Low-Cost Laser Powder Bed Fusion-Based Additive Manufacturing of Densified Ceramics

Abstract

1. Introduction

2. Materials and Methods

2.1. Machine Specifications

2.2. Materials and Substrate Mixtures

2.3. Environmental Conditions

2.4. Scanning Energy Density Variations

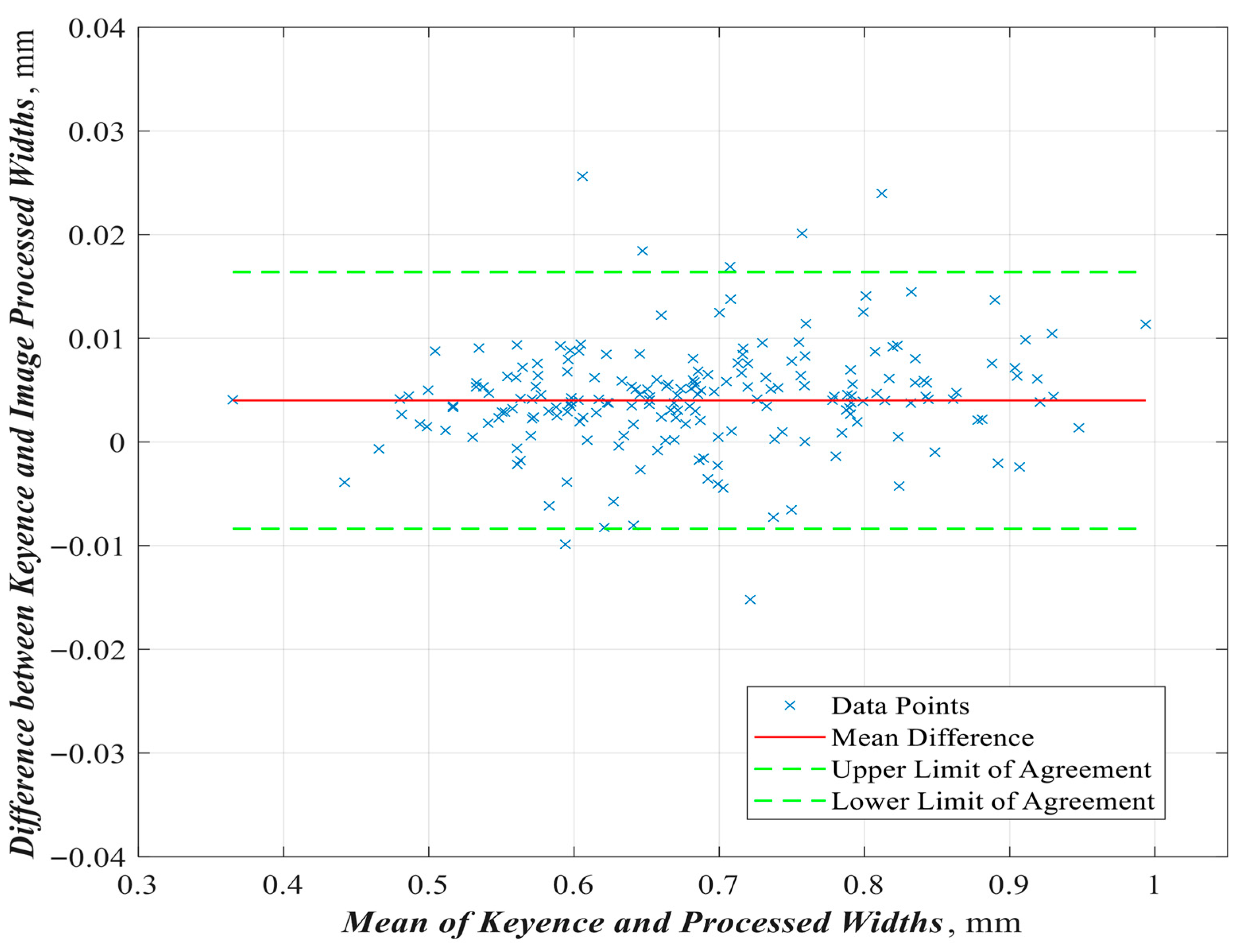

2.5. Measurements and Data Analysis

3. Results and Discussions

3.1. Effect of Substrate Mixture and SED Variation

