Procedure for Conducting Inspection Thermographic Tests of Electrical Heating Devices for Railway Turnouts

Abstract

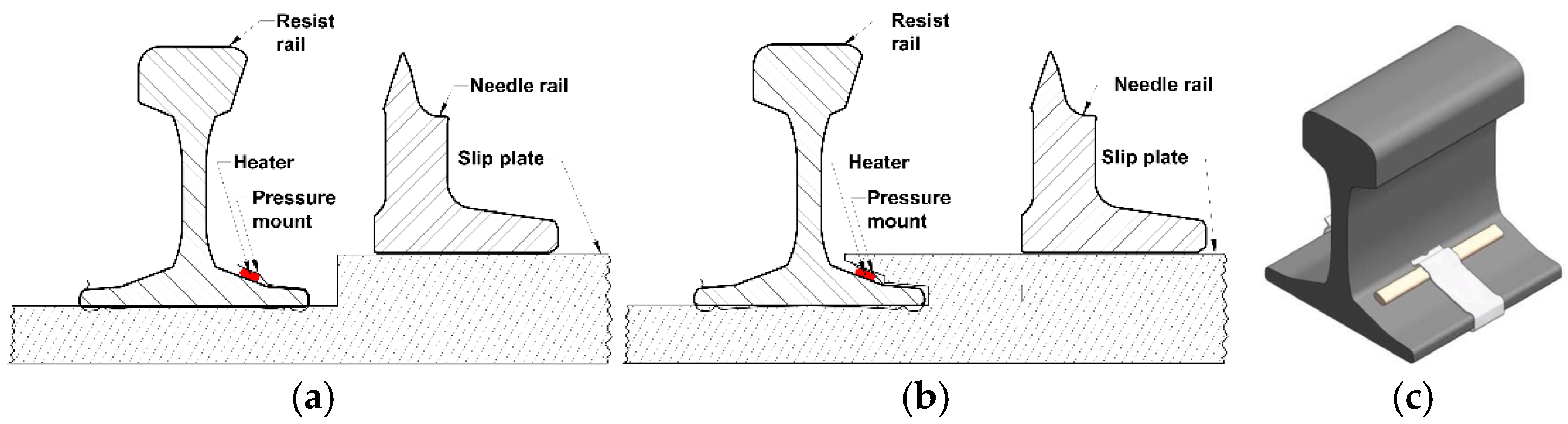

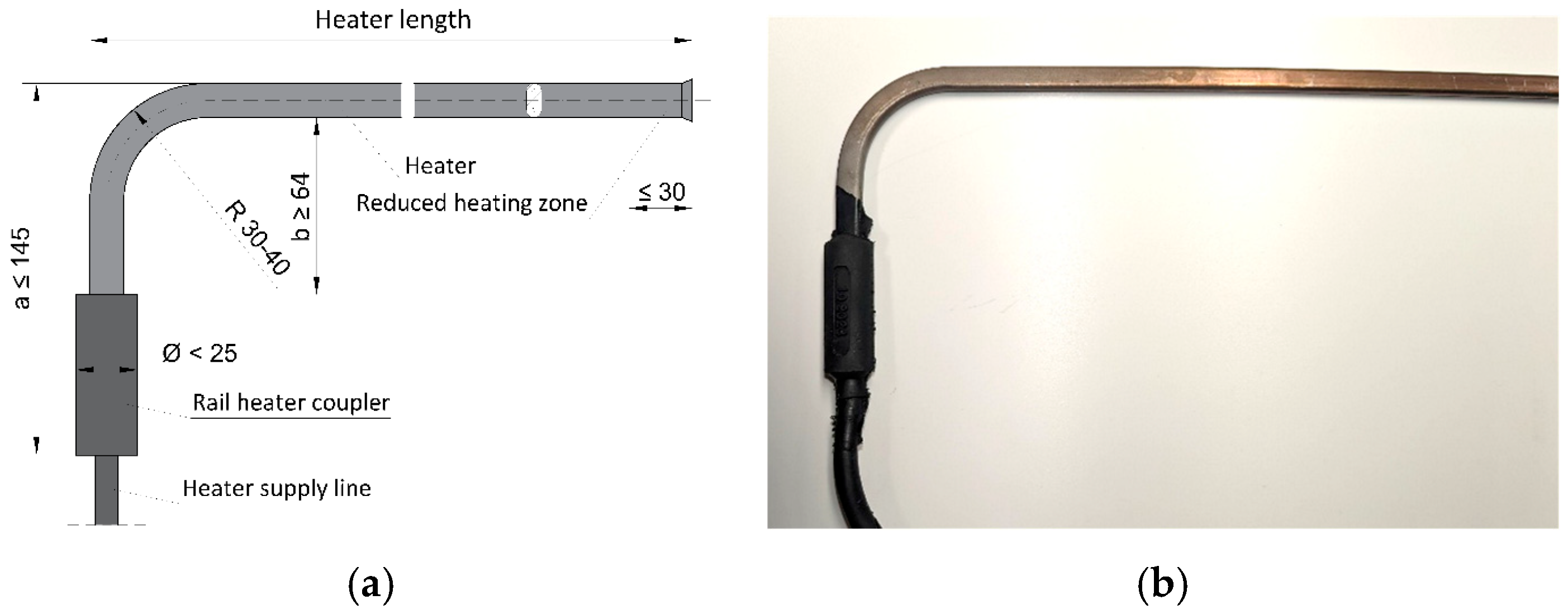

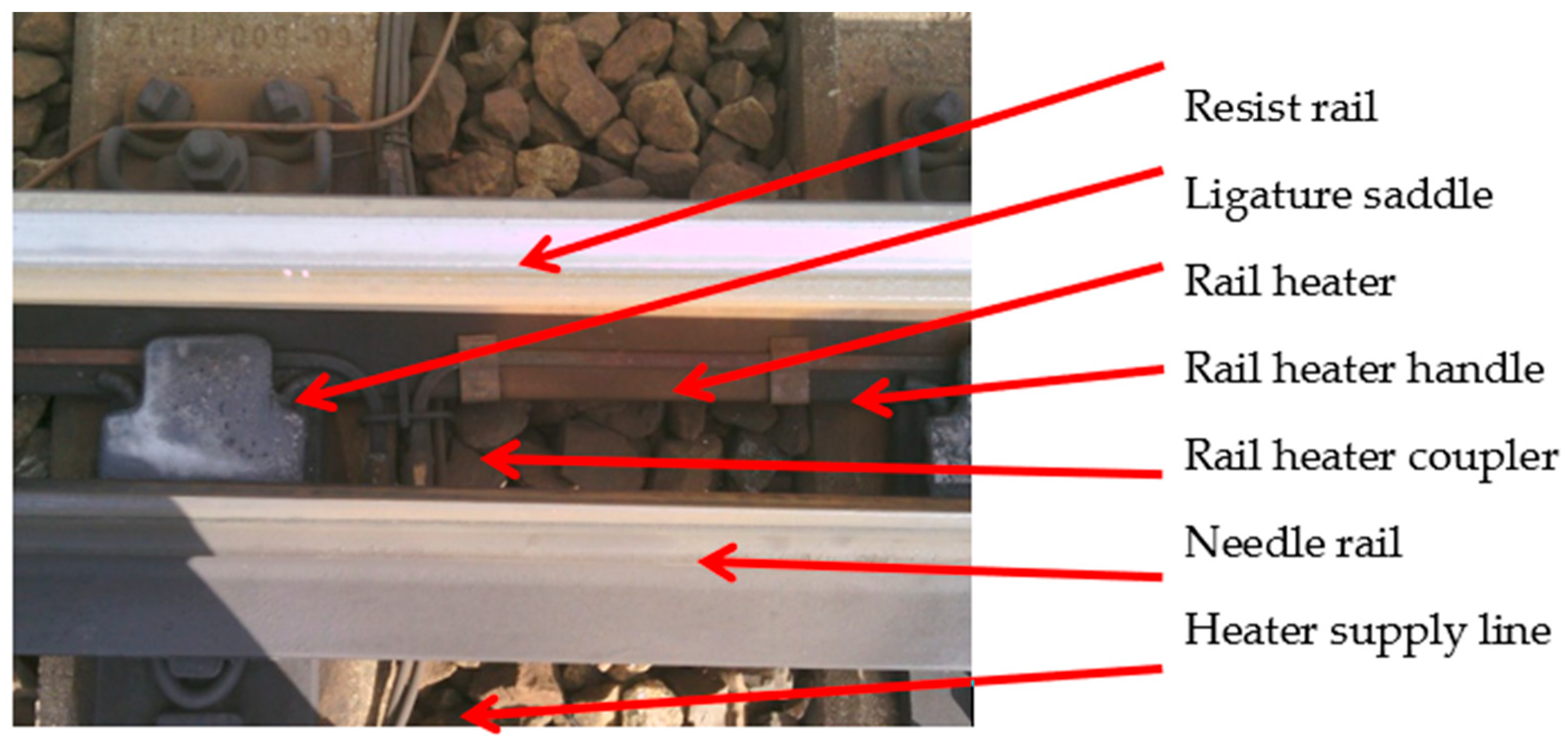

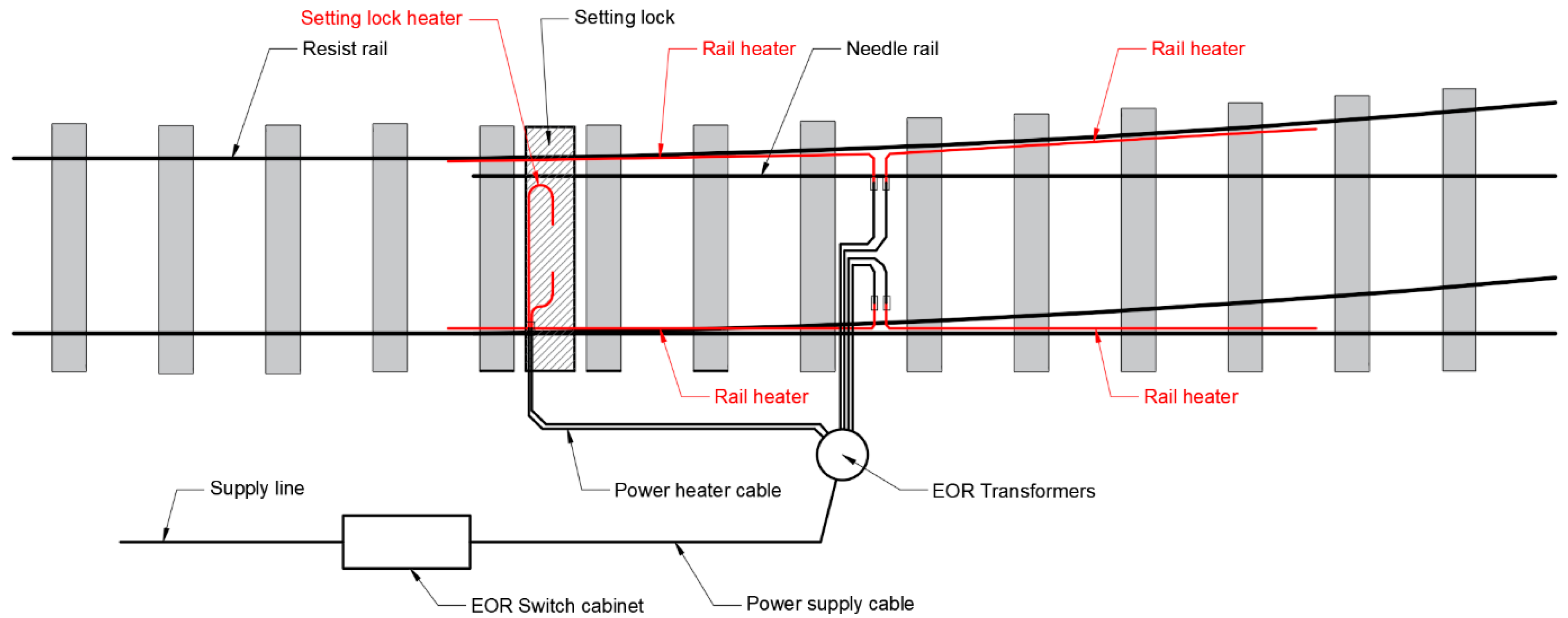

1. Introduction

2. Materials and Methods

- Visual inspection: Inspectors regularly check the condition of the turnout heating system by observing visible components such as rails, points, turnout huts, and electrical cables. Ensuring there is no visible damage, corrosion, or other mechanical problems is essential.

- Technical condition monitoring: Electric turnout heating systems are often equipped with remote monitoring, which allows their condition to be tracked continuously. Inspectors can analyse telemetry data in real time to ensure the system functions correctly.

- Operational tests: Conducting regular operational tests of the turnout heating system, including activating the heating in various weather conditions to ensure the system functions properly.

- Documentation review: Inspectors may also review the technical documentation for the electrical turnout heating system, including electrical diagrams, maintenance plans, and repair and maintenance history.

- Repairs and maintenance: If faults or damage are found during the inspection, inspectors can plan and supervise repairs and maintenance of the electrical turnout heating system to restore it to full working order.

- Staff training: Inspectors may also check whether the staff responsible for operating and maintaining the electric turnout heating system are adequately trained and aware of safety procedures and standards.

- Good condition (db)—equipment with a depreciation period that has not been exceeded, a degree of wear that has not been exceeded, and whose technical condition allows for safe operation.

- Satisfactory condition (sat)—equipment whose depreciation period is ending or has been exceeded, but whose technical condition allows for safe operation.

- Unsatisfactory condition (unsat)—equipment whose depreciation period has ended, is technically functional, but has been classified for modernisation.

- Insufficient condition (ndst)—equipment that must be taken out of service.

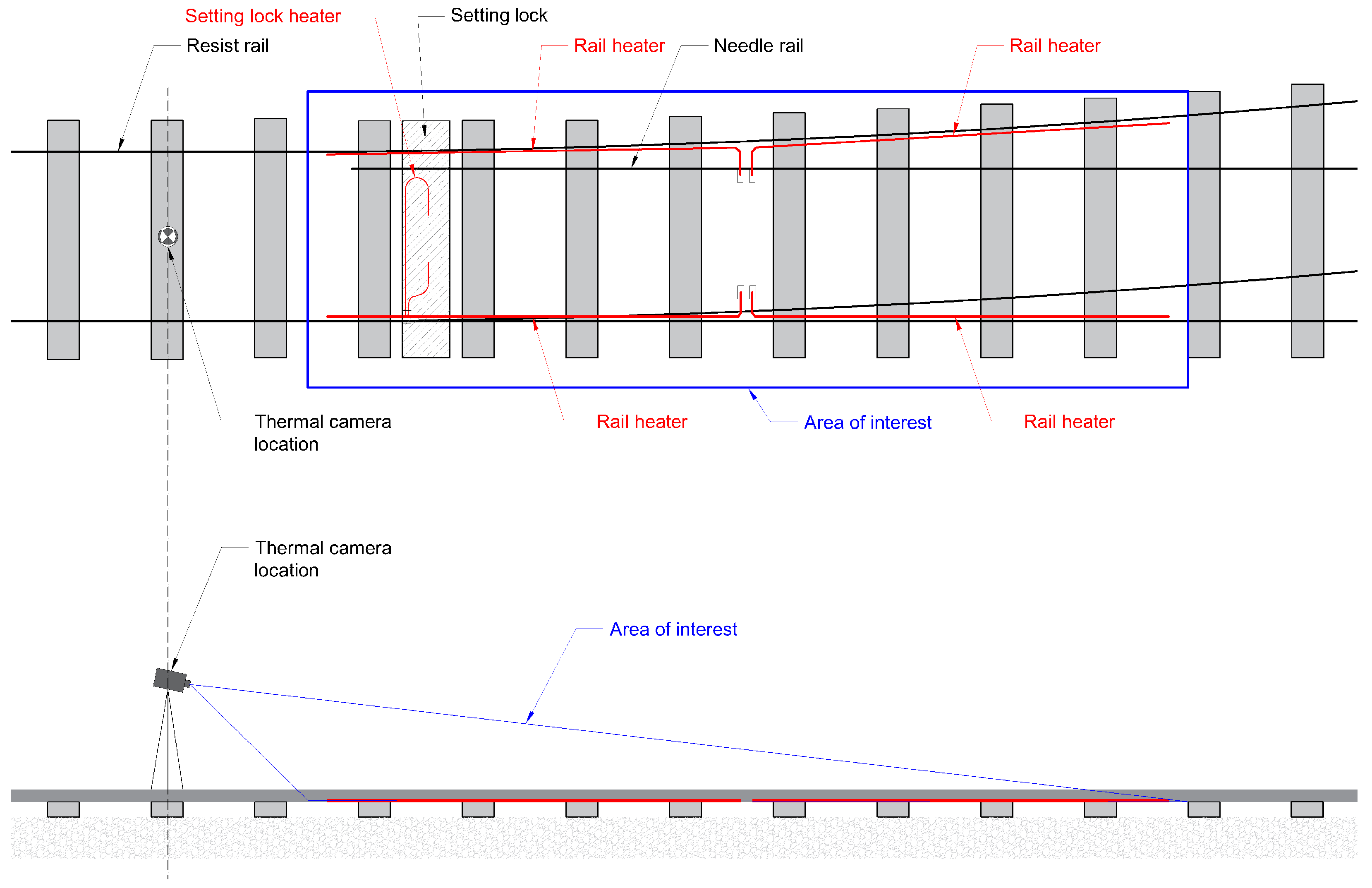

2.1. Diagnostic Testing Methodology

- the geometric arrangement of individual heating elements in the monitored turnout area is identified,

- the overall technical condition of the electric turnout heating elements is assessed,

- the correctness of the mounting of the heating elements is assessed,

