Toward Autonomous LLM-Based AI Agents for Predictive Maintenance: State of the Art, Challenges, and Future Perspectives

Abstract

1. Introduction

- it includes a summary of the state of the art on the use of AI in PdM, divided into discriminative approaches, Generative AI, and emerging LLM-based applications;

- it introduces for the first time in this context the definition of an architectural framework for AI agents in PdM integrating current and state-of-the-art technologies such as Model Context Protocol (MCP);

- it provides an analysis of potential applications with an assessment of possible risks and mitigation in light of the literature on agentic systems governance [29];

- it proposes a discussion of the drivers and barriers to real adoption, informed by economic impact evidence and recent reports on the use and adoption of AI and Generative AI in companies [31], with practical implications for a roadmap for progressive introduction.

2. State of the Art

2.1. Discriminative AI for Predictive Maintenance

2.2. Generative AI for Predictive Maintenance

2.3. LLMs and AI Agents for Predictive Maintenance

3. From LLM Tools to Agentic Systems: Architectures, Tooling, and MCP

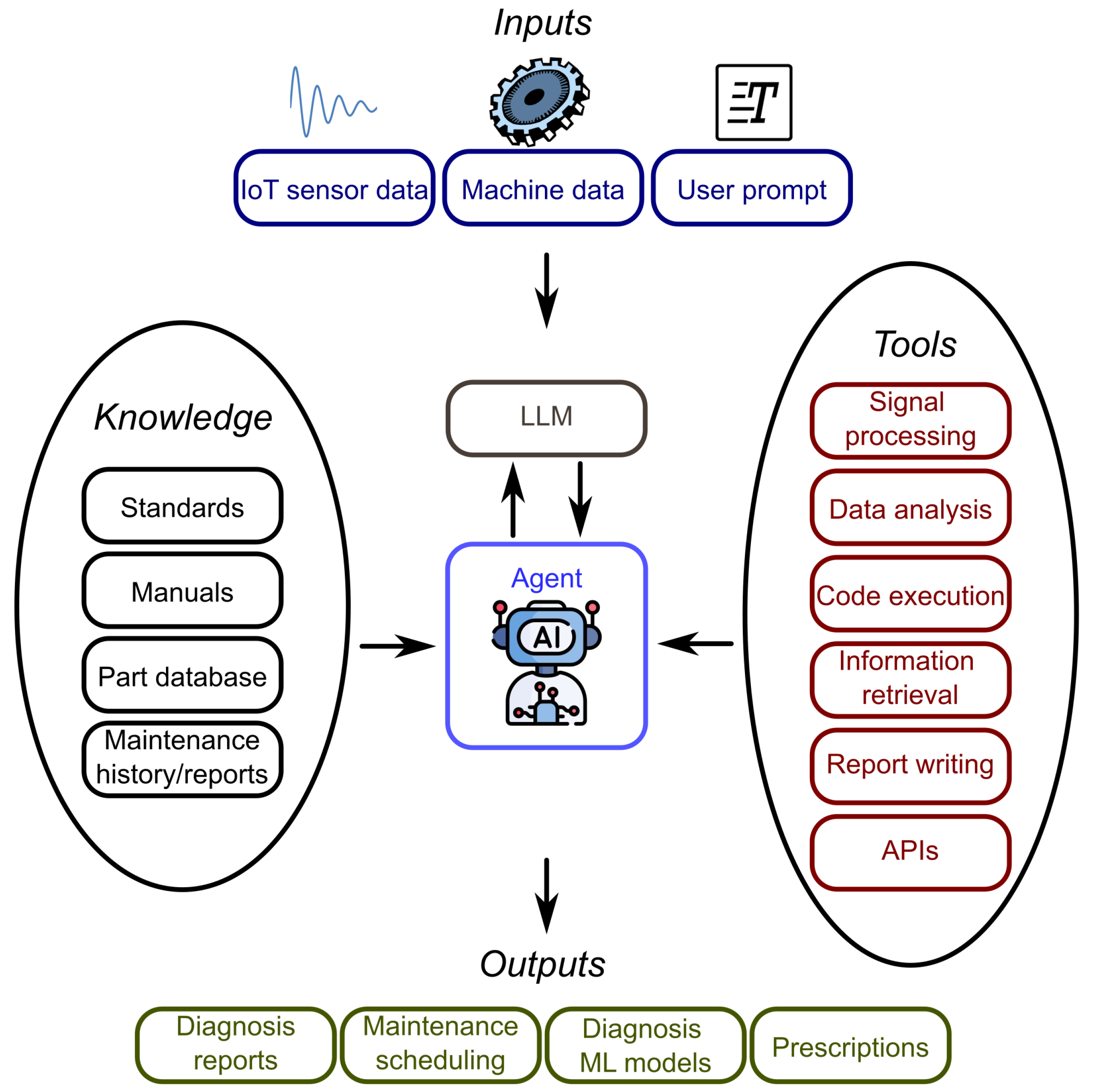

3.1. Architecture of AI Agents

- the model is the brain of the agent and is typically a LLM capable of understanding context, planning, reasoning, and making decisions. The model coordinates the workflow, decides what actions to take, and adapts to any unforeseen events;

- tools are external components, such as APIs, databases, software or hardware services, which allow data to be acquired, interact with third-party systems, and perform operations in the digital or physical world. The ability to connect to multiple tools and use them in sequence is one of the elements that differentiate AI agents from simple prompt-based language models;

- instructions define how it should behave, what tools it can use, under what conditions to interrupt an operation, and how to handle exceptions. Clear and comprehensive instructions make the agent’s behavior more predictable and robust.

- memory allows the agent to retain its state and context between different execution phases. It can include short-term memory, useful for maintaining logical flow in a single session, and long-term memory, for learning from past interactions and adapting over time;

- the reasoning engine develops strategies, plans sequences of actions, and breaks down complex objectives into more manageable sub-objectives. This is typially accompanied by a reflection mechanism, whereby the agent evaluates intermediate results and corrects its strategy in the event of errors or inefficiencies;

- guardrails [110] establish operational boundaries and safety rules. Also, they prevent risky behavior (e.g., avoid sending sensitive data to unauthorized services and manage exceptions and failures by anticipating scenarios in which the agent should not act autonomously). They can be implemented at different levels. Namely, providing initial instructions and constraints, filtering and validating the actions or responses generated or directly limiting the use of certain tools or commands.

