Abstract

This study experimentally investigates the strengthening performance and failure behavior of reinforced concrete slabs coated with high elastic modulus polyurea(HEPU). To address the limited strengthening effect of conventional polyurea due to its low elastic modulus and strength, HEPU was applied to slab specimens with varying coating thicknesses (1, 2, and 3 mm). To evaluate the effectiveness of the HEPU reinforcing method, experiments were conducted with varying coating thicknesses, and the results were compared with those of unstrengthened specimens. The results showed that HEPU strengthening significantly enhanced flexural strength and stiffness, with improvements increasing proportionally with coating thickness. Additionally, the polyurea coating enhanced crack resistance and adhered well to the concrete, preventing delamination or detachment up to final failure. The slabs maintained ductile behavior even after HEPU rupture, although load resistance decreased post-rupture. However, the strengthening effect diminished due to the rupture of the HEPU, indicating limited effectiveness in improving ductility. These findings provide insights into the design and application of polyurea-based strengthening techniques for reinforced concrete structures.

1. Introduction

Reinforced concrete (RC) structures are widely recognized for their excellent structural stability, primarily due to the composite action between steel reinforcement and concrete. However, their performance can deteriorate over time due to cracking and material degradation, such as steel corrosion. To enhance safety and extend the service life of aging structures, effective strengthening measures that restore structural integrity are essential. Numerous studies have explored methods for reinforced concrete strengthening or retrofitting, including steel jacketing [1], fiber-reinforced polymers (FRP) sheets or plates [2,3,4,5,6,7], fiber-reinforced cementitious composites (FRCC) [8,9,10,11,12,13,14,15,16,17,18,19], fabric-reinforced cementitious matrices (FRCM) [20,21,22,23,24,25,26,27,28,29,30,31,32,33], and polyurea coatings [34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50].

Strengthening with FRP composites, such as carbon fiber-reinforced polymer (CFRP) and glass fiber-reinforced polymer (GFRP), has been reported to effectively enhance the flexural and shear capacities of structural members. However, challenges such as premature debonding and end peeling at the FRP–concrete interface can significantly reduce both the strengthening efficiency and the ductility of the member [2,3,4]. In addition, due to the low fire resistance of FRP materials, their strengthening performance can rapidly deteriorate under fire conditions [5,6,7].

Fiber-Reinforced Cementitious Composites (FRCCs), including Ultra-High-Performance Fiber-Reinforced Cementitious Composites (UHPFRCC), Ultra-High-Toughness Cementitious Composites (UHTCC), and High-Ductility Concrete (HDC), have attracted considerable attention as effective strengthening materials owing to their superior properties, including high strength, toughness, and ductility [8,9,10,11,12,13]. Strengthening with these FRCCs has been reported to significantly improve the strength, ductility, and durability of structural members [14,15,16,17]. Recently, extensive research has focused on spray-type FRCCs, which aim to improve the low constructability of traditional cast-in-place FRCCs, demonstrating promising potential for efficient and practical structural strengthening applications [18,19].

Fabric-Reinforced Cementitious Matrix (FRCM) systems, consisting of a fabric mesh embedded within a cementitious matrix, have also been recognized as effective techniques for structural strengthening [20,21]. Numerous studies have investigated the influence of fabric type (such as carbon- and glass-based FRCM) and the volume fraction of the embedded mesh on the mechanical properties and strengthening performance of FRCM systems [22,23,24,25,26,27,28]. More recently, electrically conductive Carbon-Fabric-Reinforced Cementitious Matrix (C-FRCM) systems have been integrated with the Impressed Current Cathodic Protection (ICCP) technique [29]. In this dual-functional system, the C-FRCM serves both as the anode of the ICCP system and as a structural strengthening material, providing corrosion protection while maintaining the structural integrity of reinforced concrete members after corrosion has occurred [30,31,32,33].

