Featured Application

The proposed work has direct application in assessing the vulnerability of critical industrial infrastructure exposed to extreme natural events, particularly in the context of NaTech scenarios. The bidirectional approach allows for the integration of material degradation mechanisms into risk models, improving the ability to predict and manage technological incidents in adverse environmental conditions. The results are particularly relevant for facilities subject to the Seveso Directive, where assessing obsolescence and structural condition can support targeted inspection strategies, preventive maintenance, and resilient design.

Abstract

Material degradation is a critical factor in assessing the vulnerability of industrial infrastructure, particularly in the presence of extreme natural events. This study shows that the relation between material degradation and NaTech risk is both bidirectional and systemic, with important implications for industrial safety. Through the analysis of an emblematic case study, it was demonstrated that latent defects, originating during the construction phase, can remain silent for decades and manifest critically under the action of extreme natural events. The objective is to provide a useful methodological tool for the early diagnosis of systemic risk conditions and for planning preventive and resilient strategies. The proposed approach overcomes the traditional separation between degradation analysis and environmental risk assessment, promoting a holistic and adaptive view of vulnerability. Specifically, integrating the concept of structural obsolescence into NaTech risk models allows for a more realistic representation of systemic exposure and supports the planning of more effective prevention strategies. The case study analysis highlights the interaction between latent structural defects and environmental stresses, offering insights for interpreting vulnerability in complex and multifactorial scenarios. The outcome provides perspectives for the integration of quantitative indicators into NaTech risk models.

1. Introduction

Material degradation is a major cause of vulnerability in industrial infrastructure, particularly in contexts characterized by ageing facilities and extreme environmental conditions. Wintle et al. [1] highlighted that over 30% of containment loss events in the industrial sector are caused by degradation mechanisms. Candreva and Houari [2] confirmed this trend, emphasising the significant impact of ageing on industrial plants. Horrocks et al. [3] described ageing as a process of progressive deterioration, influenced by operational and environmental conditions. Kelly [4] reported that ageing management requires continuous attention to maintenance and structural safety. Bragatto and Milazzo [5] distinguished ageing from obsolescence, associating the former with the physical degradation of components. Milazzo and Bragatto [6] clarified that obsolescence, on the other hand, concerns compliance with updated technical and regulatory standards. In Europe, approximately 50% of industrial plants operate beyond their expected life cycle [7], highlighting the relevance of the problem. Managing ageing industrial infrastructure requires systematic maintenance and inspection, but these practices are often insufficiently considered in current models, as highlighted by Hansler et al. [8]: the risk is the underestimation of latent defects that can manifest themselves in extreme environmental conditions. In line with this, previous work conducted a historical analysis of 3772 industrial events, allowing for the systematization of degradation mechanisms and their impact on process safety [9,10]. The study highlighted corrosion, vibration, and fatigue as the most recurring causes, underscoring the need to integrate the concept of obsolescence into risk assessment models, particularly within the regulatory framework of the Seveso III Directive; in fact, this directive, while requires monitoring of ageing and corrosion, does not provide detailed operational guidance for their management.

The mutual influence between material degradation and natural events is a central element in the assessment of NaTech (Natural Hazard Triggering Technological Accident) risk, in which extreme natural phenomena can trigger or aggravate technological accidents. In this context, latent defects and deterioration processes can be amplified by external stresses, increasing systemic vulnerability.

NaTech events simultaneously involve natural phenomena and technological risks, generating significant impacts on the environment and public safety. Krausmann et al. [11] highlighted how such events represent an increasing criticality for industrial plants, while Valente et al. [12] analysed the application of resilience engineering to improve risk management in complex scenarios. Several recent studies have addressed the topic of NaTech risk with complementary approaches. Cruz et al. [13] proposed structural measures to reduce the impact of natural events on industrial plants. Naderpour and Khakzad [14] analysed the domino effects triggered by natural disasters, highlighting systemic vulnerability. Ibrion et al. [15] offered a life-cycle analysis perspective, studying structural resilience in nuclear contexts. Laor and De Vivo [16] introduced predictive methods for environmental risk management, based on deterministic approaches. Ju and Xing [17] integrated machine learning and GIS techniques for spatial risk mapping. Finally, Reichstein et al. [18] proposed an artificial intelligence-based framework for early warning in complex climate scenarios. In the European panorama, the inclusion of the evaluation of NaTech scenarios in Seveso plants was introduced by the third revision of the Directive [Directive 2012/18/EU on the control of major-accident hazards involving dangerous substances, amending and subsequently repealing Council Directive 96/82/EC]. Already in previous version the Directive required to provide detailed information on the meteorological conditions of the area, along with a chronological record of any past geophysical and hydrogeological event for the companies that had to prepare a safety report (Upper Tier). In this last version, these requirements have been deepened, requiring identifying and describing major accidents that may occur, including natural causes such as earthquakes and floods. NaTech risks were also explicitly addressed within the aspect to control in the Safety Management Systems, that pertains non only to Upper Tier plants, but also to Lower Tier Ones.

The increasing frequency and complexity of NaTech events has stimulated scientific interest, highlighting the need to delve deeper into the dynamics of interaction between extreme natural phenomena and technological vulnerability. Several studies have focused on historical incidents, with the aim of identifying relations and connections between the industrial sectors affected by the natural phenomena and the substances involved in these events. In the classification described by Ricci et al. [19], NaTech events are divided into four categories. The research collected a set of data including 9100 incidents that occurred in the previous 70 years, with the aim of analysing the trend of NaTech events, their geographical distribution, the technological scenarios involved and the related consequences. The study highlights that meteorological events represent the most recurring category, while the geophysical ones are responsible for the greatest losses, both in human and economic terms. This approach aims to provide a deeper understanding of the risk patterns and dynamics that characterize such incidents. Ricci et al. [20] studied the impacts of cold waves within the process industry. In detail, they examined the categories and specific elements most influenced, investigating the recurring causes, the losses recorded, and the substances involved in these situations. Furthermore, their work included an in-depth analysis of safety barriers, assessing the likelihood of these barriers to fail in the presence of cold waves. Castro Rodriguez et al. [21] have developed a repository that collects all accidents, caused by lightning, present in the main available databases. Likewise, Castro Rodriguez et al. [22] conducted an analysis of previous lightning accidents, providing a notable contribution to the design, risk assessment, inspection, and implementation phases of lightning protection measures.

