Design and Performance of Table ASSIST-EW: An Assisting Device for Elbow and Wrist

Abstract

1. Introduction

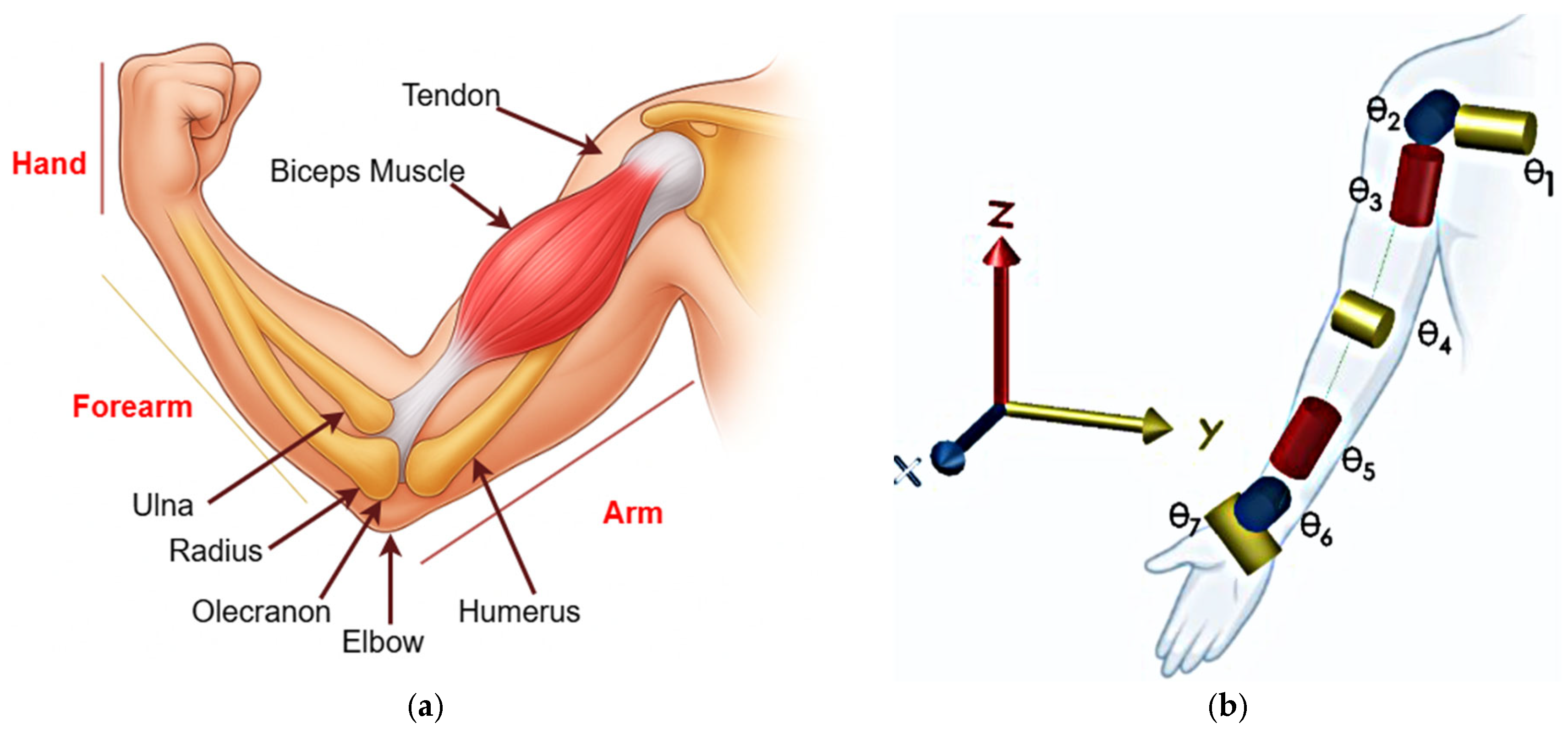

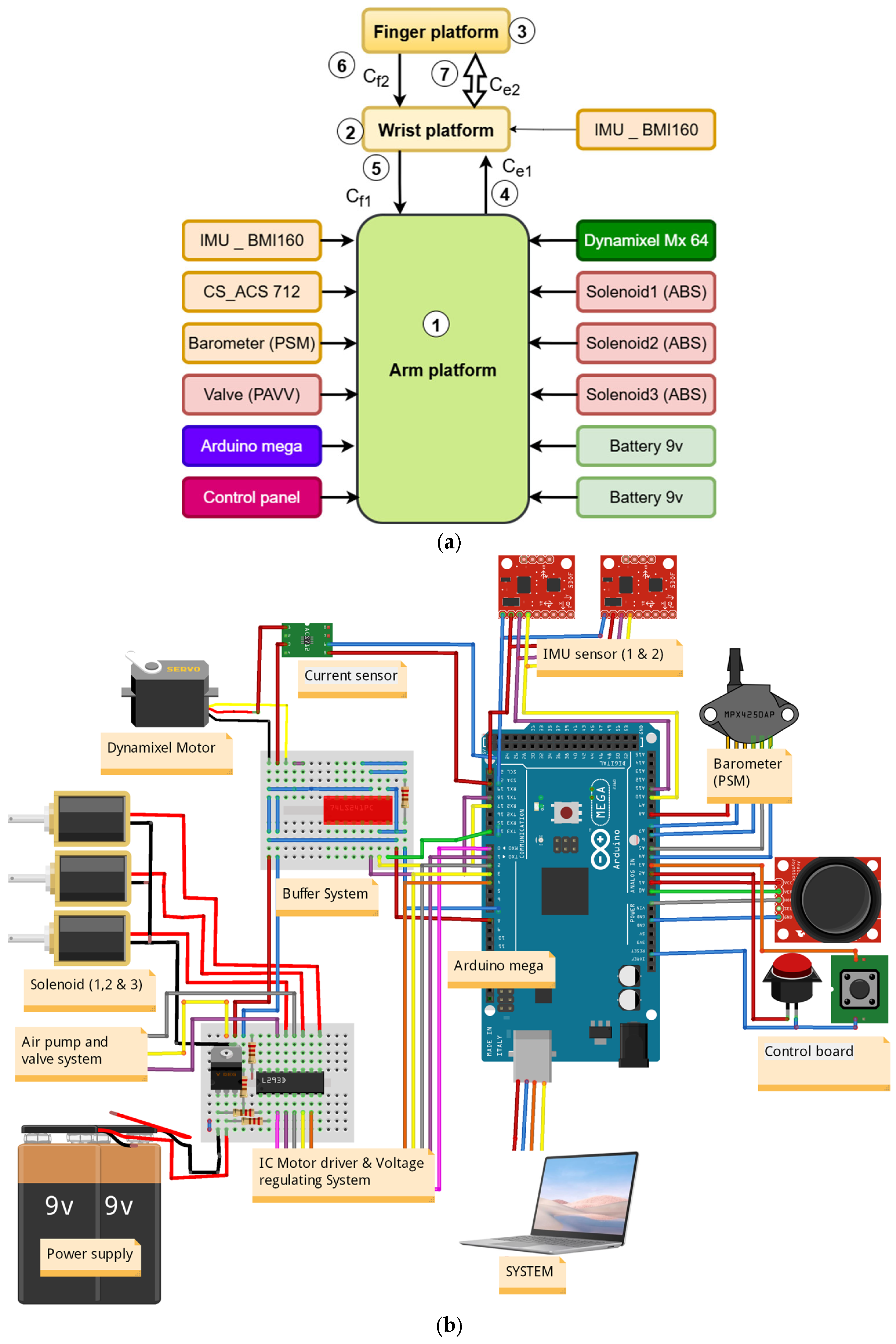

2. Materials and Methods

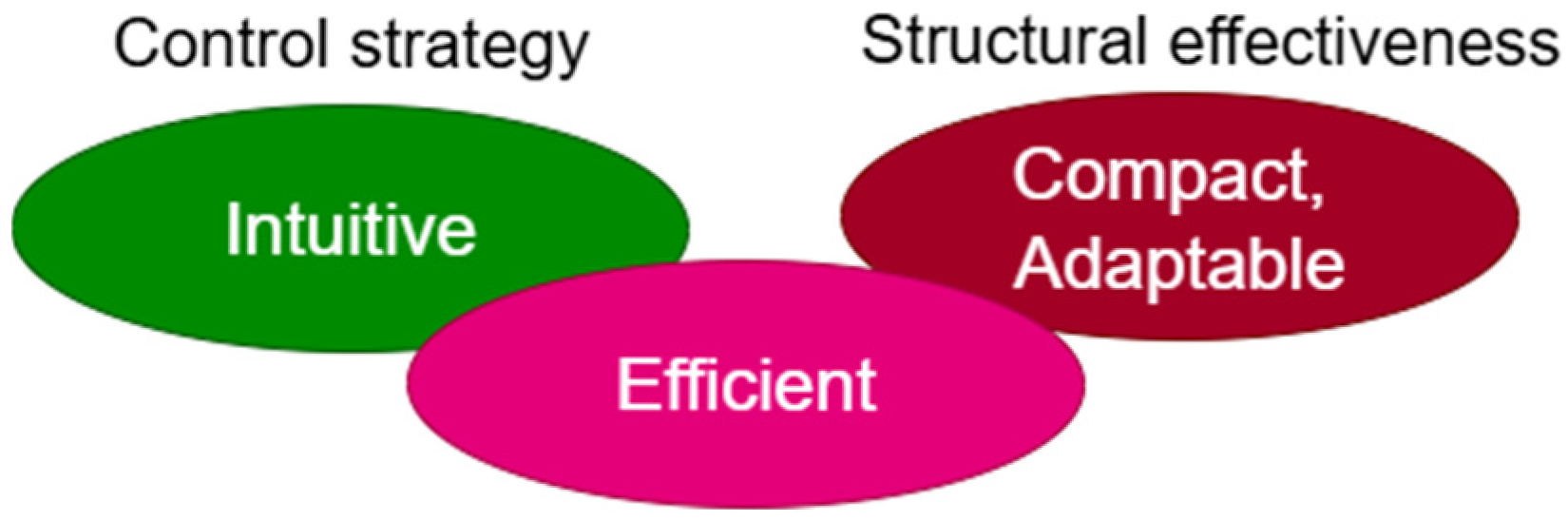

2.1. Operation and Design Requirements

- Intuitive: Operable with minimal training or external guidance.

- Efficient: Capable of delivering adequate mechanical assistance without unnecessary complexity, and capable of smooth well-controlled motion independent of the orientation of the body.

- Compact: Small and lightweight enough for domestic or clinical settings without compromising functionality.

- Adaptable: Adjustable to accommodate different body sizes, strength levels, and therapeutic needs.

