2.1. Mathematical Model

Assuming the density of the gas within the pulverizer remains constant, the gas can be regarded as an incompressible fluid. This is in accordance with the fundamental principles of mass, momentum, and energy conservation. For incompressible fluids, energy conservation does not consider thermodynamic energy conversion. This can be derived by integrating the conservation of mass with the conservation of momentum.

Bidirectional coupling generates interactions between the particle phase and the fluid phase. Coupling control equations are established between the two phases by introducing an interphase momentum term. These equations can be categorized into fluid-phase control equations and particle-phase control equations, which, respectively, describe the coupled behavior between the two phases.

- (1)

Mass Conservation Governing Equation

The principle of mass conservation in fluid dynamics dictates that the temporal rate of mass accumulation within a differential fluid element must equal the net mass flux across its boundaries. This fundamental law, mathematically formalized as the continuity equation, governs fluid motion through the following expressions:

, where

is a constant; the governing mass conservation equation for the multiphase flow within the pulverization chamber can be reduced to the following simplified form:

where

is fluid density,

is the flow time,

,

uy,

uz are the components of the fluid velocity in the direction of

,

and

.

- (2)

Momentum Conservation Control Equation

The momentum conservation principle in fluid systems establishes that the temporal variation in momentum of a discrete fluid element precisely corresponds to the resultant of surface forces acting on its boundaries and body forces distributed throughout its volume. The momentum conservation control equation can be expressed as follows:

where

is hydrostatic pressure acting on the fluid element,

is viscous stress tensor components (

i =

n: normal direction,

j =

t: tangential direction),

,

Fy, and

are cartesian components of body force per unit mass.

- (3)

The interaction between straw particles and the gas flow generates a momentum source, which can be expressed as follows:

where

is the force exerted by straw pellets on the airflow,

is the volume of the fluid element mesh.

Further analysis of the particle-phase control equations reveals that the motion of straw particles within the crushing chamber primarily consists of translational and rotational components. According to Newton’s second law, these motions can be described as follows:

where

is the mass of the straw particle, kg;

is the velocity of the straw particle, m/s;

is the contact force acting on the straw particle, N;

is the force exerted by the airflow on the straw particle, N;

is the rotational inertia of the straw particle, kg·m

2;

is the angular velocity of the straw particle, rad/s;

is the torque generated by the contact force, N·m;

is the torque generated by the airflow acting on the straw particle, N·m.

The forces exerted by airflow on straw particles manifest as drag force, pressure gradient force, and Magnus force, among others [

20,

21,

22]. Among these, drag force represents the primary force exerted by airflow on straw particles. This study adopts the widely applicable free-stream drag model. The free-stream drag model expression is as follows:

where

is the drag coefficient;

is the particle diameter, m;

is the air density, taken as 1.29 kg/m

3.

The contact force model selected for straw particles is the Hertz–Mindlin with bonding model. The crushing process involves the gradual reduction in straw particle size, and the Hertz–Mindlin with bonding model is derived from the Hertz–Mindlin (no slip) contact model [

