Abstract

This study examined the effect of particle size, moisture content, mixing, and consolidation time on the flow and mechanical behaviour of bulk rice assessed using a Schulze Ring Shear Tester RST-01. Three rice fractions: 0.5–1.0 mm, >1.0 mm, and whole grains were tested at 8% and 20% moisture. Fine particles showed high flowability in dry conditions but exhibited a strong increase in cohesion and a significant drop in the flow function coefficient at the higher moisture content. Unexpectedly, whole grains showed the highest shear resistance after moistening and consolidation, which can be attributed to force chain formation and localized capillary bonding. Extended mixing and consolidation further stabilized the structure and reduced flowability. These findings indicate that larger particles can exhibit greater mechanical stability in moist conditions. The results emphasize the need to consider particle size and preparation history in the handling and storage of bulk materials.

1. Introduction

The mechanical and flow properties of agricultural raw materials, including cereals and their derivatives, are crucial for the design and optimization of transport, storage, and processing of granular materials. Rice (Oryza sativa L.) is one of the most essential cultivated cereals, widely used not only in its unprocessed form but also as rice flour, bran, or production dust. Beyond its importance as a food source, rice and its various products represent significant raw materials in multiple industrial sectors, including food processing, animal feed, biofuels, nutraceuticals, and bioplastics. However, the full industrial potential of rice is often hindered by challenges in handling, storage, and processing. Each of these materials is characterized by different morphology, particle structure, and moisture absorption capacity, which directly affects their mechanical and tribological behaviour.

One of the critical phenomena observed during the layer movement of granular materials in contact with technological surfaces, such as silo walls or conveyors, is the stick-slip. It is an irregular, jerky movement of the material resulting from cyclic changes in friction forces. These phenomena can lead to severe disruptions in the flow of raw materials and generate vibrations, noise, and dynamic loads that are undesirable in mechanical systems. Previous studies have shown that both moisture content and particle size have a significant impact on the occurrence and intensity of the stick-slip. In low-moisture conditions, static friction dominates, which favours the occurrence of the phenomenon. An increase in moisture content can lead to a transition to boundary or hydrodynamic lubrication, in which friction fluctuations are significantly reduced.

The literature emphasizes that one of the most critical factors influencing shear forces and material flow parameters is the particle fragmentation, their moisture content, and consolidation conditions [1,2]. Several physical and mechanical properties of selected rice products have been documented in technical literature. For example, rice bran exhibits a marked increase in angle of repose and coefficient of friction with increasing water content. In contrast, fine-grained flours increase surface adhesion and slow down the transition between friction regimes. Nevertheless, most of the available data concern static parameters, such as angle of repose, bulk density, or static friction, and do not take into account the dynamic friction phenomena characteristic of moving bulk materials. The rheological properties of bulk materials, including shear resistance, are key parameters that determine their behaviour in technological processes, such as transportation, storage, and dosing. Research indicates that finer particles exhibit better flowability and lower shear stress values, mainly due to a reduced tendency to form flow-blocking structures [3]. In the case of materials with larger fractions > 0.5 mm, an increase in shear stress is observed, which is attributed to the wedging effect and greater friction between particles. These results were confirmed in studies on rice grains, where the lowest shear resistance was observed in the finest fractions. At low moisture levels < 10% the presence of water can act as a lubricant reducing friction between particles [4]. However, with further increases, especially in hygroscopic materials, capillary bridges form, which increase cohesion and lead to a deterioration in flow properties [5,6]. The duration and pressure of consolidation affect the reorganization of the internal structure of loose material, which modifies its response to shear. Longer consolidation leads to increased material density, resulting in increased shear stresses in rheological tests [7]. Additionally, in the case of materials subjected to shear after a short or long period of moistening, an increase in shear forces is observed, confirming the influence of adhesive and structural processes.

The stick-slip often occurs in materials with large particles or high cohesion. It consists of the alternating accumulation and rapid release of energy in the shear layers. The presence of moisture and intensive mixing of the material weaken this effect, resulting in a more homogeneous flow. Stick–slip friction between granular material and silo walls during discharge leads to periodic pulsations known as “silo quake,” which in turn generate acoustic vibrations termed “silo music,” posing risks to structural integrity and operational stability [8]. The variation in surface roughness significantly affects the static friction between cereal kernels and steel surfaces, which is a critical factor in determining the onset of stick–slip motion in grain handling systems [9].

In the studies [10,11], the effects of moisture and lubricating additives on the mechanical properties of biomass and powders were analyzed. It was shown that moistening caused the stick-slip to disappear and also reduced shear resistance, especially in the case of fine fractions. In studies conducted using the Jenike apparatus [12], the authors found that moisture had an impact on the classification of material flowability according to the ffc, with increased moisture reducing this coefficient, indicating a deterioration in flowability.

Chutkowski et al., [13] analyzed the effect of changes in moisture content on the mechanical properties of food powders to determine the importance of mechanical processing and mixing for improving flow conditions.

Another significant gap in the literature is the insufficient consideration of mixtures of fractions with different particle sizes and their impact on flow stability. Previous studies were mainly conducted on single granular systems or model materials, such as glass beads, salt, or cornstarch, which limits the direct applicability of the results to real raw materials, such as rice fractions. The identified gaps highlight the need for systematic research on the tribological properties of rice fractions. Such analyses will not only provide a better understanding of the mechanisms underlying the stick-slip in bulk material systems but also facilitate the development of more effective control strategies. They will also enable optimization of engineering processes, such as pneumatic transport, dosing, pressing, and compaction of rice products.

