1. Introduction

In recent years, a considerable number of new ice rinks have been constructed in Poland, alongside the modernisation of existing facilities. Advances in lightweight construction technologies have notably accelerated the development of ice sports infrastructure. In 2023, a study [

1] was published presenting an inventory of facilities intended for winter sports in Poland, revealing a total of 231 such sites. Among these, ice rinks represent some of the most frequently utilised facilities. Currently, there are 26 ice rink arenas in Poland, defined as full-size indoor ice rinks located within fully enclosed buildings and equipped with spectator stands that allow direct observation of sporting events such as ice hockey or figure skating. Furthermore, 69 additional indoor ice rinks with a minimum area of 600 m

2 have been identified across the country.

It is difficult to provide an exact number of ice rink arenas in Europe, as the data are often updated and not always readily accessible. However, ref. [

2] lists, for example, 212 arenas in Finland and 336 in Sweden, while ref. [

3] provides sample data on the number of indoor ice hockey rinks in 2023/24: 807 for Russia, 374 for Sweden, 293 for Finland, and 191 for Czechia. These figures highlight the considerable number of ice rinks across various European countries.

Ice rink arenas represent a challenge for designers, as they require specialised technical solutions. These are roofed facilities with an ice surface, intended for various types of sports and recreational activities. The intended use of the ice rink determines the shape and dimensions of the ice surface. These requirements are defined by the relevant international federations, such as the International Ice Hockey Federation (IIHF). For IIHF top-level championships, the official ice rink size shall be 60 m in length and 26–30 m in width. The corners shall be rounded in an arc with a radius of 7.0–8.5 m. Ice hockey at levels below IIHF championships may be played on rinks of different dimensions [

4]. Based on seating capacity, five categories of ice rink arenas can be distinguished: small practice arenas (0–300 seats); small competition arenas (300–1500 seats); large competition arenas (1500–5000 seats); modern multi-purpose arenas (over 5000 fixed seats); and shopping mall skating rinks [

4].

Ice rink arenas are subject to heat and moisture gains from both outdoor and internal sources. The main internal sources of heat are lighting and occupants, including spectators and skaters. Heat gains or losses also occur through the building envelope. Heat is also transferred from the air to the ice surface. Significant radiative heat transfer takes place between the ice surface and the roof. Additional heat gains or losses arise from ventilated and infiltrating outdoor air. Moisture is introduced into ice rink arenas from various sources, including water evaporating from the ice surface during melting; the facility’s users; infiltrating and ventilated outdoor air; periodic resurfacing of the ice with a Zamboni; and the ice surface itself [

5].

Fog can develop within an ice rink arena as a result of warm, humid air flowing over the cold ice surface. To prevent this phenomenon, it is essential to maintain appropriate indoor air parameters. Designers may refer to IIHF guidelines [

4] as well as relevant scientific literature [

6]. IIHF guidelines specifying requirements for indoor climate and ventilation have been in effect since 2012. To date, no detailed guidelines on this matter have been developed in Poland.

The purpose of ventilation in an ice rink arena is therefore not only to maintain appropriate thermal and humidity conditions for occupants through heating and ventilation, but also to remove excess moisture from above the ice surface through dehumidification [

7]. Excess moisture can lead, in addition to fog formation, to the undesirable phenomenon of water vapour condensation on the building envelope. This, in turn, may result in negative effects such as corrosion of metal components, decay of wooden structures and elements, and the growth of mould and fungi [

8]. There are two primary ways to remove moisture from the air: (1) cool the air below its dew point to condense the water vapour; or (2) pass the air over a desiccant material [

8]. In most cases, for ice rinks the second option is adopted.

Information on the current design values for ice and indoor air temperatures, as provided in the IIHF guidelines [

4], relates to practice and small competition ice rink arenas. The lowest values of ice temperature are specified for ice hockey, while higher values are required for figure skating, depending on the type of ice rink arena and the activity (game, competition, training, or other). For example, for an ice hockey game in a practice ice rink arena, the ice temperature should be within the range from −5 °C to −4 °C. The corresponding design air temperature above the ice surface in this case is +8 °C to +10 °C, with +10 °C in the spectator stands. The maximum air relative humidity is 60% for all types of ice rink arenas and activities. It is worth noting that earlier IIHF guidelines, issued prior to 2024, specified a higher maximum relative humidity of 70%. Furthermore, the current IIHF guidelines [

4] also provide recommended maximum air relative humidity values for different air temperature values. For instance, at an indoor air temperature of +10 °C, the recommended maximum air relative humidity is 65%, while the maximum relative humidity to avoid fog formation is 80%.

According to [

6], the practical, general requirements for ice rink arenas regarding indoor air parameters are as follows: an indoor air temperature range of 10 °C to 12 °C for training, 12 °C to 14 °C for competitions, and 14 °C to 15 °C in the spectator stands. A recommended air relative humidity range of 40–65% is also suggested [

6]. Furthermore, it is noted that it is common practice to design the ice temperature at approximately −6 °C.

The minimum air volume flow rate value that must be supplied to an ice rink arena is defined in the IIHF recommendations [

4], the ASHRAE standards [

9], as well as in the Polish Standard [

10] on building ventilation. According to the Polish Standard [

10], the required value is 20 m

3/h per person, while ASHRAE [

9] specifies 25.50 m

3/h per person or 9.14 m

3/h per m

2 of ice surface. Following ASHRAE requirements [

9], the air flow value should be calculated based on both criteria, with the higher value being applied. Additional guidelines are provided in the IIHF recommendations [

4], depending on the type of ice rink arena (practice or small competition arena) and the activity (game, competition, training, or other). For competitors, in most cases, the minimum supply air volume flow rate value is 72 m

3/h. It is again worth noting that earlier IIHF guidelines, issued prior to 2024, specified lower values, around 43.20 m

3/h.

Air can be supplied to an ice rink arena in different ways. Two types of air distribution systems are commonly used in ice rink arenas [

5,

7]. The integrated system combines the functions of ventilation, heating, and dehumidification within a single installation. In this case, the ice rink together with the spectator area is treated as a single zone, where supply air, both heated and dehumidified, is delivered, for example, through long-throw nozzles mounted beneath the roof structure. This solution is preferred for facilities with small spectator areas and a limited number of viewers. In the separated system, the functions of ventilation/heating are independent from those of dehumidification. The arena is divided into two zones: the ice rink and the spectator area. Each of these is provided with a separate supply air system, for example, through long-throw nozzles in the upper part of the arena, together with dedicated exhaust air outlets. In the spectator zone, heated supply air is introduced to ensure thermal comfort for relatively inactive occupants. The air should be directed so as not to flow over the ice surface, as this could contribute to fog formation above the ice rink. The air supplied to this zone consists of 100% outdoor ventilation air. In contrast, in the zone adjacent to the ice surface, air is drawn from the arena, dehumidified in the air handling unit, and subsequently resupplied to the arena in order to protect the ice surface from the adverse effects of moist air. Designers are familiar with the recommendation [

7] that the dehumidification airflow should account for 7–10% of the ventilation airflow, although this guideline lacks a clear justification, other than the need to limit heat exchange between the ice surface and the indoor air.

In summary, outdoor air with appropriate parameters must be supplied to an ice rink arena through the ventilation system in sufficient quantity to maintain proper indoor air conditions. In addition, dehumidification is required to remove excess moisture from above the ice surface. The implementation of air treatment processes in an ice rink arena, including the necessary dehumidification, is associated with significant energy consumption. In general, five systems can be identified in ice rink facilities as contributing to the overall energy consumption of the building: dehumidification, ventilation, cooling, heating, and lighting.

As a result, ice rink arenas represent one of the most energy-intensive building types in the sports and recreation sector, with annual energy consumption often exceeding 200 kWh/m

2 [

11]. The unique operational requirements of maintaining ice surfaces at sub-zero temperatures while providing comfortable spectator environments create complex thermal dynamics that significantly impact energy performance. Ventilation systems and air handling units play a crucial role in managing these competing thermal demands, controlling humidity levels, and maintaining air quality throughout the facility. The importance of understanding energy consumption patterns in ice rinks has grown substantially due to increasing energy costs, environmental regulations, and sustainability initiatives in the sports industry. Recent studies indicate that HVAC systems can account for 40–60% of total energy consumption in ice rink arenas, making them a primary target for energy optimization efforts [

4].

The literature includes studies on the ventilation and thermal–humidity conditions of ice rink arenas [

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21], some of which also examine the impact of ventilation system configurations on energy consumption. Comparative analyses of six different AHU layouts using numerical simulations, energy modeling, and field measurements demonstrated that optimised air handling configurations can result in up to 38% reduction in cooling demand and 60% reduction in dehumidification demand [

11]. Based on on-site measurements in two ice rink arenas and a validated numerical model, the study [

19] analysed the effects of jet and displacement ventilation systems on the indoor thermal environment, demonstrating that displacement ventilation provided superior zoning control and reduced cooling and dehumidification energy consumption by 54% and 51%, respectively, compared to jet ventilation. The study [

20], based on field measurements and entransy analysis in an Olympic-level ice rink, showed that optimization measures such as low-emissivity coatings, local air conditioning, stratification, and displacement ventilation can cut sensible heat flow into the ice by 48.4% and reduce dehumidification demand by 70%, thus markedly improving energy efficiency. Another study [

21] measured environmental conditions in six ice rinks and showed that energy demand is significantly increased by zonal mixing in large rinks and by counteraction between refrigeration and dehumidification systems, highlighting the need for optimised airflow and coordinated system operation.

All of these studies demonstrated significant potential for energy savings; however, none of them considered a comprehensive comparison of multiple AHU configuration variants combined with a full analysis of the impact of different air treatment process sequences, the integration of ventilation, recirculation, and heat recovery systems, and the effects of variable and constant air volume on the year-round energy performance of an ice rink arena under actual thermal and humidity conditions.

The aim of this paper was to analyse the energy consumption of different ventilation system and air handling units’ configurations in relation to the thermal and humidity conditions maintained within an ice rink arena. Particular emphasis was placed on identifying solutions that ensure both adequate indoor climate parameters and significant reductions in energy consumption. This focus is highly relevant in the context of the ongoing development and modernisation of ice rink facilities in Poland, where the dynamic expansion of this sector necessitates research that supports energy-efficient and environmentally responsible design and operation. As energy costs continue to rise and environmental regulations become more stringent, the importance of optimising ice rink HVAC systems will only increase.

The novelty of the present study lies in the comprehensive energy and thermal–humidity analysis encompassing nine AHU system variants with different air treatment process configurations, both integrated and separated ventilation systems, regulation of air temperature and volume flow rate—Variable Air Volume (VAV) and Constant Air Volume (CAV), and the option of using a stand-alone dehumidifier instead of a desiccant wheel. Importantly, the numerical model developed for this purpose was experimentally verified, ensuring that the simulation results accurately reflected the actual operating conditions of the analysed ice rink arena. The results of the present research are applicable to temperate climates, where most ice rink facilities are located and which provide favourable conditions for their operation.