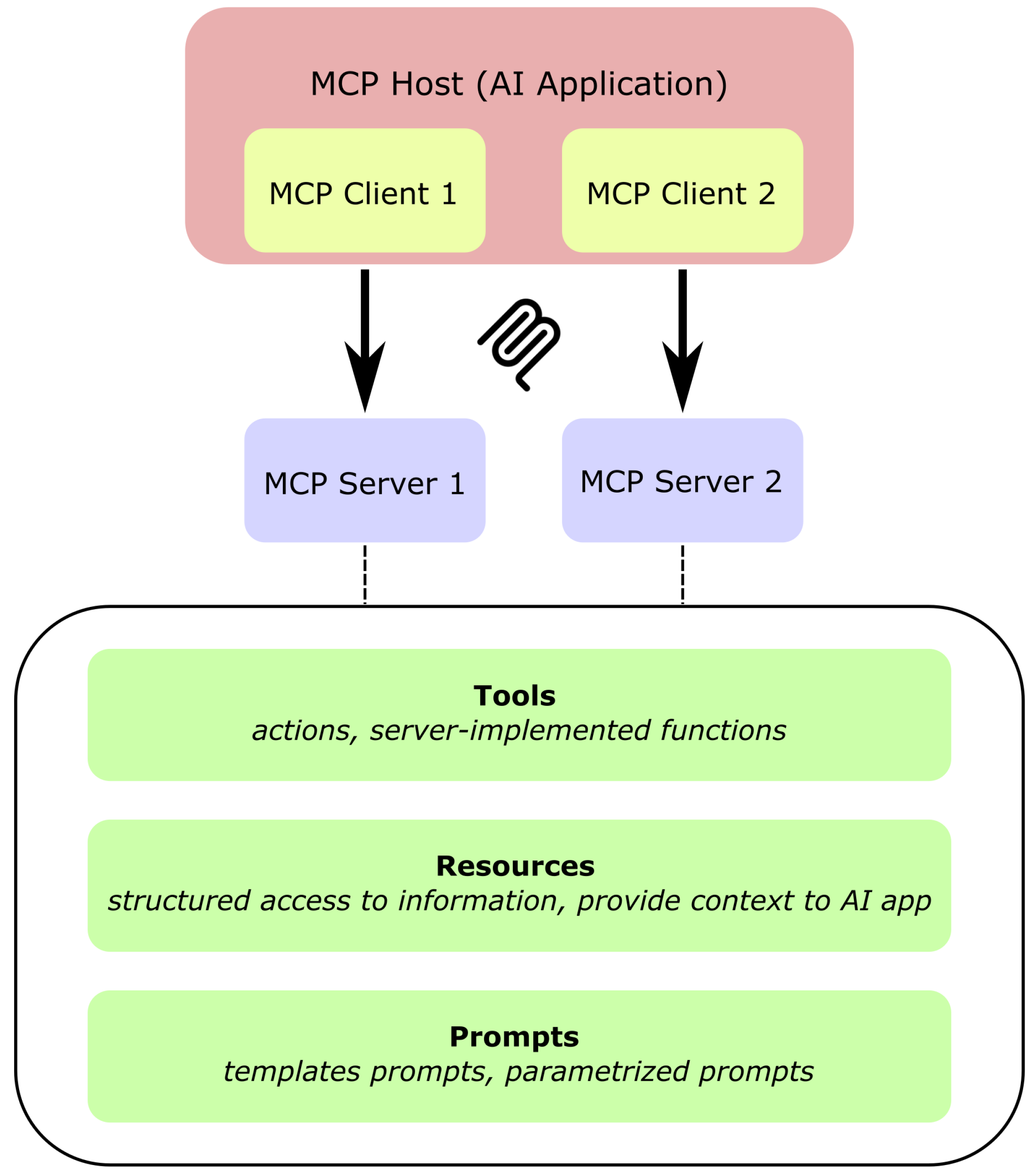

3.2. Model Context Protocol

- tools that invoke of services, APIs and external operations;

- resources that can be represented by structured and unstructured data from local files, databases, or cloud platforms;

- prompts that are reusable templates and workflows that optimize responses and standardize repetitive tasks.

3.3. Tools for Developing AI Agents

4. Potential Applications, Challenges and Risks of Agentic Systems in Industrial Maintenance

- from the technical point of view, sensor heterogeneity, vendor lock-in, and lack of standard interfaces hinder consistent and reliable condition monitoring [124,125]; models degrade as operating conditions change, and continuous learning remains unresolved; computational limitations and latency hinder real-time analytics and streaming at scale [126]; reliable system-level prognostics remain difficult, undermining user confidence [127];

- from the point of view of data, the scarcity of failure examples, the heterogeneity of formats, and limited attention to security and privacy are weighing heavily; moreover, labeling and annotation are costly and often unfeasible [124,126]. In implementation, integration with legacy, poor interoperability between vendors, and uncertain economic benefits block adoption; there is also a lack of analytical skills, especially in small and medium-sized enterprises [125];

4.1. Proposal of Conceptual Framework

4.2. Governance: Agent Alignment and Scalable Oversight

- information asymmetry, given by the fact that agents can access information not available to their principals placing humans in a vulnerable position;

- the issue of authority which concerns the extent of decision-making power granted to agents, how they interpret and implement instructions, and the risk of misconduct;

- the issue of loyalty understood as a duty to act in the user’s interest and to seek their consent when appropriate;

- the issue of delegation given by cases in in which an agent entrusts activities to other agents (human or artificial) and the applicable rules.

4.3. AI Agents for Machine Monitoring, Diagnosis and Root Cause Analsyis

4.4. Spare Parts Management and Procurement

4.5. Orchestration and Planning of Interventions Using CMMS Systems

4.6. Life-Cycle Management of Predictive Models for Machine Maintenance

5. Drivers and Barriers for the Adoption of Agentic Systems in Industrial Maintenance: A Global Economic Perspective

6. Future Perspectives and Roadmap

- Validation and foundation (1–2 years). In the short term, the integration of multimodal data, including text and sensor data, could be implemented, aiming at validation in laboratory environments that also seeks to identify evaluation standards:

- -

- multimodal integration and digital twins with robust sensor, text–image pipelines and simulations;

- -

- design evaluation standars for PdM agents: task suites, risk scenarios, autonomy levels, and security requirements;

- -

- validation in laboratory environments.

