1. Introduction

The increasing demand for lightweight, high-performance structures in space, aerospace and transportation sectors has accelerated the development of polymer-based additive manufacturing (AM) technologies. These Material Extrusion (MEX) AM processes and direct ink writing have emerged as cost-effective solutions for fabricating complex geometries with tailored mechanical properties [

1]. A key strategy in achieving lightweight components is topology optimization, which enables efficient material distribution based on structural performance constraints [

2]. Complementary approaches, including lattice structures, variable infill densities, and advanced infill patterns like gyroids, further enhance weight reduction while preserving mechanical integrity [

3].

Material Extrusion (MEX) AM is particularly well-suited for lightweighting due to its ability to produce intricate geometries with controlled material placement. Studies have reported up to 40% weight reduction in polymer AM parts without compromising structural performance [

4]. The integration of high-performance polymer composites, reinforced with carbon fibers, glass fibers, or nanomaterials, has expanded the applicability of AM to demanding sectors such as aerospace and biomedical engineering [

5].

Recent research demonstrates that combining topology optimization with lattice structures can yield up to 60% weight savings while improving mechanical performance [

6]. Gyroid infill patterns, for instance, have shown increase in tensile strength and a 41.8% reduction in weight compared to conventional grid patterns [

7]. Topology optimization of hydraulic valve blocks specifically tailored to additive manufacturing constraints demonstrated to reduce mass and integrate internal fluid channels without extra machining [

8]. At the micro-architectural scale, topology optimization has also been used to generate novel metamaterial lattices (e.g., pentamode designs) that achieve extremely effective properties while remaining manufacturable via AM. At the same time, recent advances emphasize that geometry-only optimization is insufficient. Process effects and infill strategy must be considered to guarantee as-built integrity [

9]. A digital workflow that couples topology optimization with process simulation and local lattice sizing in metal AM is recently demonstrated and showing that process-aware design leads to more reliable as-built parts [

10]. For material-extrusion AM specifically, several recent works demonstrate hybrid or concurrent methods that optimize both topology and infill orientation/angle to capture the manufacturing anisotropy and printability constraints of extrusion processes [

11,

12,

13].

In aerospace applications, compression loading is a critical design consideration, particularly for satellite components. Optimized topology and infill strategies have been shown to enhance load-bearing efficiency [

14]. Polymer AM has proven effective in fabricating satellite structures that require high strength-to-weight ratios. Robot-assisted AM for continuous fiber composites has achieved up to 30% improvements in stiffness and weight efficiency over traditional methods [

15], while field-assisted AM techniques have enhanced microstructural uniformity, leading to a 21.6% increase in compressive strength [

16]. Hybrid polymer-metal composites, such as metal mesh-reinforced polymers, have demonstrated a 40% increase in stiffness with minimal weight penalties [

17].

Gradient infill strategies have also shown promise, enabling up to 45% weight reduction while maintaining impact resistance [

18]. Satellite brackets manufactured via AM have exhibited a 35% improvement in buckling resistance through topology-optimized lattice designs [

19]. Cost-effectiveness is another advantage, with optimized infill and topology strategies reducing material usage by up to 55% [

20], and tailored infill densities improving fatigue life by 20% under cyclic loading [

21].

Applications of polymer AM lightweighting strategies continue to expand across multiple industries. In aerospace, topology-optimized AM brackets have led to a 40% weight reduction while improving load distribution under compression forces [

22]. In automotive applications, AM lattice structures have reduced component weight by up to 35% while maintaining crashworthiness and structural integrity [

23]. Applications of polymer AM lightweighting extend beyond aerospace to automotive sectors. UAV structures have achieved 30% weight reductions without compromising aerodynamics [

24], while AM implants have reduced weight by 45% while maintaining biocompatibility [

25]. Compression-loaded AM structures designed with optimized parameters can withstand forces up to 70% higher than conventional parts [

26], and high-performance polymer composites have achieved compressive strengths exceeding 100 MPa at densities below 1.2 g/cm

3 [

27]. Additionally, advancements in functionally graded infill designs have resulted in a 25% improvement in energy absorption capacity in impact applications [

28,

29].

Material selection remains a critical factor in AM lightweighting. Carbon fiber-reinforced polymers can reach tensile strengths of 150 MPa, offering superior strength-to-weight ratios with reference to virgin polymers [

30]. Processing parameters such as layer thickness and print speed also influence mechanical performance, with optimized settings improving compressive strength by up to 30% [

31].

As lightweighting becomes increasingly vital across industries, polymer AM offers a unique capability to tailor mechanical properties through the integration of topology optimization, advanced infill strategies, and composite materials. The continued evolution of AM technologies, including composite materials, adaptive infill designs, and real-time optimization algorithms, positions polymer AM as a key enabler of next-generation lightweight structures. However, existing studies often focus on single-material systems or isolated design parameters, leaving a gap in the understanding of how topology and infill strategies interact across different composite materials under compression loading. This study addresses that gap by systematically evaluating the combined effects of topology optimization and variable infill density using three polymer composites, PPA-CF, PAHT-CF, and ABS. Through experimental testing and comparative analysis, the research establishes design-to-performance relationships that inform the development of lightweight, structurally reliable satellite components. The outcomes contribute to advancing resource-efficient manufacturing practices and offering scalable solutions for space, aerospace and other high-value manufacturing sectors.

2. Materials and Methods

Figure 1 illustrates the overall workflow of the study, integrating computational optimization with experimental validation. The process begins with topology optimization to minimize part volume while maintaining structural integrity. Optimized designs are then manufactured via Material Extrusion AM and subjected to compression testing. Experimental results are analyzed to evaluate the trade-offs between topology and infill, guiding the selection of optimal configurations. The workflow culminates in a practical design and manufacturing strategy for lightweight satellite components.

2.1. Materials

Three polymer feedstock materials were selected for this study based on their mechanical properties, cost-effectiveness, and compatibility with Material Extrusion (MEX) additive manufacturing processes. These materials include Acrylonitrile Butadiene Styrene (ABS), Polyamide with Carbon Fiber reinforcements (PAHT-CF), and Polyphthalamide with Carbon Fiber reinforcements (PPA-CF).

ABS is a widely used thermoplastic in additive manufacturing due to its affordability and dimensional stability. However, its mechanical performance, particularly under compressive loads, is limited compared to reinforced composites. PAHT-CF is a composite filament composed of high-quality nylon reinforced with micro-carbon fibers. It offers a balanced combination of strength, toughness, and thermal resistance, making it suitable for moderately demanding structural applications. Its high-temperature tolerance and improved stiffness over standard polyamides make it a strong candidate for space components. PPA-CF represents a high-performance carbon fiber-reinforced polyphthalamide composite. It has superior mechanical properties, chemical resistance, and dimensional stability. PPA-CF is particularly well-suited for high-load, high-temperature environments such as satellite structures and other space applications.

Key material properties—including density, tensile strength (

Z-direction), Young’s modulus (

Z-direction), and cost per gram—were obtained from manufacturer datasheets, and they are reported in

Table 1 and used to inform design and performance comparisons throughout the study.

