Carbon Nanotube-Enhanced Silicone Fingerprint Replicas for Biometric Security Testing

Abstract

1. Introduction

2. Materials and Methods

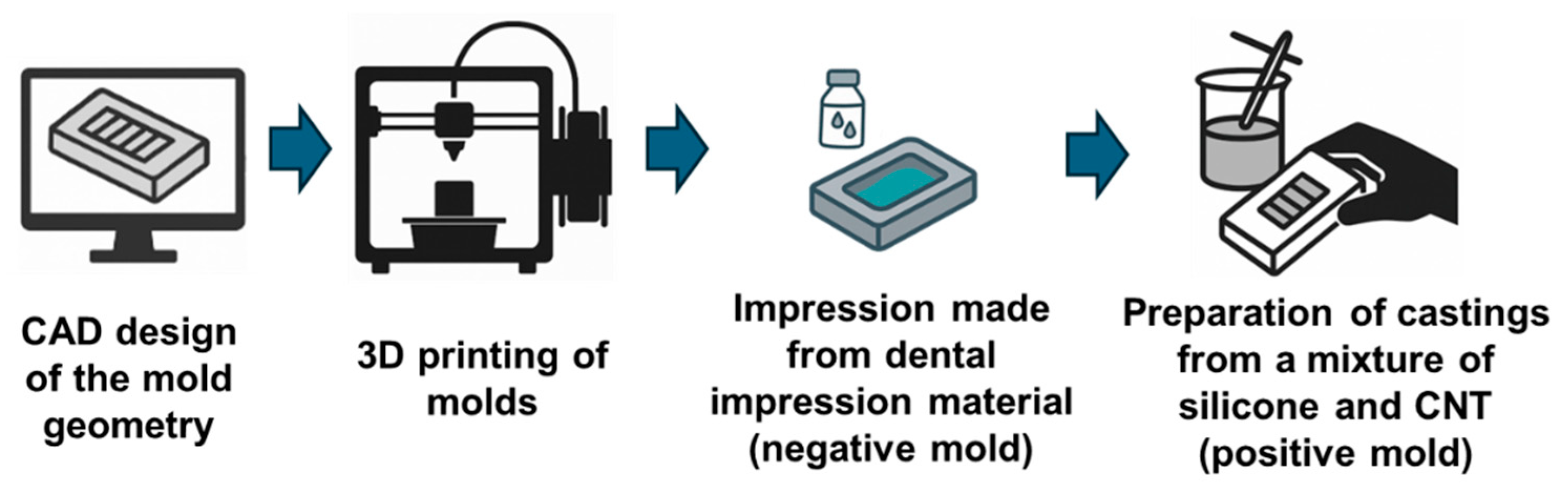

2.1. Fingerprint Mold

2.2. Polymer Impression Material

2.3. Preparation of Castings

2.4. Characteristics of the Impression and Castings