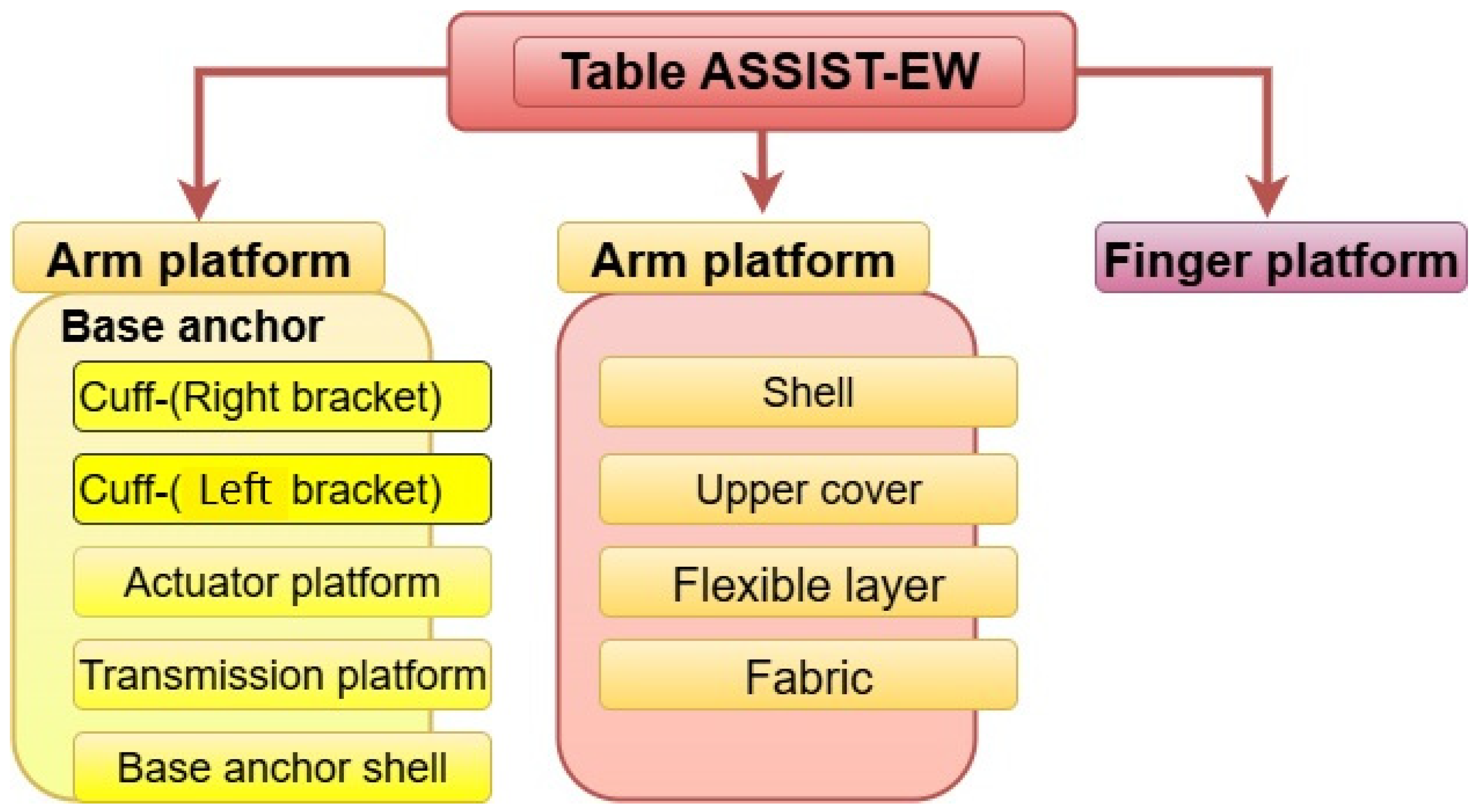

2.2. Conceptual Design

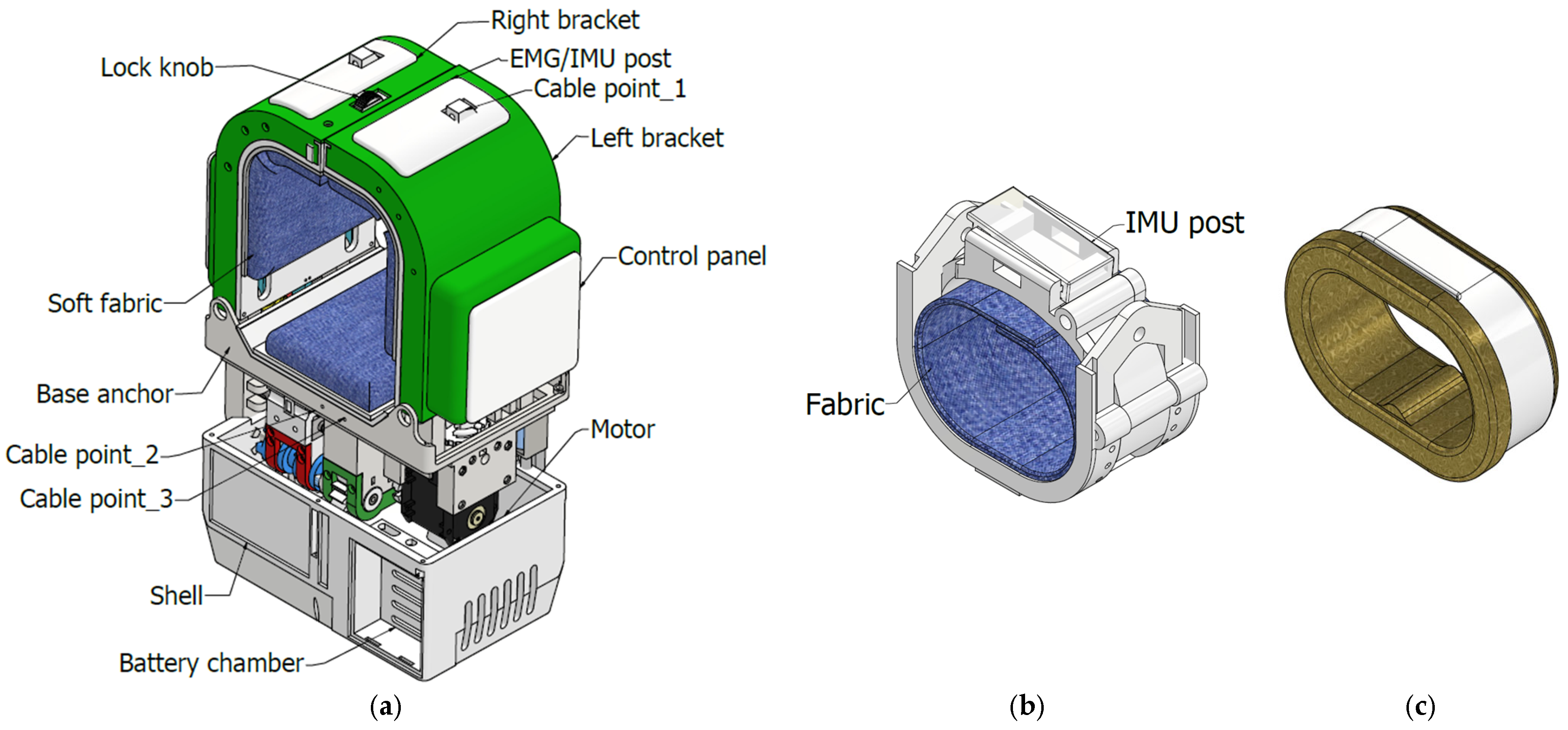

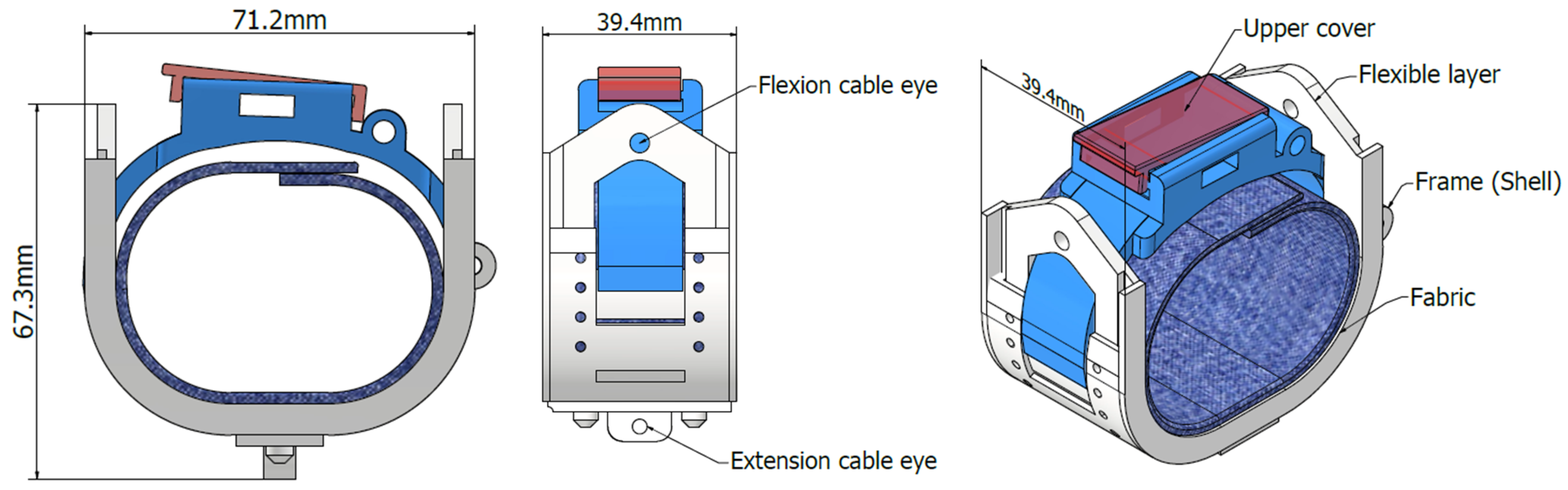

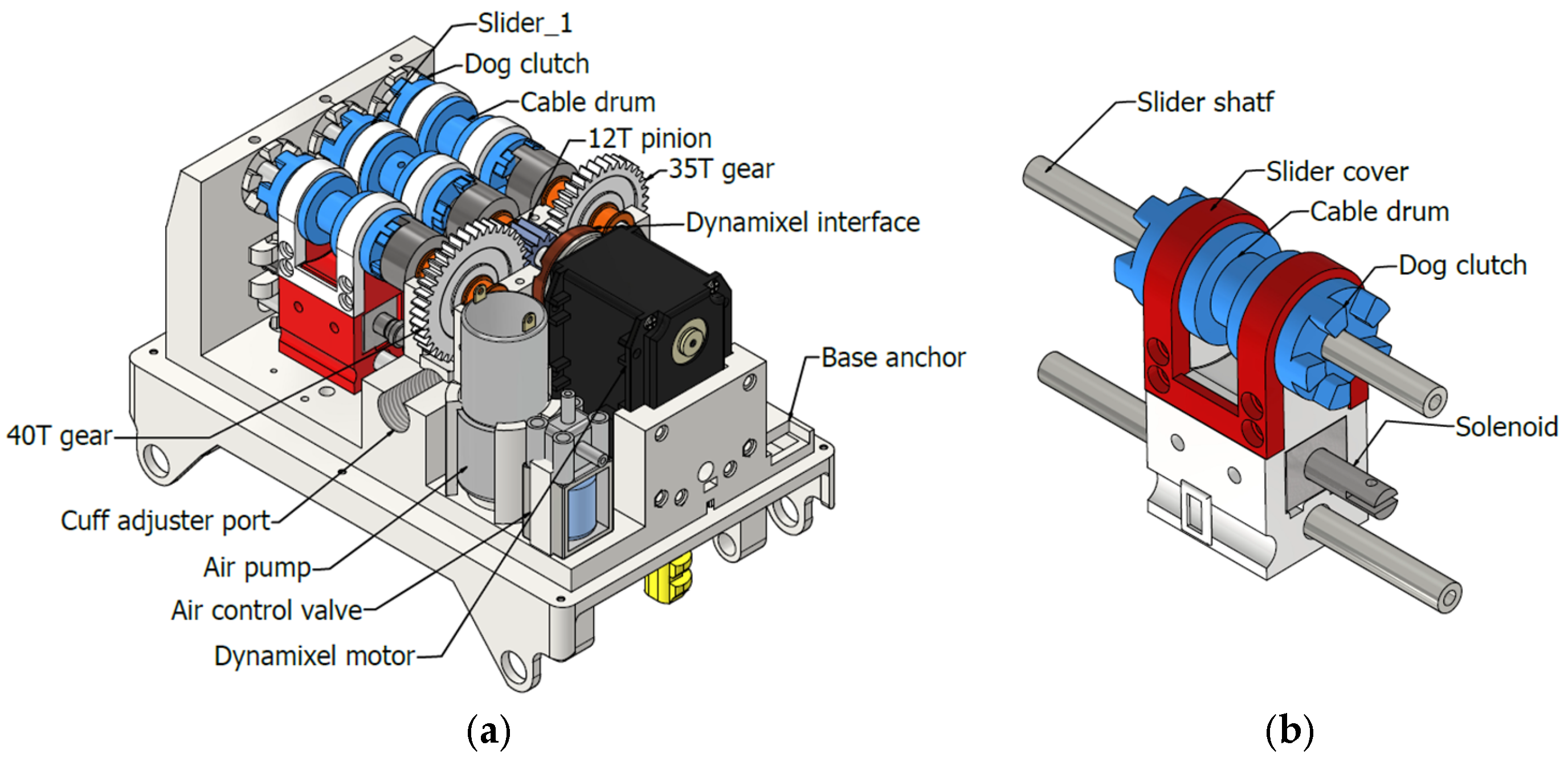

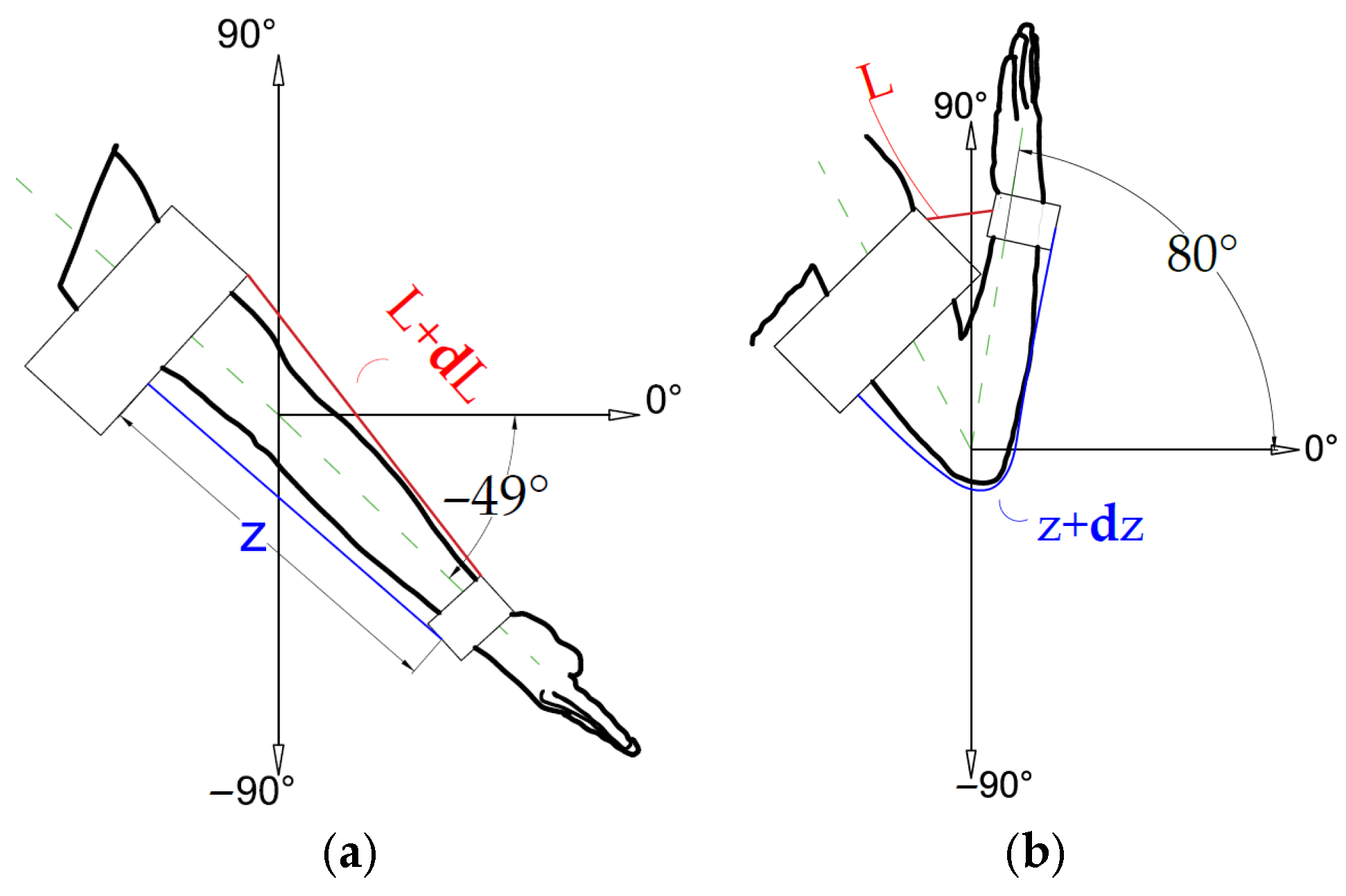

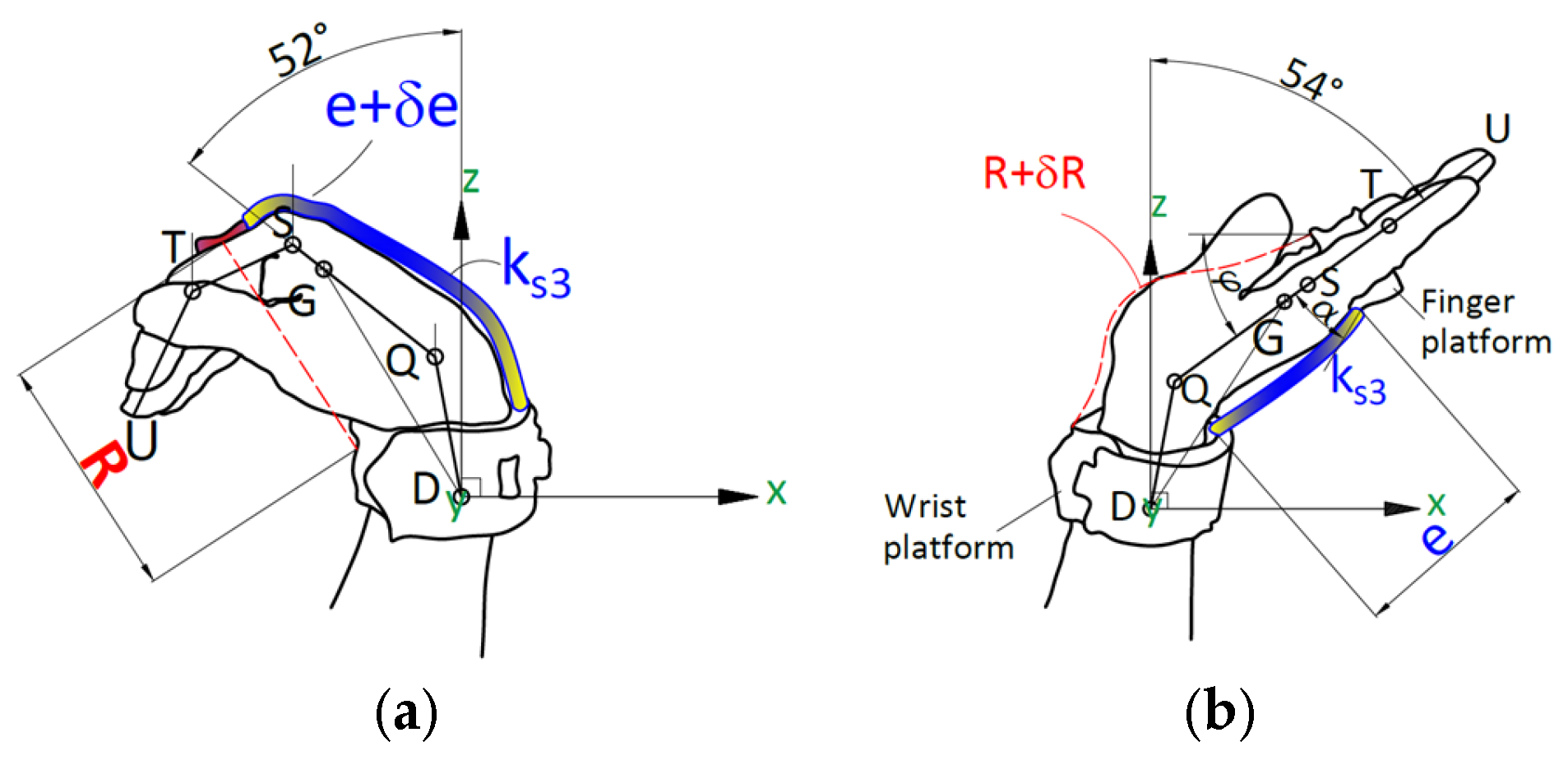

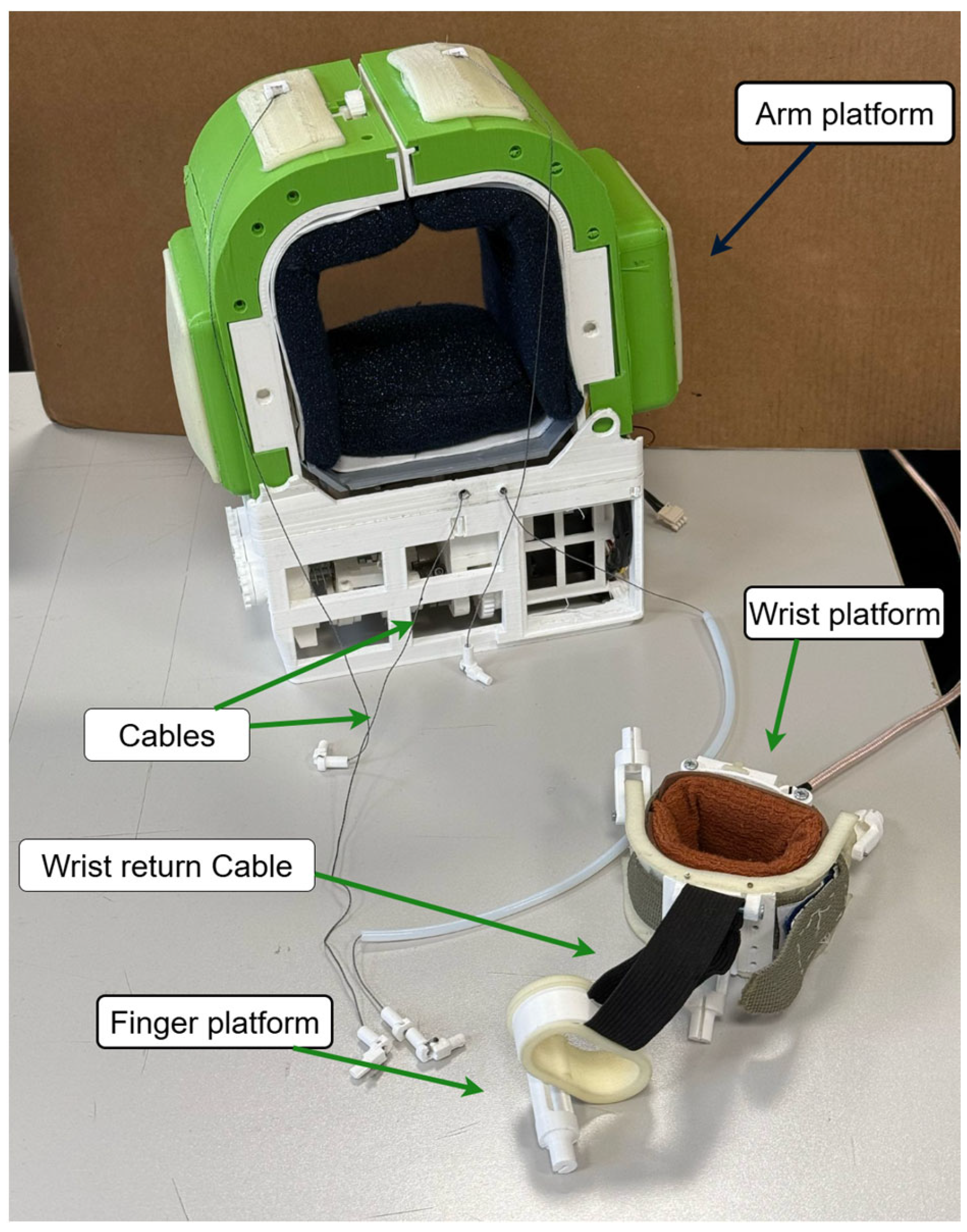

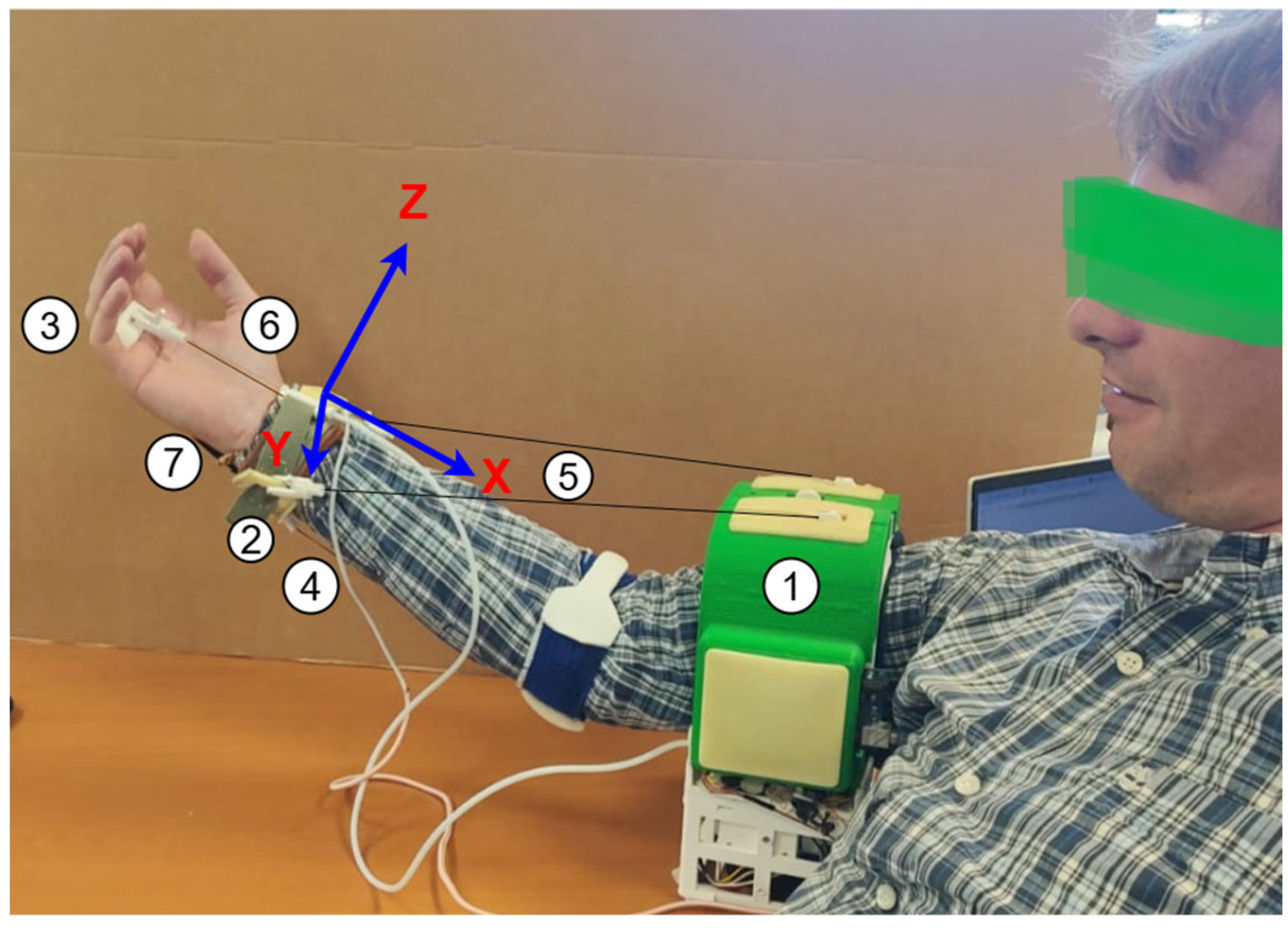

2.3. Mechanical Design

2.4. Performance Analysis

3. Results

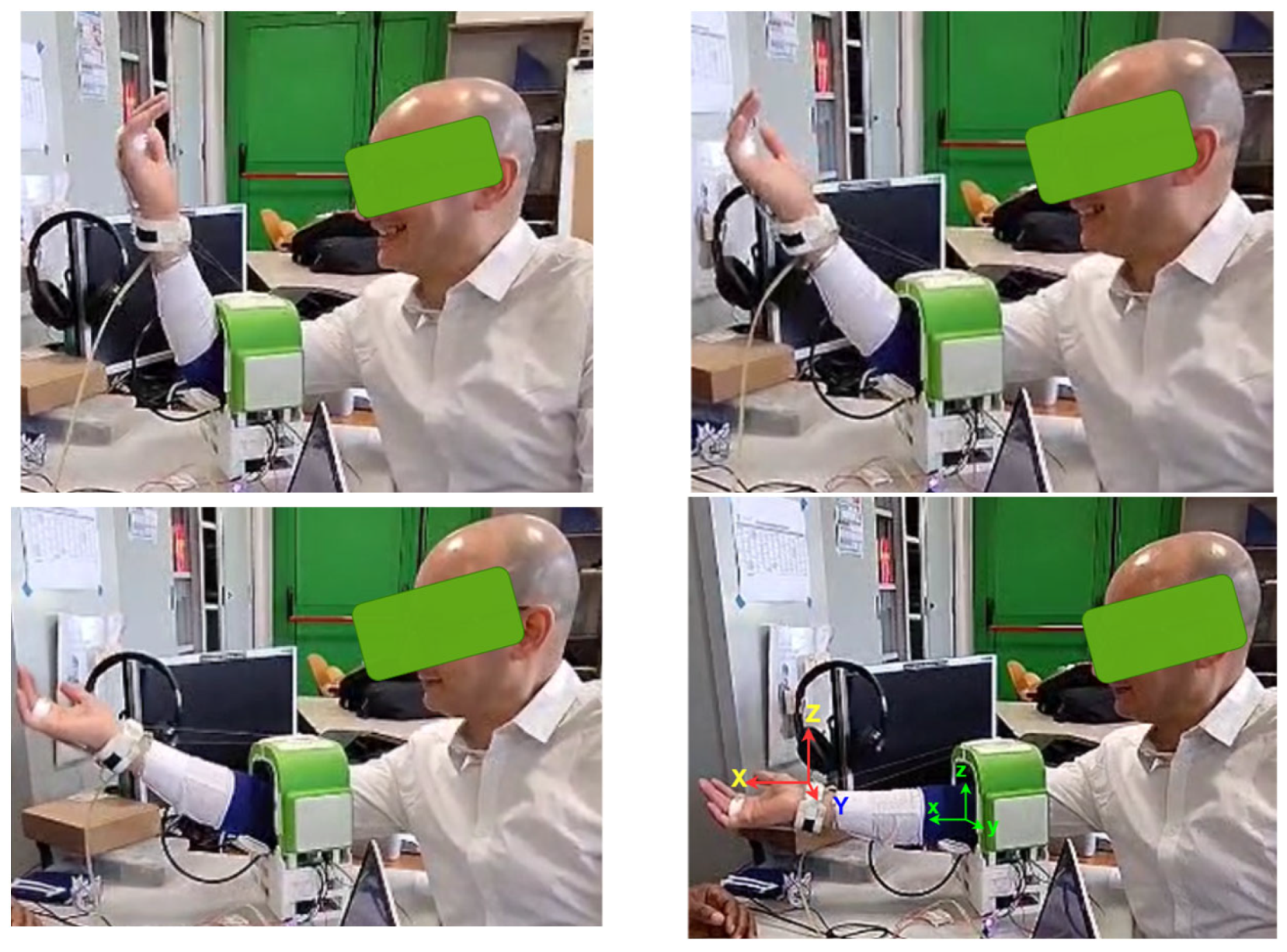