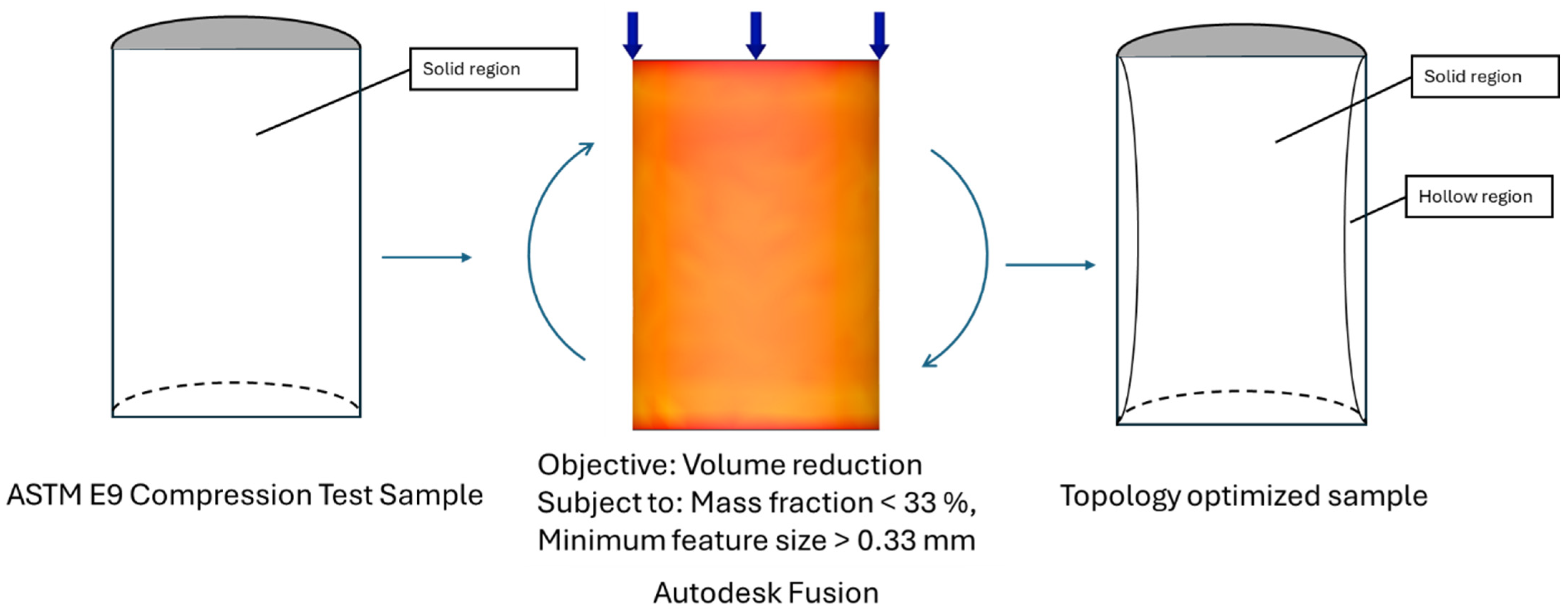

2.2. Topology Optimization of Test Samples

Topology optimization was performed using Autodesk Fusion’s built-in optimization module, targeting minimum part volume while maintaining structural integrity under compressive loading. The optimization process focuses on cylindrical specimens because these specimens are later manufactured and tested according to ASTM E9 [

32]. The optimization problem can be expressed mathematically as

where

is the total volume of the structure as a function of element densities ;

is the volume of finite element ;

is the global stiffness matrix, is the displacement vector, and is the applied load vector;

is the von Mises stress in element , constrained below ;

and enforce the target mass reduction (67–84% mass retention, corresponding to 16–33% weight savings);

is the minimum feature density to ensure manufacturability (0.2 mm minimum feature size in current study).

The optimization objective was to minimize volume, subject to two key constraints: Mass retention between 84% and 67%, corresponding to weight savings of approximately 16% to 33%. A minimum feature size of 0.2 mm was selected, ensuring manufacturability and structural continuity during Material Extrusion (MEX) AM.

A static compressive load of 40 MPa was applied to the top surface of each cylindrical model to simulate operational conditions, as shown in

Figure 2. This loading condition reflects typical stress scenarios encountered in CubeSat frames during launching phase [

33]. The optimization algorithm redistributed material within the design space to maintain stiffness and load-bearing capacity while reducing unnecessary mass. Autodesk Fusion employs a density-based (SIMP) method, where material distribution is iteratively updated using finite element analysis. The algorithm converges when the change in objective function between iterations is below 0.01%. The cylindrical domain was discretized using tetrahedral elements with element size of 0.2 mm. The SIMP penalization factor was set to 3, promoting clear void-solid distinction while avoiding numerical instabilities. CAD files of the resulting geometries were exported after optimization. This approach allows a quantitative and reproducible optimization framework, while retaining a design-centric focus to evaluate practical manufacturability in Material Extrusion AM. The optimized designs achieved weight savings of approximately 16% to 33% solely through topology optimization, prior to any infill density adjustments. These models served as the basis for further experimental evaluation, including variable infill strategies and compression testing.