This study aimed to analyze the influence of moisture and particle size on the stick-slip in systems containing fragmented rice with specific size ranges. Another aim of the research was to investigate the impact of bulk material preparation conditions on its strength properties in a steady state, determined by direct shear tests performed in a Schulze Ring Shear Tester RST-01. The research also aimed to assess the influence of selected technological and structural factors on experimental processes such as stress–strain relationships and the final values of mechanical parameters, including ultimate stress in a steady state, internal friction angle, and cohesion. In particular, the influence of the degree of material fragmentation, which may determine the contact structure and mechanical resistance through the participation of fine fractions, was analyzed. The importance of the method of material moistening was also assessed. The aim was to determine the extent to which the time and method of moistening affect the even distribution of water and the development of capillary forces in the sample structure. Additionally, the effect of an extended consolidation time was investigated, which involved subjecting the material to a vertical load of 20 kPa for 2 h before commencing the shearing process. The tests also aimed to determine the interaction between the aforementioned factors and their combined impact on strength parameters, which are essential for designing storage and transport processes and assessing the behaviour of bulk materials in operating conditions. By using rice and its fractions as a case study, this research tackles key industrial challenges related to storage, handling, and processing. The results can inform the design of improved storage, transport, and drying systems as well as tailored preprocessing methods for different rice-based materials. Better understanding of the behaviour of fractions in varying conditions can help preserve quality and reduce post-harvest losses. Overall, the study supports more efficient operations, reduced waste, and sustainable use of rice products.

2. Materials and Methods

Commercially available rice produced by SAWEX Foods, with its registered office at Wiertnicza 70, 02-952 Warsaw, Poland, was used in the experiment. The rice served as the starting material for analyses of the effect of moisture on the properties of this fragmented raw material.

The samples were moistened to 20% RH to examine the effect of environmental conditions on the properties of the crushed rice. The conditioning moisture content was 8%.

The material was ground in a blade mill, which enabled effective grinding of the rice grains into powder with various particle sizes. After grinding, the samples were sieved through a set of laboratory sieves with specific mesh sizes of 0.5 mm and 1.0 mm using a vibrating device.

Samples with moisture content of 8% and 20% were selected for further testing, as these values are typical in the technological production of granules. Humidification of samples with an initial moisture content of 8% was performed by adding distilled water and mixing the material in a laboratory mixer for 30 s and 15 min every hour for 24 h. The moisture content was measured using the weighing method. 100 g samples were weighed before and after drying in a laboratory oven at 105 °C for 24 h. Moisture was determined as “wet basis” moisture content, which allowed accurate control of the water level in the material. All variants of experiments are presented in Table 1.

Table 1.

Variants of the experiment involving rice fractions, moisture content, mixing time, and consolidation time.

