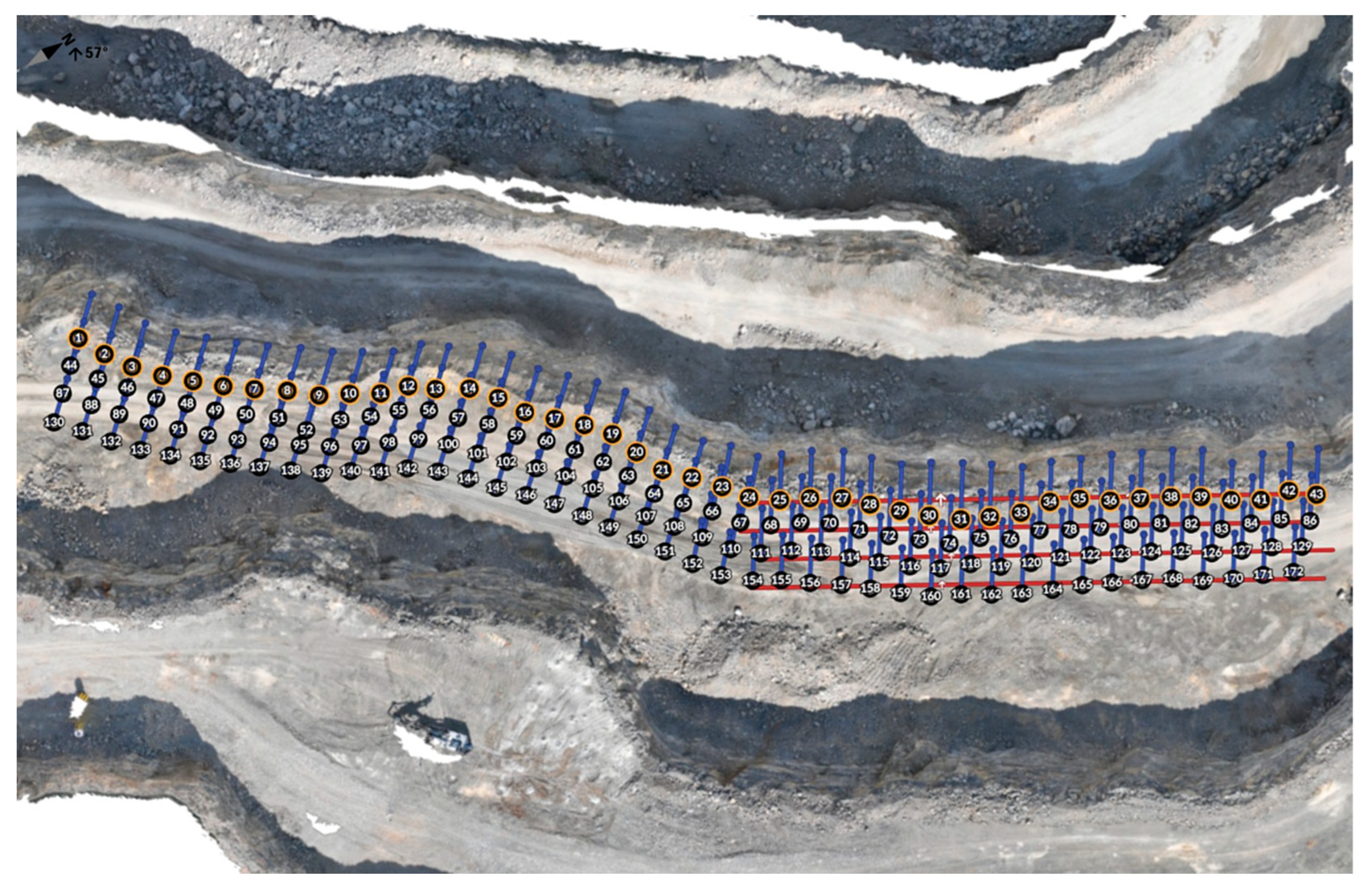

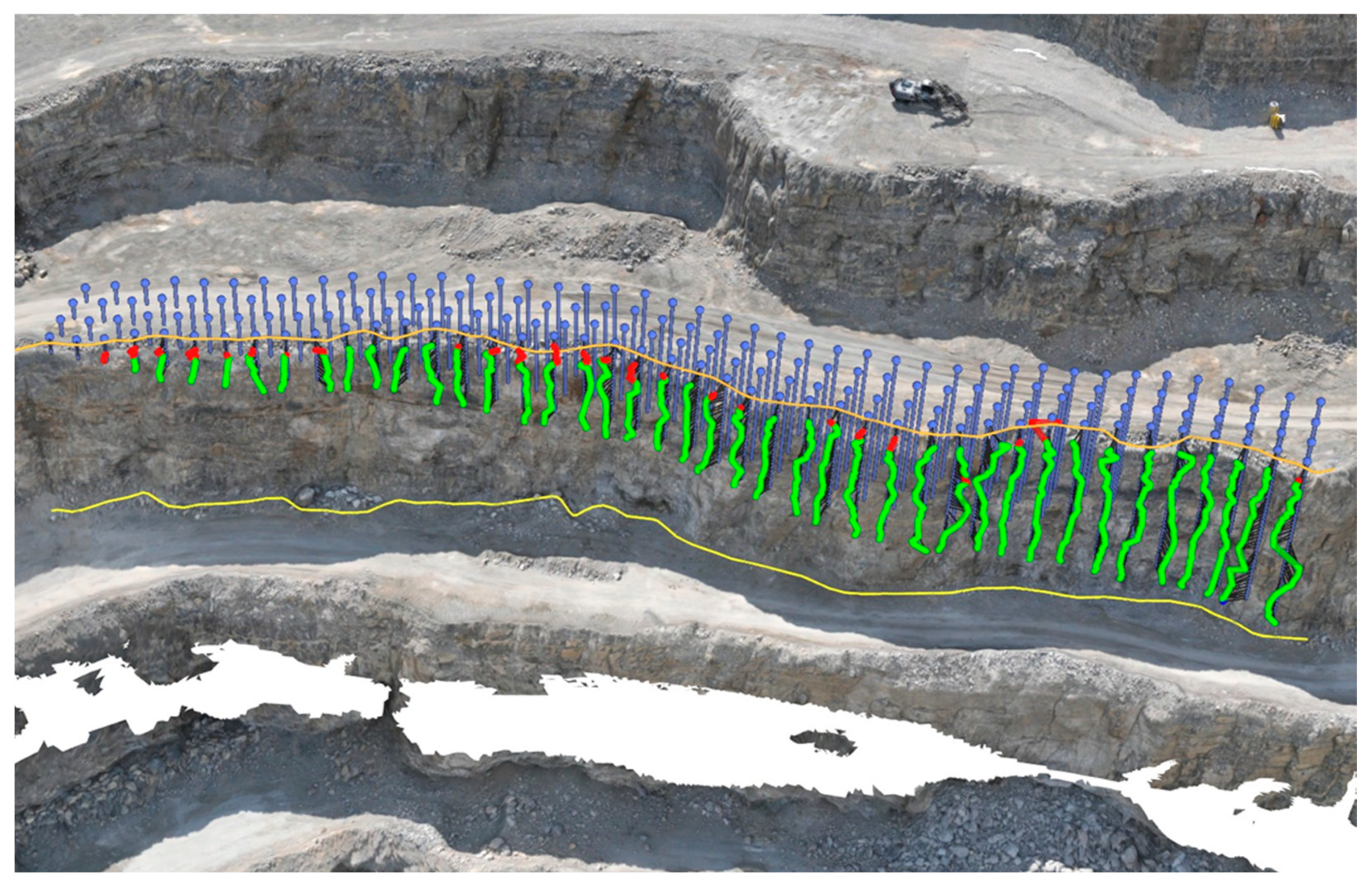

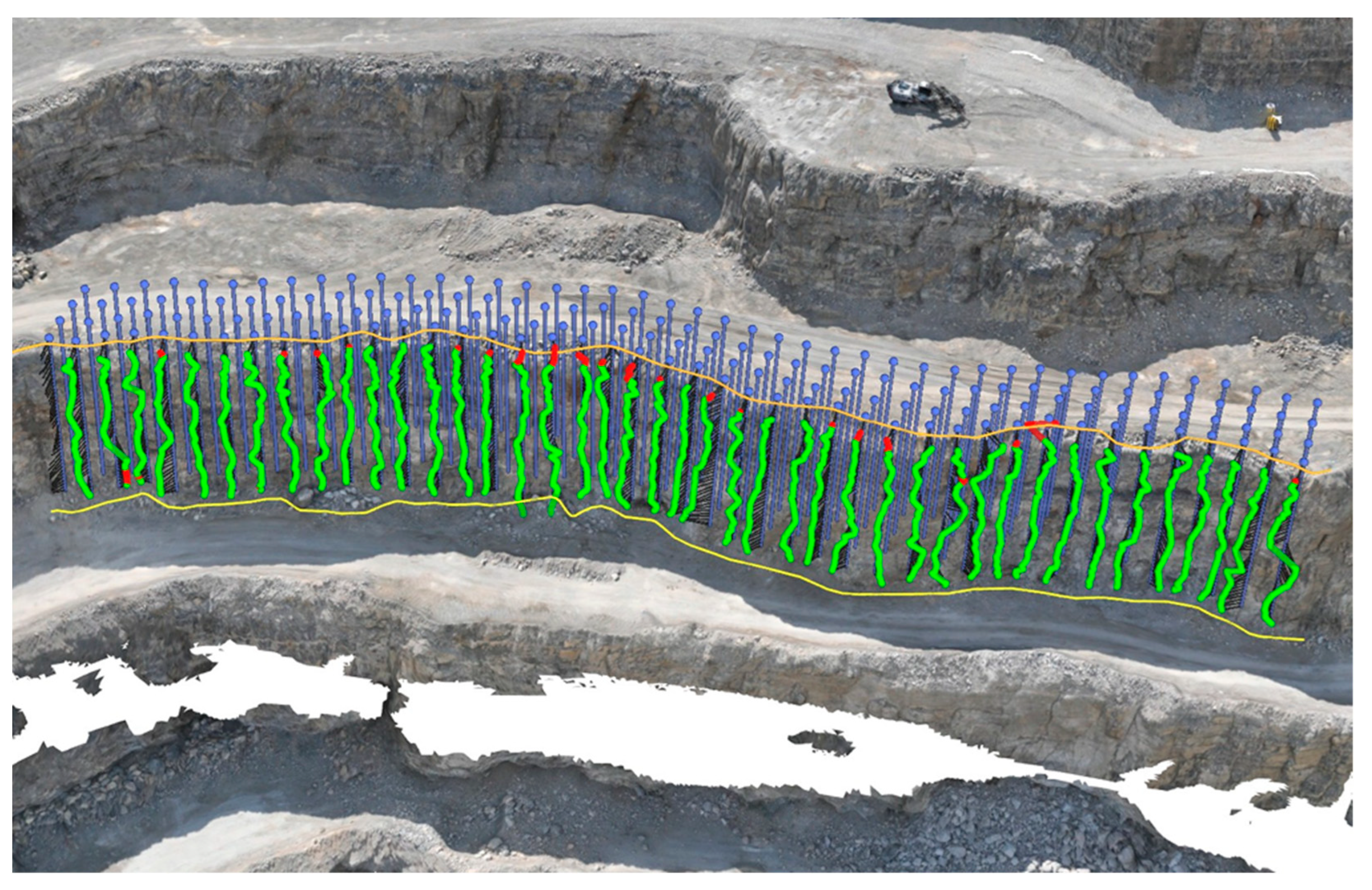

2.2.1. Drilling and Blasting Works

2.2.2. Carbon and Nitrogen Oxides Emissions

3. Results and Discussion

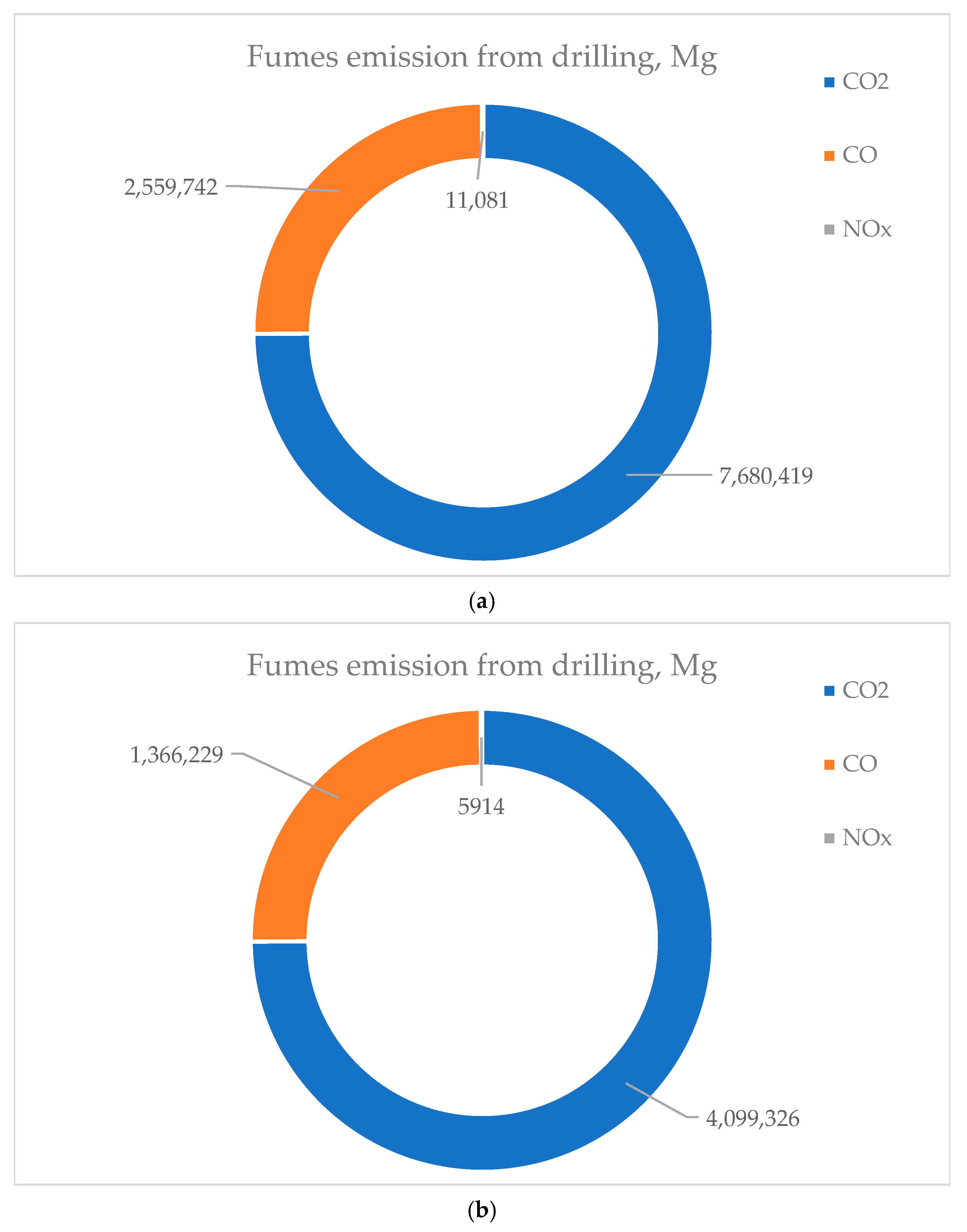

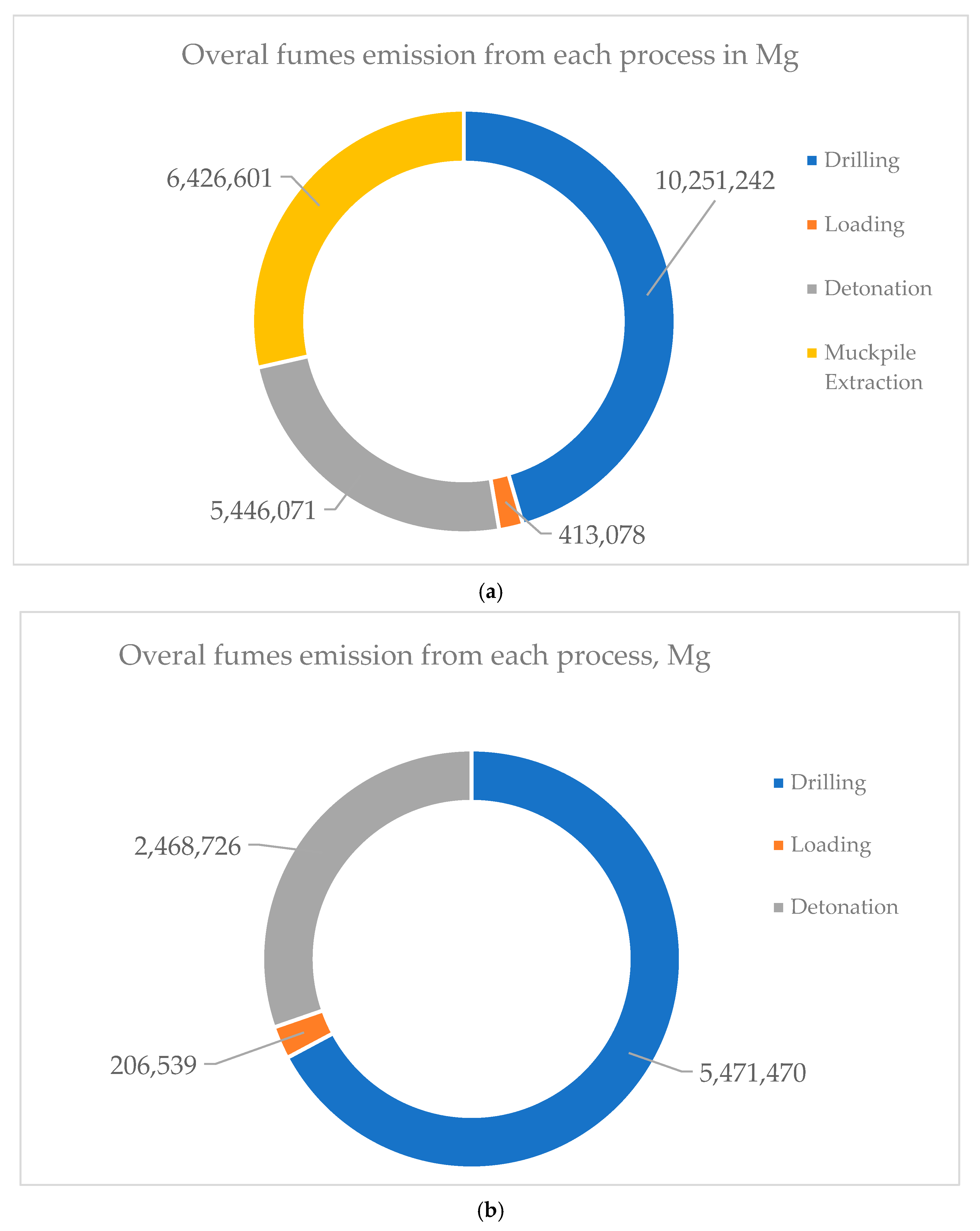

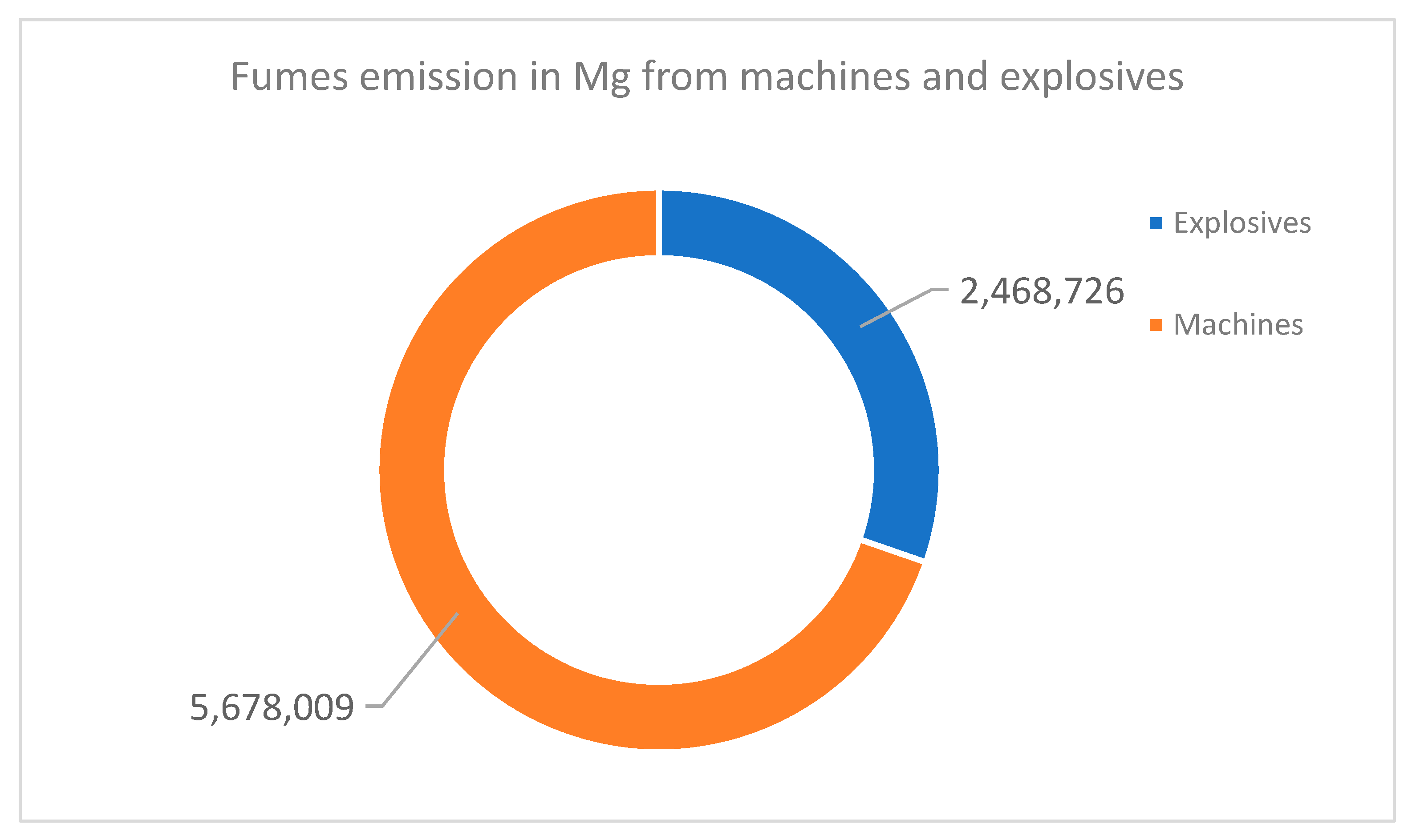

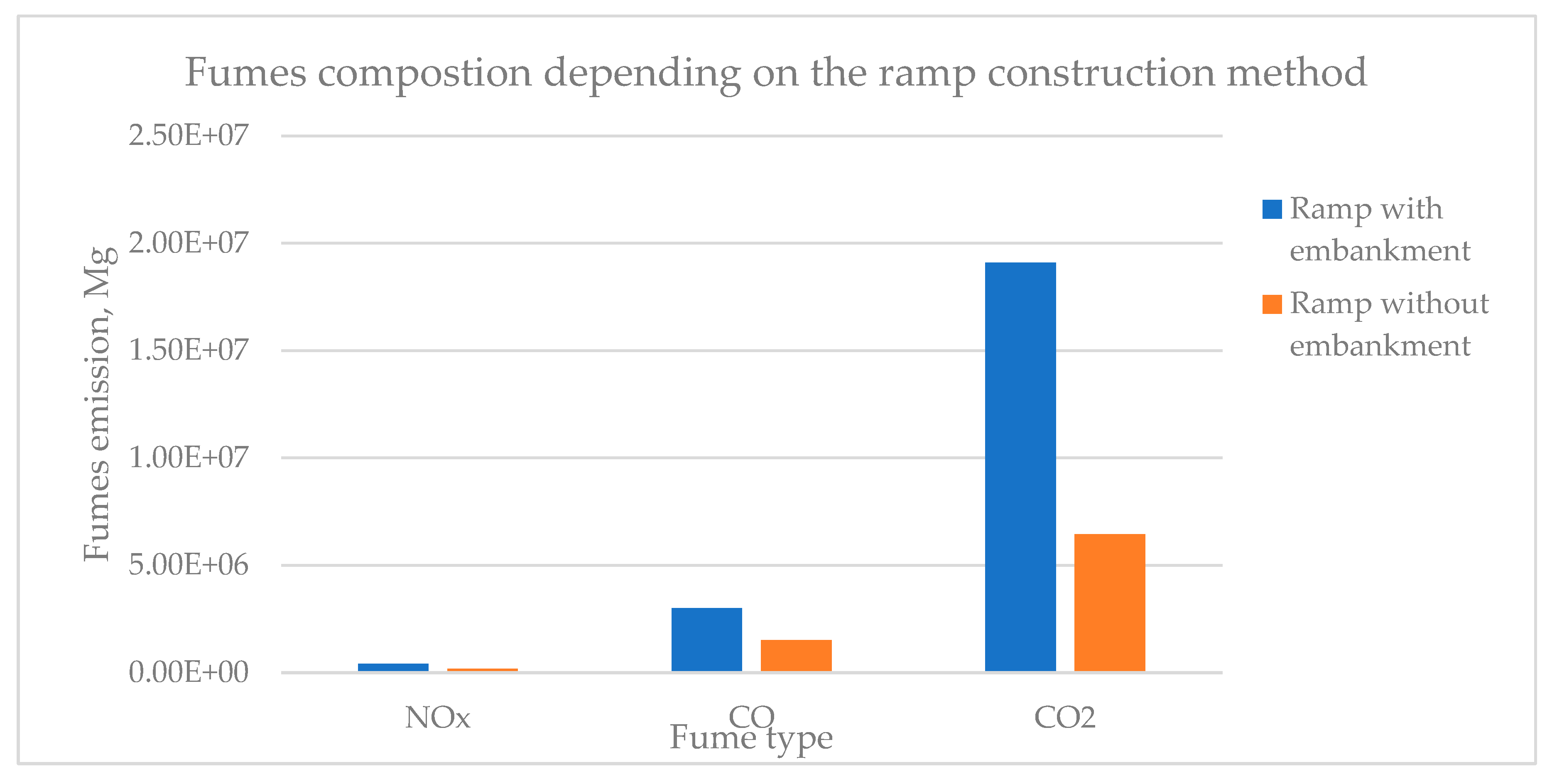

3.1. Impact of Construction Method on Fumes

3.2. Deposit Management