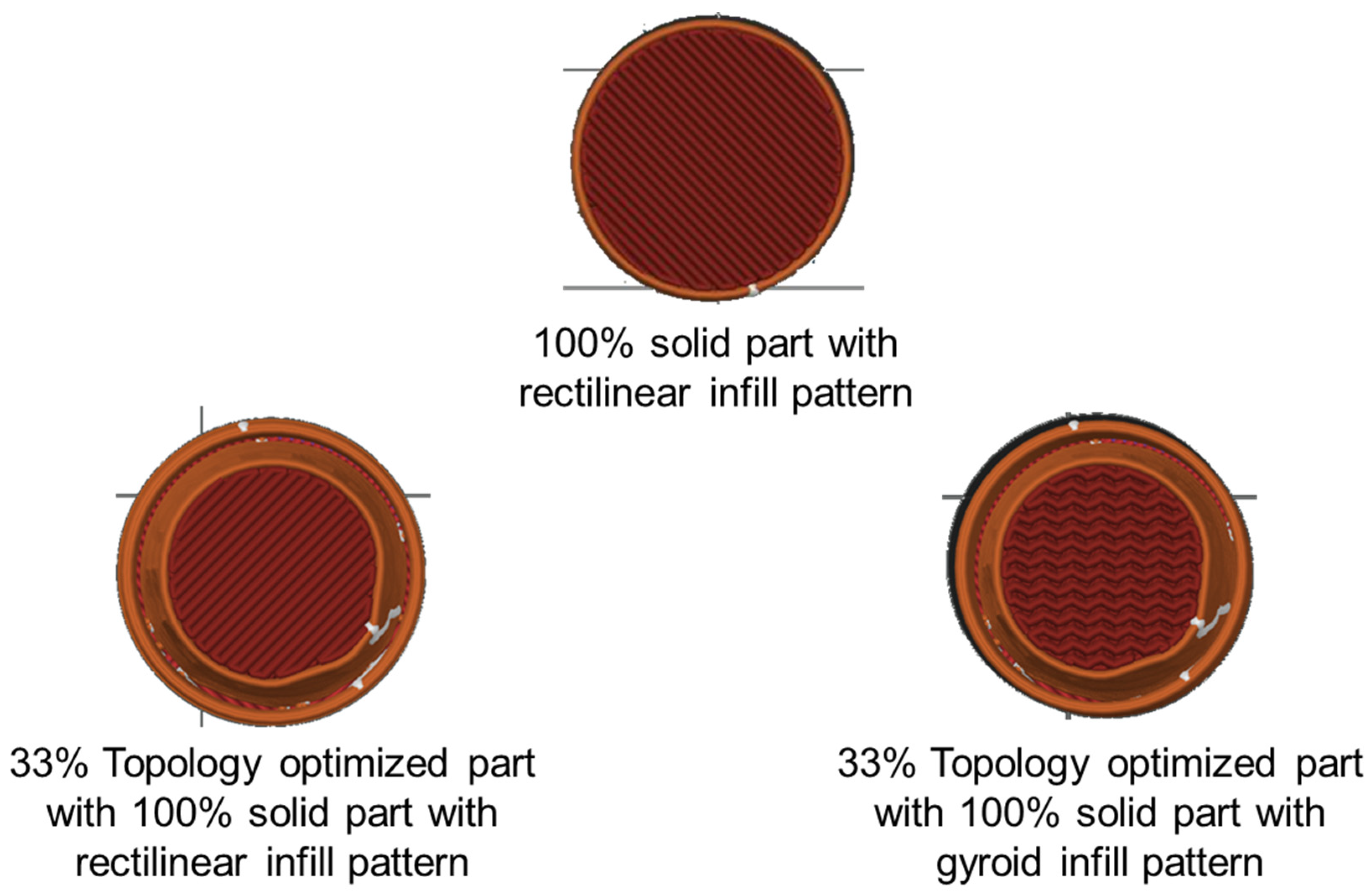

2.3. Experimental Design

A structured Design of Experiments (DoE) approach was adopted to systematically investigate the effects of topology optimization and infill density on mechanical performance. All three polymer feedstock materials were evaluated under a matrix of design and process parameters. A total of 54 experimental conditions were defined, combining the following factors: Three levels of topology optimization: 0%, 16.5%, and 33% weight reduction, achieved through Autodesk Fusion simulations under 40 MPa compressive loading. Three levels of infill density control: 0%, 16.5%, and 33% weight reduction, implemented via Bambu Studio v2.2.0 slicing software as shown in

Figure 3. Topology optimization redistributed material internally is also shown, external dimensions remain constant allowing specimen dimensions conformance to ASTM E9 standard [

32]. This resulted in nine unique design configurations per material and infill pattern, as shown in

Table 2. Two infill patterns: Rectilinear and Gyroid, selected for their contrasting structural characteristics and manufacturability.

Each configuration was fabricated in triplicate to ensure statistical reliability and repeatability, yielding a total of 162 printed specimens (3 materials × 2 infill patterns × 9 configurations × 3 replicates).

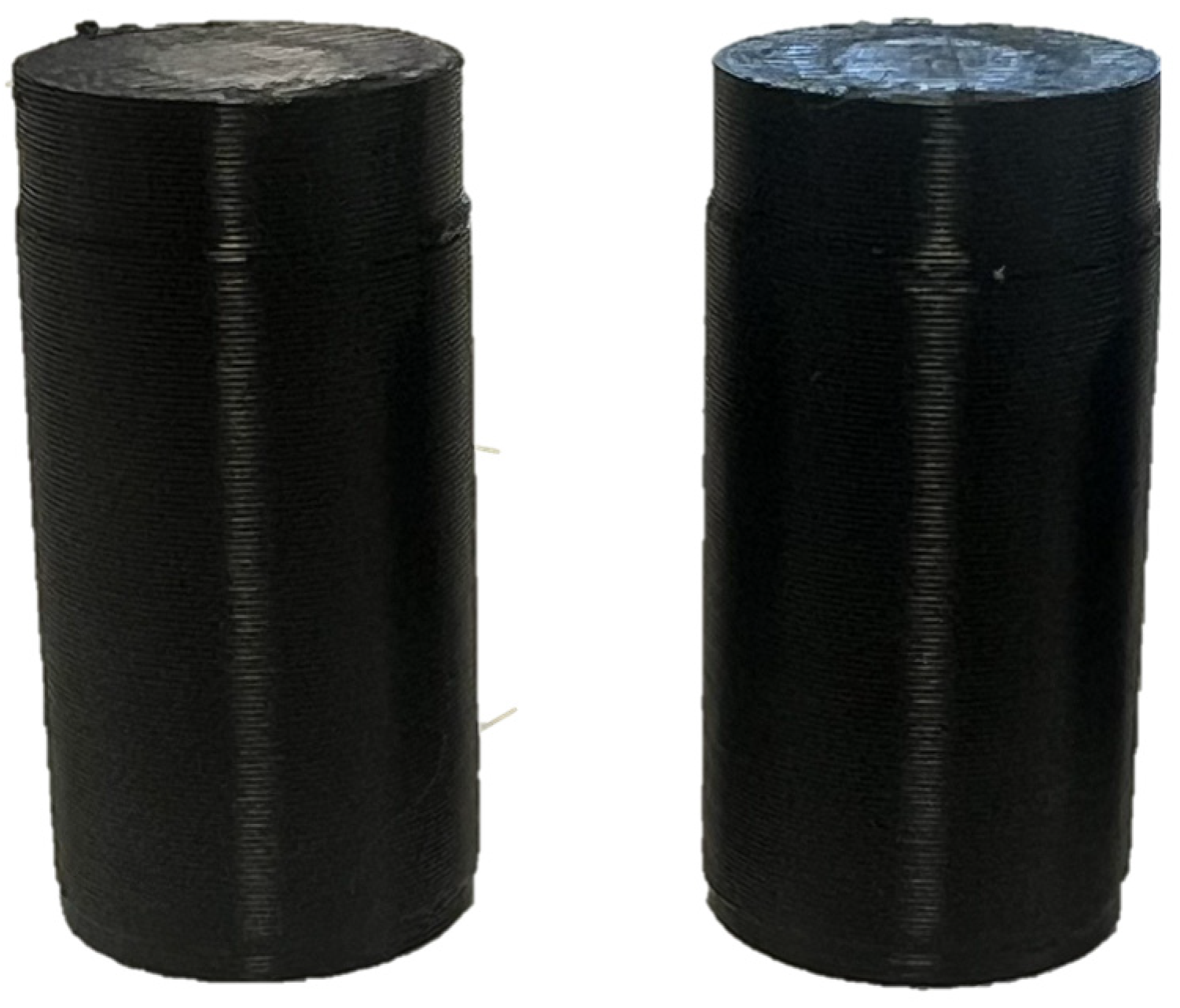

2.4. Manufacturing of Test Samples

All specimens were fabricated using the Bambu Lab X1-E desktop MEX AM system as shown in

Figure 4, selected for its precision, multi-material compatibility, and suitability for high-performance polymer additive manufacturing. The slicing and print preparation were carried out using Bambu Studio software, where optimized STEP files, generated through topology optimization, were configured with varying infill densities and patterns (rectilinear and gyroid). A standardized set of printing parameters was maintained throughout the study to ensure reproducibility and consistency across all test specimens. All samples were printed using a 0.4 mm nozzle, a first layer height of 0.2 mm, and a vertical print orientation. Retraction was disabled and part cooling fans were turned off, while a chamber heated to 60 °C was used. Filaments were pre-dried at 100 °C for 8 h, and a glue stick was applied to improve bed adhesion. In addition, two perimeters, three floor layers, and three roof layers were employed for all prints, with a layer height of 0.2 mm and a print speed of 30–50 mm/s to ensure uniform deposition across trials. Material color was standardized to black to avoid the effects of dyes or pigments on printability and mechanical performance. Extrusion and bed temperatures were set according to manufacturer datasheets (Bambu Lab, Shenzhen, China, bambulab.com/en-gb/filament/guide (accessed on 23 October 2024) for each material type (ABS, PAHT-CF, and PPA-CF). All other printer settings were kept at standard values to maintain consistency among different materials and infill patterns.

