Research on MPC Path-Tracking Control Algorithm Based on the Generalized-Dynamics Model of “Steering Robot-Controlled Vehicle”

Featured Application

Abstract

1. Introduction

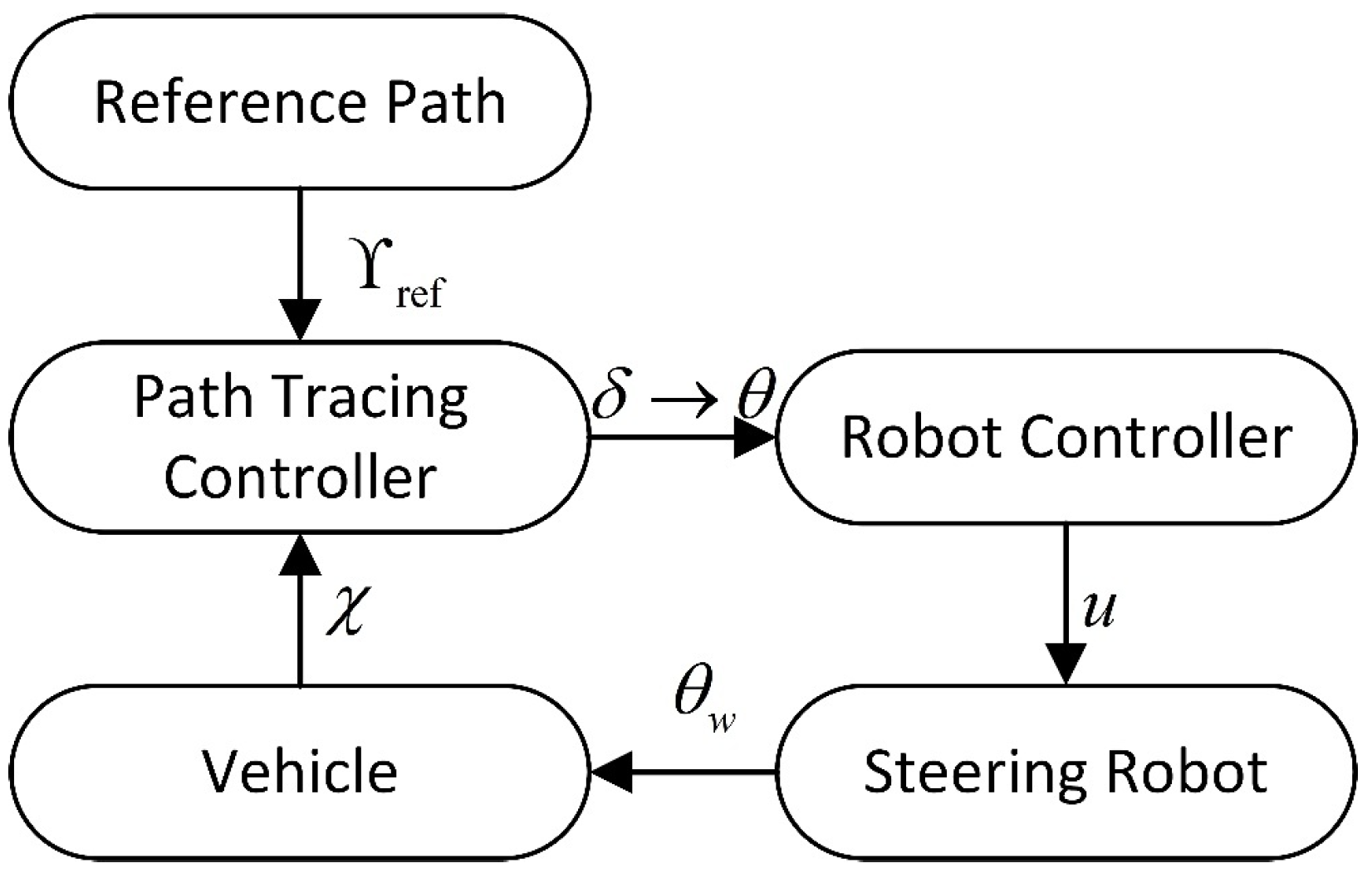

1.1. Related Work

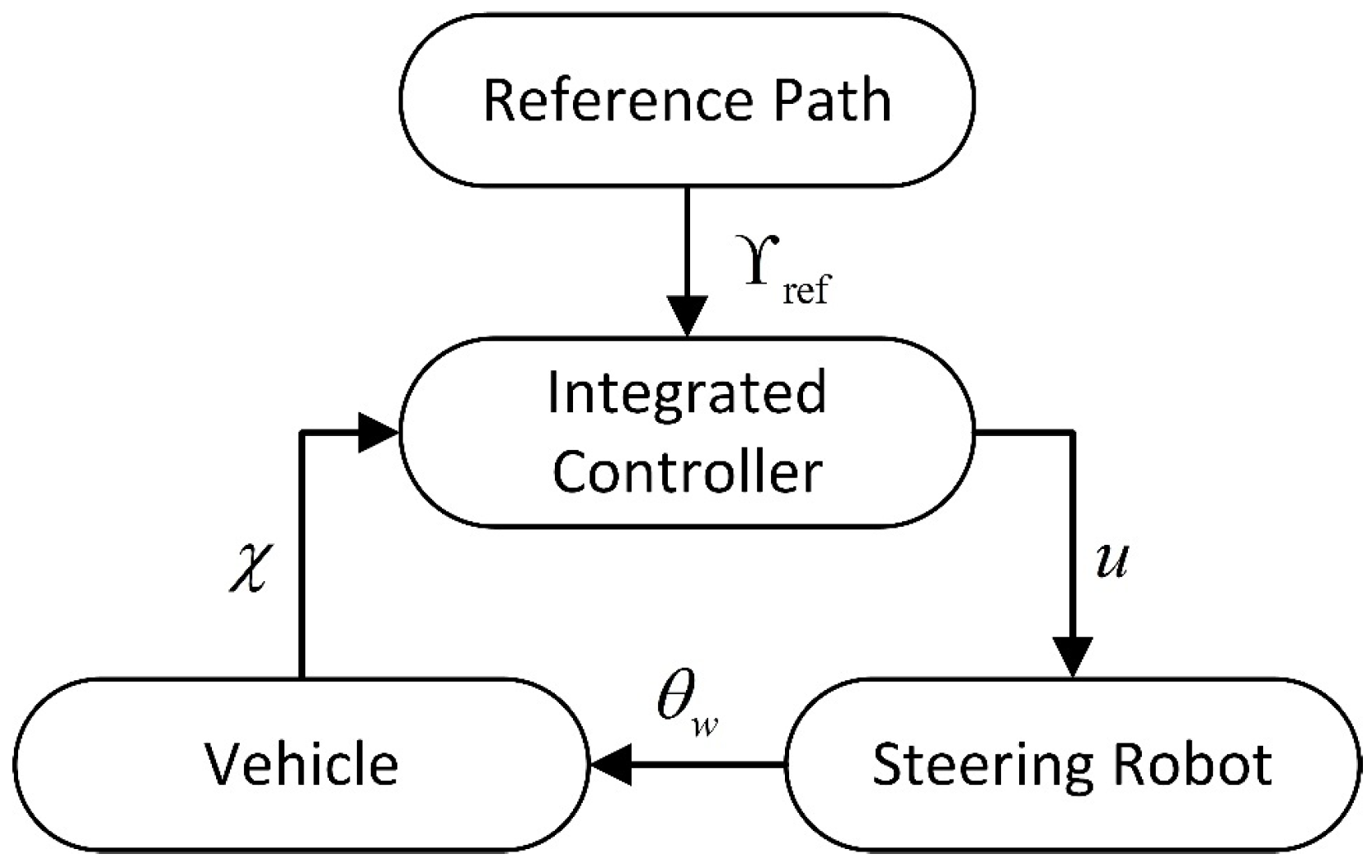

1.2. Novelty

1.3. Contribution

- Integrated formulation: A generalized vehicle-steering-robot model and an integrated MPC that uses the robot voltage as the control input, thereby avoiding cascade-induced multi-layer error accumulation;