Equipment conditions can amplify the consequences of these events. Material degradation emerges as a crucial element in NaTech risk assessment and management. Despite this, an aspect that has received limited attention in the literature is the link between material degradation and NaTech events. The concept of bidirectional vulnerability describes the mutual influence between degradation and natural stresses: indeed, structural deterioration can amplify the infrastructure vulnerability to external events, while environmental stresses can accelerate degradation processes, generating critical and potentially unstable operating conditions. Over time, infrastructures undergo structural deterioration due to factors like corrosion, wear, tear, and material fatigue. Such degradation reduces structural resistance to natural hazards like earthquakes or storms, increasing the likelihood of failure [23]. Older infrastructures may lack effective design considerations for handling NaTech events, emphasising the need to assess and enhance their resilience to such scenarios. This approach is critical to ensure the safety of infrastructures in a context of ever-evolving NaTech risks. In addition to triggering technological failures, NaTech events can intensify existing degradation processes, increasing the likelihood of structural failure. For example, floods or overflows can cause rapid corrosion or physical damage to the infrastructure, further increasing the risk of structural failure. The interplay between NaTech events and material ageing is complex and must be integrated into risk assessment procedures to enable effective prevention. Indeed, Pilone et al. [24] proposed to use a NaTech index based on two factors, one of which concerns the vulnerability of each element and includes obsolescence.

Despite the growing attention to NaTech scenarios and the ever-increasing availability of industrial accident databases, the scientific literature still lacks an integrated framework that explicitly addresses the dynamic interaction between material degradation and natural hazards. Most studies tend to treat these phenomena separately as degradation is often analysed in the context of ageing or mechanical failure managing, while NaTech risk is predominantly addressed from a perspective focused on the initiating event or its consequences. This fragmentation limits the ability to capture the synergistic effects that occur when structural deterioration and environmental stresses occur simultaneously, representing a methodological limitation in understanding industrial vulnerability. The research problem addressed in this study concerns precisely the lack of an integrated framework that considers the dynamic interaction between environmental stresses and structural defects. The integration of these two areas in a conceptual framework allows for a more realistic representation of systemic vulnerability and supports the early identification of critical conditions. This work aims to fill this gap by proposing an interpretative model that integrates material degradation into the assessment of vulnerability to NaTech events, with the aim of improving the understanding of the mechanisms that generate bidirectional vulnerability. This dynamic interaction, often overlooked in traditional models, represents a key factor in defining systemic risk in industrial contexts exposed to environmental stresses.

To illustrate this interaction, a case study is analysed, characterized by the coexistence of a latent structural defect and an extreme natural event. The analysis is conducted using consolidated tools and supported by quantitative data extracted from a database of degradation events. The results highlight how vulnerability is not a static property, but a dynamic phenomenon that evolves over time as a function of operating and environmental conditions.

From an applied perspective, the proposed approach offers a contribution to industrial risk management, enabling the integration of degradation indicators into NaTech vulnerability models, the early identification of systemic risk conditions, and the development of prevention strategies to strengthen infrastructure resilience. The study also explores the influence of multiple factors on material degradation, including the characteristics of the substances contained in the systems, the environmental conditions, and the service life of the infrastructure. By adopting a bidirectional perspective, the work contributes to the development of a holistic and operational approach to industrial risk management in environments exposed to natural stresses, consolidating a systemic and adaptive vision of resilience, consistent with the theoretical and methodological framework outlined in the introduction.

2. Case Study and Methods

To illustrate the bidirectional interaction between material degradation and NaTech risk, the paper presents the analysis of a representative case study related to a critical energy infrastructure. The selected event offers a concrete example of how degradation and environmental stress can interact. The case was chosen from the inventory of ageing events in which structural deterioration occurred in conjunction with extreme natural events. The aim is to use the case study to highlight how degradation mechanisms can amplify NaTech risk, and vice versa.

2.1. Case Study Selection

Among the events identified in the inventory [10] analysed in the previous work [9], a representative case involving a cold-triggered failure due to latent degradation was selected. A detailed description is provided in Section 3.1.

The selection was guided by criteria of technical relevance, availability of detailed information, and clarity in reconstructing the causal dynamics. The selected event offers important insights into the vulnerability of industrial infrastructure and their ability to respond to complex scenarios. Specifically, the observed dynamics can provide useful insights to better understand the implications of material degradation in terms of loss of containment and operational resilience, thus contributing to the construction of a more integrated view of risk in contexts exposed to NaTech events.

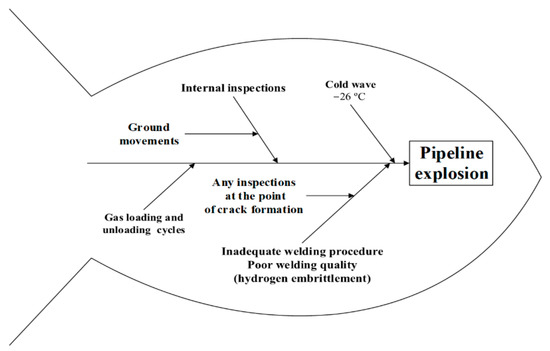

2.2. Root Cause Analysis

To carry out an accurate analysis, a detailed reconstruction of the selected case study was initially conducted, with the aim of identifying the causes that contributed to the accident and understanding the dynamics that led to the escalation of the event. In this phase, a fishbone diagram, also known as an Ishikawa or cause-and-effect diagram, was used. This technique is useful for visually representing the possible causes of a specific problem, organizing them into logical categories that branch out from a central axis, where the unwanted effect is reported. The diagram reveals how different variables interact, providing a systemic view and helping identify critical areas for further investigation [25].

Subsequently, a more in-depth analysis was conducted to investigate the relations between material degradation and natural hazards. In this phase, the event historical analysis was conducted, a process that involves the examination of incidents that have occurred in similar industrial settings to identify correlations, recurring trends, and a raw estimation of expected frequencies. This approach allows the determination of the root causes, circumstances, and dynamics that led to the event, providing useful insights for improving risk management and preventing the recurrence of similar scenarios.

Finally, further analysis was carried out to explore how material degradation and natural events can influence each other. The goal was to delve deeper into the effect of structural deterioration on infrastructure vulnerability and, consequently, understand how this vulnerability can alter the risk profile in NaTech scenarios. This integrated approach allows for a more complete and nuanced view of the complexity of risk, offering useful insights for future considerations regarding the resilience of industrial facilities.

The choice of the Ishikawa diagram as a root cause analysis tool is motivated by its ability to visually and systematically represent the causal relationships between technical, operational, and environmental factors. This approach highlights the interactions between latent defects and external conditions, facilitating the identification of structural vulnerabilities. Event historical analysis was selected for its effectiveness in exploiting lessons learned from occurred accidents. The integration of these methods allows for a multidimensional interpretation of the event, consistent with the aim of this study to analyse bidirectional vulnerability in multifactorial scenarios.

2.3. Summary of the Interpretative Model

The interpretative model proposed in this study is based on a conceptual framework that integrates two complementary analytical tools, the root cause analysis and the factor analysis, into a methodology for assessing bidirectional vulnerability in industrial systems.

- Root cause analysis, using Ishikawa diagrams, allows the construction of the causal dynamics of the event, highlighting the interactions between latent defects, operating conditions, and environmental factors.

- Factor analysis identifies and classifies the internal and external factors that influence material degradation, providing a basis for assessing structural vulnerability.