2. Methods

2.1. Research Methodology

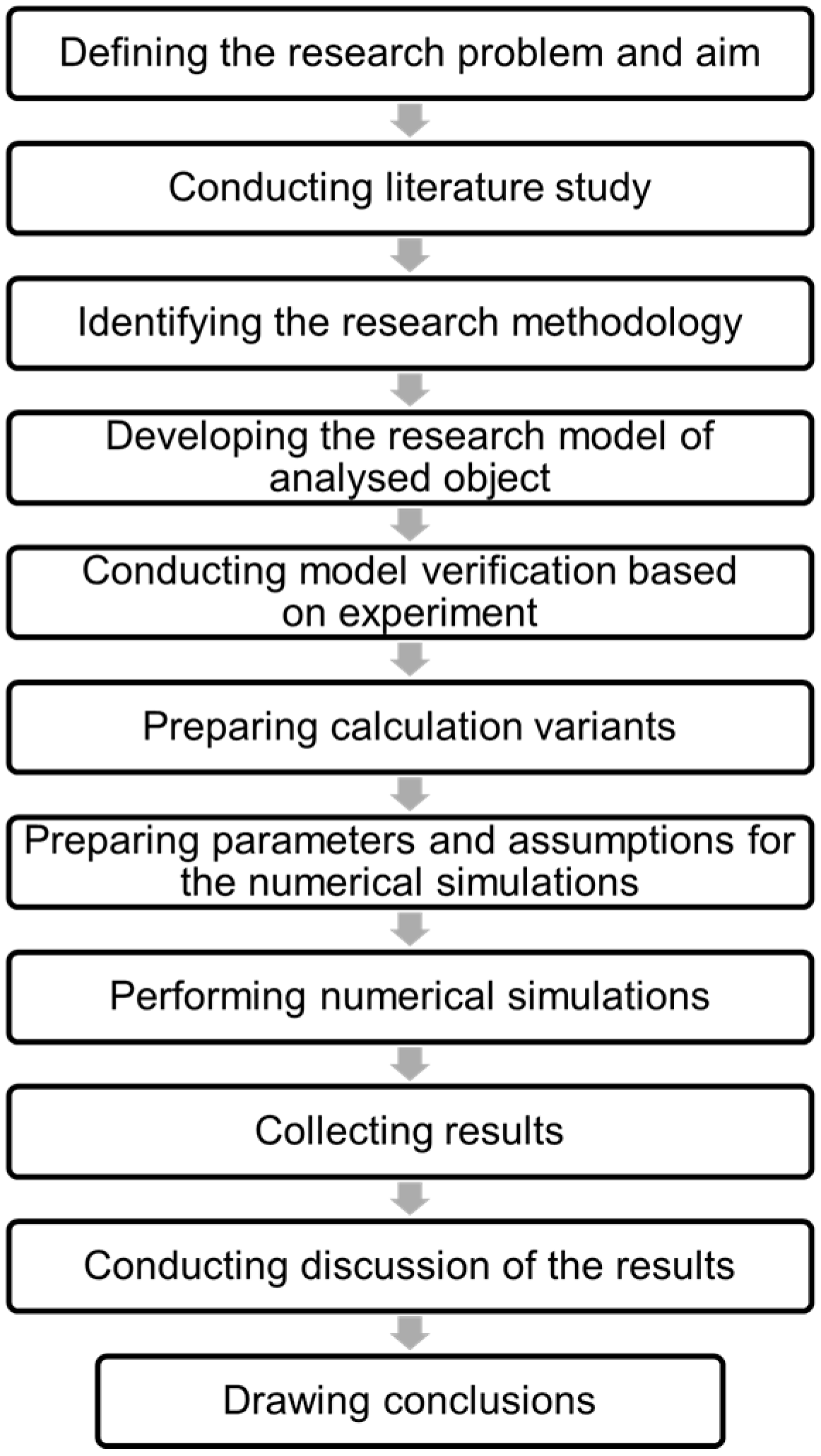

The energy analysis of different configurations of air handling units and air distribution systems for the existing ice rink arena was carried out as part of the research process illustrated by the block diagram in

Figure 1. The research began with the formulation of the research problem and objectives, followed by a literature review, identification of the research methodology, preparation of the research model, verification of the model, and subsequently numerical simulations for the developed calculation variants, their parameters, and assumptions. The simulation results of the energy analyses and thermal–humidity conditions were then compiled and discussed. Finally, conclusions were drawn.

2.2. Analysed Ice Rink Arena and Research Model

The analysed ice rink arena has dimensions of 66 m in length, 37 m in width, and 11 m in height at the highest point of the roof, resulting in a total volume of approximately 22,100 m

3.

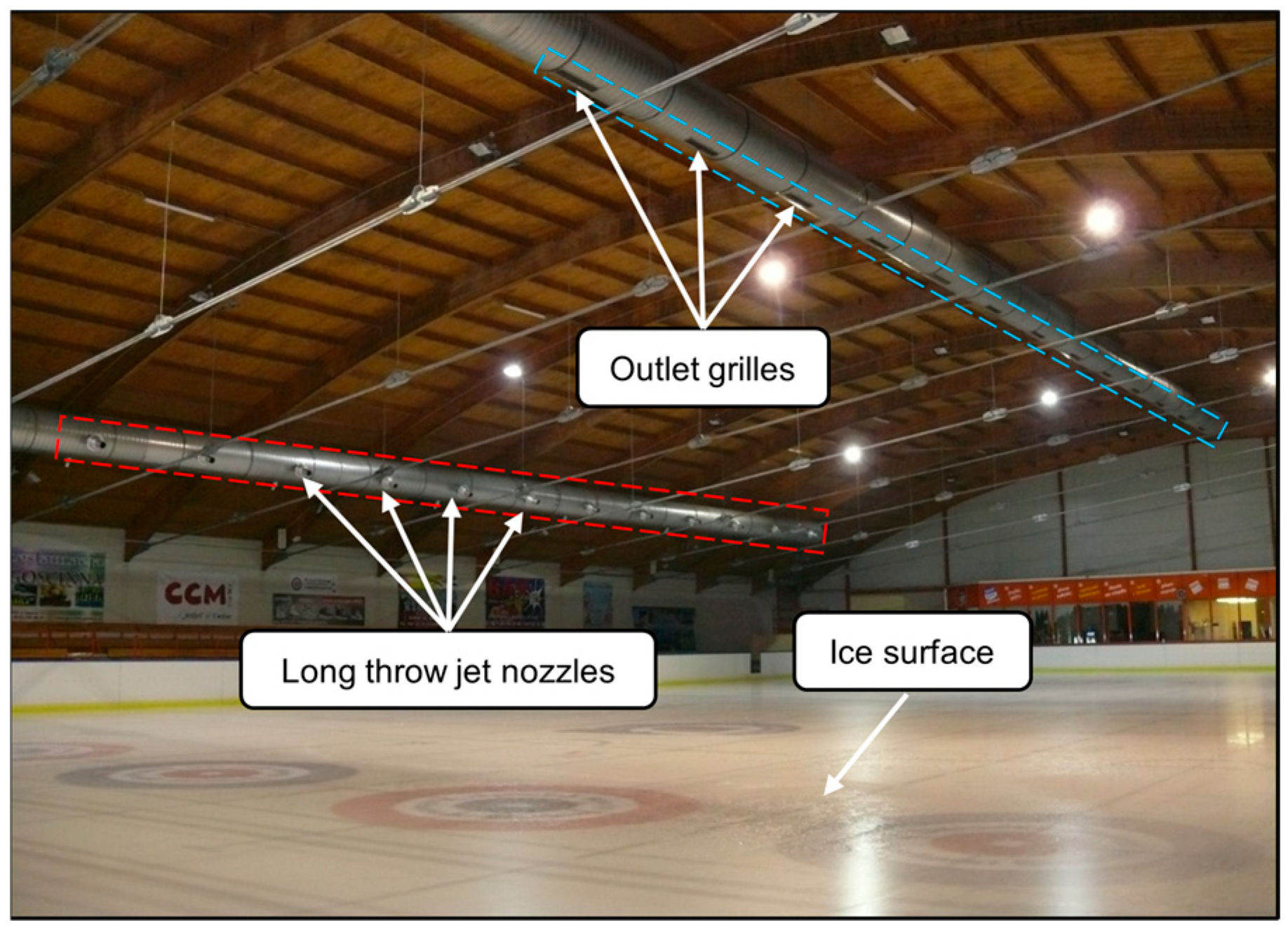

Figure 2 presents an interior view of the facility with the locations of exhaust grilles and supply openings designed as long throw jet nozzles. The ice surface, measuring 30 m × 60 m, is also visible in

Figure 2.

The ice rink arena is located in Poland and has been in operation since 2003. The facility is used from November to March, primarily for various sports and recreational activities (from 08:00 to 21:00), and occasionally for curling competitions and ice hockey games. The ice rink is utilised by both schools and individual skaters for recreational purposes, as well as by sports clubs organising competitions. The arena can accommodate a maximum of 200 people on the ice surface and 150 spectators in the stands.

The internal partitions of the analysed ice rink arena consist of the southern wall, adjacent to which is a café, the ice rink floor, and partially the northern wall, along which technical rooms are located. The outdoor partitions consist of the roof, partly the northern wall, the eastern wall, adjacent to which are spectator stands, and the western wall. The western wall is partially embedded in the ground and is inclined at an angle of 75°. The thermal transmittance (U-values) for the outdoor walls are as follows: 0.301 W/m2K for the roof, and 0.187 W/m2K for the northern and eastern walls, as well as for the portion of the western wall above ground level. The thermal transmittance coefficients were determined based on the total thermal resistance of the building envelope, which was calculated by summing the thermal resistances of the individual material layers as well as the heat transfer resistances at the internal and external surfaces, depending on the type of partition. Information regarding the materials used and their thickness was obtained from the building’s technical documentation.

The internal sources of heat in the arena are lighting, spectators, and skaters. Internal sources of moisture are primarily the occupants. Moisture also enters the facility through supplied outdoor air and infiltration. When the ice temperature is higher than the dew point of the indoor air, moisture gains from the ice surface can also be expected. Conversely, if the ice temperature is lower than the dew point, condensation occurs on the ice, followed by freezing. The frozen moisture on the ice surface must then be removed using a Zamboni.

The ice rink arena is equipped with a single mechanical supply-and-exhaust ventilation system, with the arena treated as a single zone. It is a fully air-based system operating continuously. The design maximum air volume flow rate is 17,500 m3/h, and the indoor air temperature is at least 5 °C. In the integrated system, the distribution of ventilation air is achieved via side supply and exhaust air located beneath the roof of the ice hall. Long throw jet nozzles with diameters of Ø160 mm (17 units) and Ø80 mm (8 units) are used as supply outlets. The exhaust duct is fitted with 17 rectangular exhaust grilles, each measuring 800 mm × 150 mm. The supply duct is positioned at a height of 6 m, while the exhaust duct is at approximately 9 m.

Outdoor air is conditioned by heating in a heating coil within the air handling unit, which is equipped with a supply and exhaust air intake and is located on the roof of the technical building. In addition to the heating coil, the air handling unit contains air filters, acoustic silencers, and a two-speed fan section (the unit operates at the higher speed when the outdoor air temperature exceeds 5 °C, and at the lower speed during the winter period when the outdoor air temperature is below 5 °C). Dehumidification of the air is not provided.