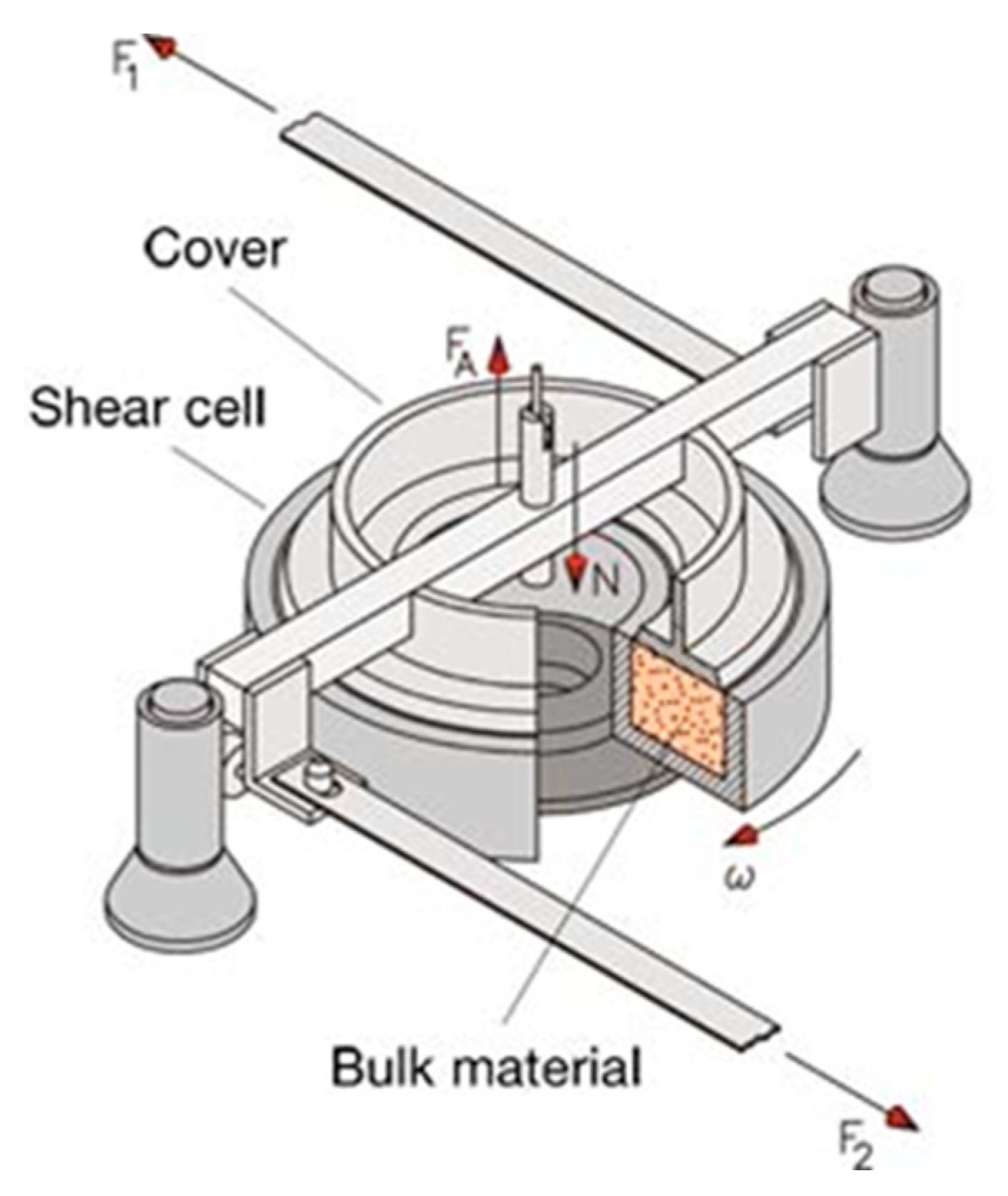

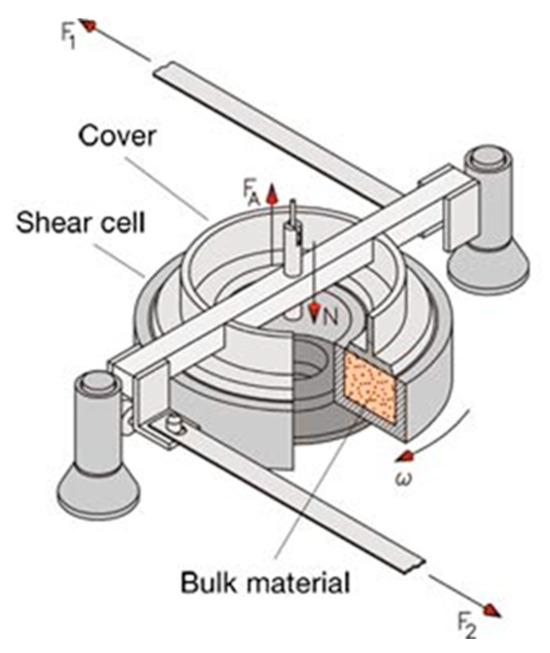

The tests were conducted using the Schulze Ring Shear Tester RST-01 (Figure 1), which enables continuous shearing of the material at controlled vertical stress and high shear displacements. The device allows determination of the strength parameters of loose materials, such as the internal friction angle and cohesion, both in dry and partially hydrated conditions. The apparatus also allows independent control of the consolidation process and continuous measurement of shear stresses [1; www.dietmar-schulze.de, accesed on 25 July 2025]. The experiments were performed at a pre-consolidation pressure of 20 kPa. The samples were then sheared at two vertical stress levels, 10 kPa and 20 kPa, typical pressures encountered in silos or storage containers considering the material type and storage height.

Figure 1.

Schematic representation of the procedure of measuring the properties of bulk materials in the Schulze Ring Shear Tester RST-01. All information can be found on the manufacturer’s website (www.dietmar-schulze.de, accessed on 25 July 2025).

The measurement was performed at a constant shear rate, as recommended by the manufacturer.

The study took into account three experimental variables: material moisture content of 8%, corresponding to the laboratory conditioning moisture content, and 20% obtained by adding a measured amount of distilled water, mixing time of the material after moistening: 30 s and 24 h, with the material being mixed for 15 min every hour.

The sample consolidation time before shearing was 0 h for samples subjected to shearing immediately after preparation and 2 h for samples consolidated in the RST-01 apparatus under the pressure of 20 kPa before shearing. Distilled water was distributed in the material before mixing. For the longer mixing time, the material was stored in a closed container and mixed cyclically for 24 h. The samples prepared in this way were then tested according to one of two variants, immediately after mixing or after additional consolidation.

The use of the Schulze RST-01 Ring Shear Tester (Figure 1) enabled the tests to be carried out in well-controlled and repeatable conditions, allowing for the assessment of the influence of the analyzed factors on the material’s strength in a steady state and at high shear displacements. This method is used, among other applications, in geotechnics, bulk material engineering, and the analysis of raw material storage and transport.

The tests were conducted in typical laboratory conditions. The relative humidity was 60% and the temperature was 21 °C. Each variant of the experiment was carried out in three repetitions.

3. Results

The mechanical and flow properties of various rice fractions were tested using a Ring Shear Tester RST-01. This device facilitates the precise determination of rheological parameters of bulk materials, such as cohesive force c, flow function coefficient ffc, internal friction angles ϕ, shear friction angles ϕ sf, and bulk density ρ. The experiment included three rice fractions: fragmented rice with a grain size of 0.5–1.0 mm, fragmented rice with a grain size of more than 1.0 mm, and whole grains. The tests were conducted at two moisture levels (8% and 20%), two mixing times (M0, 30 s, and M24, 24 h), and two consolidation times (0 h and 2 h).

