Abstract

Although existing models and theories have explained systemic behaviors such as demand amplification and disruption propagation, practical challenges in Modular Construction Supply Chains (MCSC) remain unresolved due to production heterogeneity, geographic dispersion, and conflicting stakeholder interests. In addition, the lack of digital infrastructure and process-level data integration continues to hinder the development of automation and intelligent decision-making. To address these issues, this study develops an MCSC coordination system informed by industrial input. The system features a novel dual-engine architecture that integrates blockchain-enabled smart contracts and Robotic Process Automation (RPA). It also incorporates a practice-oriented approach to MCSC Supply Batch (MSB)-based management, using industrial insights to define the MSB as the fundamental coordination unit in process execution. The automatic triggering mechanism enabled by MSBs and dual-engine enables task-to-task transitions while maintaining traceability and operational clarity across supply chain nodes. A real-world case study validates the effectiveness of the proposed system in enhancing traceability, automation, and stakeholder collaboration within MCSC environments.

1. Introduction

Modular construction (MC) can be traced back to the 1620s with early prefabrication techniques in housing and dwelling [1] and has been continuously developed, driven by technological advancements, evolving industry demands, and the diversity of national and regional contexts [2,3,4]. As one of the predominant approaches in the industrialization of construction, MC has been initially employed to address challenges such as housing cost efficiency [5] and rapid urbanization [6]. Currently, the market size of MC is projected to expand from USD 104.1 billion in 2024 to USD 140.8 billion by 2029, reflecting a compound annual growth rate of 6.2% [7]. The drivers behind this growth are no longer the previous industrialization factors but rather the demands of the new era, including high-quality urbanization [8], urban renewal [9], extreme environment construction [10], built environment resilience [11], and increasing sustainability requirements [12,13]. Currently, infrastructure projects also adopt modular construction, and many major projects, such as the Hong Kong–Zhuhai–Macao Bridge, are well known for this approach [14].

Emerging technologies, represented by Building Information Modeling (BIM), the Industrial Internet of Things (IIoT), construction robotics, and artificial intelligence (AI), have significantly accelerated the development of advanced MC in recent years [15,16,17,18]. While these technologies have been widely explored and further advanced within individual MC projects, their application remains limited in contexts that explicitly account for the structural and operational complexities of the Modular Construction Supply Chain (MCSC). Importantly, the challenges arising at the MCSC level are fundamentally distinct from those encountered at the project level. Unlike a single MC project, which focuses on the design, fabrication, and assembly of modular units, the MCSC encompasses a broader and more complex network that integrates off-site manufacturing and on-site construction. This integration faces inherent challenges due to the heterogeneity of production methods (discrete and project-based), the geographical dispersion, and the fragmented contractual relationships of stakeholders along the supply chain [19,20,21]. The domain-spanning transmissibility within the MCSC, coupled with the cascading failure impact [22], is likely to result in significant issues, including exacerbated delays [23], fragmented quality control [24], and inconsistencies in accountability [25]. To avoid these negative impacts on MCSC performance, enhancing coordination at the process level [26,27] and improving collaboration at the relationship level are identified as essential aspects [22,28].

Following extensive research efforts in mathematical modeling, network analysis, and decision optimization, the underlying mechanisms of the MCSC have been theoretically explained, with models such as the bullwhip effect [29,30], cascade effect [31,32], and ripple effect [33,34] being applicable to this emerging context [22,35]. However, despite growing theoretical interest, the digitalization, automation, and intelligentization of MCSC still lack sufficient empirical input and viable implementation approaches. In fact, numerous methods and theories that integrate practical experience and domain knowledge already exist, particularly within the lean and agile domains [36,37]. It is essential to introduce them to the MCSC coordination to redesign batches, buffers, takt times, etc. Meanwhile, the absence of sufficient digital infrastructure [38] and process-level data integration [39,40] has constrained the development of automation strategies. In turn, this lack of an automation foundation severely limits the feasibility of implementing intelligent decision-making systems, resulting in a pronounced gap between current technological capabilities and the practical needs of supply chain coordination. At this stage, a return to practice-oriented process modeling and automation mechanisms offers a promising technical pathway for bridging this foundational gap.

At the process level, business process management (BPM) and its process modeling standards have been widely implemented, often integrating BIM models [41,42,43], which can serve as digital mappings to facilitate MCSC process cooperation. Emerging blockchain-enabled smart contracts have played a role in triggering and executing process models in a traceable and semi-automated manner and can act as a global workflow engine [27], offering a novel approach to process-driven automation. Meanwhile, the development of Robotic Process Automation (RPA) provides a possibility to further detail the modules within the process models [28] and is capable of acting as a series of local engines to automate MCSC tasks. At present, AI-enhanced RPA has been explored, and it shows the potential to elevate BPM from semi-automation to full automation [44,45]. At the relationship level, blockchain-enabled smart contracts inherit the immutable, data integrity, and trusted endorsement characteristics of the underlying blockchain networks [46,47], as well as the automation and inferential capabilities of previous technologies such as rule-based expert systems and policy-oriented computing [48,49]. This combination provides a foundation for trust transfer based on technology and consensus rules rather than human participant behaviors, contributing to constant collaborative relationships in MCSC.

Despite these advances, a practical and unified mechanism that integrates process-level automation and relationship-level trust coordination across the MCSC remains lacking. Existing studies predominantly focus either on theoretical modeling or on isolated technological applications, without providing an empirical and implementable framework that connects digital workflows, automation, and trust management. In current industrial practice, coordination within the MCSC still relies heavily on manual supervision and ad hoc communication, while the integration of mature supply chain management philosophies, such as demand-driven batching and lean flow regulation, remains insufficient. Embedding such principles into digital workflows, for instance by representing demand-driven supply batches as process tokens, offers a pathway to link automation mechanisms with lean coordination logic and thereby enhance overall process efficiency. Consequently, this paper aims to address these gaps by proposing a process-oriented automation and coordination framework for MCSC. Specifically, the study seeks to:

- (1)

- Establish a blockchain-enabled workflow framework underpinned by smart-contract-driven process logic, enabling enhanced coordination, traceability, and trust at the process level; and

- (2)

- Advance the methodological integration of RPA and visualization technologies, together with lean-inspired workflow tokenization, to achieve fine-grained task automation, demand-responsive flow management, and transparent process monitoring within MCSC operations.

The remainder of this paper is organized as follows: Section 2 reviews the related literature on MCSC coordination and digital automation. Section 3 outlines the research methodology based on the Design Science Research (DSR) paradigm. Section 4 describes the system development from both managerial and technical perspectives, detailing the proposed process models and triggering mechanisms, along with the automation configuration and industrial adaptation. Section 5 validates the framework through a real-world case study, and Section 6 concludes with future research directions.

2. Literature Review

2.1. MCSC Coordination

Coordination within the Modular Construction Supply Chain (MCSC) has gradually emerged as a central topic in modular construction research, reflecting the growing complexity and interdependence of off-site manufacturing and on-site assembly. As modularization expands from single-project management to networked industrial ecosystems, effective coordination becomes essential to align design, production, logistics, and assembly activities across diverse organizational and geographical boundaries. In parallel with this shift in focus, the field has developed a set of concepts and terms that delineate how modular and prefabricated practices are organized across the supply chain, providing a common vocabulary for subsequent managerial and technical inquiry.

Terminologies and industrial practices such as Off-site Construction (OSC) [50,51] and Design for Manufacturing and Assembly (DfMA) [52,53] define broad organizational and design principles, while implementations like Prefabricated Prefinished Volumetric Construction (PPVC) in Singapore [54,55] and Modular Integrated Construction (MiC) [52,56] in Hong Kong illustrate regionally adapted delivery models. Together, these terms frame the lifecycle of modularized delivery, from design intent and manufacturability to off-site fabrication, logistics, and on-site assembly, thereby shaping what “coordination” entails at each interface. In this study, the abbreviation “MC” is used to represent modular or systematically prefabricated construction, ensuring conceptual consistency throughout the discussion. Based on this conceptual foundation, prior studies on MCSC coordination can be broadly divided into two main research paradigms, as discussed below.

In MC research, Supply Chain Management (SCM) represents a crucial area of inquiry, with two primary paradigms discernible. The first paradigm originates from traditional SCM and production theories, exploring the migration and transformation from manufacturing industries to MCSC, which often intersects with Lean Production theory [37,57,58,59,60]. The second paradigm focuses on the physical and structural attributes, geographical trajectory, and assembly methods of modular construction while integrating emerging supply chain technologies, which frequently lead to the development of systems integrating BIM, digital twin, blockchain, etc. [16,61,62,63,64]. These two paradigms are interrelated and influence each other in their application.

As MCSC includes multi-domains and interdisciplinary participants, process coordination and relational collaboration have been identified as essential enablers to improve overall performance [3,65]. The off-site and on-site domain-spanning uncertainties [66], relative productivity [67], and cascading effects [22,23] have been analyzed and provide a theoretical foundation for the MCSC coordination system. With the continued development of process modeling, BIM, database encryption, and process automation technologies, the possibility of realizing both process-level on- and off-site coordination and relationship-level trust-transferred collaboration has become increasingly feasible. Process-oriented coordination scenarios along the MCSC, including production [68,69], logistics [70,71,72], and business processes [73,74], have been identified. Meanwhile, the widespread adoption of blockchain and smart contracts shows the potential for transferring trust among MCSC participants to the underlying digital environment [75,76], which is characterized by enhanced traceability, immutability, and integrity [46,77], facilitating reliable and secure interactions for real-time and long-term MCSC collaboration. Such collaboration-oriented organizational and behavioral foundations in MCSC, in turn, are poised to significantly enhance the efficiency and effectiveness of process coordination [78,79].

2.2. Upgrade Workflow Engine: Smart Contract and RPA

Business Process Management (BPM) addresses the topic of process support from a broader perspective by integrating methods of analysis (such as simulation, verification, and process mining) and connecting processes to business and societal aspects [80]. Different process languages have been gradually developed, e.g., Petri nets, Workflow nets, Business Process Model and Notation (BPMN), and YAWL. The supply chain processes in construction have been modeled and decomposed from conceptual representation to process element specification using BPMN [23,41]. Conventional workflow engines, such as Business Process Execution Language (BPEL), currently fall short of fully satisfying the MSCS coordination requirements in terms of traceability, interoperability, and automation. Building upon the foundations provided by technological innovations, it has become imperative to develop a more reliable, visualized, real-time, multi-end concurrent, and automated workflow engine within the technical framework of MCSC process coordination.

The utilization of blockchain-enabled smart contracts as workflow engines has recently been explored across a wide range of industries [27,81,82,83,84,85]. Within the construction field, the upgraded workflow engine using blockchain-enabled smart contracts as an underlying trigger for process coordination and automation has been initially developed [27,73], where supply chain coordination and payment automation were frequently taken as use cases and application examples [47,86].

Robotic Process Automation (RPA) is an emerging automation technology in BPM that uses software agents to partially or fully automate simple or complex repetitive tasks by mimicking or learning human behaviors [87,88,89,90]. RPA provides a possibility to further detail the modules within the MCSC processes and automate tasks to improve the process coordination efficiency. RPA modules can be integrated into the overall smart contract-based workflow engines as local engines for MCSC task automation. RPA automates a specific set of tasks, while smart contract-based workflow engines automate the flow among tasks and rule-based decision-making in each logical branch [27]. Currently, AI-enhanced RPA has been explored, and it shows the potential to elevate BPM from semi-automation to full automation [91,92,93]. With increasing acting and thinking levels, RPA evolves from automated RPA to intelligent RPA with unstructured data interpretation and integration to cognitive RPA with judgments and decisions in a deep human-like mode [92].

In contrast to earlier workflow systems that typically relied on a single centralized execution logic or rule-based automation, the proposed dual-engine architecture introduces a distributed and layered coordination mechanism. The blockchain-enabled smart contract engine functions as a global process controller, ensuring transparency, immutability, and traceable execution across organizational boundaries, while the RPA modules operate as local task executors, enabling fine-grained automation within individual processes. This division of control and execution responsibilities allows information, trust, and action to circulate seamlessly across both inter-organizational and intra-organizational levels. Such a design not only enhances interoperability and real-time responsiveness but also establishes a scalable pathway from process-level semi-automation to full intelligent automation, representing a fundamental advancement beyond conventional BPM-based workflow engines.

2.3. Research Gap

Recent research has deepened the theoretical understanding of MCSC, drawing on models from operations management and network computation to explain systemic behaviors such as demand amplification, disruption propagation, and interdependency risks. Established concepts like the bullwhip effect and ripple effect have been adapted to the modular construction context, offering valuable insights into how instability spreads across off-site production and on-site construction domains. However, despite these conceptual advances, there remains a notable disconnection between theoretical abstraction and practical implementation, particularly in existing coordination challenges in MCSC, e.g., the heterogeneity of off-site manufacturing and on-site construction, the geographical dispersion, and the conflicting interests or antagonistic relationships among stakeholders.

Various methods grounded in operational and managerial experience, particularly those developed in lean and agile paradigms, have proven effective in, e.g., regulating production flow, managing variability, and coordinating task timing. However, these approaches have not been systematically incorporated into MCSC coordination frameworks. At the same time, fundamental barriers remain. The absence of adequate digital infrastructure and the lack of integrated process-level data continue to hinder the development of automation strategies. As a result, the implementation of intelligent decision-making is significantly constrained, reinforcing the gap between technological advancements and the practical requirements of supply chain coordination.