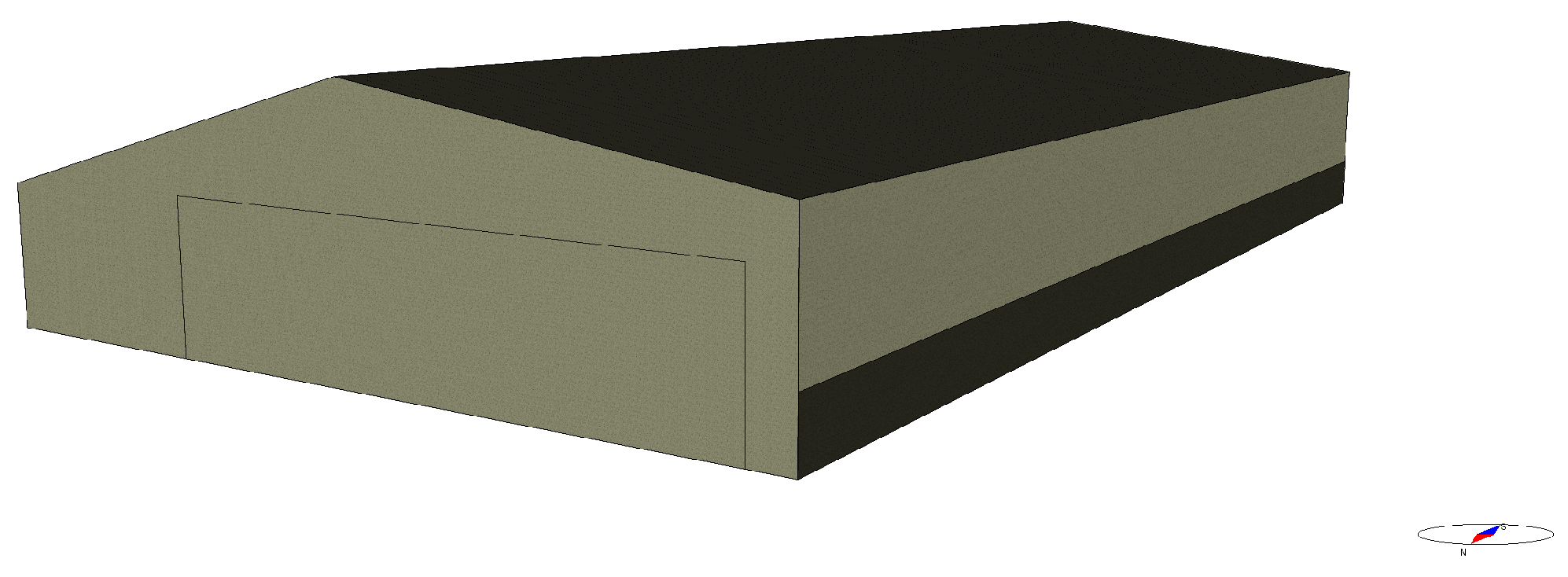

For the purposes of energy simulations, a model of the analysed ice rink arena was created in IDA ICE 4.8 (Indoor Climate and Energy) software, as shown in

Figure 3. The model was based on the actual dimensions of the facility according to its technical documentation. For simplification, two inclined roof planes were assumed instead of the actual arched roof shape, in order to preserve the arena’s volume, and the inclination of the western wall was omitted, which does not significantly affect the results of the analyses.

2.3. Experiment Data for Model Verification

For the purposes of model verification and for obtaining input data for the developed ice rink arena model, an experiment was carried out, which included the following measurements: (1) air temperature and relative humidity inside the ice rink arena, (2) supply air temperature and (3) volume flow rate of the ventilation air.

The measurements were conducted in two separate series during two different months of the ice rink’s operating period, at night-time when no people were present in the arena, and for two different fan speeds:

series 1: from 22:00 on 8 February 2014 to 04:00 on 9 February 2014, with the fan operating at speed I;

series 2: from 22:00 on 12 April 2014 to 03:30 on 13 April 2014, with the fan operating at speed II.

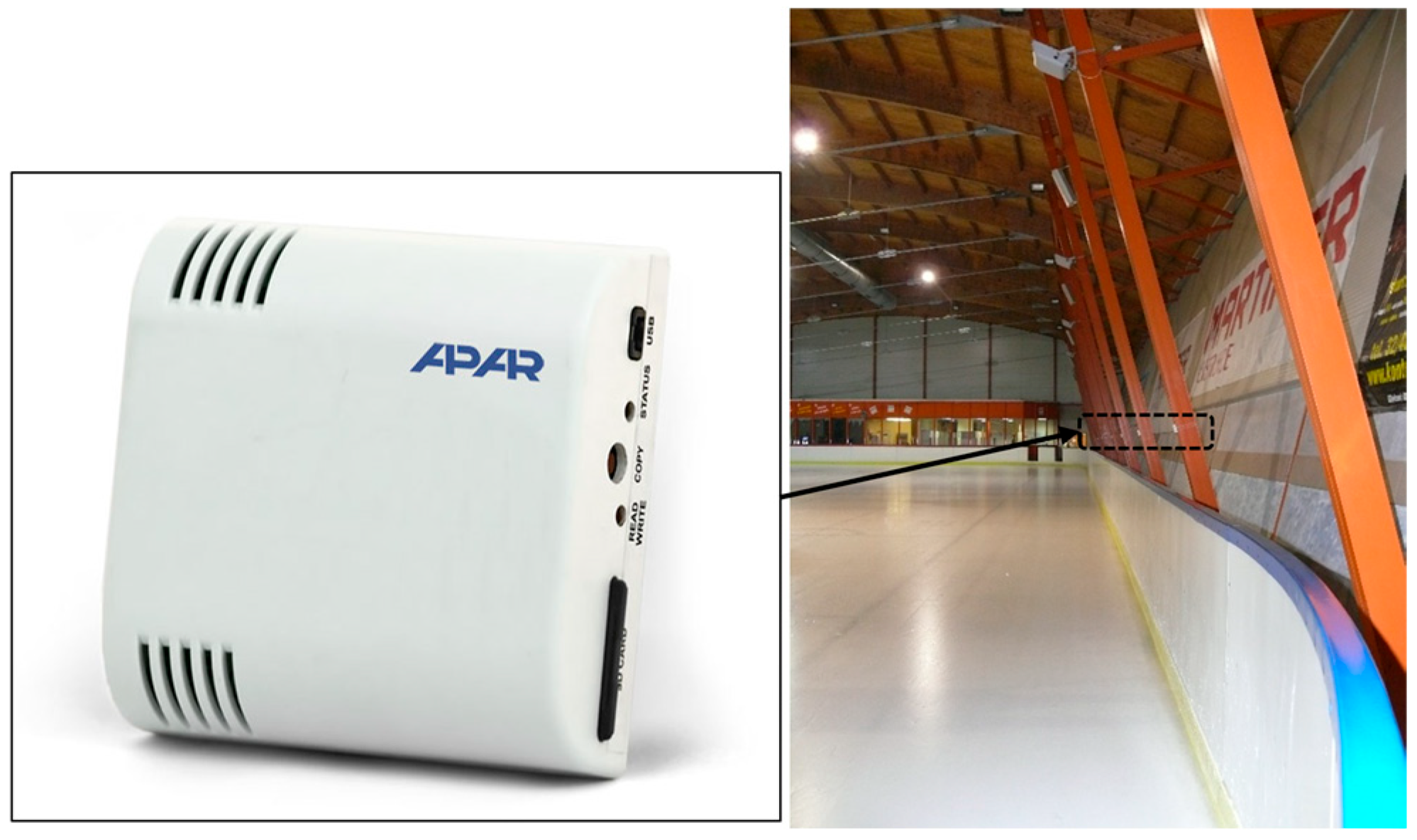

Temperature and relative humidity of both indoor and supply air were measured using APAR (Raszyn, Poland) AR235 data loggers. The measurement accuracy was 3–5% for relative humidity and 0.5–1.8 °C for temperature. Measurement data were recorded at 1 min time step [

12].

The indoor air temperature and relative humidity were measured at a height of 1.7 m along the ice surface, with the measuring devices mounted on structural columns on the outer side of the ice rink boards, as shown in

Figure 4. In addition, the air temperature above the ice surface was measured using a Sensor Electronic (Gliwice, Poland) HT-428 thermo-anemometer, also at a height of 1.7 m. The instrument used for this purpose offered a high measurement accuracy of ±0.2 °C.

The averaged values of indoor air temperature from both devices (above and beyond the ice surface), together with the indoor air relative humidity, were used to verify the results of thermal–humidity condition simulations and the energy simulations, while the supply air temperature was applied as input data for the model verification calculations.

The supply air volume flow rate was measured indirectly using two methods based on air velocity measurements. In the first method, a VPT-100 VOLTCRAFT anemometer with Pitot tube was employed to determine air velocity in the long-throw jet nozzles. The equipment was sourced from Conrad Electronic SE, Hirschau, Germany. The velocity measurement was performed by dividing the circular cross-section of the nozzle into concentric rings, the number of which depended on the nozzle diameter, in accordance with ISO 7194 [

22]. The measurement accuracy was ±0.25%. In the second method, a TESTO thermal anemometer was used to measure air velocity within the ventilation duct, downstream of the air handling unit. The velocity was determined by dividing the non-rectangular duct cross-section into squares of equal area, also in accordance with ISO 7194 [

22]. The measurement error of this device was 0.03 m/s + 5% of the measured value [

12]. The averaged results of the ventilation air volume flow rate obtained using the two measurement methods were used as input data for the calculations required for model verification.

