Assessment of Formation Damage in Carbonate Rocks: Isolated Contribution of Filtration Control Agents in Aqueous Fluids

Featured Application

Abstract

1. Introduction

2. Materials and Methods

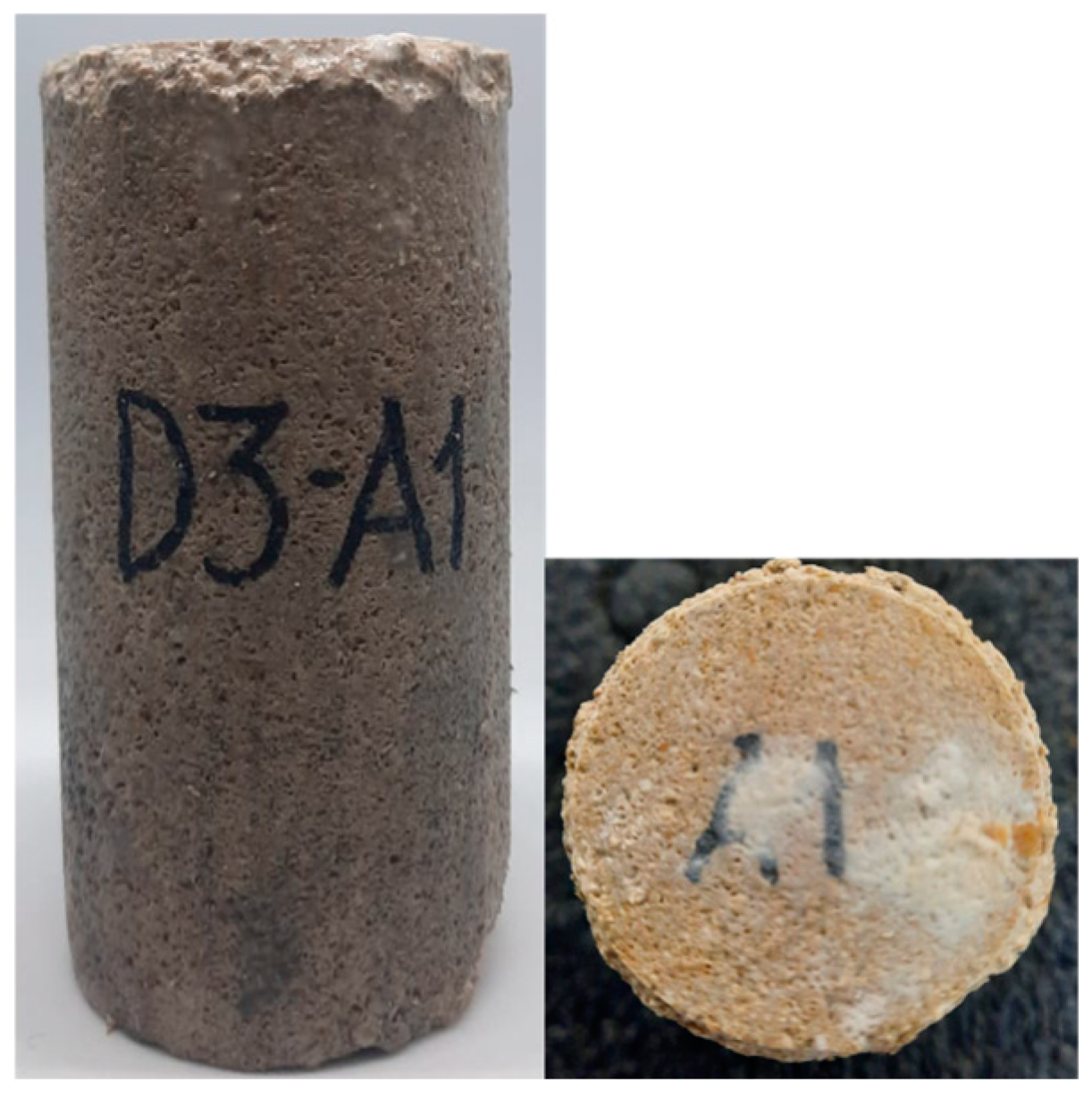

2.1. Petrophysical Characterization of the Rocks

