Research on Predicting Joint Rotation Angles Through Mechanomyography Signals and the Broad Learning System

Abstract

1. Introduction

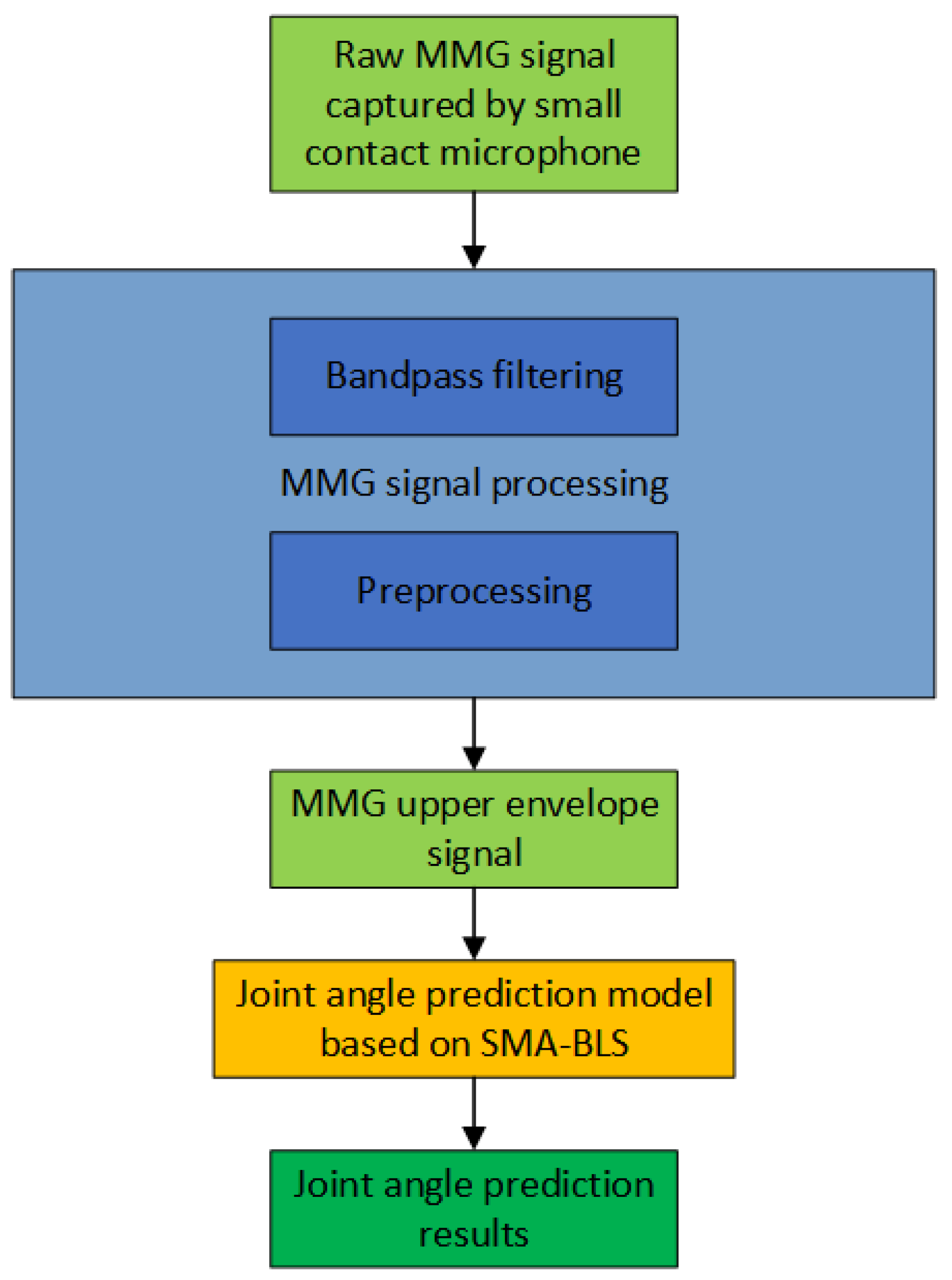