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thompson, R. Mine Haul Road Design and Management Best Practices for Safe and Cost-Efficient Truck Haulage. In Proceedings of the Society for Mining, Metallurgy and Exploration Annual Meeting & Exhibit, Phoenix, AZ, USA, 28 February–3 March 2010; Society for Mining, Metallurgy and Exploration (SME): Littleton, CO, USA, 2010; pp. 1–10. [Google Scholar]

- Kaufman, W.W.; Ault, J.C. Design of Surface Mine Haulage Roads—A Manual; United States Bureau of Mines (USBM), United States Department of the Interior: Washington, DC, USA, 1977; pp. 1–49. [Google Scholar]

- Tannant, D.; Regensburg, B. Guidelines for Mine Haul Road Design; University of British Columbia Library: Vancouver, BC, Canada, 2010; pp. 1–111. [Google Scholar]

- Hustrulid, W.A.; Kuchta, M.; Martin, R.K. Open Pit Mine Planning and Design, 3rd ed.; CRC Press: Leiden, The Netherlands, 2013; pp. 1–1288. [Google Scholar]

- Darling, P. SME Mining Engineering Handbook, 3rd ed.; Society for Mining, Metallurgy and Exploration (SME): Littleton, CO, USA, 2011; pp. 1–1837. [Google Scholar]