A total of 162 cylindrical specimens were printed, covering all combinations of material type, topology optimization level, infill density, and infill pattern, as shown in

Figure 3. Each specimen was designed to conform to ASTM E9 standards for compression testing, ensuring dimensional consistency and comparability across trials [

32]. The estimated printing time, part weight, and energy consumption were recorded from the slicing software to support sustainability and process efficiency analysis.

The calculated part weights were based on slicing software calculations and are compared with measured weights of 162 specimens. Measured weights were generally slightly lower than those calculated from slicing software, reflecting real printing effects such as shrinkage and voids. PPA-CF showed the largest deviations (~10–15%) for gyroid structures with low infill, while PAHT-CF was within ±5% of predictions. ABS exhibited moderate differences (~8%), influenced by topology and infill. These results highlight that actual printed weights deviate slightly from theoretical targets, particularly for lightweight and highly optimized designs.

2.5. Experimental Characterization

Compression testing was conducted using a Zwick Roell Z150 universal testing machine under quasi-static loading conditions. Compression tests were conducted according to ASTM E9 at a nominal strain rate of 0.001 s

−1 (≈1 mm/min). Machine compliance was determined using a rigid calibration specimen, and the corresponding displacement correction was applied to all test data to ensure accurate evaluation of mechanical properties. The tests were designed to evaluate key mechanical responses including stiffness, deformation behavior, and failure modes. As shown in

Figure 5, the standardized cylindrical geometry was used for all specimens (

Figure 5a), and visual records were captured before (

Figure 5b) and after deformation (

Figure 5c). Typical failure modes such as outer shell delamination and inner core bulging were observed (

Figure 5d), particularly in specimens manufactured and tested from experiment settings 8 and 9 of ABS and PAHT-CF with higher topology optimization-based mass reductions. These observations were critical in correlating design parameters with structural performance, enabling a robust comparison across materials and optimization strategies.

3. Results

A comprehensive set of evaluation metrics was applied across all experimental conditions to assess the performance of the fabricated specimens. Energy consumption (Wh) was calculated using machine usage time and average power consumption (Wh) for Bambu Lab X1E Series Desktop AM System, in which the preparation and printing durations for each part and material were recorded from the slicer software. Manufacturing cost (£) was determined by combining material cost per gram, part weight, fixed machine cost per minute, and total print time. Dimensional accuracy was evaluated by measuring deviations between the printed parts and their corresponding CAD models, expressed as a percentage error. These metrics provided insights into the efficiency, precision, and economic viability of each design and manufacturing configuration.

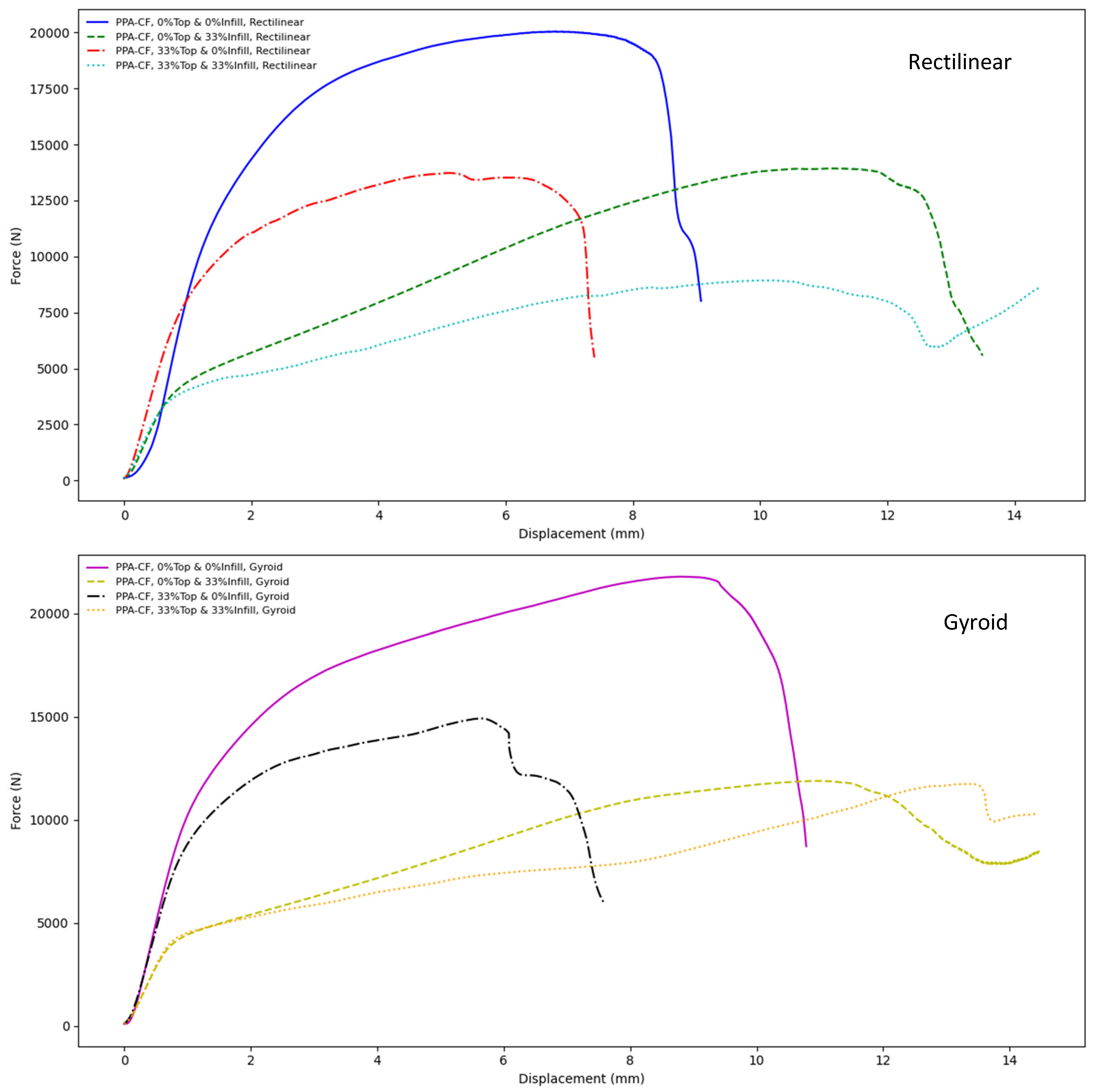

Mechanical properties were evaluated through quasi-static compression testing, where stress–strain curves were generated for each specimen. A representative comparison of stress–strain curves for PPA-CF specimens, as shown in

Figure 6, revealed similar deformation profiles for both rectilinear and gyroid infill patterns. Notably, as lightweighting increased—achieved through topology optimization and infill density reduction, exhibited a decrease in stiffness and compressive strength yet demonstrated a marked increase in strain tolerance. This behavior is attributed to the reduced internal constraint and enhanced flexibility of the composite polymer structures, which allow for greater deformation before failure. While this trade-off may reduce peak load-bearing capacity, it significantly improves energy absorption and plastic deformation capability, which are advantageous in applications requiring controlled failure or impact resistance.