- Technological consolidation (3–5 years). In the medium term, systems with standardized and proven standardized retrieval protocols should be developed to ensure security in vertical applications, including the analysis of operations on edge systems and validation on real plants:

- -

- vertical LLMs with structured retrieval, secure and standard tool calling (MCP) to reduce hallucinations and increase procedural fidelity;

- -

- egde AI with efficient, privacy-preserving models and agents with latencies compatible with operational control;

- -

- experimental validation on real plants and public benchmarks with reproducible test protocols, realistic datasets, and shared metrics for CMMS diagnostics, prescriptions, and orchestration.

- Structured organizational adoption (5+ years). In the long term, a structured adoption at the organizational level and on a large scale could be targeted:

- -

- organizational integration into processes and data, operator training, and consistent roles and permission design;

- -

- governance and explainability.

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, M.I.; Lai, N.S.; Abdulla, R. Predictive maintenance of rotational machinery using deep learning. Int. J. Electr. Comput. Eng. (IJECE) 2024, 14, 1112. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, J.; Qian, Q.; Qin, Y. A comprehensive survey of machine remaining useful life prediction approaches based on pattern recognition: Taxonomy and challenges. Meas. Sci. Technol. 2024, 35, 062001. [Google Scholar] [CrossRef]

- Ma, S.; Flanigan, K.A.; Bergés, M. State-of-the-Art Review: The Use of Digital Twins to Support Artificial Intelligence-Guided Predictive Maintenance. arXiv 2024, arXiv:2406.13117. [Google Scholar] [CrossRef]

- Mikołajewska, E.; Mikołajewski, D.; Mikołajczyk, T.; Paczkowski, T. Generative AI in AI-Based Digital Twins for Fault Diagnosis for Predictive Maintenance in Industry 4.0/5.0. Appl. Sci. 2025, 15, 3166. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Hendriks, J.; Dumond, P.; Knox, D. Towards better benchmarking using the CWRU bearing fault dataset. Mech. Syst. Signal Process. 2022, 169, 108732. [Google Scholar] [CrossRef]

- Farooq, U.; Ademola, M.; Shaalan, A. Comparative Analysis of Machine Learning Models for Predictive Maintenance of Ball Bearing Systems. Electronics 2024, 13, 438. [Google Scholar] [CrossRef]

- Giraudo, L.; Di Maggio, L.G.; Giorio, L.; Delprete, C. Dynamic Multibody Modeling of Spherical Roller Bearings with Localized Defects for Large-Scale Rotating Machinery. Sensors 2025, 25, 2419. [Google Scholar] [CrossRef]

- Vehviläinen, M.; Tahkola, M.; Keränen, J.; El Bouharrouti, N.; Rahkola, P.; Halme, J.; Pippuri-Mäkeläinen, J.; Belahcen, A. 3D Multibody Simulation of Realistic Rolling Bearing Defects for Fault Classifier Development. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Yang, B.; Lei, Y.; Jia, F.; Xing, S. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mech. Syst. Signal Process. 2019, 122, 692–706. [Google Scholar] [CrossRef]

- Martínez-Rego, D.; Fontenla-Romero, O.; Alonso-Betanzos, A. Power wind mill fault detection via one-class v-SVM vibration signal analysis. Proc. Int. Jt. Conf. Neural Netw. 2011, 10748, 511–518. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data 2021, 8, 53. [Google Scholar] [CrossRef] [PubMed]

- Di Maggio, L.G. Intelligent Fault Diagnosis of Industrial Bearings Using Transfer Learning and CNNs Pre-Trained for Audio Classification. Sensors 2022, 23, 211. [Google Scholar] [CrossRef]

- Eang, C.; Lee, S. Predictive Maintenance and Fault Detection for Motor Drive Control Systems in Industrial Robots Using CNN-RNN-Based Observers. Sensors 2024, 25, 25. [Google Scholar] [CrossRef]

- Thoppil, N.M.; Vasu, V.; Rao, C.S.P. Deep Learning Algorithms for Machinery Health Prognostics Using Time-Series Data: A Review. J. Vib. Eng. Technol. 2021, 9, 1123–1145. [Google Scholar] [CrossRef]

- Wu, Y.; Sicard, B.; Gadsden, S.A. Physics-informed machine learning: A comprehensive review on applications in anomaly detection and condition monitoring. Expert Syst. Appl. 2024, 255, 124678. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention is all you need. Adv. Neural Inf. Process. Syst. 2017, 30. [Google Scholar] [CrossRef]

- Jin, Y.; Hou, L.; Chen, Y. A Time Series Transformer based method for the rotating machinery fault diagnosis. Neurocomputing 2022, 494, 379–395. [Google Scholar] [CrossRef]

- Cao, S.; Wen, L.; Li, X.; Gao, L. Application of Generative Adversarial Networks for Intelligent Fault Diagnosis. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018. [Google Scholar] [CrossRef]

- Yang, X.; Fang, C.; Liao, Y.; Yang, J.; Gryllias, K.; Chronopoulos, D. Deep Generative Models in Condition and Structural Health Monitoring: Opportunities, Limitations and Future Outlook. arXiv 2025, arXiv:2507.15026. [Google Scholar] [CrossRef]

- OpenAI. GPT-4 Technical Report. arXiv 2023, arXiv:2303.08774. [Google Scholar] [CrossRef]

- Wu, J.; Gan, W.; Chen, Z.; Wan, S.; Yu, P.S. Multimodal Large Language Models: A Survey. arXiv 2023, arXiv:2311.13165. [Google Scholar] [CrossRef]

- Brown, T.B.; Mann, B.; Ryder, N.; Subbiah, M.; Kaplan, J.; Dhariwal, P.; Neelakantan, A.; Shyam, P.; Sastry, G.; Askell, A.; et al. Language Models are Few-Shot Learners. arXiv 2020, arXiv:2005.14165. [Google Scholar] [CrossRef]

- Lewis, P.; Perez, E.; Piktus, A.; Petroni, F.; Karpukhin, V.; Goyal, N.; Küttler, H.; Lewis, M.; Yih, W.t.; Rocktäschel, T.; et al. Retrieval-Augmented Generation for Knowledge-Intensive NLP Tasks. In Advances in Neural Information Processing Systems; Larochelle, H., Ranzato, M., Hadsell, R., Balcan, M.F., Lin, H., Eds.; Curran Associates, Inc.: Nice, France, 2020; Volume 33, pp. 9459–9474. [Google Scholar]