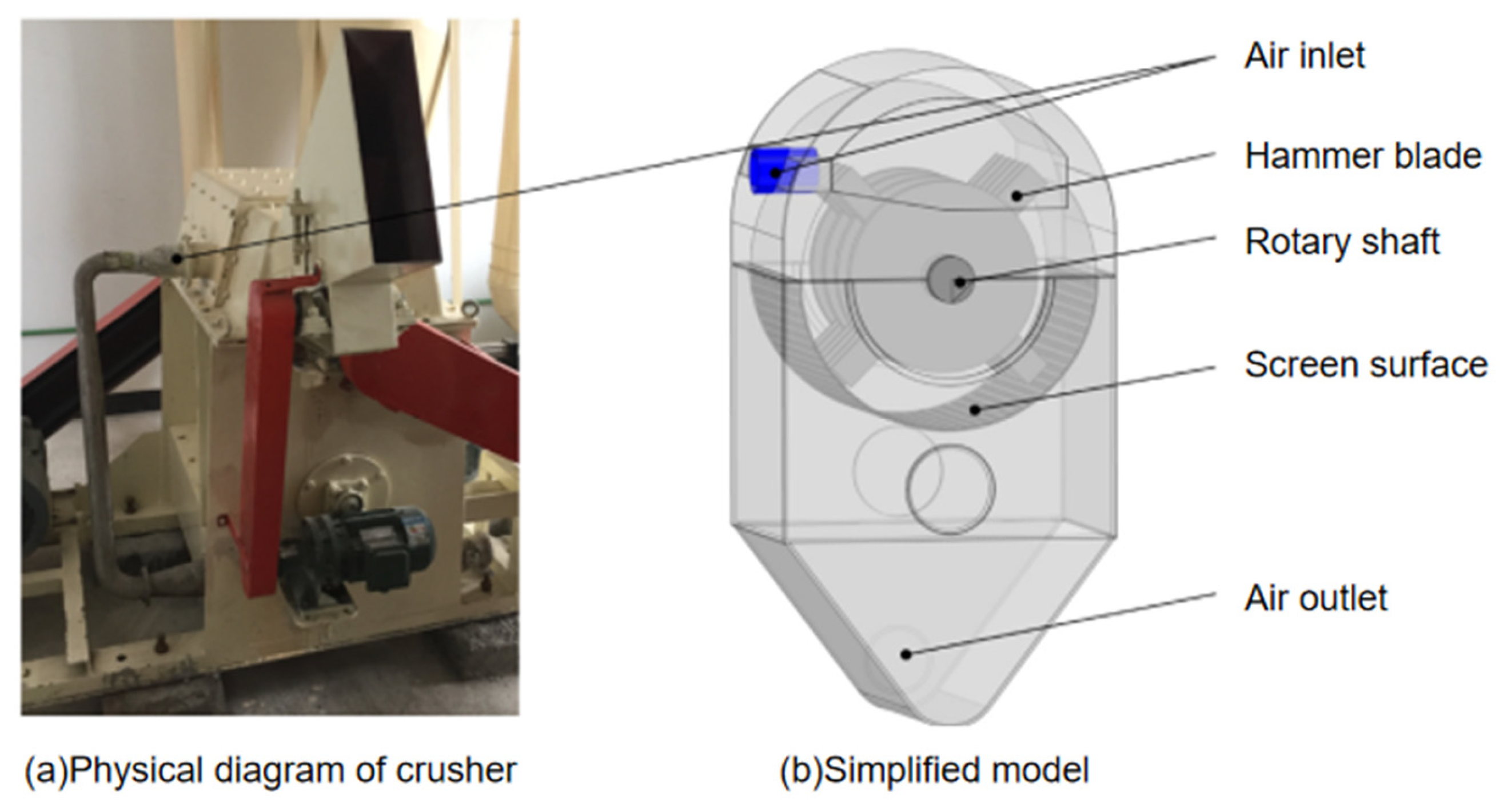

23]. Building upon the calculation of fundamental contact forces between particles, it establishes parallel bonding between adjacent particle contact points, forming adhesive bonds that generate forces and moments between particles, as shown in

Figure 1. When these adhesive bonds are disrupted by external forces, they do not reconnect. The simulation of fragmentation and fracture phenomena is achieved through the breaking of these adhesive bonds. The forces and moments acting on the adhesive bonds are as follows:

where

,

are the tangential and normal cohesive force, N;

,

are the tangential and normal cohesive stress moment, N·m;

are the particle tangential and normal velocity, m/s;

are the unit area tangential and normal stiffness, N/m;

is the cohesive bond cross-sectional area, m

2;

is the moment of inertia, kg·m

2;

is the time step, s;

is the bond radius, m.