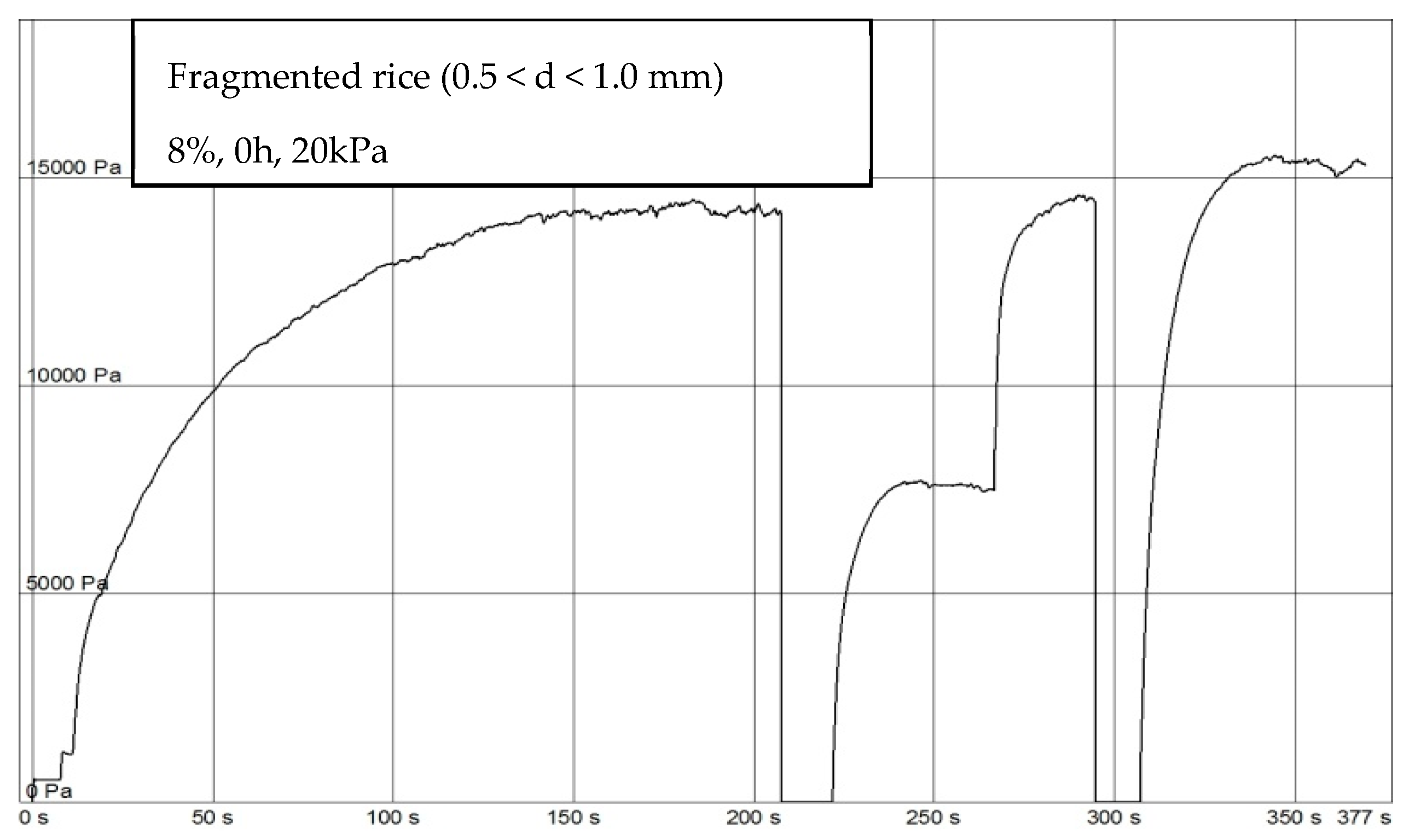

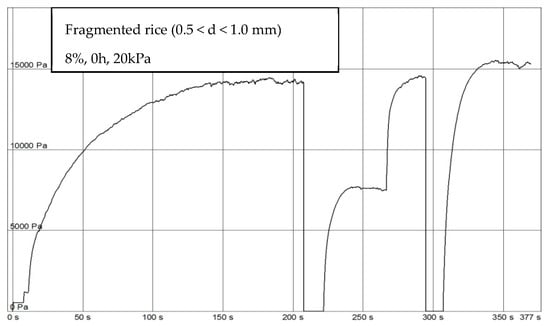

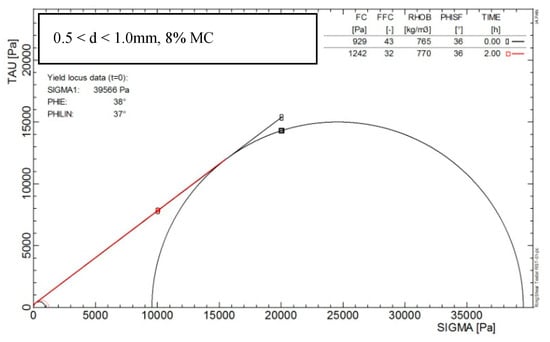

Typical experimental results of shear stress with time for fragmented rice obtained in Ring Shear Tester RST-01 for 8% moisture content, 0 h consolidation time, and preconsolidation at 20 kPa are presented in Figure 2. Typical time yield locuses for fragmented rice, 0.5 < d < 1.0 mm, obtained for 8% moisture content at 0 and 2 h time of consolidation are presented in Figure 3. The analysis of the results showed that the degree of rice fragmentation significantly affected the shear stress patterns, especially in the dry conditions with 8% moisture content. The lowest shear stress values were recorded for the 0.5–1.0 mm fraction, approximately 8 kPa and 15 kPa at pressures of 10 kPa and 20 kPa, respectively. In contrast, the highest values were recorded for the material containing whole grains, at 11 and 21 kPa, respectively. In the case of the coarser fractions, the stick-slip was also observed, which is consistent with previous observations concerning materials with uneven grain sizes [1,2].

Figure 2.

Typical evolutions of shear stress with time for fragmented rice obtained in Ring Shear Tester RST-01 for 8% moisture content, 0 h consolidation time, and preconsolidation at 20 kPa.