2. Materials and Methods

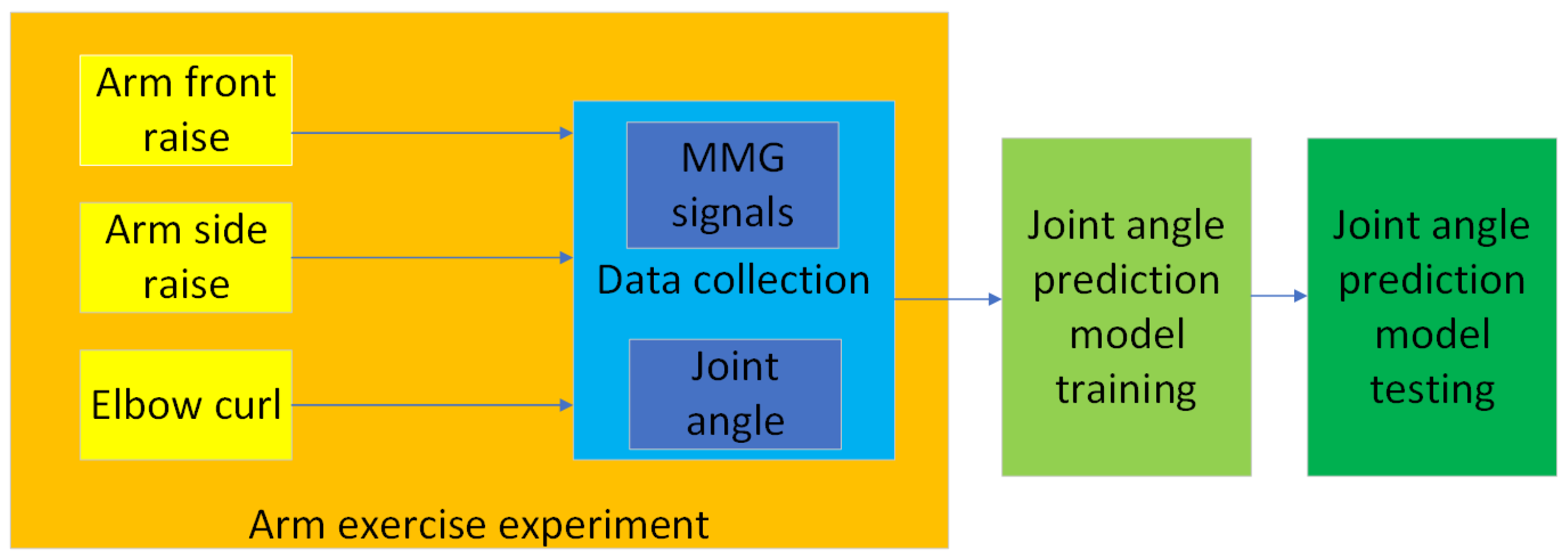

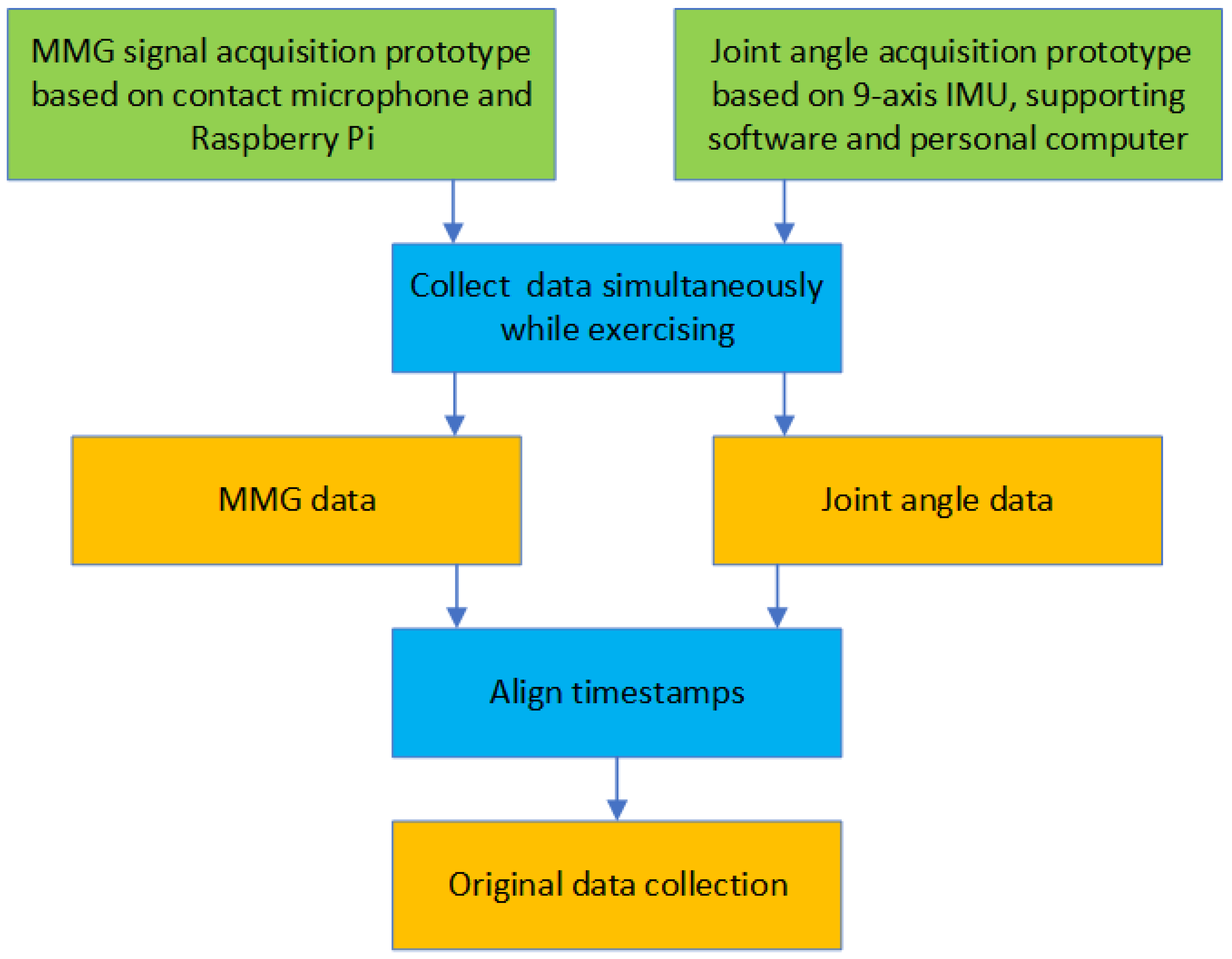

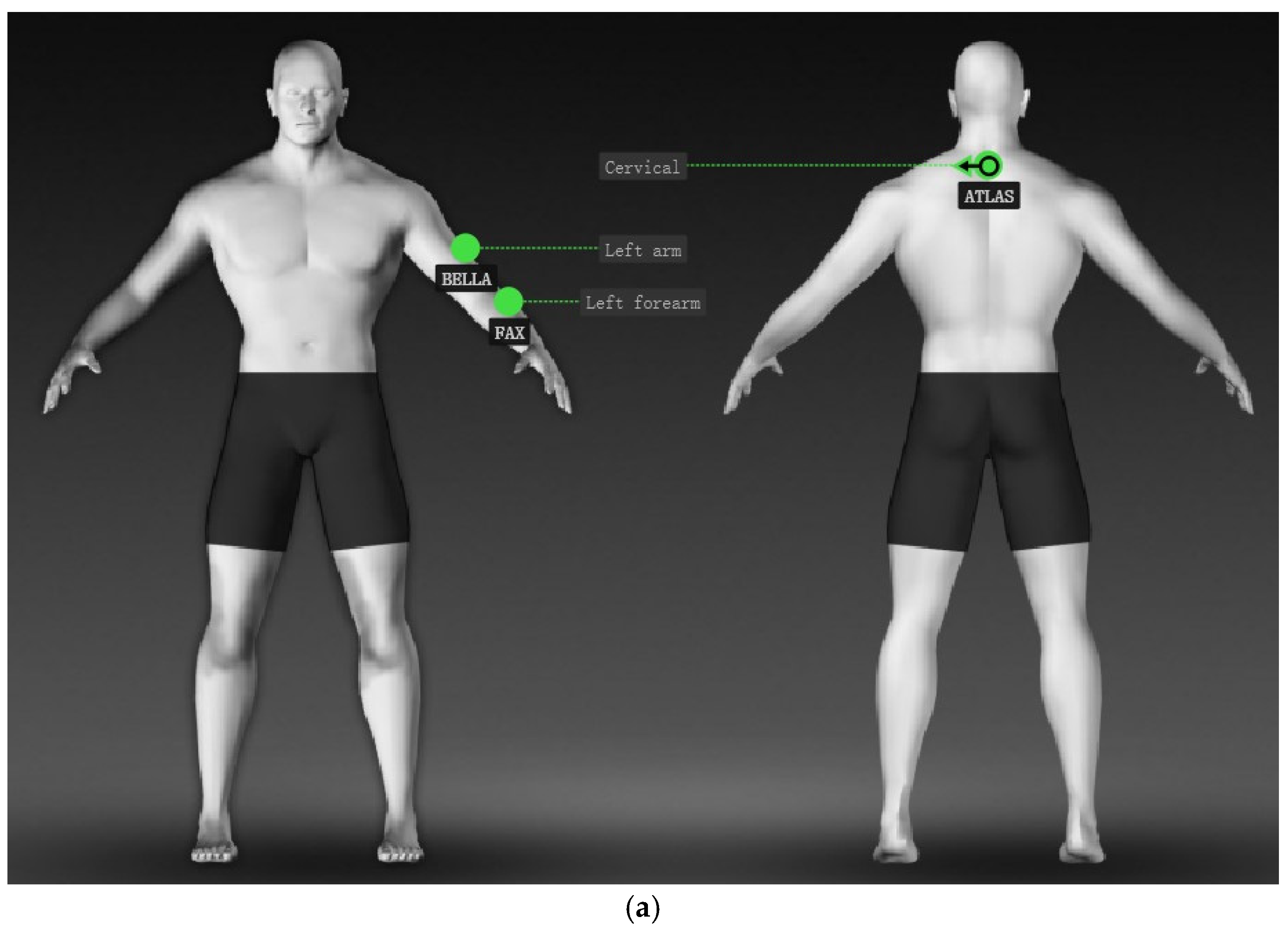

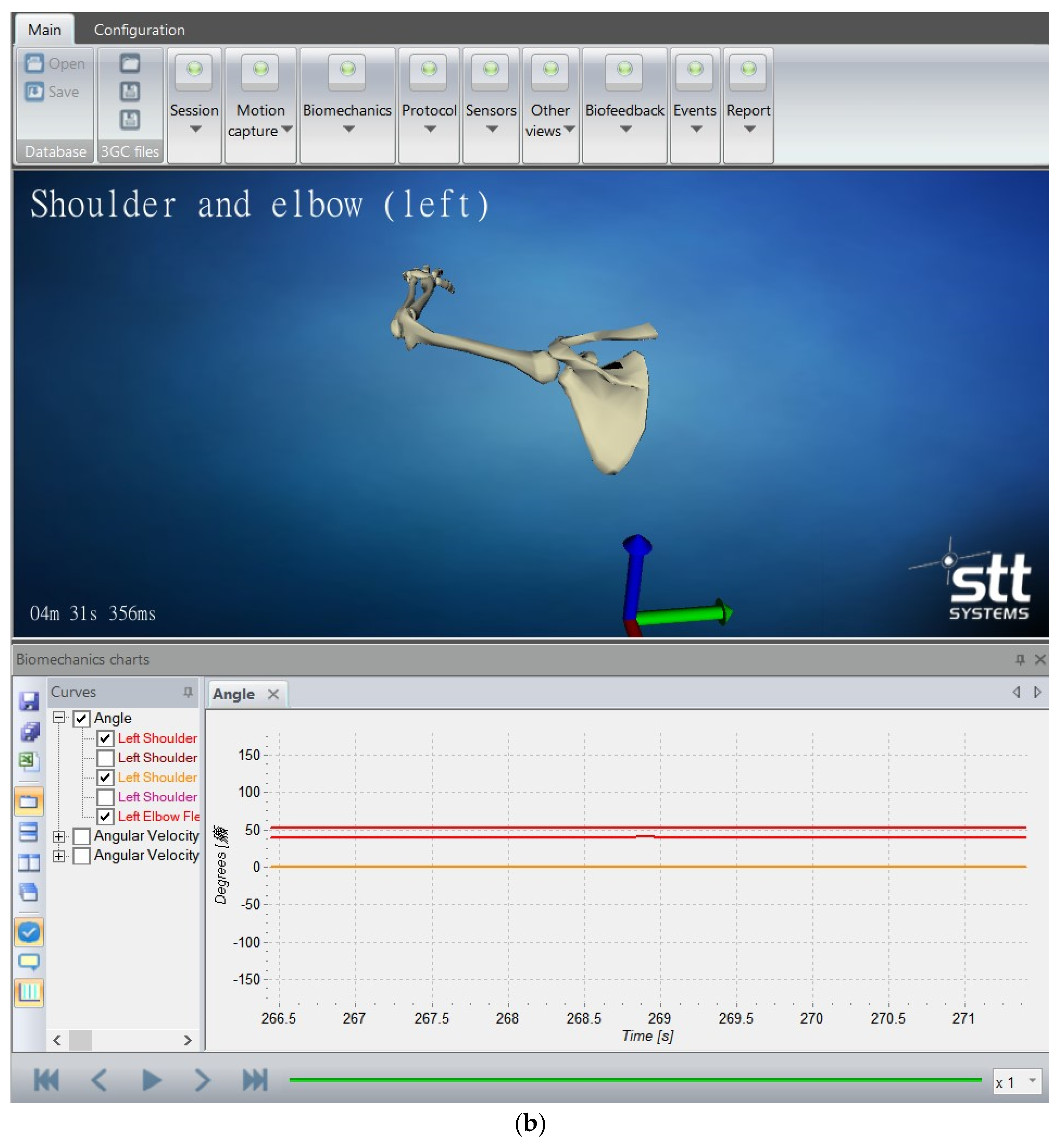

