Release and Ecological Risks of Heavy Metals During Coal Combustion in Coal-Fired Power Plants

Featured Application

Abstract

1. Introduction

- (a)

- Shanxi Province, recognized as China’s primary coal production base, faces escalating environmental challenges arising from coal combustion activities.

- (b)

- This investigation examines two representative coal-fired power plants in Shanxi using an integrated methodology combining field emission sampling, advanced laboratory analysis, and systematically controlled combustion experiments. Enrichment factors, geo-accumulation indices, long-range migration potential, and ecological risk assessments were used to address the following three research questions: (1) What is the migration rate of heavy metals in coal during the combustion process, from raw coal to slag and fly ash? (2) How do the chemical forms of heavy metals in raw coal and combustion temperature influence their migration behavior? (3) Considering the content, speciation, and leaching characteristics of heavy metals in slag and fly ash, what is their potential ecological risk level?

- (c)

- The findings of this study not only provide predictive insights into possible ecological risks associated with local coal combustion but also serve as a theoretical foundation for developing targeted management strategies to mitigate heavy metal pollution. Furthermore, the results are applicable to predicting heavy metal release during coal combustion in regions with high coal production and similar coal properties.

2. Materials and Methods

2.1. Study Area

2.2. Sampling and Chemical Analysis

2.2.1. Sampling

2.2.2. Chemical Analysis

2.3. Calculation of Heavy Metal Release Rates

2.4. Speciation Analysis of Heavy Metals

2.5. Combustion Temperature Gradient Experiment

2.5.1. Experimental Procedure

2.5.2. Analytical Method

2.6. Assessment Indices

2.6.1. Enrichment Factor (EF)

2.6.2. Geoaccumulation Index (Igeo)

2.6.3. Long-Range Atmospheric Transport

2.6.4. Potential Ecological Risk Index (RI)

2.7. Statistical Analysis

3. Results and Discussion

3.1. Key Coal Quality Parameters of the Raw Coal Samples

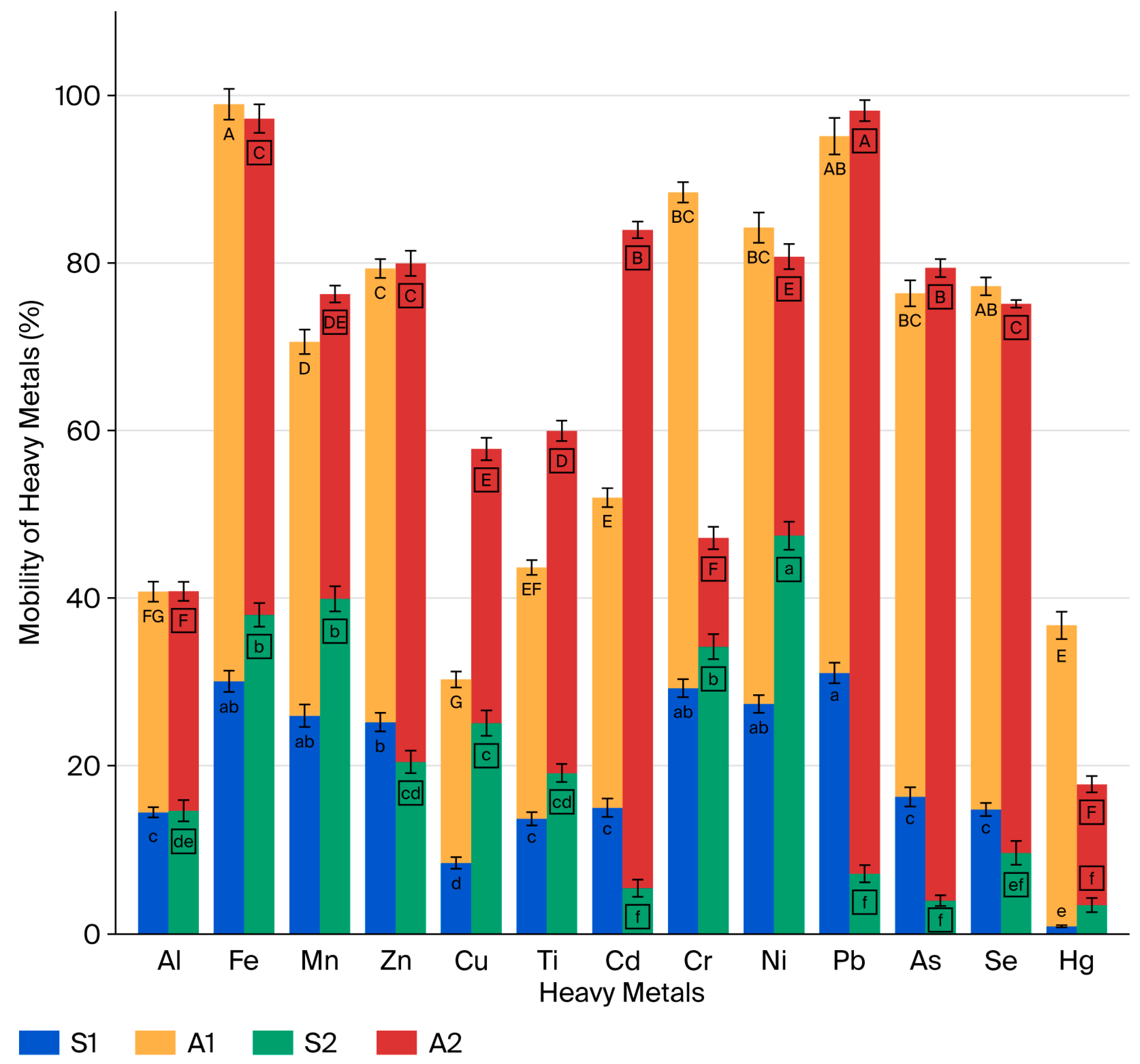

3.2. Migration of Heavy Metal Elements After Raw Coal Combustion

3.3. Speciation of Heavy Metals in Raw Coal, Slag, and Fly Ash

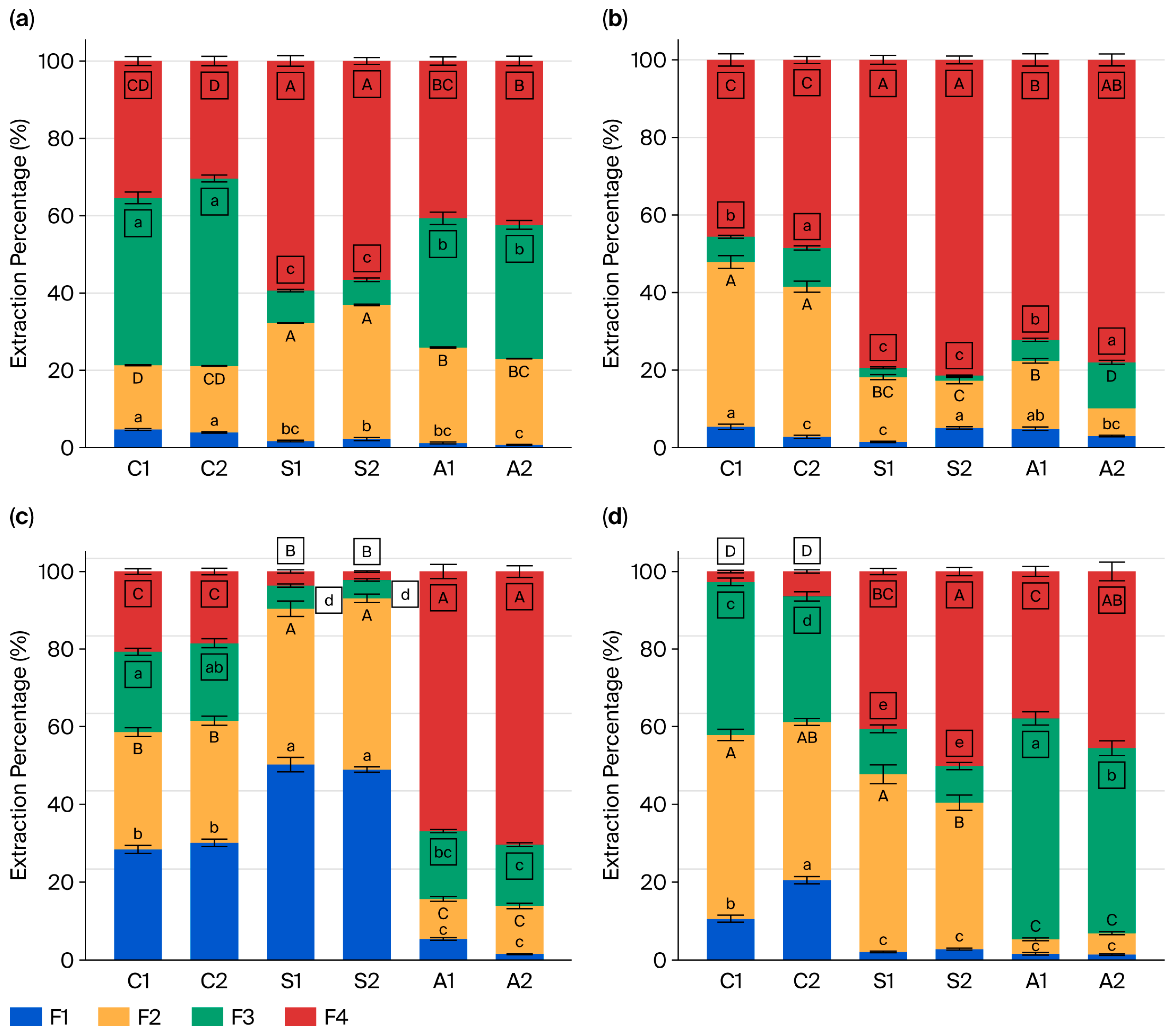

3.3.1. Speciation of Cd

3.3.2. Speciation of As

3.3.3. Speciation of Pb

3.3.4. Speciation of Hg

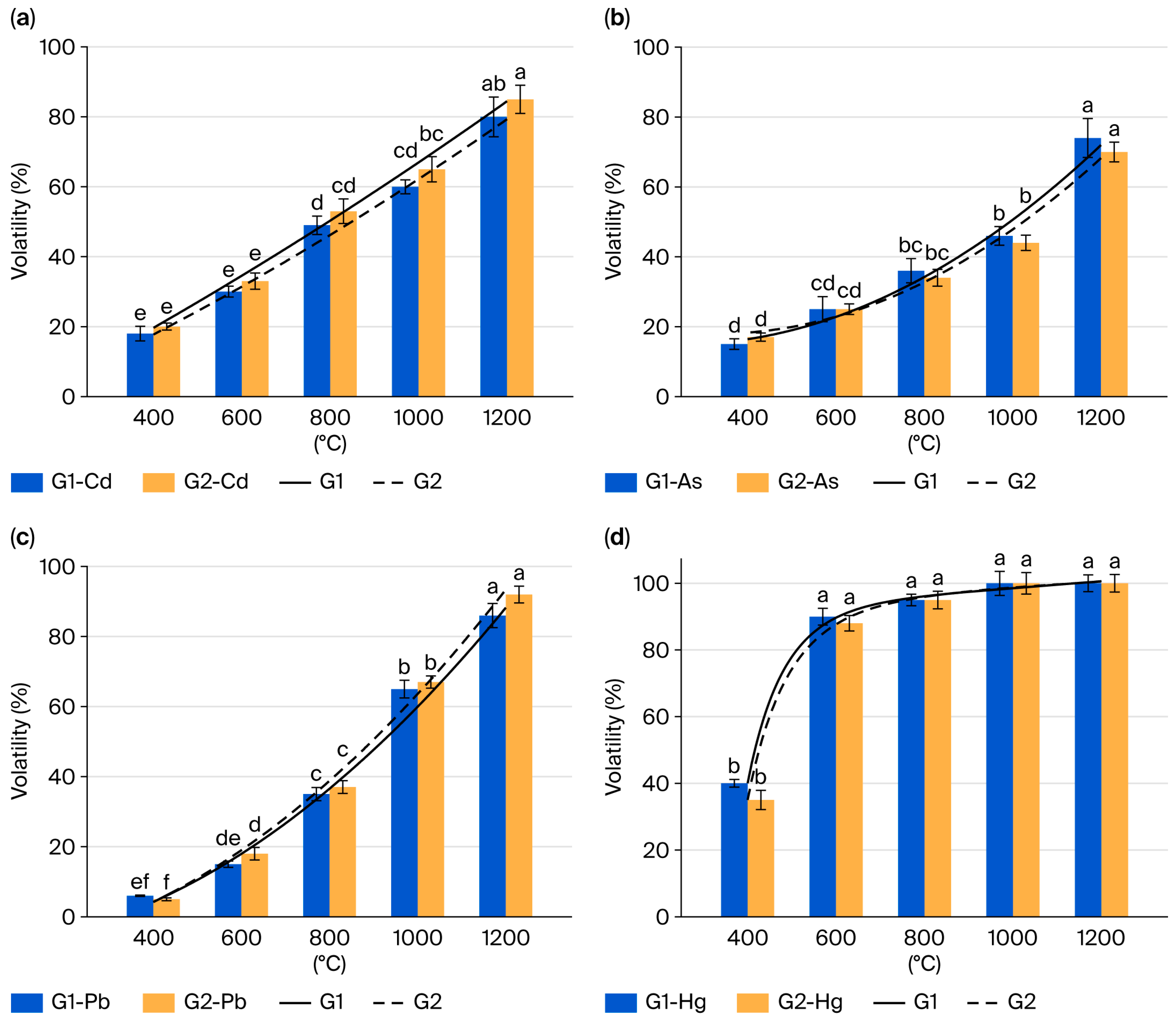

3.4. Migration of Four Heavy Metals Under Varied Combustion Temperatures

3.4.1. Release Behavior of Cd

3.4.2. Release Behavior of As

3.4.3. Release Behavior of Pb

3.4.4. Release Behavior of Hg

3.5. Ecological Risk Assessment of Heavy Metals Released from Raw Coal Combustion

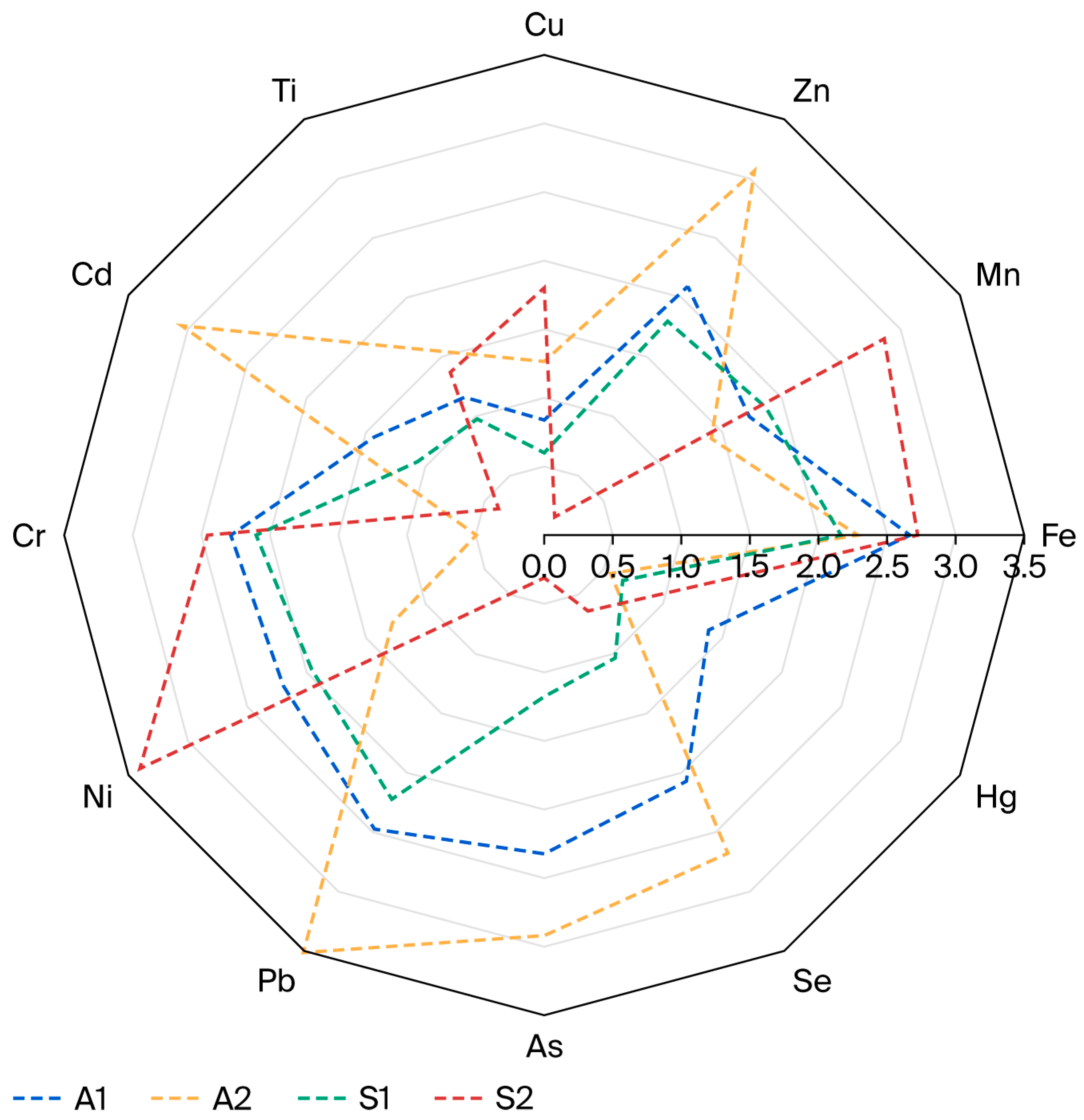

3.5.1. Enrichment Factor (EF) of Heavy Metals

3.5.2. Geo-Accumulation Index (Igeo)

3.5.3. Long-Distance Dispersion of Heavy Metals from Raw Coal Combustion

3.5.4. Potential Ecological Risk of Heavy Metals

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fdez-Ortiz de Vallejuelo, S.F.; Gredilla, A.; Da Boit, K.; Teixeira, E.C.; Sampaio, C.H.; Madariaga, J.M.; Silva, L.F. Nanominerals and Potentially Hazardous Elements from Coal Cleaning Rejects of Abandoned Mines: Environmental Impact and Risk Assessment. Chemosphere 2017, 169, 725–733. [Google Scholar] [CrossRef]