These tools are not used separately, but in synergy within the conceptual framework. In this integrated approach, the conceptual framework guides the systemic interpretation, the factor analysis supports the understanding of the critical variables, and the causal diagram allows the visualisation of the connections between the different elements. Together, they form an integrated methodological approach, useful for diagnosing vulnerability and planning preventive and resilient strategies.

3. Results and Discussion

The selected event, extracted from the Transportation Safety Board of Canada (https://www.tsb.gc.ca/eng/) database, is examined in relation to the operating conditions, the technical characteristics of the system involved, and the environmental context, to highlight the interaction between structural degradation and natural stresses in the genesis of the failure.

The analysis focuses on the sequence of events that led to the failure, with particular attention to the material degradation mechanisms and the role played by natural stresses. Through a technical reconstruction and an assessment of the root causes, the aim is to provide an integrated interpretation of the event, useful for understanding the interactions between structural and environmental factors in NaTech scenarios.

3.1. Event Description

At approximately 01:15 Central Standard Time on 25 January 2014, a natural gas pipeline rupture and ignition occurred in the vicinity of Otterburne, MB, Canada. As a result, a crater approximately 24 m long and 12.5 m wide was formed, caused by an explosion, with debris projected approximately 100 m from the crash site (Figure 1). The technical data of the Otterburne case are reported in Table 1, which also summarises the main parameters and the evidence emerging from the analysis.

Figure 1.

Uplift of the valve and pipeline section following rupture and explosion. Photo credit: courtesy of Transportation Safety Board of Canada [26].

Table 1.

Parameters and evidence of the Otterburne case analysed.

The natural gas continued to burn for about 12 h. In response to the event, five homes in the immediate vicinity were evacuated, and the provincial road remained closed until the fire was completely extinguished. Fortunately, no injuries were reported. Before the event, the system was operating normally, with an operating pressure at the event site of approximately 6330 kPa. The maximum operating pressure for this section of the system was 7030 kPa. The event happened in an agricultural land; the area was sparsely populated. Due to lack of customer demand, gas flow in the pipeline was interrupted starting 5 January 2014. However, static pressurized gas was still present in the line between the two closed valves. The line had undergone hydrostatic testing when the pipeline was originally placed in service in 1960. No other pressure tests had been performed since then. Records of welding and non-destructive testing dating back to the commissioning had not been retained. Internal inspections of the line were performed as follows: in 2001, the pipeline was inspected using a gage instrument and a high-resolution magnetic flux dispersion (MFL) instrument. In 2009 the pipeline was inspected again using a high resolution MFL instrument. The following integrity-related activities were conducted in proximity of the incident: in 1997, a single excavation was performed 9 m downstream of the line to inspect for external corrosion. Subsequently, in 1998, 1999, and 2009, a series of investigative excavations took place in adjacent sections of the valves to confirm the presence of external corrosion and stress corrosion cracking (SCC). The nearest excavation site was situated approximately 3 km downstream from the line. As a result of the 1999 excavations, a 38 m segment of the pipeline located on the line was cut and replaced due to the identification of SCC. The line rupture occurred around 1 m north of the first valve, resulting from a brittle fracture originating in a pre-existing crack. This crack is presumed to have developed during the pipeline construction phase due to an inadequate welding procedure and poor welding quality, leading to hydrogen cracking. In this context, the hydrogen is not related to the transported substance, which was methane, but was introduced locally during welding operations, where it remained trapped in the metal structure, generating HE cracks. Amazingly, the weld defect remained stable for over 50 years before failing. As a result of the failure, the first valve and an 11 m-long section of pipe to the South rose, causing a sharp bend at a circumferential weld at the top of the pipe, thus causing a secondary failure. The release of natural gas from the pipeline triggered an explosion, and the resulting fire lasted about 12 h.

During the accident, the recorded temperature was −26 °C, accompanied by light winds coming from the North. That winter, southern Manitoba was facing extreme weather, marking one of the coldest winters since 1898. Following the accident, a thorough examination of the site was conducted, which revealed the following considerations: the ground support in the vicinity of the site may have suffered weakening due to repeated excavation and backfilling activities over the years, as part of the facility standard repair and maintenance practices. Due to the extremely low temperatures recorded during the exceptionally cold winter experienced in southern Manitoba, frost in the ground likely penetrated deeper than normal. Maintenance work carried out in January 2014 in and around the site may have helped pushing the frost even deeper into the ground. Finally, thermal contraction may have taken place as the pipeline, without gas flow for 20 days, cooled. The accident was triggered by an initial crack generated during the welding process due to hydrogen. The section of pipe involved exhibited a significantly higher level of hardness, giving it greater brittleness than the base steel. Further minor cracks were also identified in other points of the pipe. The movement of the ground and the cold wave caused the pipe to collapse, leading it to rise and causing the gas to escape, generating an explosion and a consequent fire.

The Otterburne case occurred in a rural area of southern Manitoba, characterized by extreme climate conditions and low population density. This location contributed to the underestimation of environmental risk during the design phase, particularly regarding protection against cold spells. The main problem that emerged was the presence of a latent structural defect, caused by inadequate welding, which remained undetected for over fifty years. The event highlighted how the lack of post-installation checks and targeted preventive strategies can compromise the resilience of the infrastructure. Operational implications suggest the need to integrate obsolescence and environmental vulnerability criteria into inspection and maintenance programs, with particular attention to infrastructure exposed to extreme climate conditions.

3.2. Contributing Factors Analysis

The Otterburne accident highlights the importance of considering materials degradation during a potential NaTech event, as the combination of both led to the pipe explosion. The cause-and-effect diagram depicted in Figure 2 provides a clear illustration of the causes of the accident. The Ishikawa diagram for the Otterburne pipeline accident classifies the causes into four main categories, each represented by a branch highlighting specific contributing factors:

Figure 2.

Fishbone diagram illustrating the root causes and contributing factors of the Otterburne pipeline accident.

- Maintenance and inspection: Maintenance activities carried out prior to the accident caused soil displacement, altering stability and contributing to mechanical stress on the structure.

- Environmental conditions: An exceptional cold snap caused frost to penetrate the ground, amplifying the material fragility and promoting crack propagation.

- Operational factors: Gas loading and unloading cycles generated pressure fluctuations that increased mechanical stress on the pipeline.

- Construction and quality: During the construction phase, poor quality procedures were employed, including inadequate welding practices and deficient post-installation inspections, which promoted hydrogen embrittlement and the presence of latent defects.