3. Results and Discussion

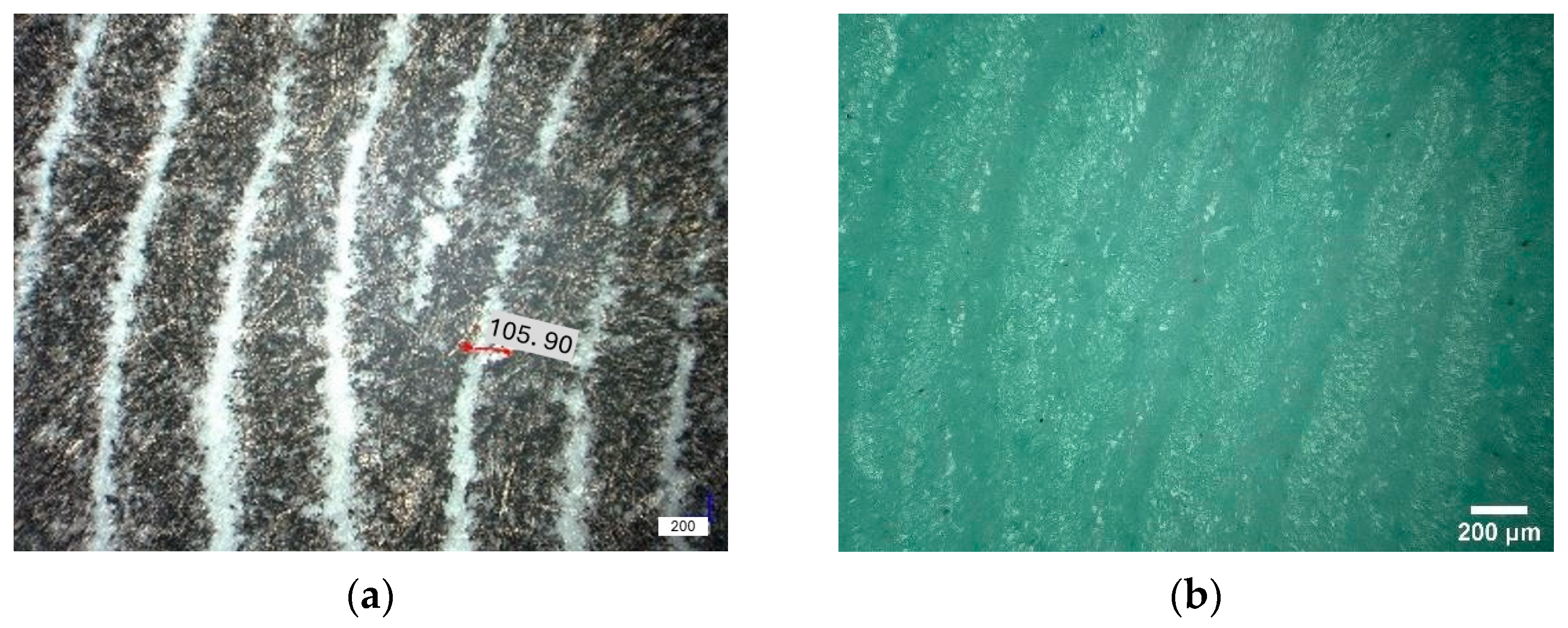

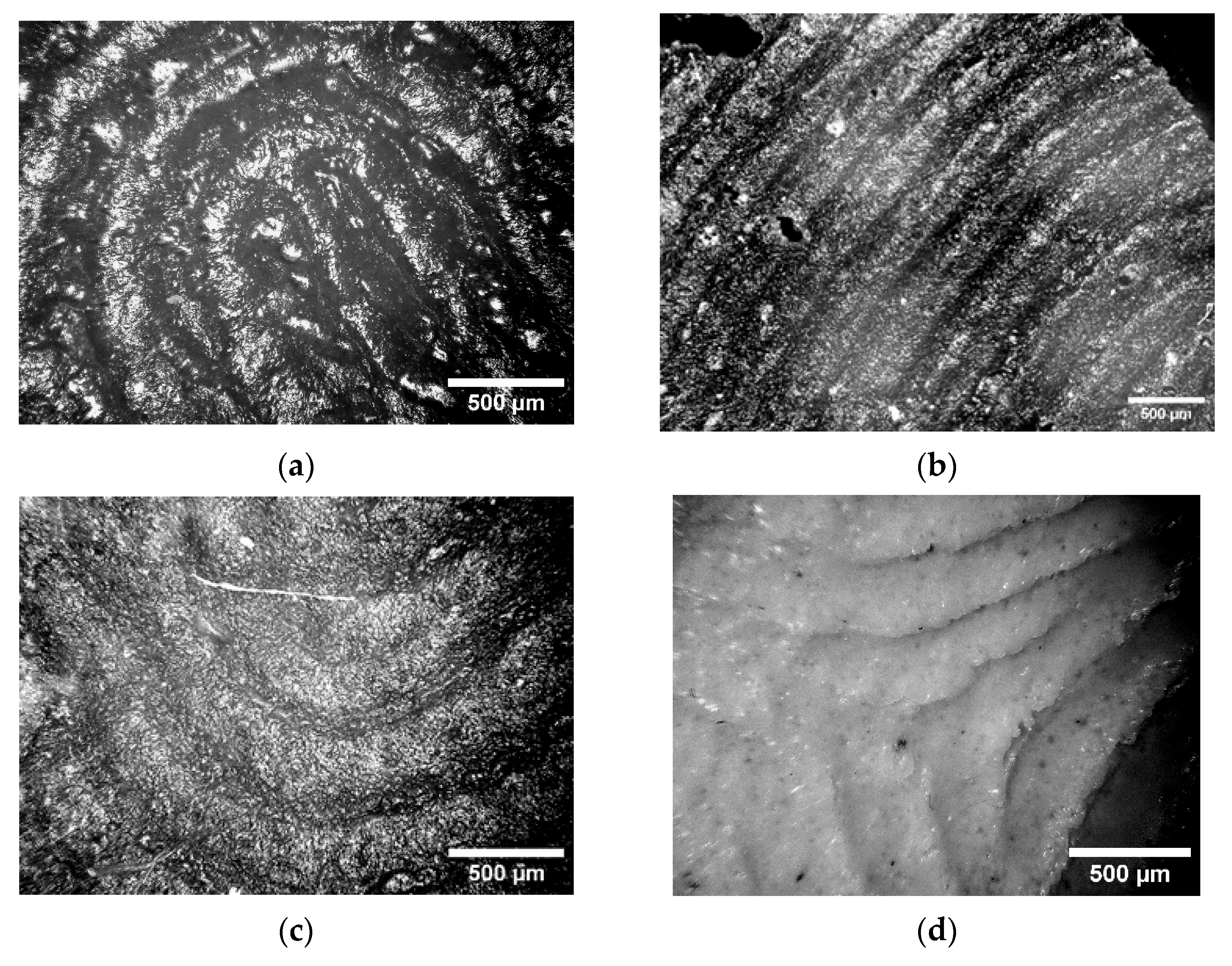

3.1. Assessment of the Structure and Hardness of Impressions

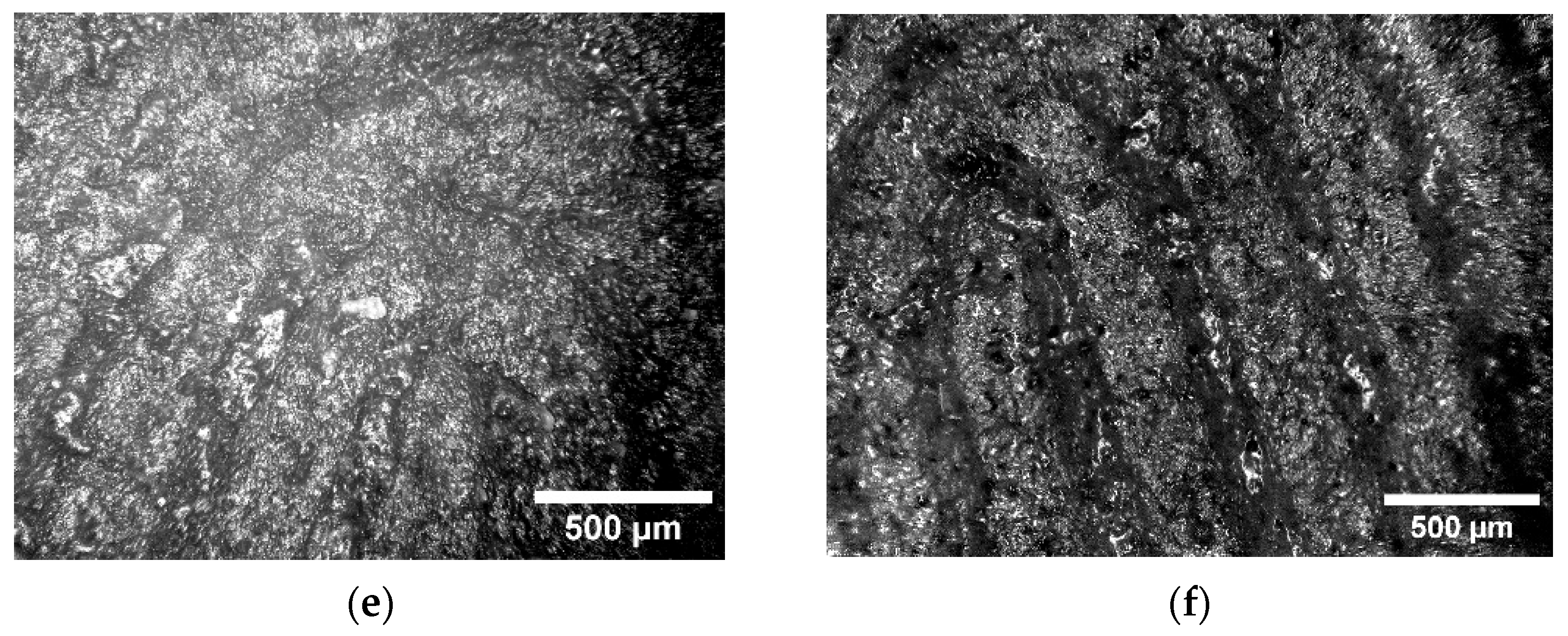

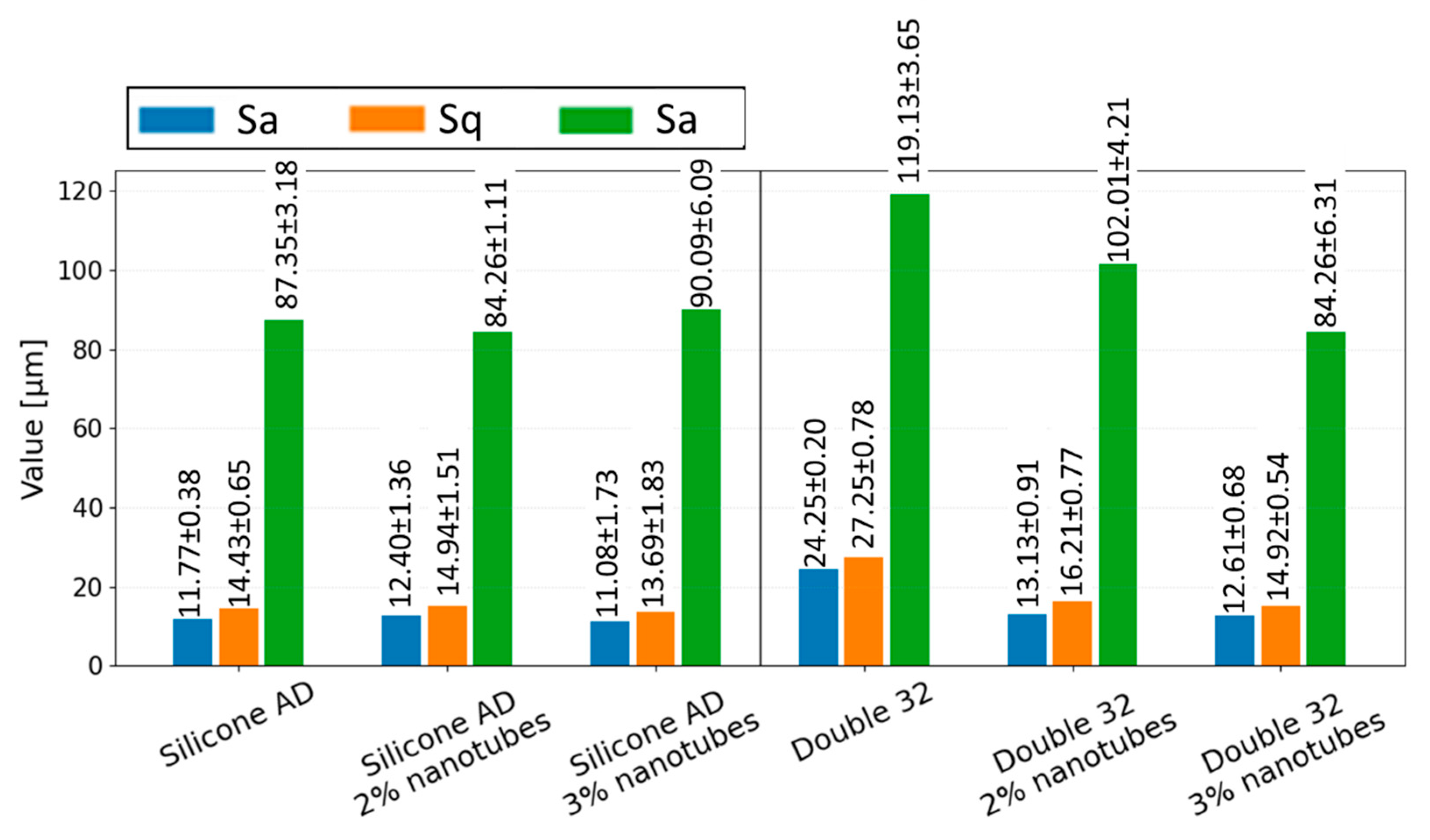

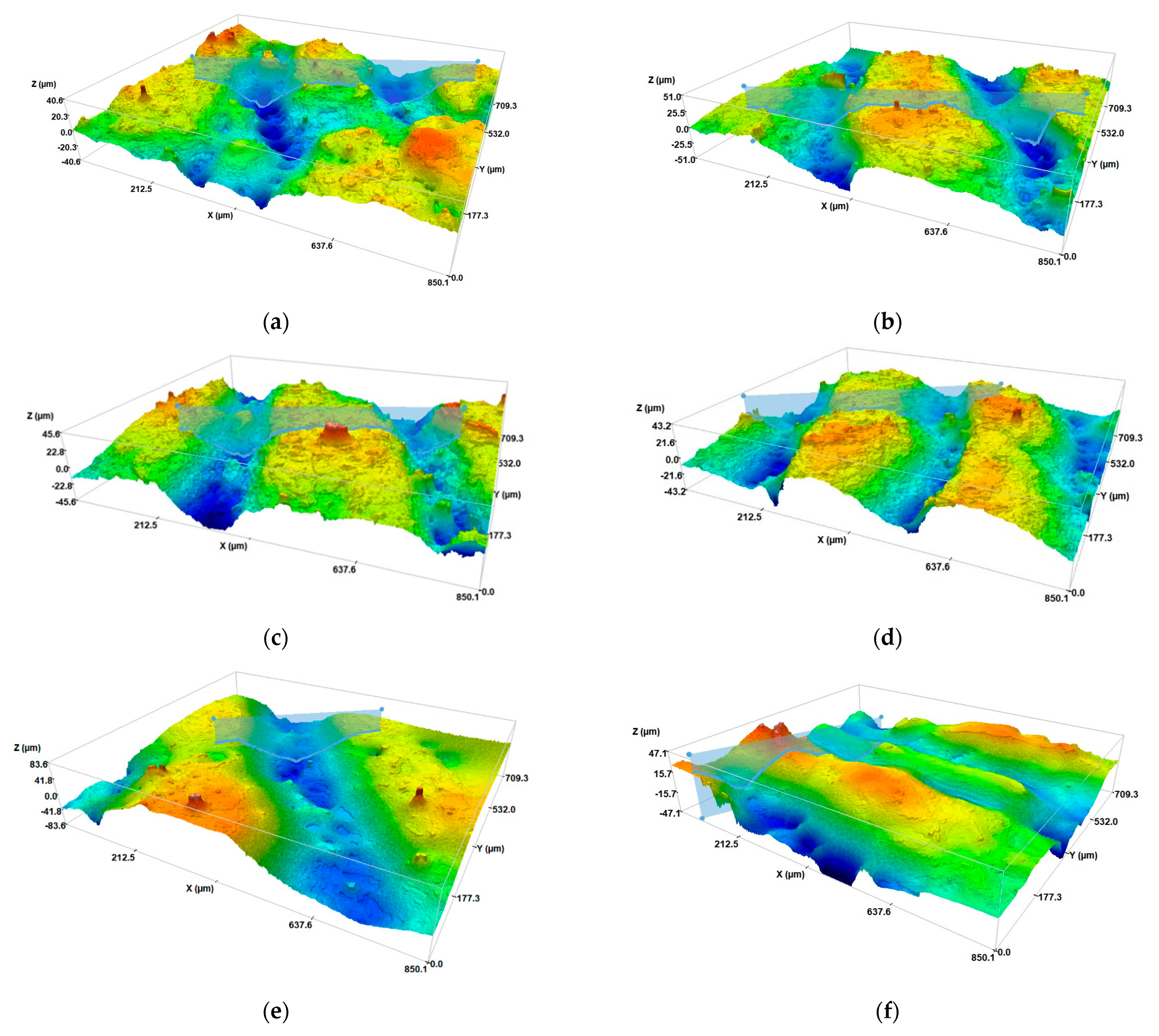

3.2. Analysis of Castings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mutalik, V.; Menon, A.; Jayalakshmi, N.; Kamath, A.; Raghu, A. Utility of cheiloscopy, rugoscopy, and dactyloscopy for human identification in a defined cohort. J. Forensic Dent. Sci. 2013, 5, 2–6. [Google Scholar] [CrossRef][Green Version]

- El Domiaty, M.; Al-gaidi, S.; Elayat, A.A.; Safwat, M.; Galal, S. Morphological patterns of lip prints in Saudi Arabia at Almadinah Almonawarah province. Forensic Sci. Int. 2010, 200, 179.e1–179.e9. [Google Scholar] [CrossRef]

- Gutiérrez-Redomero, E.; Alonso-Rodríguez, C.; Hernández-Hurtado, L.; Rodríguez-Villalba, J. Distribution of the minutiae in the fingerprints of a sample of the Spanish population. Forensic Sci. Int. 2011, 208, 79–90. [Google Scholar] [CrossRef]

- Scotcher, K.; Bradshaw, R. The analysis of latent fingermarks on polymer banknotes using MALDI-MS. Sci. Rep. 2018, 8, 8765. [Google Scholar] [CrossRef]