- Oral, R.; Pagano, G.; Siciliano, A.; Toscanesi, M.; Gravina, M.; Nunzio, A.D.; Palumbo, A.; Thomas, P.J.; Tommasi, F.; Burić, P.; et al. Soil Pollution and Toxicity in an Area Affected by Emissions from a Bauxite Processing Plant and A Power Plant in Gardanne (Southern France). Ecotoxicol. Environ. Saf. 2019, 170, 55–61. [Google Scholar] [CrossRef]

- Karbowska, B.; Włodarzewska, E.; Zembrzuski, W.; Zembrzuska, J.; Janeba-Bartoszewicz, E.; Bartoszewicz, J.; Selech, J. Determination of Some Heavy Metals in European and Polish Coal Samples. Molecules 2023, 28, 8055. [Google Scholar] [CrossRef]

- Burachevskaya, M.; Minkina, T.; Mandzhieva, S.; Bauer, T.; Chaplygin, V.; Zamulina, I.; Sushkova, S.; Fedorenko, A.; Ghazaryan, K.; Movsesyan, H.; et al. Study of Copper, Lead, and Zinc Speciation in the Haplic Chernozem Surrounding Coal-Fired Power Plant. Appl. Geochem. 2019, 104, 102–108. [Google Scholar] [CrossRef]

- Fu, B.; Liu, G.; Mian, M.M.; Sun, M.; Wu, D. Characteristics and Speciation of Heavy Metals in Fly Ash and FGD Gypsum from Chinese Coal-Fired Power Plants. Fuel 2019, 251, 593–602. [Google Scholar] [CrossRef]

- Tong, Y.L.; Gao, J.J.; Ma, J.Y. Emission Characteristics, Speciation, and Potential Environmental Risks of Heavy Metals from Coal-Fired Boilers: A Review. Sustainability 2023, 15, 11653. [Google Scholar] [CrossRef]