From the stress–strain curves, key mechanical properties were extracted, including Young’s Modulus (Ec), representing stiffness; Yield Strength (YS), indicating the onset of plastic deformation; Ultimate Compression Strength (UCS), denoting the maximum stress before failure; and Maximum Elongation (εM), reflecting the material’s ability to deform plastically. These values formed the basis for comparative analysis across different materials, infill patterns, and optimization levels, enabling a deeper understanding of how design and material choices influence structural performance under compressive loading.

The mechanical test results were analyzed statistically across three replicates per experimental condition. The corresponding standard deviations (

Table 3) quantify the repeatability of the compressive properties for each material and infill strategy. The results indicate that PPA-CF exhibited the lowest standard deviations in elastic modulus and yield strength, demonstrating highly consistent mechanical behavior and excellent process repeatability. In contrast, ABS showed the greatest scatter, reflecting its higher thermal distortion sensitivity during polymer extrusion. The gyroid infill pattern produced generally lower variability than the rectilinear pattern, suggesting that the smoother load paths in the Gyroid geometry promote more uniform stress distribution.

These findings were statistically supported through a multifactorial ANOVA, which confirmed that material type (p < 0.01) exerted the dominant influence on mechanical response, while topology optimization level and infill density also showed statistically significant, though smaller, effects (p < 0.05). This indicates that the selection of polymer composite material contributes most strongly to mechanical performance consistency, with structural design parameters providing secondary but meaningful optimization leverage.

The average values were determined from three replicates using 95% confidence intervals to ensure statistically reliable representation of each condition and used for further analysis.