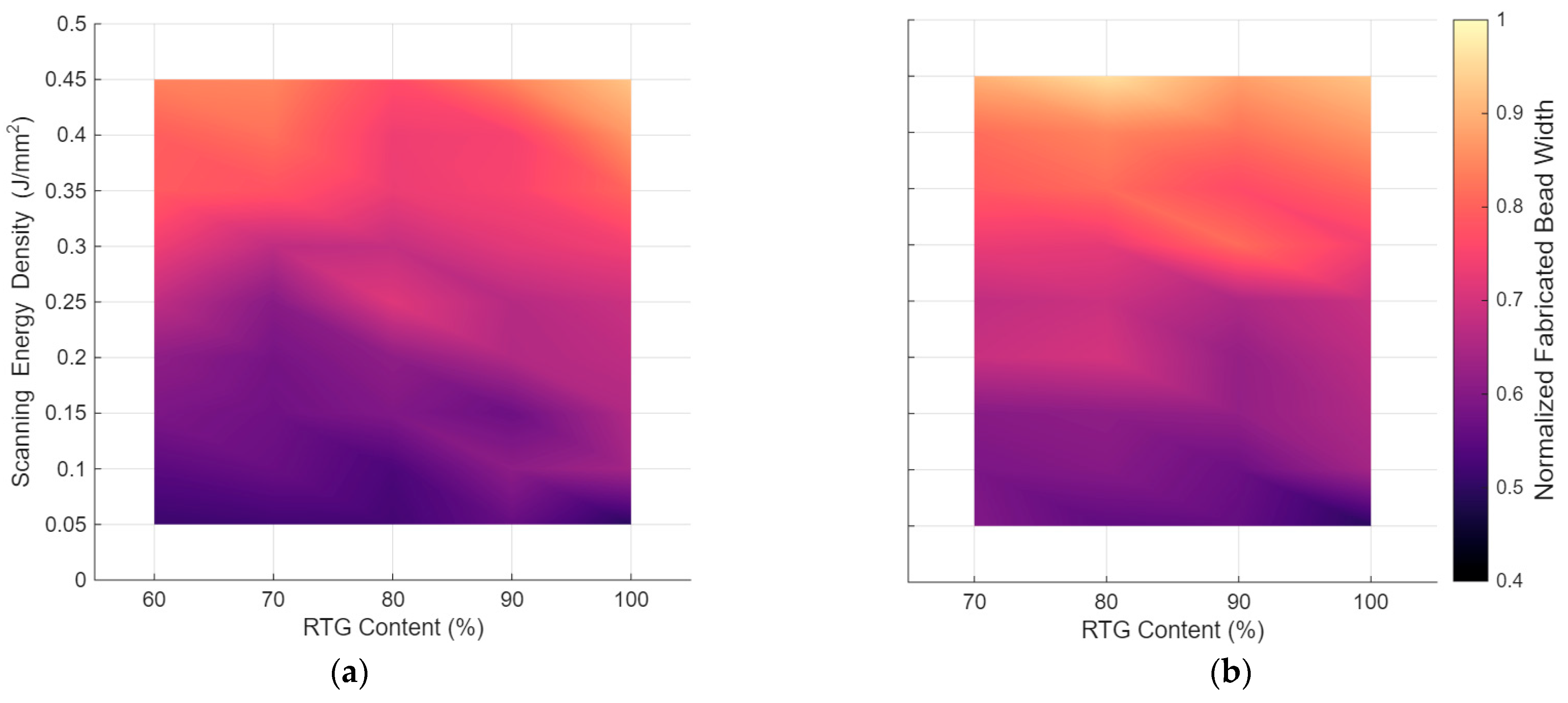

3.1.1. Fabricated Bead Width

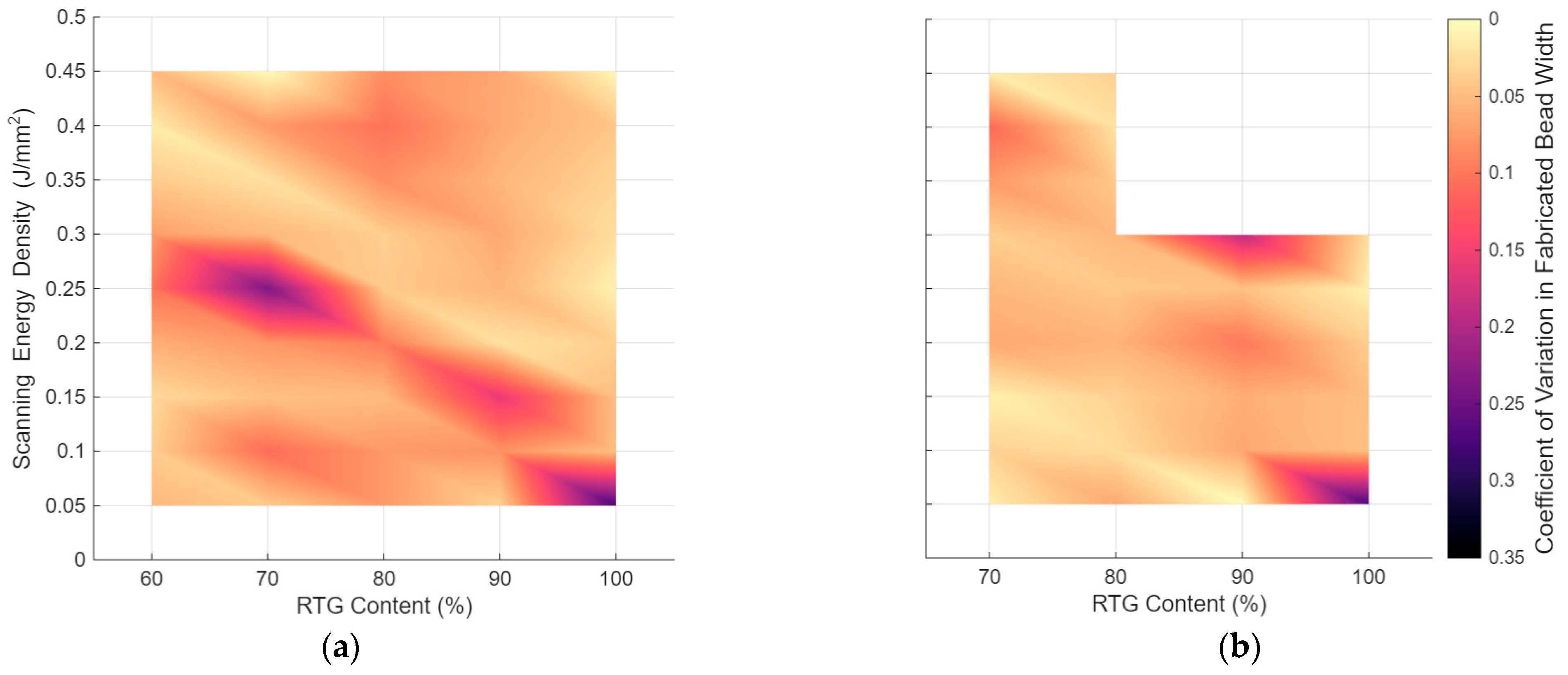

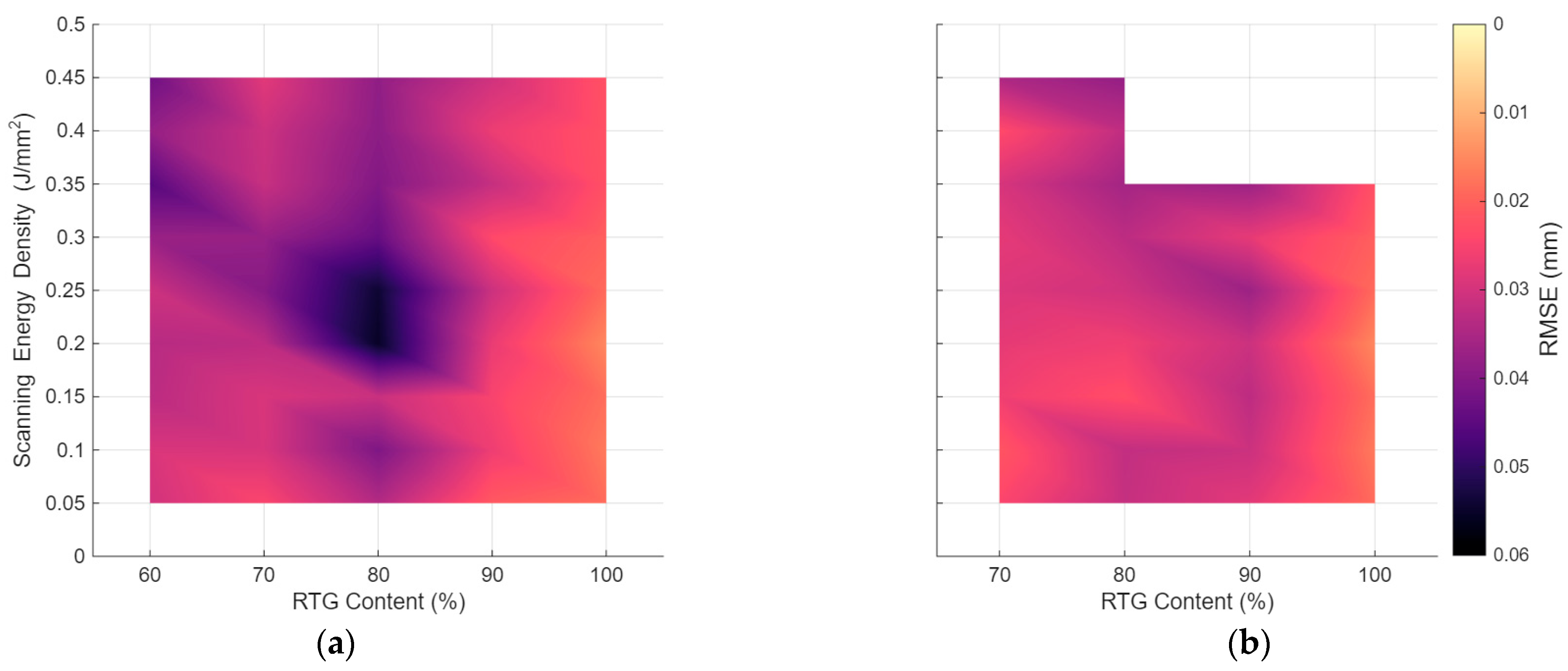

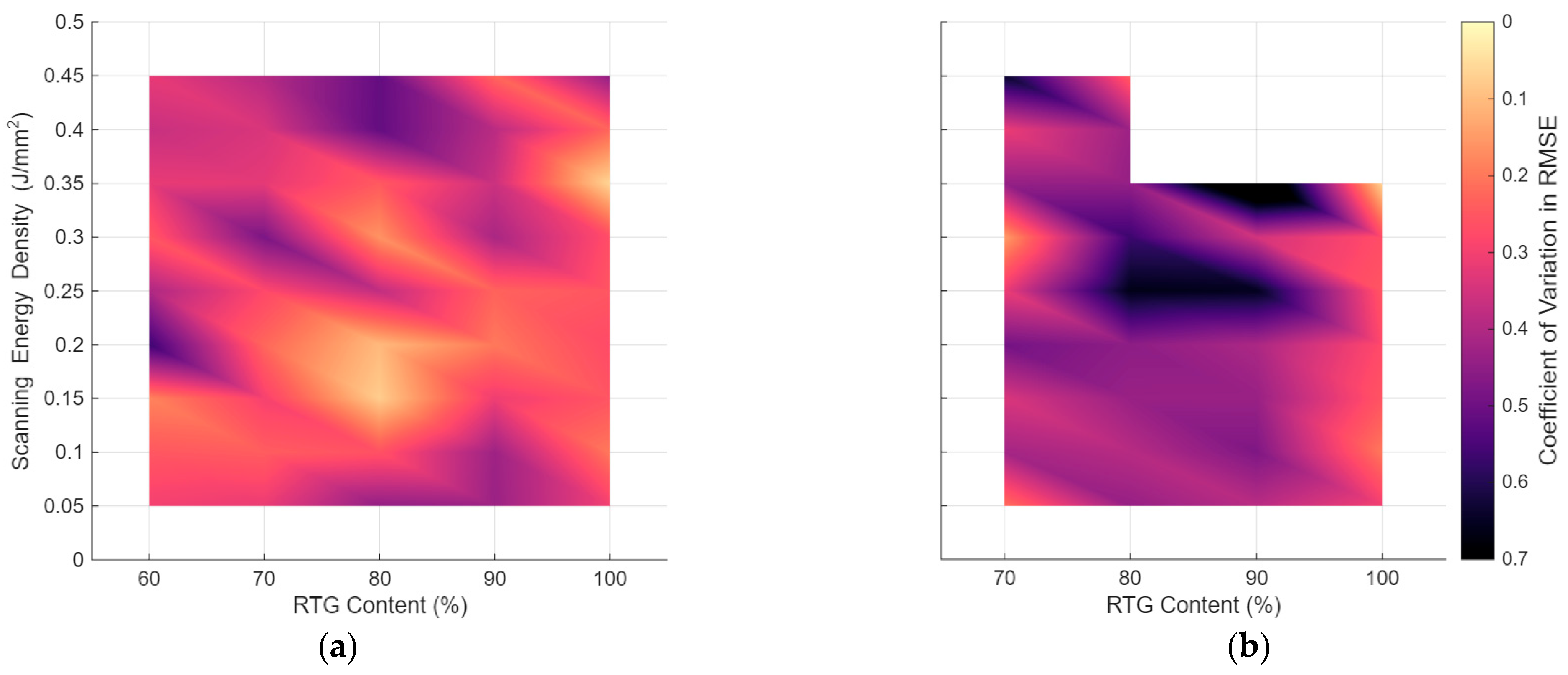