2.4. Calculation Variants and Simulation Parameters

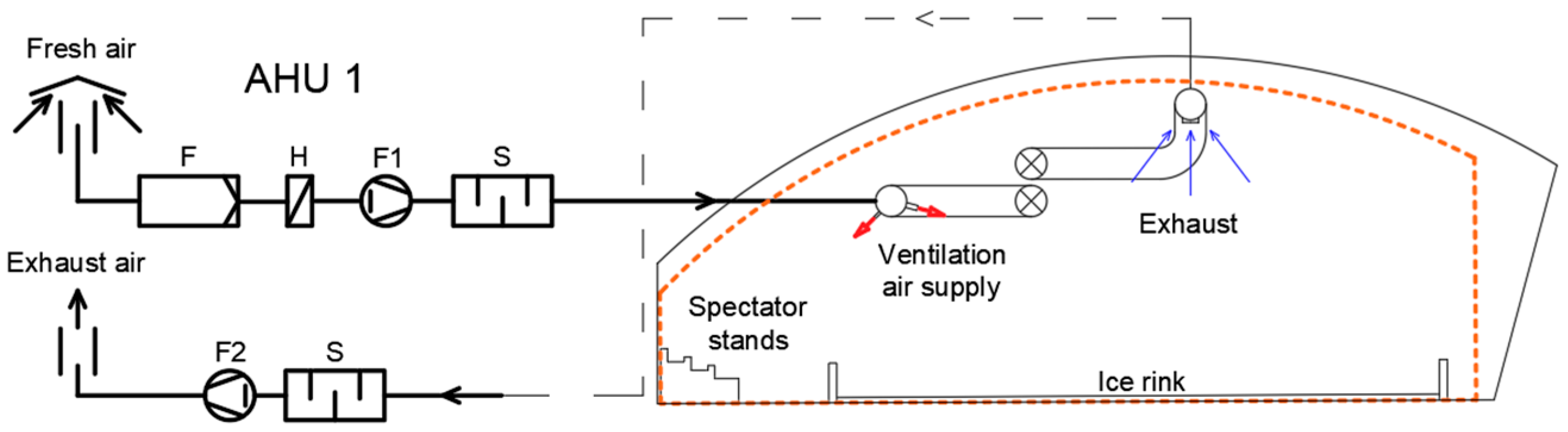

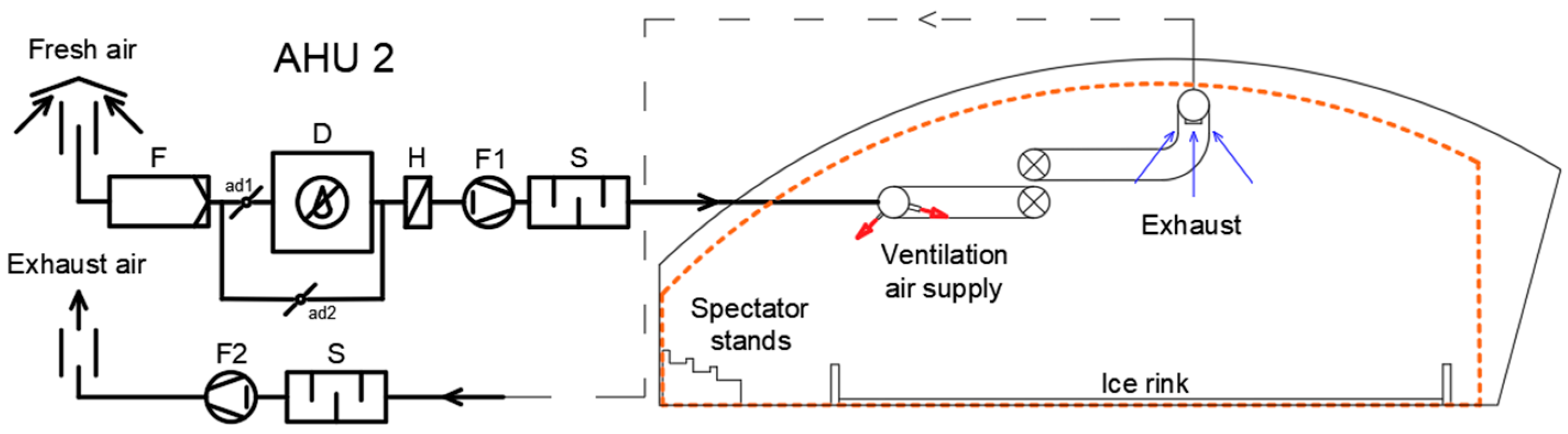

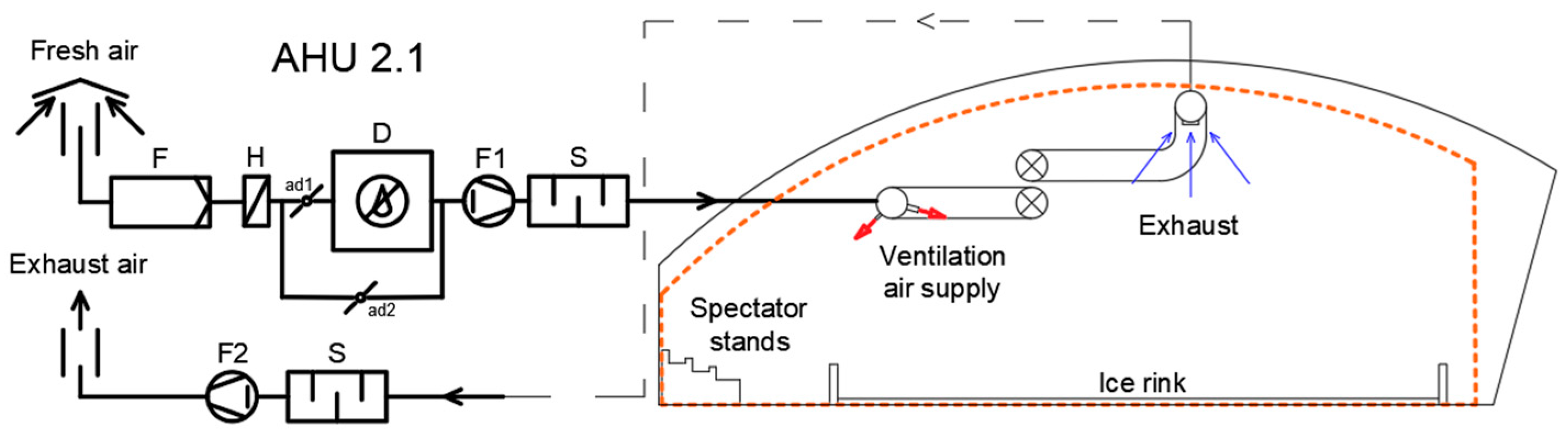

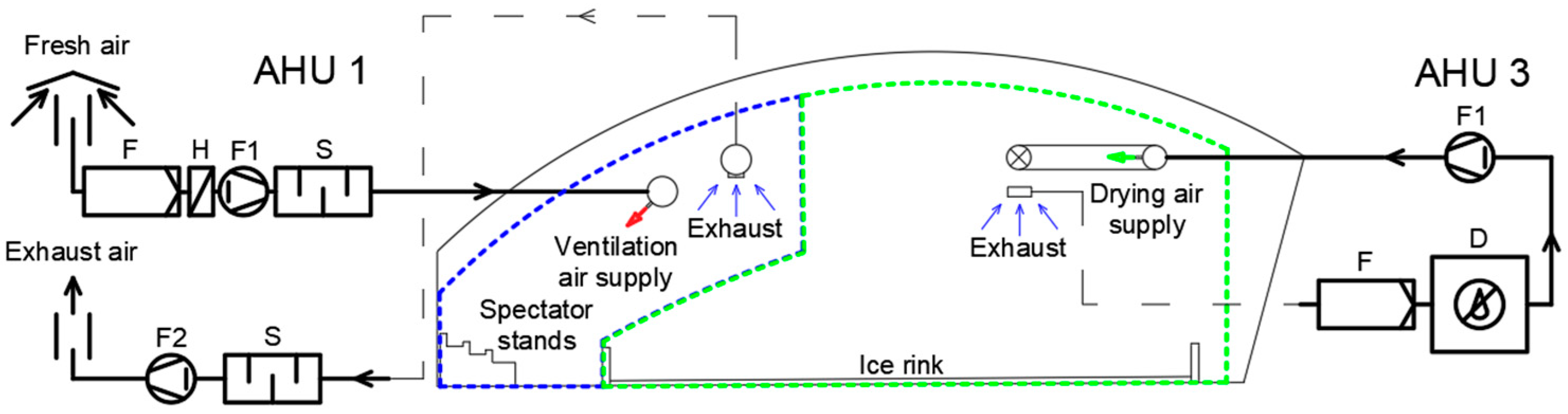

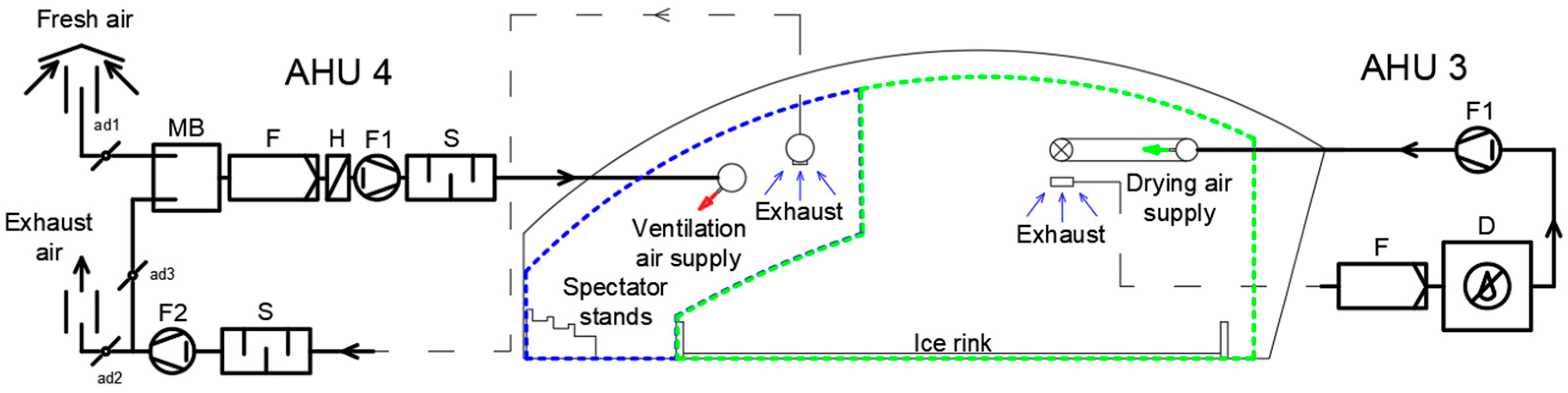

For the purposes of this research, nine calculation variants and five configurations of air handling units (AHU) were developed: Variant 1 (AHU 1), Variant 2 (AHU 1), Variant 3 (AHU 2), Variant 3.1 (AHU 2.1), Variant 4 (AHU 2), Variant 4.1 (AHU 2.1), Variant 5 (AHU 2), Variant 5.1 (AHU 2.1), Variant 6 (AHU 1, AHU 3), Variant 7 (AHU 4, AHU 3), Variant 8 (AHU 5, AHU 3), Variant 9 (AHU 1). The main assumptions of each variant configurations are presented in

Table 1, while

Table 2 summarises their boundary conditions. The schematics of the individual air handling units are shown in

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10, with the following notations used: F—filter; H—heating coil; F1—supply fan; F2—exhaust fan; S—silencer; D—dehumidifier; MB—mixing box; R—recuperator; ad1–ad3—air dampers.

Variants 1 and 2 were prepared for model verification based on the following experimental data:

which differed in outdoor and supply air parameters as well as in the ventilation air volume flow rate.

Variant 1 represented operation with the fan at speed I, while Variant 2 corresponded to fan speed II. The detailed ventilation air volume flow rate values obtained from the experiment are summarised in

Table 2.

Variants 1 and 2 were based on the existing Constant Air Volume (CAV) system in the actual facility, with ventilation air volume flow rates set according to the experimental data for the respective fan speeds. In these variants, outdoor air is supplied to AHU 1, where it is heated in a heating coil to the appropriate supply air temperature depending on the outdoor air conditions, and then delivered to the arena through the integrated air distribution system. No air dehumidification is provided.