3.1. Weight Saving Effect on Stiffness and Part Strength

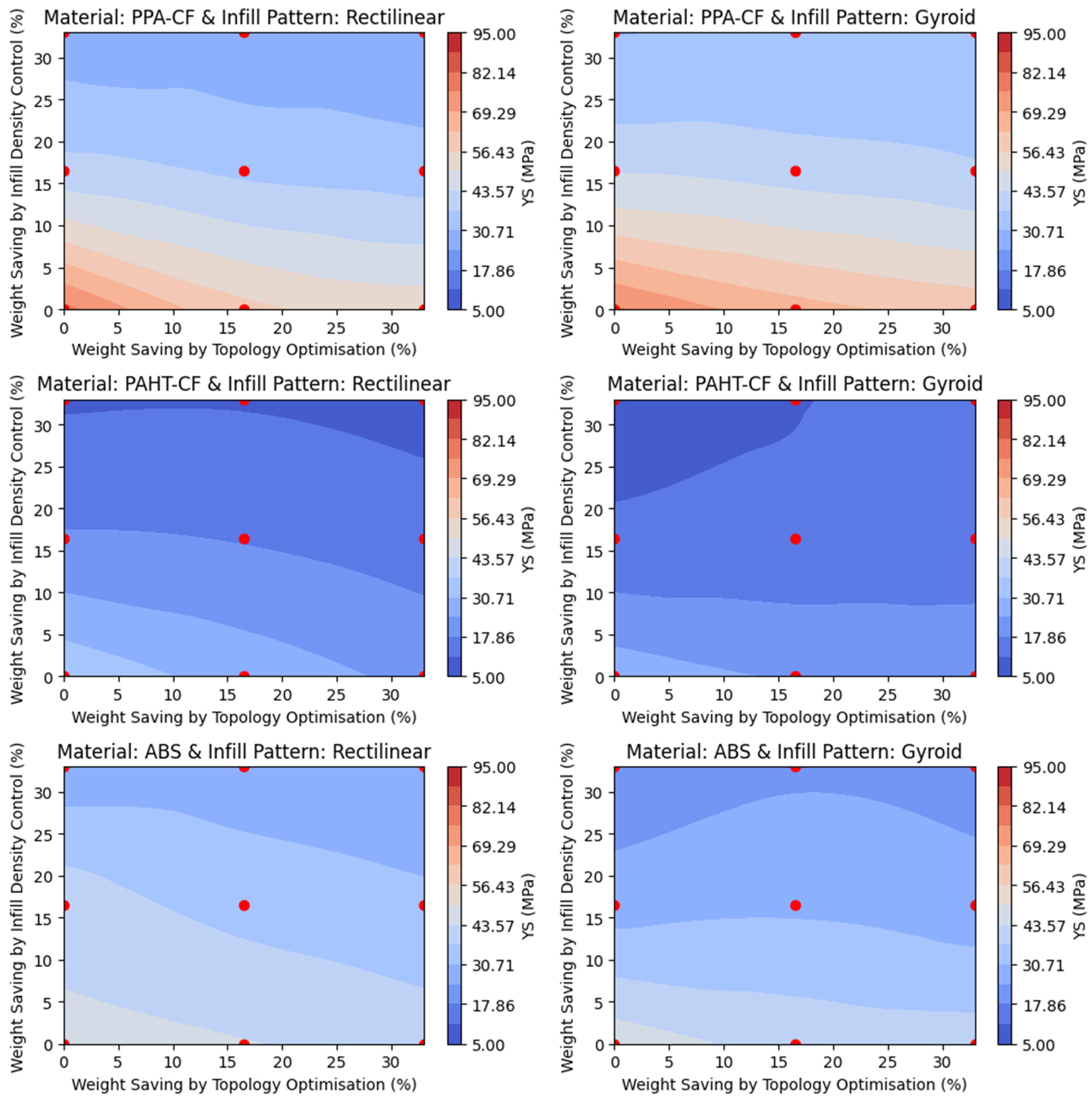

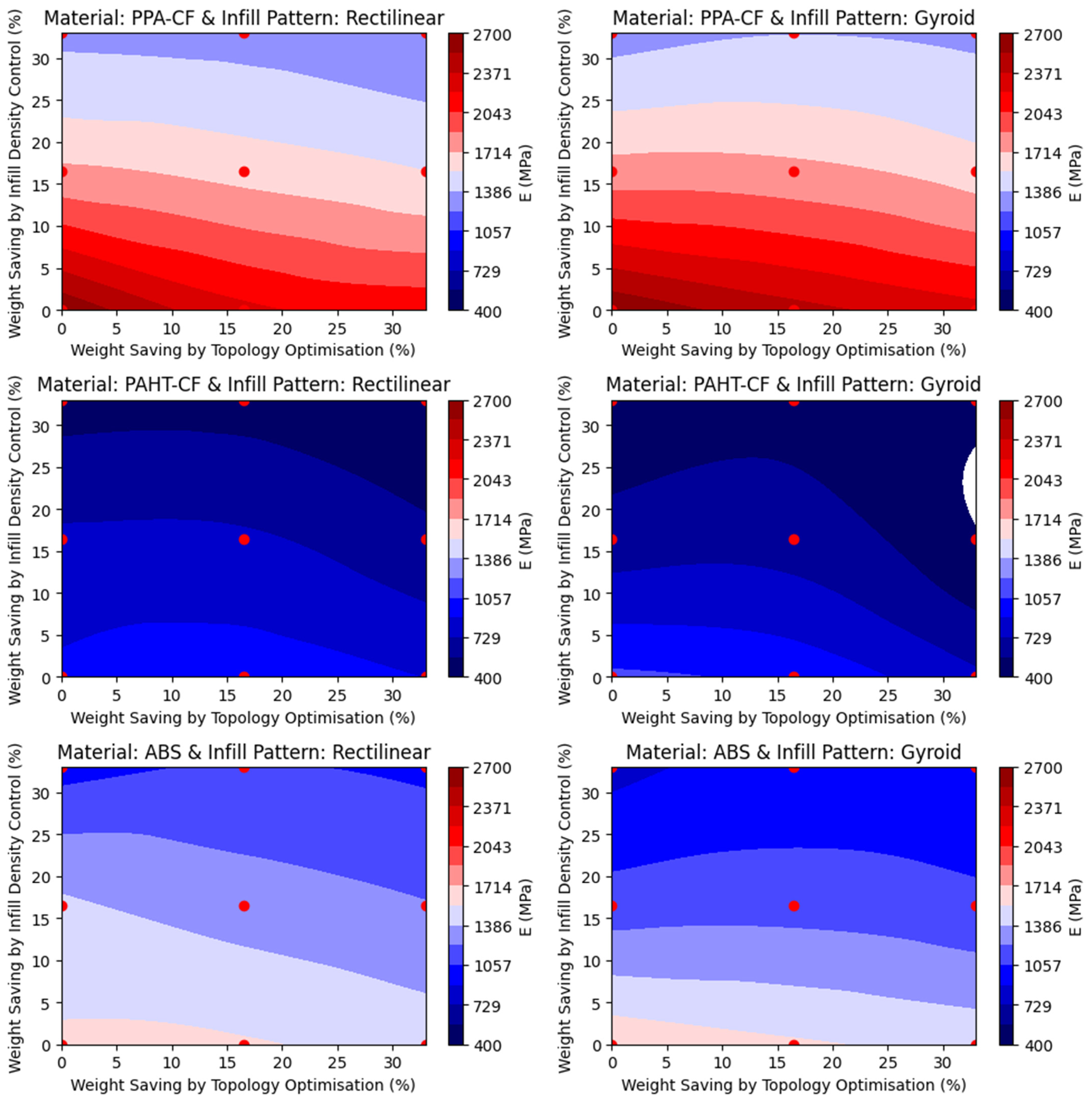

Contour plots (

Figure 7 and

Figure 8) were generated to visualize the influence of design and material parameters on mechanical performance, Young’s Modulus (Ec, MPa) and Yield Strength (YS, MPa), across varying levels of topology optimization and infill density control. These plots provided a comparative view of stiffness and strength for different combinations of material type (PPA-CF, PAHT-CF, ABS) and infill pattern (Rectilinear, Gyroid).

The analysis revealed that PPA-CF with gyroid infill consistently achieved the highest stiffness and yield strength, even at significant weight savings—exceeding 33% through topology optimization and 15% through infill density control. In contrast, PAHT-CF and ABS showed lower mechanical performance, particularly at higher lightweighting levels. The gyroid pattern demonstrated superior mechanical behavior compared to rectilinear infill, likely due to its continuous, isotropic structure that distributes stress more evenly under compression.

These contour plots highlight the trade-offs between weight reduction and mechanical integrity and underscore the importance of selecting optimal material–design combinations. The results support the use of high-performance composites and advanced infill strategies for applications requiring both lightweighting and structural reliability, such as satellite support components.

3.2. Strength-to-Weight and Strength-to-Cost Ratio

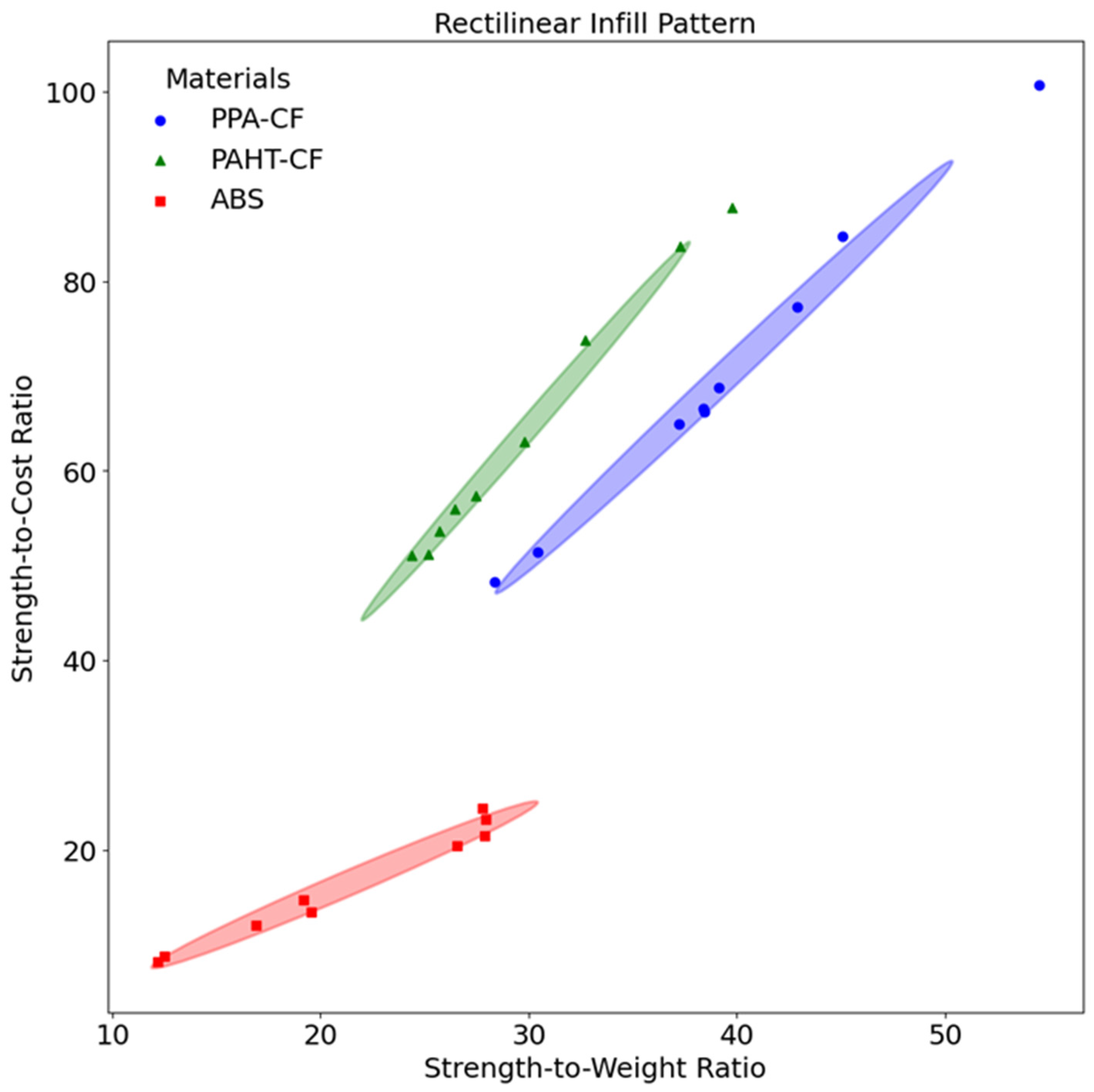

An evaluation of strength-to-weight and strength-to-cost ratios was conducted across all material and infill pattern combinations to assess structural efficiency and economic viability. The analysis shown in

Figure 9 was performed separately for rectilinear and gyroid infill patterns, with results indicating that minimal variation was observed between the two infill geometries. This suggests that the infill pattern had a relatively minor influence on these performance metrics, while material selection emerged as the dominant factor.