- Liu, K.Y.; Wang, S.X.; Wu, Q.R.; Wang, L.; Ma, Q.; Zhang, L.; Li, G.L.; Tian, H.Z.; Duan, L.; Hao, J.M. A Highly Resolved Mercury Emission Inventory of Chinese Coal-Fired Power Plants. Environ. Sci. Technol. 2018, 52, 2400–2408. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.M.; Guo, H.; Wang, X.B.; Chu, M.; Zhang, G.J.; Zhang, L.G. Effect of Occurrence Mode of Heavy Metal Elements in a Low Rank Coal on Volatility During Pyrolysis. Int. J. Coal Sci. Techn 2019, 6, 235–246. [Google Scholar] [CrossRef]

- Zhang, J.; Han, C.; Xu, Y.Q. The Release of the Hazardous Elements from Coal in the Initial Stage of Combustion Process. Fuel Process Technol. 2003, 84, 121–133. [Google Scholar] [CrossRef]

- Wu, H.; Glarborg, P.; Frandsen, F.; Dam-Johansen, K.; Jensen, P.; Sander, B. Trace Elements in Co-combustion of Solid Recovered Fuel and Coal. Fuel Process Technol. 2013, 105, 212–221. [Google Scholar] [CrossRef]

- Hakanson, L. An Ecological Risk Index for Aquatic Pollution Control: A Sedimentological Approach. Water Res. 1980, 14, 975–1001. [Google Scholar] [CrossRef]

- Wang, J.; Xie, S.; Wang, G.; Tu, G.; Fang, Z. A Comparative Study of the Capacity of Different Extractants to Extract Heavy Metals in soil. J. South China Norm. Univ. Nat. Sci. 2020, 52, 55–62. [Google Scholar] [CrossRef]

- Querol, X.; Fernández-Turiel, J.L.; López-Soler, A. Trace Elements in Coal and Their Behaviour During Combustion in a Large Power Station. Fuel 1995, 74, 331–343. [Google Scholar] [CrossRef]

- Zhou, C.C.; Liu, G.J.; Xu, Z.Y.; Sun, H.; Lam, P.K. Retention Mechanisms of Ash Compositions on Toxic Elements (Sb, Se and Pb) During Fluidized Bed Combustion. Fuel 2018, 213, 98–105. [Google Scholar] [CrossRef]

