Spudcan Reinstallation Close to Natural Footprints Considering Strength Reduction: Insights from Single-Factor and Orthogonal Experiments

Abstract

1. Introduction

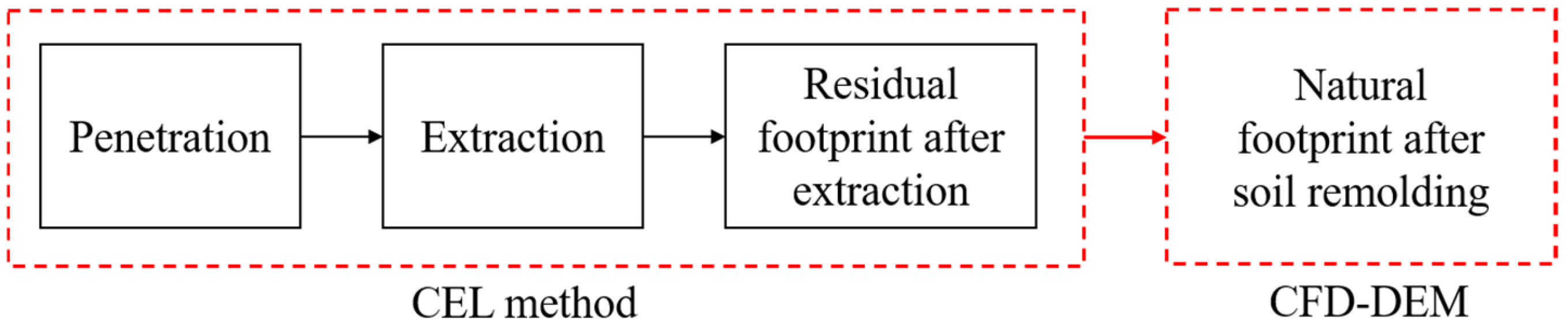

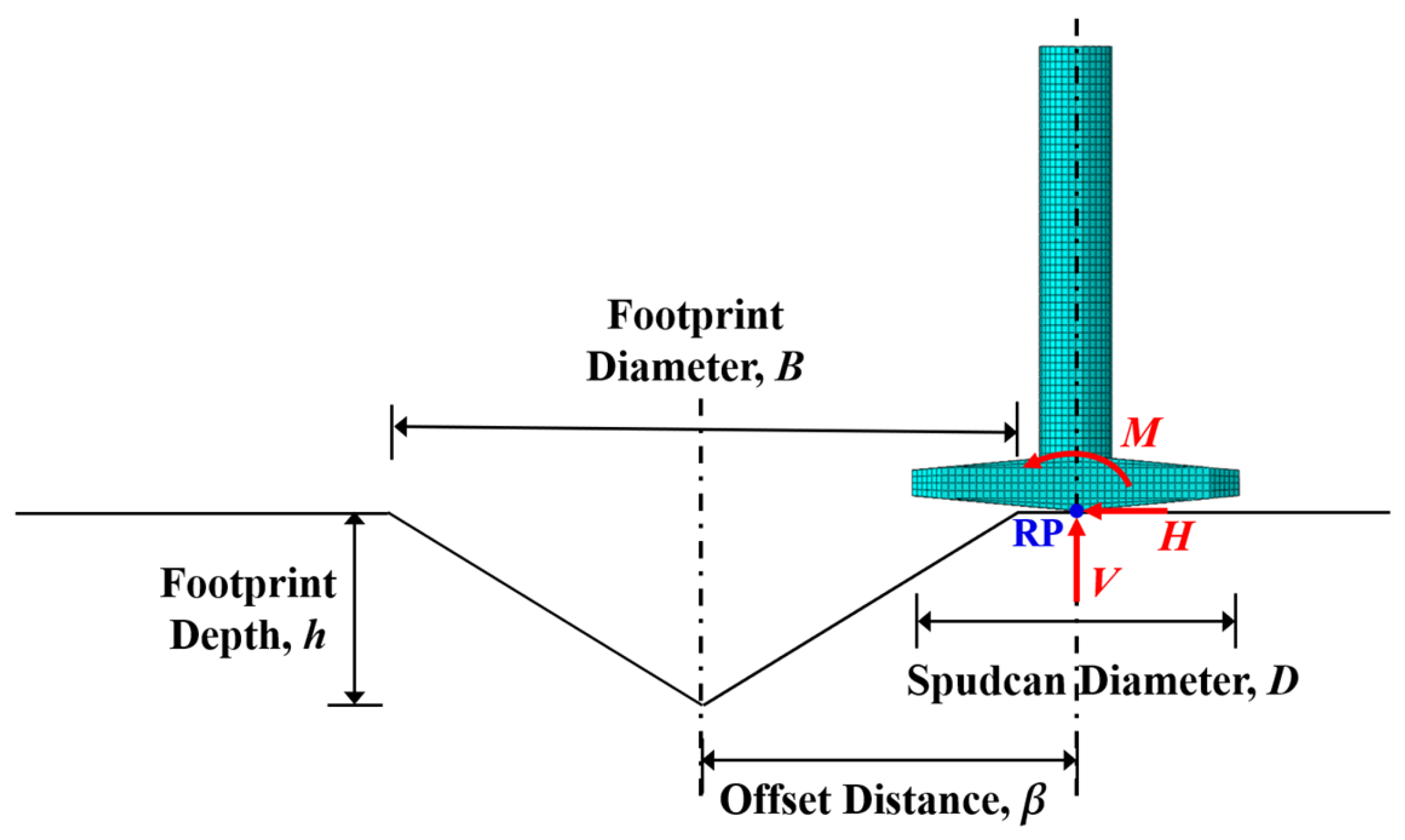

- Realistic footprint simulation: Unlike previous studies that assumed artificially defined geometries, the footprints in this study were generated by realistic simulations of the initial spudcan penetration, extraction, and subsequent soil remolding, providing a more realistic representation of natural footprints prior to reinstallation. The process is illustrated in Figure 2, and the detailed numerical implementation is presented in Section 2.1.Figure 2. Schematic diagram of the two-stage numerical approach for generating realistic spudcan footprints.Figure 2. Schematic diagram of the two-stage numerical approach for generating realistic spudcan footprints.