When the external force acting on the adhesive bond exceeds the critical stress in the tangential and normal directions, the adhesive bond will fracture, which can be expressed as follows:

Among these, and represent the critical stress in the tangential and normal directions, Pa.

2.3. Turbulence Model

Fluid flow regimes can be classified into three distinct categories: laminar, transitional, and turbulent flows, characterized by their respective Reynolds number ranges, velocity profile structures, and energy dissipation mechanisms. The pulverization chamber exhibits a highly transient multiphase flow field dominated by biomass particle–airflow coupling transport phenomena. Non-orthogonal flow channel geometry with heterogeneous boundary conditions induces non-stationary vortex dissipation patterns. Critical Reynolds number analysis (Re > 2000) confirms the fully developed turbulent flow regime, thereby justifying the application of the Reynolds-averaged Navier–Stokes (RANS) turbulence modeling for numerical simulation.

The Reynolds-averaged Navier–Stokes (RANS) methodology employs time-filtering operations to decompose instantaneous flow variables into mean and fluctuating components, establishing the Reynolds stress tensor closure problem. The standard turbulence model, derived from the Boussinesq eddy-viscosity hypothesis with isotropic turbulence dissipation assumptions is selected due to its demonstrated computational robustness in industrial applications involving complex flow separations and recirculation zones.

The standard

model constitutes a two-equation eddy-viscosity closure, where the turbulent kinetic energy (

k) and its dissipation rate (

) are governed by coupled transport equations. For incompressible flows, the system is expressed as follows:

where

is the turbulent Prandtl number for turbulent kinetic energy

k;

is the turbulent Prandtl number for turbulent dissipation rate

;

and

are the flow length and velocity in the direction;

is the production of turbulent kinetic energy due to mean velocity gradients. Following the standard calibration by Launder and Spalding, the values of these constants are adopted as follows:

,

.