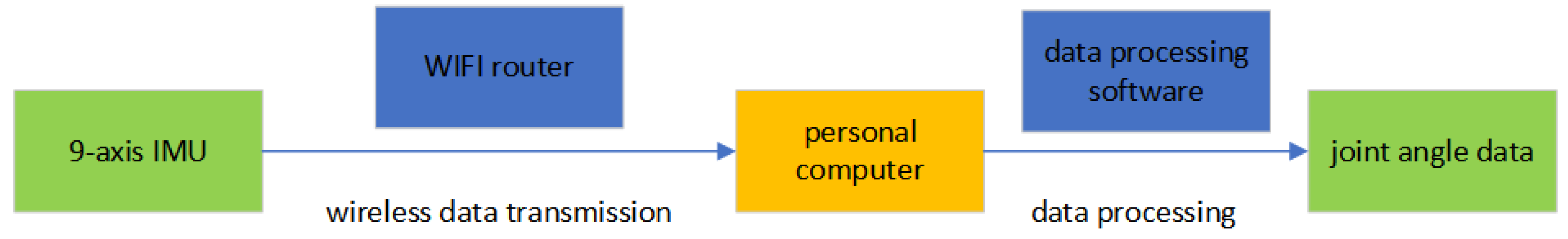

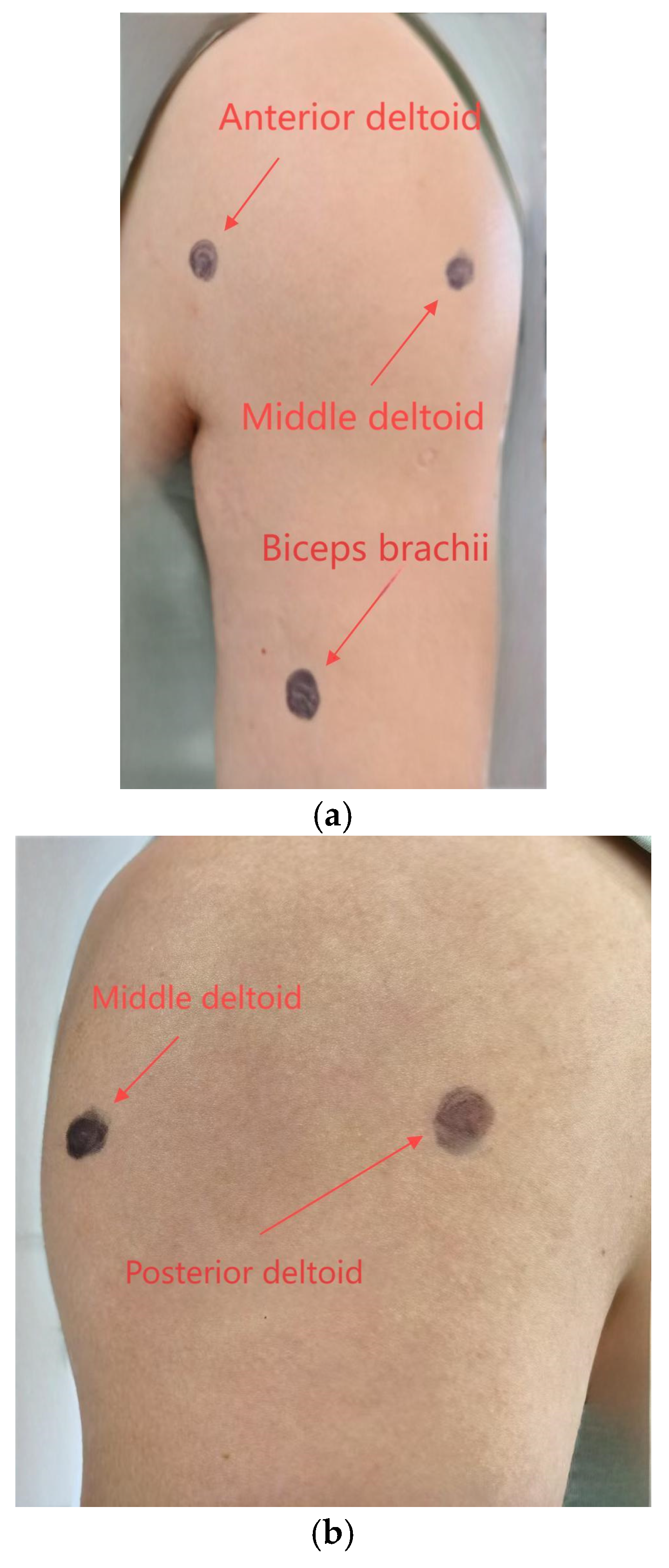

2.1. Experimental Process

- (1)

- Full-wave rectification;

- (2)

- Upper envelope signal extraction.