- Kücken, M.; Newell, A.C. A model for fingerprint formation. Europhys. Lett. 2004, 68, 141. [Google Scholar] [CrossRef]

- Su, Q.; Tian, J.; Chen, X.; Yang, X. A Fingerprint Authentication System Based on Mobile Phone. In Proceedings of the 5th International Conference Audio- and Video-Based Biometric Person Authentication, Hilton Rye Town, NY, USA, 20–22 July 2005. [Google Scholar]

- Laghari, A.; Memon, Z. Biometric authentication technique using smartphone sensor. In Proceedings of the 13th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 12–16 January 2016. [Google Scholar]

- Fudong, L.; Clarke, N.; Papadaki, M.; Haskell-Dowlan, P. Active authentication for mobile devices utilising behaviour profiling. Int. J. Inf. Secur. 2013, 13, 229–244. [Google Scholar] [CrossRef][Green Version]

- Doroz, R.; Porwik, P. Handwritten Signature Recognition with Adaptive Selection of Behavioral Features. In Computer Information Systems—Analysis and Technologies, Proceedings of the 10th International Conference, CISIM 2011, Kolkata, India, 14–16 December 2011; Communications in Computer and Information Science; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Rahmawati, E.; Listyasari, M.; Aziz, A.S.; Sukaridhoto, S.; Damastuti, F.A.; Bachtiar, M.M.; Sudarsono, A. Digital signature on file using biometric fingerprint with fingerprint sensor on smartphone. In Proceedings of the 2017 International Electronics Symposium on Engineering Technology and Applications (IES-ETA), Surabaya, Indonesia, 26–27 September 2017. [Google Scholar]

- Mudholkar, S.; Shende, P.; Sarode, M. Biometrics Authentication Technique for Intrusion Detection System. Int. J. Comput. Sci. 2012, 2, 57–65. [Google Scholar]

- Faúndez-Zanuy, M. Are inkless fingerprint sensors suitable for mobile use? IEEE Aerosp. Electron. Syst. Mag. 2004, 19, 17–21. [Google Scholar] [CrossRef]

- Amerini, I.; Becarelli, R.; Caldelli, R.; Melani, A.; Niccolai, M. Smartphone Fingerprinting Combining Features of On-Board Sensors. IEEE Trans. Inf. Forensics Secur. 2017, 12, 2457–2466. [Google Scholar] [CrossRef]

- Bayram, S.; Sencar, H.T.; Memon, N. Sensor Fingerprint Identification Through Composite Fingerprints and Group Testing. IEEE Trans. Inf. Forensics Secur. 2015, 10, 597–612. [Google Scholar] [CrossRef]

- Valsesia, D.; Coluccia, G.; Bianchi, T.; Magli, E. Compressed Fingerprint Matching and Camera Identification via Random Projections. IEEE Trans. Inf. Forensics Secur. 2015, 10, 1472–1485. [Google Scholar] [CrossRef]

- Arunalatha, G. A study on Fingerprint Sensors. Int. J. Mech. Eng. Technol. 2022, 7, 2580–2584. [Google Scholar]

- Hossain, M.S.; Mohammad, T.; Zahid, A. Incorporating deep learning into capacitive images for smartphone user authentication. J. Inf. Secur. Appl. 2022, 69, 103290. [Google Scholar] [CrossRef]

- Fernandez-Saavedra, B.; Sanchez-Reillo, R.; Ros-Gomez, R.; Liu-Jimenez, J. Small fingerprint scanners used in mobile devices: The impact on biometric performance. IET Biom. 2016, 5, 28–36. [Google Scholar] [CrossRef]

- Zhang, M.; Cui, X.; Li, N. Smartphone-based mobile biosensors for the point-of-care testing of human metabolites. Mater. Today Bio 2022, 14, 100254. [Google Scholar] [CrossRef] [PubMed]

- Henley, F.; Fortunato, B.S. Smartphone-based optical transduction for the rapid microscale assessment of iodate in table salt. Talanta 2021, 232, 122450. [Google Scholar] [CrossRef] [PubMed]

- McCracken, K.; Yoon, J. Recent approaches for optical smartphone sensing in resource-limited settings: A brief review. Anal. Methods 2016, 8, 6591–6601. [Google Scholar] [CrossRef]