Hydrogen embrittlement (HE), although it had occurred 50 years earlier, had not caused significant damage during the years. However, it was the natural event that triggered the breakup. In this situation, it emerges that although the inspections were conducted, their effectiveness was limited and they were incomplete, as the fracture dates to the construction period of the pipe, which was not adequately monitored after the installation. Furthermore, the lack of protection systems against extreme natural events is highlighted. This is a deficiency that should have been carefully evaluated during the design phase, especially considering the harsh climatic conditions of the area in which the infrastructure is located. Additionally, the accident underscores the significance of substances interacting with the material, as certain materials can expedite the degradation process. Indeed, in this scenario, the failure could have been avoided by adopting appropriate welding procedures and performing post-installation checks. Poor quality control during construction allowed a latent defect to remain undetected for over fifty years, eventually failing under extreme environmental stress. This highlights how quality management during the construction phase represents a crucial element in preventing long-term failures, especially in infrastructure exposed to extreme environmental risks.

To further explore the interaction between internal and external factors in the failure process, it is useful to distinguish the specific contribution of welding defects and extreme environmental conditions. The welding defect, generated during the construction phase, represented a latent structural weakness that remained stable for over fifty years. However, the extreme natural event acted as a trigger, inducing thermal contractions and mechanical stresses that favoured crack propagation. Although the Otterburne case is well documented, there are no specific quantitative models describing the coupling effect between material degradation and environmental stresses. This is mainly due to the retrospective nature of the event and the lack of detailed and continuous operational data over time, such as thermal stress measurements, pressure variations, or structural inspection parameters. Furthermore, the welding defect was latent and unmonitored, making predictive modelling based on historical data difficult. The literature proposes probabilistic approaches and vulnerability indices that integrate structural and environmental parameters, such as the NaTech index proposed by Pilone et al. [24], which considers obsolescence as a vulnerability factor, but does not include specific environmental variables such as the frequency of temperature excursions. For real cases such as Otterburne, integrated models based on multi-source data (historical, climatic, structural) and predictive analytics techniques would be necessary.

To explore the causes in more depth, an analysis was performed on past incidents related to material deterioration. Hydrogen embrittlement is a process in which hydrogen penetrates the interior of a material, compromising its ability to resist fracture under stress [27]. Once inside the structure of the material, hydrogen can cause the formation of micro-fractures and cracks, which can lead to sudden failure or breakage of the material.

According to Vitale et al. [9] the hydrogen embrittlement is an autonomous category among material degradation mechanisms, highlighting its specificity and relevance in critical contexts. However, the data show that this phenomenon represents only 0.3% of the total events analysed. This limited occurrence is likely due to the current low level of hydrogen utilization as an energy carrier in the process industry, thus limiting systemic exposure to this risk. Despite this, HE occurs predominantly in highly critical components: 93% of the events involved Primary containment system, while 7% involved Control & Mitigation Measures. From a sectoral perspective, the phenomenon is mainly concentrated in the Chemical & Petrochemical (71%), followed by Manufacturing (21%) and, to a much lesser extent, Pipeline (8%). This specific finding is especially noteworthy when considered in conjunction with the case study discussed: indeed, a transport infrastructure was subjected to a structural failure attributable to a hydrogen embrittlement mechanism.

In the case study, the pipeline cracked during installation, but the raising of the equipment occurred after 50 years. This behaviour is also confirmed by the data from the analysed database. Indeed, among the reports in which hydrogen embrittlement was identified as the cause of the event, 43% did not indicate the age of the plant. However, considering only the cases for which such information is available, 63% of the events occurred in plants older than 25 years. This data reinforces the hypothesis that hydrogen embrittlement, while potentially originating during the construction phase, tends to manifest itself critically only after long periods of operation, in the presence of environmental or operating conditions favourable to the propagation of the damage.

The gas flow on Line 400-1 was interrupted on 5 January 2014, due to reduced demand, as reported in the official incident record. Although gas was not flowing at the time of the event, the pipeline was still under static pressure between the closed valves. However, over the operational life of the infrastructure, the pipeline was subject to pressure fluctuations related to demand variability, which may have contributed to the onset of long-term mechanical fatigue. These cycles could have contributed to stressing the material over time, favouring the occurrence of failure. This phenomenon is a deterioration mechanism known as material fatigue and has been identified in the analysis of past events as being involved in only 4% of previous incidents, but its implications are significant and should not be overlooked. The industrial sectors most affected by fatigue are the Chemical & Petrochemical and Storage & Warehousing, which account for 72% of reports. Only 7% of events involve Pipeline. It is important to note that fatigue is not determined by the chemical nature of the substances involved but is a mechanical phenomenon. Among the mechanisms analysed, this is the only one whose most common final result is release without further consequences. This further highlights the mechanical aspect of fatigue, which develops over time. Indeed, more than half of the plants where the fatigue phenomenon occurred are more than 25 years old.

The incidental event examined in this study also involves an extreme natural event, as shown in Figure 2, the anomalous cold waves. Ricci et al. [20] highlighted that industrial sites are more susceptible to cold climate impacts than to heat waves. Low temperatures are the third leading cause of NaTech accidents in Europe, following lightning and floods. It is important to note that the perceived risk related to such accidents is significantly underestimated by the European population. In the industrial context, the Chemical & Petrochemical sector is particularly vulnerable to accidental events caused by cold waves (38% of events), mainly due to the widespread use of dangerous substances. Pipes represent the component of the system most affected by cold waves, contributing to 39% of recorded events. Furthermore, the transportation sector, especially through pipelines, is identified as the second most affected category (18% of events). This frequency is attributed to the significant impact of cold waves in causing accidents during the transportation of hazardous substances, confirming the high vulnerability of transportation systems and infrastructure to the effects of these adverse weather conditions. Extreme weather conditions linked to cold waves add further risk factors, such as ice formation on transport infrastructure. The study highlights several major direct causes of NaTech events occurring during cold spells in the process industry, included in the analysed dataset. These include equipment failures caused by low temperatures exceeding the brittle transition temperature of some materials, contributing to 16% of recorded events. Through the phenomenon known as cold fatigue, materials can be impacted over time. This process of degradation occurs when materials are subjected to repeated cycles of mechanical loading under low-temperature conditions, particularly during cold waves. As in the Otterburne pipeline accident, during a cold wave, materials can become more brittle, making them susceptible to fracture even under relatively modest mechanical stresses.

The previously analysed event clearly highlights that the management of material degradation and NaTech risk are currently not adequately handled, with insufficient inspections and a lack of preventative approaches. Indeed, as evidenced, the accident was caused by a latent welding defect that had not been detected or adequately monitored. This confirms that even localized imperfections, if neglected, can interact with extreme natural stresses and lead to catastrophic failures even decades later. The case thus illustrates the central message of this work: material degradation and NaTech risks must be assessed together, as their bidirectional interaction can critically amplify the vulnerability of infrastructure. Indeed, structures that are not adequately monitored and maintained to prevent material degradation could be more vulnerable and prone to failures in natural event situations. This gap in material degradation management is a critical factor that should be explicitly addressed in NaTech risk assessments. It is essential to pay particular attention to the connection between material degradation and natural risk. These two factors can interact synergistically, contributing to an increase not only in magnitude, as the deterioration of infrastructure could intensify the severity of such incidents, making them more dangerous or difficult to manage, but also in frequency. Indeed, it is important to consider the consequences of accidental events caused by material degradation, as they can have a significant impact on the environment. The quantitative data discussed in Vitale et al. [9] provide context for interpreting this case. For example, loss of containment accounts for over 90% of degradation-related events, and 60% lead to environmental contamination. Accidental releases of hazardous substances may result in soil, air, and water contamination, posing long-term environmental risks. This form of environmental contamination can generate long-term impacts on the climate. These data demonstrate that degradation-related failures are not isolated anomalies, but part of a systemic framework with significant implications. Integrating this evidence into NaTech risk models allows for more realistic vulnerability assessments and better targeting of inspection priorities.