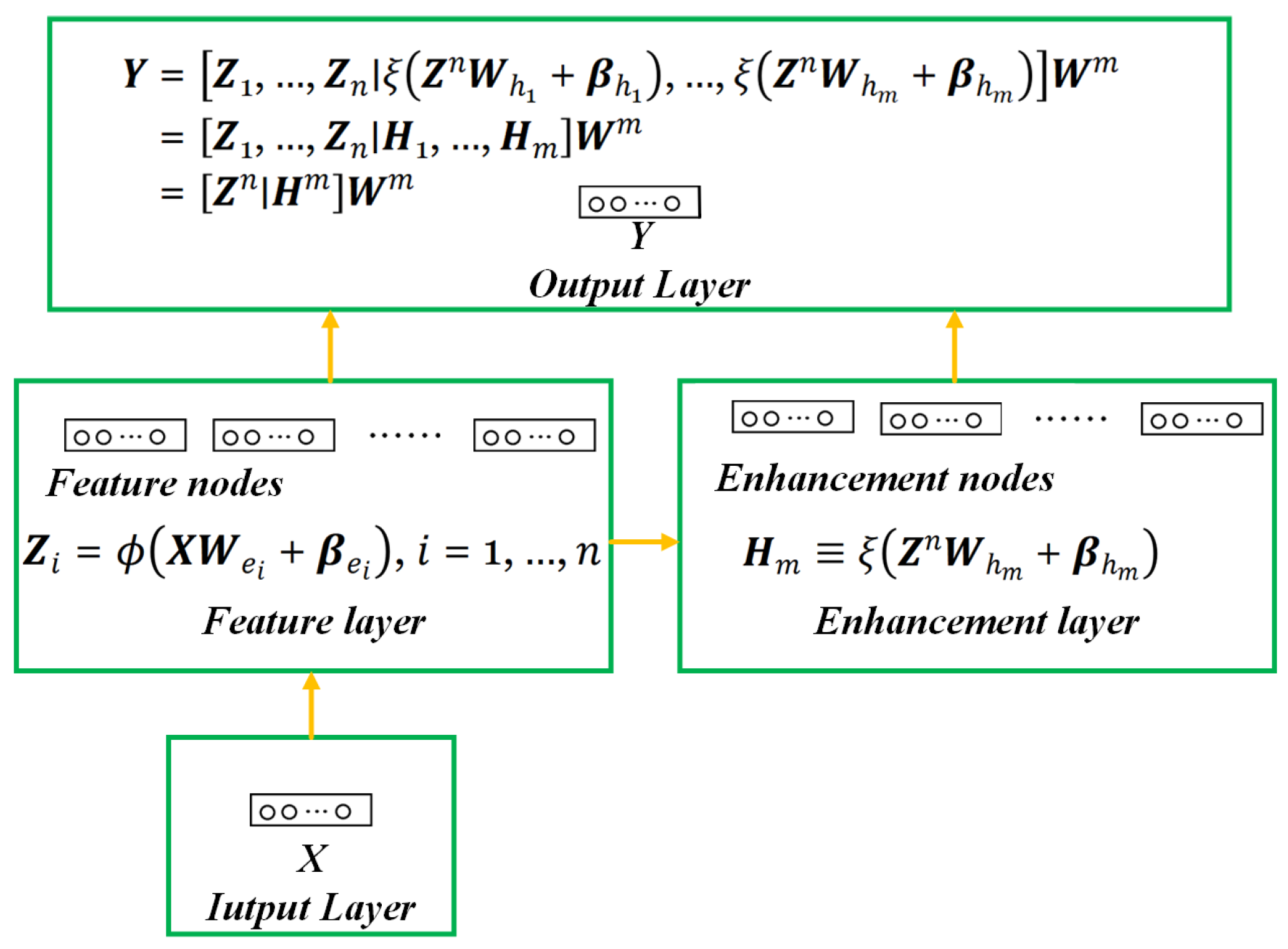

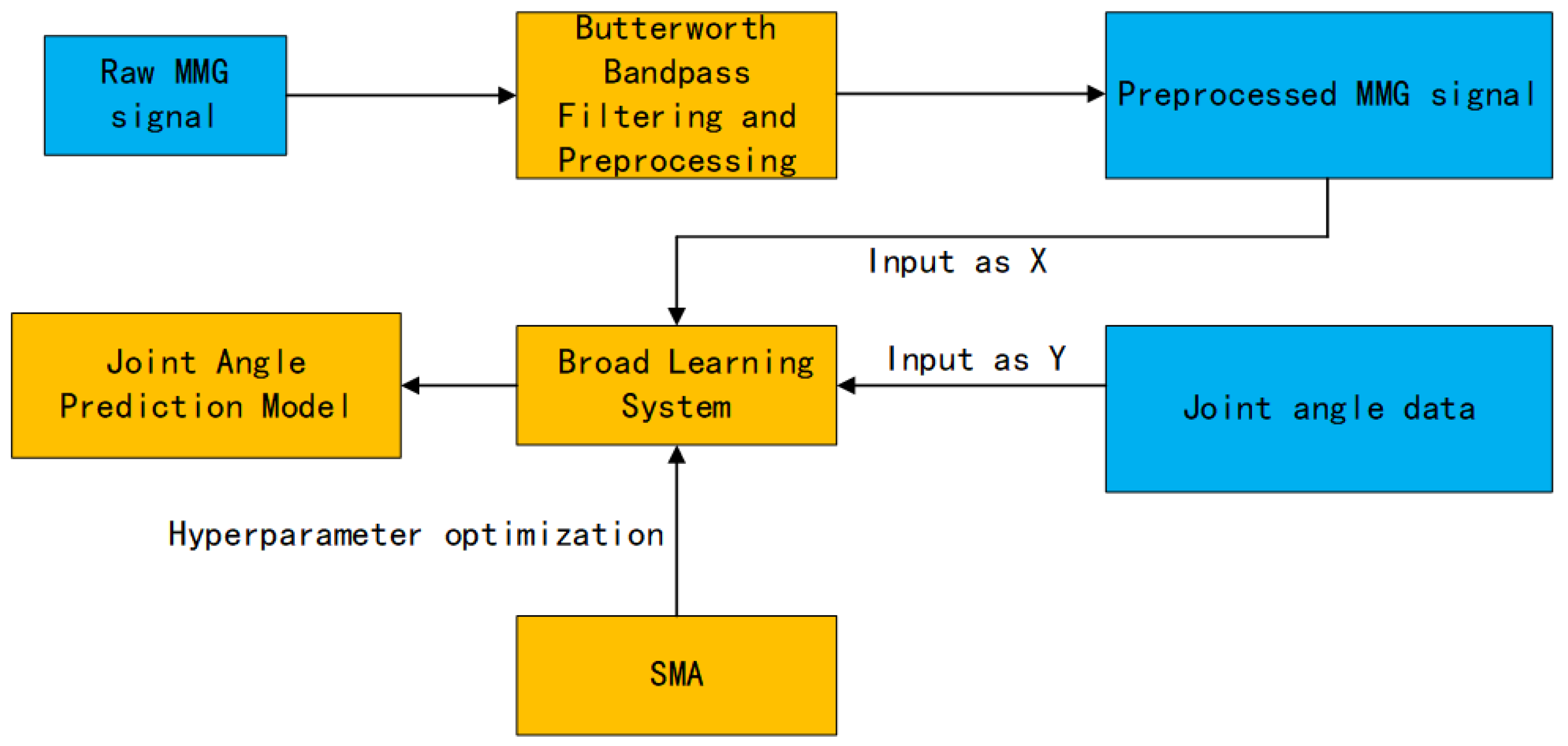

2.2. Human Joint Rotation Angle Estimation Model Based on SMA-BLS

2.2.1. Broad Learning System

| Algorithm 1 Broad Learning System |

| . . (1) Data Preparation: Extract upper envelope MMG via preprocessing (2) Initialize Feature Nodes: (3) Generate Enhancement Nodes: (4) Ridge Regression: (5) Training & Prediction: Training: : (6) Incremental Learning: If New data available End if If Performance insufficient End if |

2.2.2. Slime Mold Algorithm

| Algorithm 2 Slime Mold Algorithm |

| . . (1) Initialization: for random exploration (2) Fitness Evaluation: ): If rand() < z then else Boundary Handling: Fitness Re-evaluation: if better solution found (4) Termination: or convergence criteria met |

2.2.3. Role of SMA in BLS Parameter Optimization

- (1)

- Global Search:

- (2)

- Local Fine-Tuning:

- (3)

- Avoid Premature Convergence:

- (1)

- Flexibility:

- (2)

- Efficiency:

- (3)

- Ease of Use:

- (4)

- Improved Performance:

- (5)

- Robustness:

3. Results

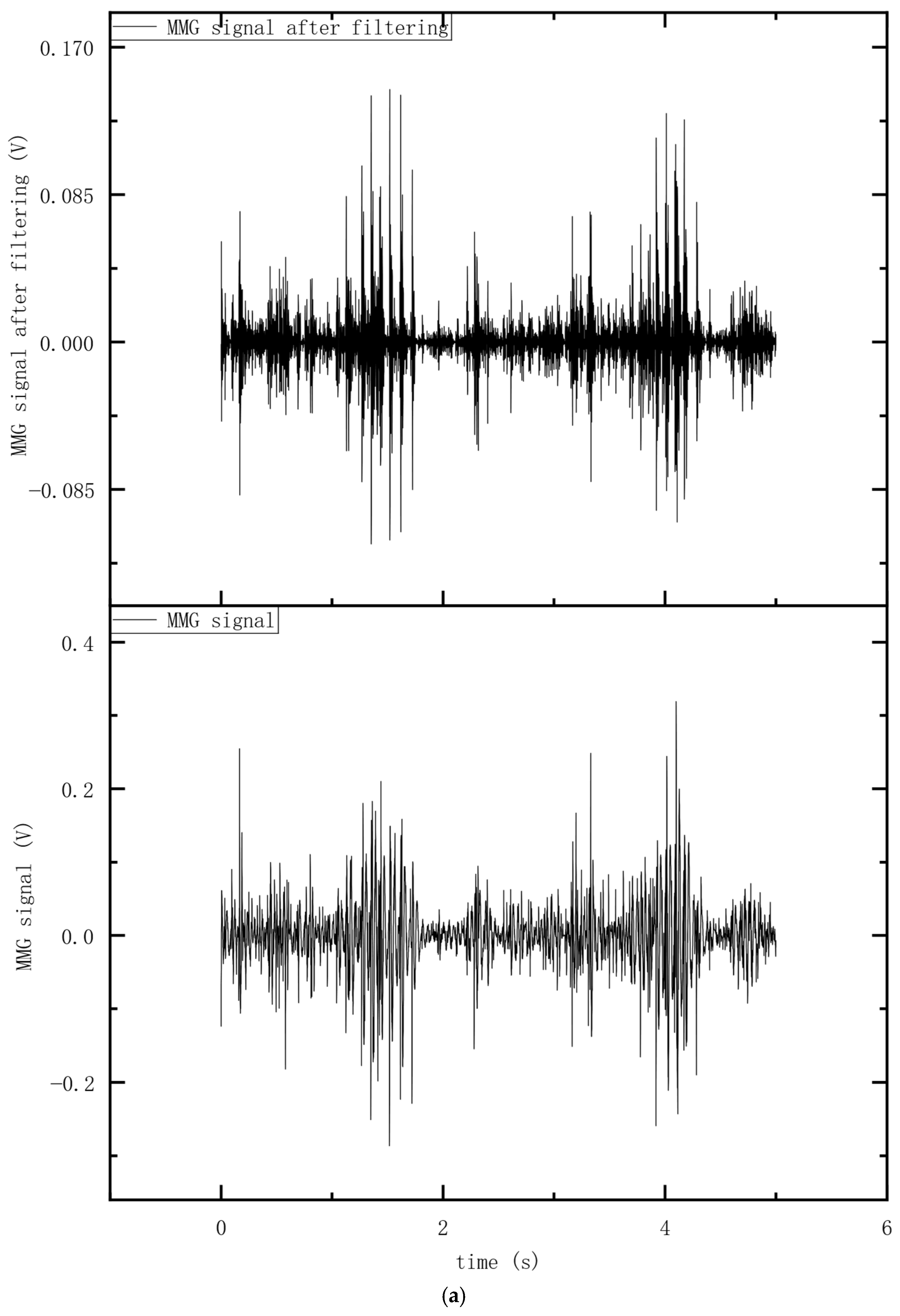

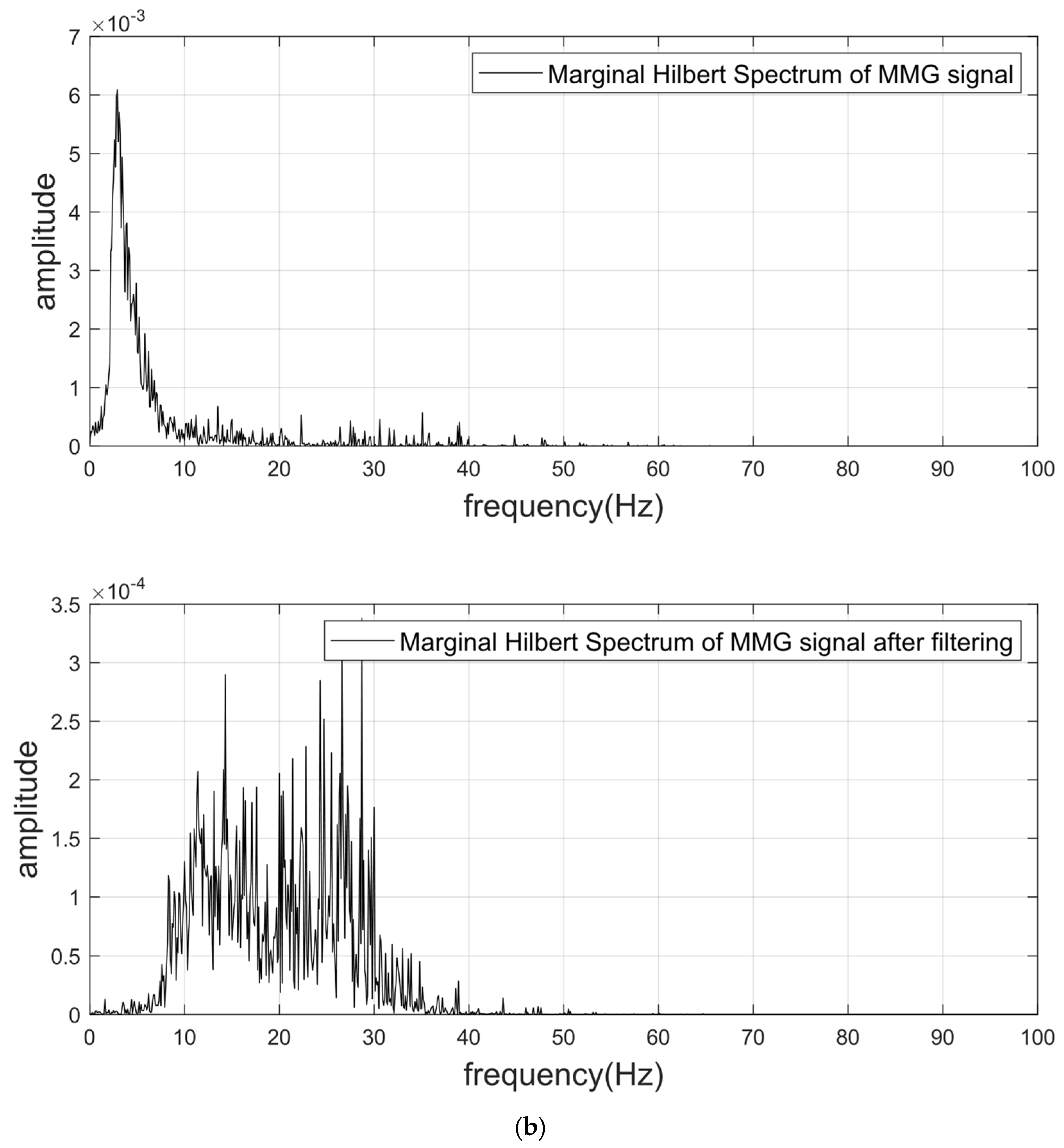

3.1. The Results of Butterworth Bandpass Filtering of the MMG Signal

3.2. The Results of Preprocessing the MMG Signal

3.3. The Results of Joint Angle Prediction

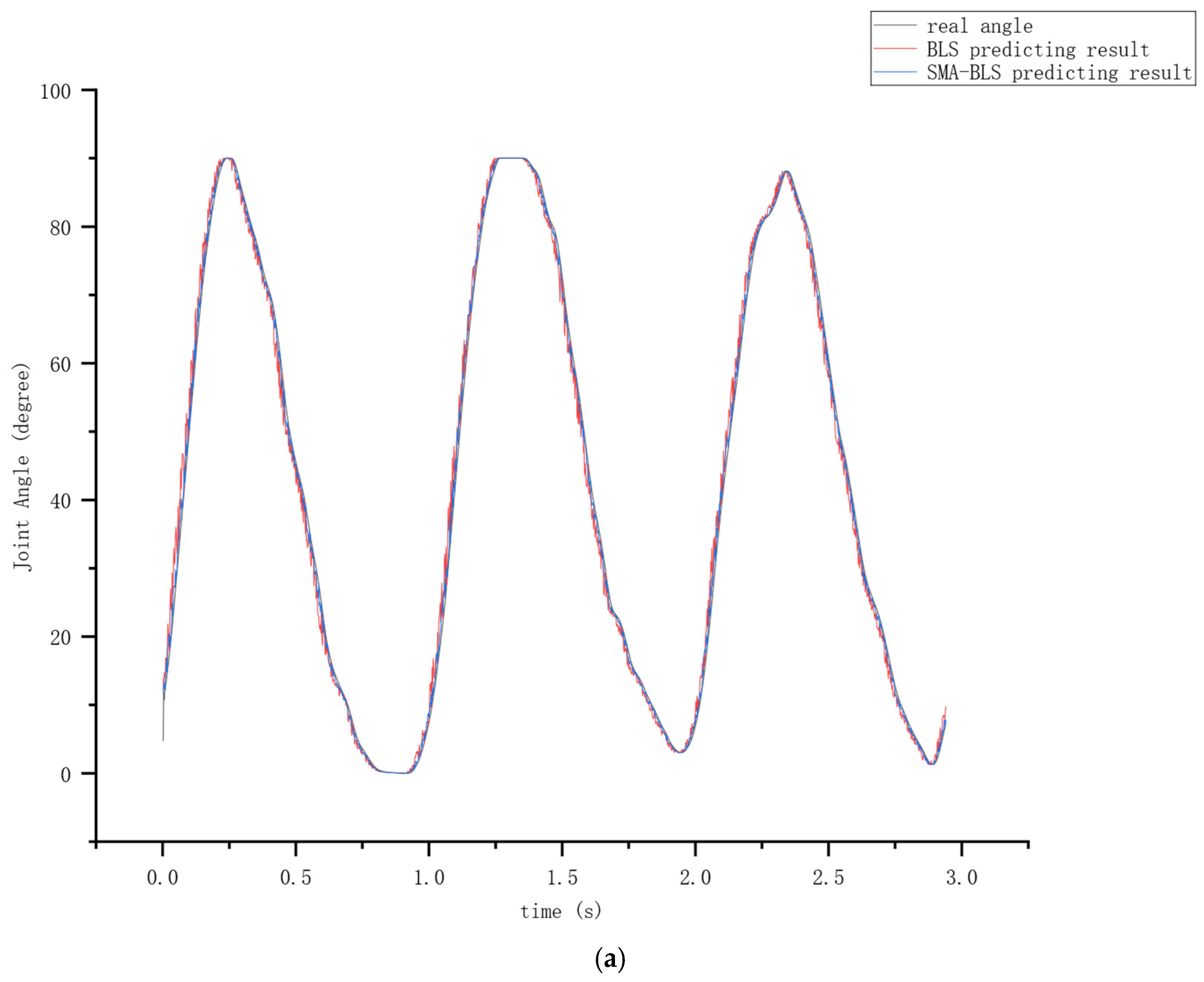

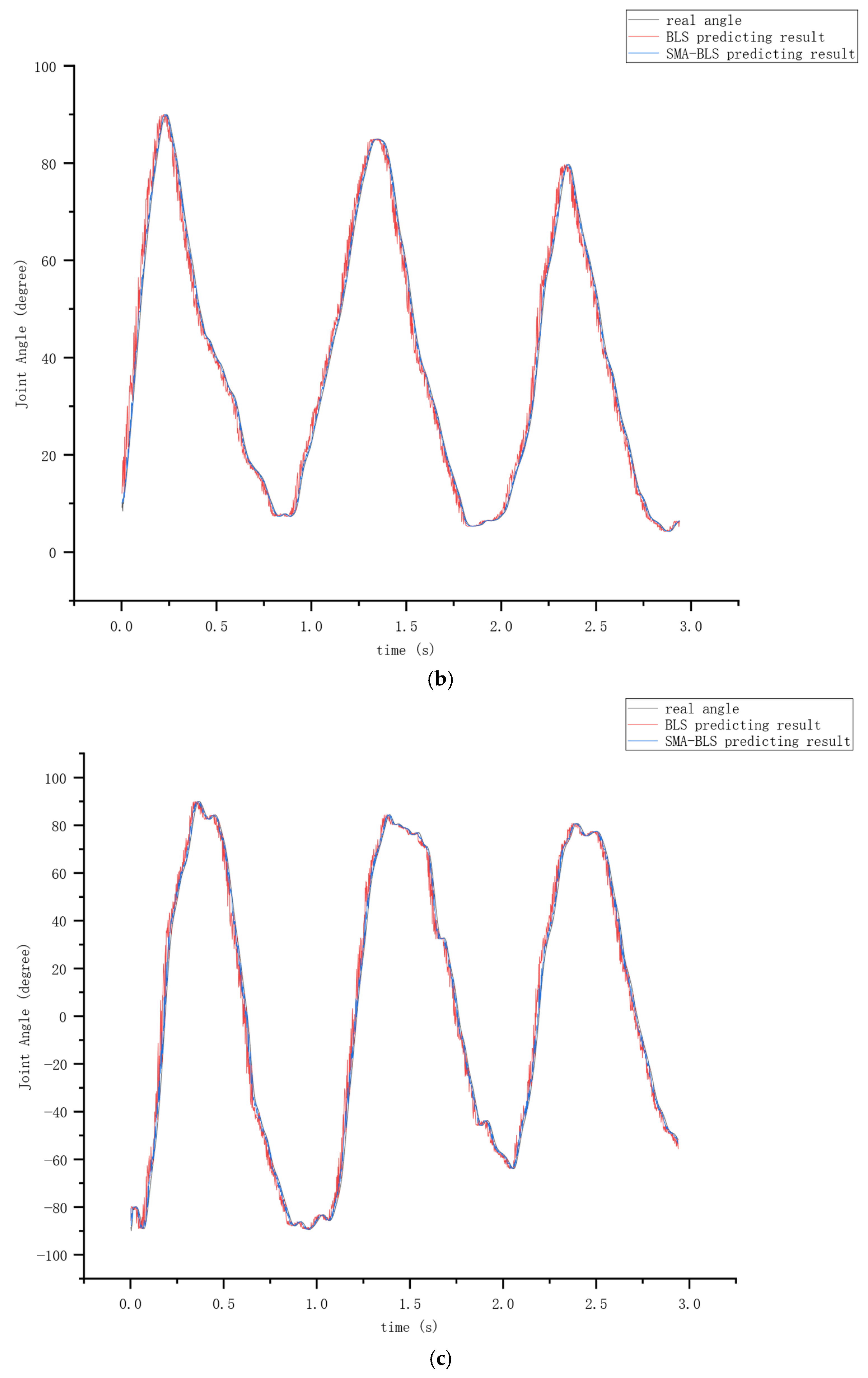

3.3.1. The Impact of the SMA on the Prediction Results

3.3.2. Prediction Results of Different Input Signals

3.3.3. Prediction Results of Different Times in the Future

3.3.4. Prediction Results of Different Loads

3.3.5. Prediction Results of Different Forecast Methods

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vélez-Guerrero, M.A.; Callejas-Cuervo, M.; Mazzoleni, S. Artificial intelligence-based wearable robotic exoskeletons for upper limb rehabilitation: A review. Sensors 2021, 21, 2146. [Google Scholar] [CrossRef] [PubMed]

- Coser, O.; Tamantini, C.; Soda, P.; Zollo, L. AI-based methodologies for exoskeleton-assisted rehabilitation of the lower limb: A review. Front. Robot. AI 2024, 11, 1341580. [Google Scholar] [CrossRef]

- Jing, H.; Zheng, T.; Zhang, Q.; Sun, K.; Li, L.; Lai, M.; Zhao, J.; Zhu, Y. Human Operation Augmentation through Wearable Robotic Limb Integrated with Mixed Reality Device. Biomimetics 2023, 8, 479. [Google Scholar] [CrossRef]

- Miller, L.E.; Zimmermann, A.K.; Herbert, W.G. Clinical effectiveness and safety of powered exoskeleton-assisted walking in patients with spinal cord injury: Systematic review with meta-analysis. Med. Devices Evid. Res. 2016, 9, 455–466. [Google Scholar] [CrossRef]