- Shen, F.H.; Liu, J.; Dong, Y.C.; Gu, C.K. Insights into the Effect of Chlorine on Arsenic Release During MSW Incineration: An On-line Analysis and Kinetic Study. Waste Manag. 2018, 75, 327–332. [Google Scholar] [CrossRef]

- Luo, G.Q.; Yao, H.; Xu, M.H.; Gupta, R.; Xu, Z.H. Identifying Modes of Occurrence of Mercury in Coal by Temperature Programmed Pyrolysis. Proc. Combust. Inst. 2011, 33, 2763–2769. [Google Scholar] [CrossRef]

- Lu, P.M.; Xie, J.L.; Zhang, X.W.; Wang, J.Y.; Feng, C.Y.; Song, X.; Bu, Y.W. Release Properties of Semi-Volatile Heavy Metals in Sewage Sludge/Coal Co-incineration under O2/CO2 Atmosphere. J. Chem. Technol. Biot. 2020, 48, 533–542. [Google Scholar]

- Zhao, J.; Yang, B.C.; Wei, X.L.; Ni, W.X.; Qiao, Y.; Lou, C. Release Characteristics of Different Alkali Metal Salts in Zhundong Coal under O2/CO2 Combustion Atmosphere Based on FES Technology. J. China Coal Soc. 2024, 49, 3216–3224. [Google Scholar] [CrossRef]

- Fan, M.Y.; Yang, H.; Huang, X.F.; Cao, R.S.; Zhang, Z.D.; Hu, J.W.; Qin, F.X. Chemical Forms and Risk Assessment of Heavy Metals in Soils Around a Typical Coal-Fired Power Plant Located in the Mountainous Area. China Environ. Sci. 2016, 36, 2425–2436. [Google Scholar]

- Yang, Z.P.; Xiao, R.B.; Chen, Y.P.; Deng, Y.R.; Han, C.L.; Liu, C.F.; Gao, Z.Y.; Huang, S.T.; Dai, W.J. Heavy Metal Distribution, Risk Assessment and a Source Analysis of Soil Around a Typical Coal-Fired Power Plant in South China. Acta Ecol. Sin. 2020, 40, 4823–4835. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Shang, P.F.; Wang, J.W.; Norris, P.; Romero, C.E.; Pan, W. Trace Element (Hg, As, Cr, Cd, Pb) Distribution and Speciation in Coal-Fired Power Plants. Fuel 2017, 208, 647–654. [Google Scholar] [CrossRef]

- Sun, S.Y.; Zheng, N.; Wang, S.J.; Li, Y.Y.; Hou, S.N.; Song, X.; Du, S.S.; An, Q.R.; Li, P.Y.; Li, X.Q.; et al. Source Analysis and Human Health Risk Assessment Based on Entropy Weight Method Modification of PM2·5 Heavy Metal in an Industrial Area in the Northeast of China. Atmosphere 2021, 12, 852. [Google Scholar] [CrossRef]

- Hao, Y.F.; Meng, X.P.; Yu, X.P.; Lei, M.L.; Li, W.J.; Yang, W.W.; Shi, F.T.; Xie, S.D. Quantification of Primary and Secondary Sources to PM2.5 Using an Improved Source Regional Apportionment Method in an Industrial City, China. Sci. Total Environ. 2020, 706, 135715. [Google Scholar] [CrossRef]

- Lindberg, S.; Bullock, B.; Ebinghaus, R.; Engstrom, D.; Feng, X.; Fitzgerald, W.; Pirrone, N.; Prestbo, E.; Seigneur, C. A Synthesis of Progress and Uncertainties in Attributing the Sources of Mercury in Deposition. AMBIO A J. Hum. Environ. 2007, 36, 19–32. [Google Scholar] [CrossRef]

- Chen, G.; Li, J.; Chen, B.; Wen, C.; Yang, Q.; Alsaedi, A.; Hayat, T. An Overview of Mercury Emissions by Global Fuel Combustion: The Impact of International Trade. Renew. Sustain. Energy Rev. 2016, 65, 345–355. [Google Scholar] [CrossRef]

- GB/T 212-2008; Method for Industri-al Analysis of Coal. National Coal Standardization Technical Committee: Beijing, China, 2008.

- Zhang, J.G.; Liu, Z.J.; Li, X.; Wang, B.; Teng, Z.C.; Han, K.H. Study on Slagging Characteristics of Co-Combustion of Meager Coal and Spent Cathode Carbon Block. Energies 2023, 16, 736. [Google Scholar] [CrossRef]

- Tessier, A.; Campbell, P.; Bisson, M. Sequential Extraction Procedure for the Speciation of Particulate Trace Metals. Anal. Chem. 1979, 51, 844–851. [Google Scholar] [CrossRef]

- Różański, S.L.; Castejón, J.M.; Garci’a Ferna’ndez, G. Bioavailability and Mobility of Mercury in Selected Soil Profiles. Environ. Earth Sci. 2016, 75, 1065. [Google Scholar] [CrossRef]

- Ngu, B.H.; Phan, H.P.; Hong, K.S.; Usop, H. Reducing Intrinsic Cognitive Load in Percentage Change Problems: The Equation Approach. Learn. Individ. Differ. 2016, 51, 81–90. [Google Scholar] [CrossRef]

- Buha Marković, J.Z.; Marinkovi’c, A.D.; Savi’c, J.Z.; Mladenovi’c, M.R.; Eri’c, M.D.; Markovi’c, Z.J.; Ristic, M. Risk Evaluation of Pollutants Emission from Coal and Coal Waste Combustion Plants and Environmental Impact of Fly Ash Landfilling. Toxics 2023, 11, 396. [Google Scholar] [CrossRef] [PubMed]