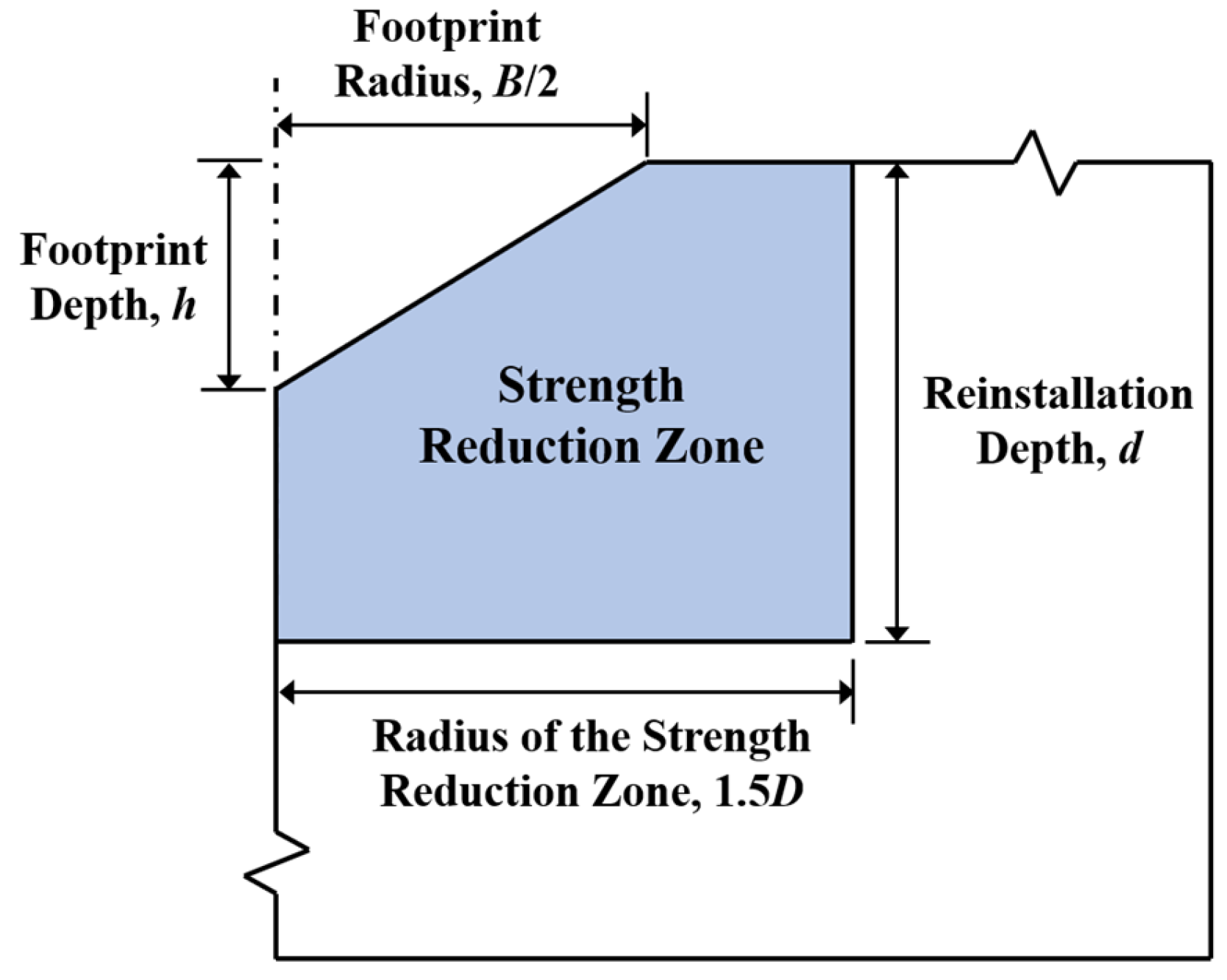

- Soil strength degradation modeling: In order to capture the degradation effects that are often neglected in numerical studies, soil strength softening is achieved by reducing the undrained shear strength within 1.5D from the footprint centerline.

- The method of combining single factor and orthogonal test: on the basis of the verified numerical model, the parameters of the system are studied by single factor and orthogonal test design. The former is used to examine the individual effects of key parameters—footprint geometry, spudcan type, and offset distance—on key reinstallation responses, and the latter is used to identify and rank the relative importance of different factors.