- Assis, A.M.L.; Costa, C.V.; Alves, M.S.; Melo, J.C.S.; de Oliveira, V.R.; Tonholo, J.; Hillman, A.R.; Ribeiro, A.S. From nanomaterials to macromolecules: Innovative technologies for latent fingerprint development. Wiley Interdiscip. Rev. Forensic Sci. 2023, 5, e1475. [Google Scholar] [CrossRef]

- Hughes, K.J.; Iyer, K.A.; Bird, R.E.; Ivanov, J.; Banerjee, S.; Georges, G.; Zhou, Q.A. Review of carbon nanotube research and development: Materials and emerging applications. ACS Appl. Nano Mater. 2024, 7, 18695–18713. [Google Scholar] [CrossRef]

- Available online: https://servident.pl/powielanie/19922-fegura-sil-ad-special-shore-18-20-1-kg-1-kg.html?utm_source=chatgpt.com (accessed on 5 January 2024).

- Available online: https://usdentaldepot.com/elite-double-32-standard-pack-zhermack-c400833?srsltid=AfmBOooh-kesGz6ptGSnTILUzk2j1GFdwCkjuZddMHNLE-PPUYCwR11E&utm_source=chatgpt.com (accessed on 5 January 2024).

- Muthusamy, L.; Uppalapati, B.; Azad, S.; Bava, M.; Koley, G. Self-Polarized P(VDF-TrFE)/Carbon Black Composite Piezoelectric Thin Film. Polymers 2023, 15, 4131. [Google Scholar] [CrossRef]

- Muthusamy, L.; Uppalapati, B.; Bava, M.; Koley, G. P(VDF-TrFE)/carbon black composite thin film based flexible piezoresistive pressure sensor with high sensitivity for low-pressure detection. Mater. Des. 2025, 256, 114201. [Google Scholar] [CrossRef]

- Sałaciński, M.; Dydek, K.; Leski, A.; Kozera, R.; Mucha, M.; Karczmarz, W. Impact of Carbon Nanotubes on the Mechanical and Electrical Properties of Silicone. Fatigue Aircr. Struct. 2022, 2022, 135–153. [Google Scholar] [CrossRef]

- Yu, Y.; Niu, Q.; Li, X.; Xue, J.; Liu, W.; Lin, D. A Review of Fingerprint Sensors: Mechanism, Characteristics, and Applications. Micromachines 2023, 14, 1253. [Google Scholar] [CrossRef]

- Tang, K.; Liu, A.; Wang, W.; Li, P.; Chen, X. A Novel Fingerprint Sensing Technology Based on Electrostatic Imaging. Sensors 2018, 18, 3050. [Google Scholar] [CrossRef]

- An, B.W.; Heo, S.; Ji, S.; Bien, F.; Park, J.U. Transparent and flexible fingerprint sensor array with multiplexed detection of tactile pressure and skin temperature. Nat. Commun. 2018, 9, 2458. [Google Scholar] [CrossRef]

- Rattani, A.; Akhtar, Z.; Foresti, G. A preliminary study on identifying fabrication material from fake fingerprint images. In Proceedings of the 2015 IEEE Symposium Series on Computational Intelligence, Cape Town, South Africa, 7–10 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 362–366. [Google Scholar]

- Saguy, M.; Almog, J.; Cohn, D.; Champod, C. Proactive forensic science in biometrics: Novel materials for fingerprint spoofing. J. Forensic Sci. 2022, 67, 534–542. [Google Scholar] [CrossRef]

- Marasco, E.; Ross, A. A survey on antispoofing schemes for fingerprint recognition systems. ACM Comput. Surv. (CSUR) 2014, 47, 1–36. [Google Scholar] [CrossRef]

- Li, Z.W. Thermoelectric properties of carbon nanotube/silicone rubber composites. J. Exp. Nanosci. 2017, 12, 188–196. [Google Scholar] [CrossRef]

- Neffati, R.; Brokken-Zijp, J.M.C. Electric conductivity in silicone-carbon black nanocomposites: Percolation and variable range hopping on a fractal. Mater. Res. Express 2019, 6, 125058. [Google Scholar] [CrossRef]

- Naeem, N.; Butt, S.; Afzal, Z.; Akram, M.W.; Irfan, M.; Rehman, M.A.U.; Baluch, A.H.; Rehman, G.U.; Farooq, M.U. Facile development of carbon nanotube (CNT)-based flexible thermoelectric materials for energy-harvesting applications. RSC Adv. 2025, 15, 569–578. [Google Scholar] [CrossRef]