Addressing this gap requires a renewed focus on practice-oriented process modeling and automation mechanisms. Traditional workflow engines such as BPEL have shown limited capacity to meet the dynamic, traceable, and interoperable demands of MCSC process coordination. In contrast, emerging technologies open new possibilities. Blockchain-enabled smart contracts provide a verifiable means of executing collaborative processes, while RPA helps automate repetitive, rule-based tasks and enhances operational efficiency. However, existing studies seldom integrate these technologies into a unified coordination architecture that reflects the multi-domain nature of MCSC, linking off-site manufacturing and on-site construction through digitally traceable, demand-driven, and semi-autonomous workflow mechanisms. Accordingly, this study focuses on designing an integrated process architecture that consolidates automation, transparency, and trust into a cohesive operational paradigm for MCSC coordination.

3. Research Methodology

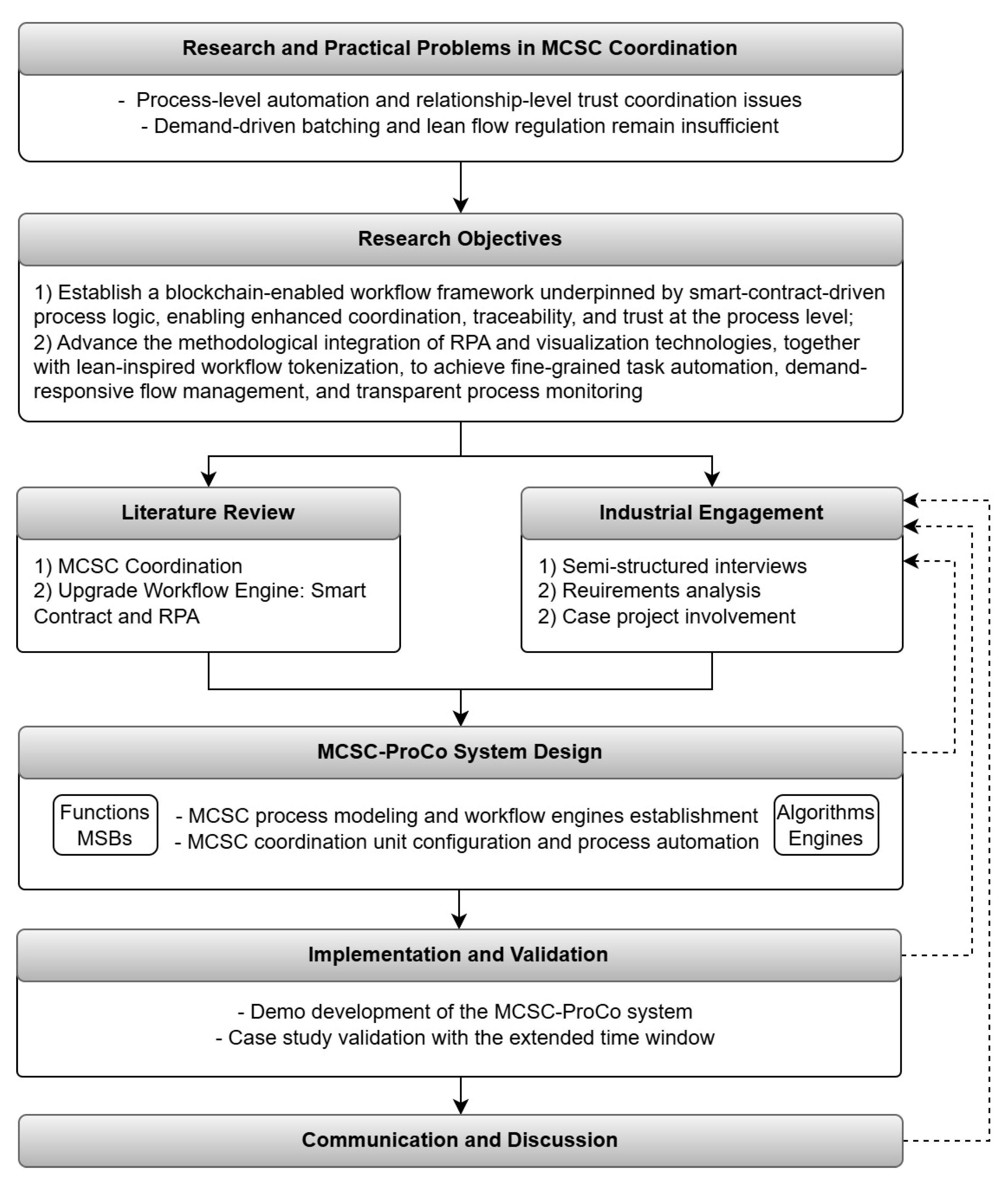

This study adopts the Design Science Research (DSR) paradigm [94,95] to develop and validate the system framework, aiming to address the dual challenges of process-level automation and relationship-level trust coordination in multi-stakeholder MCSC. Following the DSR cycle, the research proceeds through iterative phases of problem identification, artifact design, implementation, and evaluation, with continuous feedback from both academic and industrial domains, as shown in Figure 1.

Figure 1.

Research methodology following the DSR paradigm.

The research begins with the problem definition and objective formulation stage, where process inefficiencies and insufficient lean-flow regulation in MCSC coordination are analyzed. Building on this foundation, the design and development phase focuses on constructing a blockchain-enabled workflow framework underpinned by smart-contract-driven logic and RPA. This phase integrates methodological advances in workflow tokenization and visualization to enhance coordination, traceability, and transparency. Subsequently, the demonstration and evaluation phase involves prototype implementation and validation through an extended case study. A demo version of the system has been developed to test the conceptual framework in real project environments, while case-based validation over an extended time window ensures robustness and applicability across dynamic operational conditions. The results are analyzed through structured feedback and reflective discussion, completing the DSR loop by informing theoretical insights and practical refinements for future iterations of MCSC coordination frameworks.

4. Development of the MCSC-ProCo System

4.1. System Overview

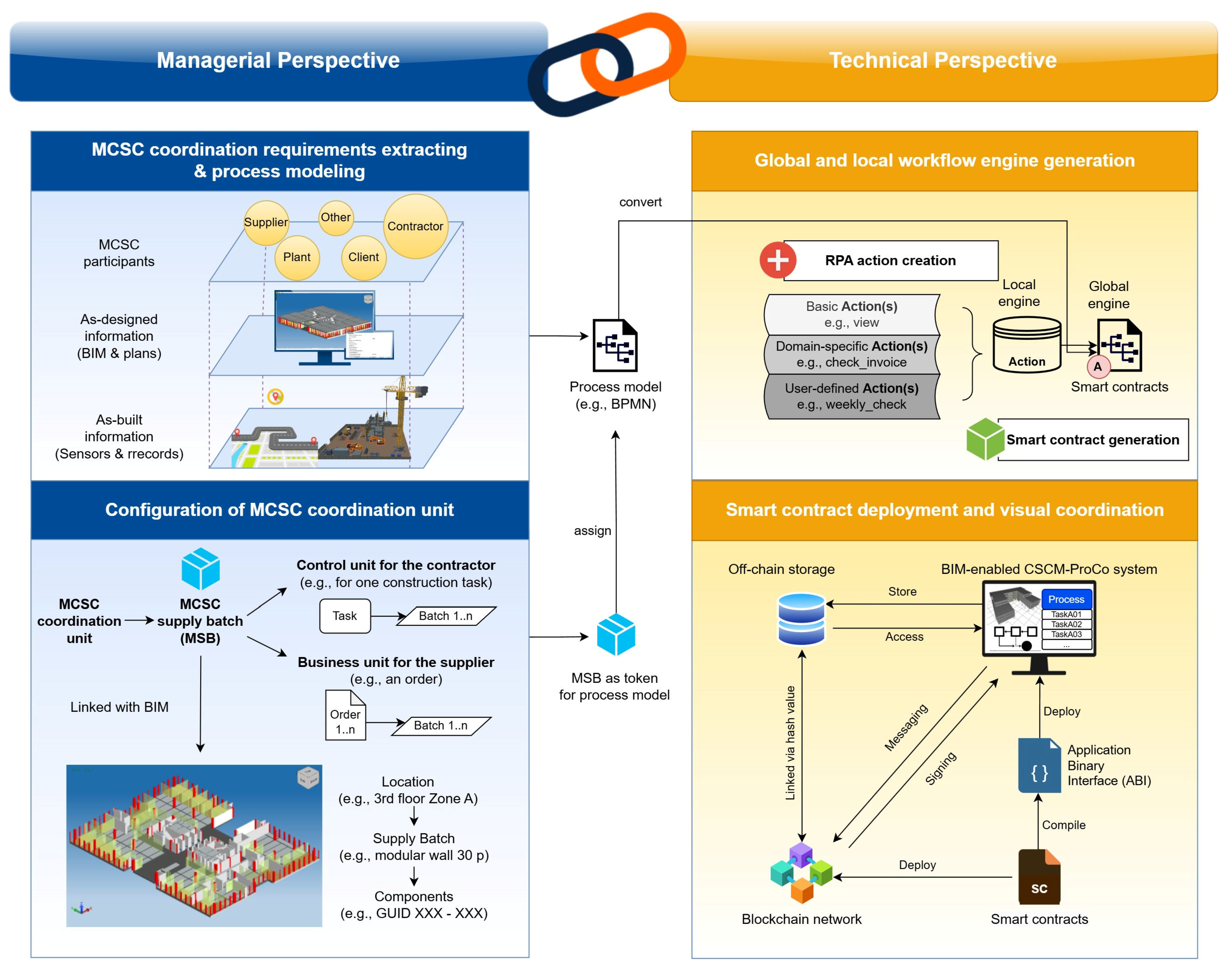

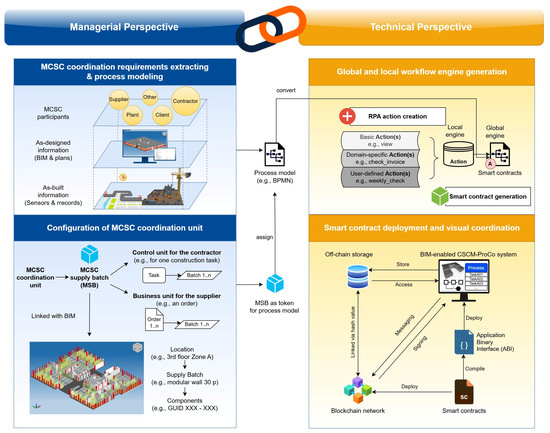

Given technical and practical insights into MCSC process coordination, this paper develops a novel system with a workflow engine that seamlessly integrates blockchain-enabled smart contracts and RPA, which meanwhile integrates information visualization approaches such as BIM (i.e., building information models) and BPMN (i.e., process information models). This system is designed to effectively tackle existing coordination challenges from both managerial and technical perspectives. The development procedure begins with a comprehensive demand analysis through a series of industry engagement initiatives (industrial interview details in Appendix A), ensuring the solution’s relevance and applicability. As MCSC process coordination transcends purely technical considerations, effective performance in coordination also necessitates proficient supply chain management strategies. Therefore, the development procedure of the MCSC process coordination (MCSC-ProCo) system incorporates both technical and managerial perspectives, as depicted in Figure 2.

Figure 2.

Conceptual design integrating managerial and technical perspectives.

From the managerial perspective, MCSC coordination requirements extraction and process modeling are the entrance points. The MCSC process encompasses complex tasks and many participants, including the client, contractors, designers, and suppliers. Process splitting and subprocess modeling can be performed to simplify highly complex processes. Because the initiation of tasks in the MCSC process is affected not only by the participants but also by as-designed and as-built information, process modeling and automation can be conducted by combining BIM and IoT applications. Another essential procedure from the managerial perspective is to configure the MCSC coordination unit, i.e., the MCSC supply batch (MSB). In the MCSC process model, MSB functions as a token, representing a package that is sequentially passed through the subsequent stages of the process. From the technical perspective, the first essential procedure is used to generate the global and local workflow engines, i.e., blockchain-enabled smart contracts and RPA actions. Then, the deployment of smart contracts with RPA actions, along with their integration into a BIM-enabled visual coordination environment, enables the realization of the application.