- Physically feasible constraints: Linear-inequality mappings that convert steering-wheel angle bounds into voltage constraints inside the optimizer, avoiding ad hoc post-saturation and ensuring actuator-level physical feasibility;

- Path-tracking evaluation: Side-by-side comparisons against a cascaded MPC–PID baseline under identical conditions, using the vehicle-level criterion—lateral tracking error as the primary metric; we report RMS and peak over matched time windows.

2. Materials and Methods

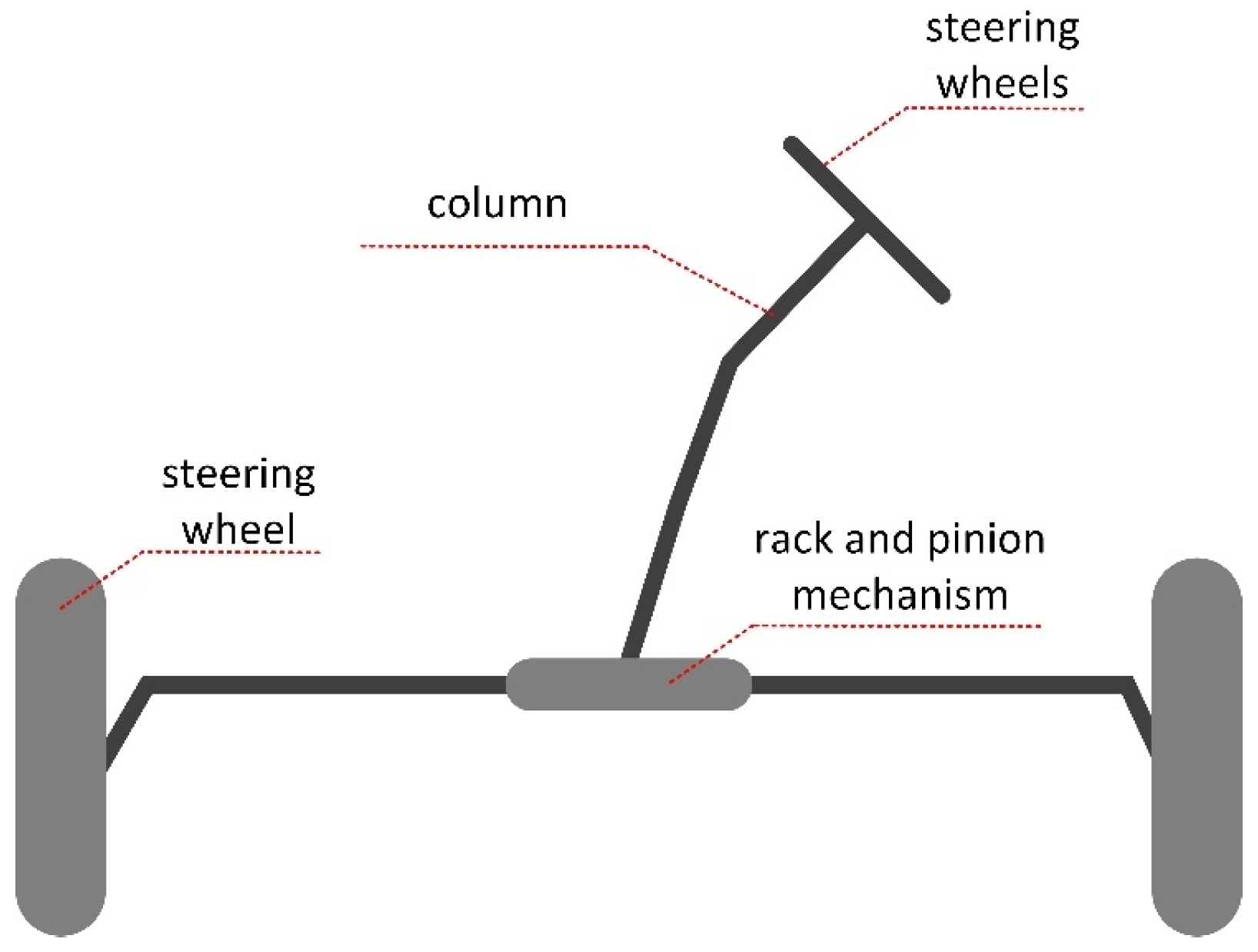

2.1. Steering Robot Modeling

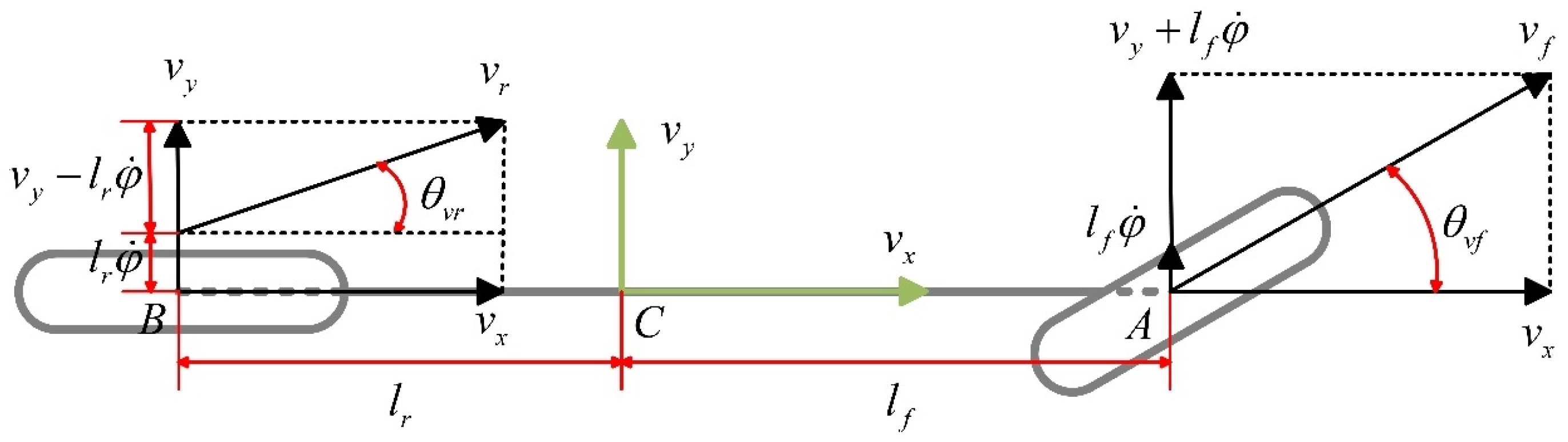

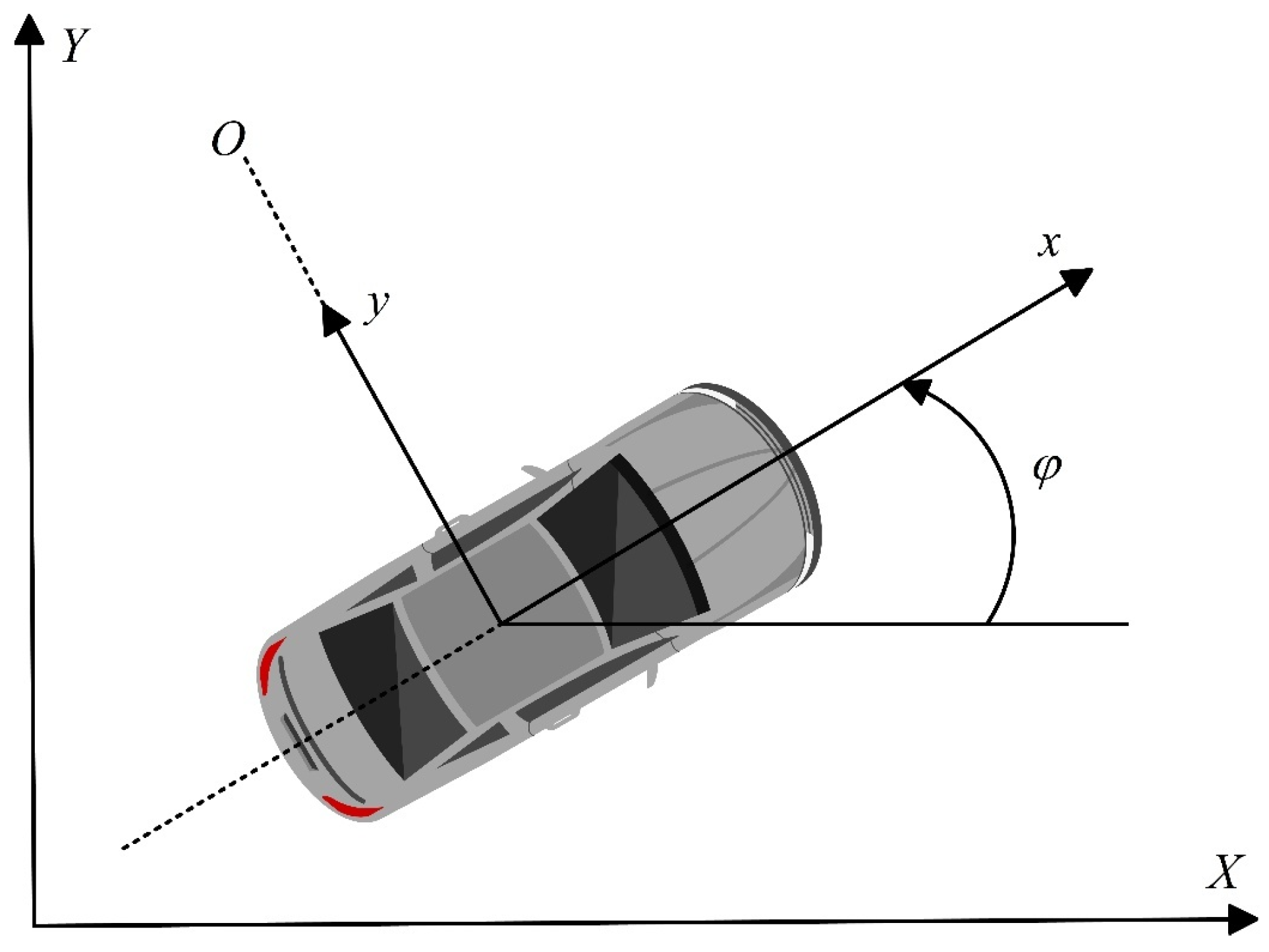

2.2. Vehicle Transverse Two-Degree-of-Freedom Dynamics Model

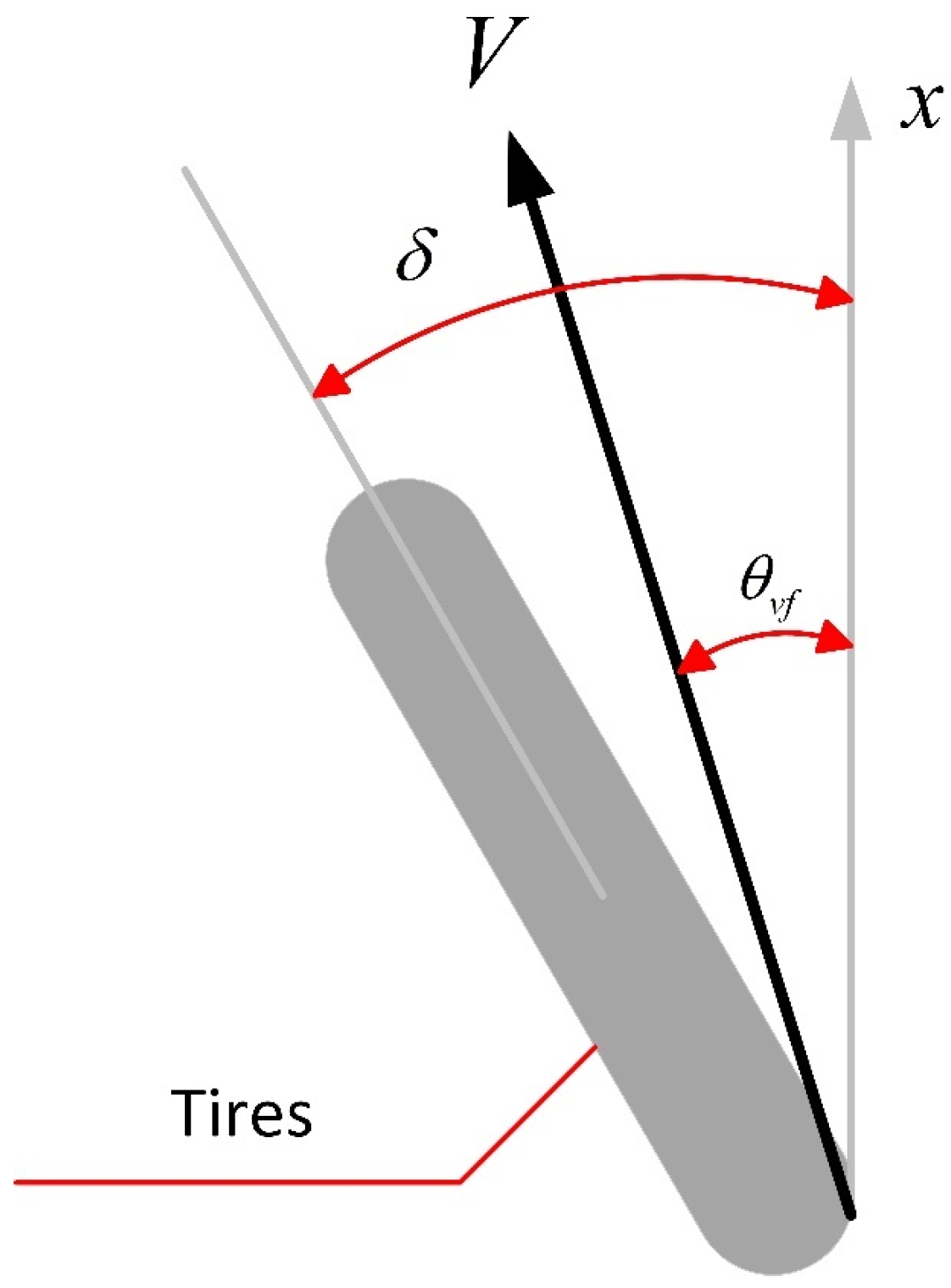

2.2.1. Basic Modeling

2.2.2. Lateral Force Analysis

2.2.3. Transverse Two-Degree-of-Freedom Dynamics Model

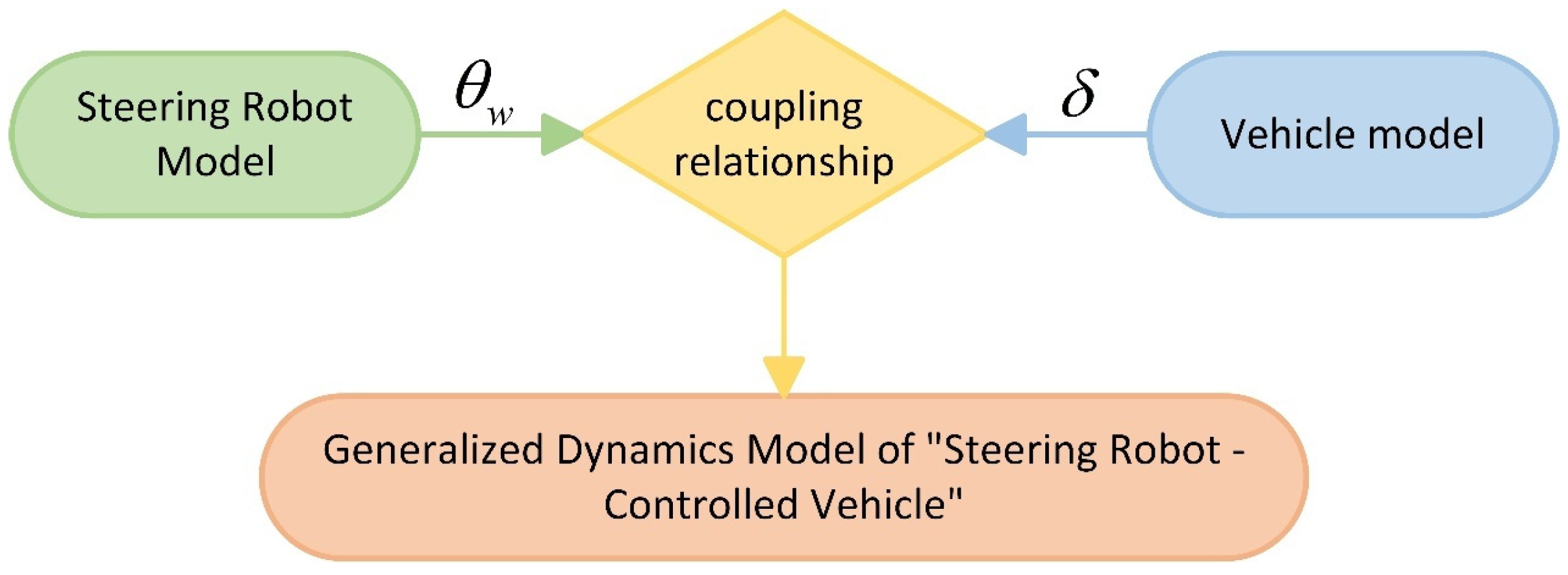

2.3. Establishment of a Generalized Dynamics Model of “Steering Robot—Controlled Vehicle”

2.4. Integrated MPC Controller Design

2.4.1. Linear State Space Equations

2.4.2. Linear Model Discretization

2.4.3. Predictive Modeling