- Reddicharla, N.; Ali, M.S. Innovating Oil and Gas Field Operations—Harnessing the Power of Generative Ai for Supporting Workforce Towards Achieving Autonomous Operations. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 4–7 November 2024; p. D011S020R005. [Google Scholar] [CrossRef]

- Kolt, N. Governing AI Agents. arXiv 2025, arXiv:2501.07913. [Google Scholar] [CrossRef]

- Jensen, M.C.; Meckling, W.H. Theory of the firm: Managerial behavior, agency costs and ownership structure. In Corporate Governance; Gower: Aldershot, UK, 2019; pp. 77–132. [Google Scholar]

- Maslej, N.; Fattorini, L.; Perrault, R.; Gil, Y.; Parli, V.; Kariuki, N.; Capstick, E.; Reuel, A.; Brynjolfsson, E.; Etchemendy, J.; et al. Artificial Intelligence Index Report 2025. arXiv 2025, arXiv:2504.07139. [Google Scholar] [CrossRef]

- Khan, S.; Yairi, T. A review on the application of deep learning in system health management. Mech. Syst. Signal Process. 2018, 107, 241–265. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Gelman, L. A Fuzzy Fusion Rotating Machinery Fault Diagnosis Framework Based on the Enhancement Deep Convolutional Neural Networks. Sensors 2022, 22, 671. [Google Scholar] [CrossRef]

- Kolar, D.; Lisjak, D.; Pająk, M.; Gudlin, M. Intelligent Fault Diagnosis of Rotary Machinery by Convolutional Neural Network with Automatic Hyper-Parameters Tuning Using Bayesian Optimization. Sensors 2021, 21, 2411. [Google Scholar] [CrossRef]

- Ranjit, M. Gawande. Machine Learning Approaches for Fault Detection and Diagnosis in Electrical Machines: A Comparative Study of Deep Learning and Classical Methods. Panam. Math. J. 2024, 34, 121–137. [Google Scholar] [CrossRef]

- Sharma, S.S.; Vivek, V.; Malviya, A. AI-Enhanced Predictive Maintenance in Intelligent Systems for Industries. In Proceedings of the 2024 International Conference on Advances in Computing Research on Science Engineering and Technology (ACROSET), Indore, India, 27–28 September 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Sperandio Nascimento, E.G.; Liang, J.S.; Figueiredo, I.S.; Guarieiro, L.L.N. T4pdm: A Deep Neural Network Based on the Transformer Architecture for Fault Diagnosis of Rotating Machinery. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Lu, Z.; Liang, L.; Zhu, J.; Zou, W.; Mao, L. Rotating Machinery Fault Diagnosis Under Multiple Working Conditions via a Time-Series Transformer Enhanced by Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Brusa, E.; Delprete, C.; Di Maggio, L.G. Eigen-spectrograms: An interpretable feature space for bearing fault diagnosis based on artificial intelligence and image processing. Mech. Adv. Mater. Struct. 2022, 30, 4639–4651. [Google Scholar] [CrossRef]

- Sawaqed, L.S.; Alrayes, A.M. Bearing fault diagnostic using machine learning algorithms. Prog. Artif. Intell. 2020, 9, 341–350. [Google Scholar] [CrossRef]

- Pan, S.J.; Yang, Q. A Survey on Transfer Learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

- He, W.; Chen, J.; Zhou, Y.; Liu, X.; Chen, B.; Guo, B. An Intelligent Machinery Fault Diagnosis Method Based on GAN and Transfer Learning under Variable Working Conditions. Sensors 2022, 22, 9175. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Lei, Y.; Xing, S.; Yan, T.; Li, N. Deep Convolutional Transfer Learning Network: A New Method for Intelligent Fault Diagnosis of Machines with Unlabeled Data. IEEE Trans. Ind. Electron. 2019, 66, 7316–7325. [Google Scholar] [CrossRef]

- Shen, S.; Lu, H.; Sadoughi, M.; Hu, C.; Nemani, V.; Thelen, A.; Webster, K.; Darr, M.; Sidon, J.; Kenny, S. A physics-informed deep learning approach for bearing fault detection. Eng. Appl. Artif. Intell. 2021, 103, 104295. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, H.; Wang, Y.; Mao, Y. Inverse physics–informed neural networks for digital twin–based bearing fault diagnosis under imbalanced samples. Knowl.-Based Syst. 2024, 292, 111641. [Google Scholar] [CrossRef]

- Ni, Q.; Ji, J.; Halkon, B.; Feng, K.; Nandi, A.K. Physics-Informed Residual Network (PIResNet) for rolling element bearing fault diagnostics. Mech. Syst. Signal Process. 2023, 200, 110544. [Google Scholar] [CrossRef]

- Lu, H.; Pavan Nemani, V.; Barzegar, V.; Allen, C.; Hu, C.; Laflamme, S.; Sarkar, S.; Zimmerman, A.T. A physics-informed feature weighting method for bearing fault diagnostics. Mech. Syst. Signal Process. 2023, 191, 110171. [Google Scholar] [CrossRef]

- Jia, N.; Huang, W.; Ding, C.; Wang, J.; Zhu, Z. Physics-informed unsupervised domain adaptation framework for cross-machine bearing fault diagnosis. Adv. Eng. Inform. 2024, 62, 102774. [Google Scholar] [CrossRef]

- Yue, K.; Li, J.; Chen, J.; Huang, R.; Li, W. Multiscale Wavelet Prototypical Network for Cross-Component Few-Shot Intelligent Fault Diagnosis. IEEE Trans. Instrum. Meas. 2023, 72, 3502411. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, F.; Wang, B.; Habetler, T. Few-Shot Bearing Fault Diagnosis Based on Model-Agnostic Meta-Learning. IEEE Trans. Ind. Appl. 2021, 57, 4754–4764. [Google Scholar] [CrossRef]

- Chang, L.; Lin, Y.H. Meta-Learning With Adaptive Learning Rates for Few-Shot Fault Diagnosis. IEEE/ASME Trans. Mechatronics 2022, 27, 5948–5958. [Google Scholar] [CrossRef]