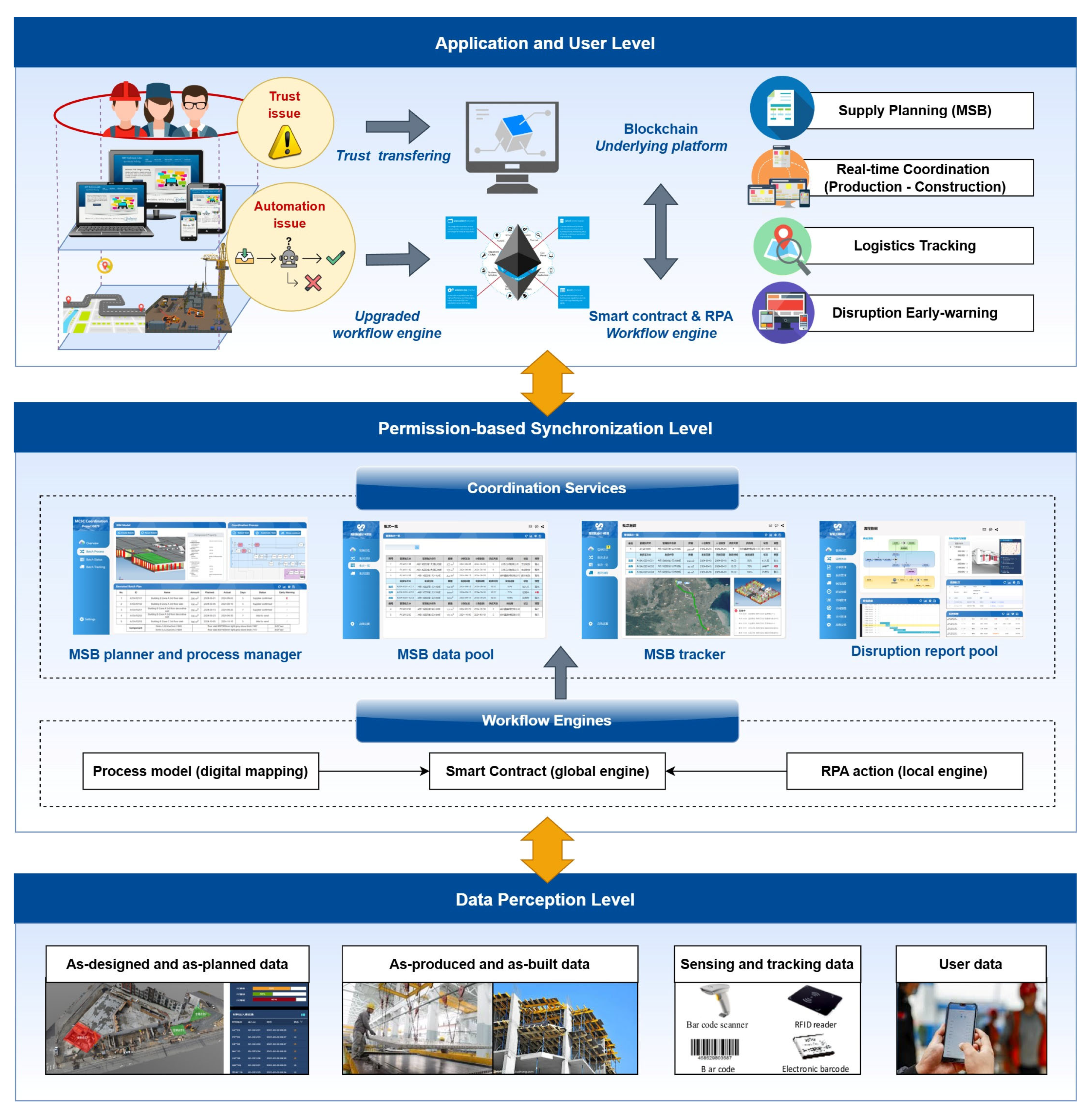

Based on the conceptual design, Figure 3 provides the framework of the proposed system with the interface examples of the original system (MCSC-ProCo System, Chinese version 1.0), while the English-translated version is provided in the related content of Section 5. The architecture consists of three levels. At the data perception level, real-time data such as as-designed, as-built, sensing, and user information are collected to support process visibility and traceability. The permission-based synchronization level serves as the coordination core, where digital process models are executed through a dual-engine workflow system. Smart contracts function as a global engine for inter-organizational collaboration, while RPA performs repetitive, rule-based tasks at the local level. Coordination services, including supply planning, logistics tracking, and disruption reporting, are supported through platforms such as the MSB planner, tracker, and data pool. At the application and user level, the system addresses the key challenges of trust and automation by using blockchain for trust transfer and an upgraded workflow engine for semi-automated process execution.

Figure 3.

System framework of MCSC-ProCo.

In summary, the MCSC-ProCo system represents a technically integrated coordination platform that extends traditional workflow management into a dual-engine, data-driven environment. The system achieves real-time interoperability between blockchain-enabled smart contracts and RPA modules, ensuring both verifiable global coordination and high-granularity local automation. By coupling these automation layers with BIM- and BPMN-based process visualization, MCSC-ProCo enables consistent data flow, traceable task execution, and responsive decision-making across distributed construction processes.

4.2. MCSC Process Modeling and Engines Establishing

The industrial opinions were collected from a survey with 146 questionnaires and a series of interviews with practitioners involved in MCSC (see Appendix A). Regarding the functionality of smart contract and RPA-enabled coordination systems or tools, the majority of respondents recognize that these tools ensure the authenticity of construction supply chain data (with 94% of respondents assigning high scores), traceability (with 81% of respondents assigning high scores), and automation capability (with 96% of respondents assigning high scores).

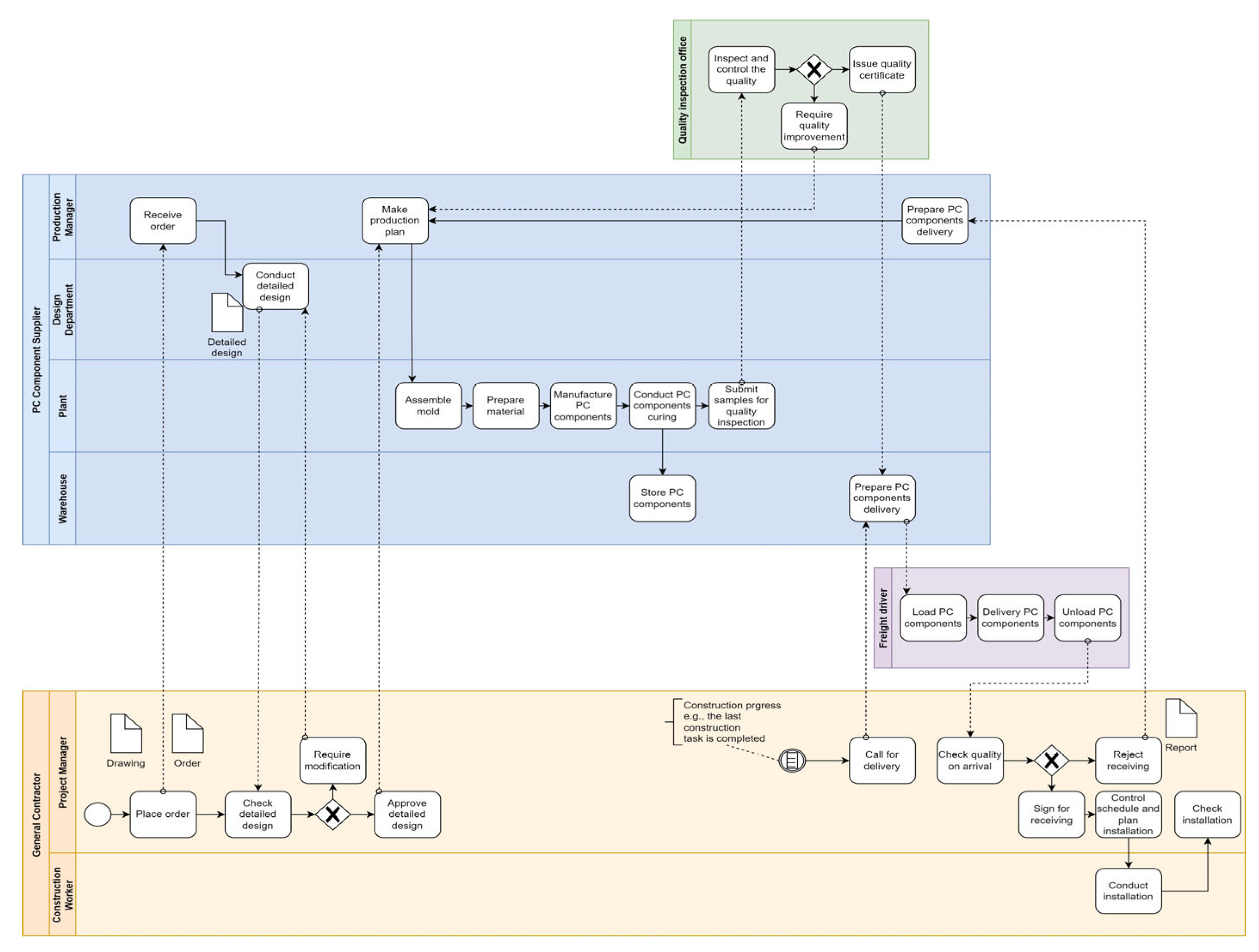

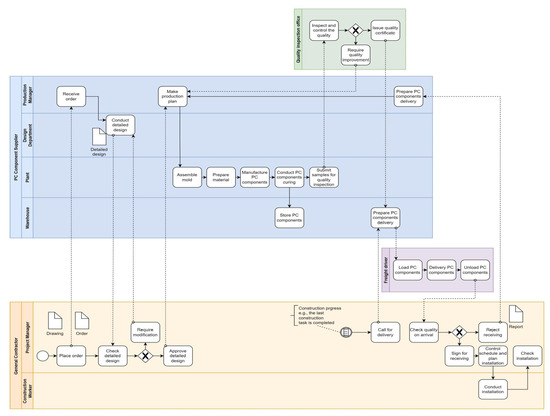

In the demand analysis of MCSC coordination, the majority of respondents identified the following key needs: preventing supply delays, interacting with suppliers to control progress and costs, obtaining quick responses from suppliers, planning and controlling inventory based on production activities, implementing more automated supply management systems, and ensuring traceability. Based on industrial requirements, this study modeled the MCSC process using precast components as an example, as shown in Figure 4.

Figure 4.

MCSC process model example.

In this process model, all essential schedules and quality control gateways are set, and the information flow among the contractor, precast component supplier, logistics service provider, and quality inspection unit are modeled.

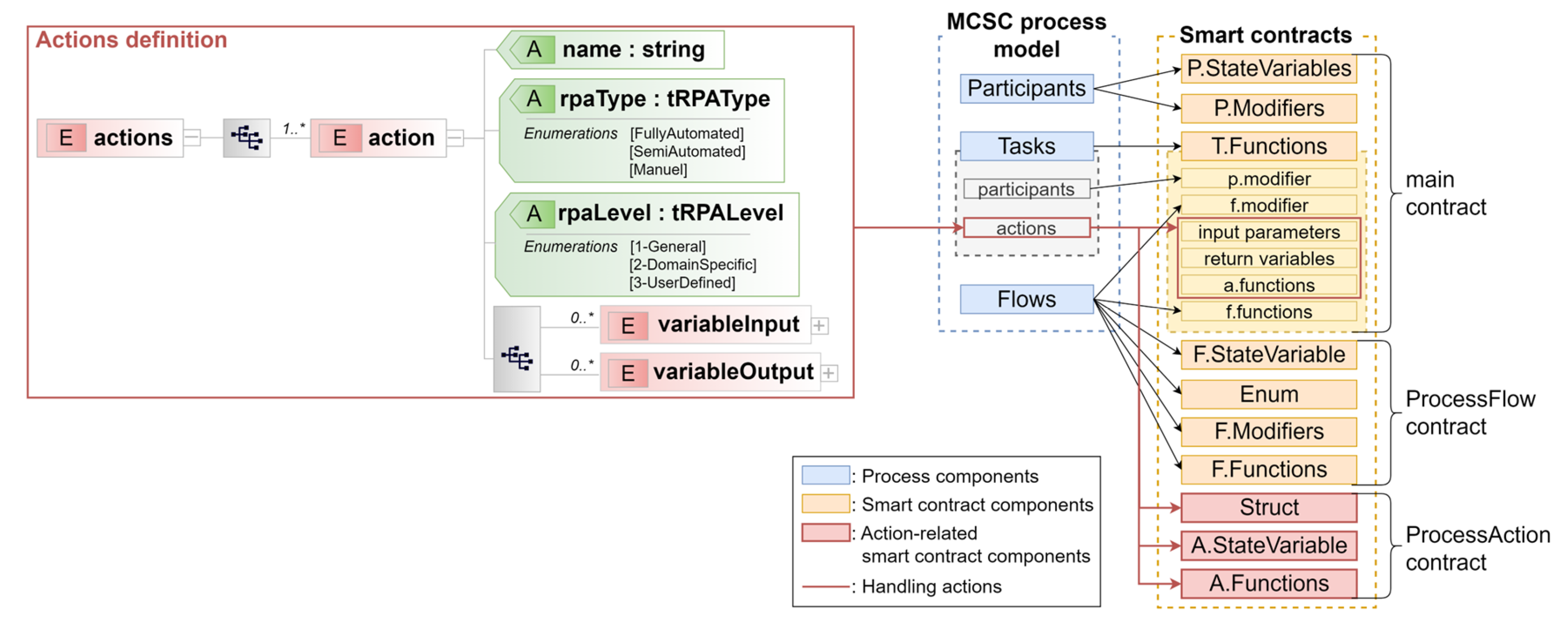

Based on the process model, blockchain-enabled smart contracts can be generated using our previously developed generation method [27]. Smart contracts work as the global workflow engine for process execution and flow automation, which can provide traceable reports of the execution records. Meanwhile, a series of RPA actions was defined for internal task automation, and the definition structure is shown in Figure 5.

Figure 5.

Smart contracts and RPA actions definition structure.