Another emerging strengthening approach involves the use of polyurea coatings, which have recently attracted attention as a promising method for enhancing the structural performance of concrete members. Polyurea, a polyurethane-based polymer, has been widely employed as a coating and adhesive material in the construction industry due to its excellent interfacial adhesion to concrete, wood, and metal surfaces, ease of application, and superior resistance to environmental, chemical, and biological degradation. Moreover, polyurea exhibits favorable mechanical properties, including high tensile strength, tear resistance, impact resistance, cohesion, and abrasion resistance, making it a promising candidate for retrofitting and strengthening deteriorated structural members [34]. In recent years, numerous studies have investigated the effectiveness of polyurea coatings in enhancing the performance of structural members under dynamic loads, such as blasts, impacts, and earthquakes [35,36,37,38,39,40]. Recent research on reinforced concrete (RC) and masonry structures has demonstrated that polyurea coatings effectively reduce fragmentation and debris dispersion during blast events while enhancing ductility, energy absorption, and post-cracking behavior due to their strain-rate–sensitive viscoelastic properties [41,42,43].

In addition to their performance under dynamic loads, polyurea coatings have been extensively studied for improving the flexural and shear behavior of RC members under static and quasi-static loading [44,45,46,47,48,49,50,51]. Polyurea exhibits strong adhesion, crack bridging, delayed crack initiation, reduced crack widths, and enhanced ductility. However, its contribution to ultimate flexural strength is generally limited compared to conventional methods such as FRP and steel plates [44,45,46,47]. Overall, these studies consistently indicate that polyurea coatings significantly enhance crack control, ductility, and service load performance. However, when used alone, polyurea generally contributes less than 20% to flexural strength. To overcome this limitation, some studies have explored polyurea variants with tailored mechanical properties. For instance, Song et al. [48] demonstrated that incorporating glass fibers into polyurea (GFRPU) improved tensile stress distribution, reduced crack widths, and substantially increased the flexural strength of RC beams. Kim et al. [49] investigated a flexible-type polyurea (FTPU) with a tensile strength of 20 MPa and an elastic modulus of 60 MPa, demonstrating high ductility and effective prevention of interface failure, although overall load-bearing enhancement was constrained by the material’s low tensile strength and elastic modulus. Subsequently, Park et al. [50] developed a stiff-type polyurea (STPU) with a higher tensile strength of 49 MPa and an elastic modulus of 160 MPa, evaluating its performance on RC slab specimens with varying coating thicknesses. Despite the improved tensile strength of STPU, the resultant increase in load-bearing capacity remained modest. This limited effect has been attributed to the relatively low elastic modulus of conventional polyurea, which delays tensile resistance development and reduces structural contribution under both service and ultimate loads.

To address this issue, the present study employs a high elastic modulus polyurea (HEPU), exhibiting both increased tensile strength and elastic modulus, to investigate its potential for effectively enhancing the flexural performance of RC slabs. Flexural tests were conducted on HEPU-strengthened slabs with varying coating thicknesses to evaluate the efficacy of this approach.

2. Materials and Methods

2.1. Materials Used

The concrete used for the slab specimens was designed for a target compressive strength of 40 MPa, and the mix proportions are provided in Table 1. The material properties of the concrete were determined through testing in accordance with KS F 2405 [51]. Cylindrical specimens (100 × 200 mm) were cast and cured under standard conditions, and the 28-day compressive strength was measured, yielding an average value of 42.5 MPa. All steel reinforcing bars used for the slab specimens were tested to validate the yield strength, ultimate strength, and strain at failure. The slab specimens were reinforced with 10 mm and 13 mm diameter rebars, having a nominal yield strength of 400 MPa, used as transverse and longitudinal reinforcement, respectively. The mechanical properties of the rebars, obtained from direct tensile tests, are summarized in Table 2.

Table 1.

Mix proportions of concrete.

Table 2.

Mechanical properties of deformed steel bars.

Polyurea is an elastic polymer with excellent adhesive properties. For strengthening the bottom surface of the slab specimens, a high elastic modulus polyurea (HEPU) was developed. (SC Corp., Busan, Republic of Korea) The HEPU had a nominal tensile strength of 56 MPa, as specified by the manufacturer, and its mechanical properties, determined from direct tensile tests, were measured to be a tensile strength of 52 MPa and an elastic modulus of 1608 MPa, as summarized in Table 3.

Table 3.

Mechanical properties of HEPU.