- Han, J.; Zhang, X.; Xie, Z.; Zhou, W.; Tan, Z. Federated Learning-Based Equipment Fault-Detection Algorithm. Electronics 2024, 14, 92. [Google Scholar] [CrossRef]

- Milasheuski, U.; Baraldi, P.; Zio, E.; Savazzi, S. Federated Generative Models for Predictive Maintenance in Industrial Environments. In Proceedings of the 2024 8th International Conference on System Reliability and Safety (ICSRS), Sicily, Italy, 20–22 November 2024; pp. 156–161. [Google Scholar] [CrossRef]

- Ma, X.; Wen, C.; Wen, T. An asynchronous and real-time update paradigm of federated learning for fault diagnosis. IEEE Trans. Ind. Inform. 2021, 17, 8531–8540. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Ma, H.; Luo, Z.; Li, X. Federated learning for machinery fault diagnosis with dynamic validation and self-supervision. Knowl.-Based Syst. 2021, 213, 106679. [Google Scholar] [CrossRef]

- Di Maggio, L.G.; Brusa, E.; Delprete, C. Novelty Detection in Rotating Machinery: Assessment of Unsupervised Machine Learning Models for Medium-Sized Industrial Bearings. In Proceedings of the 2025 International Conference on Control, Automation and Diagnosis (ICCAD), Barcelona, Spain, 1–3 July 2025; pp. 1–7. [Google Scholar] [CrossRef]

- De Fabritiis, F.; Gryllias, K. Self-supervised Learning Approach for Anomaly Detection in Rotating Machinery. Annu. Conf. Phm Soc. 2024, 16, 1–10. [Google Scholar] [CrossRef]

- Han, T.; Li, Y.F. Out-of-distribution detection-assisted trustworthy machinery fault diagnosis approach with uncertainty-aware deep ensembles. Reliab. Eng. Syst. Saf. 2022, 226, 108648. [Google Scholar] [CrossRef]

- Zhou, T.; Han, T.; Droguett, E.L. Towards trustworthy machine fault diagnosis: A probabilistic Bayesian deep learning framework. Reliab. Eng. Syst. Saf. 2022, 224, 108525. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A. An explainable artificial intelligence approach for unsupervised fault detection and diagnosis in rotating machinery. Mech. Syst. Signal Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Brusa, E.; Cibrario, L.; Delprete, C.; Di Maggio, L.G. Explainable AI for Machine Fault Diagnosis: Understanding Features’ Contribution in Machine Learning Models for Industrial Condition Monitoring. Appl. Sci. 2023, 13, 2038. [Google Scholar] [CrossRef]

- Harvinder, S. Reimagining manufacturing with generative AI: A comprehensive review of current applications and future directions. i-manager’s J. Future Eng. Technol. 2025, 20, 51. [Google Scholar] [CrossRef]

- Mohapatra, A. Generative AI for Predictive Maintenance: Predicting Equipment Failures and Optimizing Maintenance Schedules Using AI. Int. J. Sci. Res. Manag. (IJSRM) 2024, 12, 1648–1672. [Google Scholar] [CrossRef]

- Di Maggio, L.G.; Brusa, E.; Delprete, C. Zero-Shot Generative AI for Rotating Machinery Fault Diagnosis: Synthesizing Highly Realistic Training Data via Cycle-Consistent Adversarial Networks. Appl. Sci. 2023, 13, 12458. [Google Scholar] [CrossRef]

- Hakami, A. Strategies for overcoming data scarcity, imbalance, and feature selection challenges in machine learning models for predictive maintenance. Sci. Rep. 2024, 14, 9645. [Google Scholar] [CrossRef]

- Huo, L.; Qi, H.; Fei, S.; Guan, C.; Li, J. A Generative Adversarial Network Based a Rolling Bearing Data Generation Method Towards Fault Diagnosis. Comput. Intell. Neurosci. 2022, 2022, 1–21. [Google Scholar] [CrossRef]

- Guo, Q.; Li, Y.; Liu, Y.; Gao, S.; Song, Y. Data Augmentation for Intelligent Mechanical Fault Diagnosis Based on Local Shared Multiple-Generator GAN. IEEE Sens. J. 2022, 22, 9598–9609. [Google Scholar] [CrossRef]

- Ding, Y.; Ma, L.; Ma, J.; Wang, C.; Lu, C. A Generative Adversarial Network-Based Intelligent Fault Diagnosis Method for Rotating Machinery Under Small Sample Size Conditions. IEEE Access 2019, 7, 149736–149749. [Google Scholar] [CrossRef]

- Zhao, B.; Yuan, Q. Improved generative adversarial network for vibration-based fault diagnosis with imbalanced data. Measurement 2021, 169, 108522. [Google Scholar] [CrossRef]

- Brusa, E.; Delprete, C.; Giorio, L.; Di Maggio, L.G.; Zanella, V. Design of an Innovative Test Rig for Industrial Bearing Monitoring with Self-Balancing Layout. Machines 2022, 10, 54. [Google Scholar] [CrossRef]

- Yigin, B.; Celik, M. A Prescriptive Model for Failure Analysis in Ship Machinery Monitoring Using Generative Adversarial Networks. J. Mar. Sci. Eng. 2024, 12, 493. [Google Scholar] [CrossRef]

- Choubey, S.; Benton, R.; Johnsten, T. Prescriptive Equipment Maintenance: A Framework. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 4366–4374. [Google Scholar] [CrossRef]

- Ansari, F.; Glawar, R.; Nemeth, T. PriMa: A prescriptive maintenance model for cyber-physical production systems. Int. J. Comput. Integr. Manuf. 2019, 32, 482–503. [Google Scholar] [CrossRef]

- Li, L.; Fan, Y.; Tse, M.; Lin, K.Y. A review of applications in federated learning. Comput. Ind. Eng. 2020, 149, 106854. [Google Scholar] [CrossRef]

- Li, T.; Sahu, A.K.; Talwalkar, A.; Smith, V. Federated learning: Challenges, methods, and future directions. IEEE Signal Process. Mag. 2020, 37, 50–60. [Google Scholar] [CrossRef]

- Thompson, A.; Sommers, A.; Russell-Gilbert, A.; Cummins, L.; Mittal, S.; Rahimi, S.; Seale, M.; Jaboure, J.; Arnold, T.; Church, J. Multivariate Data Augmentation for Predictive Maintenance using Diffusion. In Proceedings of the 2024 IEEE International Conference on Big Data (BigData), Washington, DC, USA, 15–18 December 2024; pp. 4240–4247. [Google Scholar] [CrossRef]