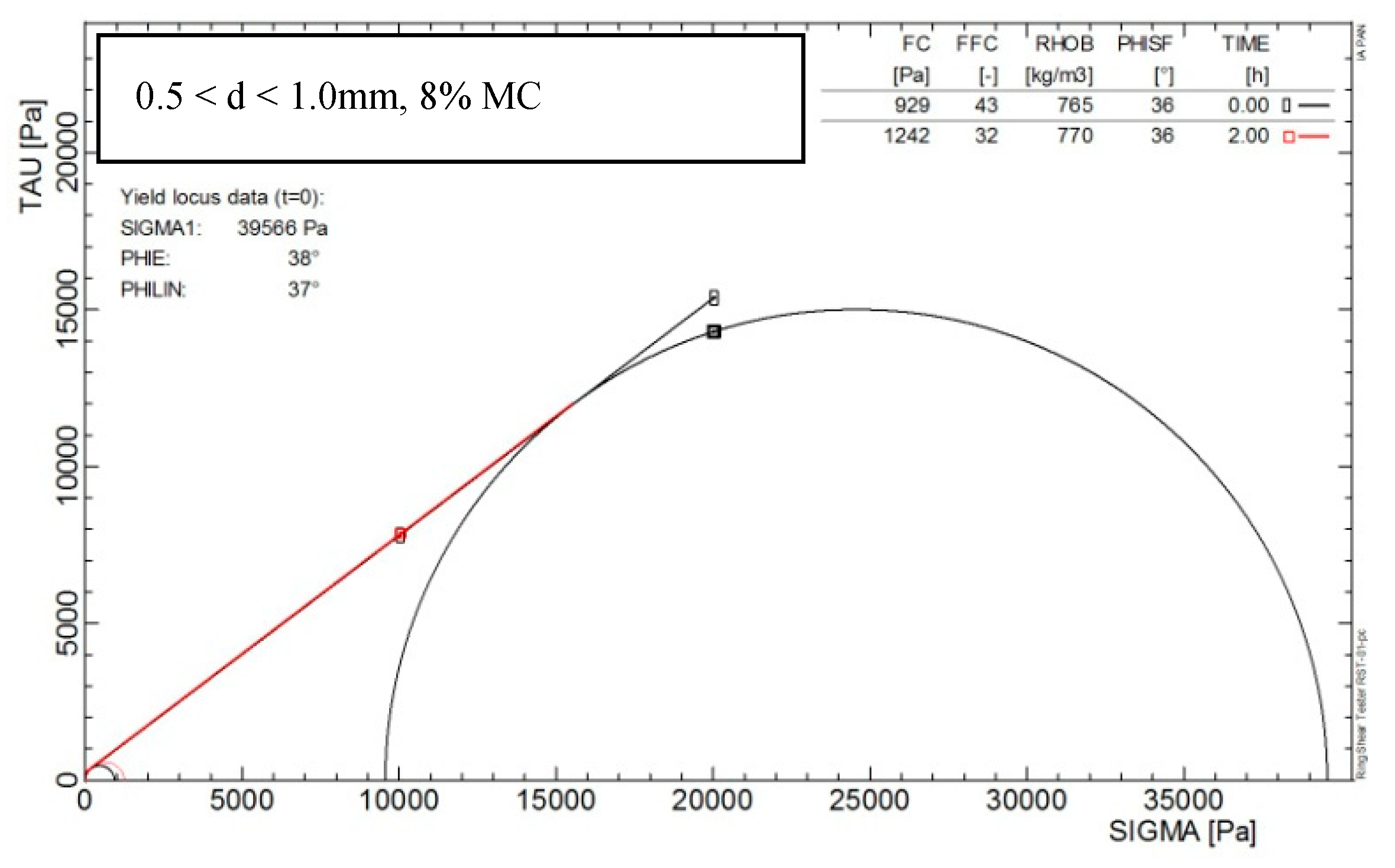

Figure 3.

Typical time yield locuses for fragmented rice, 0.5 < d < 1.0 mm, obtained for 8% moisture content at 0 and 2 h time of consolidation.

According to current research, the effect of moisture on the mechanical properties of rice is well documented, and an increase in water content leads to a decrease in grain breaking strength and greater susceptibility to deformation [14,15]. This indicates that rice behaves more plastically in wet conditions, which promotes local liquefaction and lower shear stresses. During our research, the addition of water and brief mixing resulted in the disappearance of the stick-slip, a reduction in maximum shear stress, and the appearance of lubrication.

However, under increased moisture content, the highest shear stress values were observed in samples with uncrushed rice grains. For this fraction, the stress reached 8 kPa and 17 kPa at pressures of 10 kPa and 20 kPa, which was higher than that for the finer fractions. This reverse trend, inconsistent with classical models of bulk materials, can be explained by stronger capillary forces, which act pointwise but effectively in large-grain structures [16,17]. The application of 24 h of material mixing with cyclic moisture homogenization resulted in a slight decrease in shear stress up to 7 kPa and 10 kPa in the case of the whole grains, while these values for the finest fractions decreased to 9 kPa and 17 kPa. This effect may result from the more homogeneous distribution of water and uniform compaction of the structure, which changes the mechanics of contact between particles [18,19]. Two hours of consolidation under the pressure of 20 kPa led to a reduction in the frequency of stick-slip in the dry samples. Still, they did not significantly affect the maximum shear stress values. In the moist samples, both after the short and long mixing times, an increase in shear stress of several kPa was observed, regardless of the applied vertical pressure. This confirms the results reported by [19], which showed that structures made of moist consolidated granular materials have greater shear resistance.

A notable result was the increase in shear stress in samples containing uncrushed rice grains after they were moistened and consolidated. Contrary to expectations, the samples with the largest grain size exhibited the highest shear resistance in the moist conditions. This behaviour can be explained by the presence of point contacts and the formation of force chains, which are dominant stress transfer paths despite being less frequent. These paths are stiffer and more efficient in large particle structures [20,21]. This effect was also confirmed in DEM analyses and discrete particle-based modelling [19,22]. Although classical models of bulk material flow assume the dominance of adhesion and cohesion in fine-grained materials [1,23], the present results indicate that, in some cases, large grains can form more stable systems under the influence of moisture and consolidation, which is an essential addition to current knowledge.

According to the results of our research and literature reports [1,19,24], the value of the ffc (flow function coefficient) used to assess the flowability of a material decreases with increasing moisture content and consolidation time. This indicates deterioration in the flow properties of the material and an increase in its susceptibility to arching, blockages, and flow discontinuities, which is particularly important in the design of dosing devices, silos, and feeders.

The analysis of the results showed that the increase in the moisture content of the material from 8% to 20% led to a significant increase in cohesive strength and a simultaneous decrease in the flow function coefficient ffc (see Table 2). The most important changes were observed in the case of the fine-grained fragmented rice (0.5–1.0 mm). For this material, the c value increased from 929 Pa to 3703 Pa, and the ffc decreased from 42.58 to 11.92 for M0, zero h. A similar relationship was also observed for the other fractions, but with less intensity. For the whole rice grains, the c increased from 4603 Pa to 10,873 Pa in similar conditions, while the ffc decreased from 14.70 to 3.79. The results obtained are consistent with those described in the literature [12,13], where showed that an increase in the moisture content of flour leads to a significant increase in cohesion and a decrease in flowability. These findings were also confirmed by [1], who described the effect of capillary bridging on the deterioration of the flow properties of bulk materials.