- the temperature distribution along individual heating elements located in the monitored area of the turnout is assessed,

- the average temperature value of individual heating elements is determined,

- the temperatures of individual heating elements in the monitored area are compared,

- the time taken to reach the rated operating temperatures on the surface of the monitored heating elements is assessed,

- the effectiveness of the electric turnout heating system is assessed,

- appropriate technical documentation and an inspection sheet are prepared, and an appropriate entry is made in the EOR logbook for electric turnout heating.

- Obtain the appropriate approvals and permits to conduct thermal imaging inspections of electric turnout heating systems in railway areas.

- Elements of electric heating should be replaced or repaired with the participation of authorised energy personnel [in accordance with Id-4: Instructions for Visual Inspection, Technical Testing and Maintenance of Turnouts] [27].

- Thermal imaging inspections shall be carried out by specially trained personnel with appropriate knowledge of the functioning of the EOR system and authorisation to perform thermal imaging tests and electrical tests in the field of supervision and operation.

- Visual and track inspections shall be carried out in accordance with the safety requirements for this type of track work.

- The inspection scope, consisting of a visual inspection and a thermal imaging test, shall be agreed upon with the operator (applicant, infrastructure manager) and the personnel performing the test before the measurements are taken. It shall be included in the inspection report.

- Inspection measurements and thermal imaging inspections should be carried out during daylight hours under defined weather conditions recommended for thermal imaging measurements.

- Tests carried out during inspections should be performed at the rated power of the electrical heating system for turnouts and under quasi-stationary measurement conditions.

- The impact of environmental and weather conditions (humidity, atmospheric temperature, precipitation, wind speed, cloud cover, etc., that significantly affect the measurement results) should be documented.

- Due to the possibility of significant changes in atmospheric conditions, it is recommended that thermal imaging measurements for turnouts be carried out efficiently and without undue delay.

- Due to the significant impact of wind on the heating process of turnout zones observed for different geolocations, it is recommended that inspection measurements be performed in windless weather.