The quantitative observations reported in this work highlight significant trends that can inform considerations regarding risk management and maintenance of industrial infrastructure. In particular, the association between specific degradation mechanisms and critical components, such as primary containment systems, suggests the opportunity to develop targeted inspection procedures and vulnerability-based maintenance strategies. Furthermore, the correlation between fatigue phenomena and long-lived facilities reinforce the need to integrate structural ageing considerations into NaTech risk models. This contributes to a more informed and systemic approach to industrial safety, oriented towards prevention and resilience.

As widely debated in scientific literature, climate change is related to an increase in the frequency and intensity of such events, contributing to making natural risk more significant and alarming.

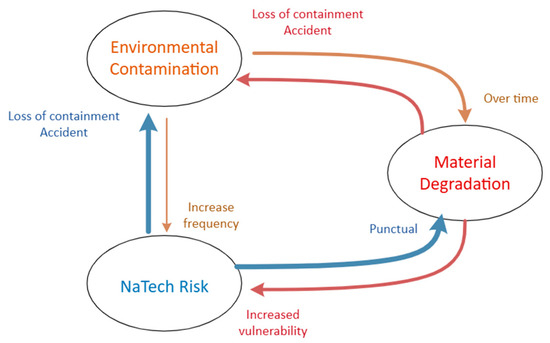

This is depicted in Figure 3, which shows the scheme devised in the study conducted by Pilone et al. [28], integrating the notion of material degradation and its influence on NaTech risk.

Figure 3.

Conceptual model of the bidirectional relationship between material degradation and NaTech risk. The colours distinguish the risk domains; the thickness of the arrows represents the intensity of the causal influence, from indirect effects to acute impacts.

Figure 3 represents the conceptual model of bidirectional vulnerability, enriched with graphical elements that enhance its analytical capacity. The three main domains are colour-coded: orange highlights the effects of environmental contamination, blue highlights those associated with NaTech risk, and red highlights those resulting from material degradation. The directional arrows represent the causal relationships between model domains and vary in thickness to indicate the intensity of their influence. Specifically, thicker arrows correspond to high-intensity interactions, i.e., phenomena that generate immediate and significant effects on the system, such as the accidental release of hazardous substances or the NaTech escalation. Conversely, thinner arrows represent low-intensity influences, typically associated with slow, cumulative, or indirect processes, such as progressive corrosion or the alteration of the mechanical properties of materials over time. This visual coding allows for the distinction between acute and chronic impact mechanisms. and supports the integration of degradation indicators into NaTech vulnerability models, providing a foundation for future quantitative developments.

Moreover, the diagram emphasises the cyclical and interconnected nature of the three domains. Each element can act as both cause and effect, generating a systemic vulnerability loop. Environmental contamination can increase the frequency and intensity of extreme natural events, which accelerate material degradation processes. Degradation, in turn, can compromise the structural resistance of infrastructure and contribute to the release of hazardous substances, further fuelling environmental contamination and closing the cycle.

Therefore, from Figure 3 emerges that natural events can influence material degradation in short timescales, material degradation can influence natural events, but the impact on frequency occurs much more slowly and gradually. Therefore, during the risk analysis, it is essential to consider the state of infrastructure on the consequences of natural events. Consequently, it is crucial to incorporate this factor into the NaTech risk assessment.

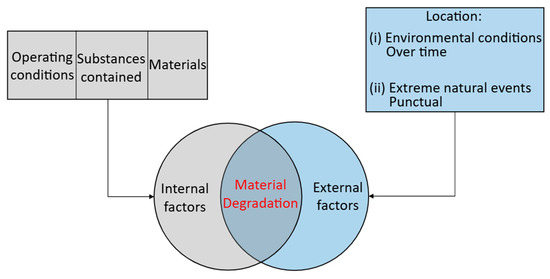

As mentioned before, Pilone et al. [24] developed a NaTech index to evaluate the risk associated with natural events that can cause technological accidents. This index is based on two main factors, one of which concerns the vulnerability of infrastructure elements. This vulnerability is assessed by considering several factors, including the location of the infrastructure, its exposure to risks from earthquakes, floods, storms, and fires, as well as the obsolescence of the infrastructure. However, the calculation methodology adopted is limited to a binary evaluation (presence/absence), without taking into account all the conditions that could influence the deterioration of the material to which the element is subject. The degree of potential deterioration of the material over time, based on the conditions to which it is exposed, should be incorporated into the analysis. Assessing material degradation and planning an inspection program requires a comprehensive understanding of the interactions between the materials used and the surrounding environment, incorporating both factors internal and external to the plant, as shown in Figure 4. The graph was developed in line with previous research [29]. From the diagram it emerges that the factors positioned in the upper part can have a negative impact on the degradation of the material. Internal factors include the operating conditions of the process, the nature of the materials used in the plant and their age, and the substances contained. In the Otterburne case, for example, pressure variations due to the discontinuity of the gas flow contributed to the mechanical stress of the material, favouring crack propagation. On the other hand, external factors are related to the geographical location of the facility. These include the environmental conditions of the surrounding area and potential exposure to natural events. Spells and frost penetration into the ground, can accelerate material degradation; in the case analysed, extreme climatic conditions acted as catalysts, inducing thermal contractions and stresses that led to structural failure.

Figure 4.

Internal and external factors contributing to material degradation in industrial infrastructures.

Thus, internal factors are intrinsic to the process and materials of the plant itself, while external factors are linked to the geographical location and surrounding environmental conditions, including natural events. A thorough understanding of both is essential for a complete and accurate assessment of the risk of material degradation and for the design of preventive maintenance programs. This approach improves the resilience of industrial structures to NaTech events, effectively reducing the risk of failures and significantly contributing to general operational safety.

3.3. Internal Factors

As previously discussed, material degradation can be accelerated by factors internal to the plant. Three key components are identified as significant contributors to this accelerated process: (i) the operating conditions, (ii) the structure materials, and (iii) the substances contained in the plant.

Operating conditions refer to the process variables within the plant, such as temperature, pressure, flow rate and other operating parameters. These conditions and their variation can significantly affect the durability and integrity of the materials used. As highlighted in the previous work, primary containment systems are the equipment most frequently involved in degradation events, accounting for over 90% of the cases analysed. These systems are subject to cyclic stress due to fluctuating operating conditions. Furthermore, the analysis by industrial macro-sector shows that the Chemical & Petrochemical sectors, as well as Pipeline, are particularly vulnerable to these mechanisms, precisely because of the complexity of the processes and the aggressive nature of the substances handled.