Table 2.

Mechanical properties of rice grains, including fragmented rice (0.5–1.0 mm and >1.0 mm) and bulk whole grains, under varying moisture contents (8% and 20%), preconsolidation at 20 kPa, and deformation times (0 and 2 h).

Extending the mixing time to M24 and the consolidation time to 2 h led to a further deterioration in the flow properties of the material. For the whole rice grains with the 20% moisture content, the c value increased from 10,873 Pa to 19,374 Pa after two hours of consolidation, and the ffc decreased from 3.79 to 2.13. Similar trends were also observed for the coarser fraction of crushed rice. These results indicate that the material’s structure becomes more stable and the interactions between particles increase over time, especially in the presence of water. These phenomena confirm the conclusions formulated by [25], who studied changes in the rheological parameters of cereal materials during consolidation and under the influence of moisture. It was observed that materials with a large specific surface area and an irregular particle shape form stable intermolecular bonds more quickly, especially at higher moisture levels.

The fractions with the finer grain size showed significantly greater sensitivity to the changes in the moisture content and consolidation time. Fine particles with a developed surface area promoted the formation of capillary bridges, leading to a rapid increase in cohesion and a decrease in the ffc. In the case of fractions greater than 1.0 mm and whole rice grains, the impact of these factors was significant but less rapid. Materials with larger particles have a lower specific surface area and lower water absorption capacity, making them less susceptible to the formation of strong bonds between particles. Similar results were obtained by [25] in their study of corn and wheat grains, whose flowability deteriorated to a lesser extent than that of flours. In turn, pelletized straw fractions studied by [11] showed relatively low sensitivity to moisture, which also confirms that particle size and structure are key factors.

In the conditions studied, no lubrication effect was observed, which could occur at very low moisture contents < 5%. The experimental data indicated that an increase in the moisture content always led to an increase in cohesive strength and shear friction angle, which clearly excludes the action of a mechanism reducing flow resistance. Instead, the observed effects were a consequence of the formation of capillary bridges, as described by [1,10].

The density was found to vary with the experimental factors. The 0.5–1.0 mm rice fraction generally exhibited lower values, ranging from approximately 702 to 770 kg/m3, while larger particles > 1.0 mm showed higher values, up to 804 kg/m3. The whole rice grains had intermediate densities, typically between 727 and 742 kg/m3. The increase in the moisture content to 20% resulted in a noticeable decrease in bulk density. For example, in fraction 0.5–1.0 mm, it dropped from 765 kg/m3 at 8% moisture to as low as 702–713 kg/m3 at 20% moisture. A slight increase in bulk density from 765 to 770 kg/m3 was observed after 2 h of consolidation.

4. Discussion

This study presents a comprehensive analysis of the influence of the grain size, moisture content, mixing time, and consolidation time on the mechanical and flow properties of bulk material, using various rice grain fractions as examples. The tests were carried out using a Schulze apparatus RST-01.pc, which allows precise determination of cohesion forces c, flow function coefficient ffc, friction angles, and bulk density. Three material fractions were analyzed: fragmented rice with a grain size of 0.5–1.0 mm, fragmented rice > 1.0 mm, and whole rice grain. The tests were performed at two moisture levels (8% and 20%), two mixing times (30 s and 24 h), and two consolidation times (0 h and 2 h). Our results confirm trends reported in the literature, where increased moisture content leads to higher cohesion and lower ffc values, indicating worse flowability. In the case of the fine fragmented rice 0.5–1.0 mm, the c value increased from 929 Pa 8% to 9367 Pa for 20%, M0, 2 h, while ffc decreased from 42.58 to 4.71. A similar behaviour was reported by [25], and also confirmed by [26], who showed that higher moisture levels reduce flowability of solid biomass. In line with [1], our data confirm that the formation of capillary bridges is the main cause of this increase in internal bonding forces. The values of angle of internal friction ranged from approximately 30.4° for the moist whole grains to 45.8° for the dry coarse grains. This is consistent with [1,25], who reported higher internal friction angles for dry, irregularly shaped, or angular particles due to increased interlocking and contact friction. Similar effects related to micro-scale cohesion and particle interactions have also been observed in cohesive powders tested using the Schulze RST-01 by [27]. As in the literature ([1,3,11]), the consolidation time contributed to increased cohesion and bulk density. In our results, 2 h of consolidation at 20% moisture further reduced ffc values by 50–70%, depending on the fraction, confirming time-dependent strengthening. Our findings regarding the contrasting behaviour of fine vs. coarse particles in moist conditions also support literature data. The fine fractions responded more strongly to moisture, as noted in [1,11], while the coarser materials developed stronger force chains [20], explaining their higher shear resistance after consolidation. The results obtained clearly showed that the degree of rice grain fragmentation significantly affected the shear stress values, with this effect being more pronounced in the dry conditions at the 8% moisture content. The lowest shear stress values were recorded for the finest fraction (0.5–1.0 mm), which is associated with the large number of contacts between particles, but at the same time, their low load-bearing capacity. Materials with larger grains, especially whole rice grains, exhibited the highest shear stresses, confirming the hypothesis of the existence of more efficient “force chains” [20,21], which are rigid paths that transfer stresses characteristic of granular materials with extensive point contacts.

In the dry conditions, the stick-slip was observed particularly in the thicker fractions, which is consistent with previous observations of materials with uneven grain sizes [1,2]. However, after moistening and briefly mixing the material, this phenomenon disappeared. Stick-slip also does not occur in materials moistened after 2 h of consolidation. This was accompanied by a decrease in maximum shear stress and the appearance of lubrication. However, this phenomenon was observed only in the initial phase of hydration and only in the finest fractions. Surprisingly, the trend was reversed under the increased moisture content. In that case, the samples with the largest grains exhibited the highest shear stresses. The interpretation of this phenomenon refers to the capillary effect in materials with larger grains, where capillaries act at specific points but with high efficiency. Bonding forces in the presence of water can then be more concentrated and effective than in fine-grained structures, where water bridges are dispersed over a larger number of weaker contacts [16,17].