2.4.4. Cost Function Design

2.4.5. Design of Constraints

2.5. The Integrated MPC Optimization Problem

2.6. Simulation Tests

2.6.1. Double-Lane-Change Path Tracking

2.6.2. Robustness Evaluation Testing

3. Results and Discussion

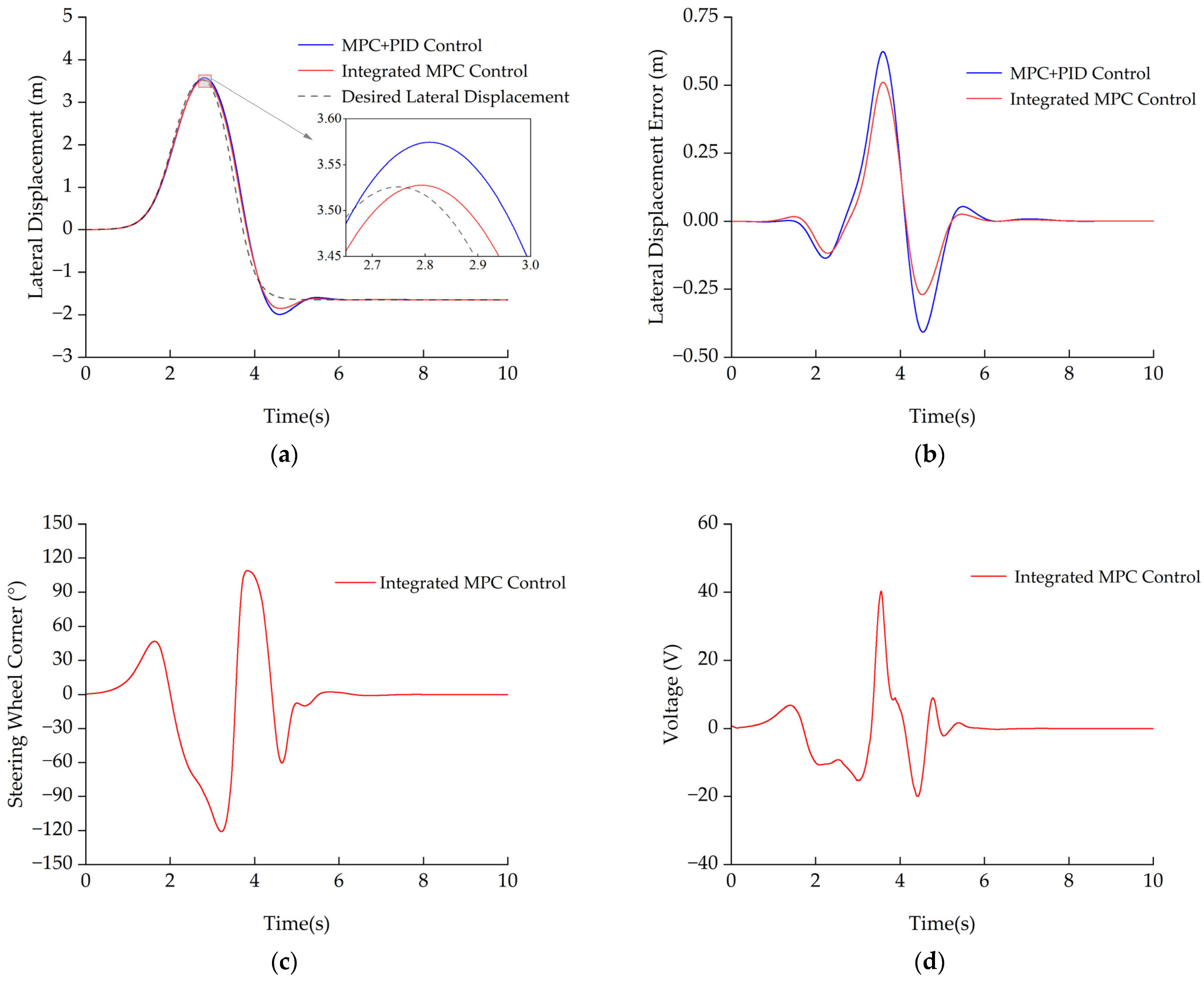

3.1. High-Speed Condition

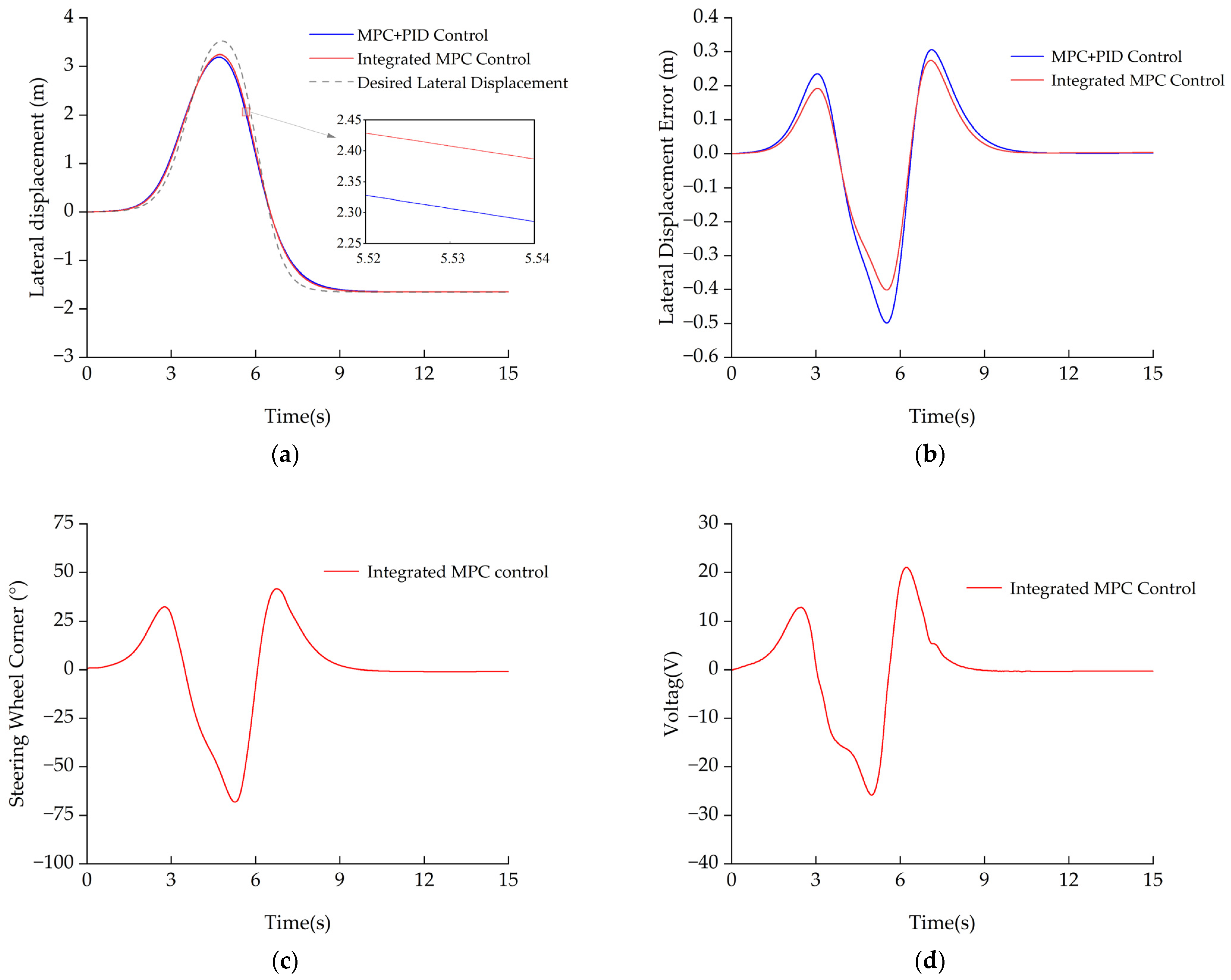

3.1.1. Comparison of Tracking Performance Under High-Speed Condition

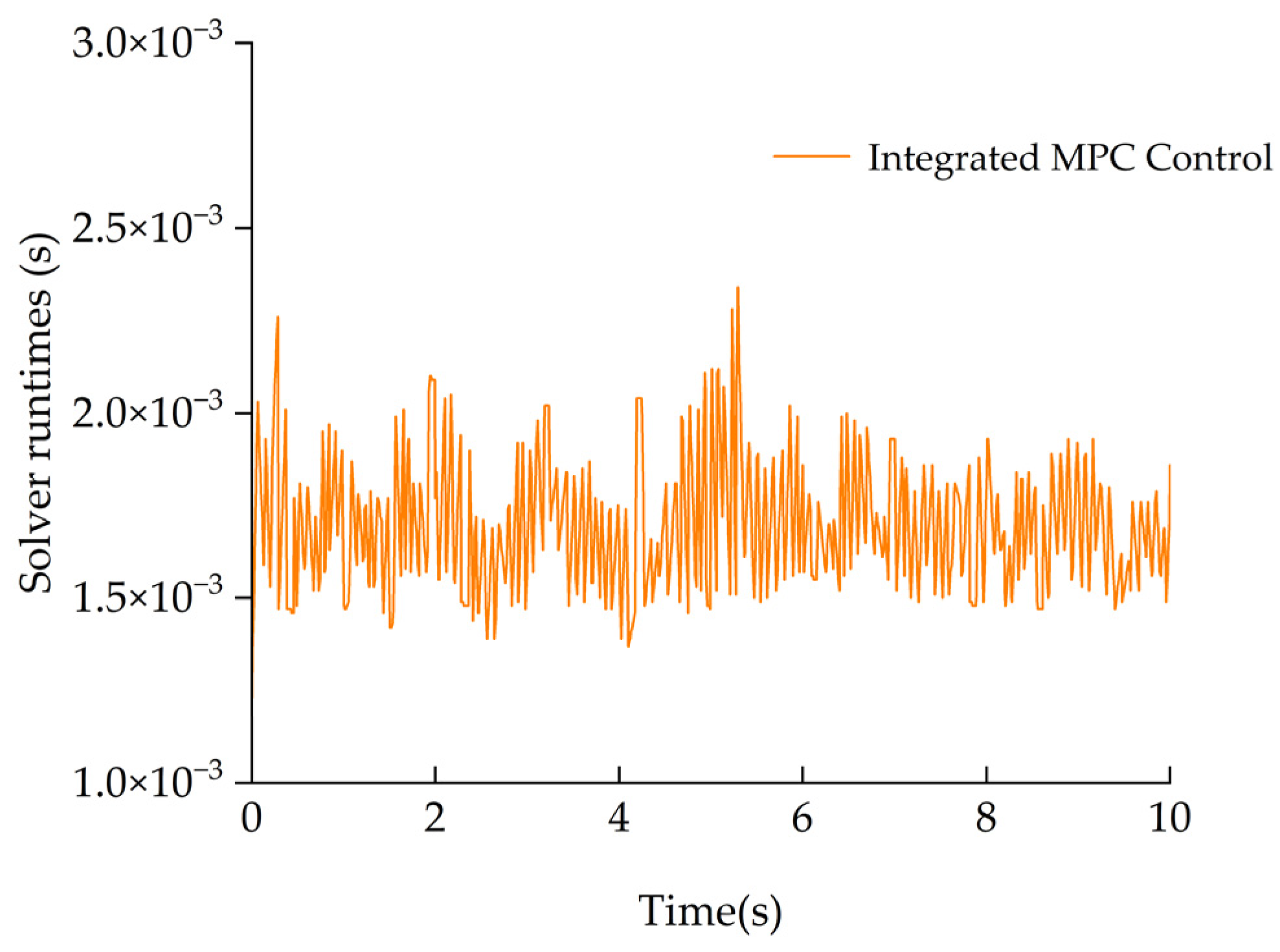

3.1.2. Real-Time Performance Under High-Speed Condition

3.2. Low-Speed Condition

3.2.1. Comparison of Tracking Performance Under Low-Speed Condition

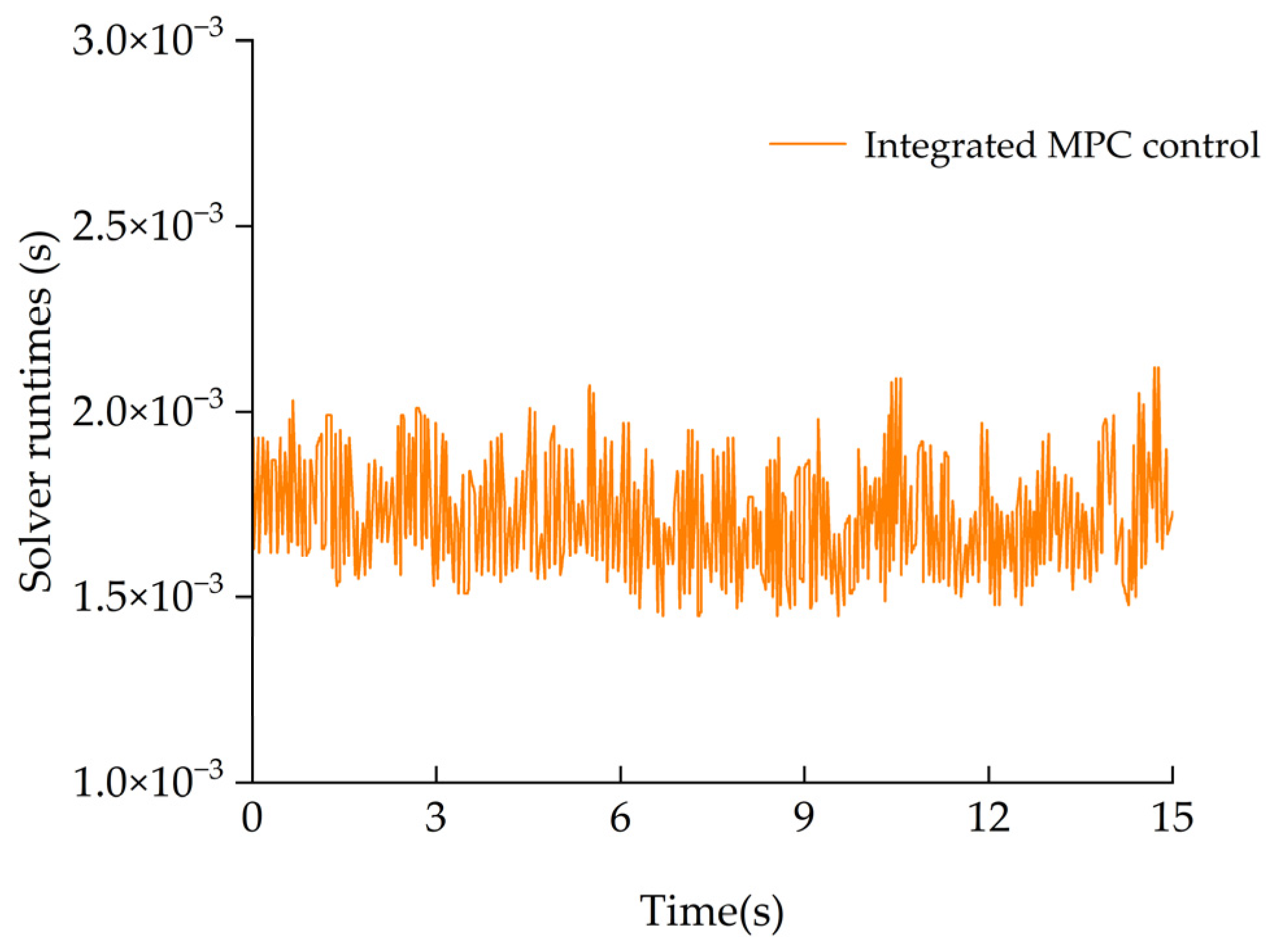

3.2.2. Real-Time Performance Under Low-Speed Condition

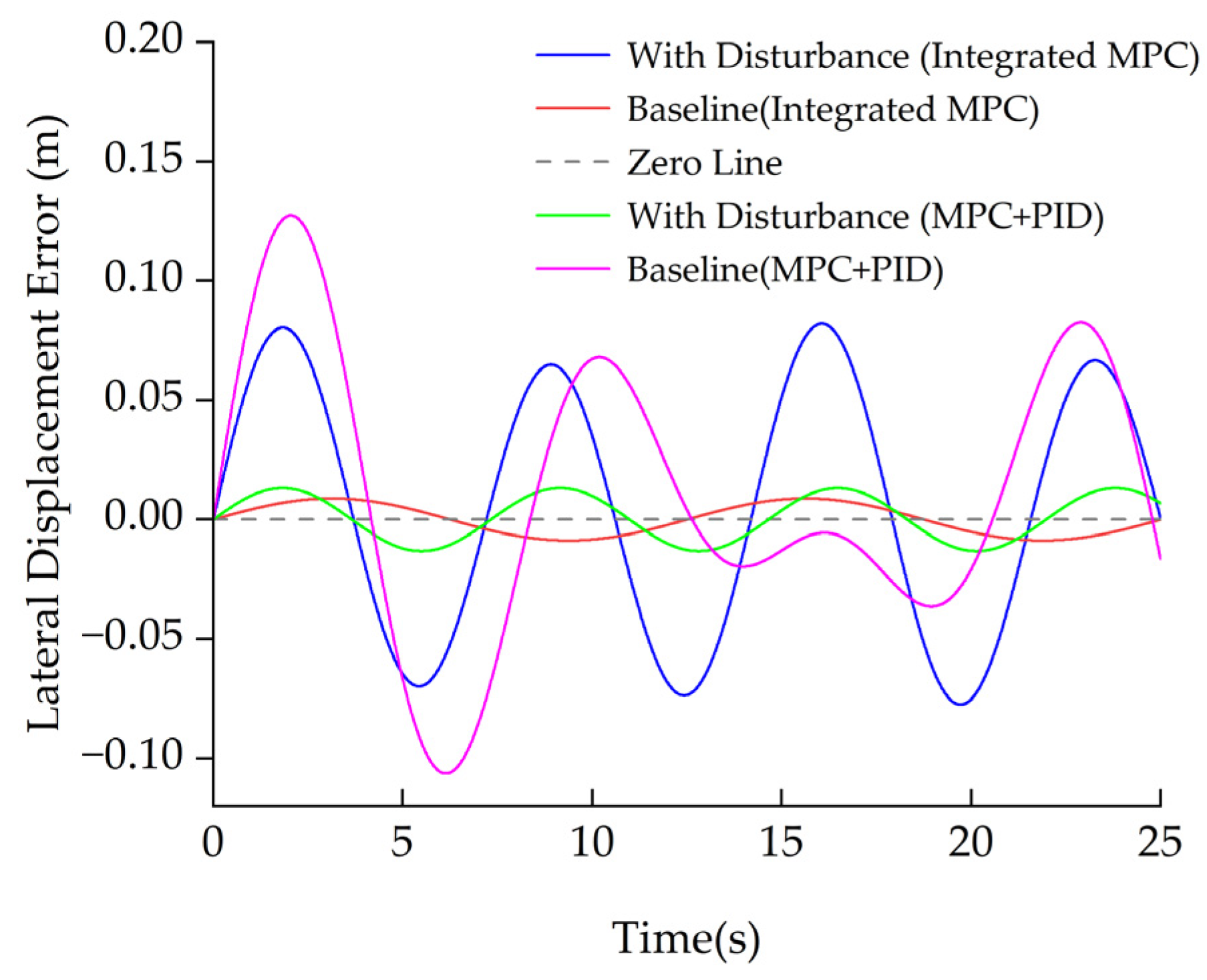

3.3. Robustness Evaluation

- Integrated MPC: The baseline (red) stays tightly around the zero line with small, symmetric micro-oscillations. Under crosswind (blue), the error follows a near-periodic pattern synchronized with the disturbance but remains bounded with no noticeable drift; within each cycle, the error returns rapidly to the zero neighborhood, and the envelope stays stable over time, never approaching the vertical plotting limits.