2.2. Polymeric Fluid Preparation

2.3. Preparation of Solutions

2.4. Apparent Viscosity (η)

2.5. Return Permeability Tests (Core Flooding)

3. Results

3.1. Apparent Viscosity of Polymeric Fluid and Solutions and Return Permeability Tests

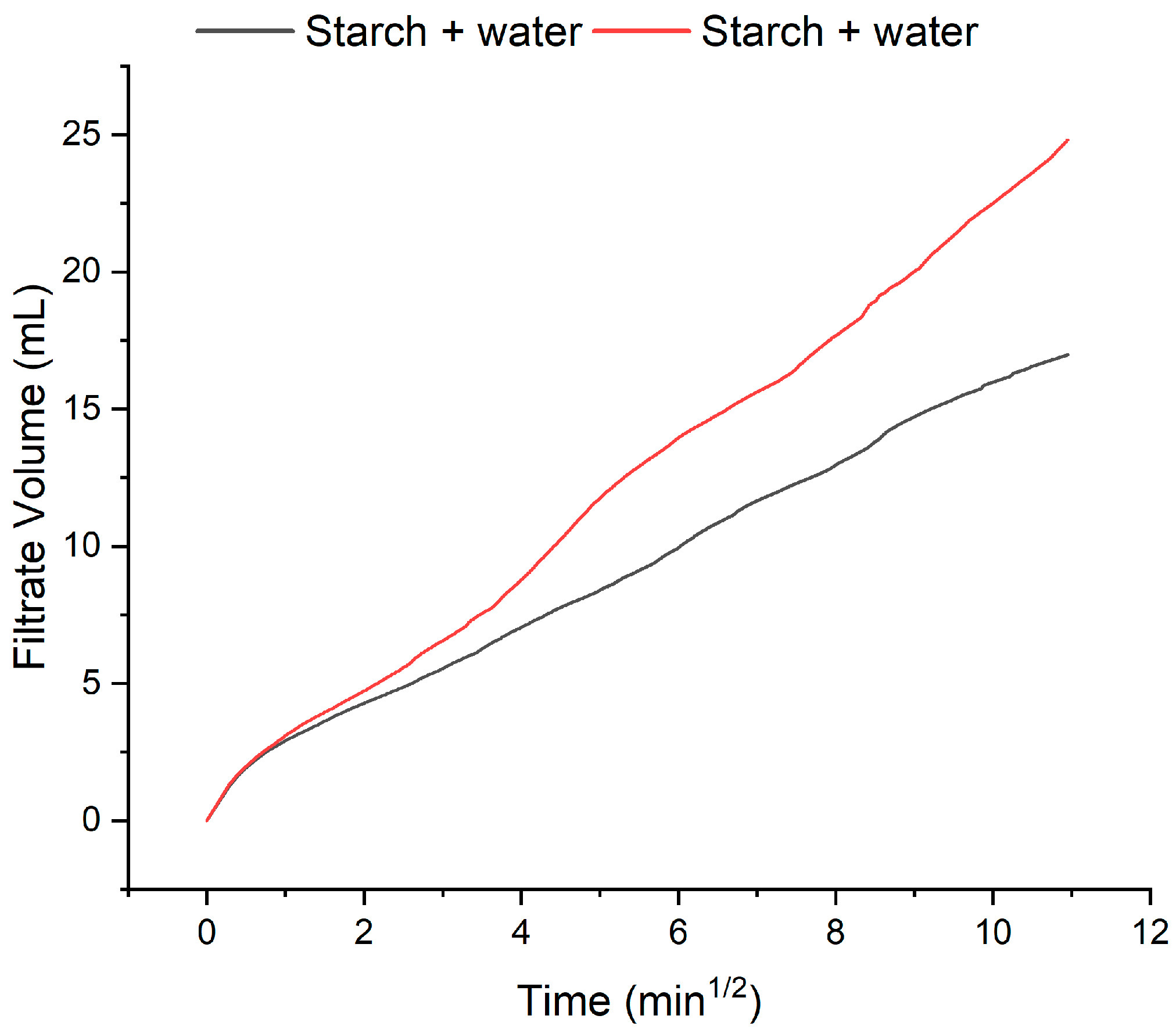

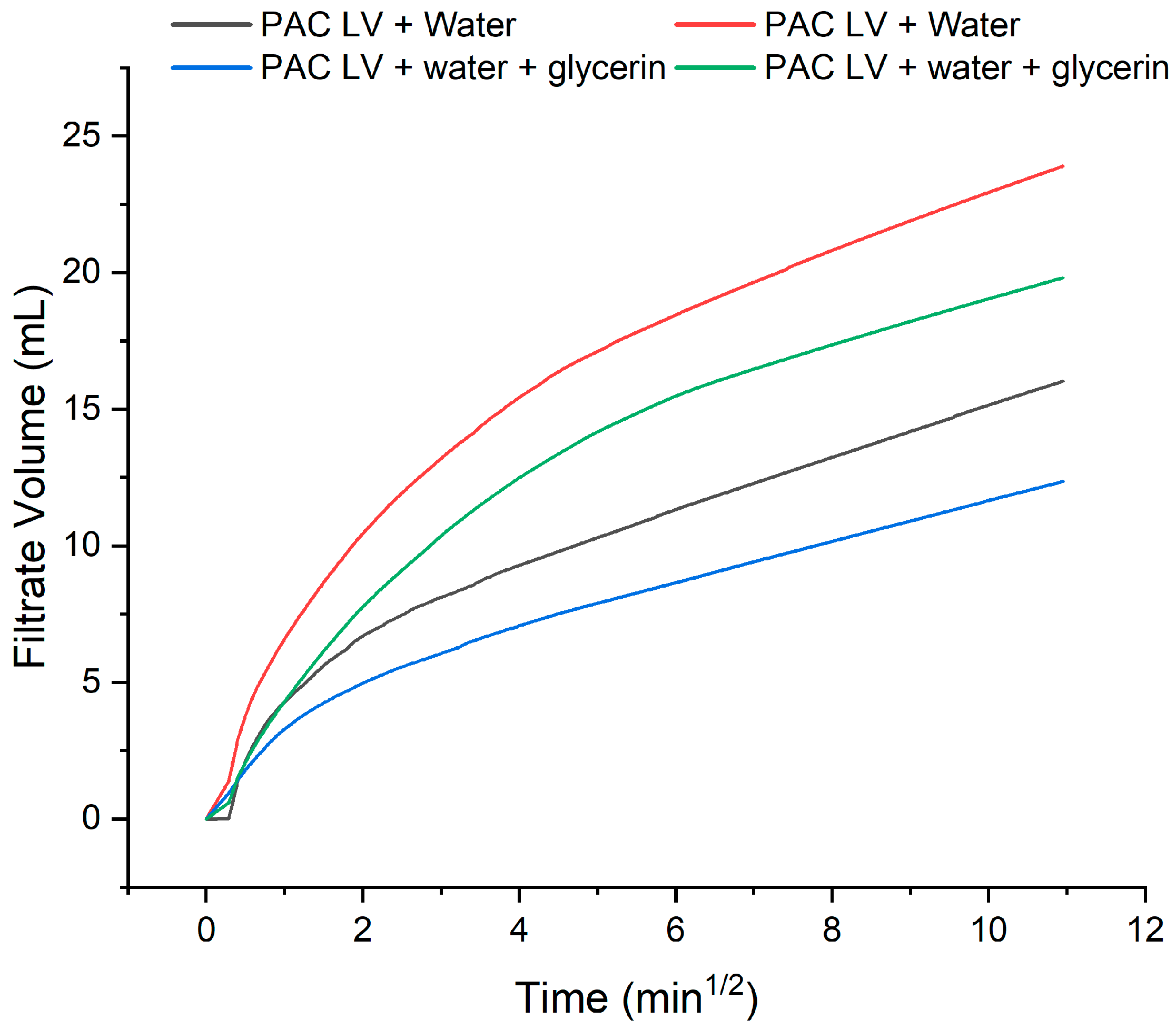