3.1.2. Fabricated Bead Uniformity

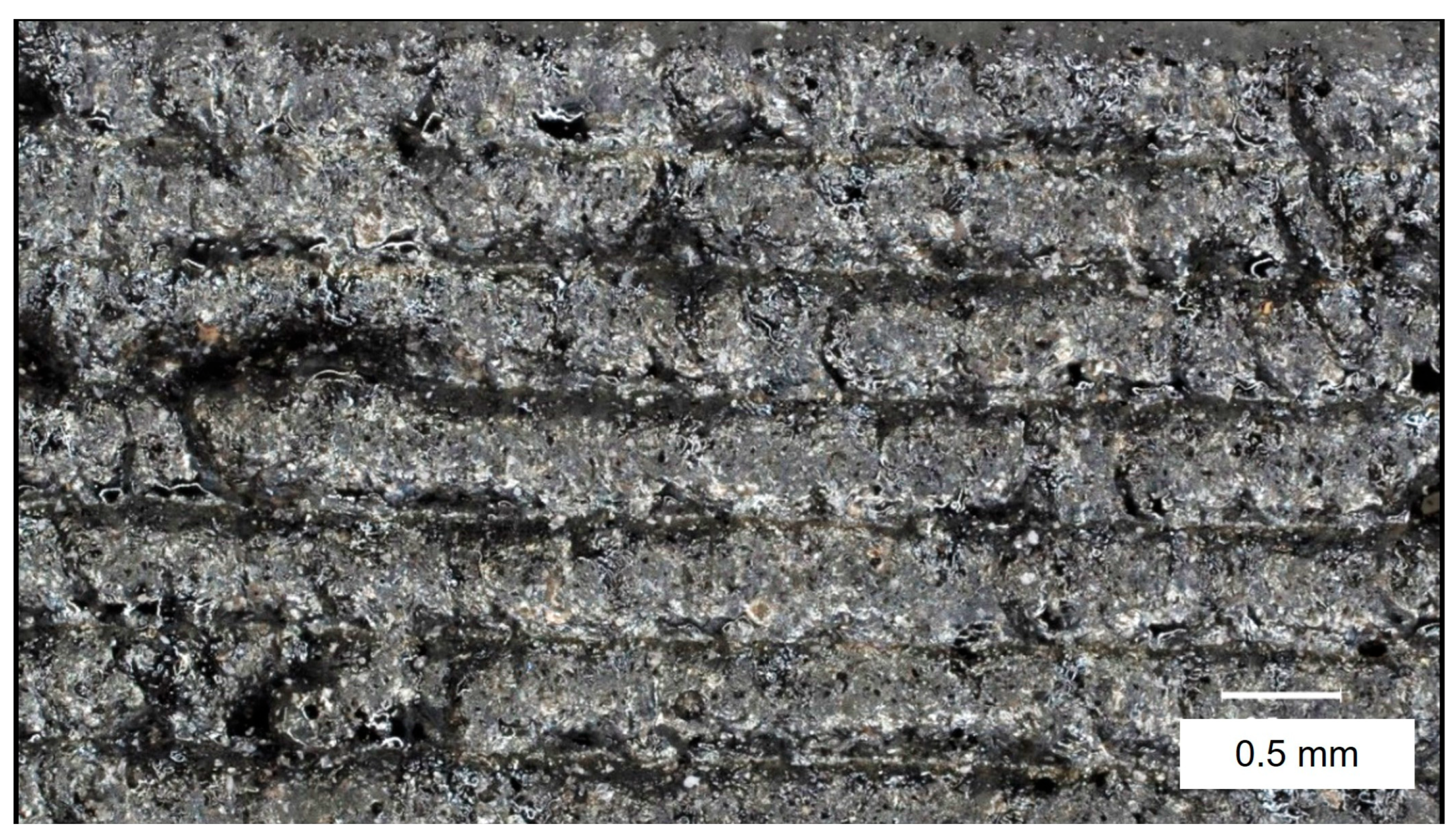

3.2. Demonstrations of Intralayer Fusion

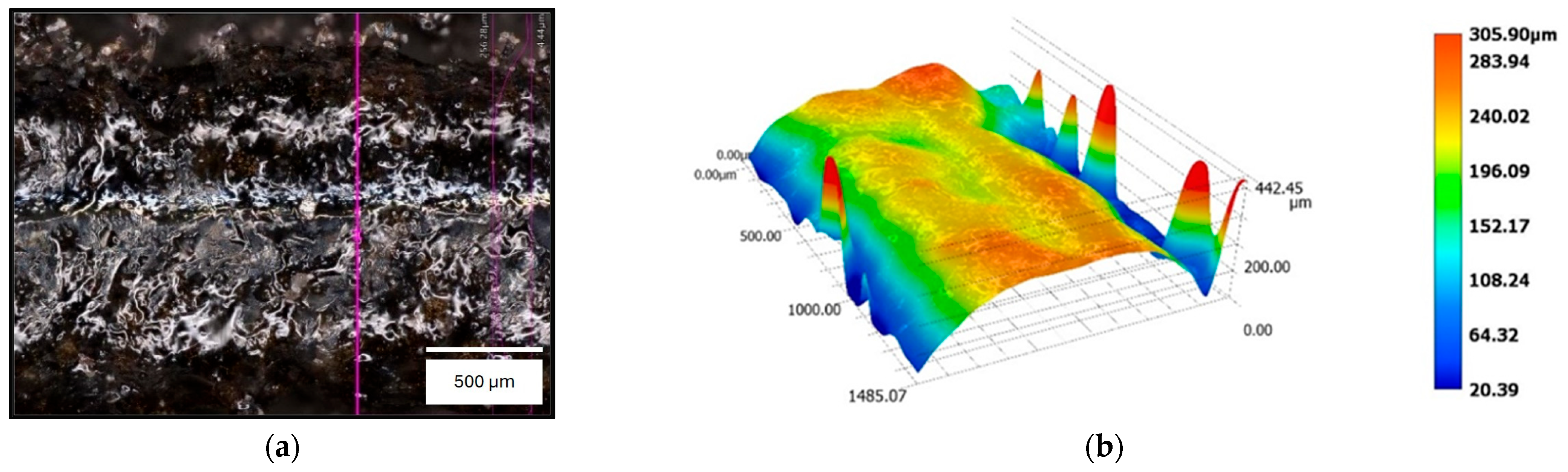

3.3. Observed Structural Defects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LPBF | Laser Powder Bed Fusion |

| SED | Scanning Energy Density |

| RMSE | Root Mean Square Error |

| CoV | Coefficient of Variation |

Appendix A

| Mixture Name | SED | Mean NFBW | Mean RMSE |

|---|---|---|---|

| 100RTG | [0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5] | [5.0, 6.4, 6.6, 6.7, 6.9, 7.4, 8.0, 8.7, 9.2] | [1.9, 1.7, 1.8, 1.5, 1.9, 2.0, 2.3, 2.3, 2.3] |