2.4. Fluid Domain Model

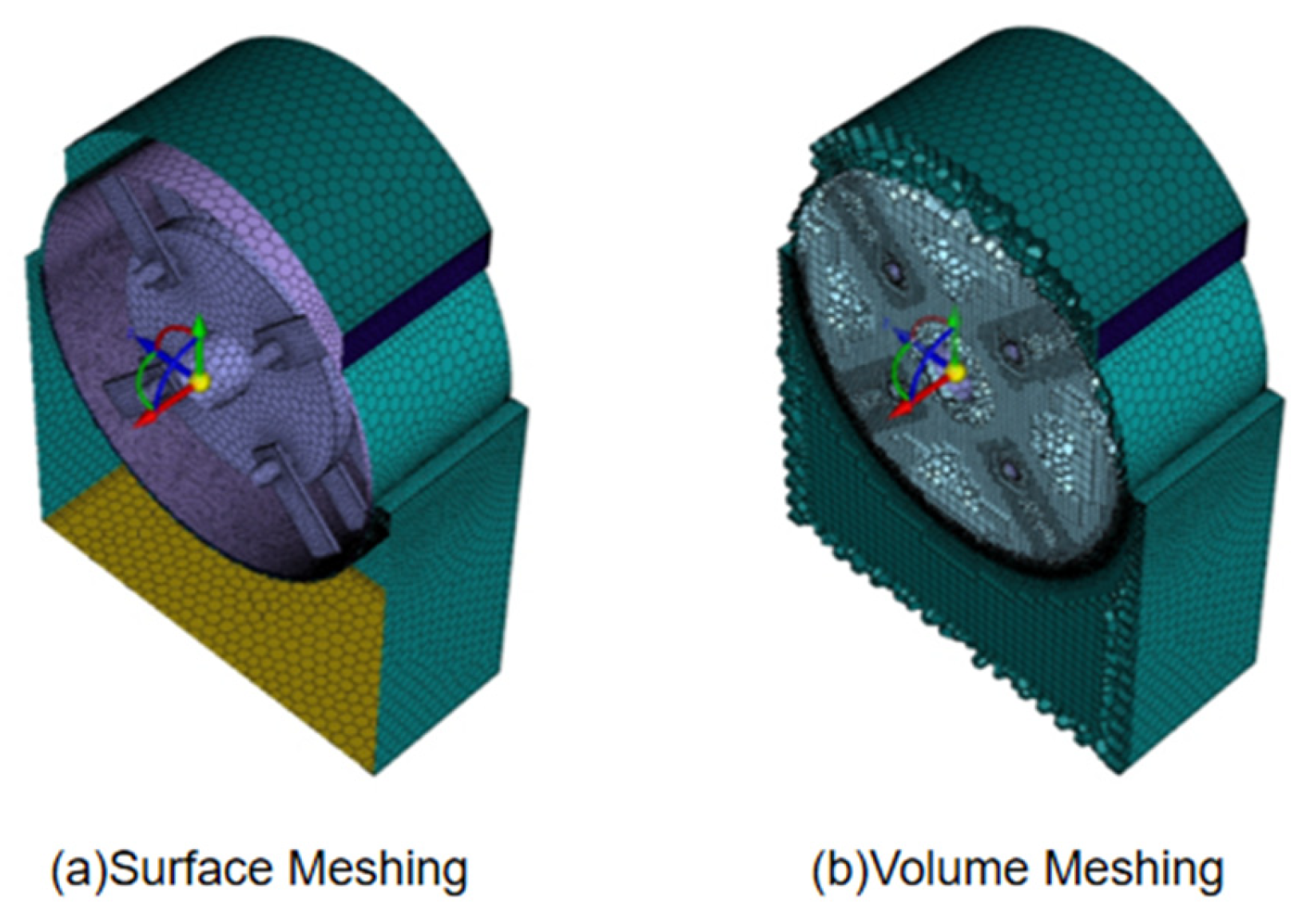

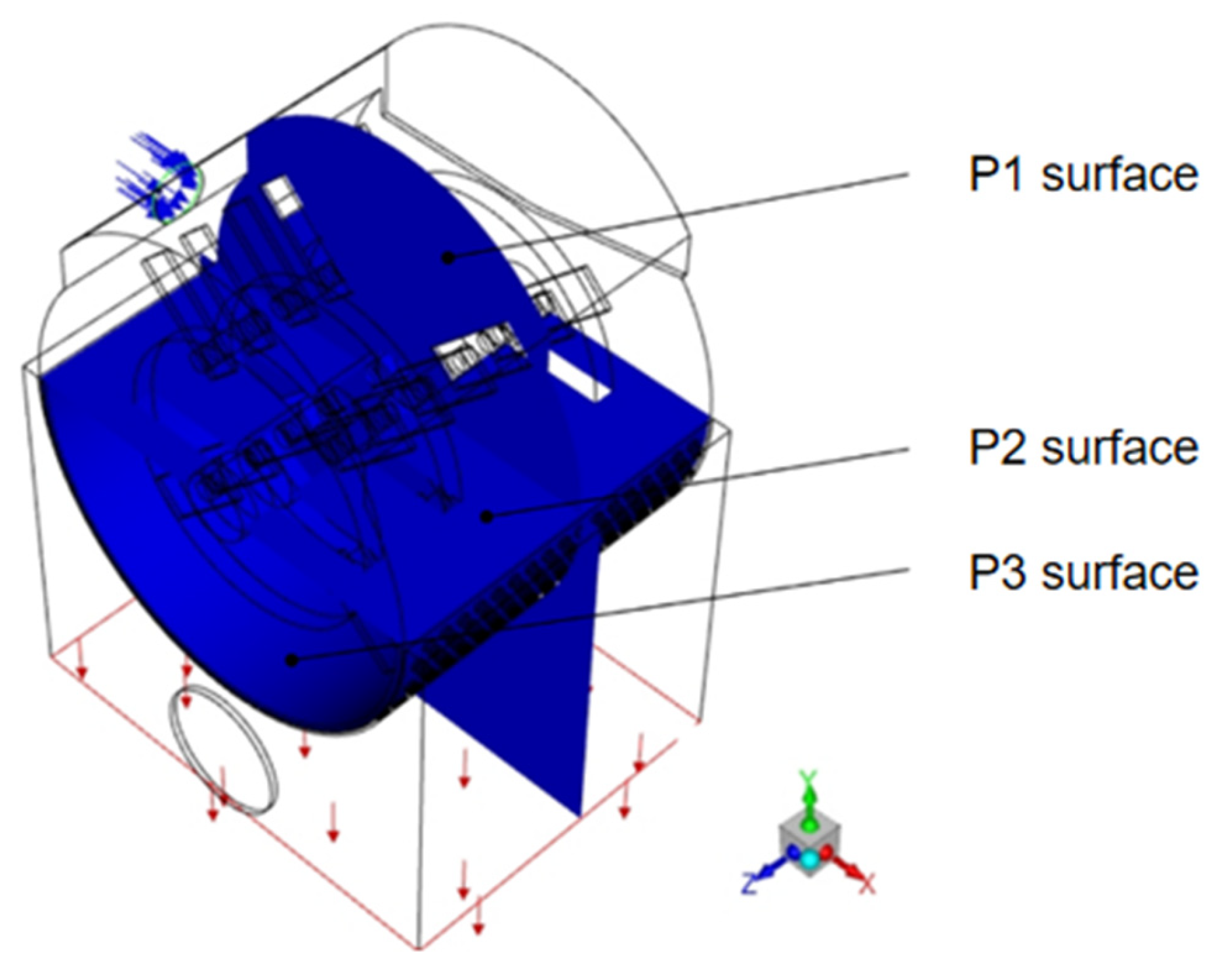

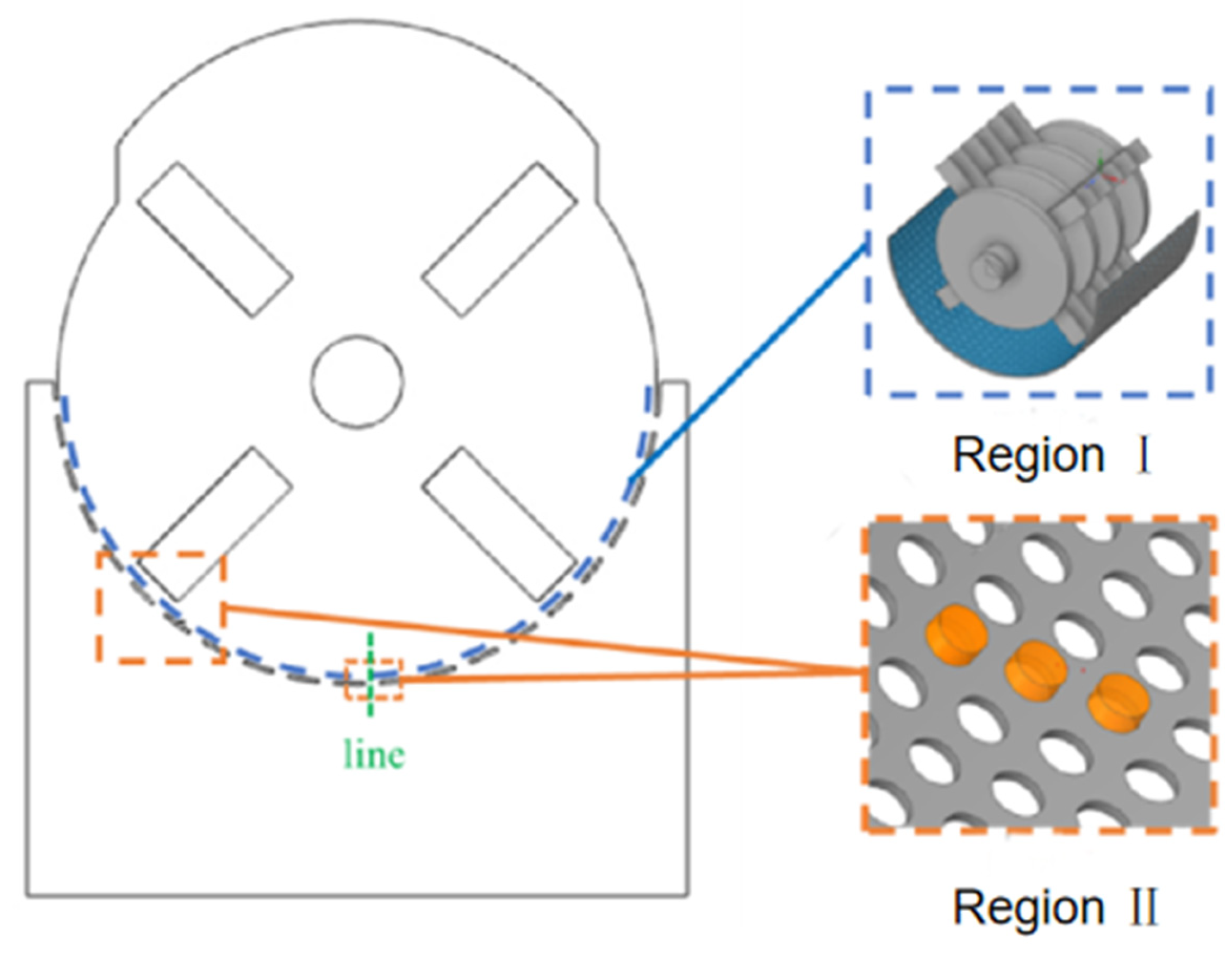

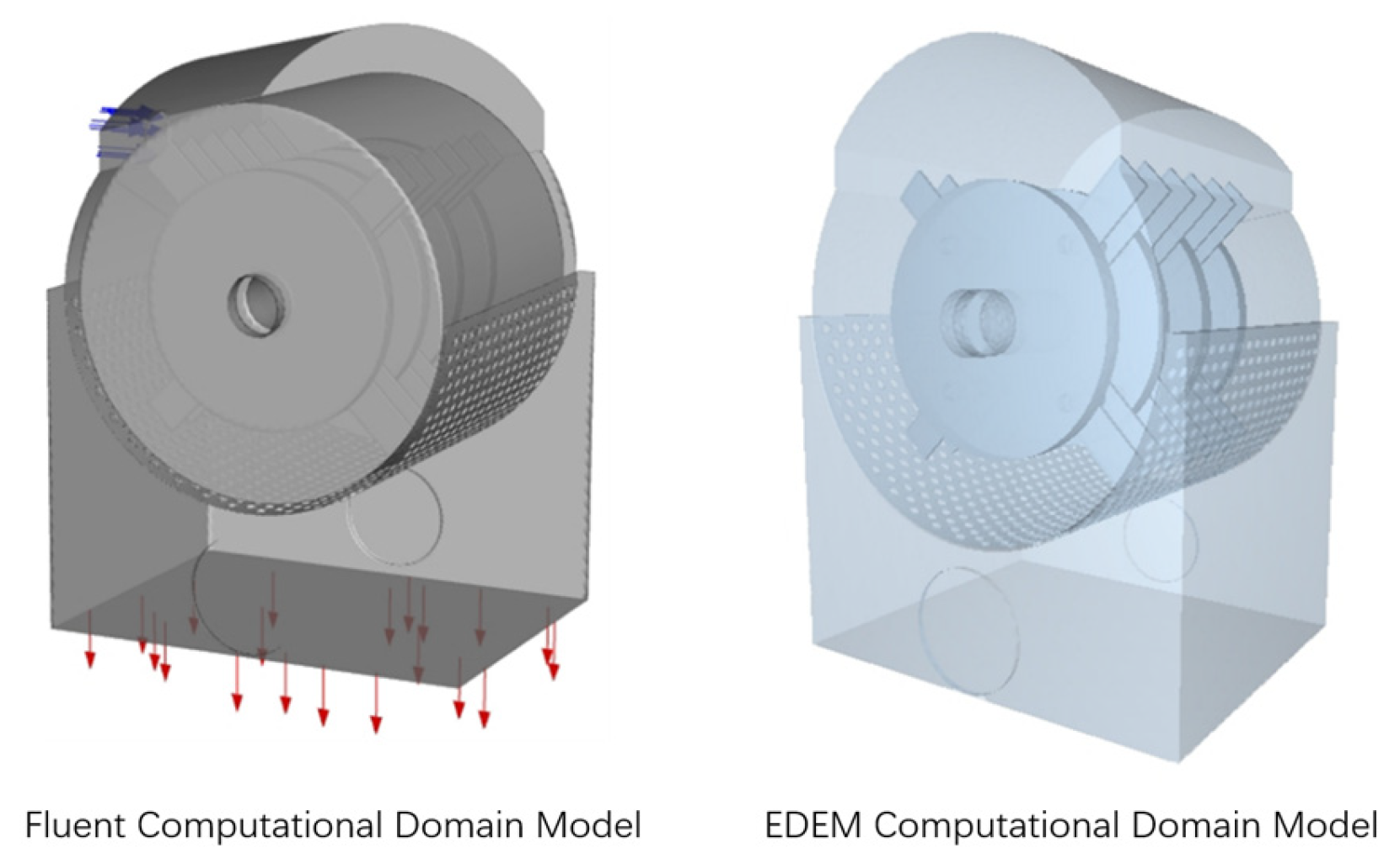

The computational analysis of flow fields necessitates the development of a fluid domain model, which precisely represents the internal airflow dynamics within the comminution chamber of the grinding system. The upper region of the geometric model was designated as the fluid domain, as illustrated in

Figure 3.

The method for extracting the flow field inside the pulverizer geometric model is to save the