- Maheswaran, R.; Shanmugavel, B.P. A critical review of the role of carbon nanotubes in the progress of next-generation electronic applications. J. Electron. Mater. 2022, 51, 2786–2800. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yin, T.; Yang, Y.; Liu, W.; Wang, D.; Wan, L.; Liao, Y. The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites. Polymers 2025, 17, 1940. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Wahab, M.A.; Will, G.; Karim, M.R.; Pan, T.; Gao, M.; Lai, D.; Lin, Y.; Miraz, M.H. Recent Advances in Stretchable andWearable Capacitive Electrophysiological Sensors for Long-Term Health Monitoring. Biosensors 2022, 12, 630. [Google Scholar] [CrossRef] [PubMed]

| Parameters | |

|---|---|

| Layer height | 0.2 mm |

| Filling density | 10% |

| Print speed | 135 mm/s |

| Nozzle diameter | 0.4 mm |

| Nozzle temperature | 210 °C (483 k) |

| Table temperature | 50 °C (323 K) |

| Properties | AD Special | Double 32 |

|---|---|---|

| Shore A hardness | 18–20 | 32 |

| Mixing time | ~1 min. | ~1 min. |

| Working time | ~5–6 min. (22 °C) | ~10 min. |

| Setting time | ~30 min. (22 °C) | ~20 min. |

| Measurement No. | Hardness Reading (1 s) | Hardness Reading (After 15 s) |

|---|---|---|

| 1 | 85 | 85 |

| 2 | 87 | 85 |

| 3 | 85 | 84 |

| 4 | 87 | 85 |

| 5 | 85 | 75 |

| mean and standard deviation | 85.8 ± 1.1 | 84.8 ± 0.4 |

| Type of Silicone | Percentage of Additives | Conductivity [S/m] | |

|---|---|---|---|

| One Side | Two Sides | ||

| AD Special | without | 0.0151 ± 0.0011 | 0.0559 ± 0.0017 |

| 2% | 0.0223 ± 0.0018 | 0.0615 ± 0.0011 | |

| 3% | 0.0253 ± 0.0019 | 0.1736 ± 0.0069 | |

| Double 32 | without | 0.0078 ± 0.0006 | 0.0532 ± 0.0014 |

| 2% | 0.0595 ± 0.0021 | 0.1014 ± 0.0086 | |

| 3% | 0.1621 ± 0.0072 | 0.8443 ± 0.0199 | |

| Device | Mobile Phone | Lexar Jumpdrive Fingerprint F35 Pendrive (Capacitive Scanner) | Fingerprint Bag Lock | ||

|---|---|---|---|---|---|

| Xiaomi Redmi Note 10 Pro | Samsung Galaxy A50 (Ultrasound Machine) | Samsung S20 Ultra | |||

| Reader touch reaction | + | + | + | + | + |

| Registering an artificial fingerprint | + | − | + | + | + |

| Unlocking a device blocked with an artificial fingerprint | + | − | − | + | − |

| Unlocking a device locked with an original fingerprint | − | − | − | − | − |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romanczuk-Ruszuk, E.; Orlow, A.; Sztorch, B.; Dydek, K.; Przybyszewski, B.; Przekop, R.E. Carbon Nanotube-Enhanced Silicone Fingerprint Replicas for Biometric Security Testing. Appl. Sci. 2025, 15, 11539. https://doi.org/10.3390/app152111539

Romanczuk-Ruszuk E, Orlow A, Sztorch B, Dydek K, Przybyszewski B, Przekop RE. Carbon Nanotube-Enhanced Silicone Fingerprint Replicas for Biometric Security Testing. Applied Sciences. 2025; 15(21):11539. https://doi.org/10.3390/app152111539

Chicago/Turabian StyleRomanczuk-Ruszuk, Eliza, Anastazja Orlow, Bogna Sztorch, Kamil Dydek, Bartłomiej Przybyszewski, and Robert E. Przekop. 2025. "Carbon Nanotube-Enhanced Silicone Fingerprint Replicas for Biometric Security Testing" Applied Sciences 15, no. 21: 11539. https://doi.org/10.3390/app152111539

APA StyleRomanczuk-Ruszuk, E., Orlow, A., Sztorch, B., Dydek, K., Przybyszewski, B., & Przekop, R. E. (2025). Carbon Nanotube-Enhanced Silicone Fingerprint Replicas for Biometric Security Testing. Applied Sciences, 15(21), 11539. https://doi.org/10.3390/app152111539