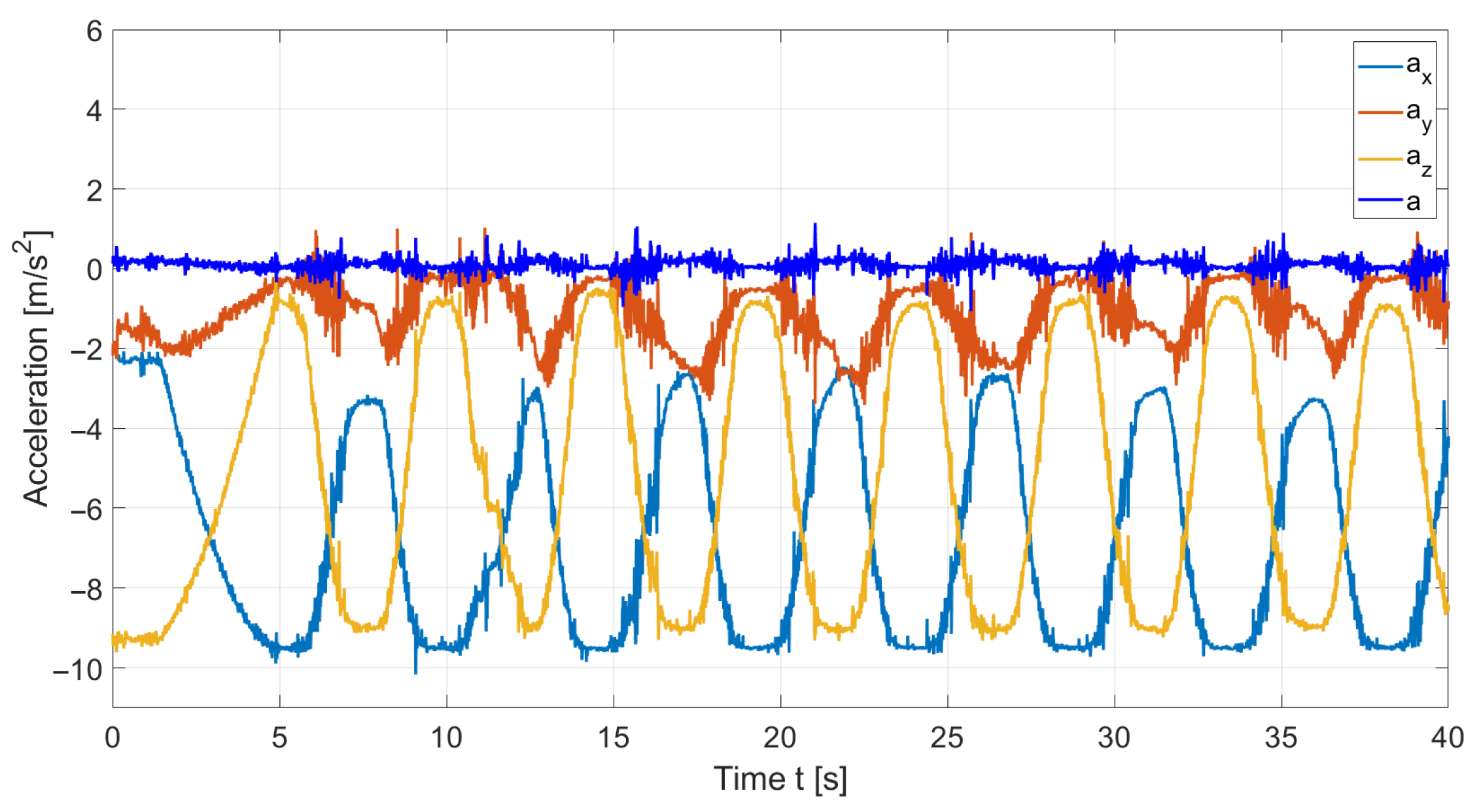

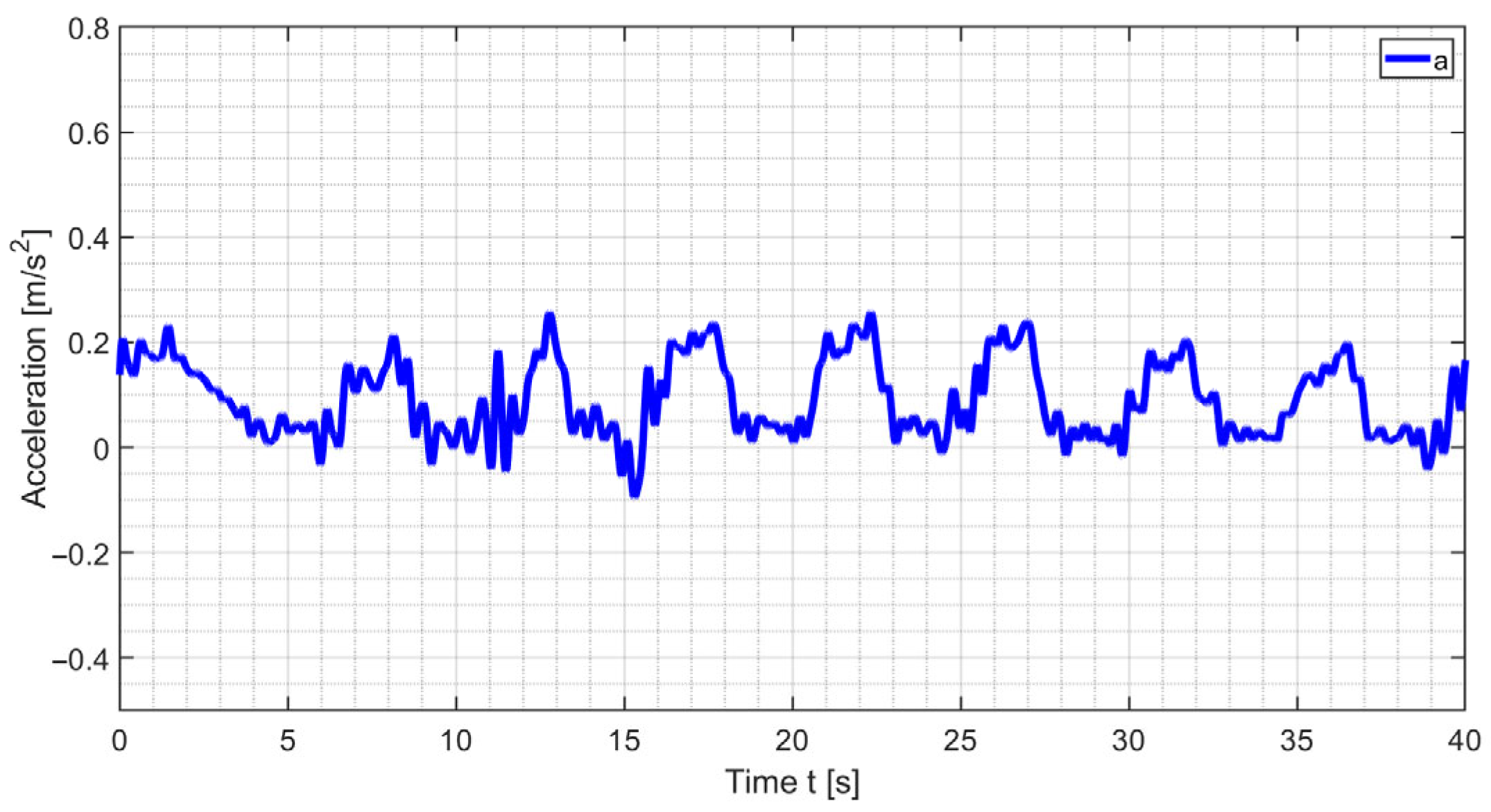

Experimental Validation

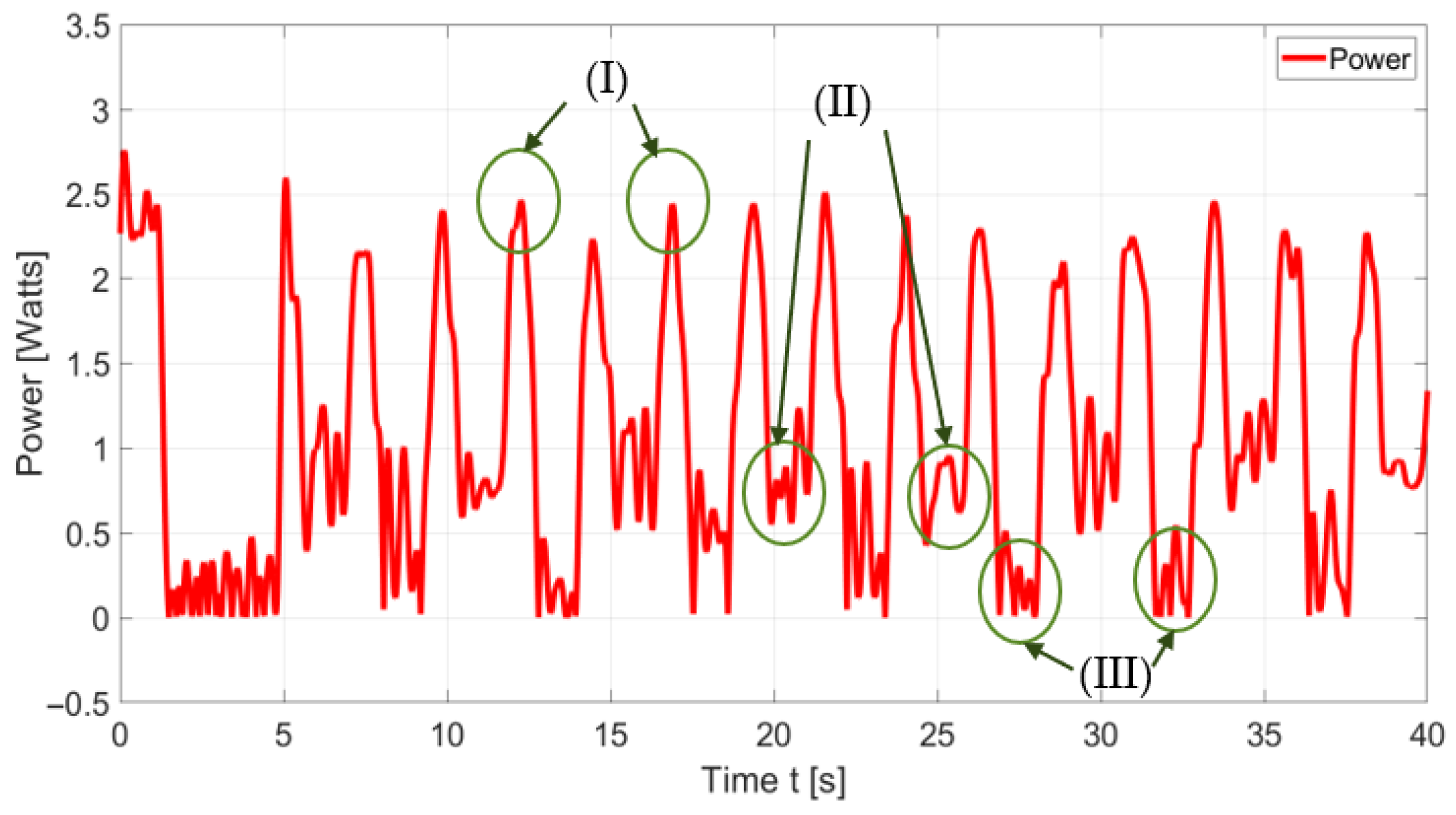

- (I)

- These peaks represent the highest power consumption during the exercise cycle. They occur during arm flexion, when the flexion cable pulls and lifts the arm against gravity, necessitating a corresponding increase in energy demand. Additional power is also required when the wrist flexion cable works against the resistance of the