- To assess and define the initial temperature conditions, thermal imaging measurements of the electrical heating system of turnouts should be performed before its start-up, in the so-called cold state.

- The atmospheric temperature near the assessed element should be recorded for the monitored turnout area under operating conditions.

- The process and heating status of individual heating elements of the turnout should be recorded after the temperature of the heating elements has stabilised or after the snow or ice has melted, allowing direct observation of the heating surfaces.

- The surface temperature for each heating element shall be recorded in a steady state, heated, at least 30 min after the system has been started.

- The surfaces of the heaters and the monitored surfaces of the turnout may have significantly different emission parameters, resulting, among other things, from their material properties and operation in difficult and varied environmental conditions. A standardised emissivity coefficient of at least 0.9 may be used for inspection tests. If the emissivity coefficient of the tested material is unknown, it is recommended to use the value of 0.95 defined for the automatic camera mode.

- When determining the image composition, the entire area of the turnout should be covered by thermal imaging, setting the camera in such a way that each heater can be analysed separately (and, if required, also for the entire working area of the heated turnout), bearing in mind the need to assess its continuity and uniformity of temperature distribution along its entire length.

- The results should be archived and compiled according to the template for thermal imaging inspection test reports.

- Thermal imaging measurements should be carried out at least as often as specified in the operating instructions for the electrical turnout heating device. If no date is specified, measurements shall be carried out at least once a year, before the autumn–winter period.

- Due to the need to observe the heating surface of the heated monitored area, measurements should be carried out in conditions without snow or ice in the monitored area.

- In the case of detailed inspections, the components, subassemblies, and EOR heaters to be inspected should be viewed from as close a distance as possible and from the best possible observation point. As in the case of electrical measurements, the DIN EN 50110-1 (VOE 0105-1) standard applies to safe distances [38]. DIN EN 16714-1 [28] and DIN EN 16714-2 [29] standards must be observed for camera adjustments.

- During measurements, pay attention to possible anomalies in false readings caused by reflections and/or differences in emissivity. Incorrect measurements caused by reflections can be detected and eliminated by adjusting the image composition, camera settings, changing the camera’s position, and/or the angle of observation of the heating elements.

- Each thermal anomaly should be photographed simultaneously with the thermogram.

- Document the condition and basic operating parameters of the installation (e.g., set power value, rated power value, current consumption, operating time) during the thermal imaging measurement.

2.2. Thermal Camera Calibration

- 1.

- Image Uniformity Calibration: Ensuring all pixels across the camera’s imager respond consistently to infrared energy.

- 2.

- Temperature Point Correlation: Correlating incoming energy with known temperature points using calibrated blackbody references in controlled laboratory conditions.

- 3.

- Ambient Temperature Compensation: Measuring camera and optical path temperatures at multiple locations to ensure accurate readings across the entire operating temperature range (−15 °C to +50 °C).

- Measurement accuracy: ±2% or ±2 K (whichever is greater) [40].

- Thermal sensitivity (NETD): <0.08 K at 30 °C for both camera models.

- Calibration certificates were obtained for both cameras with traceability to international standards.

- Emissivity variations: ±0.05 (using standardised value of 0.9–0.95 for steel surfaces).

- Atmospheric attenuation: Negligible for distances < 5 m in dry conditions.

- Reflected radiation: Compensated through background temperature settings.

- General coverage images: 3–5 wide-angle thermograms per turnout covering the heated area.

- Detailed section analysis: 8–12 focused thermograms per turnout, with overlapping measurement fields.

- Total images per measurement session: 15–20 thermal images per turnout, plus corresponding visible light photographs.

- Temporal sequence: Images captured at 0 s (cold state), 5 min, 15 min, 30 min, 1 h, and 3 h intervals during heating cycles.

- Critical heating zones: Switch blade contact areas, closure panels, and frog regions.

- Heater element distribution: Each heating element type (900 W, 1050 W, 1250 W, and 1600 W) was individually analysed.

- Thermal uniformity assessment: Sections showing the most significant temperature variations.

- Comparative analysis: Identical geometric sections between EOR and ESAR systems for direct comparison.

- Measurement field overlap: Minimum 20% overlap between adjacent measurement areas to ensure continuity.

2.3. Calculation of Energy Indicators

- 1.

- Energy efficiency indicators are employed to compare technical solutions and estimate the electrical energy demand of the electric turnout heating system.

- 2.

- For the purpose of comparing and monitoring the energy performance characteristics of the electric turnout heating system, the following indicators are utilised:

- active power supplied to the heating installation [W],

- linear power density index [W/m],

- temperature power index [W·°C−1·m−1], and

- energy consumption index [Wh/m].

- The values and indicators for each turnout are presented collectively.

- 3.

- The calculation of the energy indicators relies on the following input parameters:

- Heating installation power [W]—power supplied to the heating elements associated with the heated surface of the turnout (either aggregated or separated by specific areas) and required for the operation of the applied heating system; power calculations consider dissipated in heating cables and plates, auxiliary devices, heating control components, etc.

- Length of heating cables [m]—total length of the heating installation, understood as the sum of lengths of individual heating elements or their segments.

- Average temperature parameter [°C] for the analysed heating element.

- Operating time parameter of the heating cable [h].

- 4.

- The active power [W] related to turnout heating is determined for the system according to Equation (1):where—active power of the -th heating cable [W], and—active power of auxiliary devices in the heating installation [W].

- 5.

- The linear power density [W/m] is calculated for the entire turnout by considering the total active power supplied to linear heating elements and the total length of heating cables , as expressed in Equation (2):where—total active power supplied to the turnout heating elements [W], and—total length of heating cables [m].

- 6.

- The temperature power index [W·°C−1·m−1] for the turnout is computed based on the temperatures of individual linear heating cables according to Equation (3):where—total active power supplied to the turnout heating elements [W],—average temperature of the -th linear heating cable [°C], established via thermographic imaging, and—length of the -th linear heating cable [m].

- 7.

- The energy consumption index [Wh/m] associated with the heating cables’ operating cycle is calculated using Equation (4):where—active power supplied to the -th heating cable [W],—operating time of the -th heating cable [h], and—total length of heating cables [m].

- 8.

- The index is determined using actual operating times of the heating cables on an annual basis, considering the entire heating period (e.g., from June to June).

- 9.

- The percentage reduction coefficient of heating power for electric turnout heating installations is calculated as follows:where—active power supplied to turnout heating elements after reduction application [W] (e.g., power provided to the ESAR system), and—active power supplied to turnout heating elements before reduction application [W] (e.g., power provided to the reference EOR system).