2. Numerical Modeling and Validation

2.1. Finite Element Model

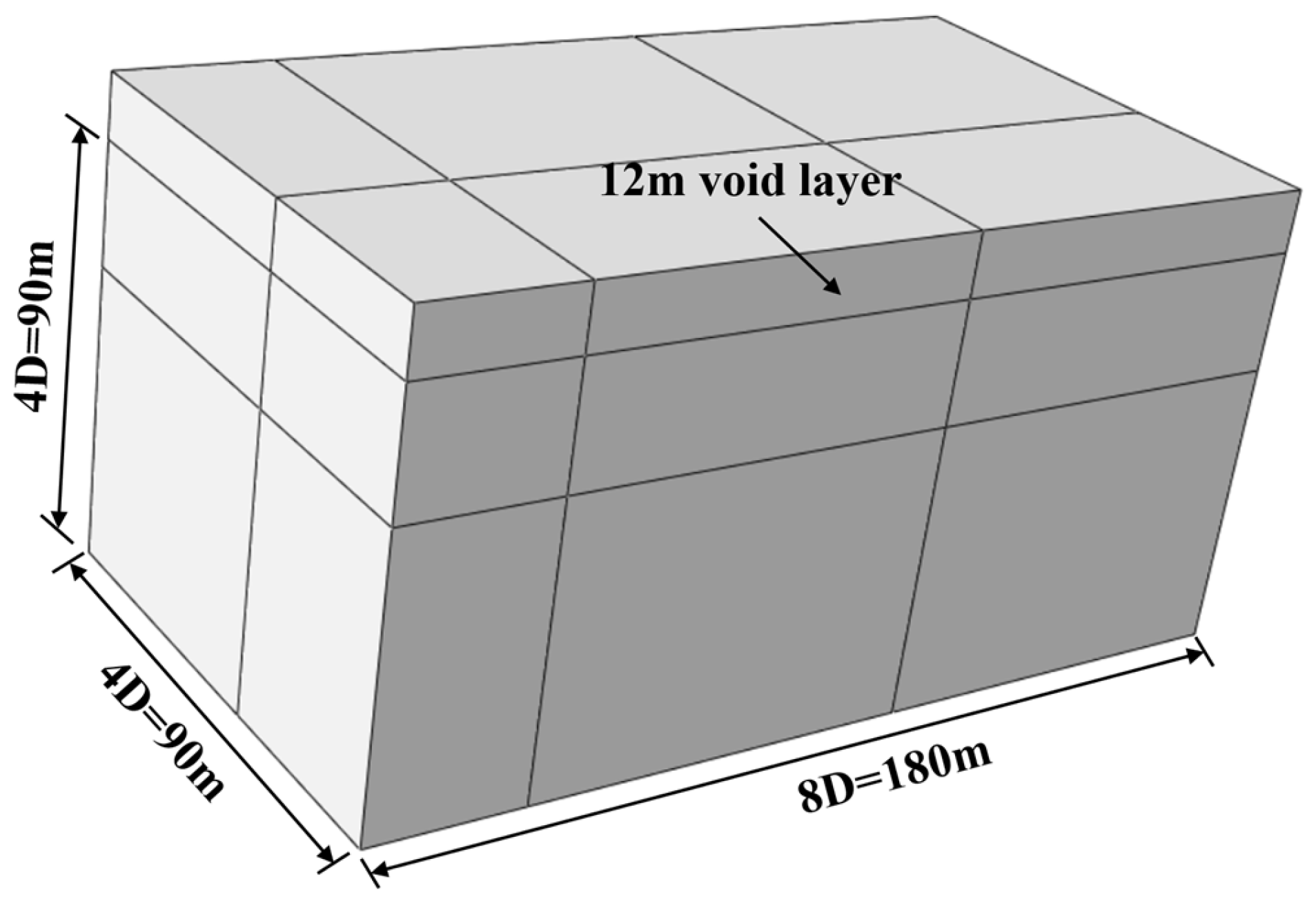

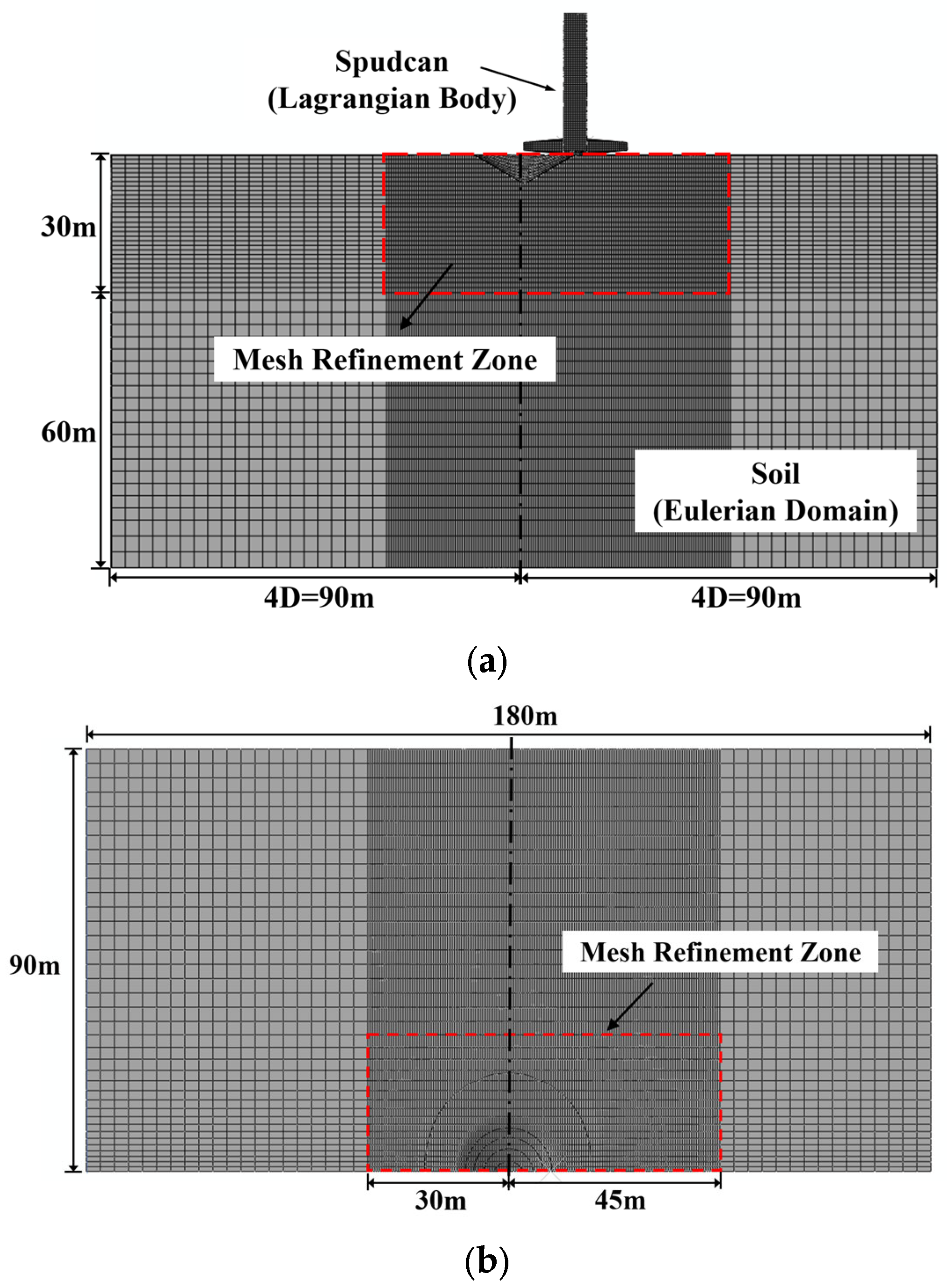

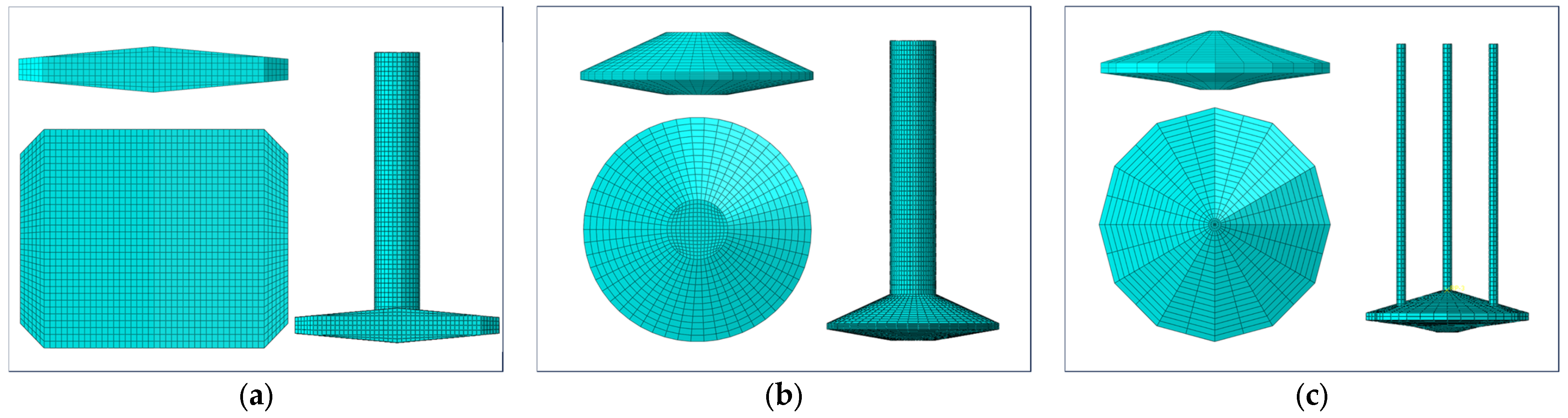

- The CEL method was used to simulate the initial penetration and subsequent extraction of three typical spudcans on a flat seabed, so as to capture the geometric shape of the footprints formed after extraction;