The application of 24 h mixing with cyclical homogenization of moisture altered the material’s structure. In the case of the whole rice grains, the shear stresses increased slightly, which can be explained by the more compact and orderly structure and the increased number of effective contacts. In the finest fractions, however, there was a decrease in stress values, suggesting that the long mixing process leads to an even distribution of moisture and a reduction in local points of force concentration. The mechanics of contacts in the loose structure are then reorganized—from the dominance of numerous but weak contacts to more homogeneous intermolecular connections [18,19].

The two-hour consolidation under a load of 20 kPa led to a significant stabilization of the sample structure. In the dry samples, the frequency of the stick-slip decreased, which can be attributed to the compaction of the material and the equalization of contact forces. In the moist samples, an increase in shear stress was observed regardless of the mixing time. This confirms the earlier findings reported by [19], which indicate that the consolidation of moist materials results in greater shear resistance due to an increased number of contacts and more effective force transmission through “force chains.”

The ffc value is a commonly used rheological indicator for assessing the flowability of materials. This study demonstrated that the moisture content and consolidation time resulted in a significant reduction in the ffc value, particularly in the case of the fine fractions. For example, for the 0.5–1.0 mm fraction and the 20% moisture content, the ffc value decreased from 42.58 to 11.92 after brief mixing and further consolidation. For the whole grains, the decrease was even more significant: from 14.70 to 2.13 after two hours of consolidation at the 20% moisture content. This indicates a drastic deterioration in flow properties resulting from the formation of permanent capillary bridges and increased cohesion between particles. These phenomena are well documented in the literature [1,11] and constitute a significant limitation in the design of transport, storage, and dosing systems for bulk materials. An increase in moisture content and consolidation time leads to an increased risk of arching, segregation, flow blockages, and the formation of dead zones in silos.

The comparative analysis showed that the fine fractions were much more sensitive to the changes in moisture and consolidation than the coarser grains. This is due to their larger specific surface area and the number of interfacial contacts, which promote water adsorption and the formation of cohesive forces. Coarse fractions, despite having fewer contacts, exhibit greater mechanical stability and shear resistance, especially in the presence of water, which contradicts classical models of bulk material flow [23]. This phenomenon can be explained by the dominance of rigid force chains and the limited influence of adhesive phenomena in structures with larger grains. The whole rice grains consistently demonstrated the highest values of shear stress and cohesion, especially after moistening and consolidation, likely due to the formation of strong force chains and localized capillary interactions. The coarser fragmented rice showed intermediate behaviour, while the finest fraction 0.5–1.0 mm was most sensitive to moisture, exhibiting the largest decrease in ffc and the highest increase in c. These differences confirm that particle morphology and size significantly modulate the response to moisture and consolidation. Larger particles tend to maintain structural rigidity and demonstrate higher internal friction angles under compression. This trend is consistent across all the tested process variants (M0 and M24, 0 h and 2 h consolidation) and confirms the need to consider the rice type when predicting bulk flow behaviour in food processing systems.

It is also important to consider that the moisture-induced changes observed in the bulk mechanical properties may partially result from structural weakening at the microscopic level, particularly within the endosperm tissue. Previous studies have shown that increased moisture can lead to plasticization and weakening of the cell walls in cereal endosperm, reducing their mechanical integrity and adhesion at the cell wall interfaces [28,29]. This phenomenon may have contributed to the observed reduction in flowability and increased cohesion, especially in samples with higher water content. Although the present study did not directly analyze the internal structure of the rice endosperm, the effects of moisture on these microstructural features likely play a role in the mechanical behaviour of the material and should be considered in future investigations.

The presented results have direct implications for industrial applications involving rice and its fractions. The observed increase in cohesion and decrease in flowability (low ffc values) with moisture content and consolidation time mirrors challenges often reported in silo discharge, pneumatic conveying, or hopper design in the food industry. Therefore, the findings of this study can be used to inform industrial decisions, such as selecting appropriate storage geometries, designing discharging aids, or optimizing drying or milling to ensure consistent material flow. The presented results are significant for process engineering, especially in the design and optimization of dosing, transport, and storage systems for bulk materials in the food industry. The variation in rheological properties between rice fractions suggests the need for an individualized approach to their technological handling, considering both the grain size and moisture content of the material. The results can serve as a basis for developing predictive models of the behaviour of bulk materials with complex structures.

5. Conclusions

The particle size of rice has a significant impact on its mechanical and rheological properties, particularly in dry conditions. The finest fractions exhibit the lowest shear stress and the highest flowability, but they are most susceptible to degradation of flowability in the presence of water.

Moisture content is a key factor influencing cohesion and ffc values. An increase in water content causes a significant deterioration in the flow properties of the material, regardless of the fraction, which is associated with the formation of capillary bridges.

The stick-slip was observed mainly in the dry samples and the coarse fractions, confirming the non-linear behaviour of granular materials in dynamic shear conditions.

A surprising result was the increase in shear resistance for the whole grains after they were moistened and consolidated. This phenomenon can be attributed to the formation of rigid force chains in the structure and the point action of capillary forces.

The prolonged mixing and consolidation times result in the consolidation of the material structure and further deterioration of flowability, which is of practical importance for storage and transportation.

The ffc parameter can be an effective predictor of the risk of material flow disturbances, but its interpretation should take into account the fraction, moisture content, and consolidation history.

The results show that while fragmented rice generally remains within the “easy to free flowing” range, whole grain rice under high moisture (20%) and extended residence times (2 h) degrades to cohesive or near non-flowing states (ffc ~2.13), signalling a high risk for flow obstructions.