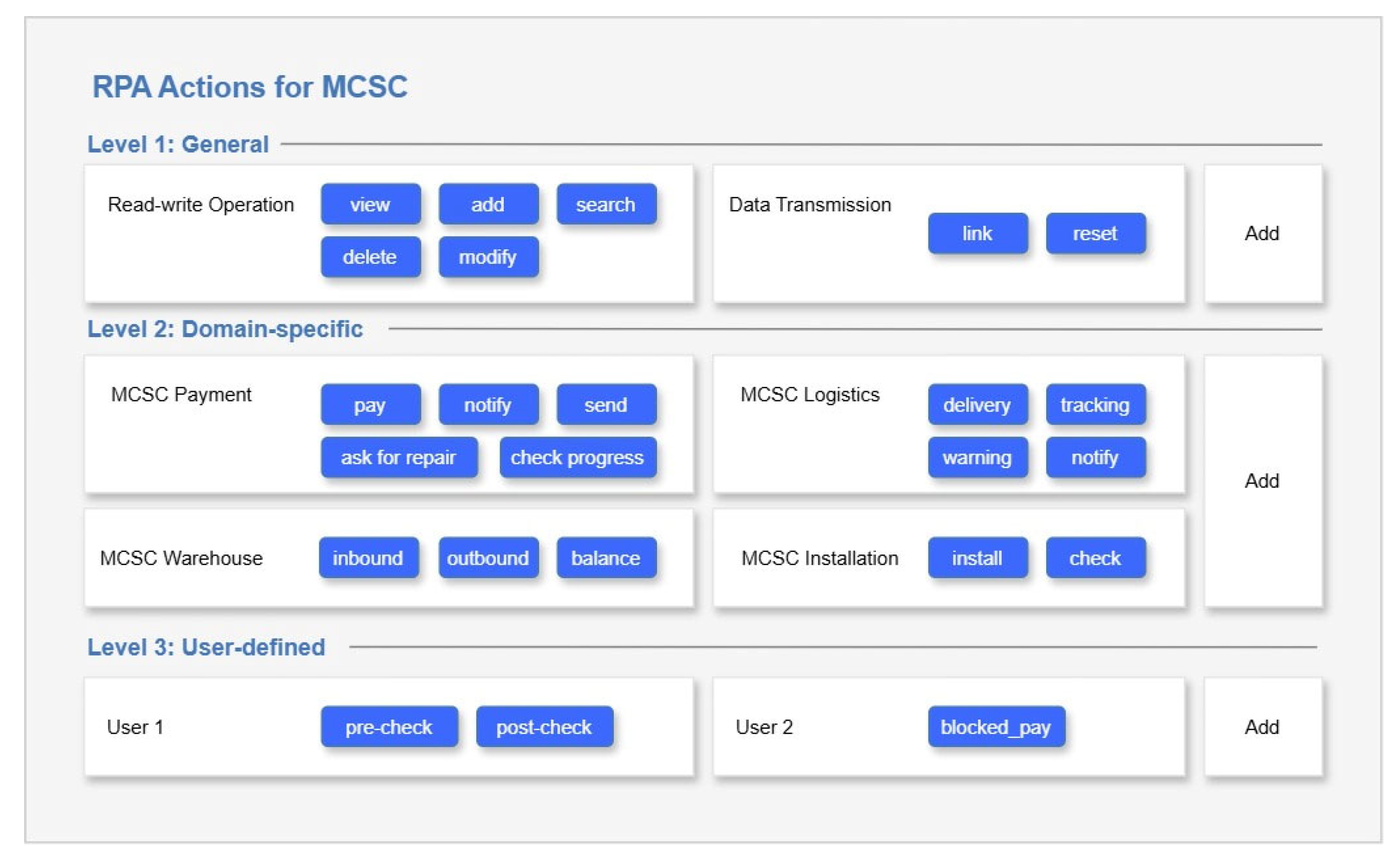

To conform to the context of MCSC, RPA actions are defined in three levels: general (basic level for general purpose), domain-specific (e.g., logistics, payment, warehouse, and construction), and user-defined (customized level under the requirements of a specific user), as shown in Figure 6.

Figure 6.

RPA action pool for MCSC process coordination.

Some manual actions can be replaced with fully or semi-automated RPA actions using smart contracts and blockchain (e.g., a “pay” RPA action), where the smart contracts are used as robots to realize RPA. Other manual actions, which cannot be simply executed via smart contracts (e.g., “check progress” action or “tracking” action), can be transformed into RPA actions by further integrating other devices or agents (e.g., sensors).

4.3. MCSC Coordination Unit Configuration and Process Automation

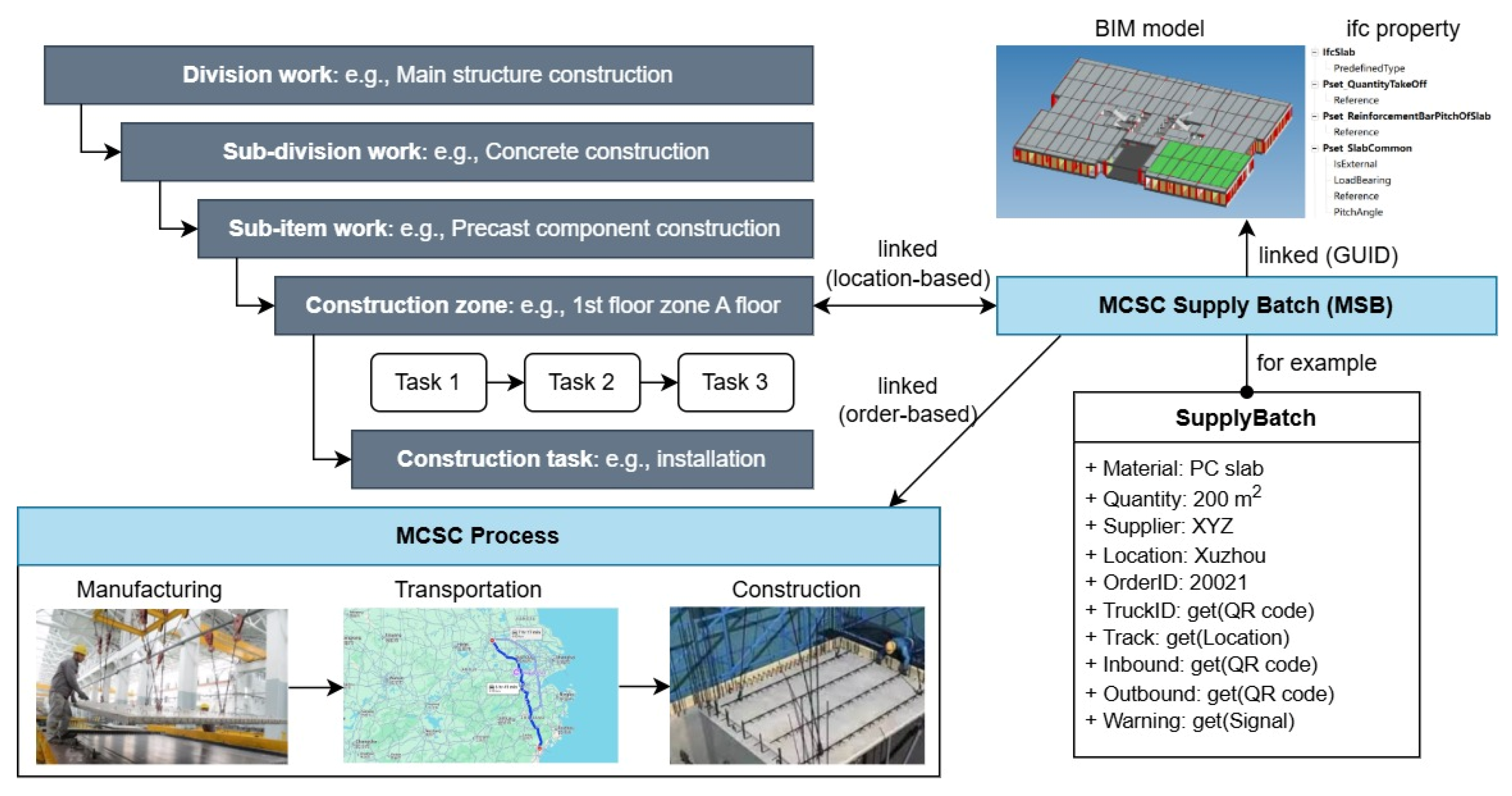

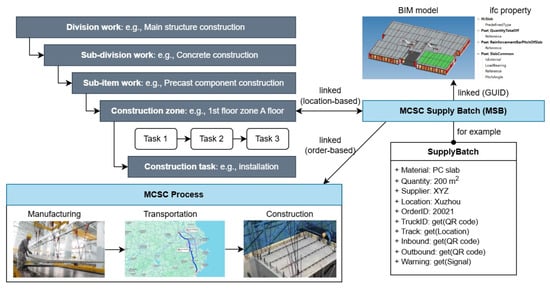

MCSC Supply Batch (MSB) is defined as the smallest element within the coordination framework, which helps facilitate interactions and processes across different stages and parties in the supply chain, as shown in Figure 7. The attributes of MSB can be generated from predefined templates and integrated IFC (Industry Foundation Classes) properties from the BIM model.

Figure 7.

MSB object definition.

The configuration of MCSC coordination with the basic unit, i.e., MSB, is shown in Figure 6. The defining and planning of MSB are based on project decomposition and a location-based perspective. A construction project can be decomposed from division work, sub-division work, and sub-item work, into construction tasks, and the MSB is linked to a construction zone, which contains a series of construction tasks following the sequence. The location-based perspective is for better collaboration to provide the MCSC participants with a BIM model view. This project decomposition and a location-based perspective is mainly for the construction and project management side, e.g., the contractor, client, and consultant.

Another essential perspective is the order-based perspective, which is mainly for the supply side, e.g., the suppliers and logistics service providers. The order can be generated automatically after the contractor sets up the MSB in the system. The supplier can prepare the delivery and related documents according to an MSB order or link the MSB order to an existing purchase contract. All automatically collected data (e.g., sensors), semi-automatically collected data (e.g., QR code), and manually input data (e.g., mobile device or computer) can be linked to the MSB unit. Therefore, the life-cycle process of an MSB from off-site to on-site can be easily tracked and monitored. With inbound and outbound functions, the as-built information of MSB can also be tracked and shown in the BIM model view.

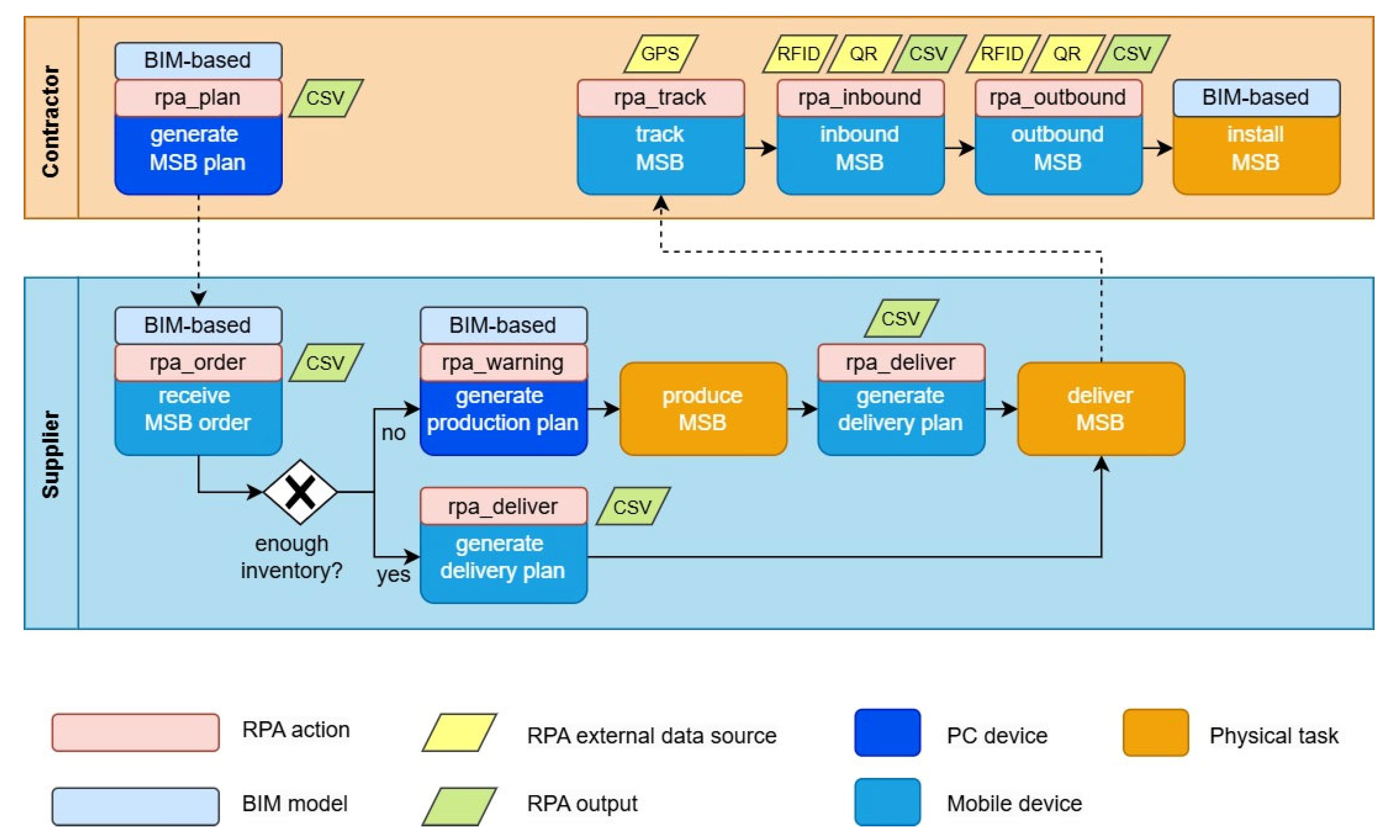

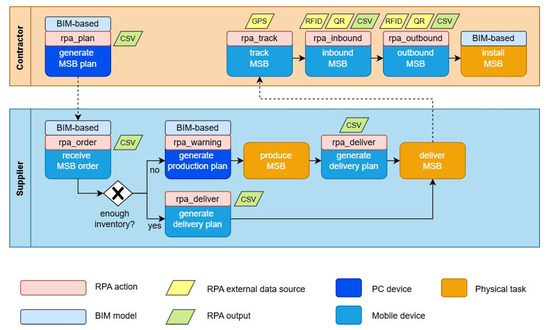

The MCSC process can be executed through semi-automatic operations by authorized personnel and predefined automatic triggers. Industrial feedback was used to refine both the process models and the RPA definition structure. Practitioners’ inputs on workflow bottlenecks, task frequency, and data exchange patterns were translated into BPMN subprocesses that required automation. These processes were then decomposed into RPA task units, with feedback guiding the triggering rules, execution logic, and exception handling. As a result, the RPA structure reflects real industrial routines and aligns with practical coordination needs in MCSC operations. Figure 8 shows the MCSC coordination process execution with RPA actions.