- Based on the extracted footprint geometry, the CFD-DEM coupling method was used to simulate the natural remolding process under the action of seawater. Through these simulations, the footprint diameter, depth and soil strength reduction coefficient of three different spudcans after extraction and remodeling were obtained, as shown in Table 1.

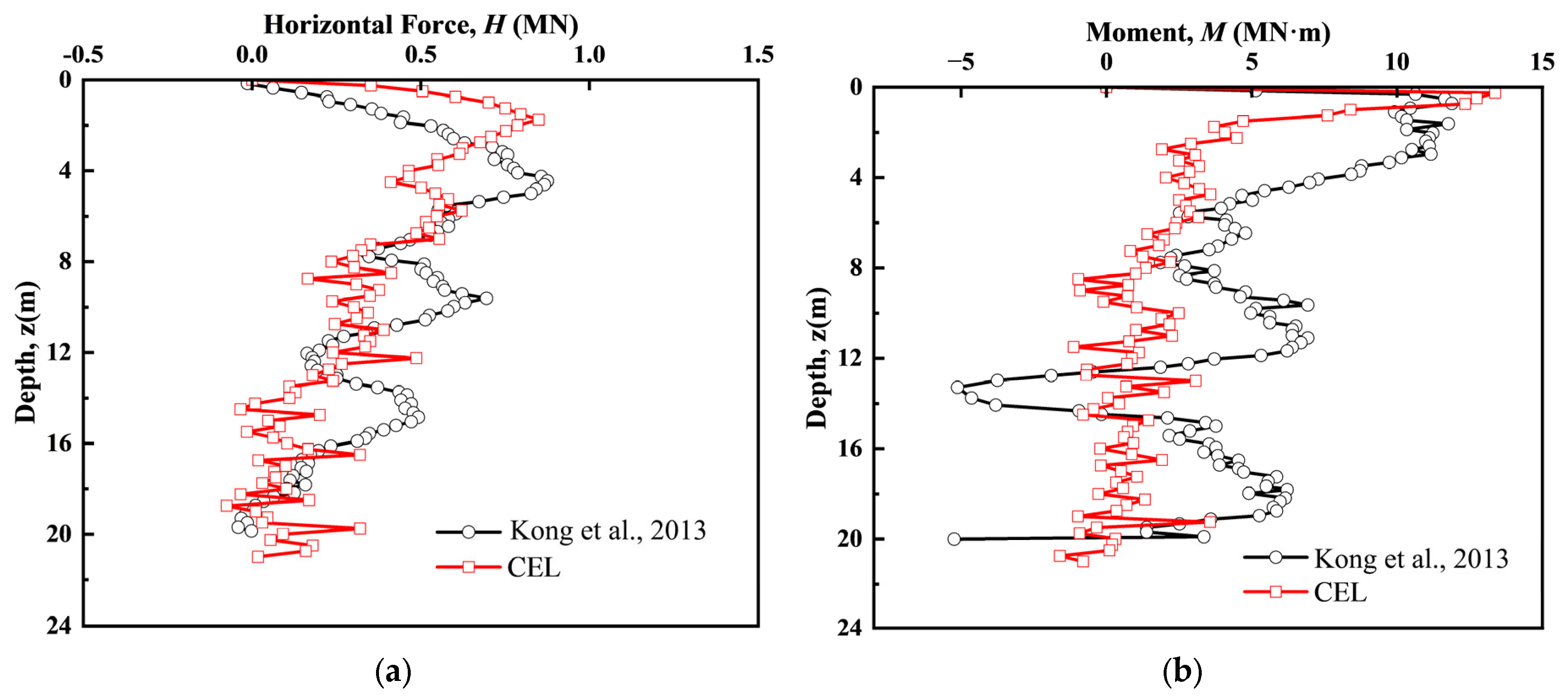

2.2. Model Validation

3. Results and Discussion

3.1. Single-Factor Test Analysis

3.1.1. Effect of Footprint Geometry

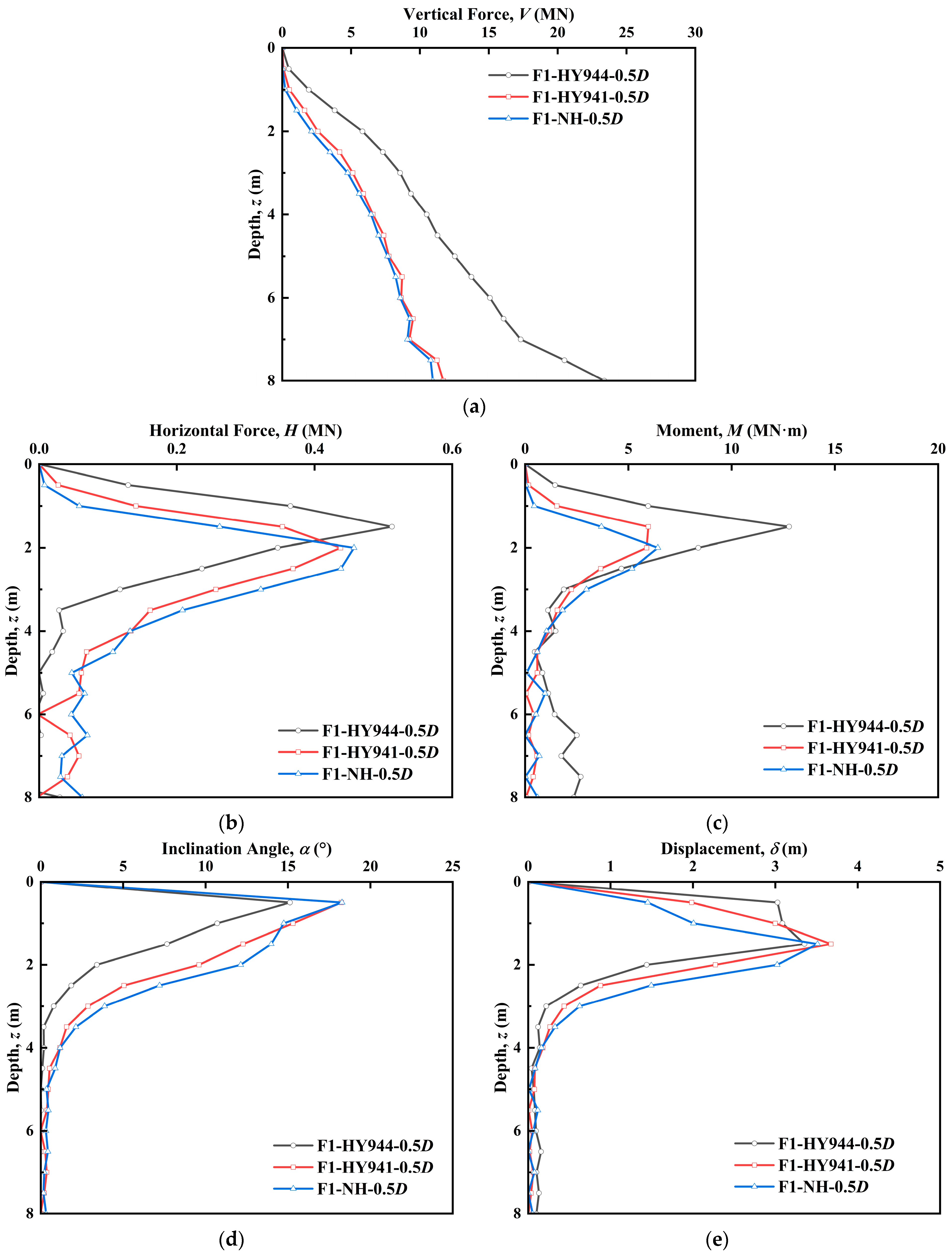

3.1.2. Effect of Spudcan Type

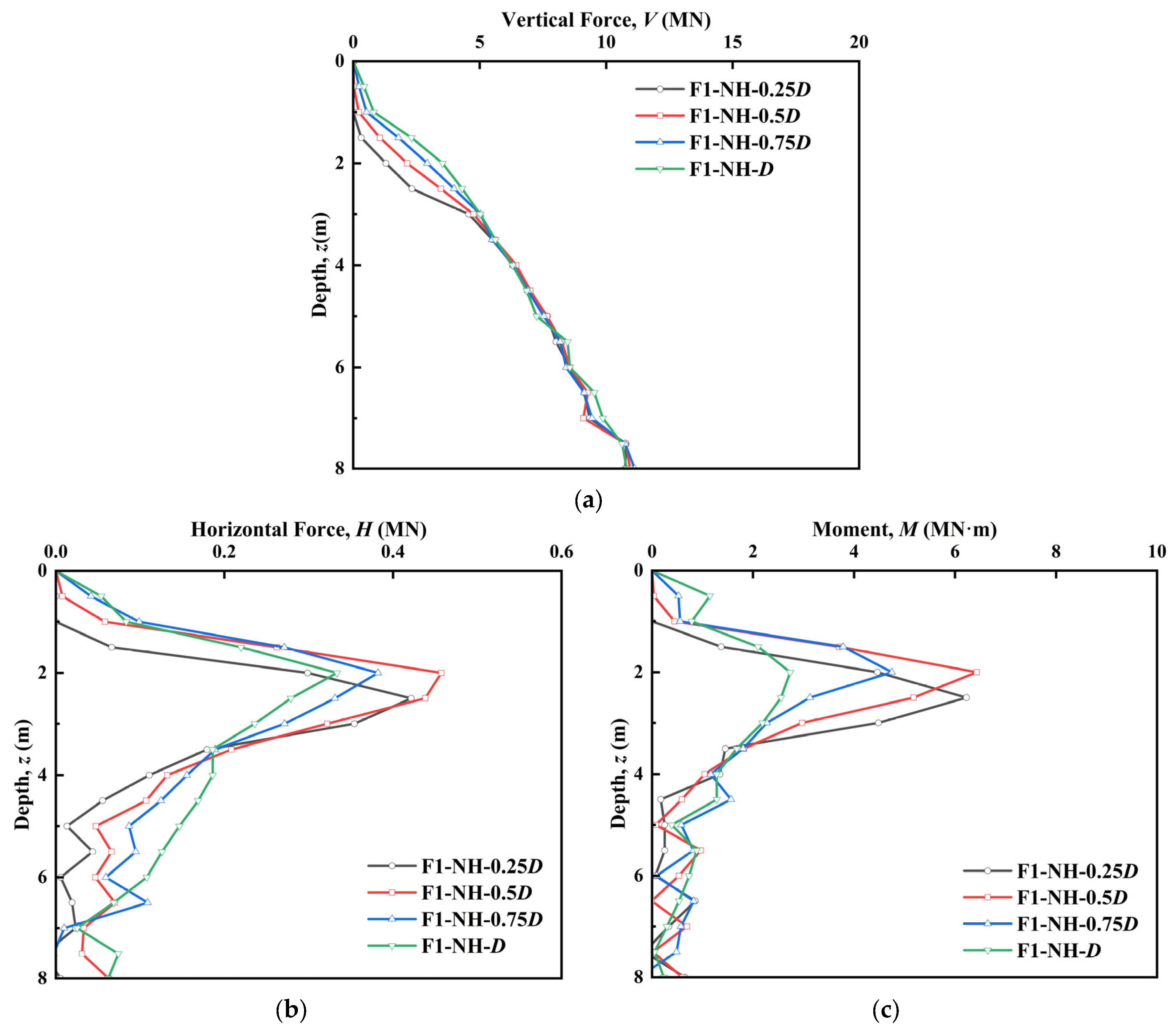

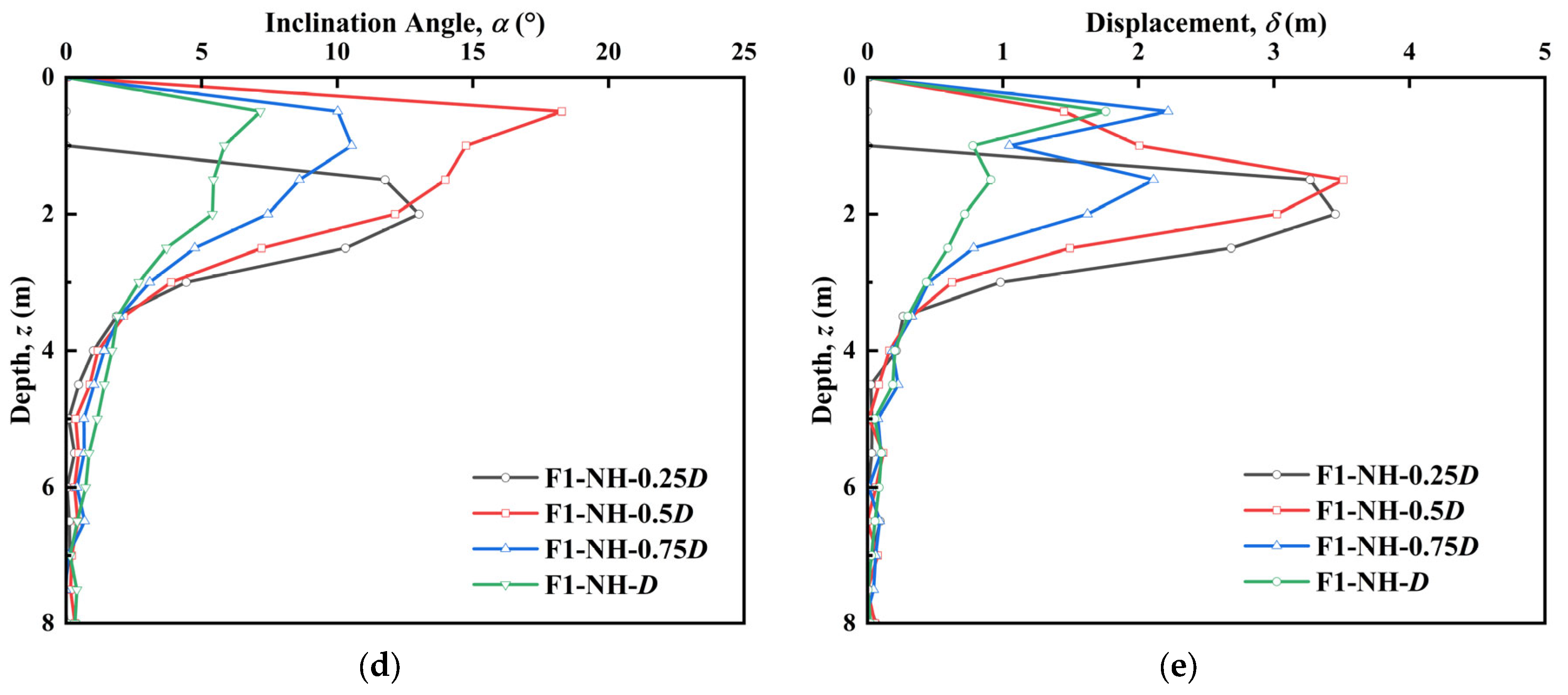

3.1.3. Effect of Offset Distance

3.2. Orthogonal Test Analysis

4. Conclusions

- (1)

- The geometry of the natural footprint has a significant effect on the reinstallation behavior of the spudcan. The lateral size (diameter) of the footprint is more critical than its depth. The larger diameter leads to severer soil asymmetry, resulting in higher horizontal force, moments, and greater inclination and displacement, thereby reducing the reinstallation stability.

- (2)

- The shape and size of different spudcan types would affect their reinstallation stability. Compared with the circular flat-based spudcan, the rectangular spudcan with a tapered base shows greater horizontal force and moment due to the corner effect. At the same time, the larger spudcan diameter provides a larger contact area and increases the vertical force, thereby reducing the spudcan inclination and lateral displacement.