elastic return cable. During this phase, the arm’s angular motion ranges from 10° to 90°, with power consumption between 2.2 and 2.7 W.

- (II)

- These peaks correspond to the lowering of the arm that is associated with arm extension. This occurs when the angle decreases from 90° to 45°, during which power is required to decelerate the arm and to bring it to a stop before reaching the lower limit. Power consumption during this phase ranges from 1.0 to 1.5 W.

- (III)

- These regions correspond to the transition between arm extension and flexion. This occurs at approximately 10°, when the arm comes to rest. Power consumption during this phase ranges from 0.2 to 1.2 W.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bajaj, N.M.; Dollar, A.M. Design and preliminary evaluation of a 3-DOF powered prosthetic wrist device. In Proceedings of the 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob), Enschede, The Netherlands, 26–29 August 2018; pp. 119–125. [Google Scholar] [CrossRef]

- Fan, H.; Wei, G.; Ren, L. Prosthetic and robotic wrists comparing with the intelligently evolved human wrist: A review. Robotica 2022, 40, 4169–4191. [Google Scholar] [CrossRef]

- Bian, H.; Chen, Z.; Wang, H.; Zhao, T. Mechanical design of EFW Exo II: A hybrid exoskeleton for elbow-forearm-wrist rehabilitation. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 689–694. [Google Scholar] [CrossRef]

- Bok Hong, M.; Yoon, D.; Park, J.; Kim, K. KULEX-Wrist: Design and analysis of linkage-driven exoskeleton for wrist assistance. J. Mech. Des. 2024, 146, 083303. [Google Scholar] [CrossRef]

- Wu, X.; Zou, Y.; Zhang, Q.; Zhang, B.; Gu, X.; Zhang, J. Design and experimental research of cable-driven upper-limb rehabilitation robot. In Intelligent Robotics and Applications; Liu, X., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Springer: Cham, Switzerland, 2021; Volume 13013. [Google Scholar] [CrossRef]