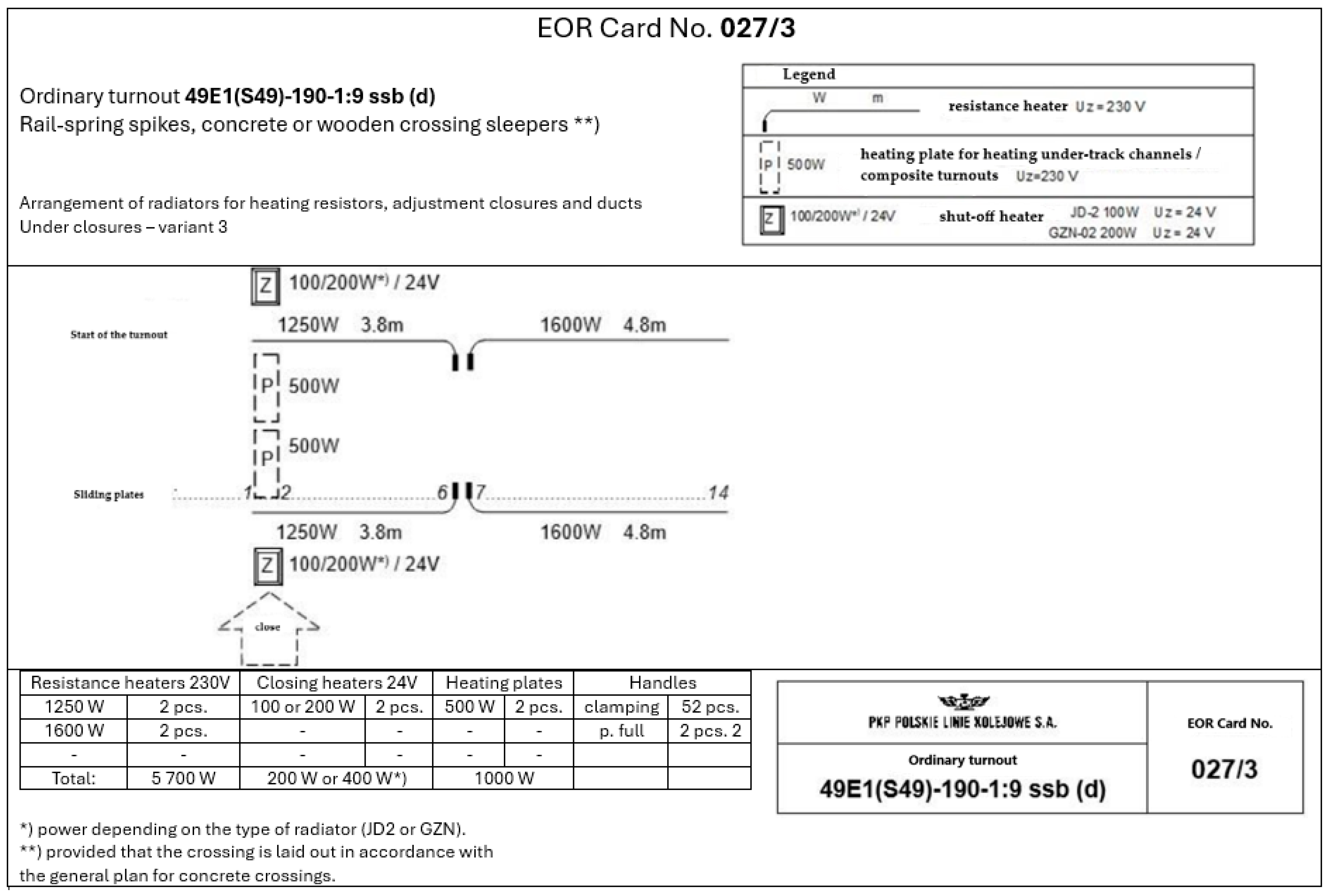

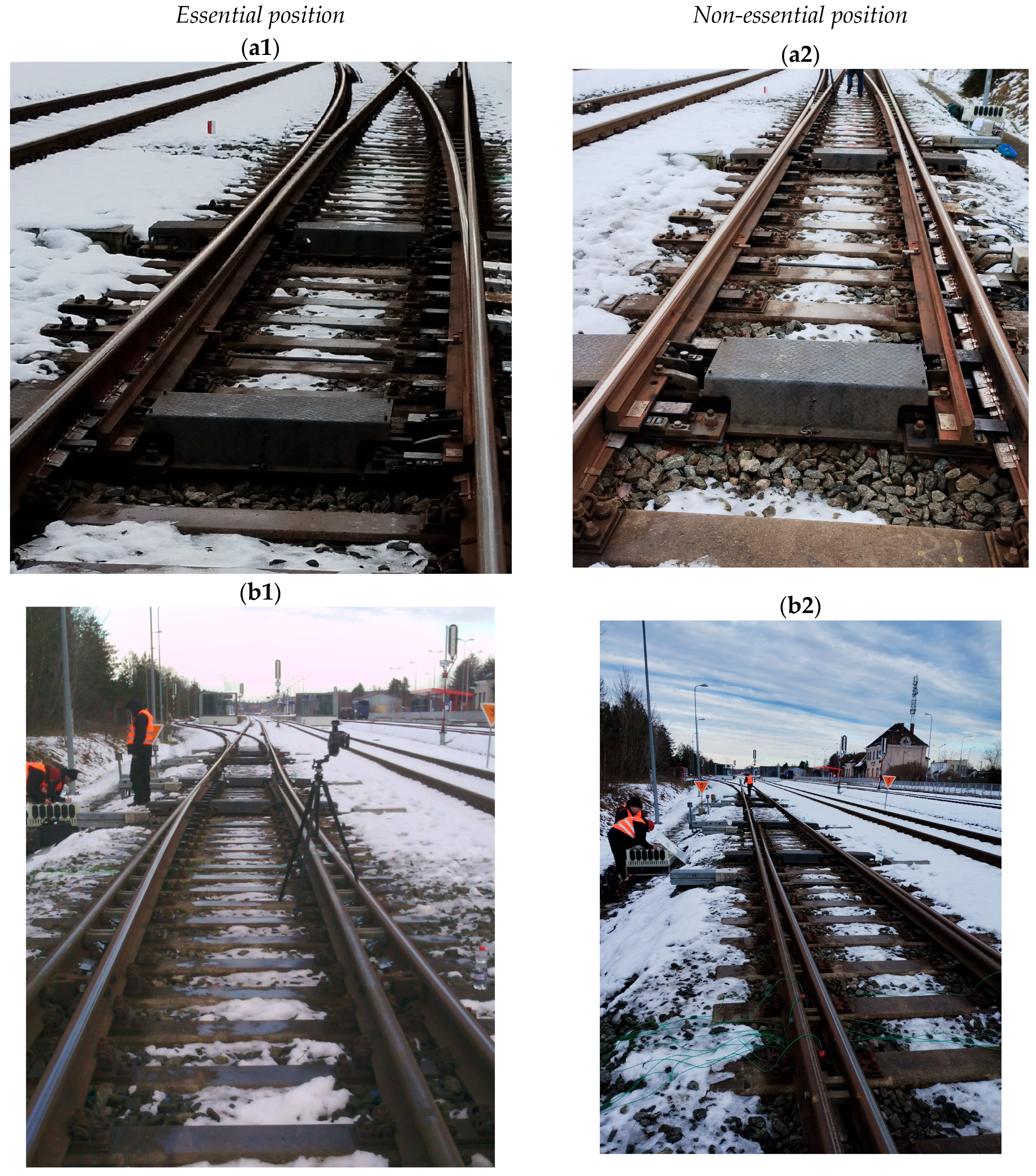

2.4. Research Objects

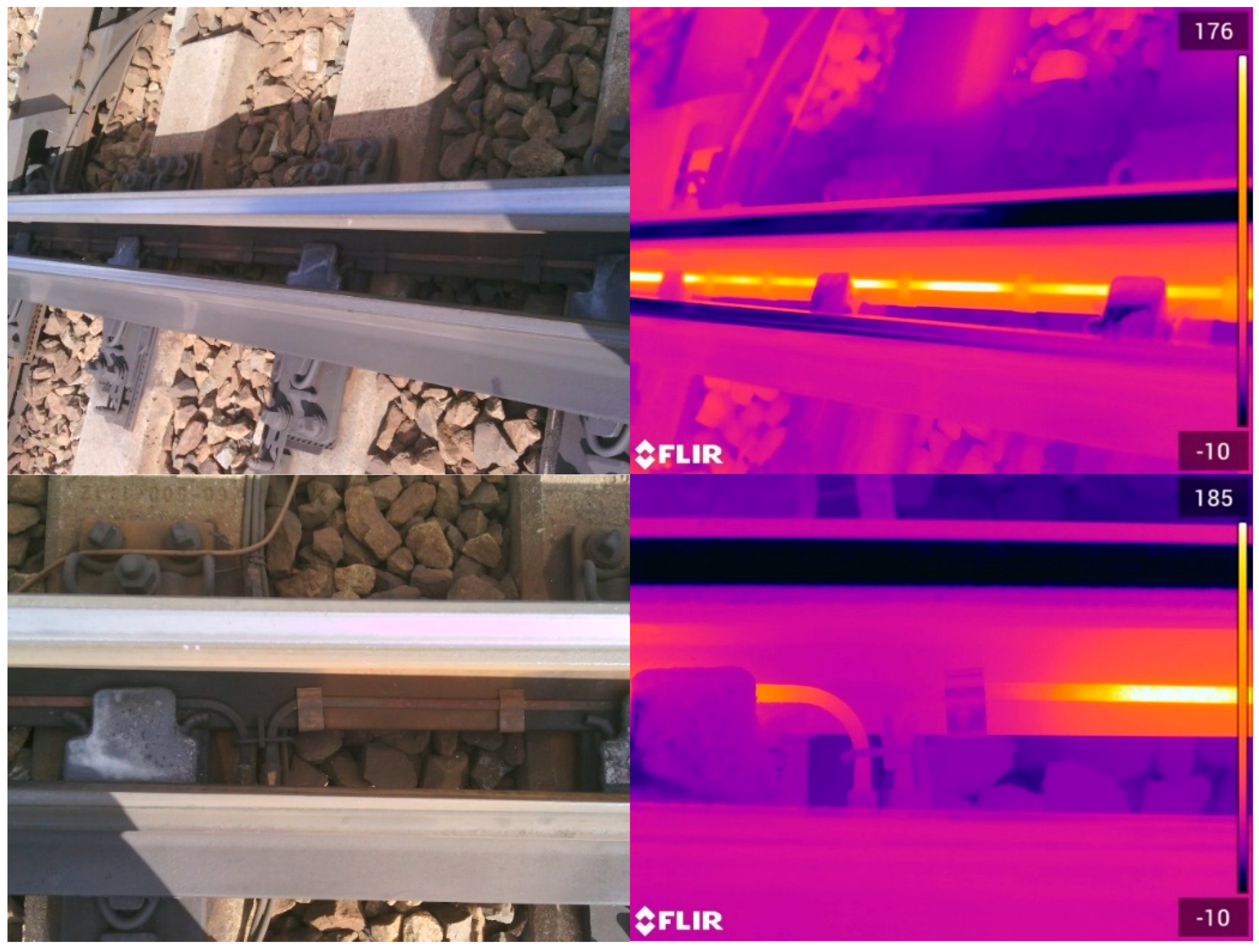

3. Results

- Rz-49E1–1:9–190,

- Rz-60E1–1:9–190,

- Rz-60E1–1:9–300,

- Rz-60E1–1:12–500, and

- Rz-60E1–1:18.5–1200.

- Gdańsk Osowa—turnouts no. 11 and 12—Rz-60E1–1:12–500,

- Międzylesie—turnout no. 38—Rz-60E1–1:9–300,

- Międzylesie—turnout no. 39—Rz-60E1–1:9–300,

- Międzylesie—turnout no. 201—Rz-49E1–1:9–190, and

- Międzylesie—turnout no. 35—Rkpd-60E1–1:9–300

- snow-free and snow-covered turnout areas, evaluated across three zones in both (+) and (−) positions; and

- heating intervals from the initiation of the heating process.

Results of Thermographic Measurements

- Measurement cycles: Gdańsk Osowa (15–17 January 2025) and Międzylesie (11–14 February 2025)—FLIR SC660 and FLIR T1020 cameras.

- needle position (partly switched turnout with needle retracted or extended),

- variable distances between the needle and the stock rail for the partly switched turnout with retracted needle,

- variable cross-section and mass distribution of the needle along its length,

- different rail types of the turnout and consequently varied heat capacity (49E1, 60E1), and

- heating intervals from the start of heating for t = 0 s, 300 s, 10 min, 30 min, 1 h, and 3 h until temperature stabilisation.

4. Discussion and Conclusions

- Non-contact heaters can reduce the time required to reach the melting point and lower overall energy consumption compared to conventional systems [7].