In the actual facility, a standalone dehumidifier is used to remove excess moisture from the arena. This solution was implemented in the final Variant 9, in which a stationary adsorption dehumidifier was assumed for the arena. In Variant 9, the configuration of the air handling unit and the air distribution system remained unchanged compared to Variants 1 and 2.

Starting from Variant 3, the ventilation air volume flow rate was modified. Instead of using the experimental values, the recommended values calculated according to ASHRAE [

9] were adopted, based on the ice surface area as the primary criterion. The calculated ventilation air volume flow rates for the individual variants are summarised in

Table 2.

Variants 3–8 were developed for different ventilation and air distribution systems, as well as for various air handling unit configurations, in order to achieve air parameters in the simulations that comply with recommended conditions for ice rink arenas. The simulations prioritised maintaining an average indoor air temperature of 10 ± 1 °C, while also ensuring that the average indoor air relative humidity did not exceed 65% (provided that the ventilation system capacity allowed), which served as a common basis for comparing the energy consumption required to achieve these conditions. Starting from Variant 3, air dehumidification became necessary; therefore, a desiccant wheel was implemented in the air handling units of Variants 3–8 to dehumidify a portion of the ventilation air, as specified in

Table 2. The minimum dehumidification rate was assumed for Variants 5 and 5.1. For the remaining variants, it was four times higher, corresponding to 70–76% of the fresh air supply.

In Variants 3–5.1, air dehumidification was incorporated in the air handling units within an integrated air distribution system. Two 2 configurations, AHU 2 and AHU 2.1, with a desiccant wheel were considered, differing in the sequence of processes. In AHU 2 for Variants 3, 4, and 5, the outdoor air is first dehumidified in the wheel to a level sufficient to remove the moisture gains in the arena and then heated in the heating coil to the required temperature to compensate for the heat losses in the arena. In AHU 2.1 for Variants 3.1, 4.1, and 5.1, the sequence of heating and dehumidification is reversed. Furthermore, in Variants 4–5.1, the system was changed from a Constant Air Volume (CAV) to a Variable Air Volume (VAV) system, with the minimum air volume flow rate set to the recommended value calculated according to ASHRAE [

9] and the maximum value as assumed. These values are presented in

Table 2.

In Variants 6–8, the integrated air distribution system was replaced with a separated system, and the CAV system was reinstated. The arena model was divided into two zones: the spectator area and the ice rink, each operated by individual air handling units. AHU 3, supplying the ice rink zone in each of these variants, draws 10% of the ventilation air from the arena, which is then dehumidified using a desiccant wheel. The air handling units supplying the spectator area had different configurations: AHU 1 (without heat recovery) in Variant 6, AHU 4 (with heat recovery) in Variant 7, and AHU 5 (with heat recovery) in Variant 8. In Variant 7, a single-stage heat recovery system was used by recirculating exhaust air and mixing it with the minimum hygienic supply of fresh air, according to the presence of occupants as per the Polish Standard [

10], whereas in Variant 8, heat recovery was provided by a recuperator.

The following calculation parameters, common to all variants, were established in the IDA ICE 4.8 software. The construction of the building partitions in the model was defined according to the design documentation. Typical values for thermal bridges, as defined in the software, were adopted. In Variants 1–5.1 and 9, the model volume was treated as a single zone, whereas in Variants 6–8 it was divided into two zones: the ice rink and the spectator area. The ice surface was defined as an area of 1702 m2 with a thermal conductivity of 2.2 W/(m·K) and an actual cooling power of 220 W/m2 to maintain an ice temperature of −5 °C, in accordance with the technology of the analysed ice rink.

The parameters for internal heat and moisture sources were defined. The heat and moisture gains from skaters and spectators were specified according to their number, activity, and clothing. It was assumed that the arena accommodates a maximum of 200 skaters and 150 spectators, although the actual number may be lower; therefore, a simultaneity factor of 0.5 was applied. The occupants were assumed to be present in the facility from 08:00 to 21:00 every day of the week during the ice rink arena’s operational period. The metabolic equivalent (MET) and clothing insulation (CLO) values were set at 4 and 1.2, respectively, for skaters, and 1.5 and 1.2, respectively, for spectators. Twelve industrial lighting fixtures with 400 W metal halide lamps were assumed, with a total power of 4.8 kW. The lighting schedule was adopted in accordance with the occupants’ schedule. In Variant 9, additional equipment in the form of an adsorption dehumidifier was included, with an electric power consumption of 4 kW and a capacity of 10.5 kg/h.

The remaining simulation parameters concerned the air handling systems. Control setpoints for the arena were adopted as follows: indoor air temperature between 5 °C and 8 °C, and CO

2 levels between 700 and 5000 ppm. The ventilation air volume flow rates were determined according to the respective calculation variant. Energy losses in the ventilation system were assumed to be 1 W/m

2, with 25% of the heat loss released into the arena. In the analysis, it was assumed that devices such as fans, heating coils, and dehumidifiers operate as separate units, as modelled in IDA ICE 4.8. The heating coil was assumed to be located within the volume of the ice rink arena, so the thermal energy supplied by the coil was delivered to the arena both through the ventilation air and through minor heat losses, e.g., radiation from the coil casing. Considering that no additional devices affecting the coil’s energy consumption were present, its efficiency was assumed to be 100%, as all supplied thermal energy remained within the facility volume. The supply air temperature for each air handling unit variant was automatically calculated by the software based on the input relationship between the supply air temperature and the outdoor air temperature, which was derived from the heat and moisture balance calculations. Exceptions were Variants 4–5.1, where a fixed supply air temperature was applied due to the VAV system, and Variants 1–2, where the supply air temperature was set as a constant based on measurements, taking the average value over the measurement period. Furthermore, in the VAV systems, the software selected the supply air volume flow rate within the specified minimum and maximum range. The average supply air volume flow rates obtained from the simulations are presented in

Table 2.

A sample schematic of the air handling unit defined in IDA ICE 4.8 for Variant 3 is shown in

Figure 11. For all variants, the supply and exhaust fans were assigned the same pressure based on the design of the ice rink ventilation system. The fan efficiency was also assumed to be identical across all variants, so that the Specific Fan Power (SFP) did not exceed the maximum allowable values specified in the Polish regulations [

23]. In IDA ICE 4.8, the fan efficiency was set at 60%, and this was accounted for in the calculations. Differences in the average energy consumption of the fans due to varying air volume flow rates between variants amount to a maximum of 16% of the fan energy, which corresponds to approximately 0.5% of the total energy consumption for the analysed variants. This difference was included in the IDA ICE 4.8 calculations; however, it was not further discussed in the analysis, as it does not affect the overall results of the study. The values of fan pressure, efficiency of the supply and exhaust fans, and their SFP values are presented in

Table 2.

The numerical simulations for Variants 3–9 were carried out for the calculation period from 22 November 2024 to 31 March 2025, while Variants 1–2 were simulated according to the duration of the measurements. The software utilised climatic data from the meteorological station in Katowice, located 20 km from Gliwice [

24]. During the analysed period, the outdoor air temperature ranged from −14 °C to 22 °C, while the outdoor air relative humidity ranged from 24% to 100%.

The primary energy demand for each variant was calculated using the non-renewable primary energy factors: w

i = 0.8 for the preparation of the heating medium in the heating coil, and w

i = 2.5 for the electricity required to power the fans [

25]. The research focused solely on the environmental costs associated with the operation of the air handling units, without accounting for the energy consumption of other building systems. For the calculation of the CO

2 emission for each variant the CO

2 emission factor of 0.446 kg CO

2/kWh was adopted for the heating system [

26].

3. Results and Discussion

The calculation results were first verified against the experimental data (

Section 3.1), followed by a verification of the thermal–humidity conditions in the analysed ice rink arena (

Section 3.2). The subsequent part focused on the energy analysis of individual variants (

Section 3.3). The key results were discussed in

Section 3.4. The discussion of results concentrated on Variants 3–8, while Variant 9 was treated as a separate case, presented in

Section 3.5.

Section 3.6 presents a summary of the discussion of the results.

3.1. Results of the Numerical Model Verification

Numerical simulations are now a standard tool in engineering, enabling the analysis of complex phenomena without the need for costly physical testing. However, in order for the simulation results to be reliable, they must be verified against experimental data. Comparing numerical results with actual measurement results makes it possible to assess the accuracy of the calculations. Therefore, the results of Variants 1–2 were first analysed and compared with the experimental data, according to the adopted research methodology.

Table 3 presents a comparison of the averaged values of indoor air temperature and relative humidity obtained from the experiment with the corresponding mean values derived from the energy simulations. In addition, the range of mean air specific humidity for the experiment was calculated taking into account the measurement device errors, while the simulation results are reported as an average value, as well.

In Variants 1 and 2, the simulated value of mean indoor air temperature was within the range of measurement error of the measuring equipment. Furthermore, it can be observed that Variant 1 yielded the lowest indoor air temperature, consistent with the experimental results. The mean indoor air relative humidity in both variants reached 100%, which is comparable to the experimental data. When assessing the thermal–humidity conditions, the indoor air specific humidity is also of importance, and in this case the simulated values were found to lie within the experimental range.

Based on the results of Variants 1 and 2, calculated for different outdoor climate conditions and values of supply air volume flow rate and supply air temperature, it was concluded that the numerical model operated correctly and reproduced the experimental results with satisfactory accuracy, making it suitable for further analyses. Furthermore, it should be noted that the actual indoor air parameters in the facility deviated significantly from the recommended values, clearly indicating the necessity for air dehumidification, which was incorporated in the subsequent calculation variants.

3.2. Thermal and Humidity Conditions Analysis

Maintaining appropriate thermal and humidity conditions in an ice rink arena is crucial both for the quality of the ice surface and for occupants’ comfort. The analysis of mean indoor air temperature and relative humidity allows for the assessment of how effectively different ventilation system variants provide the required indoor microclimate. Comparing the results in this respect enables the evaluation of the efficiency of the adopted solutions in maintaining air parameters, which constitutes an important aspect of the functional and energy assessment of the ventilation systems.