In the analysis, it is essential also to consider the materials selected for the system and their age, since they can interact in various ways with the surrounding environment and respond differently to external stresses. Therefore, for effective safety management, it is essential to conduct a detailed study of the material used, fully understanding all its characteristics. This would allow us to assess how the material could deteriorate over time, considering the environmental conditions, loads and operational variations to which it is exposed. However, in the Otterburne case, detailed technical data on the metallurgical properties of the material used or its evolution over time are not available. This limitation prevented an in-depth quantitative analysis of the material behaviour, necessitating a qualitative approach based on official sources and historical data.

The chemical and physical nature of the substances treated in the plant represents another critical internal factor in material degradation processes. The analysis conducted in Vitale et al. [9] highlighted a significant correlation between the characteristics of the substances contained in the systems and the observed degradation mechanisms. The case study analysis confirms this trend: the substances contained within or in contact with the equipment played a decisive role in triggering or amplifying the degradation phenomenon, highlighting the need to carefully consider the compatibility between materials and process substances during the design and management of the plants.

As illustrated in Section 3.2, HE is a critical degradation mechanism with a low occurrence frequency. This process, widely documented in the literature, involves complex mechanisms of physical and chemical absorption, as well as hydrogen dissolution within the crystalline structure of metals, with significant effects on tensile strength, fatigue, and fracture toughness [30]. This characteristic makes hydrogen a particularly difficult substance to store and manage safely, especially in facilities subject to mechanical or environmental stress. In the Otterburne case, the failure was triggered by HE phenomena that developed during the welding process. Although the pipeline transported natural gas and not hydrogen, the fracture, originated during the pipe construction, remained stable for decades, until it propagated under extreme environmental stresses. This demonstrates how degradation mechanisms generated during construction can manifest themselves many years later, under unfavourable environmental conditions

3.4. Environmental and Geographical Influences

The geographic location of an industrial facility is a key factor in assessing the risk and durability of infrastructure, although it often receives less attention than other technical factors [31]. However, the environmental and climatic context in which a facility is located can significantly influence the degradation mechanisms of materials and the overall weakness of the system.

Different geographic areas are subject to variable environmental conditions, such as extreme temperatures, high humidity, temperature fluctuations, or recurring natural events such as floods, earthquakes, and cold waves. These factors can accelerate corrosion, embrittlement, or erosion, compromising the structural integrity of equipment. For example, in cold climates or climates subject to cold spells, as demonstrated in the Otterburne case, materials may be more vulnerable to embrittlement, while higher corrosion rates are observed in hot and humid environments. In marine or coastal environments, the presence of salty air and constant humidity promotes atmospheric corrosion, while in arid areas, wind erosion can damage exposed surfaces. Urban air pollution can also contribute to degradation through the action of aggressive chemical agents.

Furthermore, the nature of the soil and proximity to seismic faults can increase structural risk, affecting the stability of foundations and the dynamic response of the facility. Infrastructure located in flood-prone areas faces challenges related to soil saturation, loss of bearing capacity, and accelerated corrosion due to prolonged contact with water.

Geographic location also affects the likelihood and intensity of NaTech events, amplifying exposure to complex accidental scenarios. Mesa-Gómez et al. [32] highlight a critical gap in current NaTech quantitative risk analysis methodologies, emphasising that the geographical location of the plant is not adequately considered in the risk assessment process, despite its direct influence on exposure and vulnerability. Therefore, a truly holistic risk assessment must integrate both chronic environmental factors, which act over the long term, and acute factors related to extreme natural events. This approach allows for the development of more effective prevention and management strategies, improving the structural and operational resilience of facilities over time.

3.5. Systemic Vulnerability

In light of the evidence presented in the previous Sections, it is clear that structural vulnerability cannot be considered a static attribute, but rather a dynamic condition that evolves over time [33] as a function of the interaction between internal and external factors. The case study analysis has shown how the degradation of materials, often latent and progressive, can significantly amplify the effects of extreme natural events, generating complex and highly severe accident scenarios. In this context, vulnerability emerges as the result of two pressures: on the one hand, the operating conditions and intrinsic characteristics of the system; on the other, the environmental and geographical context in which the infrastructure is located, which can expose it to recurrent or exceptional natural phenomena.

In the context of NaTech risk, vulnerability represents the convergence between system exposure and fragility. It manifests not only in the presence of acute events but can also derive from chronic pressures that act over time, progressively compromising the system’s ability to resist and adapt. For this reason, its assessment requires a systemic approach capable of integrating information on the life cycle of materials, the operating conditions, and the evolution of the local context.

Recent studies have shown that the combination of corrosion and subsequent seismic stresses (aftershocks) can drastically reduce the structural resilience of industrial plants, doubling the annual damage rate and significantly increasing life cycle costs [23]. In particular, structural components subject to corrosion are more prone to collapse than non-structural components, highlighting the urgency of targeted and timely maintenance strategies.

Managing vulnerability requires early identification through monitoring, predictive maintenance, and resilient design. Only an integrated view of internal and external factors can reduce systemic risk and strengthen the infrastructure ability to withstand adverse events. In this sense, adopting predictive maintenance techniques during the design phase, as suggested by Kubba [34], allows for the early identification of structural and environmental criticalities, reducing intervention costs and increasing operational sustainability.

Therefore, it is essential to recognise how material degradation can amplify the consequences of extreme or prolonged events. This highlights the need for effective risk management strategies and targeted interventions to preserve structural integrity over time and prevent serious damage in critical situations. Although the analysis conducted does not aim to define operational guidelines, it provides useful elements to guide future methodological and applicative reflections, contributing to the construction of a more informed and systemic interpretative framework of industrial vulnerability in contexts exposed to NaTech risk.

The main contribution of this study lies in the integration of material degradation and NaTech risk, which enables a systemic understanding of technological risk in contexts exposed to extreme natural events.

However, the study has some limitations: the retrospective nature of the case, the lack of continuous quantitative data, and the absence of specific predictive models for degradation in critical environmental conditions.

Going forward, it will be necessary to validate the model in other industrial contexts, develop quantitative vulnerability indicators, and propose regulatory updates that include obsolescence and degradation parameters in risk assessment criteria. These elements are essential to strengthening the resilience of industrial infrastructure and improving risk management in multifactorial scenarios.

3.6. Application of the Bidirectional Vulnerability Model to the Otterburne Case

The conceptual model presented in Figure 3 describes bidirectional vulnerability as the dynamic interaction between material degradation and NaTech risk. Applying this framework to the Otterburne case, it is possible to observe how a latent defect made the infrastructure vulnerable for decades. The extreme natural event acted as an external trigger, accelerating the failure process.