- Solís-Martín, D.; Galán-Páez, J.; Borrego-Díaz, J. difLIME: Enhancing Explainability with a Diffusion-Based LIME Algorithm for Predictive Maintenance. Int. J. Progn. Health Manag. 2025, 16. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, J.; Wang, W.; Yang, H.; Niyato, D. TranDRL: A Transformer-Driven Deep Reinforcement Learning Enabled Prescriptive Maintenance Framework. IEEE Internet Things J. 2024, 11, 35432–35444. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Sun, K.; Lei, P.; Zhang, Y.; Zio, E.; Xia, A.; Li, Y. RmGPT: A Foundation Model With Generative Pre-trained Transformer for Fault Diagnosis and Prognosis in Rotating Machinery. IEEE Internet Things J. 2025, 12, 41562–41573. [Google Scholar] [CrossRef]

- Lynch, K.; Lorenzi, F.; Sheehan, J.; Kabakci-Zorlu, D.; Eck, B. FMEA Builder: Expert Guided Text Generation for Equipment Maintenance. arXiv 2024, arXiv:2411.05054. [Google Scholar] [CrossRef]

- Moran, G.E.; Aragam, B. Towards Interpretable Deep Generative Models via Causal Representation Learning. arXiv 2025, arXiv:2504.11609. [Google Scholar] [CrossRef]

- He, H.; Huang, J.; Li, Q.; Wang, X.; Zhang, F.; Yang, K.; Meng, L.; Chu, F. MaintAGT:Sim2Real-Guided Multimodal Large Model for Intelligent Maintenance with Chain-of-Thought Reasoning. arXiv 2024, arXiv:2412.00481. [Google Scholar] [CrossRef]

- Wei, J.; Wang, X.; Schuurmans, D.; Bosma, M.; Ichter, B.; Xia, F.; Chi, E.; Le, Q.V.; Zhou, D. Chain-of-Thought Prompting Elicits Reasoning in Large Language Models. In Advances in Neural Information Processing Systems; Koyejo, S., Mohamed, S., Agarwal, A., Belgrave, D., Cho, K., Oh, A., Eds.; Curran Associates, Inc.: Nice, France, 2022; Volume 35, pp. 24824–24837. [Google Scholar]

- Klekowicki, M.; Szymański, G.M.; Waligórski, M.; Misztal, W. Application of large language models in diagnostics and maintenance of aircraft propulsion systems. Adv. Sci. Technol. Res. J. 2024, 19, 304–320. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.F. Large-Scale Language Models for PHM in Railway Systems - Potential Applications, Limitations, and Solutions. In Proceedings of the 6th International Conference on Electrical Engineering and Information Technologies for Rail Transportation (EITRT) 2023; Qin,, Y., Jia, L., Yang,, J., Diao, L., Yao, D., An, M., Eds.; Springer Nature: Singapore, 2024; Volume 1137, pp. 591–599. [Google Scholar] [CrossRef]

- Tao, L.; Liu, H.; Ning, G.; Cao, W.; Huang, B.; Lu, C. LLM-based Framework for Bearing Fault Diagnosis. arXiv 2024, arXiv:2411.02718. [Google Scholar] [CrossRef]

- Qaid, H.A.A.M.; Zhang, B.; Li, D.; Ng, S.K.; Li, W. FD-LLM: Large Language Model for Fault Diagnosis of Machines. arXiv 2024, arXiv:2412.01218. [Google Scholar] [CrossRef]

- Deng, H.; Namoano, B.; Zheng, B.; Khan, S.; Ahmet Erkoyuncu, J. From Prediction to Prescription: Large Language Model Agent for Context-Aware Maintenance Decision Support. PHM Soc. Eur. Conf. 2024, 8, 10. [Google Scholar] [CrossRef]

- Walker, C.; Rothon, C.; Aslansefat, K.; Papadopoulos, Y.; Dethlefs, N. Using Large Language Models to Recommend Repair Actions for Offshore Wind Maintenance. J. Phys. Conf. Ser. 2024, 2875, 012025. [Google Scholar] [CrossRef]

- Lukens, S.; Ali, A. Evaluating the Performance of ChatGPT in the Automation of Maintenance Recommendations for Prognostics and Health Management. Annu. Conf. PHM Soc. 2023, 15, 1–18. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Q.; Bao, J.; Lu, Y.; Liu, S. Empowering digital twins with large language models for global temporal feature learning. J. Manuf. Syst. 2024, 74, 83–99. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W.; Chen, K.; Jiang, R. A multimodal expert system for the intelligent monitoring and maintenance of transformers enhanced by multimodal language large model fine-tuning and digital twins. IET Collab. Intell. Manuf. 2024, 6, e70007. [Google Scholar] [CrossRef]

- Ferdousi, R.; Hossain, M.A.; Yang, C.; Saddik, A.E. DefectTwin: When LLM Meets Digital Twin for Railway Defect Inspection. arXiv 2024, arXiv:2409.06725. [Google Scholar] [CrossRef]

- Alsaif, K.; Albeshri, A.; Khemakhem, M.; Eassa, F. Multimodal Large Language Model-Based Fault Detection and Diagnosis in Context of Industry 4.0. Electronics 2024, 13, 4912. [Google Scholar] [CrossRef]

- Kumar, A.; Alam, M.; Farahat, A.; Somineni, M.; Gupta, C. Diagnostics-LLaVA: A Visual Language Model for Domain-Specific Diagnostics of Equipment. Annu. Conf. PHM Soc. 2024, 16. [Google Scholar] [CrossRef]

- Bengtsson, M.; D’Cruze, R.S.; Ahmed, M.U.; Sakao, T.; Funk, P.; Sohlberg, R. Combining Ontology and Large Language Models to Identify Recurring Machine Failures in Free-Text Fields. In Advances in Transdisciplinary Engineering; Andersson, J., Joshi, S., Malmsköld, L., Hanning, F., Eds.; IOS Press: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.F. Large Language Model Empowered by Domain-Specific Knowledge Base for Industrial Equipment Operation and Maintenance. In Proceedings of the 2023 5th International Conference on System Reliability and Safety Engineering (SRSE), Beijing, China, 20–23 October 2023; pp. 474–479. [Google Scholar] [CrossRef]