- (3)

- The offset distance is the main factor affecting the reinstallation behavior, and the least favorable condition occurs at the offset distance of 0.5 D. When the offset is smaller than this distance, the obvious soil asymmetry leads to a larger inclination angle and a larger lateral displacement. When the offset distance exceeds 0.5 D, the soil distribution becomes more symmetrical, which reduces the inclination and displacement, thereby improving the overall stability of the reinstallation process near the existing footprint.

- (4)

- Both single-factor test and orthogonal analysis show that among the three factors evaluated, the offset distance has the greatest influence on the reinstallation performance compared with the footprint geometry and spudcan type.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gan, C.T.; Leung, C.F.; Cassidy, M.J.; Gaudin, C.; Chow, Y.K. Effect of Time on Spudcan–Footprint Interaction in Clay. Géotechnique 2012, 62, 401–413. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Gao, P.; Gao, Y.L.; Bi, J.Z.; Gao, Q. Probabilistic Prediction of Spudcan Bearing Capacity in Stiff-over-Soft Clay Based on Bayes’ Theorem. J. Mar. Sci. Eng. 2025, 13, 1344. [Google Scholar] [CrossRef]

- Butterfield, R.; Houlsby, G.T.; Gottardi, G. Standardized Sign Conventions and Notation for Generally Loaded Foundations. Géotechnique 1997, 47, 1051–1054. [Google Scholar] [CrossRef]