- Mohutsiwa, M.; Musingwini, C. Parametric estimation of capital costs for establishing a coal mine: South Africa case study. J. S. Afr. Inst. Min. Metall. 2015, 115, 789–797. [Google Scholar] [CrossRef]

- Nancel-Penard, P.; Parra, A.; Morales, M.; Díaz, C.; Widzyk-Capehart, E. Value-optimal design of ramps in open pit mining. Arch. Min. Sci. 2019, 64, 399–413. [Google Scholar] [CrossRef]

- Purhamadani, E.; Bagherpour, R.; Tudeshki, H. Energy consumption in open-pit mining operations relying on reduced energy consumption for haulage using in-pit crusher systems. J. Clean. Prod. 2021, 291, 125228. [Google Scholar] [CrossRef]

- Tadubana, G.K. Prediction of Fuel Consumption of Haulage Trucks in Open Pit Mines. Master’s Thesis, Botswana International University of Science & Technology, Palapye, Botswana, 2021. [Google Scholar]

- Kecojevic, V.; Komljenovic, D. Haul truck fuel consumption and CO2 emission under various engine load conditions. Min. Eng. 2010, 62, 44–48. [Google Scholar]

- Akay, A.E.; Aruga, K.; Bettinger, P.; Sessions, J. Using optimisation techniques in designing forest roads and road networks. J. Fac. For. Istanb. Univ. 2013, 15, 49–62. [Google Scholar]

- Aleksandrova, E. Ikonomicheski podhod pri proektiraneto na rudnitsi. In Proceedings of the Mezhdunarodna Nauchna Konferentsia “The Challenges Facing Science in Connection with Bulgaria’s Membership in the EU”, Stara Zagora, Bulgaria, 8 June 2007. [Google Scholar]