- Kok, I.; Demirci, O.; Ozdemir, S. When IoT Meet LLMs: Applications and Challenges. arXiv 2024, arXiv:2411.17722. [Google Scholar] [CrossRef]

- Mahr, F.; Angeli, G.; Sindel, T.; Schmidt, K.; Franke, J. A Reference Architecture for Deploying Large Language Model Applications in Industrial Environments. In Proceedings of the 2024 IEEE 30th International Symposium for Design and Technology in Electronic Packaging (SIITME), Sibiu, Romania, 16–18 October 2024; pp. 19–23. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, Y.; Qian, B.; Shi, X.; Shu, Y.; Chen, J. A Review on Edge Large Language Models: Design, Execution, and Applications. arXiv 2024, arXiv:2410.11845. [Google Scholar] [CrossRef]

- Friha, O.; Amine Ferrag, M.; Kantarci, B.; Cakmak, B.; Ozgun, A.; Ghoualmi-Zine, N. LLM-Based Edge Intelligence: A Comprehensive Survey on Architectures, Applications, Security and Trustworthiness. IEEE Open J. Commun. Soc. 2024, 5, 5799–5856. [Google Scholar] [CrossRef]

- Dashdamirli, N. Integration of Large Language Models with microcontrollers to optimize industrial automation processes. InterConf 2024, 46, 500–507. [Google Scholar] [CrossRef]

- Vyas, J.; Mercangöz, M. Autonomous Industrial Control using an Agentic Framework with Large Language Models. arXiv 2024, arXiv:2411.05904. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, H. Intelligent industrial production process automatic regulation system based on LLM agents. In Proceedings of the 2024 5th International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Shenzhen, China, 14–16 June 2024; pp. 133–137. [Google Scholar] [CrossRef]

- Mavroudis, V. LangChain. 2024. Available online: https://www.preprints.org/manuscript/202411.0566 (accessed on 20 August 2024). [CrossRef]

- Xia, Y.; Jazdi, N.; Zhang, J.; Shah, C.; Weyrich, M. Control Industrial Automation System with Large Language Model Agents. arXiv 2024, arXiv:2409.18009. [Google Scholar] [CrossRef]

- Xi, Z.; Chen, W.; Guo, X.; He, W.; Ding, Y.; Hong, B.; Zhang, M.; Wang, J.; Jin, S.; Zhou, E.; et al. The rise and potential of large language model based agents: A survey. Sci. China Inf. Sci. 2025, 68, 121101. [Google Scholar] [CrossRef]

- Masterman, T.; Besen, S.; Sawtell, M.; Chao, A. The Landscape of Emerging AI Agent Architectures for Reasoning, Planning, and Tool Calling: A Survey. arXiv 2024, arXiv:2404.11584. [Google Scholar] [CrossRef]

- OpenAI. A Practical Guide to Building Agents. 2025. Available online: https://cdn.openai.com/business-guides-and-resources/a-practical-guide-to-building-agents.pdf (accessed on 15 September 2025).

- Putta, P.; Mills, E.; Garg, N.; Motwani, S.; Finn, C.; Garg, D.; Rafailov, R. Agent Q: Advanced Reasoning and Learning for Autonomous AI Agents. arXiv 2024, arXiv:2408.07199. [Google Scholar] [CrossRef]

- Wilkins, D.E. Practical Planning: Extending the Classical AI Planning Paradigm; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Maes, P. Designing Autonomous Agents: Theory and Practice from Biology to Engineering and Back; MIT Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Bommasani, R.; Hudson, D.A.; Adeli, E.; Altman, R.; Arora, S.; von Arx, S.; Bernstein, M.S.; Bohg, J.; Bosselut, A.; Brunskill, E.; et al. On the Opportunities and Risks of Foundation Models. arXiv 2022, arXiv:2108.07258. [Google Scholar]

- Gozalo-Brizuela, R.; Garrido-Merchan, E.C. ChatGPT is not all you need. A State of the Art Review of large Generative AI models. arXiv 2023, arXiv:2301.04655. [Google Scholar] [CrossRef]

- Russell, S. Human Compatible: AI and the Problem of Control; Penguin: London, UK, 2019. [Google Scholar]

- Ray, P.P. A Survey on Model Context Protocol: Architecture, State-of-the-art, Challenges and Future Directions. TechRxiv 2025. [Google Scholar] [CrossRef]

- Hou, X.; Zhao, Y.; Wang, S.; Wang, H. Model Context Protocol (MCP): Landscape, Security Threats, and Future Research Directions. arXiv 2025, arXiv:2503.23278. [Google Scholar] [CrossRef]

- Xi, Z.; Ding, Y.; Chen, W.; Hong, B.; Guo, H.; Wang, J.; Yang, D.; Liao, C.; Guo, X.; He, W.; et al. AgentGym: Evolving Large Language Model-based Agents across Diverse Environments. arXiv 2024, arXiv:2406.04151. [Google Scholar] [CrossRef]

- Walker, C.; Gharaibeh, T.; Alsmadi, R.; Hall, C.; Baggili, I. Forensic Analysis of Artifacts from Microsoft’s Multi-Agent LLM Platform AutoGen. In Proceedings of the 19th International Conference on Availability, Reliability and Security, Vienna, Austria, 30 July–2 August 2024; pp. 1–9. [Google Scholar] [CrossRef]

- Chen, W.; Su, Y.; Zuo, J.; Yang, C.; Yuan, C.; Chan, C.M.; Yu, H.; Lu, Y.; Hung, Y.H.; Qian, C.; et al. AgentVerse: Facilitating Multi-Agent Collaboration and Exploring Emergent Behaviors. arXiv 2023, arXiv:2308.10848. [Google Scholar] [CrossRef]

- Huang, K.; Huang, J. AI Agent Tools and Frameworks. In Agentic AI: Theories and Practices; Huang, K., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 23–50. [Google Scholar] [CrossRef]

- Bhattacharjee, A. Overview of Amazon Bedrock Agents. In A Practical Guide to Generative AI Using Amazon Bedrock: Building, Deploying, and Securing Generative AI Applications; Apress: Berkeley, CA, USA, 2025; pp. 229–248. [Google Scholar] [CrossRef]