Across both infill types, PPA-CF consistently demonstrated superior performance, achieving strength-to-weight ratios ranging from 28 to 55 and strength-to-cost ratios between 48 and 100 in rectilinear configurations. Similar trends were observed in gyroid patterns, where PPA-CF values ranged from 32 to 52 for strength-to-weight ratio and 58 to 94 for strength-to-cost ratio. These results confirm the high mechanical efficiency and cost-effectiveness of carbon fiber-reinforced polyphthalamide, particularly in lightweight applications. PAHT-CF, while moderately effective, exhibited lower performance in rectilinear patterns. In gyroid configurations, these values declined further, indicating reduced efficiency under more aggressive lightweighting.

ABS, the least performant material, showed significantly lower ratios across both infill types. Rectilinear and Gyroid patterns yielded similar results, with strength-to-weight ratios as low as 13 and strength-to-cost ratios dropping to 9, underscoring the limitations of ABS in high-performance structural applications.

Overall, the analysis confirmed that material choice had a far greater impact on structural efficiency than infill geometry, with PPA-CF emerging as the most suitable candidate for applications requiring high strength-to-weight and strength-to-cost performance. These findings support the prioritization of advanced composite materials in extrusion-based additive manufacturing for space and other high-value manufacturing sectors.

The energy consumption and cost per part for test specimens fabricated from three material types, ABS, PAHT-CF, and PPA-CF, using gyroid and rectilinear infill patterns were evaluated. It should be noted that the cost and energy estimations are based on laboratory-scale cylinder manufacturing and machine power calculation under theoretical conditions from slicing software. Therefore, the reported values represent indicative trends rather than absolute metrics and may vary with production scale, equipment efficiency, or process settings.

As summarized in

Figure 10, PPA-CF exhibited the lowest overall energy demand (≈3.95 Wh per part) and the lowest cost per part (£1.63), demonstrating clear advantages in both manufacturing efficiency and economic performance. Among the infill strategies, minor variations were observed between gyroid and rectilinear patterns, indicating that material selection exerts a more dominant influence on energy and cost than infill geometry in this case. Moreover, superior specific strength, stiffness, and thermal stability of PPA-CF make it not only the most energy- and cost-efficient option, but also structurally advantageous for lightweight, high-integrity applications. These parameters were therefore incorporated into the subsequent multi-objective optimization framework to balance mechanical performance with sustainability and cost efficiency.

3.3. Multi-Objective Optimization

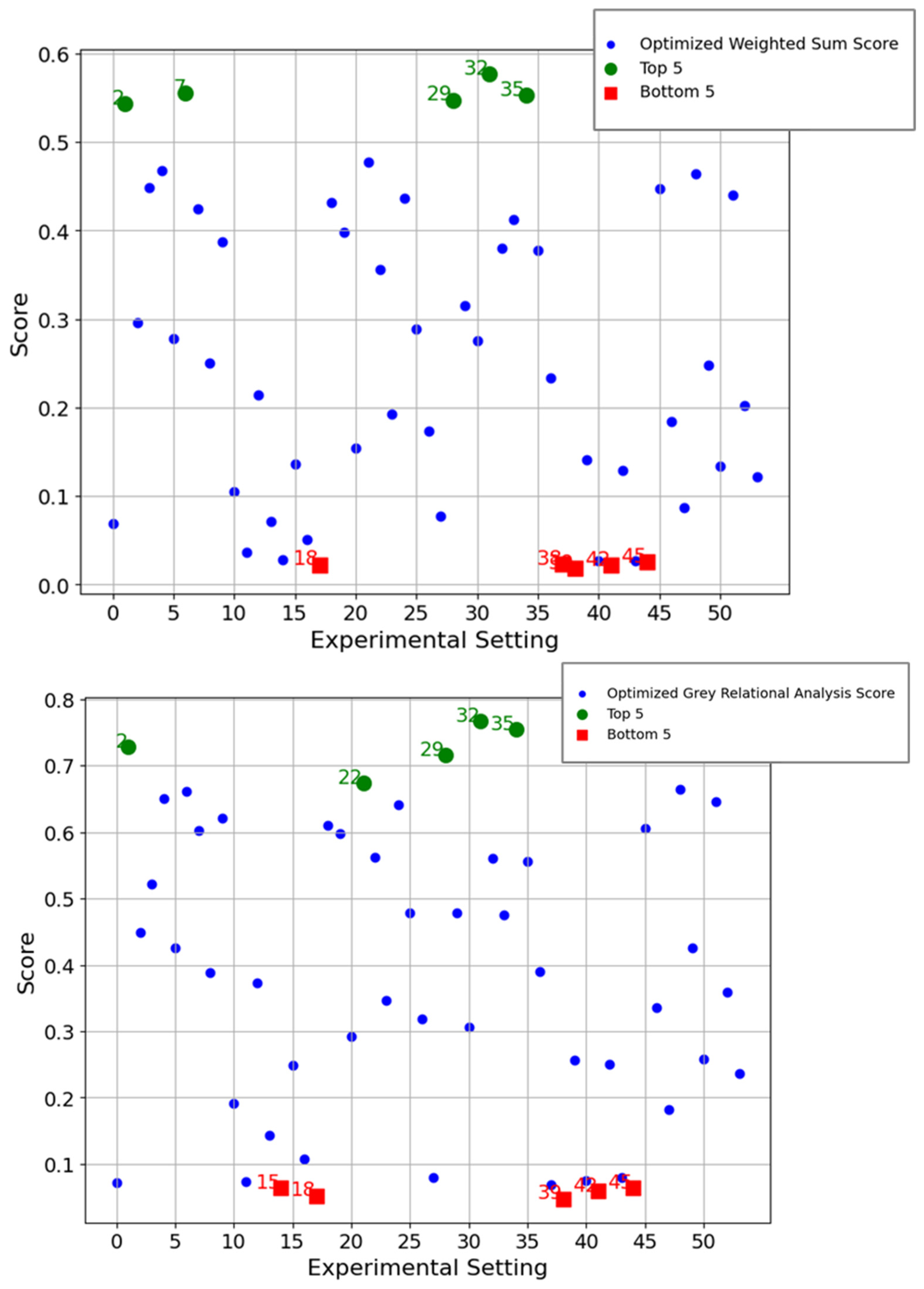

A multi-criteria evaluation of all experimental configurations was conducted using two decision-making techniques: the Weighted Sum Method (WSM) and Grey Relational Analysis (GRA). These methods were selected to identify optimal combinations of topology optimization, infill density control, and material selection based on multiple performance metrics relevant to industrial implementation. The metrics considered included energy consumption, manufacturing cost, dimensional error, stiffness (Young’s Modulus, Ec), and yield strength (YS).