| 90RTG_A | “ | [5.6, 6.1, 5.7, 6.6, 6.6, 7.2, 7.5, 7.5, 8.5] | [2.1, 2.6, 2.5, 2.7, 3.1, 2.4, 3.2, 2.7, 3.0] |

| 90RTG_B | “ | [5.6, 5.7, 6.2, 6.2, 6.5, 8.1, 7.6, 8.2, 8.8] | [2.8, 3.1, 3.3, 3.1, 3.7, 2.8, 3.7, Na, 2.9] |

| 80RTG_A | “ | [5.2, 5.3, 5.9, 6.1, 7.1, 6.8, 7.3, 7.4, 7.7] | [3.4, 4.1, 3.1, 5.5, 5.4, 4.4, 4.0, 3.9, 3.8] |

| 80RTG_B | “ | [5.5, 6.0, 6.1, 7.0, 6.9, 7.2, 8.1, 8.4, 9.6] | [3.2, 3.2, 2.3, 2.6, 3.0, 3.3, 3.6, 3.2, 3.8] |

| 70RTG_A | “ | [5.2, 5.7, 5.7, 5.8, 6.0, 6.7, 7.8, 8.2, 8.5] | [2.5, 2.9, 2.9, 3.3, 4.0, 3.8, 3.1, 3.1, 2.8] |

| 70RTG_B | “ | [5.9, 5.9, 6.0, 6.9, 6.8, 7.3, 7.9, 8.2, 9.0] | [2.5, 2.2, 2.6, 2.8, 2.9, 2.8, 3.0, 2.4, 3.5] |

| 60RTG_A | “ | [5.1, 5.5, 5.9, 6.1, 6.7, 7.4, 7.9, 8.0, 8.4] | [3.0, 2.9, 3.3, 3.4, 3.1, 3.7, 4.6, 3.8, 4.3] |

References

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Belmonte, M. Advanced ceramic materials for high temperature applications. Adv. Eng. Mater. 2006, 8, 693–703. [Google Scholar] [CrossRef]

- Randhawa, K.S. A state-of-the-art review on advanced ceramic materials: Fabrication, characteristics, applications, and wettability. Pigment Resin Technol. 2024, 53, 768–785. [Google Scholar] [CrossRef]

- Ullah, A.; Shah, M.; Ali, Z.; Asami, K.; Ur Rehman, A.; Emmelmann, C. Additive manufacturing of ceramics via the laser powder bed fusion process. Int. J. Appl. Ceram. Technol. 2025, 22, e15087. [Google Scholar] [CrossRef]

- Karabulut, Y.; Ünal, R. Additive manufacturing of ceramic particle-reinforced aluminum—Based metal matrix composites: A review. J. Mater. Sci. 2022, 57, 19212–19242. [Google Scholar] [CrossRef]

- Wang, J.-C.; Dommati, H.; Hsieh, S.-J. Review of additive manufacturing methods for high-performance ceramic materials. Int. J. Adv. Manuf. Technol. 2019, 103, 2627–2647. [Google Scholar] [CrossRef]

- Villa, R.; Billings, C.; Siddique, Z.; Liu, Y. A Look at Two Nuisance Process Hurdles Encountered by New Laser Powder Bed Fusion Operators Printing Ti6Al4V. J. Mater. Eng. Perform. 2025, 34, 21941–21948. [Google Scholar] [CrossRef]

- Lamm, B.W.; Karakoc, O.; Mao, K.; Koyanagi, T.; Liu, J.; Katoh, Y. Phase separation during the direct powder bed fusion of SiC. Int. J. Appl. Ceram. Technol. 2024, 21, 1722–1734. [Google Scholar] [CrossRef]

- Qiao, L.; Gan, Y.; Wu, Y.; Zhai, M.; Wang, M.; Li, R.; Li, T.; Zhang, X.; Chang, T. Preparation and characterization of corrosion-resistant FeCrMoNiCuBSiC metallic glass coating by HVOF spraying. Surf. Coat. Technol. 2025, 513, 132507. [Google Scholar] [CrossRef]

- De Leon, E.; Riensche, A.; Bevans, B.D.; Billings, C.; Siddique, Z.; Liu, Y. A Review of Modeling, Simulation, and Process Qualification of Additively Manufactured Metal Components via the Laser Powder Bed Fusion Method. J. Manuf. Mater. Process. 2025, 9, 22. [Google Scholar] [CrossRef]

- Liu, R.; Yang, H. Multimodal probabilistic modeling of melt pool geometry variations in additive manufacturing. Addit. Manuf. 2023, 61, 103375. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, B.; Fan, L. Optimizing powder morphology and scanning strategies to enhance shape accuracy in L-PBF alumina ceramic formation. Ceram. Int. 2025, 51, 8042–8053. [Google Scholar] [CrossRef]