Figure 8.

MCSC coordination process execution with RPA actions.

In the initiation stage, an MSB plan can be generated with BIM models (component selection) and schedules, including the MSB name, construction zone, and required date. The quantity and associated components can be extracted from the IFC properties. The generation process can be semi-automatically executed using the rpa_plan action. For example, a CSV document of the MSB plan can be automatically created with manual adjustments on the quantity unit and the required date.

When the supplier receives the MSB plan, the rpa_order action will automatically convert it into an order so that it can be better understood from a business perspective, which also can be a part of a purchase contract.

When there is enough inventory, the supplier can confirm the MSB order and provide a delivery plan with a planned arrival date and other essential information, including related staff account information. The rpa_deliver can automatically create a CSV document and send it back to the contractor. This situation is common in practice when a series of MSBs belong to one purchase contract. However, when the MSB is an ETO or MTO-type material or equipment, the production process is required, and the rpa_warning action will calculate if there will be any potential production delay according to real-time data.

After the supplier delivers the MSB, the rpa_track action can update the transportation location automatically, integrating GPS data, while the rpa_warning action will also calculate if there will be any potential transportation delay.

When the MSB arrives, the rpa_inbound action will automatically generate an inbound receipt according to previous WSB data and related staff account information to better assign responsibility. When the MSB is taken for use, the rpa_outbound action will automatically generate an outbound record and assign as-built information, such as construction zone, material requisitioner and outbound clerk.

All manual operations can be performed using mobile devices, except MSB planning and production planning, which are usually integrated into existing PC systems. The overall workflow is deployed on the blockchain network, and all tasks and gateway decisions will be recorded into transactions to ensure traceability. The automation mechanism of blockchain-enabled smart contracts has been introduced in our previous study [27]. Meanwhile, the status of internal task RPA actions can also be recorded and ensured via the blockchain network.

Data security and privacy mechanisms were likewise designed in accordance with industrial requirements. In the blockchain linkage of the MSB, only workflow state transitions and token statuses are recorded on-chain, while detailed MSB information remains stored off-chain within each participant’s trusted internal database. The configuration, issuance, and management of MSBs are controlled by contractors, who also define access permissions. Supplier orders are aggregated under MSBs based on predefined business rules, making order data visible to both parties, whereas MSB-level information is shareable only at the contractor’s discretion. Workflow visibility follows this principle: contractors can perform demand forecasting and progress analysis, while suppliers access early-order insights solely through the contractor’s controlled data release. This hybrid on-/off-chain structure ensures that transparency, automation, and data confidentiality are maintained simultaneously within the MCSC-ProCo coordination process.

5. Implementation and Validation

5.1. Demo-System of MCSC-ProCo

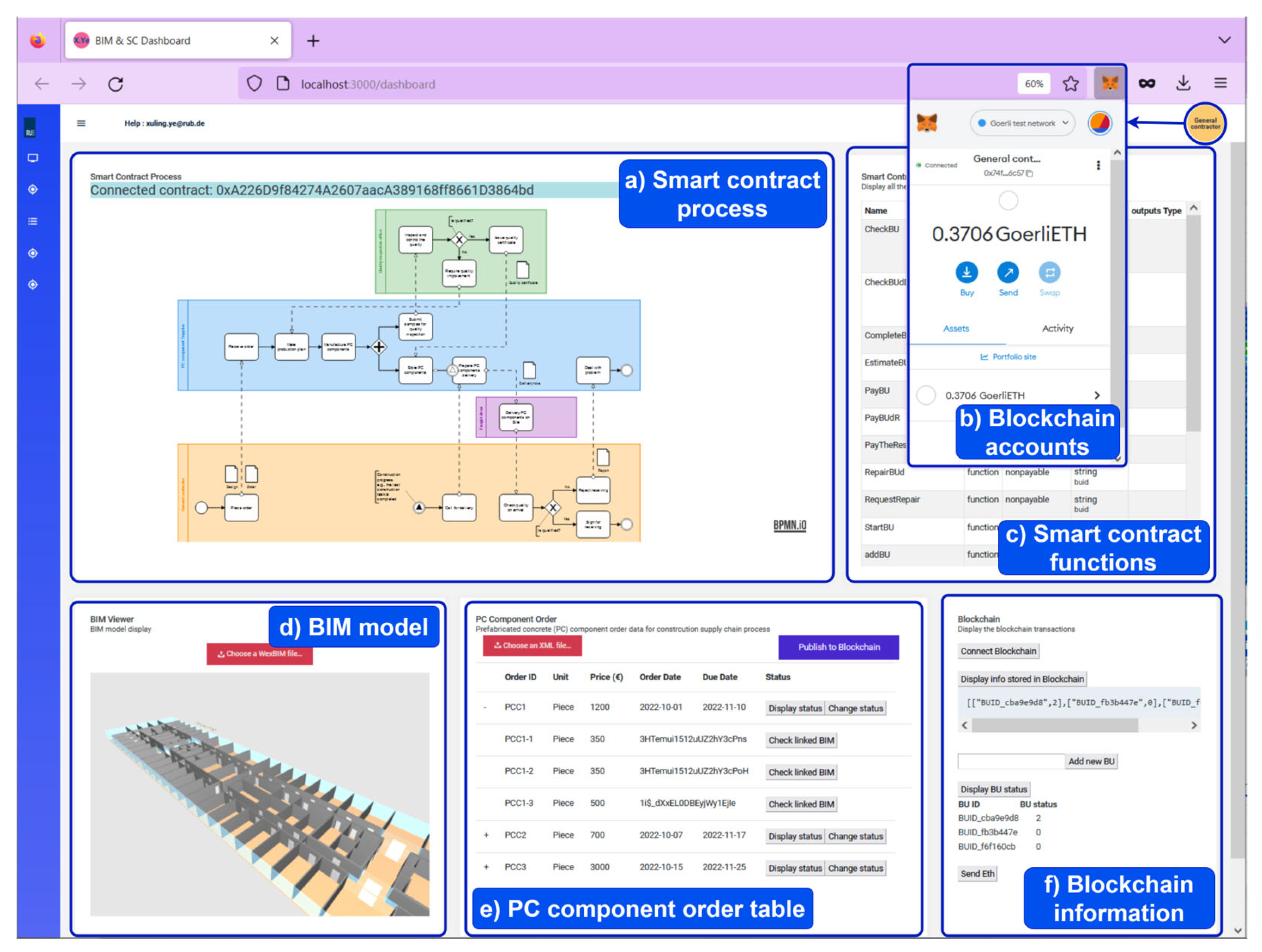

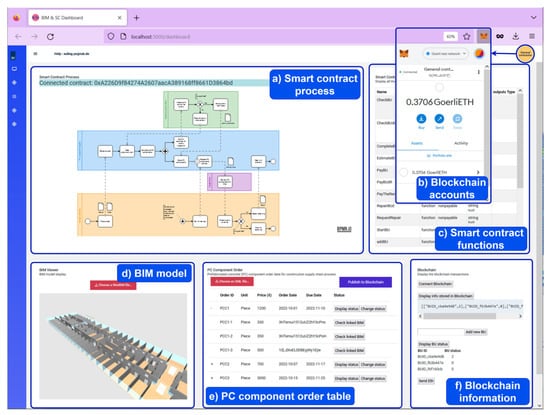

This study applied the initially developed system to a project in Nanjing South New Town in China, one of the smart construction pilot projects in Nanjing city, covering commercial, office, and residential areas, to test the proposed blockchain-enabled smart contracts and RPA integrated method. The demo system of the blockchain-enabled smart contracts for precast components supply coordination is shown in Figure 9, with core data of Version 1.0 available in GitHub (https://github.com/XulingYe/MCSC-ProCo) (accessed on 21 October 2025) and a recorded test demo video available at: https://ruhr-uni-bochum.sciebo.de/s/eQ3S5EytqNQr3Kx (accessed on 21 October 2025).

Figure 9.

Demo system of MCSC-ProCo with precast components supply coordination.

The Demo system, as shown in Figure 8, combines smart contract execution with BIM viewer and component tracking, enabling traceable and semi-automated process control:

- (a)

- Smart contract process: This section displays the structured process logic defined by the smart contract, including MCSC tasks, decision points, and information flows, providing a visual representation of the automated workflow. The basic coordination unit in the process is an MSB, which serves as the token passed along task-to-task transitions throughout the workflow.

- (b)

- Blockchain accounts: This panel shows the active blockchain wallet (e.g., MetaMask) connected to the system, including the account balance in testnet ETH (GoerliETH), which is used to interact with deployed smart contracts. The underlying blockchain network can also be implemented using a consortium chain or a private chain. In the current setup, it primarily serves this demo system. The specific choice of blockchain type and its permission structure should be determined based on the requirements of the MC project stakeholders.

- (c)

- Smart contract functions: This module lists executable functions in the contract, allowing users to trigger or query on-chain actions such as verification, approval, or data submission. Additionally, if an rpa_action requires on-chain status recording, it is also integrated into this module.

- (d)

- BIM model: The embedded BIM viewer (IFC-based) visualizes the digital representation of the physical construction project, enabling users to cross-reference geometric and semantic data. The MSB is linked with the BIM model via the batch-to-component (MSB ID matches GUIDs) method.

- (e)

- Component order table: This table manages the tracking of MC component orders, detailing order IDs, product types, dimensions, delivery times, and status. It allows users to publish relevant data to the blockchain and link it to corresponding BIM elements. The MSBs are also linked with an order using the batch-to-order (one or multiple MSB IDs match one order ID) method.

- (f)

- Blockchain information: This section displays the status of blockchain interactions, including transaction hashes and event logs, ensuring transparency and traceability of recorded actions. In this demo system, order and MSB information are mandatorily recorded on-chain, while BIM models and process status are optionally recorded on-chain.

The blockchain module in the demo system was deployed and tested on the Ethereum Goerli Test Network to verify smart contract functionality under realistic blockchain conditions. The contracts were developed in Solidity v0.8.17 and compiled using the corresponding Solidity compiler, with deployment performed through Hardhat v2.12.2 and the Remix IDE environment. MetaMask v10.28.1 was used for wallet connection and transaction signing. During the testing, the average gas price ranged from approximately 20 to 30 gwei, with the Goerli default gas limit of 30,000,000 per transaction. Typical transaction latency was observed between 15 and 30 s, which was acceptable for this demonstration purpose.

In terms of security and data management, all participants accessed the demo system through individual blockchain accounts linked to institutional credentials. Private keys were managed via standard wallet applications (MetaMask) with password-protected local storage. To safeguard privacy, only hashed identifiers and pseudonymized data were recorded on-chain, while detailed information was maintained in secure off-chain databases. The smart contracts followed a modular and upgradable design, allowing new versions to be deployed when business logic or regulatory requirements change. This design ensures flexibility without compromising the immutability of previous records.