3.2. Filtration Curves

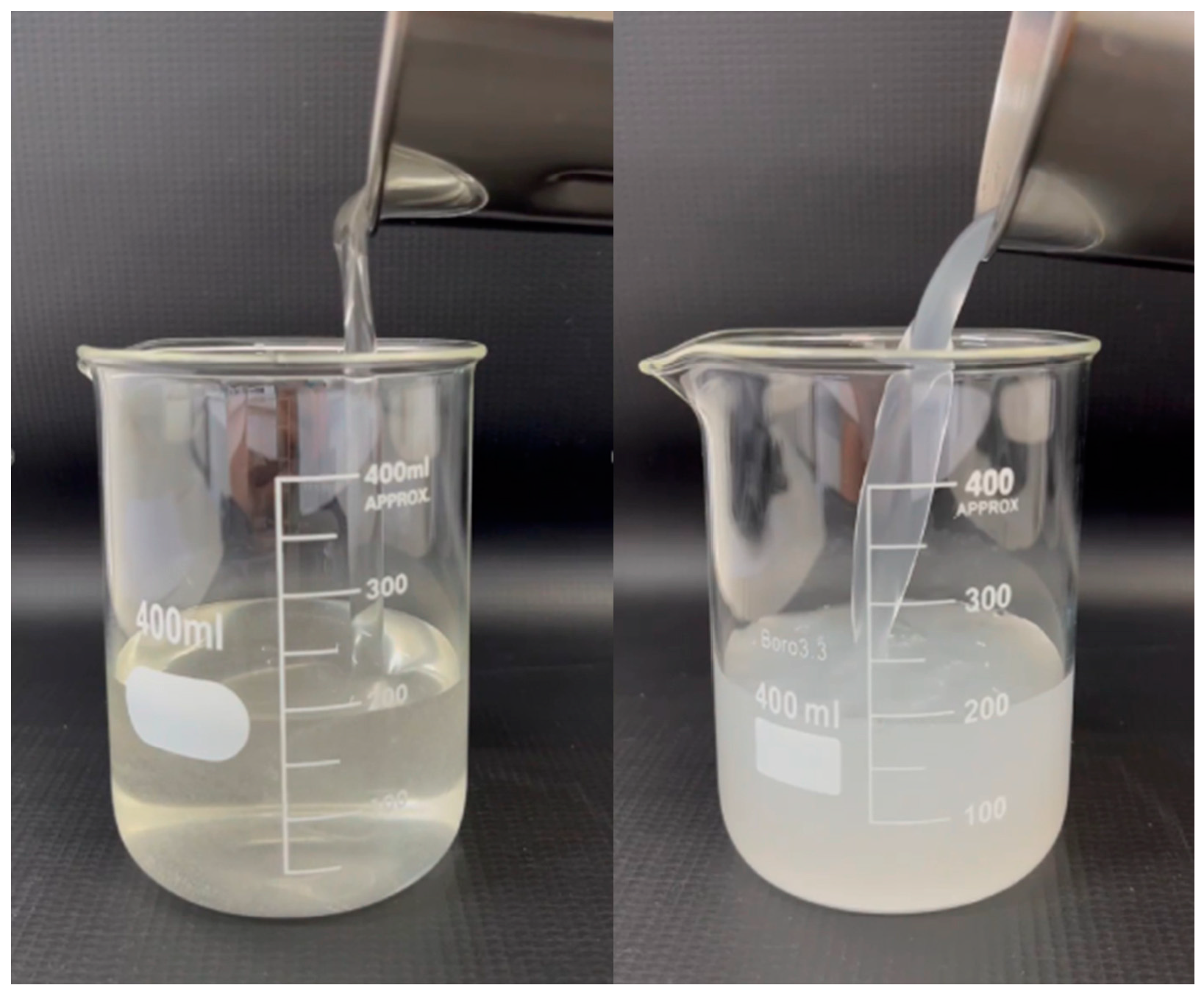

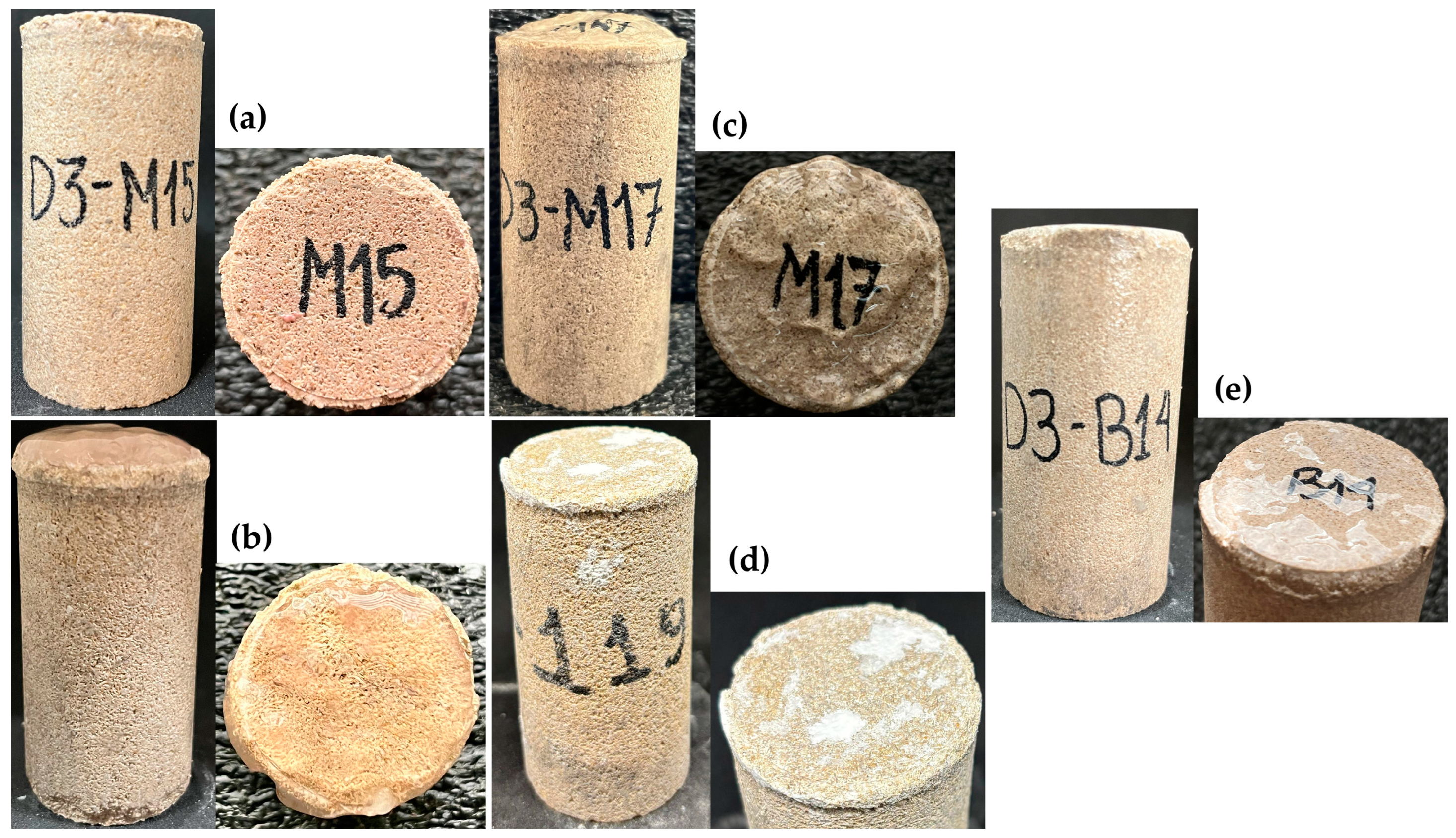

3.3. Visual Inspection Results

4. Discussion

4.1. Apparent Viscosity of Polymeric Fluid and Solutions and Return Permeability Tests

4.2. Filtration Curves

4.3. Discussion of Visual Inspection Results

5. Conclusions

- The presence of glycerin in the solutions of polymeric fluid components promoted an increase in system viscosity but did not exert a significant influence on formation damage.

- The HPA starch polymer solution exhibited lower apparent viscosity, higher filtrate volumes, and more severe formation damage. These findings reinforce that the use of this material does not represent a suitable alternative to PAC LV in the formulation of fluids intended for direct contact with the reservoir, given its inferior performance and high potential to induce formation damage.