- Wang, W.; Liang, S.Y. Prediction of molten pool height, contact angle, and balling occurrence in laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2022, 119, 6193–6202. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Bedmar, J.; Abu-warda, N.; Torres, B.; Rams, J. Microstructure and corrosion behavior of 316L stainless steel lattice and bulk parts manufactured by LPBF using fiber and CO2 lasers. Mater. Des. 2024, 244, 113214. [Google Scholar] [CrossRef]

- Shen, Z.; Su, H.; Yu, M.; Yang, P.; Guo, Y.; Cao, Y.; Jiang, H.; Li, X.; Dong, D.; Zhang, Z. Synergistic dual-scale laser beams for fabricating high-temperature eutectic ceramic coatings with nano microstructures via LPBF. J. Mater. Sci. Technol. 2025, 234, 292–306. [Google Scholar] [CrossRef]

- Seyfarth, B.; Schade, L.; Matthäus, G.; Ullsperger, T.; Heidler, N.; Hilpert, E.; Nolte, S. Laser powder bed fusion of glass: A comparative study between CO2 lasers and ultrashort laser pulses. In Laser 3D Manufacturing VII; SPIE: San Francisco, CA, USA, 2020; pp. 87–92. [Google Scholar]

- Liu, K.; Wu, T.; Bourell, D.L.; Tan, Y.; Wang, J.; He, M.; Sun, H.; Shi, Y.; Chen, J. Laser additive manufacturing and homogeneous densification of complicated shape SiC ceramic parts. Ceram. Int. 2018, 44, 21067–21075. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect formation mechanisms in selective laser melting: A review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Pfeiffer, S.; Florio, K.; Puccio, D.; Grasso, M.; Colosimo, B.M.; Aneziris, C.G.; Wegener, K.; Graule, T. Direct laser additive manufacturing of high performance oxide ceramics: A state-of-the-art review. J. Eur. Ceram. Soc. 2021, 41, 6087–6114. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, T. Laser powder bed fusion of powder material: A review. 3D Print. Addit. Manuf. 2023, 10, 1439–1454. [Google Scholar] [CrossRef] [PubMed]

| Supplier | Chemical Makeup (Purity) | Model | Average Particle Diameter |

|---|---|---|---|

| SackOrange (Shenzhen, China) | Black Fused Alumina (N.L.) | Step-3 500 Grit Silicon Carbide Rock Tumbler Grit | 50 μm |

| LFA Machines (Fort Worth, TX, USA) | SiO2 (99.9%) | Silicon Dioxide Anticaking Agent | 20 nm |

| Chemsavers (Bluefield, VA, USA) | SiO2 (99.5%) | Silicon Dioxide (Silica), Powder—325 Mesh | 57.8 μm |

| Mixture Name | RTG Content (vol%) | 57.8 μm SiO2 Content (vol%) | 20 nm SiO2 Content (vol%) |

|---|---|---|---|

| 100RTG | 100 | N/A | N/A |

| 90RTG_A | 90 | 10 | N/A |

| 90RTG_B | 90 | N/A | 10 |

| 80RTG_A | 80 | 20 | N/A |

| 80RTG_B | 80 | N/A | 20 |

| 70RTG_A | 70 | 30 | N/A |

| 70RTG_B | 70 | N/A | 30 |

| 60RTG_A | 60 | 40 | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brownlee, S.K.; Liu, Y. Low-Cost Laser Powder Bed Fusion-Based Additive Manufacturing of Densified Ceramics. Appl. Sci. 2025, 15, 12091. https://doi.org/10.3390/app152212091

Brownlee SK, Liu Y. Low-Cost Laser Powder Bed Fusion-Based Additive Manufacturing of Densified Ceramics. Applied Sciences. 2025; 15(22):12091. https://doi.org/10.3390/app152212091

Chicago/Turabian StyleBrownlee, Sean K., and Yingtao Liu. 2025. "Low-Cost Laser Powder Bed Fusion-Based Additive Manufacturing of Densified Ceramics" Applied Sciences 15, no. 22: 12091. https://doi.org/10.3390/app152212091

APA StyleBrownlee, S. K., & Liu, Y. (2025). Low-Cost Laser Powder Bed Fusion-Based Additive Manufacturing of Densified Ceramics. Applied Sciences, 15(22), 12091. https://doi.org/10.3390/app152212091