- Cascaded MPC+PID: Both baseline (magenta) and disturbed (green) cases exhibit larger low-frequency oscillations and more evident phase lag. Under the same disturbance, the return to zero is slower and the error envelope is wider, indicating weaker disturbance rejection—consistent with the error accumulation and serial delay inherent to cascaded structures where the actuator PID loop limits the overall robustness.

- Takeaway: For the same external disturbance, the Integrated MPC keeps the trajectories closer to the zero line with a tighter envelope, evidencing a stronger disturbance rejection and larger safety margins, whereas the cascaded MPC+PID shows broader excursions and a slower recovery, reflecting inferior overall robustness.

3.4. Summary

4. Conclusions

- High-speed DLC (70 km·h−1): The Integrated MPC reduces lateral-error RMS/Peak/P95 by 22.3%/18.0%/17.7% relative to the cascaded baseline, adheres more closely to the reference around the maneuver apex, and yields smoother, non-saturating actuator commands;

- Low-speed DLC (40 km·h−1): Reductions of 17.0%/19.5%/18.9% in RMS/Peak/P95 demonstrate that benefits persist beyond high-dynamic conditions;

- Real-time feasibility: With T = 10 ms, the per-update solve time clusters around 1.7 ms on average, with worst-case execution time ≈ 2.1~2.3 ms, giving utilization ratio ≈ 0.17—comfortably within hard real-time;

- Robustness (straight + crosswind): Both controllers satisfy the ±0.15 m constraint. Without disturbance, the integrated MPC is lower in RMS/Peak/P95 than the cascaded design by roughly 34%/33%/33%. With sinusoidal crosswind, the Integrated MPC further improves over the cascaded scheme by 9.7%/35.6%/30.8% on RMS/Peak/P95, indicating stronger disturbance rejection and larger safety margins.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Yuan, J. Nonlinear dynamics analysis of shift manipulator for robot driver considering multiple revolute clearance joints and variable load. Mech. Based Des. Struct. Mach. 2020, 49, 596–614. [Google Scholar] [CrossRef]

- Chen, G.; Chen, S.; Langari, R.; Li, X.; Zhang, W. Driver-behavior-based adaptive steering robust nonlinear control of unmanned driving robotic vehicle with modeling uncertainties and disturbance observer. IEEE Trans. Veh. Technol. 2019, 68, 8183–8190. [Google Scholar] [CrossRef]