Author Contributions

Conceptualization, M.S.; methodology, M.S. and P.K.; software, J.W., and R.K.; validation, R.R., and M.G.; formal analysis, R.R., and M.G.; investigation, P.K.; data curation, R.K.; writing—original draft preparation, M.S. and J.W.; writing—review and editing, S.O., A.L., E.G. and M.C.; visualization, M.S.; supervision, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

No funding information.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schulze, D. Powders and Bulk Solids: Behavior, Characterization, Storage and Flow; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Nedderman, R.M. Statics and Kinematics of Granular Materials; Cambridge University Press: Cambridge, UK, 1992. [Google Scholar]

- Teunou, E.; Fitzpatrick, J.J. Effect of powder properties and storage conditions on the flowability of food powders. Powder Technol. 1999, 102, 59–69. [Google Scholar]

- Ketterhagen, W.R.; Curtis, J.S.; Hancock, B.C. Granular material flow behavior in bins: Effects of particle properties and moisture content. Powder Technol. 2009, 193, 303–312. [Google Scholar]

- Tomas, J. Adhesion of ultrafine particles—A micromechanical approach. Chem. Eng. Sci. 2004, 59, 1653–1666. [Google Scholar] [CrossRef]

- Saleh, K.; Thomas, C.; Guigon, P.; Fages, J. Influence of water content on the flowability of crushed pharmaceutical powders. Int. J. Pharm. 2004, 280, 123–131. [Google Scholar]

- Beverloo, W.A.; Leniger, H.A.; Van de Velde, J. The flow of granular solids through orifices. Chem. Eng. Sci. 1961, 15, 260–269. [Google Scholar] [CrossRef]

- Muite, B.K.; Quinn, S.F.; Sundaresan, S.; Rao, K.K. Silo music and silo quake: Granular flow-induced vibration. Powder Technol. 2004, 145, 190–202. [Google Scholar] [CrossRef]

- Kaliniewicz, Z.; Żuk, Z.; Krzysiak, Z. Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels. Sustainability 2018, 10, 1003. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Horabik, J.; Mueller, P.; Opaliński, I. Mechanical properties of potato starch modified by moisture content and addition of lubricant. Int. Agro. 2014, 28, 471–477. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Gancarz, M.; Wiącek, J.; Parafiniuk, P.; Lisowski, A. Characterization of shear behaviour in consolidated granular biomass. Powder Technol. 2018, 327, 120–127. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Stasiak, M. Characterizing moist food-powder flowability using a Jenike shear tester. J. Food Eng. 2012, 108, 51–58. [Google Scholar] [CrossRef]

- Chutkowski, M.; Opaliński, I.; Stasiak, M.; Leś, K.; Olechowski, M.; Przywara, M. Studies on moisture effects on powder flow and mechanochemical improvement of powder flowability. Adv. Sci. Technol. Res. J. 2021, 15, 228–246. [Google Scholar] [CrossRef]

- Kruszelnicka, W.; Chen, Z.; Ambrose, K. Moisture-Dependent Physical-Mechanical Properties of Maize, Rice, and Soybeans as Related to Handling and Processing. Materials 2022, 15, 8729. [Google Scholar] [CrossRef]

- Dong, W.; Liu, X.; Sun, B.; Huang, D. Moisture-induced plasticity and strength degradation of rice endosperm structures. J. Food Process Eng. 2024, 47, e14671. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Wright, B.D.; Yang, R.Y.; Xu, B.H.; Yu, A.B. Rolling friction in the dynamic simulation of sandpile formation. Phys. A Stat. Mech. Its Appl. 2002, 269, 536–553. [Google Scholar] [CrossRef]

- Johansson, M.; Edeskär, T. Influence of moisture on friction and flow properties of granular materials. Powder Technol. 2013, 245, 143–152. [Google Scholar]

- Reddy, K.R.; Joshi, M.; McCall, K. Influence of sample preparation on shear strength of fine-grained soils. Geotech. Test. J. 2008, 31, 497–507. [Google Scholar]

- Zhang, Q.; Yu, Z.; Xu, J. Effect of fines and moisture on shear strength of granular soils. Materials 2023, 16, 567. [Google Scholar] [CrossRef]

- Santamarina, J.C.; Klein, K.A.; Fam, M.A. Soils and Waves: Particulate Materials Behavior, Characterization and Process Monitoring; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Antony, S.J. Link between single-particle properties and macroscopic properties in particulate assemblies: Role of structures within structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2004, 362, 1953–1968. [Google Scholar] [CrossRef]

- O’Sullivan, C. Particulate Discrete Element Modelling: A Geomechanics Perspective; Spon Press: Londen, UK, 2011. [Google Scholar]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Carson, J.W.; Wilms, J.A. How to measure and interpret flow properties of bulk solids. Chem. Eng. 2000, 107, 141–151. [Google Scholar]

- Molenda, M.; Horabik, J.; Thompson, S.A. Effect of moisture content on mechanical properties of cereal grains. Int. Agro. 2006, 20, 117–122. [Google Scholar]

- Zapała, W.; Opaliński, I. Mechanical Properties of Solid Biomass as Affected by Moisture Content. AgriEngineering 2023, 5, 71. [Google Scholar] [CrossRef]

- Manokaran, M.; Morgeneyer, M.; Weiss, D. Effect of Microscopic Properties on Flow Behavior of Industrial Cohesive Powder. Powders 2024, 3, 19. [Google Scholar] [CrossRef]

- Lisle, A.T.; Martin, M.; Fitzgerald, M.A. Microscopic and chemical structure of rice grain and its relationship to cooking quality. Cereal Chem. 2000, 77, 594–599. [Google Scholar]

- Tian, Y.; Zhang, Y.; Zhu, L. Effect of moisture content on mechanical properties and microstructure of rice endosperm. J. Cereal Sci. 2020, 93, 102975. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).