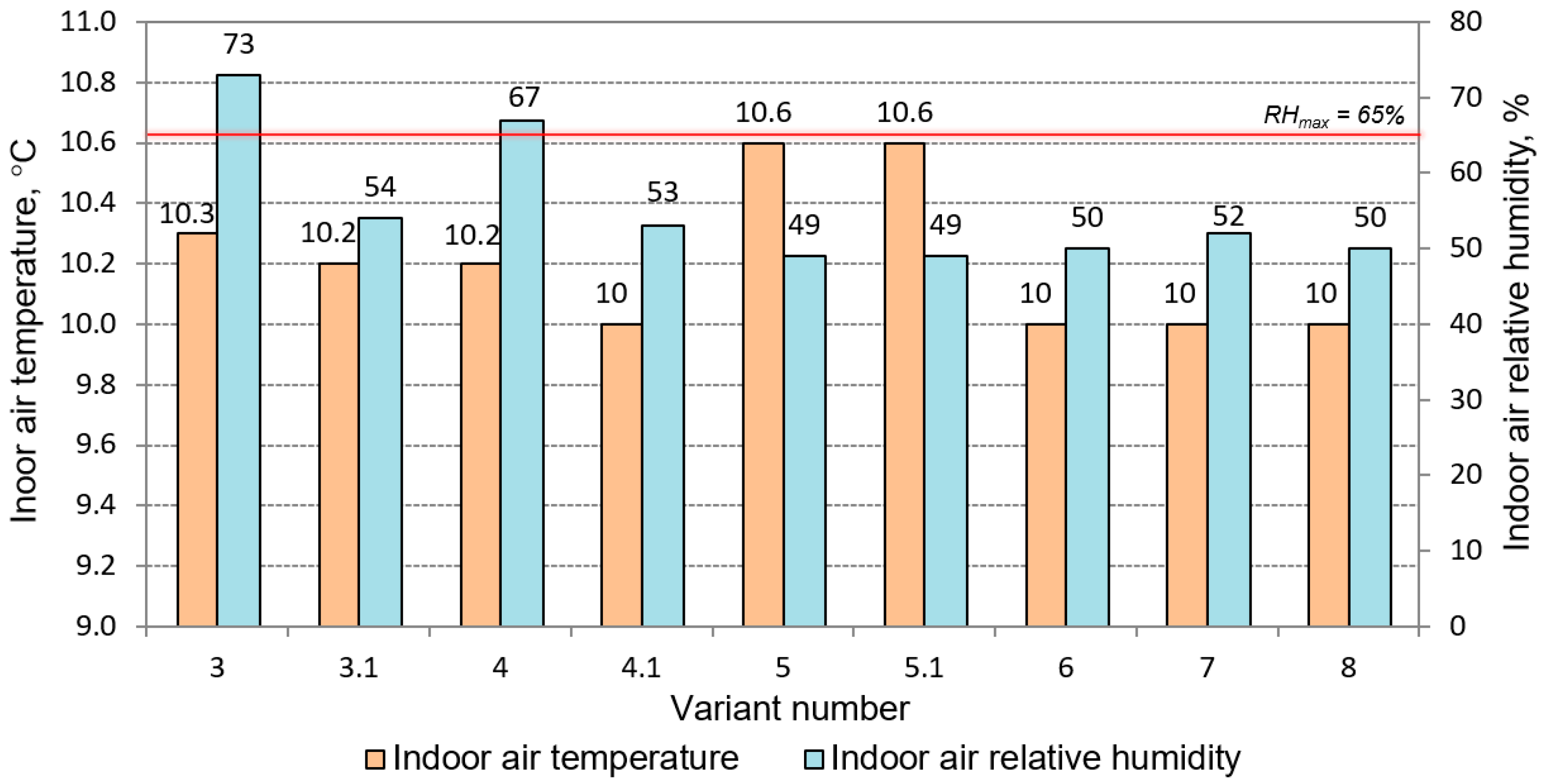

Figure 12 presents the mean indoor air temperature and relative humidity values for Variants 3–8. It can be observed that all mean air temperature values remained within the assumed range of 9–11 °C. The highest mean air temperature value, equal to 10.6 °C, was obtained in Variants 5 and 5.1. These variants featured the largest proportion of outdoor air, which led to an increase in indoor air temperature due to the supply of a greater air volume flow rate at a constant high supply air temperature of 25 °C. This also allowed for the use of the lowest proportion of air directed to the desiccant wheel. In other words, reducing the air volume flow rate directed to the desiccant wheel in these variants decreased the volume flow rate of air undergoing dehumidification, resulting in a higher share of heated outdoor air and, consequently, an increase in the indoor air temperature.

Among the integrated system variants, the lowest mean indoor air temperature value, and the one most closely matching the recommended value was obtained for Variant 4.1. For the separated systems, all analysed variants yielded indoor air temperature values consistent with the recommended value. Regarding mean indoor air relative humidity, Variants 3 and 4 exceeded the recommended value of 65% (indicated by the red line in the figure) by 8% and 2%, respectively. In the remaining variants the values were similar to each other, ranging between 49% and 54%.

Analysing only the mean values of indoor air temperature and relative humidity does not provide a complete picture of the thermal and humidity conditions in the ice rink arena, as it fails to capture daily fluctuations or short-term deviations that can affect both occupant comfort and ice quality. Therefore, it was decided to analyse the daily profiles of indoor air temperature and relative humidity for each of the variants. This approach allows an assessment of the stability of air parameters over a 24 h period and the effectiveness of the ventilation systems in maintaining the required microclimate under varying thermal and moisture loads.

Figure 13 and

Figure 14 present the daily profiles of indoor air temperature and relative humidity, respectively, in the ice rink arena for each of the calculation variants.

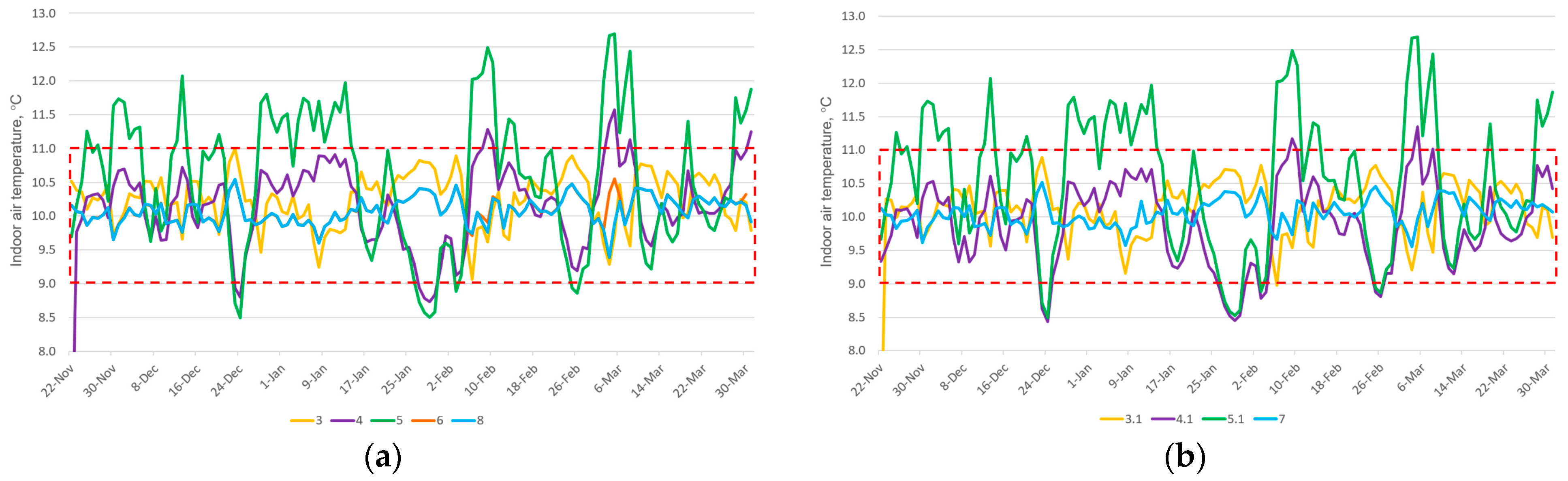

In terms of indoor air temperature (

Figure 13), the best results were obtained for Variants 3 and 3.1 with the integrated system, and Variants 6, 7, and 8 with the separate system, in which 100% of the results fell within the recommended range. In the other integrated system Variants 4 and 4.1, 90% of the results were within the recommended range, while in Variants 5 and 5.1 only 57% complied. The conformity of indoor air temperature (t) results is summarised in

Table 4. The most stable temperature profiles were observed in the separate system Variants 6, 7, and 8, with values ranging from 9.5 °C to 10.5 °C. In the integrated system Variants 3 and 3.1, temperatures fluctuated more widely, between 9 °C and 11 °C. Thus, it can be concluded that the separate system Variants 6, 7, and 8 provided the highest consistency in daily indoor air temperature results.

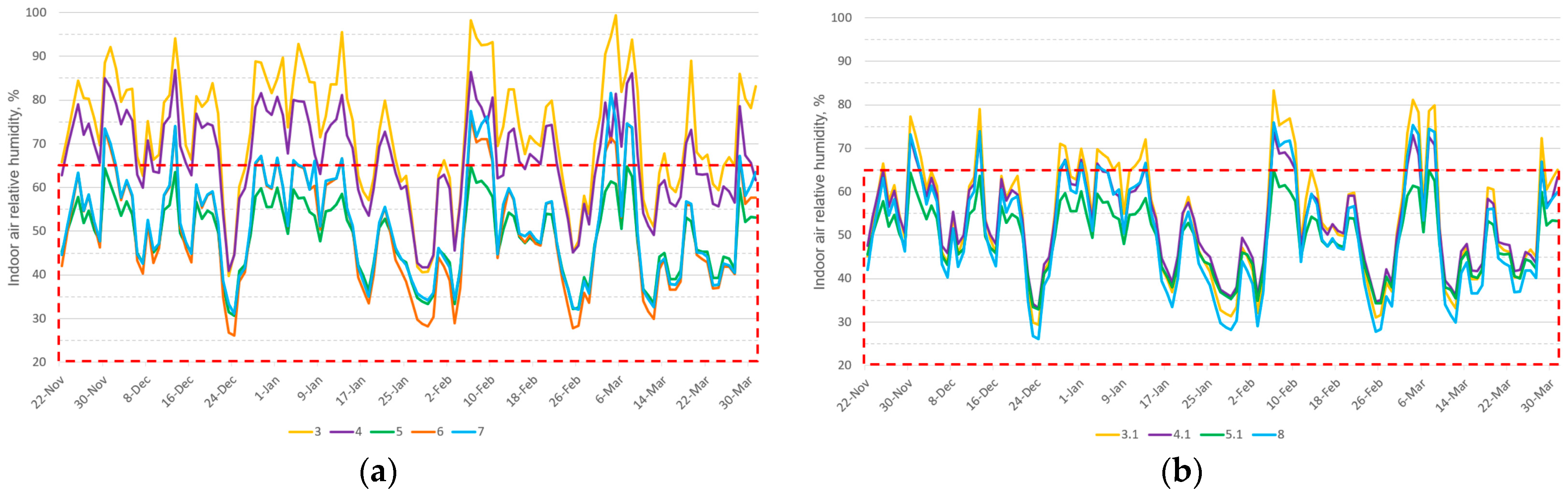

For the daily distribution of indoor air relative humidity (

Figure 14), the most favourable results were obtained for Variants 5 and 5.1 with the integrated system, where 100% of the results remained below the recommended limit. In Variant 4.1 with the integrated system and in the separate system Variants 6, 7, and 8, 85% of the results complied with the recommendations. In the remaining integrated system Variants 3.1, 4, and 3, the proportions of results below the recommended value were 78%, 43%, and 29%, respectively. The conformity of indoor air humidity (RH) results is summarised in

Table 4.

The fluctuations of indoor air relative humidity, as shown in

Figure 14, were strongly influenced by the outdoor air conditions used as input data in the simulation. During the winter months, low outdoor air temperature values reduce the moisture-holding capacity of the supply air, leading to a decrease in indoor air relative humidity. Extremely low humidity values result from the influx of very cold and dry air, in line with the climatic data applied in the simulation.