- The addition of micronized calcite, in synergy with PAC LV and glycerin, contributed to reducing formation damage and achieving more efficient filtration control. On average, the presence of calcite (together with PAC LV and glycerin) resulted in approximately 70% lower filtrate volume and 54% lower formation damage compared with the PAC LV + water + glycerin system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, B.; Liu, X.; Tan, X. Well Workover. In Petroleum Production Engineering, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2017; Chapter 15. [Google Scholar]

- Riley, S.M.; Potter, G.F.; Holmes, J.M.; Reeves, H.C., III. Controlling incompatibilities of formation and kill-weight fluids during workover. In Proceedings of the 59th Annual Conference and Exhibition of the Society of Petroleum Engineers, Houston, TX, USA, 16–19 September 1984. [Google Scholar]

- M-I SWACO. Basic Mud School Presentation Manual; M-I SWACO: Houston, TX, USA, 2013; pp. 1–13. [Google Scholar]

- Liu, X.; Yuan, Z.; Wang, A.; Wang, C.; Qu, J.; Chen, B.; Wei, B.; Kapu, N.S.; Wen, Y. Cellulose nano-fibril-polymer hybrids for protecting drilling fluid at high salinity and high temperature. Carbohydr. Polym. 2020, 229, 115516. [Google Scholar] [CrossRef] [PubMed]

- Qun, L.; Yiliang, L.; Tao, L.; Hui, L.; Baoshan, G.; Guoqiang, B.; Jialu, W.; Dingwei, W.; Shouzhi, H.; Weiye, H. Technical status and development direction of workover operation of PetroChina. Pet. Explor. Dev. 2020, 47, 161–170. [Google Scholar] [CrossRef]

- Beltrão, R.L.C.; Sombra, C.L.; Lage, A.C.V.M.; Netto, J.R.F.; Henriques, C.C.D. Pre-salt Santos basin—Challenges and new technologies for the development of the pre-salt cluster, Santos Basin, Brazil. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009. [Google Scholar]

- Thomas, D.C. Thermal stability of starch- and carboxymethyl cellulose-based polymers used in drilling fluids. Soc. Pet. Eng. J. 1982, 22, 171–180. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Yao, J.; Zhang, K.; Iglauer, S.; Linda, L.; Wang, Z. Formation damage evaluation of a sandstone reservoir via pore-scale X-ray computed tomography analysis. J. Pet. Sci. Eng. 2019, 183, 106420. [Google Scholar] [CrossRef]

- Maxey, M.R.; van Zanten, R. Filter cake deposition mechanisms and modeling in drilling and completion fluids. SPE Drill. Complet. 2012, 27, 552–563. [Google Scholar]

- Klungtvedt, K.R.; Saasen, A. A method for assessing drilling fluid induced formation damage in permeable formations using ceramic discs. J. Pet. Sci. Eng. 2022, 213, 110324. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, Z. Research Status and Development Direction of Formation Damage Prediction and Diagnosis Technologies. Appl. Sci. 2025, 15, 1169. [Google Scholar] [CrossRef]

- Barbosa, F.L.V.; Oliveira, G.V.B.; Silva Filho, E.D.; Arruda, G.M.; Nóbrega, A.M.; Robaina, P.P.S.; Camargo Júnior, S.T.; Rodrigues, M.A.F.; Wanderley Neto, A.O. Effect of drilling mud circulation and reservoir parameters on formation damage in carbonate reservoirs. Fuel 2025, 405, 136706. [Google Scholar] [CrossRef]

- Olalla, A.S.; Talavera, V.H.; García, D.L.; Torres, E.G.; García, M.F. Glycerol-based enzymatically synthesized renewable polyesters: Control of molecular weight, degree of branching and functional end groups. Eur. Polym. J. 2022, 170, 111173. [Google Scholar] [CrossRef]

- Lipton, D.; Burnett, D.B. Comparisons of polymers used in workover and completion fluids. In Proceedings of the SPE California Regional Meeting, Long Beach, CA, USA, 24–26 March 1976. [Google Scholar]