- Adaptive heating power control can significantly reduce energy consumption and operating costs without compromising safety and reliability [7,10,46]. Adaptive control strategies that adjust heating power based on real-time environmental and operational data have shown promising results in reducing energy consumption. Experimental studies indicate that such systems can reduce energy consumption by 15–20% over the entire winter compared to conventional on/off methods [7,10]. Adaptive systems also allow for removing contact temperature sensors, improving system reliability, and reducing maintenance requirements [7].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brodowski, D.; Flis, M. Experimental Verification of Contactless Heating Method in Railway Turnouts Heating System. Probl. Kolejnictwa-Railw. Rep. 2022, 66, 73–79. [Google Scholar] [CrossRef]

- Wołoszyn, M. Analysis of Resistive and Inductive Heating of Railway Turnouts. Prz. Elektrotech. 2016, 1, 54–57. [Google Scholar] [CrossRef][Green Version]

- Toletti, A.; Weidmann, U. Mitigating the Impacts of Unreliable Railway Components on Service Availability and Punctuality. In Safety and Reliability of Complex Engineered Systems, Proceedings of the 25th European Safety and Reliability Conference, ESREL 2015, Zürich, Switzerland, 7–10 September 2015; CRC Press: Boca Raton, FL, USA, 2015; Volume 7–10, pp. 2307–2314. [Google Scholar] [CrossRef]

- Luan, X.; Wang, Y.; Schutter, B.D.; Meng, L.; Lodewijks, G.; Corman, F. Integration of Real-Time Traffic Management and Train Control for Rail Networks—Part 1: Optimization Problems and Solution Approaches. Transp. Res. Part B Methodol. 2018, 115, 41–71. [Google Scholar] [CrossRef]

- Oh, H.; Park, C.-B.; Lee, S.H.; Lee, H. Study on 200w-Class Heating System of Induction Heating Type to Melt Snow in Railway Turnout. J. Korean Soc. Railw. 2019, 22, 762–767. [Google Scholar] [CrossRef]

- Heger, J. Inductive Railway Turnout Heating Systems—A Review of Scientific Publications. In Proceedings of the 8th International Conference on Road and Rail Infrastructure, Cavtat, Croatia, 15–17 May 2024; Volume 8, pp. 533–541. [Google Scholar] [CrossRef]

- Szychta, E.; Szychta, L. Comparative Analysis of Effectiveness of Resistance and Induction Turnout Heating. Energies 2020, 13, 5262. [Google Scholar] [CrossRef]

- Rajabighamchi, F.; Hajlou, E.M.H.; Hassannayebi, E. A Multi-Objective Optimization Model for Robust Skip-Stop Scheduling With Earliness and Tardiness Penalties. Urban Rail Transit 2019, 5, 172–185. [Google Scholar] [CrossRef]

- Lotfi, A.; Yousuf, A.; Virk, M.S. Study of Heat Distribution in Railway Switch Using Resistive Heater in Cold Climate Conditions. Appl. Sci. 2024, 14, 8151. [Google Scholar] [CrossRef]

- Żelazny, R.; Jabłoński, P.; Szczegielniak, T. Operation of the Prototype Device for Induction Heating of Railway Turnouts at Various Operating Frequencies. Energies 2021, 14, 476. [Google Scholar] [CrossRef]

- Oh, H.; Kim, D.-K.; Hong, S.-M.; Ryu, S.-G.; Park, C.-B.; Lee, J.; Lee, J.; Lee, H.-W. Anti-Icing System on Railway Turnouts Using Induction Heating Technology for Energy Saving. In Proceedings of the 2022 IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022; pp. 342–347. [Google Scholar] [CrossRef]

- Paś, J. Diagnostic of railway turnouts condition on high-speed railway lines. J. Civ. Eng. Transp. 2025, 3, 23–32. [Google Scholar]

- Reetz, F.; Zimmermann, J.; Meier, A. Trackside Monitoring of Railway Turnouts with Accelerometers for Condition-Based Maintenance. Sensors 2024, 24, 477. [Google Scholar] [CrossRef]

- Ou, D.; Ji, Y.; Zhang, L.; Liu, H. An Online Classification Method for Fault Diagnosis of Railway Turnouts. Sensors 2020, 20, 4627. [Google Scholar] [CrossRef]

- Alfieri, F.; Bracco, S.; Delfino, F.; Pampararo, F. Energy management strategies for railway infrastructure. Energies 2018, 11, 3456. [Google Scholar] [CrossRef]

- Sysyn, M.; Gerber, U.; Nabochenko, O. Life cycle cost analysis of railway turnouts. In Proceedings of the International Symposium on Rail Infrastructure Systems Engineering, Aachen, Germany, 26–28 November 2019. [Google Scholar]

- Wu, X.; Li, W. Sound signal-based lightweight fault diagnosis for railway turnout system via combining transformer and CNN. Eng. Res. Express 2025, 7, 25225. [Google Scholar] [CrossRef]

- Chen, C.; Shao, H.; Xu, Z.; Huang, K.; Chen, Q.; Mei, M. A Fault Detection Method for Railway Turnout with Convex Hull-based One-Class Tensor Machine. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Kuala Lumpur, Malaysia, 22–25 May 2023. [Google Scholar] [CrossRef]

- Yu, C.; Lu, Z. YOLO-VSI: An Improved YOLOv8 Model for Detecting Railway Turnouts Defects in Complex Environments. Comput. Mater. Contin. 2024, 81, 3261–3280. [Google Scholar] [CrossRef]

- Adke, P.; Kushwaha, A.K.; Khatavkar, S.M.; Shende, D. Use of Improved Generative Adversarial Network (GAN) Under Insufficient Data. In Cognitive Computing and Cyber Physical Systems, Proceedings of the 4th EAI International Conference, IC4S 2023, Bhimavaram, India, 4–6 August 2023; Springer: Cham, Switzerland, 2024; Volume 536, pp. 288–299. [Google Scholar] [CrossRef]

- Wang, G.; Xu, T.; Tang, T.; Yuan, T.; Wang, H. A Bayesian network model for prediction of weather-related failures in railway turnout systems. Expert Syst. Appl. 2017, 69, 247–256. [Google Scholar] [CrossRef]

- Wang, G.; Xu, T.; Wang, H.; Zou, Y. AdaBoost and Least Square Based Failure Prediction of Railway Turnouts. In Proceedings of the 2016 9th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 10–11 December 2016; Volume 1, pp. 434–437. [Google Scholar] [CrossRef]

- Ma, Y.; Yuan, J.; Ni, J. A strategy for the sensor placement optimization for machine thermal errr compensation. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Nashville, TN, USA, 14–19 November 1999; pp. 629–637. [Google Scholar] [CrossRef]

- Stypułkowski, Ł.; Żelazny, B. Thermal Imaging for Railway Turnout Heating Systems Diagnostics. Arch. Transp. 2021, 58, 45–58. [Google Scholar]

- Barkhordari, P.; Galeazzi, R.; Tejada, A.d.M.; Santos, I.F. Identification of Behavioural Models for Railway Turnouts Monitoring. arXiv 2019, arXiv:1910.06582. [Google Scholar] [CrossRef]

- Kisilowski, J.; Kowalik, R. Railroad Turnout Wear Diagnostics. Sensors 2021, 21, 6697. [Google Scholar] [CrossRef]

- Du, J.; King, P.; Gardiner, A.; Li, J.-P. Railway Electric Points Heating: From Design to Maintenance; Polish Railways: Warsaw, Poland, 2024; 51p. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Raport Roczny 2023; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2024. [Google Scholar]

- Energooszczędny System Elektrycznego Ogrzewania Rozjazdów z Adaptacyjną Dystrybucją Mocy Grzewczej. Available online: https://arex.pl/energooszczedny-system-elektrycznego-ogrzewania-rozjazdow-z-adaptacyjna-dystrybucja-mocy-grzewczej/ (accessed on 28 October 2025).

- Kim, J.-C.; Ji, W.-Y.; Park, C.-B.; Lee, J.-B.; Jeong, G.; Lee, H.-W. Design considering the impedance of induction heating system for 200W-class railway turnout. J. Korean Soc. Railw. 2020, 23, 1124–1132. [Google Scholar] [CrossRef]

- PKP Polskie Linie Kolejowe S.A. Wytyczne Projektowania Urządzeń Elektrycznego Ogrzewania Rozjazdów Iet-5; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2015. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Iet-118 Dokument Normatywny 01-8/ET/2008. Grzejniki Elektrycznego Ogrzewania Rozjazdów; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2008. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Iet-119 Dokument Normatywny 01-9/ET/2008. Uchwyty Grzejników Elektrycznego Ogrzewania Rozjazdów; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2008. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Iet-117 Dokument Normatywny 01-7/ET/2008. Skrzynia Transformatorowa Elektrycznego Ogrzewania Rozjazdów; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2008. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Iet-116 Dokument Normatywny 01-6/ET/2008. Szafa Rozdzielcza Elektrycznego Ogrzewania Rozjazdów; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2008. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Warunki Techniczne Utrzymania Nawierzchni na Liniach Kolejowych; PKP Polskie Linie Kolejowe S.A.: Warsaw, Poland, 2015. [Google Scholar]

- VdS Schadenverhütung GmbH: VdS 2859: Anerkennung von Sachverständigen für Elektrothermografie (Elektrothermografen). Anhang C: Mindestanforderungen an Geeignete Kamerasysteme. 2019. Available online: https://shop.vds.de/download/vds-2859/6fa97b10-14cb-4894-bde7-66c5467c7fe5 (accessed on 29 October 2025).

- DIN EN 50110-1 (VDE 0105-1); Operation of Electrical Installations—Part 1: General Requirements. Deutsches Institut für Normung (DIN): Berlin, Germany, 2014.

- FLIR Systems: How Do You Calibrate a Thermal Imaging Camera? Available online: https://www.flir.com/discover/professional-tools/how-do-you-calibrate-a-thermal-imaging-camera/ (accessed on 28 October 2025).