2.2. Specimen Design

To evaluate the strengthening performance and flexural behavior of slabs reinforced with HEPU, four specimen groups were prepared, as summarized in Table 4. These consisted of an unstrengthened reference group (RS) and three strengthened groups (S-1, S-2, and S-3) with HEPU coating thicknesses of 1, 2, and 3 mm, respectively. To ensure adequate reinforcement coverage and minimize experimental errors due to variations in the polyurea spray thickness, three identical specimens were fabricated for each group, resulting in a total of 12 specimens.

Table 4.

Test Specimen Details.

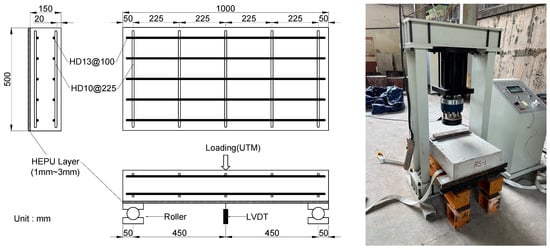

The cross-sectional shape and reinforcement details of the slab specimens are presented in Figure 1. Each slab specimen measured 1000 mm in length, 500 mm in width, and 150 mm in thickness. The reinforcement ratio was intentionally kept low to induce flexural failure before shear failure. For longitudinal reinforcement, 13 mm diameter rebars were placed at 100 mm intervals in the top and bottom layers of the slab, with five bars each. Transverse reinforcement consisted of 10 mm diameter rebars evenly spaced in both the top and bottom layers, with five bars each. The concrete cover was set at 20 mm. In the strengthened specimens, HEPU was applied exclusively to the bottom surface of the slab according to the designated coating thickness for each group.

Figure 1.

Details of test specimen and test set-up.

2.3. Specimen Fabrication and Test Method

Prior to concrete casting, strain gauges were attached to the bottom tensile reinforcement at the center of each slab, where the maximum bending moment occurs, to determine the yield point of the specimens. After casting, all specimens were air-cured for at least 28 days. For polyurea strengthening, the slab specimens were turned over, and surface preparation and primer application were performed on their bottom surfaces.

As shown in Figure 2, HEPU was applied to the surface of each slab using a high-pressure spray device, and the final coating thickness was controlled by adjusting the number of spray passes. The thickness of the HEPU layer formed by a single spray pass was determined through a preliminary experiment in which HEPU was applied to stainless steel plates. HEPU was sprayed 2, 4, 6, 8, and 10 times onto a 1 mm-thick stainless steel plate, and the increase in coating thickness was measured after each test. The results indicated that the average coating thickness per single spray pass was approximately 0.197 mm, which was rounded to 0.2 mm for estimating the total coating thickness in this study. Although polyurea typically achieves its mechanical properties within 60 s of spraying due to rapid curing, all structural tests were conducted at least three days after application to ensure the adequate strength development of the HEPU coating.

Figure 2.

Slab specimens strengthened with HEPU.

Flexural tests were performed on one specimen from each group at 3, 5, and 7 days after the application of polyurea. The tests were conducted using a 500 kN-capacity hydraulic universal testing machine (UTM), as shown in Figure 1. Each specimen was placed on two steel rollers providing simple support, with a clear span of 900 mm. A three-point bending configuration was adopted, and the vertical load was applied at the mid-span through a steel loading plate at a displacement-controlled rate of 1 mm/min until failure. The applied load was recorded by a load cell integrated into the UTM, while the mid-span deflection at the bottom surface of the slab was measured using a linear variable differential transducer (LVDT). The tests were terminated when the mid-span deflection exceeded 30 mm or when the load-carrying capacity dropped significantly due to shear cracking or other failure modes.