- Dai, W.T.; Dong, J.H.; Yan, W.L.; Xu, J.R. Study on Each Phase Characteristics of the Whole Coal Life Cycle and Their Ecological Risk Assessment–A Case of Coal in China. Environ. Sci. Pollut. Res. 2017, 24, 1296–1305. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, M.A.; Parvez, L.; Islam, M.A.; Dampare, S.; Suzuki, S. Heavy Metal Pollution of Coal Mine-Affected Agricultural Soils in the Northern Part of Bangladesh. J. Hazard. Mater. 2010, 173, 384–392. [Google Scholar] [CrossRef] [PubMed]

- Cui, W.; Meng, Q.J.; Feng, Q.Y.; Zhou, L.; Cui, Y.H.; Li, W.B. Occurrence and Release of Cadmium, Chromium, and Lead from Stone Coal Combustion. Int. J. Coal Sci. Techn 2019, 6, 586–594. [Google Scholar] [CrossRef]

- Douay, F.; Pelfrêne, A.; Planque, J.; Fourrier, H.; Richard, A.; Roussel, H.; Roussel, B. Assessment of Potential Health Risk for Inhabitants Living Near a Former Lead Smelter, Part I: Metal Concentrations in Soils, Agricultural Crops, and Home-Grown Vegetables. Environ. Monit. Assess. 2013, 185, 3665–3680. [Google Scholar] [CrossRef]

- Tang, Y.G.; Guo, X.; Pan, X.; Finkelman, R.B.; Wang, Y.F.; Huan, B.B.; Wang, S.Q. Changes and Distribution of Modes of Occurrence of Seventeen Potentially-Hazardous Trace Elements during Entrained Flow Gasification of Coals from Ningdong, China. Minerals 2018, 8, 202. [Google Scholar] [CrossRef]

- Kong, L.W.; Tan, Q.W.; Feng, M.; Qu, Y.; An, J.L.; Liu, X.G.; Cheng, N.L.; Deng, Y.J.; Zhai, R.X.; Wang, Z. Investigating the Characteristics and Source Analyses of PM2.5 Seasonal Variations in Chengdu, Southwest China. Chemosphere 2020, 243, 125267. [Google Scholar] [CrossRef]

- Contreras, M.L.; Arostegui, J.M.; Armesto, L. Arsenic Interactions During Co-Combustion Processes Based on Thermodynamic Equilibrium Calculations. Fuel 2009, 88, 539–546. [Google Scholar] [CrossRef]

- Quick, J.C.; Senior, C.L.; Kolker, A. Mercury in Coal and the Impact of Coal Quality on Mercury Emissions from Combustion Systems. Appl. Geochem. 2006, 21, 1821–1836. [Google Scholar] [CrossRef]

- Luttrell, G.H.; Kohmuench, J.N.; Yoon, R.H. An Evaluation of Coal Preparation Technologies for Controlling Trace Element Emissions. Fuel Process Technol. 2000, 65–66, 407–422. [Google Scholar] [CrossRef]

- Liu, H.M.; Wang, C.B.; Zhang, Y.; Sun, Z.; Shao, H. Effect of Temperature and Occurrence Form of Arsenic on Its Migration and Volatilization During Coal Combustion. CIESC J. 2015, 66, 4643–4651. [Google Scholar] [CrossRef]

- Wang, H. Study on the Mode of Occurrence and Migration of Trace Elements in Shanbei Jurassic Coals. Ph.D. Thesis, Xi’an University of Science and Technology, Shaanxi, China, 2017. [Google Scholar]

- Mei, D.F. A Thesis Submitted in Partial Fulfillment of the Requirements for the Doctorial Degree of Engineering. Ph.D. Thesis, Huazhong University of Science & Techology, Wuhan, China, 2015. [Google Scholar] [CrossRef]

- Wei, B.; Tan, H.Z.; Wang, X.B.; Ruan, R.H.; Hu, H.F.; Wang, Y.B. Effect of Na/Ca/Fe on Slagging Behavior of Zhundong Coal During Combustion Process. J. Chin. Soc. Power Eng. 2017, 37, 685–690. [Google Scholar] [CrossRef]

- Georgii, K.; Denis, S.; Magnus, E.K.; Evgueni, J. The Thermodynamic Modelling of the Zn Slag Fuming with the Use of Coal and Ammonia. JOM 2023, 75, 2003–2015. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Q.; Jung, H.; Tang, Y.Z. Speciation, Distribution, and Mobility of Hazardous Trace Elements in Coal Fly Ash: Insights from Cr, Ni, and Cu. Energy Fuels 2020, 34, 14333–14343. [Google Scholar] [CrossRef]

- Sun, X.; Qian, F.; Wei, X.; Zhang, C. Effects of Combustion Conditions on Migration and Transformation of Heavy Metals During Coal Combustion. Chin. J. Environ. Eng. 2017, 11, 473–482. [Google Scholar] [CrossRef]

- Zou, C.; Wang, C.B.; Liu, H.M.; Chen, L.; Anthony, E. Effect of H2O on the Volatilization Characteristics of Arsenic During Isothermal O2/CO2 Combustion. Int. J. Greenh. Gas Control. 2019, 83, 228–235. [Google Scholar] [CrossRef]

- Li, Q.H.; Meng, A.H.; Jia, J.Y.; Zhang, Y.G. Investigation of Heavy Metal Partitioning Influenced by Flue Gas Moisture and Chlorine Content During Waste Incineration. J. Environ. Sci. 2010, 22, 760–768. [Google Scholar] [CrossRef]

- Frandsen, F.; Dam-Johansen, K.; Rasmussen, P. Trace Elements from Combustion and Gasification of Coal—An Equilibrium Approach. Prog. Energ. Combust. Sci. 1994, 20, 115–138. [Google Scholar] [CrossRef]