The accident cannot therefore be interpreted as a simple causal sequence, but rather as the result of an evolving vulnerability, developed over time under the influence of internal and external factors. The bidirectional approach allows the interpretation of the incident not as a simple chain of causes, but as the result of a systemic vulnerability that has matured over time.

While the Otterburne case represents a prime example, the proposed interpretative model can be extended to other industrial contexts, such as chemical plants, reaction vessels, storage systems, and pipelines. In these facilities, bidirectional vulnerability manifests itself in different ways yet maintaining the same systemic structure: internal factors interact with external factors, amplifying the risk.

For example, in storage vessels, degradation can be accelerated by temperature variations and atmospheric phenomena such as hail or floods, while in chemical reactors, the combination of high pressures and aggressive substances can generate critical conditions in the presence of seismic events or fires. Pipelines, as shown in the case study, are particularly sensitive to mechanical and thermal stress induced by extreme weather events.

Analysis of historical data highlights that degradation mechanisms and the types of NaTech events vary depending on the sector, but the principle of bidirectional interaction remains valid. Specifically, studies conducted by Vitale et al. [9], Ricci et al. [19,20] report statistical data on the frequency of occurrence of events related to material degradation, NaTech accidents and extreme natural events such as cold waves, in different sectors of the process industry. These results support the extensibility of the proposed model to different plant contexts, confirming its validity in multifactorial scenarios and the versatility of the model, which can be adapted by integrating plant-specific parameters. This adaptability makes the model a useful tool for assessing vulnerability in complex and multifactorial scenarios.

4. Conclusions

A representative case study was selected and analysed, allowing for a concrete observation of the dynamics of interaction between structural deterioration and extreme environmental stresses. In particular, the Otterburne case showed how a welding defect, latent for over fifty years, can be triggered by an extreme natural event, leading to a sudden rupture and an explosion. The analysis highlighted the correlation between the age of the plant, the lack of post-installation inspections, and structural vulnerability. These findings confirm the trends observed in historical data on hydrogen embrittlement and mechanical fatigue and demonstrate how material degradation can be a determining factor in the genesis and escalation of complex accidents. This study provides useful insights for the design and operational management of industrial facilities exposed to NaTech risk. First, integrating material degradation into vulnerability assessment models represents a fundamental step towards moving beyond the traditionally static approach to structural safety. During the design phase, this requires adopting material selection criteria and construction solutions that consider not only operational stresses, but also potential exposure to extreme natural events and the synergistic interactions between these factors.

The results obtained support future methodological and applicative developments. From a scientific perspective, the developed interpretative model can be further validated through the analysis of case studies in different industrial contexts, contributing to the development of more robust predictive tools for the integrated management of technological risk in complex and multifactorial scenarios.

Considering the results obtained, some recommendations are proposed to improve technological risk management in NaTech scenarios:

- Regulatory update: Integrate explicit structural obsolescence parameters into the Seveso Directive, such as the age of the system, maintenance history, and exposure to critical environmental factors. These parameters should be included in safety reports and risk assessment criteria.

- Vulnerability-based inspections: Adopt targeted inspection strategies, prioritizing critical components (such as primary containment systems) exposed to extreme environmental conditions or subject to latent degradation mechanisms. The use of predictive models based on historical data and climate simulations can support intervention planning.

- Integrated risk indicators: Develop analytical tools that include key variables such as the timescale of degradation, the intensity of environmental exposure, and the frequency of natural events. These indicators can transform the conceptual model into an operational tool for quantitative vulnerability assessment.

These recommendations aim to strengthen the resilience of industrial infrastructure, overcoming the currently prevalent fragmented approach and promoting a systemic and adaptive vision of safety.

Author Contributions

Conceptualization: M.V., A.A.B. and M.D.; Methodology: M.V.; Investigation: M.V.; Resources: A.A.B. and M.D.; Data Curation: A.A.B. and M.D.; Writing—original draft preparation: M.V. and A.A.B.; Writing—review and editing: M.V., A.A.B. and M.D.; Visualization: M.V.; Supervision: A.A.B. and M.D.; Project administration: A.A.B.; Funding acquisition: A.A.B. and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a PhD scholarship funded by the Italian Ministry of University and Research (MUR) under the DM 351/22, as part of the National Recovery and Resilience Plan (PNRR). This study was carried out within the RETURN Extended Partnership and received funding from the European Union NextGenerationEU (National Recovery and Resilience Plan—NRRP, Mission 4, Component 2, Investment 1.3—D.D. 1243, 2 August 2022, PE0000005).

Data Availability Statement

The data supporting the findings of this study are available from publicly accessible sources. The case study was reconstructed using information from the Transportation Safety Board of Canada (TSB): https://www.tsb.gc.ca/eng/. Additionally, the degradation mechanisms discussed in the introduction and analysis are based on a previously developed dataset of material degradation events in the process industry, available at: https://doi.org/10.17632/6hd3xky6kb.1.

Acknowledgments

The authors would like to thank David Javier Castro Rodriguez for his valuable contribution to the conceptual development of this work. Part of this work was orally presented at NaTech 2024, 8th International Symposium on Natural Hazard-Triggered Technological Accident, Trondheim, Norway, 1–2 July 2024.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| HE | Hydrogen Embrittlement |

| LOC | Loss of Containment |

| MFL | Magnetic Flux Leakage |

| NaTech | Natural Hazard Triggering Technological Accident |

| SCC | Stress Corrosion Cracking |

| TSB | Transportation Safety Board of Canada |

References

- Wintle, J.; Moore, P.; Henry, N.; Smalley, S.; Amphlett, G. Plant Ageing: Management of Equipment Containing Hazardous Fluids or Pressure; Scientific Report RR509; HSE: Warrington, UK, 2006. [Google Scholar]

- Candreva, F.; Houari, M. Plant screening for ageing impact in the process industry. Chem. Eng. Trans. 2013, 31, 253–258. [Google Scholar] [CrossRef]

- Horrocks, P.; Mansfield, D.; Parker, K.; Thomson, J.; Atkinson, T.; Worsley, J.; Park, B. Managing Ageing Plant; Technical Report 823; HSE: Warrington, UK, 2010. [Google Scholar]

- Kelly, B.D. Challenges to managing aging process equipment and infrastructure. Process Saf. Prog. 2021, 40, 266–271. [Google Scholar] [CrossRef]

- Bragatto, P.; Milazzo, M.F. Risk due to the ageing of equipment: Assessment and management. Chem. Eng. Trans. 2016, 53, 253–258. [Google Scholar] [CrossRef]

- Milazzo, M.F.; Bragatto, P. A framework addressing a safe ageing management in complex industrial sites: The Italian experience in «Seveso» establishments. J. Loss Prev. Process Ind. 2019, 58, 70–81. [Google Scholar] [CrossRef]

- Vairo, T.; Reverberi, A.P.; Milazzo, M.F.; Fabiano, B. Ageing and creeping management in major accident plants according to Seveso III directive. Chem. Eng. Trans. 2018, 67, 403–408. [Google Scholar] [CrossRef]