constructed geometric model in step format, import it into Ansys SpaceClaim 2021 R1 (Ansys, Inc., Canonsburg, PA, USA), and create “Inlet” and “Outlet” boundaries, with the “Inlet” boundary being the air inlet and the “Outlet” boundary being the rectangular area under the sieve, for model closure to extract the fluid field and subsequent solution settings using the Volume Extract function of SpaceClaim. Using the Volume Extract function in SpaceClaim, select the airflow inlet and outlet loop, extract the fluid domain, obtain the undivided fluid domain model, and establish the model coordinate system, the vertical direction as the Y-axis, the pulverizer axis as the Z-axis, and the origin located on the side of the rotary axis, as shown in

Figure 3a.

Classification of the extracted fluid domain into dynamic and static domains. The dynamic domain corresponds to the cylindrical region swept by the rotor’s rotational motion. This cylindrical domain was constructed by aligning its central axis with the rotor’s rotational axis. A Boolean subtraction operation was then executed between the cylindrical volume and the rotor geometry to isolate the dynamic fluid domain, as depicted in

Figure 3b. The resultant dynamic domain strictly adheres to the spatial envelope defined by the rotor’s rotation about its central axis. The static domain model was obtained by performing a Boolean subtraction operation between the global fluid domain and the dynamic subdomain (which encompasses the rotor-swept cylindrical region). This process excluded the rotating components, yielding the stationary fluid volume as illustrated in

Figure 3c. Interface surfaces were established between the dynamic and static domains to enforce flow field continuity and facilitate robust data transfer of nodal solutions.