- Baek, J.; Cho, Y. A new method for haul road design in open-pit mines to support efficient truck haulage operations. Appl. Sci. 2017, 7, 747. [Google Scholar] [CrossRef]

- Morales, N.; Nancel-Penard, P.; Parra, A. An integer linear programming model for optimising open pit ramp design. In Proceedings of the 38th APCOM Proceedings 2017, Golden, CO, USA, 9–11 August 2017; Session 11. pp. 9–16. [Google Scholar]

- Yarmuch, J.; Brazil, M.; Rubinstein, H.; Thomas, D.A. Optimum ramp design in open pit mines. Comput. Oper. Res. 2020, 115, 104739. [Google Scholar] [CrossRef]

- Terziyski, D.; Kaykov, D. Haul road design optimization approach following technological constraints in open-pit mining. Sustain. Extr. Process. Raw Mater. J. 2022, 3, 78–88. [Google Scholar] [CrossRef]

- Aleksandrova, E. Guide to the Exercises on Technology in Open-Pit Mining of Minerals (Technological Schemes of Driving Open-Pit Mines); Avangard Prima: Sofia, Bulgaria, 2013. (In Bulgarian) [Google Scholar]

- Koprev, I. Technology of Extraction of Rock Facing Materials; Avangard Prima: Sofia, Bulgaria, 2016. (In Bulgarian) [Google Scholar]

- Zlatanov, P.; Aleksandrova, E. Course Design Guide for Open Pit Mining Technologist; Komlivest-LM: Sofia, Bulgaria, 2005. (In Bulgarian) [Google Scholar]

- Thompson, R.J.; Visser, A.T. The functional design of surface mine haul roads. J. S. Afr. Inst. Min. Metall. 2000, 100, 169–180. [Google Scholar]

- EN 13631-16:2004; Explosives for Civil Uses. High Explosives. Part 16: Detection and Measurement of Toxic Gases. European Committee for Standardization: Brussels, Belgium, 2004.

- Biessikirski, A.; Dworzak, M.; Pytlik, M.; Nachlik, S. Impact of the Type of Energetic Material on the Fume Emission in Open-Pit Mining. Sustainability 2025, 17, 2075. [Google Scholar] [CrossRef]

- European Commission. Technical Guidance Document on Monitoring and Emission Reporting for Non-Road Mobile Machinery (NRMM) under Regulation (EU) 2016/1628; Publications Office of the European Union: Brussels, Belgium, 2018; pp. 1–87. [Google Scholar]

- Dallmann, T.; Menon, A. Technology Pathways for Diesel Engines Used in Non-Road Vehicles and Equipment; International Council on Clean Transportation: Washington, DC, USA, 2016. [Google Scholar]

- European Parliament and Council. Directive 97/68/EC of 16 December 1997 on the Approximation of the Laws of the Member States Relating to Measures Against the Emission of Gaseous and Particulate Pollutants from Internal Combustion Engines to Be Installed in Non-Road Mobile Machinery. Off. J. Eur. Union 1998, L 59, 1–86. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:01997L0068-20070101 (accessed on 22 September 2025).

- European Commission. Commission Directive 2010/22/EU of 15 March 2010 Amending, for the Purposes of Their Adaptation to Technical Progress, Directives 80/720/EEC, 86/298/EEC, 86/415/EEC, 87/402/EEC, 2000/25/EC, 2005/13/EC and 2009/60/EC of the European Parliament and of the Council Relating to the Type-Approval of Agricultural or Forestry Tractors. Off. J. Eur. Union 2010, L 129, 1–34. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010L0022 (accessed on 22 September 2025).

- Environmental Protection Agency (EPA). Control of Emissions of Air Pollution from Non-Road Diesel Engines and Fuel. Fed. Regist. 2004, 69, 38958–38988. [Google Scholar]

- Babamohammadi, S.; Birss, A.R.; Pouran, H.; Pandhal, J.; Borhani, T.N. Emission control and carbon capture from diesel generators and engines: A decade-long perspective. Carbon Capture Sci. Technol. 2025, 14, 100379. [Google Scholar] [CrossRef]

- Piumetti, M.; Bensaid, S.; Fino, D.; Russo, N. Catalysis in Diesel engine NOx aftertreatment: A review. Catal. Struct. React. 2015, 1, 155–173. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.; Lee, S.; Oh, K.; Jang, S. Fuel Consumption and Emission Reduction for Non-Road Diesel Engines with Electrically Heated Catalysts. Catalysts 2023, 13, 950. [Google Scholar] [CrossRef]

- Dudek, M.; Dworzak, M.; Biessikirski, A. Impact of Blasting Scenario for Construction of in-Pit Ramp on the Fumes Emission. Sustainability, 2025; submitted. [Google Scholar]

- Menéndez, J.; Merlé, N.; Fernández-Oro, J.M.; Galdo, M.; Álvarez de Prado, L.; Loredo, J.; Bernardo-Sánchez, A. Concentration, Propagation and Dilution of Toxic Gases in Underground Excavations under Different Ventilation Modes. Int. J. Environ. Res. Public Health 2022, 19, 7092. [Google Scholar] [CrossRef] [PubMed]