- Gu, F.; Chung, M.-H.; Chignell, M.; Valaee, S.; Zhou, B.; Liu, X. A survey on deep learning for human activity recognition. ACM Comput. Surv. (CSUR) 2021, 54, 1–34. [Google Scholar] [CrossRef]

- Jobanputra, C.; Bavishi, J.; Doshi, N. Human activity recognition: A survey. Procedia Comput. Sci. 2019, 155, 698–703. [Google Scholar] [CrossRef]

- Plaza, A.; Hernandez, M.; Puyuelo, G.; Garces, E.; Garcia, E. Lower-limb medical and rehabilitation exoskeletons: A review of the current designs. IEEE Rev. Biomed. Eng. 2021, 16, 278–291. [Google Scholar] [CrossRef]

- Dwivedi, A.; Groll, H.; Beckerle, P. A systematic review of sensor fusion methods using peripheral bio-signals for human intention decoding. Sensors 2022, 22, 6319. [Google Scholar] [CrossRef]

- An, S.; Feng, J.; Song, E.; Kong, K.; Kim, J.; Choi, H. High-accuracy hand gesture recognition on the wrist tendon group using pneumatic mechanomyography (pMMG). IEEE Trans. Ind. Inform. 2023, 20, 1550–1561. [Google Scholar] [CrossRef]

- Wattanasiri, P.; Wilson, S.; Huo, W.; Vaidyanathan, R. Gesture Recognition through Mechanomyogram Signals: An Adaptive Framework for Arm Posture Variability. IEEE J. Biomed. Health Inform. 2024, 29, 2453–2462. [Google Scholar] [CrossRef]

- Shi, Y.; Dong, W.; Lin, W.; He, L.; Wang, X.; Li, P.; Gao, Y. Human joint torque estimation based on mechanomyography for upper extremity exosuit. Electronics 2022, 11, 1335. [Google Scholar] [CrossRef]

- Talib, I.; Sundaraj, K.; Hussain, J.; Lam, C.K.; Ahmad, Z. Analysis of anthropometrics and mechanomyography signals as forearm flexion, pronation and supination torque predictors. Sci. Rep. 2022, 12, 16086. [Google Scholar] [CrossRef] [PubMed]