The MCSC-ProCo demo system incorporates multiple rpa_action modules to support task automation within the coordination workflow. Among them, rpa_warning and rpa_inbound serve as illustrative examples, as depicted in Algorithm 1 and Algorithm 2.

| Algorithm 1. The “rpa_warning” action in the Demo system of MCSC-ProCo. |

| Input: Ordered MSB (Modular Supply Batch) Omsb; WMS (warehouse management system) database Wdb; Supplier data Sd; Contractor data Cd; Output: true or false |

| /* Obtain the same MSB in Wdb as Wmsb */ Wmsb ← Wdb.find(Omsb); /* Fulfill the condition, then proceed */ if (Wmsb != null) AND (Omsb.count() > Wmsb.count()) then /* First calculate how many products in MSB should be produced, and last for how long */ MsbNumber ← Omsb.count() - Wmsb.count(); DelayedDays ← Omsb.productionDay * MsbNumber; ------------------------------------------------------------- /* Call email API & notify supplier with product info */ SupplierMsg ← “Dear ” + Sd.Username + “, You need to produce ” + MsbNumber + “ ” + Omsb.OrderName + “ for ” + Omsb.ProjectName + “, and you might encounter ” + DelayedDays + “ days delay.”; isSupplierSent ← emailAPI.send(Sd.email, SupplierMsg); ------------------------------------------------------------- /* Call email API & notify contractor with delay info */ ContractorMsg ← “Dear ” + Cd.Username + “, Your project ” + Omsb.ProjectName + “ is expected to be delayed for ” + DelayedDays + “ days.”; isContractorSent ← emailAPI.send(Cd.email, ContractorMsg); ------------------------------------------------------------- return (isSupplierSent AND isContractorSent); else return false; end |

| Algorithm 2. Algorithm of rpa_inbound in the Demo system of MCSC-ProCo. |

| Input: Scanned MSB Smsb; On-site database OSdb; Inbound staff data ISd Output: Signed inbound PDF file Spdf |

| /* Check if the MSB is received by scanning the QR code */ if Smsb != null then /* Retrieve the same MSB in database */ OSmsb ← OSdb.find(Smsb); /* Check if this MSB exists */ if OSmsb != null then /* Change its status into inbounded */ OSmsb.Status ← “inbounded”; /* Retrieve its inbound table InboundTable */ InboundTable ← OSmsb.inboundTable; /* Sign this table by the inbound staff */ Spdf ← OSdb.sign(ISd.identifier, InboundTable); /* Return this table in PDF */ return Spdf; else return false; end else return false; end |

The RPA_warning algorithm in the MCSC-ProCo demo system is designed to automate delay warnings based on real-time discrepancies between planned and actual progress of an MSB. By comparing the expected production quantity with the recorded output in the warehouse management system, the algorithm calculates the remaining units and the potential delay in days. If a shortfall is detected, it automatically generates and sends tailored email notifications to both the supplier and contractor using predefined message templates. These notifications include production details and delay estimates to enable timely intervention. This RPA action enhances coordination efficiency by embedding rule-based exception handling directly into the digital workflow.

The rpa_inbound algorithm in the MCSC-ProCo demo system automates the inbound confirmation process for MSBs on construction sites. Upon scanning the QR code of an arriving MSB, the algorithm verifies whether the scanned batch exists in the as-planned MSB database. If the MSB is found, its status is updated to “inbounded,” and the corresponding inbound checklist is retrieved. The inbound staff member’s identifier is then used to digitally sign the checklist, generating a signed PDF record (Spdf) as official proof of receipt. This RPA action streamlines on-site verification and documentation, ensuring traceability, reducing manual effort, and enhancing the reliability of MSB status management within the overall supply chain coordination framework.

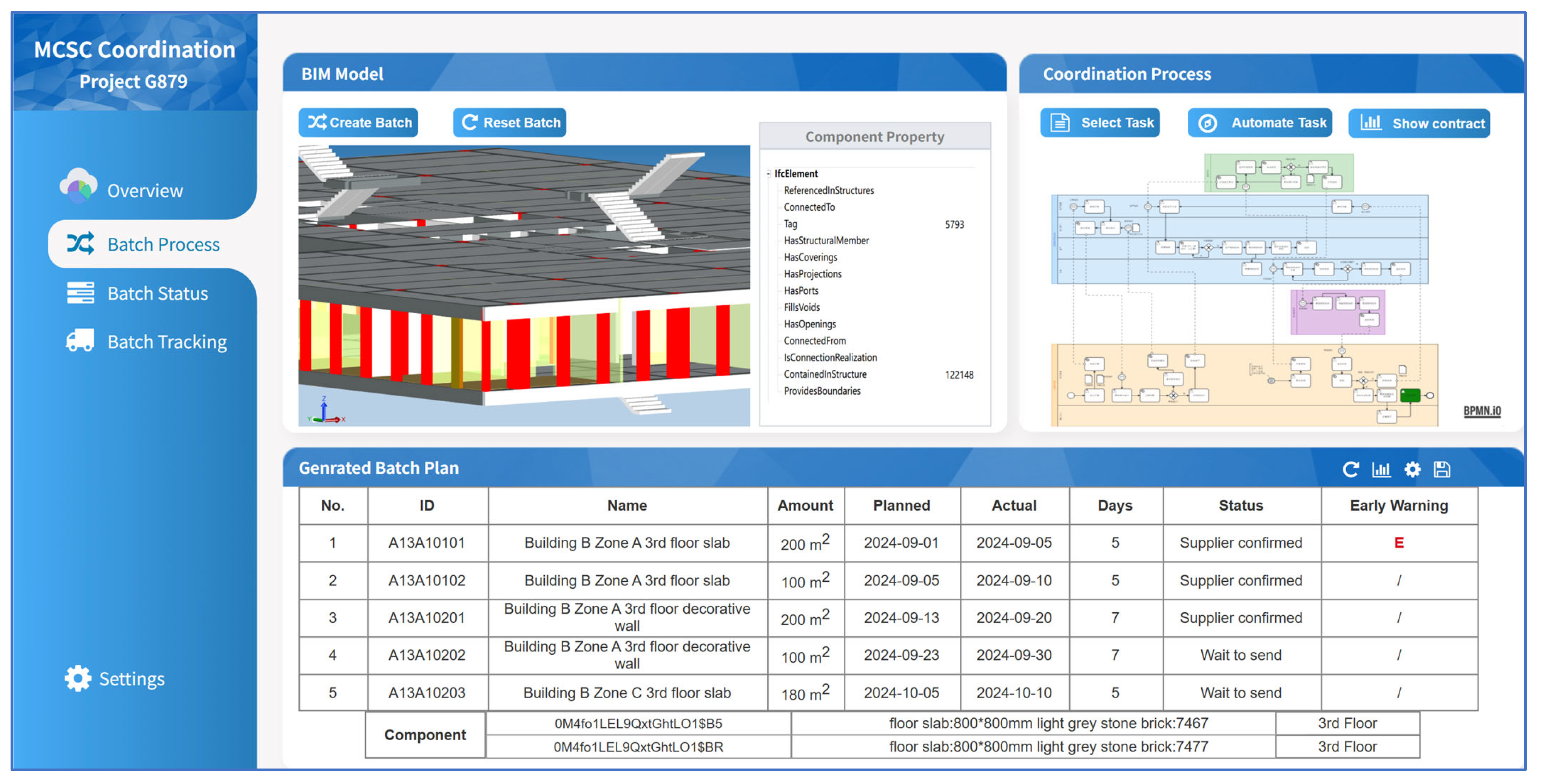

5.2. Case Study Validation

Based on the further requirements from the project managers and communication with suppliers, the first version of the MCSC system has integrated the MSB concept and RPA actions. In this project, the MCSC coordination is not only about the precast components but also includes the prefabricated decoration components, for example, wood flooring materials and decorative aluminum wall plates. An example of the user interface of this system, translated into English, is shown in Figure 10.

Figure 10.

The interface of the MCSC-ProCo system in the case project (translated example).

In this case, an example of an MSB is “Building B Zone A 3rd floor slab,” which has a quantity of 200 m2 and a required arrival date of 1 September 2024. This MSB was assigned to the process model and triggered by predefined conditions and manual decision input. The process model was displayed using the BPMN standard in the interface, while on the backend, it was deployed on the private blockchain in the form of smart contracts.

In this project, the B/S system was mainly applied for the main contractor to plan, generate, and track the MSBs. The planning of MSBs is the most difficult step since it guides all the following data collection, tracking and warning. Therefore, in this project, the MSBs were defined and planned by a small group of one project manager, one construction manager, and one researcher. The supplier only used mobile devices to receive MSB orders and deliver MSB products. All the logistics processes utilized GPS devices for tracking, and the inbound and outbound processes used QR codes, which are attached to each MSB and scanned by the on-site staff and construction workers’ phones.

During this project execution, several issues arise, such as a lack of understanding of new technologies, especially among material suppliers with low levels of information technology adoption. Distinguished by the abstract, on-chain coding mechanisms, smart contracts differ fundamentally from more visually intuitive technologies like BIM or Virtual Reality. This often requires significant effort and time for communication and system adjustments. This is one of the key reasons for choosing mobile devices on the supplier side. Most experienced project managers have no problems with the B/S system and can easily deal with BIM elements. Meanwhile, most MCSC participants are not familiar with BPMN tools, and sometimes, additional UI design is required to simplify the process models for better coordination.

To evaluate the effectiveness of the newly implemented MCSC-ProCo system, the marble floor was used as the analysis object. Quantitative data were collected from two periods: August 2024 (pre-implementation) and December 2024 (post-implementation). This analysis was conducted to assess the system’s performance after its official deployment in October 2024, while accounting for the potential instability of the system’s learning phase. By comparing data from these two periods, we aim to exclude any early-phase learning effects, ensuring that the results reflect the system’s true operational efficiency after reaching a stable operational state, as shown in Table 1.

Table 1.

Comparative analysis of MCSC performance metrics.

Average MSB Planning Time decreased from 8.2 h to 3.1 h (−62.2%), mainly due to the rpa_plan module, which automated the extraction of component data from BIM models and template generation, reducing manual data entry and coordination efforts. Order-to-Delivery Lead Time shortened from 15.7 days to 9.4 days (−41.7%) following the adoption of smart contracts that automated order generation, logistics confirmation, and communication. The rpa_track module enabled real-time GPS-based delivery tracking, further improving coordination efficiency. MSB Multi-party Coordination Negotiation Time dropped from 6 h to 2 h (−66.7%). Blockchain-enabled smart contracts provided transparent, immutable records and automatically enforced terms, reducing disputes and unnecessary communication loops. Meanwhile, Supply Delay Incidents declined from 5 to 2 per month, and Cumulative Supply Delay Time fell from 14 to 3 days, representing 60.0% and 78.6% reductions, respectively. These gains stemmed from the rpa_warning module’s ability to detect early production or logistics anomalies and trigger preventive actions.

Given the exploratory nature of this study and the limited observation window available for empirical testing, an Interrupted Time Series (ITS) approach was adopted to extend the analysis period. In addition, schedule disturbances (i.e., expedite and slowdown scenarios) were introduced to enrich the validation context and examine the multi-scenario performance of the proposed MSB workflow method under varying operational conditions. The ITS model quantifies the system’s intervention effect over time using the following specification:

Yₜ = β0 + β1t + β2Dₜ + β3(t − T0)Dₜ + φ1(Dₜ × Eₜ) + φ2(Dₜ × Sₜ) + κ1(Dₜ × MSB_SIₜ) + εₜ

Yₜ: Outcome variable at week t (e.g., lead time days, approval cycle hours);

t: Time index (1 … T);

Dₜ: Intervention dummy (0 = pre, 1 = post);

T0: Intervention week (system go-live);

Eₜ, Sₜ: Schedule regime dummies for expedite and slowdown (regular = reference);

MSB_SIₜ: Supply Batch Stability Index (0–1), higher = more stable batch flow;

β0: The baseline level of the outcome (e.g., average lead time, approval hours) at the start of the observation period (week 1).

β1: The underlying trend before intervention, i.e., how the outcome was changing over time before the system was implemented.

β2: Immediate level change after intervention;

β3: Slope change (trend difference post-intervention);

φ1, φ2: Interaction effects under expedite / slowdown regimes;

κ1: Effect of MSB stability on post-intervention outcome;

εₜ: Error term, HAC-robust (Newey–West SEs).

Heteroskedasticity- and autocorrelation-consistent (HAC) standard errors (Newey–West) are computed as:

Var(β^)ₙw = (X′X)−1 (Σₕ = -ᴸᴸ wₕ Σₜ = |ₕ|₊1ᵀ uₜuₜ−|ₕ| xₜxₜ−|ₕ|′) (X′X)−1

lag length L ≈ ⌊4(T/100)2/9⌋

Bartlett weights wₕ = 1 − |h|/(L + 1)

Table 2 presents the results of the ITS estimation with Newey–West HAC standard errors. The coefficients reflect both the immediate and long-term effects of introducing the proposed MSB workflow system on modular construction supply chain performance.

Table 2.

ITS with Newey–West HAC Standard Errors.

The interaction terms capture contextual effects. The Expedite×Post coefficient (φ1) is negative, showing that accelerated schedules benefit most from workflow automation. Conversely, the Slowdown×Post term (φ2) is positive, implying that prolonged or delayed projects partially offset these gains. The MSB-SI×Post coefficient (κ1) is consistently negative and significant, confirming that higher supply batch stability strengthens the post-implementation improvements.

To further analyze the MCSC performance metrics, interviews were conducted with key stakeholders, including the overall project manager, construction manager, procurement manager, quality control manager, and supplier representatives, to understand the key system features that contributed to the observed efficiency improvements. Table 3 shows an overview of the interview participants.

Table 3.

Overview of the Participants of the Interviews.