- Randolph, M.; Cassidy, M.; Gourvenec, S.; Erbrich, C. Challenges of Offshore Geotechnical Engineering. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005. [Google Scholar]

- Stewart, D.P.; Finnie, I.M.S. Spudcan-Footprint Interaction during Jack-up Workovers. In Proceedings of the 11th International Offshore and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2001. [Google Scholar]

- Gaudin, C.; Cassidy, M.J.; Donovan, T. Spudcan Reinstallation near Existing Footprints. In Proceedings of the 6th International Offshore Site Investigation and Geotechnics Conference: Confronting New Challenges and Sharing Knowledge, London, UK, 11–13 September 2007. [Google Scholar]

- Hunt, R.J.; Marsh, P.D. pportunities to Improve the Operational and Technical Management of Jack-up Deployments. Mar. Struct. 2004, 17, 261–273. [Google Scholar] [CrossRef]

- Young, A.G.; Remmes, B.D.; Meyer, B.J. Foundation Performance of Offshore Jack-up Drilling Rigs. J. Geotech. Eng. 1984, 110, 841–859. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Y.; Tao, J.; Zhang, C. Numerical Study of Spudcan Penetration Induced Loading on an Adjacent Jacket Pile in Soft Clays. In Proceedings of the 25th International Ocean and Polar Engineering Conference, Kona, HI, USA, 21–26 June 2015. [Google Scholar]

- Dier, A.; Carroll, B.; Abolfathi, S. Guidelines for Jack-Up Rigs with Particular Reference to Foundation Integrity; MSL Engineering Limited: Ringaskiddy, Ireland, 2004. [Google Scholar]