- Dziarski, K.; Hulewicz, A. Uncertainty of Thermographic Temperature Measurement with an Additional close-up Lens. Meas. Sci. Rev. 2021, 21, 185–190. [Google Scholar] [CrossRef]

- National KOBiZE Database Management Team. CO2, SO2, NOx, CO and total dust emission factors for electricity based on information contained in the National Database on Greenhouse Gas Emissions and Other Substances for 2023. In National Database on Greenhouse Gas Emissions and Other Substances; National KOBiZE Database Management Team: Warsaw, Poland, 2024. [Google Scholar]

- Flis, M. Metody ogrzewania rozjazdów kolejowych. Pozn. Univ. Technol. Acad. Journals. Electr. Eng. 2015, 83, 245–252. [Google Scholar]

- Kiraga, K.; Szychta, E.; Andrulonis, J. Wybrane metody ogrzewania rozjazdów kolejowych—artykuł przeglądowy. Prz. Elektrotech. 2010, 86, 247–252. [Google Scholar]

- Stypułkowski, K.; Gołda, P.; Lewczuk, K.; Tomaszewska, J. Monitoring System for Railway Infrastructure Elements Based on Thermal Imaging Analysis. Sensors 2021, 21, 3819. [Google Scholar] [CrossRef] [PubMed]

- Szychta, E.; Szychta, L.; Luft, M.; Kiraga, K. Application of 3D Simulation Methods to the Process of Induction Heating of Rail Turnouts. In Infrastructure Design, Signalling and Security in Railway; InTechOpen: London, UK, 2012. [Google Scholar]

- Yousuf, A.; Khawaja, H.; Virk, M.S. A review of infrared thermography applications for ice detection and mitigation. Cold Reg. Sci. Technol. 2024, 218, 104058. [Google Scholar] [CrossRef]

- Laiton-Bonadiez, C.; Branch-Bedoya, J.W.; Zapata-Cortes, J.; Paipa-Sanabria, E.; Arango-Serna, M. Industry 4.0 Technologies Applied to the Rail Transportation Industry: A Systematic Review. Sensors 2022, 22, 2491. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Induction Thermography for Surface Crack Detection and Depth Determination. Appl. Sci. 2018, 8, 257. [Google Scholar] [CrossRef]

- Lotfi, A.; Virk, M.S. Ice mitigation in railway turnouts using a conductive heater: An experimental study. Transp. Res. Interdiscip. Perspect. 2025, 31, 101474. [Google Scholar] [CrossRef]

- Tuschl, J.; Oswald-Tranta, B.; Eck, S. Inductive Thermography as Non-Destructive Testing for Railway Rails. Appl. Sci. 2021, 11, 1003. [Google Scholar] [CrossRef]

- Kukulski, B.; Stypułkowski, M. The use of thermal imaging studies in the diagnosis of railroad infrastructure elements. Rail Veh. 2023, 2023, 40–46. [Google Scholar]

- Usamentiaga, R.; Sfarra, S.; Fleuret, J.; Yousefi, B.; Garcia, D. Rail inspection using active thermography to detect rolled-in material. In Proceedings of the 2018 International Conference on Quantitative InfraRed Thermography, Berlin, Germany, 25–29 June 2018. [Google Scholar]

- Phusakulkajorn, W.; Núñez, A.; Wang, H.; Jamshidi, A.; Zoeteman, A.; Ripke, B.; Dollevoet, R.; De Schutter, B.; Li, Z. Artificial intelligence in railway infrastructure: Current research, challenges, and future opportunities. Intell. Transp. Infrastruct. 2023, 2, liad016. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.; Castedo, L. Towards the Internet of Smart Trains: A Review on Industrial IoT-Connected Railways. Sensors 2017, 17, 1457. [Google Scholar] [CrossRef] [PubMed]

| No. | Rated Power [W] | Heater Length ‘L’ [mm] | Nominal Resistance of Heating Coil [Ω] |

|---|---|---|---|

| 1. | 900 ± 45.0 | 2800 ± 85 | 58.8 |

| 2. | 1050 ± 52.5 | 3300 ± 100 | 50.4 |

| 3. | 1250 ± 62.5 | 3800 ± 115 | 42.3 |

| 4. | 1600 ± 80.0 | 4800 ± 145 | 33.1 |

| No. | Function | Requirements |

|---|---|---|

| 1 | Temperature measurement range | min: −20 °C to +500 °C |

| 2 | Geometric resolution for FOV 20–25° lens, recommended 45° lens: FOV 45° × 34° | max. two mrad (smallest measurable object: ≤3 mm) or min. 500:1, |

| 3 | Bolometric matrix resolution | minimum 320 × 240 pixels, recommended 640 × 480 |

| 4 | Thermal sensitivity NETD | max. 0.08 K (at 30 °C), |

| 5 | Measurement accuracy | max. ±2% or 2 K, |

| 6 | Emissivity | camera settings |

| 7 | Background temperature | camera settings |

| 8 | Recorded image formats | separate files: visible and thermal imaging |

| 9 | Data registration | recording to SD card |

| 10 | Lens | the possibility of using a wide-angle lens and a telephoto lens |

| 11 | Thermal operating conditions of the camera | min: −10 to +40 °C |

| 12 | Displaying data | built-in display |

| 13 | Temperature calibration | built-in |

| 14 | Measurement function | measurement point, isotherm, line, and fusion |

| 15 | Documentation | radiometric data recorded in infrared |

| Wind Speed Management: | Solar Radiation Control: | Additional Environmental Monitoring: | Data Quality Assurance: |