- Quan, J.; Uchitomi, H.; Shigeyama, R.; Gao, C.; Ogata, T.; Inaba, A.; Orimo, S.; Miyake, Y. High-sensitivity acceleration sensor detecting micro-mechanomyogram and deep learning approach for parkinson’s disease classification. Sci. Rep. 2024, 14, 22941. [Google Scholar] [CrossRef]

- Ahn, S.; Shin, I.; Kim, Y. The effect of accelerometer mass in mechanomyography measurements. J. Vibroeng. 2016, 18, 4736–4742. [Google Scholar] [CrossRef]

- Jaskólska, A.; Madeleine, P.; Jaskólski, A.; Kisiel-Sajewicz, K.; Arendt-Nielsen, L. A comparison between mechanomyographic condenser microphone and accelerometer measurements during submaximal isometric, concentric and eccentric contractions. J. Electromyogr. Kinesiol. 2007, 17, 336–347. [Google Scholar] [CrossRef] [PubMed]

- Castillo, C.S.M.; Wilson, S.; Vaidyanathan, R.; Atashzar, S.F. Wearable MMG-plus-one armband: Evaluation of normal force on mechanomyography (MMG) to enhance human-machine interfacing. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 29, 196–205. [Google Scholar] [CrossRef]

- Szumilas, M.; Władziński, M.; Wildner, K. A coupled piezoelectric sensor for mmg-based human-machine interfaces. Sensors 2021, 21, 8380. [Google Scholar] [CrossRef]

- Pan, C.T.; Chang, C.C.; Yang, Y.S.; Yen, C.-K.; Kao, Y.-H.; Shiue, Y.-L. Development of MMG sensors using PVDF piezoelectric electrospinning for lower limb rehabilitation exoskeleton. Sens. Actuators A Phys. 2020, 301, 111708. [Google Scholar] [CrossRef]

- Fang, Q.; Cao, S.; Qin, H.; Yin, R.; Zhang, W.; Zhang, H. A Novel Mechanomyography (MMG) Sensor Based on Piezo-Resistance Principle and with a Pyramidic Microarray. Micromachines 2023, 14, 1859. [Google Scholar] [CrossRef]

- Esposito, D.; Andreozzi, E.; Fratini, A.; Gargiulo, G.D.; Savino, S.; Niola, V.; Bifulco, P. A piezoresistive sensor to measure muscle contraction and mechanomyography. Sensors 2018, 18, 2553. [Google Scholar] [CrossRef]

- Caulcrick, C.; Huo, W.; Hoult, W.; Vaidyanathan, R. Human joint torque modelling with MMG and EMG during lower limb human-exoskeleton interaction. IEEE Robot. Autom. Lett. 2021, 6, 7185–7192. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, X.; Cheng, Y.; Xi, N. Surface EMG based continuous estimation of human lower limb joint angles by using deep belief networks. Biomed. Signal Process. Control 2018, 40, 335–342. [Google Scholar] [CrossRef]

- Coker, J.; Chen, H.; Schall, M.C., Jr.; Gallagher, S.; Zabala, M. EMG and joint angle-based machine learning to predict future joint angles at the knee. Sensors 2021, 21, 3622. [Google Scholar] [CrossRef] [PubMed]

- Hondo, N.; Tsuji, T. Knee Joint Torque Estimation in Femoral Prosthesis Users Using MMG and Low-Frequency Acceleration. IEEE Access 2024, 12, 174996–175005. [Google Scholar] [CrossRef]

- Gong, X.; Zhang, T.; Chen, C.L.P.; Liu, Z. Research review for broad learning system: Algorithms, theory, and applications. IEEE Trans. Cybern. 2021, 52, 8922–8950. [Google Scholar] [CrossRef]

- Chen, C.L.P.; Liu, Z. Broad learning system: An effective and efficient incremental learning system without the need for deep architecture. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 10–24. [Google Scholar] [CrossRef]

- Li, S.; Chen, H.; Wang, M.; Heidari, A.A.; Mirjalili, S. Slime mould algorithm: A new method for stochastic optimization. Future Gener. Comput. Syst. 2020, 111, 300–323. [Google Scholar] [CrossRef]

- Søgaard, K.; Gandevia, S.C.; Todd, G.; Petersen, N.T.; Taylor, J.L. The effect of sustained low-intensity contractions on supraspinal fatigue in human elbow flexor muscles. J. Physiol. 2006, 573, 511–523. [Google Scholar] [CrossRef]

- Wang, S.; Yang, J.; Yang, H.; Sun, T.; Dong, M.; Hou, Z.G. Prediction of Upper Limb Joint Angles Based on Multi-Source Information Fusion using Temporal Convolutional Network. In Proceedings of the 2024 30th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Leeds, UK, 3–5 October 2024; pp. 1–6. [Google Scholar]

- Yao, J.; Xia, C.; Zhang, H.; Zhu, C. Research on the Prediction of Elbow Joint Angle Based on Mechanomyography. In Proceedings of the 2022 IEEE 10th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 17–19 June 2022; Volume 10, pp. 547–553. [Google Scholar]

- Zhu, M.; Guan, X.; Li, Z.; He, L.; Wang, Z.; Cai, K. sEMG-based lower limb motion prediction using CNN-LSTM with improved PCA optimization algorithm. J. Bionic Eng. 2023, 20, 612–627. [Google Scholar] [CrossRef]

- Chaurasia, B.D. Human Anatomy; CBS Publisher: New Delhi, India, 2004. [Google Scholar]

- Meagher, C.; Franco, E.; Turk, R.; Wilson, S.; Steadman, N.; McNicholas, L.; Vaidyanathan, R.; Burridge, J.; Stokes, M. New advances in mechanomyography sensor technology and signal processing: Validity and intrarater reliability of recordings from muscle. J. Rehabil. Assist. Technol. Eng. 2020, 7, 2055668320916116. [Google Scholar] [CrossRef]

- Li, C.; Yu, G.; Fu, B.; Hu, H.; Zhu, X.; Zhu, Q. Fault separation and detection for compound bearing-gear fault condition based on decomposition of marginal Hilbert spectrum. IEEE Access 2019, 7, 110518–110530. [Google Scholar] [CrossRef]

- Fu, K.; Qu, J.; Chai, Y.; Zou, T. Hilbert marginal spectrum analysis for automatic seizure detection in EEG signals. Biomed. Signal Process. Control 2015, 18, 179–185. [Google Scholar] [CrossRef]