- Jiao, F.; Zhang, L.; Yamada, N.; Sato, A.; Ninomiya, Y. Effect of HCl, SO2 and H2O on the Condensation of Heavy Metal Vapors in Flue Gas Cooling Section. Fuel Process Technol. 2013, 105, 181–187. [Google Scholar] [CrossRef]

- Zou, R.J.; Luo, G.Q.; Lyu, M.; Fang, C.; Wang, L.; Fu, B.; Li, Z.H.; Hong, Y. Current Status of Whole Process Control Technologies of Heavy Metals As, Se and Pb Coal-Fired Power Plants. Clean. Coal Technol. 2022, 28, 68–85. [Google Scholar] [CrossRef]

- Strezov, V.; Evans, T.; Ziolkowsli, A.; Nelson, P. Mode of Occurrence and Thermal Stability of Mercury in Coal. Energy Fuels 2010, 24, 53–57. [Google Scholar] [CrossRef]

- Galbreath, K.; Zygarlicke, C. Mercury Transformations in Coal Combustion Flue Gas. Fuel Process Technol. 2000, 65–66, 289–310. [Google Scholar] [CrossRef]

- Chang, L.; Zhao, Y.C.; Zhang, Y.; Yu, X.H.; Li, Z.H.; Gong, B.G.; Liu, H.; Wei, S.Z.; Wu, H.; Zhang, J.Y. Mercury Species and Potential Leaching in Sludge from Coal-Fired Power Plants. J. Hazard. Mater. 2021, 403, 123927. [Google Scholar] [CrossRef]

- Wang, Y.F.; Tang, Y.G.; Li, R.Q.; Guo, X.; Hurley, J.P.; Finkelman, R. Measurements of the Leachability of Potentially Hazardous Trace Elements from Solid Coal Gasification Wastes in China. Sci. Total Environ. 2021, 759, 143463. [Google Scholar] [CrossRef]

- Krupnova, T.G.; Rakova, O.V.; Struchkova, G.P.; Tikhonova, S.; Kapitonova, T.A.; Gavrilkina, S.V.; Bulanova, A.V.; Yakimova, O.N. Insights into Particle-Bound Metal(Loid)s in Winter Snow Cover: Geochemical Monitoring of the Korkinsky Coal Mine Area, South Ural Region, Russia. Sustainability 2021, 13, 4596. [Google Scholar] [CrossRef]

- Pacyna, J.; Pacyna, E. An Assessment of Global and Regional Emissions of Trace Metals to the Atmosphere from Anthro-Pogenic Sources Worldwide. Environ. Rev. 2001, 9, 269–298. [Google Scholar] [CrossRef]

- GB15618-2018; Soil Environmental Quality Risk Control Standard for Soil Contamination of Agricultural Land. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2018.

- Dragović, S.; Ćujić, M.; Slavković-Beškoski, L.; Gajić, B.; Bajat, B.; Kilibarda, M.; Onjia, A. Trace Element Distribution in Surface Soils from a Coal Burning Power Pproduction Area: A Case Study from the Largest Power Plant Site in Serbia. Catena 2013, 104, 288–296. [Google Scholar] [CrossRef]

- GB 2762-2022; National Food Safety Standard–Limits of Contaminants in Food. China’s National Health Commission (NHC): Beijing, China, 2022.

- Li, X.H.; Teng, Y.; Zhang, K.; Peng, H.; Cheng, F.Q.; Yoshikawa, K. Mercury Migration Behavior from Flue Gas to Fly Ashes in a Commercial Coal-Fired CFB Power Plant. Energies 2020, 13, 1040. [Google Scholar] [CrossRef]

- Yue, Y.; Liu, Z.Y.; Liu, Z.Z.; Zhang, J.; Lu, M.; Zhou, J.Z.; Qian, G.R. Rapid Evaluation of Leaching Potential of Heavy Metals from Municipal Solid Waste Incineration Fy Ash. J. Environ. Manag. 2019, 238, 144–152. [Google Scholar] [CrossRef]

- Moskovchenko, D.V.; Pozhitkov, R.Y.; Soromotin, A.V. Snow Contamination by Metals and Metalloids in a Polar Town: A Case Study of Nadym, Russia. Arch. Environ. Contam. Toxicol. 2024, 86, 304–324. [Google Scholar] [CrossRef]

- Zhao, S.L.; Duan, Y.F.; Lu, J.C.; Gupta, R.; Pudasainee, D.; Liu, S.; Lu, M.; Liu, J.H. Chemical Speciation and Leaching Characteris-Tics of Hazardous Trace Elements in Coal and Fly Ash from Coal-Fired Power Plants. Fuel 2018, 232, 463–469. [Google Scholar] [CrossRef]

- Charvalas, G.; Molla, A.; Lolas, A.; Skoufogianni, E.; Papadopoulos, S.; Chatzikirou, E.; Emmanouil, C.; Christopoulou, O. Evaluation of Potential Toxic Elements in Soils from Three Urban Areas Surrounding a Steel Industrial Zone. Toxics 2025, 13, 51. [Google Scholar] [CrossRef]

- Leshukov, T.; Legoshchin, K.; Yakovenko, O.; Bach, S.; Russakov, D.; Dimakova, D.; Vdovina, E.; Baranova, E.; Avdeev, K.; Kolpina, E.; et al. Fractional Composition and Toxicity Coal–Rock of PM10-PM0.1 Dust near an Opencast Coal Mining Area and Coal-Fired Power Station. Sustainability 2022, 14, 16594. [Google Scholar] [CrossRef]

- Ramires, P.F.; Santos, M.D.; da Rodrigues, S.; Júnior, F. Multiple Exposure Pathways and Health Risk Assessment of Potentially Harmful Elements for Children and Adults Living in a Coal Region in Brazil. Environ. Geochem. Health 2023, 45, 305–318. [Google Scholar] [CrossRef] [PubMed]