|---|---|---|---|

|

|

|

|

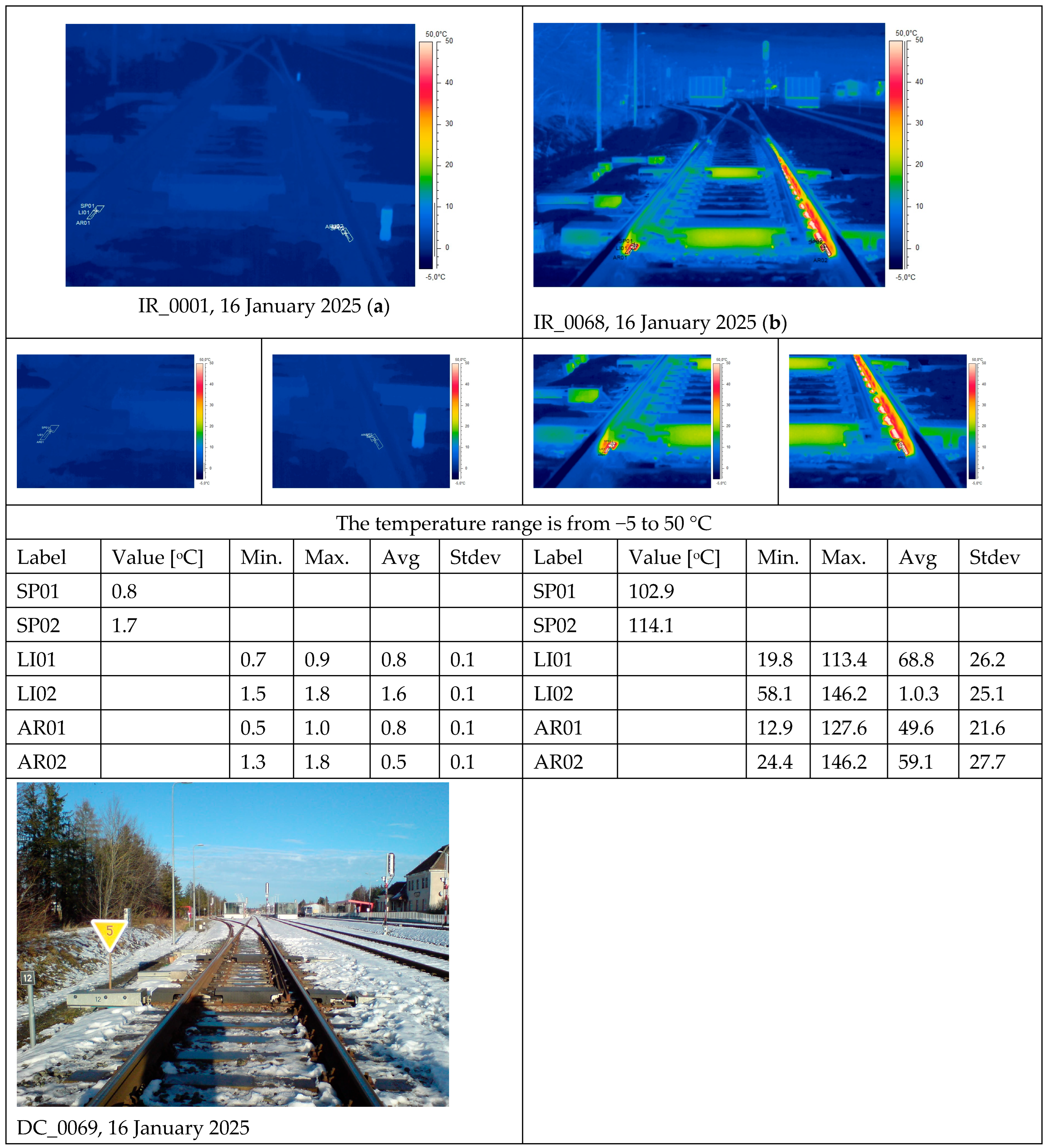

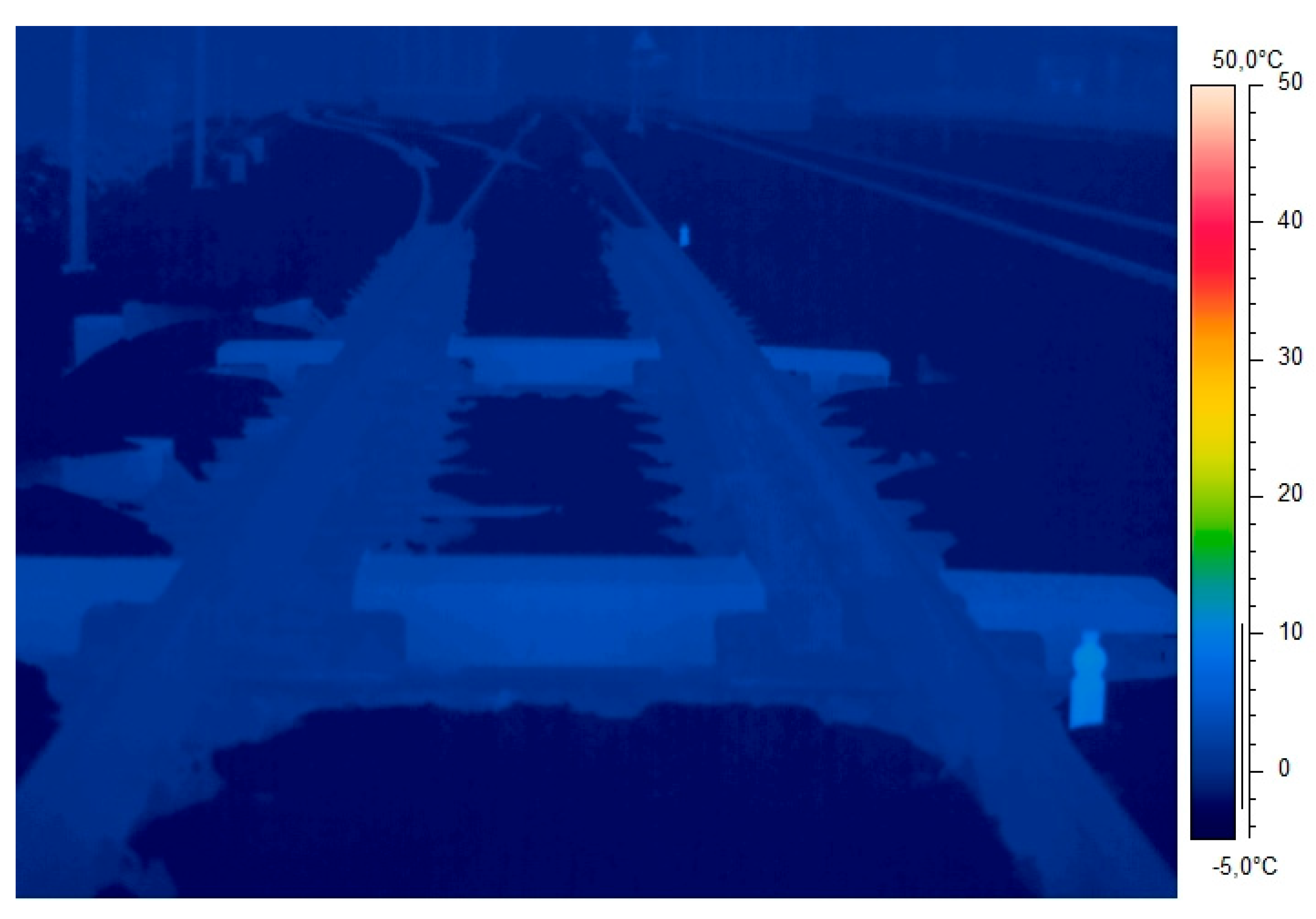

| Station | Date of Measurement | Turnout Type and Number | Photograph of Turnout | Thermogram in Cold State | Thermogram in Heated State | ||||

|---|---|---|---|---|---|---|---|---|---|

| Gdańsk Ossowa | 15–17 January 2025 | Rz 60E1-1:12–500—turnout no. 11 |  DC_0067, 16 January 2025 |  IR_0010, 16 January 2025 |  IR_0074, 16 January 2025 | ||||

| Heating Element Powers and Lengths of the Needles | Heating Element Power for Closure | ||||||||

| 1600 W–4.8 m | 1250 W–3.8 m | 1050 W–3.3 m | 900 W–2.8 m | 100 W |  DC_0142, 15 January 2025 |  IR_0144, 15 January 2025 |  IR_0322, 15 January 2025 | ||

| - | 4 pcs. | 2 pcs. | - | ||||||

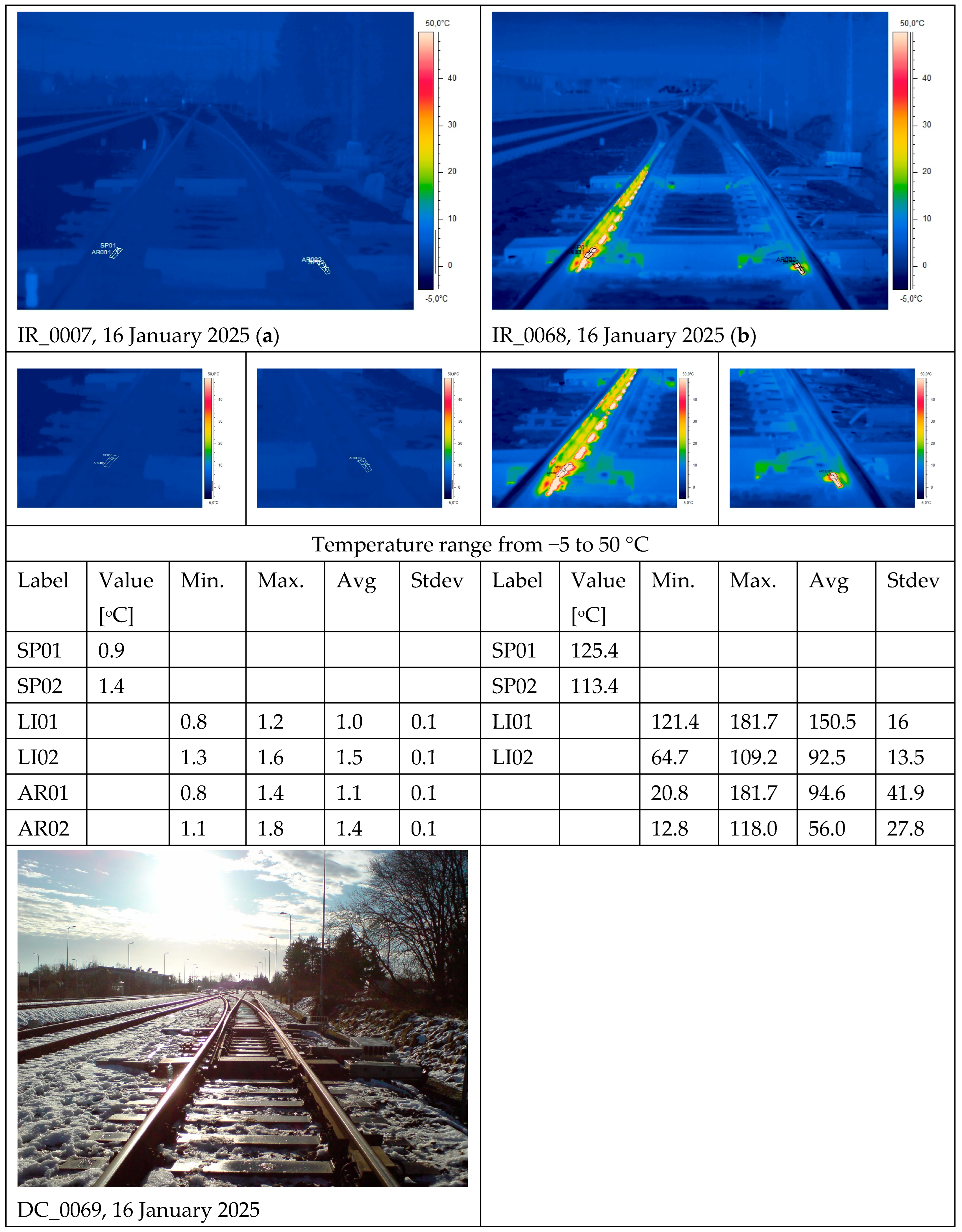

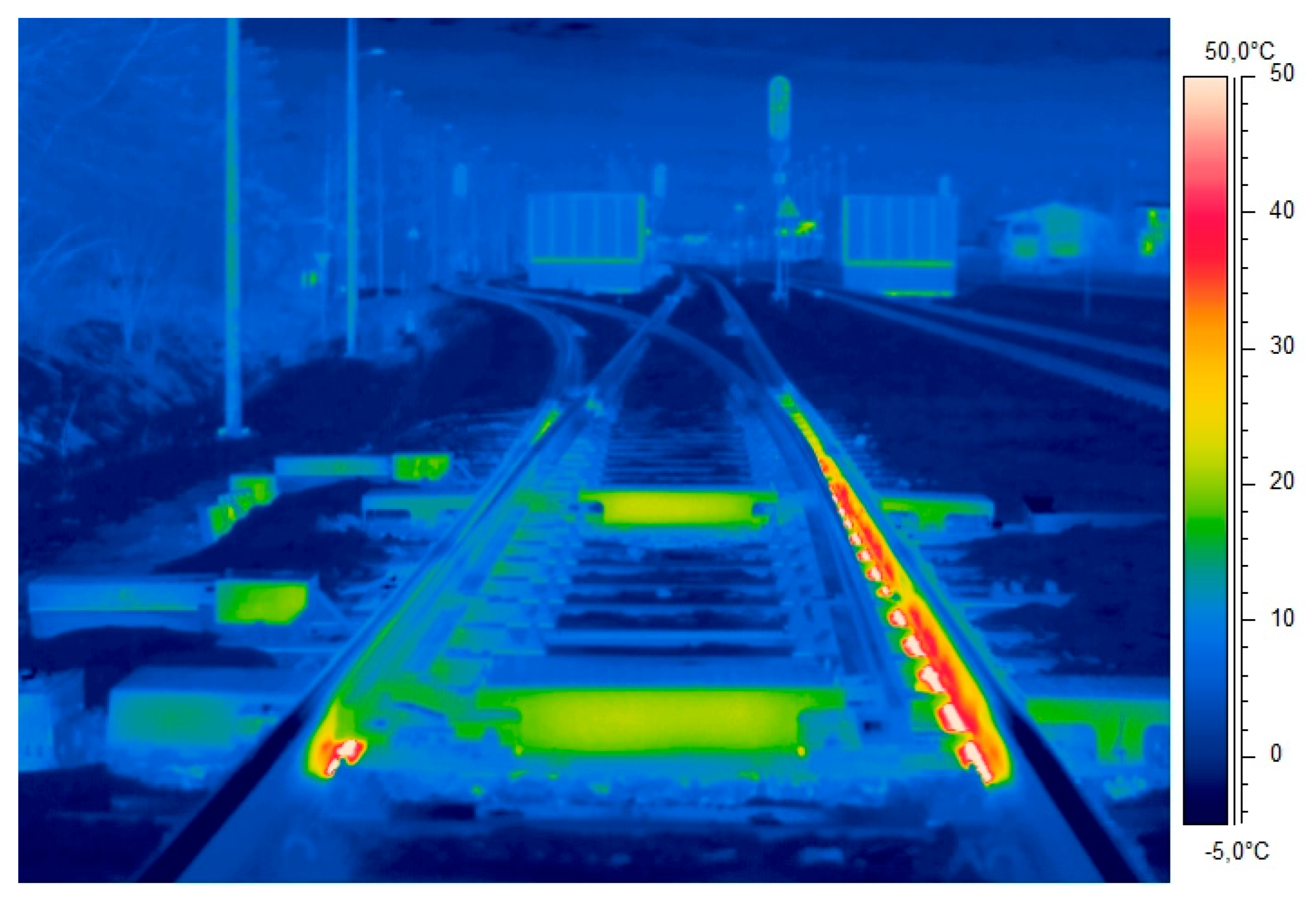

| Station | Date of Measurement | Turnout Type and Number | Photograph of Turnout | Thermogram in Cold State | Thermogram in Heated State | ||||