- Hansler, R.J.; Bellamy, L.J.; Akkermans, H.A. Ageing assets at major hazard chemical sites–The Dutch experience. Saf. Sci. 2022, 153, 105788. [Google Scholar] [CrossRef]

- Vitale, M.; Shi, H.; Castro Rodriguez, D.J.; Barresi, A.; Demichela, M. Material degradation: Findings from historical accident analysis in process industries. Reliab. Eng. Syst. Saf. 2026, 266, 111769. [Google Scholar] [CrossRef]

- Vitale, M.; Castro Rodriguez, D.J.; Barresi, A.; Demichela, M. Database of Material Degradation Event Within Process Industry, Mendeley Data, version 1; Polytechnic University of Turin: Torino, Italy, 2025. [Google Scholar] [CrossRef]

- Krausmann, E.; Cozzani, V.; Salzano, E.; Renni, E. Industrial accidents triggered by natural hazards: An emerging risk issue. Nat. Hazards Earth Syst. Sci. 2011, 11, 921–929. [Google Scholar] [CrossRef]

- Valente, M.; Ricci, F.; Cozzani, V. A systematic review of resilience engineering applications to NaTech accidents in the chemical and process industry. Reliab. Eng. Syst. Saf. 2025, 255, 110670. [Google Scholar] [CrossRef]

- Cruz, A.M.; Krausmann, E.; Kato, N.; Girgin, S. Reducing Natech risk: Structural measures. In Natech Risk Assessment and Management: Reducing the Risk of Natural-Hazard Impact on Hazardous Installations; Krausmann, E., Cruz, A.M., Salzano, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 205–225. [Google Scholar]

- Naderpour, M.; Khakzad, N. Texas LPG fire: Domino effects triggered by natural hazards. Process Saf. Environ. Prot. 2018, 116, 354–364. [Google Scholar] [CrossRef]

- Ibrion, M.; Paltrinieri, N.; Nejad, A.R. Learning from non-failure of Onagawa nuclear power station: An accident investigation over its life cycle. Results Eng. 2020, 8, 100185. [Google Scholar] [CrossRef]

- Laor, E.; De Vivo, B. Disaster prediction and civil preparedness. In Earthquakes and Sustainable Infrastructure: Neodeterministic (NDSHA) Approach Guarantees Prevention Rather than Cure; Panza, G., Kossobokov, V.G., Laor, E., De Vivo, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 77–95. [Google Scholar]

- Ju, W.; Xing, Z. A novel technology for unraveling the spatial risk of Natech disasters based on machine learning and GIS: A case study from the city of Changzhou, China. Earth Sci. Inform. 2024, 17, 5751–5770. [Google Scholar] [CrossRef]

- Reichstein, M.; Benson, V.; Blunk, J.; Camps-Valls, G.; Creutzig, F.; Fearnley, C.J.; Han, B.; Kornhuber, K.; Rahaman, N.; Schölkopf, B.; et al. Early warning of complex climate risk with integrated artificial intelligence. Nat. Commun. 2025, 16, 2564. [Google Scholar] [CrossRef]

- Ricci, F.; Casson Moreno, V.; Cozzani, V. A comprehensive analysis of the occurrence of Natech events in the process industry. Process Saf. Environ. Prot. 2021, 147, 703–713. [Google Scholar] [CrossRef]

- Ricci, F.; Casson Moreno, V.; Cozzani, V. Natech accidents triggered by cold waves. Process Saf. Environ. Prot. 2023, 173, 106–119. [Google Scholar] [CrossRef]

- Castro Rodriguez, D.J.; Tufano, C.; Vitale, M.; Mietkiewicz, J.; Baldissone, G.; Barresi, A.A.; Demichela, M. Dataset of NaTech Events Triggered by Lightning Within the Process Industry, Mendeley Data, version 3; Polytechnic University of Turin: Torino, Italy, 2023. [Google Scholar] [CrossRef]

- Castro Rodriguez, D.J.; Mietkiewicz, J.; Vitale, M.; Baldissone, G.; Barresi, A.A.; Demichela, M. NaTech triggered by lightning: Novel insights from past events in the process industry. Heliyon 2024, 10, e31610. [Google Scholar] [CrossRef] [PubMed]

- Majidian, A.; Di-Sarno, L. Seismic risk assessment of an existing oil refinery subjected to earthquake swarms. Reliab. Eng. Syst. Saf. 2025, 265 Pt A, 111482. [Google Scholar] [CrossRef]

- Pilone, E.; Demichela, M.; Camuncoli, G. Na-Tech risk: A new challenge for local planners. Chem. Eng. Trans. 2022, 90, 223–228. [Google Scholar] [CrossRef]

- Slameto, S. The application of fishbone diagram analisis to improve school quality. Din. Ilmu 2016, 16, 59–74. [Google Scholar] [CrossRef]

- Transportation Safety Board of Canada. Pipeline Investigation Report P14H0011 [WWW Document]. 2014. Available online: https://www.tsb.gc.ca/eng/rapports-reports/pipeline/2014/p14h0011/p14h0011.html (accessed on 1 October 2025).

- Li, X.; Ma, X.; Zhang, J.; Akiyama, E.; Wang, Y.; Song, X. Review of hydrogen embrittlement in metals: Hydrogen diffusion, hydrogen characterization, hydrogen embrittlement mechanism and prevention. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 759–773. [Google Scholar] [CrossRef]

- Pilone, E.; Demichela, M.; Camuncoli, G. Seveso Directives and LUP: The mutual influence of natural and anthropic impacts. J. Loss Prev. Process Ind. 2017, 49, 94–102. [Google Scholar] [CrossRef]

- Castro Rodríguez, D.J.; Benítez, O.G.; Acosta, J.B.; Rodíguez, J.P.; Rabassa, D.R.; Ribot, O.V.; Pérez, E.C.; Chiampo, F.; Godio, A.; Demichela, M. Resilient safer approach to cope the oily waste generation in industrial facilities: Lessons learned from Cuban installations. Chem. Eng. Trans. 2022, 90, 589–594. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- OECD; UNECE; JRC. Managing Risks from Natural Hazards to Hazardous Installations (Natech): A Guide for Senior Leaders in Industry and Public Authorities; OECD Series on Chemical Accidents; OECD Publishing: Paris, France, 2024; [WWW Document]; Available online: https://unece.org/environment-policy/publications/managing-risks-natural-hazards-hazardous-installations-natech (accessed on 1 July 2025).

- Mesa-Gómez, A.; Casal, J.; Sánchez-Silva, M.; Muñoz, F. Advances and gaps in Natech quantitative risk analysis. Processes 2021, 9, 40. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Kubba, S. Green Construction Project Management and Cost Oversight, 1st ed.; Butterworth-Heinemann: Burlington, MA, USA, 2010. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).