- Cassidy, M.J.; Quah, C.K.; Foo, K.S. Experimental Investigation of the Reinstallation of Spudcan Footings Close to Existing Footprints. J. Geotech. Geoenvironmental Eng. 2009, 135, 474–486. [Google Scholar] [CrossRef]

- Yuan, Y.; Duan, M.L.; Zhang, C.L.; Gao, P.; Bai, X.L. Experimental study on the global behaviour of jack-up unit reinstalled near a footprint. Appl. Ocean Res. 2021, 106, 102456. [Google Scholar] [CrossRef]

- Hendriyawan, D.; Vebrian, A.; Denny, T.; Indra, N.H.; Rildova; Farid, P.B. Effects of Prior Footprints on the Bearing Capacity of Spudcan Foundations: A Case Study. IOP Conf. Ser. Earth Environ. Sci. 2023, 1249, 012032. [Google Scholar] [CrossRef]

- Kong, V.; Cassidy, M.J.; Gaudin, C. Experimental Study of Effect of Geometry on Reinstallation of Jack-up next to Footprint. Can. Geotech. J. 2013, 50, 557–573. [Google Scholar] [CrossRef]

- Kong, V.; Cassidy, M.J.; Gaudin, C. Failure Mechanisms of a Spudcan Penetrating next to an Existing Footprint. Theor. Appl. Mech. Lett. 2015, 5, 64–68. [Google Scholar] [CrossRef]

- Fang, Y.S.; Shih, Y.C.; Liu, C.; Hsieh, J.Y. Reduction of footprint problems on spudcan in sand with infilling method Available to Purchase. Int. J. Phys. Model. Geotech. 2023, 23, 150–165. [Google Scholar]

- Hartono, H.; Tho, K.K.; Leung, C.F.; Chow, Y.K. Centrifuge and Numerical Modelling of Reaming as a Mitigation Measure for Spudcan-Footprint Interaction. In Proceedings of the Offshore Technology Conference-Asia, Kuala Lumpur, Malaysia, 25–28 March 2014. [Google Scholar]

- Qiu, G.; Henke, S. Controlled Installation of Spudcan Foundations on Loose Sand Overlying Weak Clay. Mar. Struct. 2011, 24, 528–550. [Google Scholar] [CrossRef]

- Hamann, T.; Qiu, G.; Grabe, J. Application of a Coupled Eulerian–Lagrangian Approach on Pile Installation Problems under Partially Drained Conditions. Comput. Geotech. 2015, 63, 279–290. [Google Scholar] [CrossRef]

- Tho, K.K.; Leung, C.F.; Chow, Y.K.; Swaddiwudhipong, S. Eulerian Finite-Element Technique for Analysis of Jack-up Spudcan Penetration. Int. J. Geomech. 2012, 12, 64–73. [Google Scholar]

- Yu, L.; Zhang, H.; Li, J.; Wang, X. Finite Element Analysis and Parametric Study of Spudcan Footing Geometries Penetrating Clay Near Existing Footprints. J. Mar. Sci. Eng. 2019, 7, 175. [Google Scholar] [CrossRef]

- Gao, P.; Liu, Z.; Shi, D.; Fu, X.; Yan, K. Mitigation Effect of Perforation Drilling on the Sliding Risk during Spudcan Installation Close to Footprints. J. Mar. Sci. Eng. 2020, 8, 118. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, H.Y.; Liu, J.; Huang, Y. Numerical Study of Footprint Generation and Reinstallation of Jack-Up Footings. J. Geotech. Geoenvironmental Eng. 2021, 147, 04021089. [Google Scholar] [CrossRef]

- Yu, H.F.; Sun, Z.Z.; He, L.L.; Yang, L. Research on Optimal Design of Spudcan Structures to Ease Spudcan-Footprint Interactions in Clay and Comparative Analyses with Different Measures. Pol. Marit. Res. 2022, 29, 43–56. [Google Scholar] [CrossRef]

- Yang, L.; Yang, J.; Cheng, L.; Ma, C. Bearing mechanism analysis and PSO-CatBoost error-corrected prediction for spudcan reinstallation over existing footprints in spatially variable clay. Ocean Eng. 2025, 340, 122422. [Google Scholar] [CrossRef]

- Dean, E.T.R. A Spudcan Foundation Model with Excess Pore Pressures. Part 1. A Principle of Effective Loads. Mar. Struct. 2004, 17, 219–243. [Google Scholar] [CrossRef]

- Byrne, B.W.; Villalobos, F.; Houlsby, G.T.; Martin, C.M. Laboratory Testing of Shallow Skirted Foundations in Sand. In Proceedings of the BGA International Conference on Foundations: Innovations, Observations, Design and Practice, Dundee, Scotland, 2–5 September 2003. [Google Scholar]

- Landon, M.M.; Gaudin, C.; Cassidy, M.J. Jack-up Installation on an Uneven Seabed: Recommendations from Model Testing in Overconsolidated Clay. In Proceedings of the 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. [Google Scholar]

- Leung, C.F.; Gan, C.T.; Chow, Y.K. Shear Strength Changes within Jack-up Spudcan Footprint. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007. [Google Scholar]

- Gan, C. Centrifuge Model Study on Spudcan-Footprint Interaction. Ph.D. Thesis, National University of Singapore, Singapore, 2009. [Google Scholar]

- Hossain, M.S.; Dong, X. Extraction of Spudcan Foundations in Single and Multilayer Soils. J. Geotech. Geoenvironmental Eng. 2014, 140, 170–184. [Google Scholar] [CrossRef]

- Jun, M.J.; Kim, Y.H.; Hossain, M.S.; Cassidy, M.J.; Hu, Y.; Sim, J.W. Numerical Investigation of Novel Spudcan Shapes for Easing Spudcan-Footprint Interactions. J. Geotech. Geoenvironmental Eng. 2018, 144, 4018055. [Google Scholar] [CrossRef]

- Jun, M.J.; Kim, Y.H.; Hossain, M.S.; Cassidy, M.J.; Hu, Y.; Park, S.G. Optimising Spudcan Shape for Mitigating Horizontal and Moment Loads Induced on a Spudcan Penetrating near a Conical Footprint. Appl. Ocean Res. 2018, 79, 62–73. [Google Scholar] [CrossRef]

- Jun, M.J.; Kim, Y.H.; Hossain, M.S.; Cassidy, M.J.; Hu, Y.; Park, S.G. Global Jack-up Rig Behaviour next to a Footprint. Mar. Struct. 2019, 64, 421–441. [Google Scholar] [CrossRef]