Significant daily fluctuations in indoor air temperature (up to 4 °C) were observed in Variants 5 and 5.1. Since a fixed supply air temperature was set and the supply air volume flow rate through the desiccant wheel was reduced, the ventilation system had to supply a considerably larger volume of untreated fresh air in order to remove moisture under all outdoor conditions. This led to indoor air temperature values significantly exceeding the target range of 9 °C to 11 °C.

In Variants 4 and 4.1, the ventilation system supplied drier air to the ice rink arena than in Variants 5 and 5.1. As a result, to maintain indoor air relative humidity within the required range (when outdoor conditions allowed), the system could introduce a smaller volume flow rate of outdoor air, thereby keeping the indoor air temperature lower. Limiting the maximum supply air volume flow rate in Variants 4 and 4.1 meant that under extreme conditions, the system could not remove all the moisture. However, this also prevented the indoor air temperature from exceeding the set values. Consequently, the mean indoor air relative humidity value was higher.

In Variants 3 and 3.1, indoor air temperature values were similar to those in variants 4 and 4.1, but the indoor air relative humidity values were higher. This resulted from the lower supply air volume flow rate to the facility, as the system could not adjust the airflow due to the use of a CAV system.

Comparing the AHU 2 system (desiccant wheel followed by heating coil) with the AHU 2.1 system (heating coil followed by desiccant wheel) in Variants 3, 3.1, 4, and 4.1, differences in the resulting air parameters can be observed (

Table 4). In Variants 3.1 and 4.1, preheating the air before it reached the desiccant wheel increased the supply air temperature at the point of contact with the rotor, enhancing its moisture absorption capacity. As a result, most indoor air relative humidity values remained within the recommended range, indicating a significantly improved control of the thermal and humidity conditions in these variants. In Variants 5 and 5.1, although the sequence of the heating coil and desiccant wheel differed, 100% of indoor air relative humidity values fell within the recommended range. This was due to the nearly fourfold reduction in the airflow directed through the rotor, which substantially limited the intensity of dehumidification. In both cases, this effect was dominant enough that the order of the components no longer had a significant impact on the final indoor air relative humidity value—in each variant, the desiccant wheel provided moderate dehumidification, ensuring compliance with the recommended values.

In Variants 5 and 5.1, the adopted assumptions effectively limited the risk of exceeding the maximum permissible indoor air relative humidity value. Despite the reduced contribution of the desiccant wheel to the dehumidification process, the increased supply air volume flow rate ensured sufficient air exchange and moisture removal, maintaining the indoor air parameters within the recommended range. Although Variants 5 and 5.1 achieved perfect compliance in terms of relative humidity (100%), they exhibited low temperature conformity (57%), which limited their effectiveness in providing full thermal comfort for the occupants and maintaining optimal operational conditions of the arena.

In Variant 4.1, with a supply air volume flow rate over 1400 m3/h lower than in Variant 5.1, 15% of the indoor air relative humidity results exceeded the recommended limit. A similar trend was observed for Variants 3 and 3.1 with the CAV system, where the supply air volume flow rate was over 2900 m3/h lower than in Variant 5.1. This resulted in more than 70% of the values in Variant 3 and over 20% in Variant 3.1 exceeding the permissible indoor air relative humidity value. These observations indicated that the VAV system allowed for more flexible responses to varying moisture loads, whereas the CAV system had limited regulation capabilities, causing a larger proportion of values to deviate from the optimal range. It is also noteworthy that Variants 3.1 and 4.1 achieved a higher proportion of results within the recommended limits compared to Variants 3 and 4.

Based on the analysed values of indoor air temperature and relative humidity, it can be concluded that Variant 4.1 with the integrated system and Variants 6, 7, and 8 with the separated system demonstrated the best compliance with the recommended indoor air parameters, taking into account both air temperature and relative humidity. Variant 4.1 achieved 90% compliance for air temperature and 85% for air relative humidity, indicating a good balance between air heating and dehumidification. Variants 6, 7, and 8 ensured full compliance for air temperature (100%) and high compliance for air relative humidity (85%) due to the implementation of the separated ventilation system.

3.3. Energy Analysis

A key aspect of the analysis of the ventilation unit variants is the comparison of their final energy consumption, as this parameter reflects the actual energy consumption of the system under operational conditions. This comparison allows for the assessment of the energy efficiency of the adopted solutions, directly influencing both the operational costs of the facility and its environmental impact. In the case of an ice rink arena, where maintaining a specific microclimate is required alongside significant heat losses, selecting the optimal variant with the lowest possible final energy consumption is crucial to ensure both economic viability and sustainable operation of the air handling units.

The energy consumption of the ventilation systems is largely determined by the power required to heat the supply air delivered to the ice rink arena, supplemented by the auxiliary energy needed to drive the fans in the air handling units. The energy consumption for the air handling units’ operation was determined based on the energy analyses conducted in IDA ICE 4.8. The electricity demand for fan operation accounted for approximately 5% of the total energy consumption of the air handling units; therefore, the subsequent analysis focused primarily on the energy required for the heating coil.

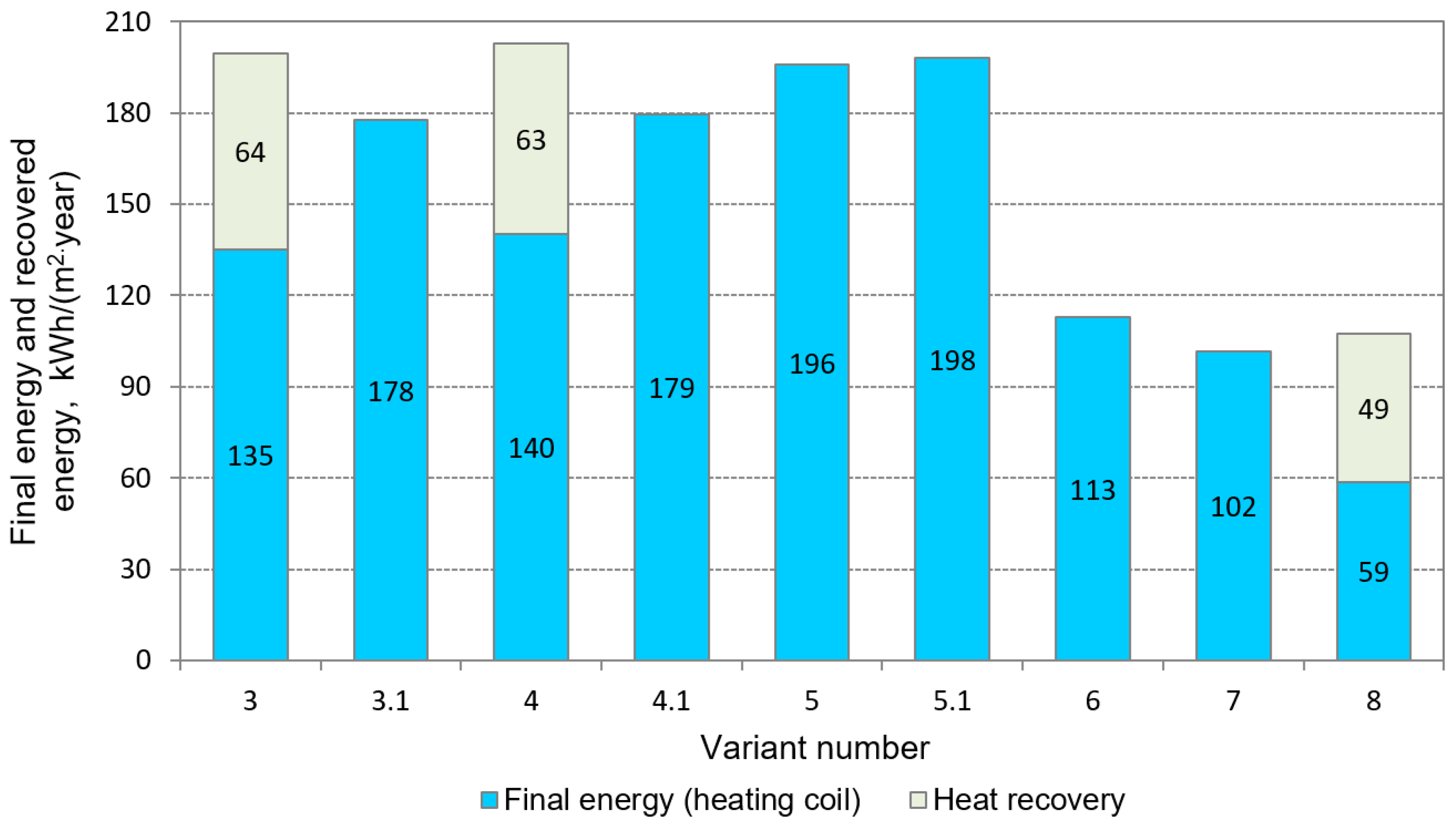

Figure 15 presents the final energy indicators for heating the supply air in the air handling units. Additionally, the figure includes energy recovered from the adsorptive air dehumidification process via preheating on the desiccant wheel in Variants 3 and 4, as well as heat recovery from the recuperator in Variant 8. In the remaining Variants (3.1, 4.1, 5, 5.1, 6, 7), the heat recovered from the dehumidifier was negligible.

When comparing Variants 3, 4, and 5 (integrated systems with the air-treatment sequence of dehumidification followed by heating), it can be observed that, after accounting for heat recovery in the desiccant wheel, the lowest energy consumption was achieved in Variant 3, slightly higher in Variant 4, and significantly higher in Variant 5. However, it should be noted that neither Variant 3 nor Variant 4 fully met the predefined indoor climate requirements. Variant 5 required approximately 40% more energy than the previous variants yet provided greater compliance with the recommended thermal and moisture conditions. In this case, heat recovery in the desiccant wheel was negligible due to the lowest airflow through the rotor in this configuration. Without considering desiccant wheel heat recovery, Variants 3, 4, and 5 exhibited a similar energy consumption among the integrated air handling units.

When comparing the subsequent integrated system Variants 3.1, 4.1, and 5.1 (air-treatment sequence: heating followed by dehumidification), it can be observed that the lowest energy consumption was obtained for Variant 3.1, slightly higher for Variant 4.1, and significantly higher for Variant 5.1. At the same time, it should be noted that neither Variant 3.1 nor Variant 4.1 fully met the recommended thermal and moisture conditions, although to a lesser extent than Variants 3 and 4. Variant 5.1 required approximately 10% more energy and likewise did not fully meet the requirements for indoor air parameters, but only in terms of air temperature. Moreover, with the adopted order of air-treatment processes in Variants 3.1, 4.1, and 5.1, heat recovery in the desiccant wheel was negligible. This was due to the lower relative humidity of the air entering the desiccant wheel, resulting from preheating in the heating coil.

When comparing the AHU 2 systems (air-treatment sequence: dehumidification followed by heating) with the AHU 2.1 systems (air-treatment sequence: heating followed by dehumidification), it can be observed that in Variants 3, 3.1, 4, and 4.1, lower energy consumption was achieved for AHU 2. In Variants 3 and 4, heat recovery accounted for more than 30% of the total energy consumption. Significantly higher energy consumption was recorded for AHU 2.1, where heat recovery in the desiccant wheel was negligible. The difference in final energy consumption between AHU 2 and AHU 2.1 amounted to approximately 30% relative to AHU 2. However, it should be noted that Variants 3 and 4 deviated more significantly from the recommended thermal and moisture conditions than Variants 3.1 and 4.1. No significant difference was observed between Variants 5 and 5.1, as the share of dehumidified air was negligible, and the systems operated under nearly identical conditions.