- Audibert, A.; Argillier, J.; Ladva, H.K.J.; Way, P.W.; Hove, A.O. Role of polymers on formation damage. In Proceedings of the SPE European Formation Damage Conference, The Hague, The Netherlands, 15–16 June 1999. [Google Scholar]

- Ezell, R.; Harrison, D.J. Design of improved high-density, thermally stable drill-in fluid for HTHP applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Caenn, R.; Darley, H.C.H.; Gray, G.R. Composition and Properties of Drilling and Completion Fluids, 7th ed.; Gulf Professional Publishing: Houston, TX, USA, 2017; pp. 245–283. [Google Scholar]

- Ghazali, N.A.; Alias, N.H.; Mohd, T.A.T.; Adeib, S.I.; Noorsuhana, M.Y. Potential of corn starch as fluid loss control agent in drilling mud. Appl. Mech. Mater. 2015, 754–755, 682–687. [Google Scholar] [CrossRef]

- Neto, Q.; Ribeiro, B.; Lopes, R.T.; Anjos, M.J.; Bianco, B.; Coelho, M.V. Characterization of the invasion profile and its components due to drilling fluid mudcake filtration, using the synchrotron light X-ray fluorescence. In Proceedings of the SPE European Formation Damage Conference, Scheveningen, The Netherlands, 25–27 May 2005. [Google Scholar]

- Kafashi, S.; Rasaei, M.; Karim, G. Effects of sugarcane and polyanionic cellulose on rheological properties of drilling mud: An experimental approach. Egypt. J. Pet. 2017, 26, 371–374. [Google Scholar] [CrossRef]

- Fang, Q.; Zhao, X.; Sun, H.; Wang, Z.; Qiu, Z.; Shan, K.; Ren, X. Formation-damage mechanism and gel-breaker-free drill-in fluid for carbonate reservoir. Gels 2022, 8, 565. [Google Scholar] [CrossRef] [PubMed]

- Bilck, A.P.; Müller, C.M.O.; Olivato, J.B.; Mali, S.; Grossmann, M.V.E.; Yamashita, F. Using glycerol produced from biodiesel as a plasticiser in extruded biodegradable films. Polímeros 2015, 25, 331–335. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Khalina, A. Effect of glycerol plasticizer loading on the physical, mechanical, thermal, and barrier properties of arrowroot (Maranta arundinacea) starch biopolymers. Sci. Rep. 2021, 11, 13900. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Silva, D.; Dare, A.; Saasen, A.; Alsafran, A. Optimization of calcium carbonate particles and pH in oil-based drilling fluids to minimize barite sag. In Proceedings of the AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 12–13 April 2016. [Google Scholar]

- Talukdar, P.; Gogoi, S.B. A study on the role of pre-gelatinized starch (PGS) in the non-damaging drilling fluid (NDDF) for the Tipam sand of Geleki oilfield of Upper Assam Basin. Int. J. Appl. Sci. Biotechnol. 2015, 3, 291–300. [Google Scholar] [CrossRef]

- Silva, S.S.S.; Nóbrega, K.C.; Amorim, L.V.; Lira, H.L. Avaliação de amidos modificados empregados na mineração para aplicação em fluidos de perfuração de poços de petróleo. Matéria 2019, 24, 12409. [Google Scholar] [CrossRef]

- Pacheco, L.V. Estudo da Dissolução de NaCl em Fluidos de Perfuração à Base de Glicerina e Água. Master’s Thesis, Universidade Federal Rural do Rio de Janeiro, Seropédica, Brazil, 2018. [Google Scholar]

- Rocha, L.A.S.; Azevedo, C.T. Projetos de Poços de Petróleo: Geopressões e Assentamento de Colunas de Revestimento; Interciência: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Rahmati, M.; Khosravi, M.; Tanha, A.A.; Albajalan, A.R. Evaluation of formation damage and filter cake removal with a new LPM drilling fluid additive. Results Eng. 2024, 23, 102656. [Google Scholar] [CrossRef]