In the WSM approach, normalization was first applied to all raw performance values using the min-max normalization method, as defined in Equation (1):

where X represents the raw value of each metric, and X

norm is the normalized value. This ensured that all metrics were scaled between 0 and 1, allowing for direct comparison. Equal weights of 0.2 were assigned to each metric to reflect balanced importance across structural and economic objectives. Equal weighting was applied to obtain rapid insights; the top five experimental settings were mapped to form a Pareto front and discussed below. For each experimental configuration, a weighted score was calculated using Equation (2):

Based on the computed scores, all configurations were ranked, and the top five and bottom five settings were identified for further analysis. In parallel, Grey Relational Analysis (GRA) was applied to assess the proximity of each configuration to the ideal and negative ideal solutions. The ideal solution was defined by the best values for each metric (e.g., minimum energy, cost, and error; maximum Ec and YS), while the negative ideal represented the worst-case scenario. The Grey Relational Coefficient (GRC) was calculated using Equation (3):

where D is the absolute difference between the normalized value and the ideal value, D

min and D

max are the minimum and maximum differences across all settings, and ρ is the distinguishing coefficient, set to 0.5. The Grey Relational Grade (GRG) was then computed by averaging the GRCs across all metrics for each configuration. Rankings were established based on GRG values, and the top-performing settings were identified.

The results from both methods were visualized in

Figure 11, where each point represents an experimental configuration and its corresponding score. The top five configurations were highlighted in green, and the bottom five in red. Notably, the configuration involving PPA-CF with 33% topology optimization and gyroid infill emerged as the most effective, offering optimal trade-offs between mechanical integrity, cost, and manufacturability. Other high-ranking configurations included moderate topology optimization (16.5%) combined with controlled infill density (16.5%) using PPA-CF.

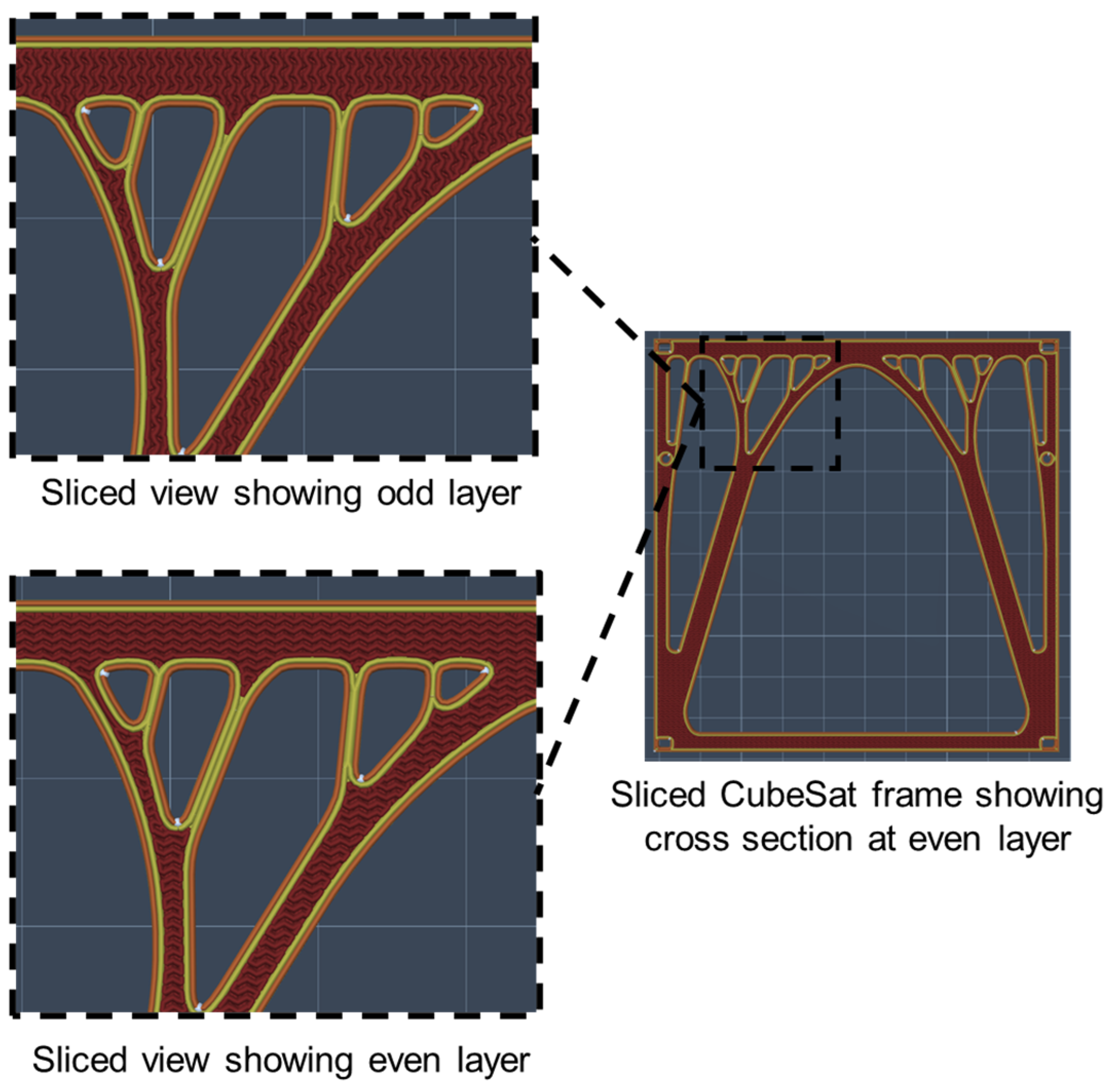

In order to illustrate the practical relevance of the optimized configurations, a CubeSat frame was conceptually designed and manufactured using the best-performing setting identified through multi-objective optimization. The selected configuration, PPA-CF with gyroid infill and 33% topology optimization, served as a demonstrator for lightweight structural design in small satellite platforms (

Figure 12). The frame exhibited notable weight reduction relative to aluminum and unoptimized polymeric structures while maintaining sufficient mechanical integrity under simulated compressive loads (~40 MPa). This conceptual demonstration highlights the feasibility and potential of applying the proposed design methodology to space-grade components, providing an early proof-of-concept for future experimental validation and integration into satellite systems. It highlights the potential for cost-effective, scalable, and structurally sound solutions in satellite design, particularly for low-Earth orbit missions and modular payload systems.

4. Discussion

The results of this study demonstrate the effectiveness of integrating topology optimization and infill density control in Material Extrusion (MEX) AM to achieve lightweight, structurally sound components. The findings align with previous research that emphasizes the role of design-driven material distribution in enhancing mechanical performance while reducing resource consumption. However, this study expands the scope by applying multi-objective decision-making techniques to simultaneously evaluate energy, cost, dimensional accuracy, and mechanical properties.

The use of PPA-CF with gyroid infill and 33% topology optimization consistently ranked highest across both Weighted Sum Method and Grey Relational Analysis, confirming the hypothesis that high-performance composite materials combined with advanced infill geometries yield optimal trade-offs. These results are particularly relevant for aerospace and space applications, where mass reduction directly translates to lower launch costs and increased payload capacity.

The CubeSat frame demonstration validates the practical applicability of the proposed methodology, showcasing how optimized polymer AM components can meet structural requirements in real-world space systems. Beyond satellite structures, the approach can be extended to sensor housing, brackets, and deployable mechanisms in aerospace, automotive, and defense sectors. The methodology also supports sustainability goals by minimizing material usage and energy consumption.

Future research should explore additional load cases, material combinations, and integrated testing methods to further enhance scalability and real-time optimization capabilities.