- Attalla, M.I.; Day, S.J.; Lange, T.; Lilley, W.; Morgan, S. NOx emissions from blasting operations in open-cut coal mining. Atmos. Environ. 2008, 42, 7874–7883. [Google Scholar] [CrossRef]

- Mainiero, R.J.; Harris, M.L.; Rowland, J.H. Dangers of toxic fumes from blasting. In Proceedings of the 33rd Annual Conference on Explosives and Blasting Technique, Nashville, TN, USA, 28–31 January 2007; pp. 1–6. [Google Scholar]

- Rowland, J.H.; Mainiero, R.; Hurd, D.A. Factors Affecting Fumes Production of an Emulsion and ANFO/Emulsion Blends. In Proceedings of the 27th ISEE Annual Conference on Explosives and Blasting Technique, Orlando, FL, USA, 28–31 January 2001; pp. 133–141. [Google Scholar]

- Suceska, M.; Tumara, S.; Skrlec, V.; Stankovic, S. Prediction of concentration of toxic gases produced by detonation of commercial explosives by thermochemical equilibrium calculations. Def. Technol. 2022, 18, 2181–2189. [Google Scholar] [CrossRef]

| Parameter | Blasting at the Location of the Ramp (Ramp Without Embankment) | Peripheral Blasting (Ramp with Embankment) |

|---|---|---|

| Number of rows | 4 | 4 |

| Number of boreholes | 172 | 172 |

| Boreholes depth range, m | 1.9–22.1 | 21.0–23.0 |

| Subdrill, m | 0.5 | 0.5 |

| Hole diameter, mm | 89 | 89 |

| Total drilling length, m | 2012.1 | 3769.8 |

| Average face burden, m | 3.3 | 3.4 |

| Average pattern burden, m | 3.4 | 3.3 |

| Average spacing, m | 3.8 | 3.8 |

| Average bench height, m | 11.3 | 21.2 |

| Rock volume, m3 | 24,964.9 | 47,476.9 |

| Total ANFO explosives weight, kg | 7883.7 | 17,478.9 |

| Number of boosters | 172 | 172 |

| Total weight of booster explosives, kg | 77.4 | 77.4 |

| Type of Explosives | Fumes Volume, m3⋅kg−1 | ||

|---|---|---|---|

| CO2 | CO | NOx | |

| ANFO | 0.1445 | 0.0164 | 0.0131 |

| Dynamite | 0.1513 | 0.0057 | 0.00139 |

| Parameter | Fume Emission, kg | ||

|---|---|---|---|

| CO2 | CO | NOx | |

| Index value, in the case of CO2 kg·dm−3, other: g·h−1 | 3167 | 240 | 72 |

| In-pit ramp with embankment | 41,171 | 1.08 | 0.29 |

| In-pit ramp without embankment | 20,586 | 0.54 | 0.15 |

| Type of Construction | Explosive | Fume Emission, kg | ||

|---|---|---|---|---|

| CO2 | CO | NOx | ||

| Ramp with embankment | ANFO | 4697.8 | 329.7 | 396.1 |

| Priming | 21.8 | 0.5 | 0.2 | |

| Overall | 4719.6 | 330.2 | 396.3 | |

| Ramp without embankment | ANFO | 2118.9 | 148.7 | 178.7 |

| Priming | 21.8 | 0.5 | 0.2 | |

| Overall | 2140.7 | 149.2 | 178.9 | |

| Mining Method | Overall Fume Emission from Each Construction Stage, tons | |||

|---|---|---|---|---|

| Drilling | Loading | Detonation | Muckpile Extraction | |

| Blasting at the location of the ramp (ramp without embankment) | 5.471 | 0.207 | 2.469 | 0.000 |

| Peripheral blasting (ramp with embankment) | 10.251 | 0.413 | 5.446 | 6.427 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudek, M.; Dworzak, M.; Biessikirski, A. Influence of Blasting Approaches in In-Pit Haul Road Construction on Emission Levels and Resource Management: A Case Study from the Holcim “Dubie” Open-Pit Mine. Appl. Sci. 2025, 15, 12310. https://doi.org/10.3390/app152212310

Dudek M, Dworzak M, Biessikirski A. Influence of Blasting Approaches in In-Pit Haul Road Construction on Emission Levels and Resource Management: A Case Study from the Holcim “Dubie” Open-Pit Mine. Applied Sciences. 2025; 15(22):12310. https://doi.org/10.3390/app152212310

Chicago/Turabian StyleDudek, Michał, Michał Dworzak, and Andrzej Biessikirski. 2025. "Influence of Blasting Approaches in In-Pit Haul Road Construction on Emission Levels and Resource Management: A Case Study from the Holcim “Dubie” Open-Pit Mine" Applied Sciences 15, no. 22: 12310. https://doi.org/10.3390/app152212310

APA StyleDudek, M., Dworzak, M., & Biessikirski, A. (2025). Influence of Blasting Approaches in In-Pit Haul Road Construction on Emission Levels and Resource Management: A Case Study from the Holcim “Dubie” Open-Pit Mine. Applied Sciences, 15(22), 12310. https://doi.org/10.3390/app152212310