| Component |

|---|

| Deionized water |

| Antifoam |

| Sodium bicarbonate |

| PAC LV |

| Magnesium oxide |

| Crude glycerin |

| Saturated NaCl brine |

| Sodium hydroxide (to adjust pH = 10) |

| Micronized calcite (1–10 µm) (to adjust density to 10 lb/gal) |

| Glutaraldehyde |

| Solution | Composition |

|---|---|

| Glycerin + water | Crude glycerin 20% v/v |

| PAC LV + water | PAC LV 6 lb/bbl |

| PAC LV + water + glycerin | PAC LV 6 lb/bbl, crude glycerin 20% v/v |

| PAC LV + water + glycerin + calcite | PAC LV 6 lb/bbl, crude glycerin 20% v/v, micronized calcite (1–10 µm) 44.67 lb/gal |

| Starch + water | Hydroxypropyl starch (HPA) 6 lb/bbl |

| Sample | Porosity (%) | k Initial (mD) | k Final (mD) | Formation Damage (%) | Return of Permeability (%) | Filtrate Volume (mL) | Apparent Viscosity (cP) |

|---|---|---|---|---|---|---|---|

| Glycerin + water | 16.93 | 28.56 | 28.56 | 0.0 | 100.0 | 73.0 | 1.76 |

| PAC LV + water | 19.35 | 44.81 | 11.15 | 75.1 | 24.9 | 16.7 | 267.64 |

| 19.56 | 45.51 | 6.59 | 85.5 | 14.5 | 24.2 | ||

| PAC LV + water + glycerin | 16.89 | 26.24 | 6.56 | 75.0 | 25.0 | 13.1 | 358.01 |

| 19.44 | 24.27 | 5.39 | 77.8 | 22.2 | 19.8 | ||

| PAC LV + water + glycerin + calcite | 19.65 | 40.46 | 25.74 | 36.3 | 63.7 | 5.2 | 468.98 |

| 20.35 | 31.05 | 20.26 | 34.7 | 65.3 | 4.8 | ||

| Polymeric fluid | 19.29 | 26.77 | 21.97 | 19.8 | 80.2 | 3.3 | 447.28 |

| 20.54 | 27.89 | 21.29 | 23.7 | 76.3 | 3.0 | ||

| Starch + water | 16.97 | 26.17 | 2.75 | 89.5 | 10.5 | 17.8 | 4.23 |

| 19.58 | 43.47 | 1,32 | 97.0 | 3.0 | 24.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, M.C.d.S.; Romualdo, V.B.; Oliveira, G.V.B.d.; Filho, E.D.d.S.; Nóbrega, K.C.; Costa, A.C.A.; Souza, E.A.d.; Junior, S.T.C.; Rodrigues, M.A.F.; Amorim, L.V. Assessment of Formation Damage in Carbonate Rocks: Isolated Contribution of Filtration Control Agents in Aqueous Fluids. Appl. Sci. 2025, 15, 11572. https://doi.org/10.3390/app152111572

Lima MCdS, Romualdo VB, Oliveira GVBd, Filho EDdS, Nóbrega KC, Costa ACA, Souza EAd, Junior STC, Rodrigues MAF, Amorim LV. Assessment of Formation Damage in Carbonate Rocks: Isolated Contribution of Filtration Control Agents in Aqueous Fluids. Applied Sciences. 2025; 15(21):11572. https://doi.org/10.3390/app152111572

Chicago/Turabian StyleLima, Mário C. de S., Victória B. Romualdo, Gregory V. B. de Oliveira, Ernani D. da S. Filho, Karine C. Nóbrega, Anna C. A. Costa, Elessandre A. de Souza, Sergio T. C. Junior, Marcos A. F. Rodrigues, and Luciana V. Amorim. 2025. "Assessment of Formation Damage in Carbonate Rocks: Isolated Contribution of Filtration Control Agents in Aqueous Fluids" Applied Sciences 15, no. 21: 11572. https://doi.org/10.3390/app152111572

APA StyleLima, M. C. d. S., Romualdo, V. B., Oliveira, G. V. B. d., Filho, E. D. d. S., Nóbrega, K. C., Costa, A. C. A., Souza, E. A. d., Junior, S. T. C., Rodrigues, M. A. F., & Amorim, L. V. (2025). Assessment of Formation Damage in Carbonate Rocks: Isolated Contribution of Filtration Control Agents in Aqueous Fluids. Applied Sciences, 15(21), 11572. https://doi.org/10.3390/app152111572