- Dinesh, S. Chemical Characteristics and Public Health Risk Assessment of PM2.5-Bound Elements in Sheohar, India. Aerosol Sci. Eng. 2024, 8, 275–287. [Google Scholar] [CrossRef]

- Zhuravleva, N.V.; Zhuravleva, E.V.; Mikhailova, E.S.; Ismagilov, Z.R. Methods and Approaches to the Determination of the Carbon-Containing Dust Concentrations in the Atmospheric Air During Coal Mining and Processing (Conference Paper). J. PHY Conf. Ser. 2021, 1749, 012035. [Google Scholar] [CrossRef]

- An, D.H.; Han, X.L.; Cheng, X.X.; Zhou, B.X.; Zheng, Y.; Dong, Y. Effect Mechanisms of Different Flue Gas on Adsorption of Mercury by Powder Activated Coke. CIESC J. 2019, 70, 1575–1582. [Google Scholar] [CrossRef]

| Samples | Proximate Analysis | Ultimate Analysis | ||||||

|---|---|---|---|---|---|---|---|---|

| Mad | Ad | St,d | Vdaf | Carbon | Hydrogen | Nitrogen | Oxygen | |

| (%) | (%) | (%) | (%) | (%) | (%) | (%) | (%) | |

| C1 | 1.01 | 22.09 | 2.54 | 14.78 | 57.8 | 2.7 | 1.5 | 4.8 |

| C2 | 2.77 | 21 | 1.01 | 39.71 | 55.9 | 3.1 | 1.4 | 2.2 |

| EF Range | Pollution Level | Source Interpretation |

|---|---|---|

| EF < 1 | No enrichment | Natural sources |

| 1 ≤ EF < 3 | Mild enrichment | Natural or minor anthropogenic |

| 3 ≤ EF < 10 | Significant enrichment | Dominant anthropogenic (e.g., industry) |

| 10 ≤ EF < 50 | Strong enrichment | Clear anthropogenic origin |

| EF ≥ 50 | Extreme enrichment | Severe pollution (e.g., mining) |

| HM | C1 (mg·kg−1) | C2 (mg·kg−1) | Risk Screening Value (pH > 7.5) | Risk Control Value |

|---|---|---|---|---|

| Zn | 154.8 | 308.9 | 300 | 500 |

| Cu | 50.1 | 69.1 | 100 | 200 |

| Cd | 1.75 | 2.22 | 0.6 | 1.5 |

| Cr | 13.6 | 46.0 | 250 | 800 |

| Ni | 8.25 | 15.4 | 100 | 300 |

| Pb | 67.3 | 100.7 | 140 | 400 |

| As | 30.8 | 11.6 | 15 | 40 |

| Hg | 3.3 | 3.4 | 1 | 2 |

| C1 | C2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| S1 | A1 | S1 | A1 | S2 | A2 | S2 | A2 | ||

| Zn | 1 | 0.20 | 0.43 | 0.20 | 0.43 | 0.03 | 1.25 | 0.03 | 1.25 |

| Cu | 5 | 0.16 | 0.40 | 0.80 | 2.00 | 0.64 | 0.83 | 3.20 | 4.15 |

| Cd | 30 | 0.69 | 1.70 | 20.70 | 51 | 0.32 | 4.60 | 9.60 | 138 |

| Cr | 2 | 0.11 | 0.22 | 0.22 | 0.44 | 0.42 | 0.16 | 0.84 | 0.32 |

| Ni | 5 | 0.13 | 0.27 | 0.65 | 1.35 | 0.42 | 0.29 | 2.10 | 1.45 |

| Pb | 5 | 0.25 | 0.52 | 1.25 | 2.60 | 0.09 | 1.10 | 0.45 | 5.50 |

| As | 10 | 0.09 | 0.35 | 0.90 | 3.50 | 0.01 | 0.16 | 0.10 | 1.60 |

| Hg | 40 | 0.14 | 5.60 | 5.60 | 224 | 0.57 | 2.36 | 22.8 | 94.4 |

| RI | 30.32 | 285.32 | 39.12 | 246.67 | |||||

| Pollution Degree | RI | Risk Degree | |

|---|---|---|---|

| < 30 | Slight | RI < 40 | Slight |

| 30 ≤ < 60 | Medium | 40 ≤ RI < 80 | Medium |

| 60 ≤ < 120 | Strong | 80 ≤ RI< 160 | Strong |

| 120 ≤ < 240 | Very strong | 160 ≤ RI< 320 | Very strong |

| ≥ 240 | Extremely strong | RI ≥ 320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Wang, H.; Sun, Z.; Gu, X. Release and Ecological Risks of Heavy Metals During Coal Combustion in Coal-Fired Power Plants. Appl. Sci. 2025, 15, 11360. https://doi.org/10.3390/app152111360

Ma R, Wang H, Sun Z, Gu X. Release and Ecological Risks of Heavy Metals During Coal Combustion in Coal-Fired Power Plants. Applied Sciences. 2025; 15(21):11360. https://doi.org/10.3390/app152111360

Chicago/Turabian StyleMa, Rui, Haifang Wang, Zhumei Sun, and Xianmo Gu. 2025. "Release and Ecological Risks of Heavy Metals During Coal Combustion in Coal-Fired Power Plants" Applied Sciences 15, no. 21: 11360. https://doi.org/10.3390/app152111360

APA StyleMa, R., Wang, H., Sun, Z., & Gu, X. (2025). Release and Ecological Risks of Heavy Metals During Coal Combustion in Coal-Fired Power Plants. Applied Sciences, 15(21), 11360. https://doi.org/10.3390/app152111360