The interview analysis revealed several key themes. First, participants consistently emphasized the practical alignment between the system’s functions and real operational demands. The automation of MSB planning and order generation was viewed as directly addressing the long-standing challenge of fragmented coordination between design, procurement, and site teams. Both managers and suppliers highlighted that the integration of BIM data with smart contracts significantly reduced uncertainty in material scheduling and accountability, which had been major pain points in previous manual workflows.

Second, respondents agreed that the introduction of blockchain-based records enhanced trust and transparency in multi-party collaboration. Contractors and suppliers noted that automated contract execution and traceable records reduced negotiation time and minimized disputes over delivery responsibilities. The RPA modules were particularly valued for their ability to handle repetitive data transfer and reporting tasks, freeing up human resources for higher-level planning and supervision. Respondents suggested that future versions of the system could incorporate real-time production monitoring, cross-project coordination, and integration with enterprise resource planning (ERP) platforms, allowing broader application across organizations.

Beyond the specific case, the applicability of the proposed system is not limited by construction type or project scale. As clarified in Section 2.1, this study addresses modular construction (MC) in a broad sense: any construction process involving standardized prefabricated components, or even non-standardized yet homogeneous elements that can be grouped into MSB, can adopt the proposed workflow. The underlying workflow engine is also domain- and region-independent: its process logic can be customized for various project requirements and regulatory environments. Users can configure or extend process models through client-defined rules or integrate the system with mainstream workflow modeling tools such as Camunda. Therefore, the proposed MSB workflow system provides a flexible and scalable framework capable of supporting diverse construction typologies, including residential, commercial, and infrastructure projects, and can be adapted to international contexts with different regulatory frameworks.

6. Conclusions

This paper presents an integrated system for enhancing process coordination in MCSC by embedding advanced digital technologies into a practice-driven solution. A novel workflow engine is developed that combines blockchain-enabled smart contracts and RPA, forming a dual-engine-driven mechanism where smart contracts operate as a global coordination logic and RPA executes localized, rule-based tasks. This dual-engine architecture helps address persistent challenges in MCSC related to trust and automation.

Moreover, the system innovatively incorporates a practice-oriented approach to MSB (MCSC Supply Batch)-based management, drawing on industrial insights to define MSB as the basic coordination unit within process execution. This abstraction supports task-to-task transitions while ensuring traceability and operational clarity across supply chain nodes. By embedding process models and workflow triggers into multi-terminal devices, the system enables synchronized, real-time coordination across production, logistics, and on-site assembly.

A real-world case study is conducted to validate the feasibility and effectiveness of the proposed system. The results demonstrate that the developed platform can effectively address coordination issues such as delivery mismatches, production delays, and information asymmetry, offering enhanced visibility, automation, and decision-making support. Overall, this study contributes to the ongoing digital transformation of construction supply chains by providing a scalable and verifiable solution that integrates theoretical rigor with practical adaptability.

A comprehensive benchmarking of algorithm performance and failure mode analysis is recognized as an important next step. Future work will include controlled experiments to systematically assess execution efficiency, scalability, and robustness under varying project conditions. Meanwhile, future research will focus on enhancing the current dual-engine architecture by incorporating AI workflows and upgrading the RPA actions to AI agents, thereby advancing MCSC coordination from the stage of automation to that of intelligent decision-making. A key area of investigation will involve the integration of multi-source data across heterogeneous platforms, particularly addressing the technical challenges related to on-chain and off-chain data storage through blockchain-enabled smart contracts. From a practical perspective, future work will also explore the integration of buffering strategies, early-warning mechanisms, and adaptive monitoring methods informed by industry experience, with the aim of improving the responsiveness, robustness, and scalability of coordination processes in MCSC.

Author Contributions

Conceptualization, N.Z.; methodology, N.Z.; software, X.Y.; validation, N.Z., X.Y. and S.C.; formal analysis, N.Z.; investigation, S.C. and Y.L.; resources, Y.L.; data curation, S.C.; writing—original draft preparation, N.Z. and Y.L.; writing—review and editing, N.Z.; visualization, N.Z.; supervision, Q.L.; project administration, N.Z.; funding acquisition, N.Z. and Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant Nos. 72301068, 72201125, and 52378492) and the China Postdoctoral Science Foundation (No. 2023M740592).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all of the data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

During the preparation of this manuscript, the authors used OpenAI ChatGPT-5 for the purposes of academic writing improvement. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Details of respondents.

Table A1.

Details of respondents.

| Characteristic | Category | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 110 | 75.30% |

| Female | 36 | 24.70% | |

| Education | Master’s degree and above | 94 | 64.40% |

| Bachelor’s degree | 50 | 34.20% | |

| Junior college | 2 | 1.40% | |

| Organization | Construction company | 34 | 23.30% |

| Client and developer | 27 | 18.50% | |

| Consulting company | 11 | 7.50% | |

| Manufacturing company | 33 | 22.60% | |

| Technology company | 23 | 15.80% | |

| Research institution | 5 | 3.40% | |

| Government agency | 5 | 3.40% | |

| Others | 8 | 5.50% | |

| Years of work experience | 1–5 | 32 | 21.90% |

| 6–10 | 47 | 32.20% | |

| 11–15 | 43 | 29.50% | |

| 16–20 | 15 | 10.30% | |

| >20 | 9 | 6.20% | |

| Expertise in smart contract and RPA-enabled systems or similar tools | First time learned about | 21 | 14.38% |

| Basic understanding | 37 | 25.34% | |

| Scenario-based knowledge | 80 | 54.79% | |

| Advanced knowledge | 8 | 5.48% |

References

- Lane, B.M. Housing and Dwelling: Perspectives on Modern Domestic Architecture; Routledge: London, UK, 2006. [Google Scholar]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Lim, Y.-W.; Ling, P.C.H.; Tan, C.S.; Chong, H.-Y.; Thurairajah, A. Planning and Coordination of Modular Construction. Autom. Constr. 2022, 141, 104455. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative Analysis of Modular Construction Practices in Mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of Modular Construction in High-Rise Buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- MarketsandMarkets Research Pvt. Ltd. Modular Construction Market; MarketsandMarkets Research Pvt. Ltd.: Delray Beach, FL, USA, 2024. [Google Scholar]

- Pan, W.; Yang, Y.; Pan, M. Implementing Modular Integrated Construction in High-Rise High-Density Cities: Perspectives in Hong Kong. Build. Res. Inf. 2023, 51, 354–368. [Google Scholar] [CrossRef]

- Qi, A.; Sun, J.; Lin, H. Research on the Design of Prefabricated Framework System Based on Spatial Needs in the Context of Urban Renewal. J. Civ. Eng. Urban Plan. 2024, 6, 1–10. [Google Scholar] [CrossRef]

- Han, W.; Zhang, C.; Sun, J.; Zhou, C.; Ding, L. Experimental and Numerical Study on the Structural Behavior of Assembled Interlocking Lunar Landing Pad. Acta Astronaut. 2023, 207, 77–88. [Google Scholar] [CrossRef]

- Shafei, H.; Rahman, R.A.; Lee, Y.S. Effectiveness Evaluation of Construction 4.0 Technologies in Improving Built Environment Resilience. Int. J. Disaster Resil. Built Environ. 2024, 15, 530–550. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and Economic Performance of Prefabricated Construction: A Review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A. Modular Construction’s Capacity to Reduce Embodied Carbon Emissions in California’s Housing Sector. Build. Environ. 2023, 240, 110432. [Google Scholar] [CrossRef]

- Liu, Y.; Houwing, E.-J.; Hertogh, M.; Yuan, Z.; Liu, H. Explorative Learning in Infrastructure Development Megaprojects: The Case of the Hong Kong-Zhuhai-Macao Bridge. Proj. Manag. J. 2022, 53, 113–127. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Yang, Y.; Tetteh, M.O. Building Information Modeling (BIM)-Based Modular Integrated Construction Risk Management–Critical Survey and Future Needs. Comput. Ind. 2020, 123, 103327. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital Twin-Enabled Smart Modular Integrated Construction System for on-Site Assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Rangasamy, V.; Yang, J.-B. The Convergence of BIM, AI and IoT: Reshaping the Future of Prefabricated Construction. J. Build. Eng. 2024, 84, 108606. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.P.; Lu, W.; Huang, G.Q. An Internet of Things-Enabled BIM Platform for Modular Integrated Construction: A Case Study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Koolwijk, J.S.J.; van Oel, C.J.; Wamelink, J.W.F.; Vrijhoef, R. Collaboration and Integration in Project-Based Supply Chains in the Construction Industry. J. Manag. Eng. 2018, 34, 04018001. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. Revisiting the Three Peculiarities of Production in Construction. In Proceedings of the 13th International Group for Lean Construction Conference: Proceedings; International Group on Lean Construction Sydney, Sydney, Australia, 19–21 July 2005; pp. 19–27. [Google Scholar]

- Zeng, N. BIM-Enabled Construction Supply Chain Integration: Bridging on-Site and off-Site Processes. Doctoral Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2021. [Google Scholar]

- Abdul Nabi, M.; Elsayegh, A.; El-adaway, I.H. Understanding Collaboration Requirements for Modular Construction and Their Cascading Failure Impact on Project Performance. J. Manag. Eng. 2023, 39, 04023043. [Google Scholar] [CrossRef]

- Zeng, N.; Liu, Y.; König, M. 4D BIM-Enabled Look-Ahead Scheduling for Early Warning of Off-Site Supply Chain Disruptions. J. Constr. Eng. Manag. 2023, 149, 04022154. [Google Scholar] [CrossRef]

- Sheng, D.; Ding, L.; Zhong, B.; Love, P.E.; Luo, H.; Chen, J. Construction Quality Information Management with Blockchains. Autom. Constr. 2020, 120, 103373. [Google Scholar] [CrossRef]

- Pan, W.; Parker, D.; Pan, M. Problematic Interfaces and Prevention Strategies in Modular Construction. J. Manag. Eng. 2023, 39, 05023001. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Understanding Disputes in Modular Construction Projects: Key Common Causes and Their Associations. J. Constr. Eng. Manag. 2022, 148, 04021184. [Google Scholar] [CrossRef]

- Ye, X.; Zeng, N.; Tao, X.; Han, D.; König, M. Smart Contract Generation and Visualization for Construction Business Process Collaboration and Automation: Upgraded Workflow Engine. J. Comput. Civ. Eng. 2024, 38, 04024030. [Google Scholar] [CrossRef]

- Chen, G.; Liu, M.; Li, H.; Hsiang, S.M.; Jarvamard, A. Motivating Reliable Collaboration for Modular Construction: Shapley Value–Based Smart Contract. J. Manag. Eng. 2023, 39, 04023042. [Google Scholar] [CrossRef]

- Metters, R. Quantifying the Bullwhip Effect in Supply Chains. J. Ops. Manag. 1997, 15, 89–100. [Google Scholar] [CrossRef]

- Osadchiy, N.; Schmidt, W.; Wu, J. The Bullwhip Effect in Supply Networks. Manag. Sci. 2021, 67, 6153–6173. [Google Scholar] [CrossRef]

- Hossain, N.U.I.; Ahmed, I.; Chowdhury, S.; Govindan, K.; Jaradat, R. Assessing the Cascading Impact of Industry 4.0 Disruption on Supply Chain Analytics through the Lens of Dependency Concepts. Comput. Ind. Eng. 2024, 192, 110225. [Google Scholar] [CrossRef]

- Zuccaro, G.; De Gregorio, D.; Leone, M.F. Theoretical Model for Cascading Effects Analyses. Int. J. Disaster Risk Reduct. 2018, 30, 199–215. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Ripple Effect in the Supply Chain: An Analysis and Recent Literature. Int. J. Prod. Res. 2018, 56, 414–430. [Google Scholar] [CrossRef]

- Duong, A.T.B.; Pham, T.; Truong Quang, H.; Hoang, T.G.; McDonald, S.; Hoang, T.-H.; Pham, H.T. Ripple Effect of Disruptions on Performance in Supply Chains: An Empirical Study. Eng. Constr. Archit. Manag. 2024, 31, 1–22. [Google Scholar] [CrossRef]

- Ye, M.; Li, Y.; Ye, K. Developing an Assessment Model of Supply Chain Resilience in Prefabricated Construction Based on the Ripple Effect and Supply Chain Performance. Eng. Constr. Archit. Manag. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Lagos, C.I.; Herrera, R.F.; Mac Cawley, A.F.; Alarcón, L.F. Predicting Construction Schedule Performance with Last Planner System and Machine Learning. Autom. Constr. 2024, 167, 105716. [Google Scholar] [CrossRef]

- Zeng, N.; Ye, X.; Liu, Y.; König, M. BIM-Enabled Kanban System in Construction Logistics for Real-Time Demand Reporting and Pull Replenishment. Eng. Constr. Archit. Manag. 2024, 31, 3069–3096. [Google Scholar] [CrossRef]

- Rai, A.; Patnayakuni, R.; Seth, N. Firm Performance Impacts of Digitally Enabled Supply Chain Integration Capabilities. MIS Q. 2006, 30, 225–246. [Google Scholar] [CrossRef]

- Reiner, G.; Hofmann, P. Efficiency Analysis of Supply Chain Processes. Int. J. Prod. Res. 2006, 44, 5065–5087. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. A Framework for Procurement Process Re-Engineering in Industry 4.0. Bus. Process Manag. J. 2020, 27, 439–458. [Google Scholar] [CrossRef]