- Cael, C. Functional Anatomy: Musculoskeletal Anatomy, Kinesiology, and Palpation for Manual Therapists with Navigate Advantage Access; Jones & Bartlett Learning: Burlington, MA, USA, 2022; ISBN 978-1284234800. [Google Scholar]

- Ceccarelli, M. Challenges in service robot devices for elderly motion assistance. Robotica 2024, 42, 4186–4199. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Cruz, C.M.; Ofonaike, E. Problems and design for a cable-driven device for elbow-wrist assistance. In Proceedings of the 2025 IEEE International Conference on Mechatronics (ICM), Wollongong, Australia, 28 February–2 March 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Kotov, S.; Ofonaike, E.; Russo, M. Test results and considerations for design improvements of L-CADEL v.3 elbow-assisting device. Machines 2024, 12, 808. [Google Scholar] [CrossRef]

- Cheng, H.H.; Kwok, T.M.; Yu, H. Design and control of the portable upper-limb elbow-forearm exoskeleton for ADL assistance. In Proceedings of the 2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023; pp. 343–349. [Google Scholar] [CrossRef]

- Cornejo, J.; Huamanchahua, D.; Huamán-Vizconde, S.; Terrazas-Rodas, D.; Sierra-Huertas, J.; Janampa-Espinoza, A.; Gonzáles, J.; Cardona, M. Mechatronic exoskeleton systems for supporting the biomechanics of shoulder-elbow-wrist: An innovative review. In Proceedings of the 2021 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), Toronto, ON, Canada, 21–24 April 2021; pp. 1–9. [Google Scholar] [CrossRef]

- Delgado, P.; Yihun, Y. Integration of task-based exoskeleton with an assist-as-needed algorithm for patient-centered elbow rehabilitation. Sensors 2023, 23, 2460. [Google Scholar] [CrossRef] [PubMed]

- Dias, E.A.F.; Andrade, R.M. Design of a cable-driven actuator for pronation and supination of the forearm to integrate an active arm orthosis. Proceedings 2020, 64, 4. [Google Scholar] [CrossRef]

- Jeong, J.; Yasir, I.B.; Han, J.; Park, C.H.; Bok, S.-K.; Kyung, K.-U. Design of shape memory alloy-based soft wearable robot for assisting wrist motion. Appl. Sci. 2019, 9, 4025. [Google Scholar] [CrossRef]

- Laribi, M.A.; Ceccarelli, M.; Sandoval, J.; Bottin, M.; Rosati, G. Experimental validation of light cable-driven elbow-assisting device L-CADEL design. J. Bionic Eng. 2022, 19, 416–428. [Google Scholar] [CrossRef]

- Lin, T.-Y.; Chen, Z.-Y.; Chang, J.-Y. Design and implementation of a cable-driven wrist exoskeleton with enhanced adaptability. In Proceedings of the IET International Conference on Engineering Technologies and Applications (ICETA 2024), Taipei, Taiwan, 25–27 October 2024; pp. 146–147. [Google Scholar] [CrossRef]

- Maciejasz, P.; Eschweiler, J.; Gerlach-Hahn, K.; Jansen-Troy, A.; Leonhardt, S. A survey on robotic devices for upper limb rehabilitation. J. NeuroEng. Rehabil. 2014, 11, 1–29. [Google Scholar] [CrossRef]

- Meattini, R.; Palli, G.; Melchiorri, C. Experimental evaluation of a sEMG-based control for elbow wearable assistive devices during load lifting tasks. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 140–145. [Google Scholar] [CrossRef]

- Mobedi, E.; Kim, W.; Leonori, M.; Tsagarakis, N.G.; Ajoudani, A. Design and control of an assistive device for elbow effort-compensation. IEEE ASME Trans. Mechatron. 2023, 28, 3446–3457. [Google Scholar] [CrossRef]

- Wei, F.; Luo, K.; Zhang, Y.; Jiang, J. Structural design and kinematic analysis of cable-driven soft robot. Actuators 2024, 13, 497. [Google Scholar] [CrossRef]

- Pang, Z.; Wang, T.; Wang, Z.; Yu, J.; Sun, Z.; Liu, S. Design and analysis of a wearable upper limb rehabilitation robot with characteristics of tension mechanism. Appl. Sci. 2020, 10, 2101. [Google Scholar] [CrossRef]

- Palazzi, E.; Luzi, L.; Dimo, E.; Meneghetti, M.; Vicario, R.; Luzia, R.F.; Vertechy, R.; Calanca, A. An affordable upper-limb exoskeleton concept for rehabilitation applications. Technologies 2022, 10, 22. [Google Scholar] [CrossRef]

- Sanjuan, J.D.; Castillo, A.D.; Padilla, M.A.; Quintero, M.C.; Gutierrez, E.E.; Sampayo, I.P.; Hernandez, J.R.; Rahman, M.H. Cable driven exoskeleton for upper-limb rehabilitation: A design review. Robot. Auton. Syst. 2020, 126, 103445. [Google Scholar] [CrossRef]

- Shi, K.; Song, A.; Li, Y.; Li, H.; Chen, D.; Zhu, L. A cable-driven three-DOF wrist rehabilitation exoskeleton with improved performance. Front. Neurorobot. 2021, 15, 664062. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Jiao, Z.; Yu, H.; Zhang, W. Design and evaluation of a novel upper limb rehabilitation robot with space training based on an end effector. Mech. Sci. 2021, 12, 639–648. [Google Scholar] [CrossRef]

- Vazzoler, G.; Camardella, C.; Gabardi, M.; Marcheschi, S.; Solazzi, M.; Berselli, G.; Frisoli, A. Design and performance assessment of a cable-driven, 3-DOFs exoskeleton for orthopedic and poststroke rehabilitation of the wrist. IEEE ASME Trans. Mechatron. 2025, 30, 3892–3903. [Google Scholar] [CrossRef]

- Wu, K.-Y.; Su, Y.-Y.; Yu, Y.-L.; Lin, C.-H.; Lan, C.-C. A 5-degrees-of-freedom lightweight elbow-wrist exoskeleton for forearm fine-motion rehabilitation. IEEE ASME Trans. Mechatron. 2019, 24, 2684–2695. [Google Scholar] [CrossRef]

- Zuccon, G.; Bottin, M.; Ceccarelli, M.; Rosati, G. Design and performance of an elbow assisting mechanism. Machines 2020, 8, 68. [Google Scholar] [CrossRef]

- Lau, D.; Pott, A.; Bruckmann, T. (Eds.) Cable-Driven Parallel Robots. In Mechanisms and Machine Science, Proceedings of the 7th International Conference on Cable-Driven Parallel Robots, Hong Kong, 8–11 July 2025; Springer: Cham, Switzerland, 2025; Volume 182. [Google Scholar] [CrossRef]

- Holzbaur, K.R.S.; Murray, W.M.; Delp, S.L. A model of the upper extremity for simulating musculoskeletal surgery and analyzing neuromuscular control. Ann. Biomed. Eng. 2005, 33, 829–840. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef]

- Robotis. Dynamixel MX-64 Series. Robotis e-Manual. Available online: https://emanual.robotis.com/docs/en/dxl/mx/mx-64/ (accessed on 7 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ofonaike, E.U.; Ceccarelli, M. Design and Performance of Table ASSIST-EW: An Assisting Device for Elbow and Wrist. Appl. Sci. 2025, 15, 11482. https://doi.org/10.3390/app152111482

Ofonaike EU, Ceccarelli M. Design and Performance of Table ASSIST-EW: An Assisting Device for Elbow and Wrist. Applied Sciences. 2025; 15(21):11482. https://doi.org/10.3390/app152111482

Chicago/Turabian StyleOfonaike, Earnest Ugonna, and Marco Ceccarelli. 2025. "Design and Performance of Table ASSIST-EW: An Assisting Device for Elbow and Wrist" Applied Sciences 15, no. 21: 11482. https://doi.org/10.3390/app152111482

APA StyleOfonaike, E. U., & Ceccarelli, M. (2025). Design and Performance of Table ASSIST-EW: An Assisting Device for Elbow and Wrist. Applied Sciences, 15(21), 11482. https://doi.org/10.3390/app152111482