- Giada, C.V.; Rossella, P. Barriers to Predictive Maintenance implementation in the Italian machinery industry. IFAC-PapersOnLine 2021, 54, 1266–1271. [Google Scholar] [CrossRef]

- Chen, Q.; Cao, J.; Zhu, S. Data-Driven Monitoring and Predictive Maintenance for Engineering Structures: Technologies, Implementation Challenges, and Future Directions. IEEE Internet Things J. 2023, 10, 14527–14551. [Google Scholar] [CrossRef]

- Tiddens, W.; Braaksma, J.; Tinga, T. Exploring predictive maintenance applications in industry. J. Qual. Maint. Eng. 2022, 28, 68–85. [Google Scholar] [CrossRef]

- Molęda, M.; Małysiak-Mrozek, B.; Ding, W.; Sunderam, V.; Mrozek, D. From Corrective to Predictive Maintenance—A Review of Maintenance Approaches for the Power Industry. Sensors 2023, 23, 5970. [Google Scholar] [CrossRef] [PubMed]

- Azari, M.S.; Flammini, F.; Santini, S.; Caporuscio, M. A Systematic Literature Review on Transfer Learning for Predictive Maintenance in Industry 4.0. IEEE Access 2023, 11, 12887–12910. [Google Scholar] [CrossRef]

- Strielkowski, W.; Vlasov, A.; Selivanov, K.; Muraviev, K.; Shakhnov, V. Prospects and Challenges of the Machine Learning and Data-Driven Methods for the Predictive Analysis of Power Systems: A Review. Energies 2023, 16, 4025. [Google Scholar] [CrossRef]

- Ross, S.A. The economic theory of agency: The principal’s problem. Am. Econ. Rev. 1973, 63, 134–139. [Google Scholar]

- Engels, J.; Baek, D.D.; Kantamneni, S.; Tegmark, M. Scaling Laws For Scalable Oversight. arXiv 2025, arXiv:2504.18530. [Google Scholar] [CrossRef]

- Marks, S.; Treutlein, J.; Bricken, T.; Lindsey, J.; Marcus, J.; Mishra-Sharma, S.; Ziegler, D.; Ameisen, E.; Batson, J.; Belonax, T.; et al. Auditing language models for hidden objectives. arXiv 2025, arXiv:2503.10965. [Google Scholar] [CrossRef]

- Handa, K.; Tamkin, A.; McCain, M.; Huang, S.; Durmus, E.; Heck, S.; Mueller, J.; Hong, J.; Ritchie, S.; Belonax, T.; et al. Which Economic Tasks are Performed with AI? Evidence from Millions of Claude Conversations. arXiv 2025, arXiv:2503.04761. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Li, D.; Raymond, L. Generative AI at Work. Q. J. Econ. 2025, 140, 889–942. [Google Scholar] [CrossRef]

| Topic | Capabilities | Sources |

|---|---|---|

| CNN-based diagnosis |

| [15,34,35,36] |

| RNN, LSTM and CNN–RNN hybrids |

| [17,18,37] |

| Transformers and CNN–Transformer hybrids |

| [20,21,38,39] |

| Traditional ML, SVM |

| [13,14,40] |

| Traditional ML, Ensembles |

| [9,41] |

| Transfer learning for domain shift |

| [12,42,43,44] |

| Physics-informed and hybrid approaches |

| [19,45,46,47,48,49] |

| Few-shot and meta-learning |

| [50,51,52] |

| Federated learning in PdM |

| [53,54,55,56] |

| Key challenges (data and interpretability) |

| [1,22,49,51,57,58,61,62] |

| Topic | Capabilities | Sources |

|---|---|---|

| Rotating machinery foundation model |

| [80] |

| FMEA drafting with LLMs |

| [81] |

| Enterprise deployment (oil & gas) |

| [28] |

| Multimodal agent |

| [83,84] |

| Sectoral applications: aeronautics; railways; rotating machinery |

| [80,85,86,87,88] |

| Context-aware, tool-calling agent (prescriptive) |

| [89] |

| Offshore wind agent; PHM evaluation |

| [90,91] |

| Digital Twin, multimodal agents |

| [92,93,94] |

| Multimodal LLM framework and safety |

| [95] |

| Specialized vision language models for PHM |

| [96] |

| CMMS knowledge extraction; Information retreval |

| [97,98] |

| LLMOps and edge–fog–cloud integration |

| [99,100,101,102,103] |

| Autonomous industrial control with LLM agents |

| [104,105,106,107] |

| Use Case | Inputs and Actions | Key Risks and Concerns | Mitigations and Controls |

|---|---|---|---|

| Monitoring, diagnosis and RCA |

|

|

|

| Spare parts management and procurement |

|

|

|

| CMMS orchestration and planning |

|

|

|

| PdM model life-cycle management |

|

|

|

| Factor | Type | Evidence | Implication |

|---|---|---|---|

| Investment momentum in AI and Generative AI | Driver |

|

|

| Organizational adoption acceleration | Driver |

|

|

| Productivity gains | Driver |

|

|

| Robotics base growth | Driver |

|

|

| Modest average financial impact | Barrier |

|

|

| Regional and sector asymmetries | Barrier |

|

|

| Usage pattern mainly augmentative | Barrier |

|

|

| Limited physical-interaction skills in LLM usage survey | Barrier |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Maggio, L.G. Toward Autonomous LLM-Based AI Agents for Predictive Maintenance: State of the Art, Challenges, and Future Perspectives. Appl. Sci. 2025, 15, 11515. https://doi.org/10.3390/app152111515

Di Maggio LG. Toward Autonomous LLM-Based AI Agents for Predictive Maintenance: State of the Art, Challenges, and Future Perspectives. Applied Sciences. 2025; 15(21):11515. https://doi.org/10.3390/app152111515

Chicago/Turabian StyleDi Maggio, Luigi Gianpio. 2025. "Toward Autonomous LLM-Based AI Agents for Predictive Maintenance: State of the Art, Challenges, and Future Perspectives" Applied Sciences 15, no. 21: 11515. https://doi.org/10.3390/app152111515

APA StyleDi Maggio, L. G. (2025). Toward Autonomous LLM-Based AI Agents for Predictive Maintenance: State of the Art, Challenges, and Future Perspectives. Applied Sciences, 15(21), 11515. https://doi.org/10.3390/app152111515