|---|---|---|---|---|---|---|---|---|---|

| Gdańsk Ossowa | 15–17 January 2025 | Rz 60E1-1:12–500—turnout no. 12 |  DC_0069, 16 January 2025 |  IR_0001, 16 January 2025 |  IR_0068, 16 January 2025 | ||||

| Heating Element Powers and Lengths of the Needles | Heating Element Power for Closure | ||||||||

| 1600 W–4.8 m | 1250 W–3.8 m | 1050 W–3.3 m | 900 W–2.8 m | 100 W 4. pcs. |  DC_0122, 15 January 2025 |  IR_0133, 15 January 2025 | --- | ||

| Heating plates | |||||||||

| 4 pcs. | - | 2 pcs. | 2 pcs. | 500 W 4 pcs. | |||||

| Indicator | [g/kWh] |

|---|---|

| Carbon dioxide (CO2) | 597 |

| Sulphur oxides (SOx/SO2) | 0.363 |

| Nitrogen oxides (NOx/NO2) | 0.392 |

| Carbon monoxide (CO) | 0.222 |

| Total dust | 0.014 |

| No. | Type and Number of Railway Turnouts | P [W] | l [m] | WP [W/m] | WT [W/°C·m] | WE [Wh/m] |

|---|---|---|---|---|---|---|

| 1. | Rz 60E1-1:12–500—No. 11—ESAR system and radiation overlays (Gdańsk Osowa) | 8950 | 31.4 | 208.6 | 1.5 | 207.7 |

| 2. | Rz 60E1-1:12–500—No. 12 Reference turnout with the standard EOR system (Gdańsk Osowa) | 12,700 | 31.4 | 328 | 2.22 | 207.7 |

| 3. | Rkpd 60E1-1:9–300—No. 35—radiation covers and heating power reduction (Międzylesie) | 17,000 | 52.8 | 322 | 2.9 | 207.7 |

| 4. | Rz 60E1-1:9–300—No. 38—radiation covers and heating power reduction (Międzylesie) | 7100 | 21.8 | 311 | 1.5 | 207.7 |

| 5. | Rz 60E1-1:9–300—No. 39 Reference turnout with the standard EOR system | 7100 | 22.8 | 311 | 1.5 | 207.7 |

| 6. | Rz 49E1-1:9–190—No. 201—radiation covers and heating power reduction (Międzylesie) | 5700 | 17.2 | 331 | 1.3 | 206.5 |

| No. | Heating Element | Heater Length [m] | Installed Heater Power P [W] | Power Reduction Ratio [%] | Power Delivered to Heater P [W] | Annual Energy Consumption [kWh] |

|---|---|---|---|---|---|---|

| 1 | Linear route left (open side) | 3.3 | 1050 | 100 | 1050 | 210 |

| 2 | Linear route left (open side) | 4.8 | 1600 | 100 | 1600 | 320 |

| 3 | Linear route left (open side) | 4.8 | 1600 | 100 | 1600 | 320 |

| 4 | Linear route left (open side) | 2.8 | 900 | 100 | 900 | 180 |

| 5 | Linear route right (closed side) | 3.3 | 1050 | 100 | 1050 | 210 |

| 6 | Linear route right (closed side) | 4.8 | 1600 | 100 | 1600 | 320 |

| 7 | Linear route right (closed side) | 4.8 | 1600 | 100 | 1600 | 320 |

| 8 | Linear route right (closed side) | 2.8 | 900 | 100 | 900 | 180 |

| 9 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 10 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 11 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 12 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 13 | Switch closures | - | 100 | 100 | 100 | 20 |

| 14 | Switch closures | - | 100 | 100 | 100 | 20 |

| 15 | Switch closures | - | 100 | 100 | 100 | 20 |

| 16 | Switch closures | - | 100 | 100 | 100 | 20 |

| Sum | 31.4 | 12,700 | 8950 | 2540 |

| No. | Heating Element | Heater Length [m] | Installed Heater Power [W] | Power Reduction Ratio [%] | Power Delivered to Heater P [W] | Annual Energy Consumption [kWh] |

|---|---|---|---|---|---|---|

| 1 | Linear route left (open side) | 3.3 | 1050 | 80 | 840 | 168 |

| 2 | Linear route left (open side) | 4.8 | 1600 | 70 | 1120 | 224 |

| 3 | Linear route left (open side) | 4.8 | 1600 | 60 | 960 | 192 |

| 4 | Linear route left (open side) | 2.8 | 900 | 60 | 540 | 108 |

| 5 | Linear route right (closed side) | 3.3 | 1050 | 60 | 630 | 126 |

| 6 | Linear route right (closed side) | 4.8 | 1600 | 60 | 960 | 192 |

| 7 | Linear route right (closed side) | 4.8 | 1600 | 60 | 960 | 192 |

| 8 | Linear route right (closed side) | 2.8 | 900 | 60 | 540 | 108 |

| 9 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 10 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 11 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 12 | Heating plates in troughs | - | 500 | 100 | 500 | 100 |

| 13 | Switch closures | - | 100 | 100 | 100 | 20 |

| 14 | Switch closures | - | 100 | 100 | 100 | 20 |

| 15 | Switch closures | - | 100 | 100 | 100 | 20 |

| 16 | Switch closures | - | 100 | 100 | 100 | 20 |

| Sum | 31.4 | 12,700 | 8950 | 1790 |

| No. | Parameter | Turnout 12 EOR | Turnout 11 ESAR |

|---|---|---|---|

| 1 | Total Power Dissipated on All Heaters [W] | 12,700 | 8950 |

| 2 | Power Dissipated on Linear Heaters [W] | 10,300 | 6550 |

| 3 | Total Length of Linear Heating Elements [m] | 31.4 | 31.4 |

| 4 | Linear Power Coefficient Wp [W/m] | 328.0 | 208.6 |

| 5 | Annual Operating Time [h] | 200.0 | 200.0 |

| 6 | Annual Electrical Energy Consumption [kWh/year] | 2540 | 1790 |

| 7 | Average Surface Temperature of Linear Heaters in Steady State [°C] | 147 | 138 |

| 8 | Average Radiator Surface Temperature [°C] | No radiator | 18.5 |

| 9 | Temperature Power Coefficient WT [W·°C−1·m−1] | 2.22 | 1.5 |

| 10 | Energy Consumption Coefficient WE [Wh/m] | 65.31 | 41.61 |

| Description | Value | Unit |

|---|---|---|

| Power Reduction | 29.53 | % |

| Power Reduction | 3.75 | kW |

| Reduction in Electrical Energy Consumption | 750 | kWh/year |

| No. | Emission Parameter | Emission Indicator | Emission in EOR | Emission in ESAR | Electric Energy Consumption Reduction (One Turnout) |

|---|---|---|---|---|---|

| g/kWh | kg/year | kg/year | kg/year | ||

| 1 | Carbon dioxide (CO2) | 597.000 | 1516.380 | 1068.630 | 447.750 |

| 2 | Sulphur oxides (SOx/SO2) | 0.363 | 0.922 | 0.650 | 0.272 |

| 3 | Nitrogen oxides (NOx/NO2) | 0.392 | 0.996 | 0.702 | 0.294 |

| 4 | Carbon monoxide (CO) | 0.222 | 0.564 | 0.397 | 0.167 |

| 5 | Total dust | 0.014 | 0.036 | 0.025 | 0.011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukulski, J.; Stypułkowski, K.; Tomczuk, P.; Jaskowski, P. Procedure for Conducting Inspection Thermographic Tests of Electrical Heating Devices for Railway Turnouts. Appl. Sci. 2025, 15, 11671. https://doi.org/10.3390/app152111671

Kukulski J, Stypułkowski K, Tomczuk P, Jaskowski P. Procedure for Conducting Inspection Thermographic Tests of Electrical Heating Devices for Railway Turnouts. Applied Sciences. 2025; 15(21):11671. https://doi.org/10.3390/app152111671

Chicago/Turabian StyleKukulski, Jacek, Krzysztof Stypułkowski, Piotr Tomczuk, and Piotr Jaskowski. 2025. "Procedure for Conducting Inspection Thermographic Tests of Electrical Heating Devices for Railway Turnouts" Applied Sciences 15, no. 21: 11671. https://doi.org/10.3390/app152111671

APA StyleKukulski, J., Stypułkowski, K., Tomczuk, P., & Jaskowski, P. (2025). Procedure for Conducting Inspection Thermographic Tests of Electrical Heating Devices for Railway Turnouts. Applied Sciences, 15(21), 11671. https://doi.org/10.3390/app152111671