- Chen, G.; Su, S. Driver-behavior-based robust steering control of unmanned driving robotic vehicle with modeling uncertainties and external disturbance. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 1585–1596. [Google Scholar] [CrossRef]

- Su, S.; Chen, G. Lateral robust iterative learning control for unmanned driving robot vehicle. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2020, 234, 792–808. [Google Scholar] [CrossRef]

- Wang, H.; Chen, G.; Zhang, W. A method for vehicle speed tracking by controlling driving robot. Trans. Inst. Meas. Control 2019, 42, 1521–1536. [Google Scholar] [CrossRef]

- Chen, G.; Lu, W.; Mei, J.; Wang, L.; Zhang, W. Longitudinal robust dynamic programming control for driving robot vehicles with performance self-learning. Int. J. Control 2024, 98, 2304–2314. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, X.; Ren, S.; Chen, W.; Wang, H.; Wang, J. Preview path tracking control for autonomous vehicle with actuator saturation. In Proceedings of the 36th Chinese Control and Decision Conference (CCDC), Xi’an, China, 25–27 May 2024; pp. 2729–2734. [Google Scholar] [CrossRef]

- Zheng, R.; Li, R. Autonomous Vehicle Collision Avoidance Path Planning and F-MPC Tracking Control. Int. J. Fuzzy Syst. 2025. [Google Scholar] [CrossRef]

- Lin, D.; Qiu, J.; Tang, M.; Zhang, Q.; Xu, S.; Song, H. Obstacle avoidance path planning and trajectory tracking of unmanned logistics vehicle based on MPC. In Proceedings of the 2024 China Automation Congress (CAC), Qingdao, China, 1–3 November 2024; pp. 1190–1195. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Yang, L. Path tracking control for autonomous vehicles based on MPC combined with adaptive potential field optimization. In Proceedings of the 2024 IEEE 19th Conference on Industrial Electronics and Applications (ICIEA), Kristiansand, Norway, 5–8 August 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Švancar, J.; Haniš, T. MPC-based path-tracking algorithm using a priori known road friction condition for the over-actuated subscale vehicle platform. In Proceedings of the 2024 18th International Conference on Control, Automation, Robotics and Vision (ICARCV), Dubai, United Arab Emirates, 12–15 December 2024; pp. 1017–1022. [Google Scholar] [CrossRef]