- Cheng, J.C.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R.D. Modeling and Monitoring of Construction Supply Chains. Adv. Eng. Inform. 2010, 24, 435–455. [Google Scholar] [CrossRef]

- Hagedorn, P.; Liu, L.; König, M.; Hajdin, R.; Blumenfeld, T.; Stöckner, M.; Billmaier, M.; Grossauer, K.; Gavin, K. BIM-Enabled Infrastructure Asset Management Using Information Containers and Semantic Web. J. Comput. Civ. Eng. 2023, 37, 04022041. [Google Scholar] [CrossRef]

- Häußler, M.; Esser, S.; Borrmann, A. Code Compliance Checking of Railway Designs by Integrating BIM, BPMN and DMN. Autom. Constr. 2021, 121, 103427. [Google Scholar] [CrossRef]

- Patrício, L.; Varela, L.; Silveira, Z.; Felgueiras, C.; Pereira, F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Appl. Sci. 2025, 15, 7402. [Google Scholar] [CrossRef]

- Zhan, J.X.; Ling, Z.; Xu, Z.; Guo, L.; Zhuang, S. Driving Efficiency and Risk Management in Finance through AI and RPA. J. Adv. Comput. Syst. 2024, 4, 1–9. [Google Scholar] [CrossRef]

- Li, J.; Kassem, M. Applications of Distributed Ledger Technology (DLT) and Blockchain-Enabled Smart Contracts in Construction. Autom. Constr. 2021, 132, 103955. [Google Scholar] [CrossRef]

- Ye, X.; Zeng, N.; König, M. Systematic Literature Review on Smart Contracts in the Construction Industry: Potentials, Benefits, and Challenges. Front. Eng. Manag. 2022, 9, 196–213. [Google Scholar] [CrossRef]

- Grosan, C.; Abraham, A. Rule-Based Expert Systems. In Intelligent Systems; Intelligent Systems Reference Library; Springer: Berlin/Heidelberg, Germany, 2011; Volume 17, pp. 149–185. ISBN 978-3-642-21003-7. [Google Scholar]

- Murali Dhar, M.S.; Manimegalai, R. A Policy-Oriented Secured Service for the e-Commerce Applications in Cloud. Pers. Ubiquitous Comput. 2018, 22, 911–919. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical Evaluation of Off-Site Construction Research: A Scientometric Analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Hou, L.; Tan, Y.; Luo, W.; Xu, S.; Mao, C.; Moon, S. Towards a More Extensive Application of Off-Site Construction: A Technological Review. Int. J. Constr. Manag. 2022, 22, 2154–2165. [Google Scholar] [CrossRef]

- Jin, X.; Shen, G.; Luo, L.; Zhou, X. Influence of Policies on Stakeholders to Drive the Success of Modular Integrated Construction in Hong Kong. Eng. Constr. Archit. Manag. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for Manufacture and Assembly (DfMA) in Construction: The Old and the New. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Key Constraints and Mitigation Strategies for Prefabricated Prefinished Volumetric Construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Liu, Z.; Hwang, B.-G.; Lim, J.M. Prefabricated and Prefinished Volumetric Construction: Assessing Implementation Status, Perceived Benefits, and Critical Risk Factors in the Singapore Built Environment Sector. J. Manag. Eng. 2023, 39, 04023045. [Google Scholar] [CrossRef]

- Zhan, W.; Pan, W.; Law, W.; Shen, H. Stakeholders’ Knowledge, Attitudes, and Intentions of Adopting Modular Integrated Construction for Sustainable Development in Hong Kong. J. Manag. Eng. 2024, 40, 04023070. [Google Scholar] [CrossRef]

- Arshad, H.; Zayed, T. Critical Influencing Factors of Supply Chain Management for Modular Integrated Construction. Autom. Constr. 2022, 144, 104612. [Google Scholar] [CrossRef]

- Doran, D.; Giannakis, M. An Examination of a Modular Supply Chain: A Construction Sector Perspective. Supply Chain Manag. Int. J. 2011, 16, 260–270. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, W. Lean Modular Integrated Construction Production Phase Planning under Uncertainties: A Big Data–Driven Optimization Approach. J. Constr. Eng. Manag. 2024, 150, 04024048. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, M.; Pan, W.; Yang, Y.; Wu, J. Enhancing Modular Construction Supply Chain: Drivers, Opportunities, Constraints, Concerns, Strategies, and Measures. Dev. Built Environ. 2024, 18, 100408. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. IoT-BIM and Blockchain Integration for Enhanced Data Traceability in Offsite Manufacturing. Autom. Constr. 2024, 159, 105266. [Google Scholar] [CrossRef]

- Chen, C.; Dong, C.; Ng, C.T.; Shi, X. Operations Strategy for a Construction Supply Chain: Modular Integrated Construction and Blockchain Adoption. Int. Trans. Oper. Res. 2024, 31, 3999–4024. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Kang, K.; Wang, Z.; Zhong, R.Y.; Huang, G.Q. Blockchain-Enabled Cyber-Physical Smart Modular Integrated Construction. Comput. Ind. 2021, 133, 103553. [Google Scholar] [CrossRef]

- Wu, L.; Lu, W.; Xue, F.; Li, X.; Zhao, R.; Tang, M. Linking Permissioned Blockchain to Internet of Things (IoT)-BIM Platform for off-Site Production Management in Modular Construction. Comput. Ind. 2022, 135, 103573. [Google Scholar] [CrossRef]

- Chen, Q.; Hall, D.M.; Adey, B.T.; Haas, C.T. Identifying Enablers for Coordination across Construction Supply Chain Processes: A Systematic Literature Review. Eng. Constr. Archit. Manag. 2021, 28, 1083–1113. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Lee, E.W.M.; Chan, R.; Hosseini, M.R. Analysis of Interacting Uncertainties in On-Site and off-Site Activities: Implications for Hybrid Construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Eastman, C.M.; Sacks, R. Relative Productivity in the AEC Industries in the United States for On-Site and Off-Site Activities. J. Constr. Eng. Manag. 2008, 134, 517–526. [Google Scholar] [CrossRef]

- Goh, M.; Goh, Y.M. Lean Production Theory-Based Simulation of Modular Construction Processes. Autom. Constr. 2019, 101, 227–244. [Google Scholar] [CrossRef]

- Wu, H.; Li, H.; Luo, X.; Jiang, S. Blockchain-Based on-Site Activity Management for Smart Construction Process Quality Traceability. IEEE Internet Things J. 2023, 10, 21554–21565. [Google Scholar] [CrossRef]

- Almashaqbeh, M.; El-Rayes, K. Minimizing Transportation Cost of Prefabricated Modules in Modular Construction Projects. Eng. Constr. Archit. Manag. 2022, 29, 3847–3867. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Angeloudis, P.; Aurisicchio, M. Optimal Logistics Planning for Modular Construction Using Two-Stage Stochastic Programming. Autom. Constr. 2018, 94, 47–61. [Google Scholar] [CrossRef]

- van Groesen, W.; Pauwels, P. Tracking Prefabricated Assets and Compliance Using Quick Response (QR) Codes, Blockchain and Smart Contract Technology. Autom. Constr. 2022, 141, 104420. [Google Scholar] [CrossRef]

- Hamledari, H.; Fischer, M. Construction Payment Automation Using Blockchain-Enabled Smart Contracts and Robotic Reality Capture Technologies. Autom. Constr. 2021, 132, 103926. [Google Scholar] [CrossRef]

- Yang, R.; Wakefield, R.; Lyu, S.; Jayasuriya, S.; Han, F.; Yi, X.; Yang, X.; Amarasinghe, G.; Chen, S. Public and Private Blockchain in Construction Business Process and Information Integration. Autom. Constr. 2020, 118, 103276. [Google Scholar] [CrossRef]

- Qian, X.; Papadonikolaki, E. Shifting Trust in Construction Supply Chains through Blockchain Technology. Eng. Constr. Archit. Manag. 2021, 28, 584–602. [Google Scholar] [CrossRef]

- Tezel, A.; Papadonikolaki, E.; Yitmen, I.; Hilletofth, P. Preparing Construction Supply Chains for Blockchain Technology: An Investigation of Its Potential and Future Directions. Front. Eng. Manag. 2020, 7, 547–563. [Google Scholar] [CrossRef]

- Sangari, M.S.; Mashatan, A. A Data-Driven, Comparative Review of the Academic Literature and News Media on Blockchain-Enabled Supply Chain Management: Trends, Gaps, and Research Needs. Comput. Ind. 2022, 143, 103769. [Google Scholar] [CrossRef]

- Celik, Y.; Petri, I.; Rezgui, Y. Integrating BIM and Blockchain across Construction Lifecycle and Supply Chains. Comput. Ind. 2023, 148, 103886. [Google Scholar] [CrossRef]

- Lu, W.; Wu, L. A Blockchain-Based Deployment Framework for Protecting Building Design Intellectual Property Rights in Collaborative Digital Environments. Comput. Ind. 2024, 159–160, 104098. [Google Scholar] [CrossRef]

- Reijers, H.A. Business Process Management: The Evolution of a Discipline. Comput. Ind. 2021, 126, 103404. [Google Scholar] [CrossRef]

- Alimoğlu, A.; Özturan, C. An Autonomous Blockchain-based Computational Broker for E-science. Concurr. Comput. 2024, 36, e8087. [Google Scholar] [CrossRef]

- Kang, G.; Cheng, H.; Liu, J.; Wen, Y.; Peng, J. Business Process Modeling for Industrial Internet Application via BPMN Extension. IEEE Trans. Autom. Sci. Eng. 2025, 22, 813–829. [Google Scholar] [CrossRef]

- López-Pintado, O.; Dumas, M.; García-Bañuelos, L.; Weber, I. Controlled Flexibility in Blockchain-Based Collaborative Business Processes. Inf. Syst. 2022, 104, 101622. [Google Scholar] [CrossRef]

- Mertens, D.; Kim, J.; Xu, J.; Kim, E.; Lee, C. Smart Flow: A Provenance-Supported Smart Contract Workflow Architecture. Clust. Comput. 2024, 27, 8173–8187. [Google Scholar] [CrossRef]

- Pham, V.H.S.; Vo, T.T.; Dang, N.T.N. Applying Blockchain Technology in Smart Contracts for Construction Payment: A Comprehensive Solution for Lumpsum Contracts. Asian J. Civ. Eng. 2024, 25, 3549–3564. [Google Scholar] [CrossRef]

- Yoon, J.H.; Aurangzeb, I.; McNamara, S. BIM- and Blockchain-Enabled Automatic Procurement System (BBAPS) Removing Relationship Bias. Autom. Constr. 2024, 168, 105779. [Google Scholar] [CrossRef]

- Agostinelli, S.; Hohenadl, T.; Marrella, A.; Martínez-Rojas, A. SmartRPA: Generating Software Robots from User Interface Logs. SoftwareX 2025, 29, 101995. [Google Scholar] [CrossRef]

- Cabello Ruiz, R.; Jiménez Ramírez, A.; Escalona Cuaresma, M.J.; González Enríquez, J. Hybridizing Humans and Robots: An RPA Horizon Envisaged from the Trenches. Comput. Ind. 2022, 138, 103615. [Google Scholar] [CrossRef]

- Nielsen, I.E.; Piyatilake, A.; Thibbotuwawa, A.; Silva, M.M.D.; Bocewicz, G.; Banaszak, Z.A. Benefits Realization of Robotic Process Automation (RPA) Initiatives in Supply Chains. IEEE Access 2023, 11, 37623–37636. [Google Scholar] [CrossRef]

- Syed, R.; Suriadi, S.; Adams, M.; Bandara, W.; Leemans, S.J.J.; Ouyang, C.; ter Hofstede, A.H.M.; van de Weerd, I.; Wynn, M.T.; Reijers, H.A. Robotic Process Automation: Contemporary Themes and Challenges. Comput. Ind. 2020, 115, 103162. [Google Scholar] [CrossRef]

- Afrin, S.; Roksana, S.; Akram, R. AI-Enhanced Robotic Process Automation: A Review of Intelligent Automation Innovations. IEEE Access 2024, 13, 173–197. [Google Scholar] [CrossRef]

- Chakraborty, A.; Bhattacharyya, S.; De, D.; Mahmud, M.; Banerjee, J.S. Intelligent Automation Framework Using AI and RPA: An Introduction. In Confluence of Artificial Intelligence and Robotic Process Automation; Bhattacharyya, S., Banerjee, J.S., De, D., Eds.; Springer Nature: Singapore, 2023; pp. 1–13. ISBN 978-981-19-8296-5. [Google Scholar]

- Kanakov, F.; Prokhorov, I. Analysis and Applicability of Artificial Intelligence Technologies in the Field of RPA Software Robots for Automating Business Processes. Procedia Comput. Sci. 2022, 213, 296–300. [Google Scholar] [CrossRef]

- Zeng, N.; Han, L.; Liu, Y.; Yuan, J.; Li, Q. Design Science Research (DSR) in Construction: Theoretical Conceptualization of Practice and Practical Realization of Theory. Autom. Constr. 2025, 176, 106298. [Google Scholar] [CrossRef]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design Science in Information Systems Research. MIS Q. 2004, 28, 75–105. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).