The lowest final energy consumption among all variants, amounting to 59 kWh/(m2·year), was achieved by Variant 8 with a separated system incorporating heat recovery in a recuperator. Other separated-system Variants, 7 and 6, showed higher final energy consumption, of 43 and 54 kWh/(m2·year) respectively. Variant 6, similarly to Variants 7 and 8, was equipped with two AHUs, of which the one located above the ice rink (AHU 3) was fitted only with a desiccant wheel. This ensured humidity reduction in the ice surface zone but did not provide adequate temperature control in the spectator zone, as the rotor dehumidified recirculated air rather than fresh air. Although the entire outdoor air volume flow rate had to be heated in the second AHU (supplying the spectator zone: AHU 1, AHU 4 or AHU 5 depending on the variant) to the air supply temperature, the high share of outdoor air in the ice rink arena resulted in lower energy consumption compared with the integrated Variants (3–5.1), since a smaller zone required heating. The addition of a mixing box in Variant 7 (AHU 4 supplying the spectator zone) enabled partial recirculation of indoor air, thereby reducing the amount of outdoor air that needed to be heated from ambient conditions to supply parameters. This lowered the heating coil load and consequently the final energy consumption. However, the benefits were limited due to the need to control recirculation with respect to both humidity and air quality. Variant 8, in turn, incorporated a counterflow heat exchanger instead of a mixing box (AHU 5), which significantly increased the efficiency of heat recovery from exhaust air. As a result, approximately 45% of the heating demand for outdoor air was covered through heat recovery rather than direct heating. The application of different heat recovery strategies in the spectator-zone AHU improved the overall thermal balance. Moreover, the AHU located above the ice rink (AHU 3), operating mainly with recirculated air (with only a 10% share of outdoor air), reduced the volume of air subjected to dehumidification (and thus limited heat recovery on the desiccant wheel). Consequently, despite the negligible rotor contribution, Variant 8 demonstrated the lowest final energy consumption compared with the integrated-system variants.

The assessment of the energy efficiency of an air handling unit requires the simultaneous consideration of both final and primary energy consumption. The evaluation of primary energy consumption accounts for the total energy inputs related to the generation and delivery of energy carriers, including transmission losses and conversion processes, thus providing a more comprehensive picture of the actual efficiency of the system. In the case of an ice rink arena, where maintaining a specific indoor microclimate requires substantial energy inputs, conducting both types of analyses makes it possible to identify the AHU variant that is most advantageous in terms of energy consumption, as well as economic and environmental efficiency.

Figure 16 presents a comparison of the calculation variants in terms of non-renewable primary energy consumption and CO

2 emission. A strong correlation can be observed—higher primary energy consumption directly translates into greater CO

2 emissions, as the latter are inherently linked to the energy source. The variants with the lowest environmental impact were the separated system configurations (Variants 6–8), particularly Variant 8, which demonstrated the highest energy efficiency, amounting to 47 kWh/(m

2·year), as well as the lowest CO

2 emission, reaching 0.026 tCO

2/(m

2·year). Conversely, the least favourable solutions, both in terms of energy consumption and CO

2 emission, were Variants 5 and 5.1, with primary energy consumption of approximately 159 kWh/(m

2·year) and CO

2 emission of around 0.088 tCO

2/(m

2·year). The results indicate that system configurations based on the separation of air-handling units combined with the application of heat recovery offer the greatest potential for reducing non-renewable primary energy consumption and CO

2 emission, making them the most recommended options for energy-efficient sports facilities such as ice rink arenas.

3.4. Discussion of the Principal Results

As part of the discussion of the principal results, an analysis of the change in final energy consumption for the preparation of the heating medium in the air-handling unit heating coil was carried out, focusing on three principal design aspects (

Table 5). Firstly, the impact of reversing the heating and dehumidification processes was analysed in order to assess how the thermodynamic sequence of processes within the unit may influence the energy efficiency of air treatment. Secondly, VAV and CAV systems were compared to evaluate differences in energy consumption under variable load conditions. Finally, separate and integrated ventilation systems were considered to determine the effect of air distribution strategies on energy consumption. The analysis of these three aspects provides deeper insight into the factors determining final energy consumption and may help identify directions for the optimisation of ventilation systems in ice rink arenas.

Firstly, the annual percentage change in final energy consumption was compared resulting from the inversion of the sequence of the heating coil and the desiccant wheel in the AHUs for Variants 3.1, 4.1, and 5.1 relative to Variants 3, 4, and 5. In Variants 3.1 and 4.1, a similar increase in final energy consumption for preparing the heating medium was observed, approximately 22%, whereas in Variant 5.1 the difference was significantly smaller, around 1%. The AHUs in Variants 3/3.1 and 4/4.1 operate at the nominal airflow directed through the desiccant wheel, meaning that the adsorption dehumidification process plays a major role in the energy balance and the amount of energy required to reheat the air after heating in the desiccant wheel. Therefore, reversing the sequence of the heating coil and the desiccant wheel in these variants can affect the degree of air heating downstream of the desiccant wheel as well as the quantity of moisture removed, resulting in notable differences in energy consumption. In Variants 5/5.1, the lower airflow through the desiccant wheel limited the dehumidification and heating process and thus reduced the amount of energy associated with reheating the air by the desiccant wheel. Consequently, reversing the order of the components has a negligible effect on the overall energy balance, since the desiccant wheel’s contribution in this variant is relatively smaller compared to the other variants.

Next, the annual change in final energy consumption was compared resulting from the implementation of the VAV system in Variants 4.1 and 5.1 relative to Variant 3.1. The comparison was made for variants with this sequence of devices in the AHUs due to the higher conformity of indoor air temperature and relative humidity with recommended values, compared to Variants 3, 4, and 5. In Variant 4.1, the increase in final energy consumption was only 1%, whereas in Variant 5.1 it reached 12%. The rise in energy consumption in Variant 5.1 is attributed to the increased supply air volume flow rate which resulted in greater consumption of energy for heating.

When comparing the variants with a separate ventilation system (Variants 6, 7, and 8), a significant reduction in final energy consumption can be observed compared to the integrated system Variant 4.1. In Variant 6, by heating only one zone (the spectator area), the heating load was limited, resulting in a 37% reduction in energy consumption. In Variant 7, the additional use of recirculation in the mixing box further optimised the heating process, increasing savings to 43%. The greatest effect was achieved in Variant 8, where a high-efficiency counter-flow heat exchanger allowed for the recovery of a significant portion of thermal energy, resulting in a total final energy saving of 67%.

Based on the conducted thermal–humidity and energy analyses, it can be concluded that the best results were provided by Variants 6, 7, and 8 with a separate ventilation system, which combine high compliance with the ice rink arena’s microclimate requirements with significant final energy savings. All these variants ensured full indoor air temperature compliance (100%) and high relative humidity compliance (85%), surpassing the performance of Variant 4.1 with an integrated system, which achieved slightly lower indoor air temperature compliance (90%) while matching the relative humidity compliance (85%). At the same time, the use of separate AHUs allowed for a substantial reduction in energy consumption: 37% in Variant 6, 43% in Variant 7, and 67% in Variant 8 compared to Variant 4.1. Therefore, Variant 8 can be considered the optimal solution, where the counter-flow heat exchanger with heat recovery provides the highest energy efficiency while maintaining the required thermal–humidity conditions. Variants 6 and 7 may also be recommended as advantageous alternative solutions, combining stable microclimate conditions with significant energy savings.

3.5. Alternative Dehumidification Approach in Ice Rink Arena Operation

In common practice, ice rink arenas employ solutions involving the installation of a stationary dehumidifier operating independently of the air handling unit [

27]. In the current research, such a solution was represented by the final Variant 9, in which the dehumidifier consumed 12,476 kWh/year of energy, while the air handling unit required 129,971 kWh/year for the heating coil, resulting in a total demand of 142,447 kWh/year. This value is approximately 15,000 kWh/year lower than in Variant 8 (the most energy-efficient option).

Variant 9 ensured the maintenance of indoor air relative humidity at 56% (below the permissible limit of 65%); however, the mean indoor air temperature in the arena was 11.3 °C, exceeding the recommended value by 0.3 °C.

This solution may appear to some extent to be an effective alternative to separate systems, yet its main limitation lies in the risk, particularly in larger facilities, of difficulties in simultaneously ensuring full compliance of both humidity and temperature conditions throughout the entire arena, as dehumidification is performed locally and its impact on the overall distribution of air parameters remains uncertain. This may negatively affect occupants’ thermal comfort and the stability of ice rink operating conditions.

The solution does not allow precise control of air parameters in individual zones of the arena (ice surface, spectator stands), despite their differing operational requirements. Moreover, the lack of integration of the dehumidification function with the supply–exhaust ventilation system reduces the stability of air parameters and complicates their maintenance within permissible limits. A particular issue may be the indoor air velocity, which is not controlled by such a solution (as the air is not distributed evenly like in a dedicated air distribution system), yet has a significant influence on the ice surface due to heat exchange.

In addition, this solution poses practical challenges in its application, such as the need for power supply (including electrical safety measures) and the provision of a dedicated installation for condensate drainage in the case of condensation-based dehumidifiers, as well as the necessity of installing a larger number of dehumidifiers in larger facilities.

3.6. Summary Remarks on Results

The multi-variant thermal–humidity and energy analyses made it possible to observe the following key relationships:

The specific configuration of each air handling unit had a significant impact on the ability to maintain thermal and humidity conditions within the defined ranges of indoor air temperature and relative humidity;

Thermal conditions in the arena were variable, with indoor air temperature fluctuations depending primarily on the type of air distribution system applied;

Humidity conditions in the arena were also unstable and strongly correlated with the parameters of the outdoor air;

In every analysed variant, given the assumed system parameters (supply air temperature range and air volume flow rate), thermal and humidity conditions were, to a greater or lesser extent, temporarily not fully compliant with the required setpoints; however, it was possible to achieve 100% compliance for either indoor air temperature or relative humidity, but not for both simultaneously;

The sequence of air treatment processes in the AHUs (dehumidification–heating versus heating–dehumidification) was relevant to the potential for heat recovery by the desiccant wheel, which in turn influenced the heating coil energy consumption;

The potential for heat recovery by the dehumidifier in the AHU also depended on the supply air volume flow rate: the smaller the airflow, the lower the heat recovery; moreover, in such cases, the order of components within the AHU was irrelevant;

AHU configurations with different sequences of the dehumidifier and heating coil also affected thermal–humidity conditions; from the perspective of maintaining the target indoor air temperature and relative humidity, better results were achieved when the supply air was first heated and subsequently dehumidified;

Dividing the ice rink arena into two separate zones (the spectator stands and the ice rink) was of critical importance, both in terms of energy performance and in ensuring stable thermal and humidity conditions.