- Ma, N.; Zhuang, H.; Kang, S.; Ge, P.; He, T.; Cui, Z. Autonomous driving intelligent vehicle overtaking path tracking based on MPC. In Proceedings of the 2024 IEEE 4th International Conference on Electronic Technology, Communication and Information (ICETCI), Changchun, China, 24–26 May 2024; pp. 520–524. [Google Scholar] [CrossRef]

- Bai, G.; Liu, S.; Zhou, B.; Huang, J.; Zheng, Y.; Elham, E. Path Tracking for Electric Mining Articulated Vehicles Based on Nonlinear Compensated Multiple Reference Points Linear MPC. World Electr. Veh. J. 2024, 15, 427. [Google Scholar] [CrossRef]

- Feng, K.; Li, X.; Li, W. Adaptive MPC path-tracking controller based on reinforcement learning and preview-based PID controller. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024; in press. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Zhao, L.; Hu, Y. Variable-parameter MPC Multi-objective Control for Intelligent Vehicle Path Tracking Based on Reinforcement Learning. China J. Highw. Transp. 2024, 37, 157–169. (In Chinese) [Google Scholar] [CrossRef]

- Ren, H.; Li, Y.; Wang, L.; Yang, L. Lateral path tracking control based on tube MPC. In Proceedings of the 2024 3rd International Symposium on Intelligent Unmanned Systems and Artificial Intelligence (SIUSAI ’24), New York, NY, USA, 17–19 May 2024; pp. 130–135. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Wu, G. Tube-MPC Based Path Tracking for I Vehicle Considering Data-Driven Stable Region and External Disturbances; SAE Technical Paper 2025-01-8262; SAE International: Warrendale, PA, USA, 2025. [Google Scholar] [CrossRef]

- Yangin, V.B.; Yalcin, Y.; Akalin, O. A tunable explicit nonlinear MPC for a vehicle considering improved path tracking performance and computational efficiency. J. Mech. Sci. Technol. 2025, 39, 2877–2888. [Google Scholar] [CrossRef]

- Tuer, S.; Panahandeh, P.; Alghooneh, A.R.; Sun, C.; Zhang, R.; Ning, M. Real-time MPC for WATonoBus path tracking. In Proceedings of the 2024 IEEE 27th International Conference on Intelligent Transportation Systems (ITSC), Edmonton, AB, Canada, 24–27 September 2024; pp. 3233–3238. [Google Scholar] [CrossRef]

- Hou, Y.; Ren, Y.; Meng, S. Research on vehicle path tracking control based on MPC. In Proceedings of the 2022 6th International Conference on Electronic Information Technology and Computer Engineering (EITCE ’22), New York, NY, USA, 21–23 October 2022; pp. 449–453. [Google Scholar] [CrossRef]

- Bo, Y.; Guo, H.; Shen, C.; Liu, J. MPC-based path tracking controller design for intelligent driving vehicle. In Proceedings of the 2019 Chinese Control Conference (CCC), Guangzhou, China, 27–30 July 2019; pp. 3006–3011. [Google Scholar] [CrossRef]

- Tang, C.; Li, T.; Li, T.; Ma, J.; Xiong, H. All-wheel steering path tracking control for multi-axle vehicle based on adaptive MPC. In Proceedings of the 2024 4th International Conference on Computer, Control and Robotics (ICCCR), Shanghai, China, 19–21 April 2024; pp. 183–190. [Google Scholar] [CrossRef]

- Chen, M.; Ren, Y. MPC-based path tracking control for autonomous vehicle with multi-constraints. In Proceedings of the 2017 International Conference on Advanced Mechatronic Systems (ICAMechS), Xiamen, China, 6–9 December 2017; pp. 477–482. [Google Scholar] [CrossRef]

- Ma, N.; Kang, S.; Zhuang, H.; Ge, P.; He, T.; Cui, Z. A MPC-based mix function controller on path planning and path tracking of autonomous vehicles. In Proceedings of the 2024 IEEE 4th International Conference on Electronic Technology, Communication and Information (ICETCI), Changchun, China, 24–26 May 2024; pp. 525–530. [Google Scholar] [CrossRef]

- Zhou, Z.; Bao, Y. Path tracking control of autonomous vehicle based on MPC. In Proceedings of the 2024 3rd International Conference on Energy and Power Engineering, Control Engineering (EPECE), Chengdu, China, 23–25 February 2024; pp. 211–216. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 1230 | 1343 | ||

| 2.58 | −56,864 | ||

| 1.22 | −66,864 | ||

| 27 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 48 | 0.72 | ||

| 3.6 | 0.2 | ||

| 2000 | 0.01 | ||

| 1 | 0.03 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 10 | 10 | ||

| −30 | 30 |

| Group | RMS | Peak | P95 |

|---|---|---|---|

| Cascaded MPC+PID | 0.17368 | 0.62321 | 0.44708 |

| Integrated MPC | 0.13492 | 0.51082 | 0.36798 |

| Statistic | Value | Statistic | Value |

|---|---|---|---|

| 10 | 2.34 | ||

| 1.697 | 0.17 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 10 | 10 | ||

| −30 | 30 |

| Group | RMS | Peak | P95 |

|---|---|---|---|

| Cascaded MPC+PID | 0.17300 | 0.49843 | 0.41930 |

| Integrated MPC | 0.143615 | 0.40146 | 0.34018 |

| Statistic | Value | Statistic | Value |

|---|---|---|---|

| 10 | 2.12 | ||

| 1.717 | 0.172 |

| Group | RMS | Peak | P95 |

|---|---|---|---|

| Baseline (Integrated MPC) | 0.00622 | 0.00880 | 0.00877 |

| With Disturbance (Integrated MPC) | 0.05234 | 0.08209 | 0.07832 |

| Baseline (MPC+PID) | 0.00942 | 0.01320 | 0.01316 |

| With Disturbance (MPC+PID) | 0.05794 | 0.127440 | 0.11318 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; You, L.; Cai, Y.; Yuan, C.; Li, Y.; Tian, L. Research on MPC Path-Tracking Control Algorithm Based on the Generalized-Dynamics Model of “Steering Robot-Controlled Vehicle”. Appl. Sci. 2025, 15, 12245. https://doi.org/10.3390/app152212245

He Y, You L, Cai Y, Yuan C, Li Y, Tian L. Research on MPC Path-Tracking Control Algorithm Based on the Generalized-Dynamics Model of “Steering Robot-Controlled Vehicle”. Applied Sciences. 2025; 15(22):12245. https://doi.org/10.3390/app152212245

Chicago/Turabian StyleHe, Youguo, Linchao You, Yingfeng Cai, Chaochun Yuan, Yicheng Li, and Liwei Tian. 2025. "Research on MPC Path-Tracking Control Algorithm Based on the Generalized-Dynamics Model of “Steering Robot-Controlled Vehicle”" Applied Sciences 15, no. 22: 12245. https://doi.org/10.3390/app152212245

APA StyleHe, Y., You, L., Cai, Y., Yuan, C., Li, Y., & Tian, L. (2025). Research on MPC Path-Tracking Control Algorithm Based on the Generalized-Dynamics Model of “Steering Robot-Controlled Vehicle”. Applied Sciences, 15(22), 12245. https://doi.org/10.3390/app152212245