- Yuan, Y.; Fan, L.; Li, J.; Gao, J.; Duan, M. Numerical Investigation on Reinstallation of Jack-up Unit with Rectangular Spudcan Close to Footprint. Ocean Eng. 2022, 252, 111212. [Google Scholar] [CrossRef]

- Hu, P.; Wang, D.; Cassidy, M.; Cassidy, M.; Stanier, S.A. Predicting the resistance profile of a spudcan penetrating sand overlying clay. Can. Geotech. J. 2014, 51, 1151–1164. [Google Scholar] [CrossRef]

| Footprint | Diameter, B (m) | Depth, h (m) | Strength Reduction Factor (%) |

|---|---|---|---|

| F1 (HY944) | 22 | 6.52 | 63.76 |

| F2 (HY941) | 18.5 | 7.34 | 61.93 |

| F3 (NH-4) | 28.2 | 5.1 | 64.69 |

| Case No. | Case Name | Footprint Geometry | Spudcan Type | Offset Distance |

|---|---|---|---|---|

| 1 | F1-NH-0.5D | F1 | NH-4 | 0.5D |

| 2 | F2-NH-0.5D | F2 | NH-4 | 0.5D |

| 3 | F3-NH-0.5D | F3 | NH-4 | 0.5D |

| 4 | F1-HY944-0.5D | F1 | HY944 | 0.5D |

| 5 | F1-HY941-0.5D | F1 | HY941 | 0.5D |

| 6 | F1-NH-0.25D | F1 | NH-4 | 0.25D |

| 7 | F1-NH-0.75D | F1 | NH-4 | 0.75D |

| 8 | F1-NH-D | F1 | NH-4 | D |

| Case No. | Case Name | Maximum Horizontal Force | Maximum Moment | ||

|---|---|---|---|---|---|

| Hmax (MN) | αmax (°) | Mmax (MN·m) | δmax (m) | ||

| 1 | F1-NH-0.5D | 0.457 | 18.279 | 6.428 | 3.512 |

| 2 | F2-NH-0.5D | 0.368 | 16.486 | 5.823 | 2.558 |

| 3 | F3-NH-0.5D | 0.491 | 19.025 | 6.458 | 4.504 |

| Case No. | Case Name | Maximum Horizontal Force | Maximum Moment | ||

|---|---|---|---|---|---|

| Hmax (MN) | αmax (°) | Mmax (MN·m) | δmax (m) | ||

| 4 | F1-HY944-0.5D | 0.513 | 15.125 | 12.785 | 3.354 |

| 5 | F1-HY941-0.5D | 0.438 | 18.236 | 5.967 | 3.676 |

| 1 | F1-NH-0.5D | 0.457 | 18.279 | 6.428 | 3.512 |

| Case No. | Case Name | Maximum Horizontal Force | Maximum Moment | ||

|---|---|---|---|---|---|

| Hmax (MN) | αmax (°) | Mmax (MN·m) | δmax (m) | ||

| 6 | F1-NH-0.25D | 0.422 | 13.016 | 6.226 | 3.453 |

| 1 | F1-NH-0.5D | 0.457 | 18.279 | 6.428 | 3.512 |

| 7 | F1-NH-0.75D | 0.382 | 10.533 | 4.750 | 2.219 |

| 8 | F1-NH-D | 0.334 | 7.160 | 2.736 | 1.758 |

| Factor | Level 1 | Level 2 | Level 2 |

|---|---|---|---|

| Footprint geometry | F1 | F2 | F3 |

| Spudcan type | HY944 | HY941 | NH-4 |

| Offset distance | 0.25D | 0.5D | 0.75D |

| Case No. | Factor | Result | |||

|---|---|---|---|---|---|

| Footprint Geometry | Spudcan Type | Offset Distance | αmax (°) | δmax (m) | |

| ① | F1 | HY944 | 0.25D | 13.95 | 5.05 |

| ② | F1 | HY941 | 0.5D | 15.89 | 3.73 |

| ③ | F1 | NH-4 | 0.75D | 10.78 | 2.20 |

| ④ | F2 | HY944 | 0.5D | 13.56 | 3.11 |

| ⑤ | F2 | HY941 | 0.75D | 11.43 | 2.35 |

| ⑥ | F2 | NH-4 | 0.25D | 16.22 | 5.09 |

| ⑦ | F3 | HY944 | 0.75D | 9.83 | 2.56 |

| ⑧ | F3 | HY941 | 0.25D | 20.05 | 6.50 |

| ⑨ | F3 | NH-4 | 0.5D | 17.03 | 4.37 |

| Result | Factor | K1 | K2 | K3 | Ranking | |

|---|---|---|---|---|---|---|

| αmax(°) | Footprint geometry | 13.54 | 13.74 | 15.64 | 2.10 | 3 |

| Spudcan type | 12.45 | 15.79 | 14.68 | 3.35 | 2 | |

| Offset distance | 16.74 | 15.49 | 10.68 | 6.06 | 1 | |

| δmax(m) | Footprint geometry | 3.66 | 3.52 | 4.48 | 0.96 | 2 |

| Spudcan type | 3.57 | 4.20 | 3.89 | 0.62 | 3 | |

| Offset distance | 5.55 | 3.74 | 2.37 | 3.18 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Jiao, J.; Xu, G.; Cui, L.; Gao, X.; Lin, X.; Cai, G. Spudcan Reinstallation Close to Natural Footprints Considering Strength Reduction: Insights from Single-Factor and Orthogonal Experiments. Appl. Sci. 2025, 15, 11765. https://doi.org/10.3390/app152111765

Zou X, Jiao J, Xu G, Cui L, Gao X, Lin X, Cai G. Spudcan Reinstallation Close to Natural Footprints Considering Strength Reduction: Insights from Single-Factor and Orthogonal Experiments. Applied Sciences. 2025; 15(21):11765. https://doi.org/10.3390/app152111765

Chicago/Turabian StyleZou, Xin, Jingang Jiao, Guoxian Xu, Linjian Cui, Xinkai Gao, Xinyi Lin, and Guoqing Cai. 2025. "Spudcan Reinstallation Close to Natural Footprints Considering Strength Reduction: Insights from Single-Factor and Orthogonal Experiments" Applied Sciences 15, no. 21: 11765. https://doi.org/10.3390/app152111765

APA StyleZou, X., Jiao, J., Xu, G., Cui, L., Gao, X., Lin, X., & Cai, G. (2025). Spudcan Reinstallation Close to Natural Footprints Considering Strength Reduction: Insights from Single-Factor and Orthogonal Experiments. Applied Sciences, 15(21), 11765. https://doi.org/10.3390/app152111765