| (a) | |

| Parameters | Value |

| L2 regularization parameters and enhanced node reduction ratio | 0.959 |

| Number of windows in feature layer | 52 |

| Number of feature nodes per window in feature layer | 51 |

| Number of nodes in the enhancement layer | 199 |

| (b) | |

| Parameters | Value |

| L2 regularization parameters and enhanced node reduction ratio | 0.958 |

| Number of windows in feature layer | 53 |

| Number of feature nodes per window in feature layer | 51 |

| Number of nodes in the enhancement layer | 200 |

| (c) | |

| Parameters | Value |

| L2 regularization parameters and enhanced node reduction ratio | 0.960 |

| Number of windows in feature layer | 52 |

| Number of feature nodes per window in feature layer | 51 |

| Number of nodes in the enhancement layer | 202 |

| (d) | |

| Parameters | Value |

| Population number | 10 |

| Maximum number of iterations | 20 |

| Objective function | MSE |

| Bottom of search area | [0.01, 10, 10, 10] |

| Top of search area | [1, 100, 100, 300] |

| (a) | |||||

|---|---|---|---|---|---|

| Method | MSE | RMSE | MAE | R2 | p-Value |

| SMA-BLS | 0.0001 | 0.0012 | 0.0006 | 0.002 | / |

| BLS | 0.0002 | 0.0021 | 0.0025 | 0.004 | 0.0077 |

| (b) | |||||

| Method | MSE | RMSE | MAE | R2 | p-Value |

| SMA-BLS | 0.0001 | 0.0009 | 0.0007 | 0.001 | / |

| BLS | 0.0004 | 0.0033 | 0.0027 | 0.004 | 0.0086 |

| (c) | |||||

| Method | MSE | RMSE | MAE | R2 | p-Value |

| SMA-BLS | 0.0001 | 0.0010 | 0.0006 | 0.002 | / |

| BLS | 0.0004 | 0.0032 | 0.0021 | 0.003 | 0.0084 |

| (a) | |||||

|---|---|---|---|---|---|

| Input Signals | MSE | RMSE | MAE | R2 | p-Value |

| MMG | 0.0001 | 0.0012 | 0.0006 | 0.002 | / |

| IMU rotation angle | 0.0003 | 0.0019 | 0.0036 | 0.005 | 0.0065 |

| (b) | |||||

| Input signals | MSE | RMSE | MAE | R2 | p-Value |

| MMG | 0.0001 | 0.0009 | 0.0007 | 0.001 | / |

| IMU rotation angle | 0.0003 | 0.0026 | 0.0037 | 0.003 | 0.0053 |

| (c) | |||||

| Input signals | MSE | RMSE | MAE | R2 | p-Value |

| MMG | 0.0001 | 0.0010 | 0.0006 | 0.002 | / |

| IMU rotation angle | 0.0002 | 0.0036 | 0.0026 | 0.002 | 0.0041 |

| (a) | ||||

|---|---|---|---|---|

| Time in the Future (ms) | MSE | RMSE | MAE | R2 |

| 10 | 0.0001 | 0.0012 | 0.0006 | 0.002 |

| 30 | 0.0002 | 0.0017 | 0.0021 | 0.003 |

| 60 | 0.0003 | 0.0023 | 0.0027 | 0.002 |

| (b) | ||||

| Time in the Future(ms) | MSE | RMSE | MAE | R2 |

| 10 | 0.0001 | 0.0009 | 0.0007 | 0.001 |

| 30 | 0.0002 | 0.0018 | 0.0022 | 0.003 |

| 60 | 0.0004 | 0.0024 | 0.0036 | 0.003 |

| (c) | ||||

| Time in the Future(ms) | MSE | RMSE | MAE | R2 |

| 10 | 0.0001 | 0.0010 | 0.0006 | 0.002 |

| 30 | 0.0003 | 0.0031 | 0.0023 | 0.003 |

| 60 | 0.0003 | 0.0033 | 0.0041 | 0.003 |

| (a) | ||||

|---|---|---|---|---|

| Load Weight (KG) | MSE | RMSE | MAE | R2 |

| 0 | 0.0001 | 0.0012 | 0.0006 | 0.002 |

| 0.5 | 0.0001 | 0.0011 | 0.0005 | 0.001 |

| 1 | 0.0001 | 0.0010 | 0.0005 | 0.001 |

| (b) | ||||

| LoadWeight (KG) | MSE | RMSE | MAE | R2 |

| 0 | 0.0001 | 0.0009 | 0.0007 | 0.001 |

| 0.5 | 0.0001 | 0.0009 | 0.0005 | 0.002 |

| 1 | 0.0001 | 0.0008 | 0.0004 | 0.001 |

| (c) | ||||

| LoadWeight (KG) | MSE | RMSE | MAE | R2 |

| 0 | 0.0001 | 0.0010 | 0.0006 | 0.002 |

| 0.5 | 0.0001 | 0.0010 | 0.0005 | 0.002 |

| 1 | 0.0001 | 0.0009 | 0.0005 | 0.001 |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Method | MSE | RMSE | MAE | R2 | p-Value | Training Time (s) | Forecast Time (ms) |

| SMA-BLS | 0.0001 | 0.0012 | 0.0006 | 0.002 | / | 174.3 ± 5.36 | 4.1 ± 0.32 |

| CNN | 0.0003 | 0.0015 | 0.0026 | 0.002 | 0.00760 | 259.2 ± 13.67 | 21.4 ± 2.41 |

| SVM | 0.0002 | 0.0013 | 0.0027 | 0.003 | 0.00519 | 336.6 ± 11.94 | 19.8 ± 2.63 |

| BP | 0.0003 | 0.0025 | 0.0048 | 0.004 | 0.00218 | 95.6 ± 2.67 | 11.6 ± 1.80 |

| ELM | 0.0003 | 0.0011 | 0.0016 | 0.002 | 0.00308 | 135.5 ± 5.19 | 16.3 ± 2.24 |

| RF | 0.0003 | 0.0024 | 0.0034 | 0.002 | 0.00143 | 168.3 ± 6.95 | 26.5 ± 1.31 |

| RBF | 0.0003 | 0.0026 | 0.0031 | 0.002 | 0.00394 | 195.3 ± 6.74 | 13.9 ± 1.08 |

| LSTM | 0.0002 | 0.0011 | 0.0014 | 0.003 | 0.00821 | 267.4 ± 8.18 | 14.2 ± 1.94 |

| (b) | |||||||

| Method | MSE | RMSE | MAE | R2 | p-Value | Training Time (s) | Forecast Time (ms) |

| SMA-BLS | 0.0001 | 0.0009 | 0.0007 | 0.001 | / | 176.6 ± 5.44 | 4.2 ± 0.27 |

| CNN | 0.0002 | 0.0014 | 0.0016 | 0.001 | 0.00760 | 257.8 ± 13.16 | 20.1 ± 2.32 |

| SVM | 0.0003 | 0.0012 | 0.0023 | 0.004 | 0.00497 | 337.7 ± 10.58 | 19.2 ± 2.56 |

| BP | 0.0003 | 0.0027 | 0.0035 | 0.003 | 0.00196 | 98.3 ± 2.57 | 10.9 ± 1.73 |

| ELM | 0.0004 | 0.0013 | 0.0021 | 0.002 | 0.00321 | 138.2 ± 5.11 | 16.7 ± 2.15 |

| RF | 0.0003 | 0.0026 | 0.0025 | 0.003 | 0.00137 | 169.6 ± 6.82 | 26.3 ± 1.24 |

| RBF | 0.0004 | 0.0021 | 0.0029 | 0.003 | 0.00364 | 194.2 ± 6.63 | 13.8 ± 1.14 |

| LSTM | 0.0002 | 0.0012 | 0.0013 | 0.002 | 0.00842 | 262.6 ± 8.08 | 14.3 ± 1.84 |

| (c) | |||||||

| Method | MSE | RMSE | MAE | R2 | p-Value | Training Time (s) | Forecast Time (ms) |

| SMA-BLS | 0.0001 | 0.0010 | 0.0006 | 0.002 | / | 185.3 ± 15.48 | 4.2 ± 0.95 |

| CNN | 0.0003 | 0.0019 | 0.0028 | 0.002 | 0.00705 | 258.6 ± 6.42 | 19.9 ± 2.18 |

| SVM | 0.0003 | 0.0014 | 0.0026 | 0.004 | 0.00451 | 339.4 ± 9.18 | 19.3 ± 2.26 |

| BP | 0.0002 | 0.0016 | 0.0034 | 0.003 | 0.00308 | 97.6 ± 2.06 | 11.1 ± 1.96 |

| ELM | 0.0002 | 0.0012 | 0.0014 | 0.002 | 0.00275 | 137.9 ± 4.96 | 16.9 ± 2.14 |

| RF | 0.0004 | 0.0032 | 0.0038 | 0.004 | 0.00096 | 169.0 ± 5.99 | 25.6 ± 1.06 |

| RBF | 0.0002 | 0.0029 | 0.0033 | 0.002 | 0.00169 | 194.5 ± 5.96 | 13.3 ± 1.64 |

| LSTM | 0.0001 | 0.0008 | 0.0010 | 0.003 | 0.00806 | 266.8 ± 8.06 | 14.2 ± 1.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Guan, X.; Li, H.; Cheng, S.; Zhang, R.; He, L. Research on Predicting Joint Rotation Angles Through Mechanomyography Signals and the Broad Learning System. Appl. Sci. 2025, 15, 6454. https://doi.org/10.3390/app15126454

Bai Y, Guan X, Li H, Cheng S, Zhang R, He L. Research on Predicting Joint Rotation Angles Through Mechanomyography Signals and the Broad Learning System. Applied Sciences. 2025; 15(12):6454. https://doi.org/10.3390/app15126454

Chicago/Turabian StyleBai, Yu, Xiaorong Guan, Huibin Li, Shi Cheng, Rui Zhang, and Long He. 2025. "Research on Predicting Joint Rotation Angles Through Mechanomyography Signals and the Broad Learning System" Applied Sciences 15, no. 12: 6454. https://doi.org/10.3390/app15126454

APA StyleBai, Y., Guan, X., Li, H., Cheng, S., Zhang, R., & He, L. (2025). Research on Predicting Joint Rotation Angles Through Mechanomyography Signals and the Broad Learning System. Applied Sciences, 15(12), 6454. https://doi.org/10.3390/app15126454