3. Test Results of Strengthened Slabs

3.1. Crack Patterns and Failure Modes

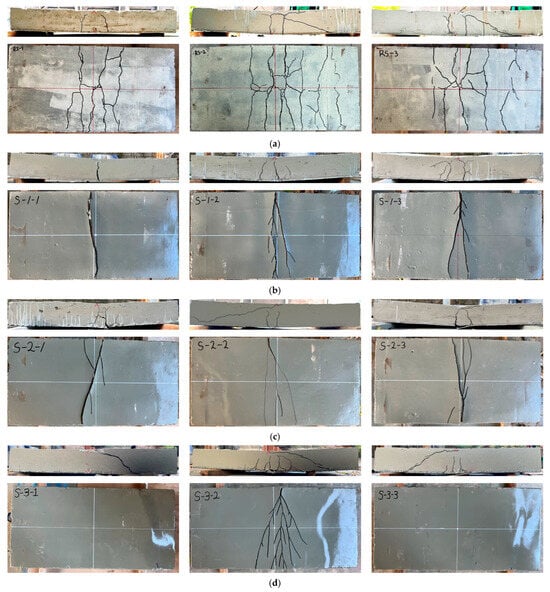

The crack patterns and failure modes observed in the specimens are presented in Figure 3. Cracks on the specimen sides were monitored in real time during loading, whereas cracks on the bottom surface were inspected after the tests by turning the specimens over. In the unstrengthened (RS series) specimens, flexural cracks initially developed at the bottom center of the slab, where the bending moment was maximum, as the tensile stress at the slab bottom reached the concrete’s tensile strength. With increasing load, these cracks propagated upward toward the neutral axis, and additional flexural cracks formed, spreading from the center toward the supports. After yielding of the steel reinforcement, no new flexural cracks appeared; however, the width of existing cracks continued to increase until final failure. In some specimens, excessive deformation following steel yielding induced load imbalance, resulting in shear cracking and eventual collapse. (refer to Figure 3a).

Figure 3.

Crack patterns and failure modes of slab specimens: (a) RS specimens, unstrengthened; (b) S-1 specimens, strengthened with 1 mm HEPU; (c) S-2 specimens, strengthened with 2 mm HEPU; (d) S-3 specimens, strengthened with 3 mm HEPU.

For the S-1 series specimens, strengthened with 1 mm HEPU, initial flexural cracks developed at the bottom center of the slab, similarly to the unstrengthened specimens, but without rupture of the polyurea on the bottom surface. As the load increased, the concrete cracks propagated upward; however, fewer additional flexural cracks formed compared to the unstrengthened specimens, resulting in a narrower cracking region. Prior to steel yielding, the concrete and polyurea remained bonded without separation. Following steel yielding, rupture of the HEPU coating occurred as the existing cracks widened. Although the rupture contributed to further crack widening, final failure did not immediately occur, and the specimens continued to exhibit flexural behavior. Even under continued deformation, complete detachment between the concrete and polyurea was not observed, although localized areas around the rupture showed polyurea detaching along with the cover concrete. Post-test inspections revealed that HEPU developed single, localized cracks, distinct from the multiple cracks observed in the concrete. In some specimens, shear cracking and eventual failure occurred due to load imbalance induced by large deformations after HEPU rupture. (refer to Figure 3b).

The S-2 series specimens exhibited cracking behavior largely similar to that of the S-1 series; as in the S-1 specimens, complete detachment between the concrete and polyurea was not observed, and localized areas around the rupture showed polyurea detaching along with the cover concrete. However, as the HEPU strengthening thickness increased from 1 mm to 3 mm, rupture of the HEPU was accompanied by a louder sound and instantaneous vibrations. Post-test inspections confirmed that HEPU developed single, localized cracks, distinct from the multiple cracks observed in the concrete. In some specimens, shear cracking and eventual failure occurred due to load imbalance induced by large deformations after HEPU rupture (refer to Figure 3c).

For the S-3 specimens, strengthened with 3 mm HEPU, the crack patterns and failure behavior prior to steel yielding were similar to those of the S-1 and S-2 series; as in the S-1 and S-2 specimens, complete detachment between the concrete and polyurea was not observed, and localized areas around the rupture showed polyurea detaching along with the cover concrete. However, in specimens S-3-1 and S-3-3, shear cracks developed and led to final failure without rupture of the polyurea following steel yielding. These results suggest that the increased flexural strengthening effect provided by the thicker HEPU layer caused shear failure to occur first. In contrast, in specimen S-3-2, polyurea rupture occurred after steel yielding, followed by the formation of multiple additional flexural cracks as deformation increased. Unlike earlier cases, where polyurea rupture resulted in a single, instantaneous crack, these additional cracks appeared to develop gradually and spread more widely (refer to Figure 3d).

From these results, it can be concluded that strengthening with HEPU coating is effective in controlling cracks in the slabs. Moreover, considering that shear failure occurred prior to HEPU rupture in the S-3 series specimens with thicker coating, the HEPU reinforcement appears to have a positive effect on enhancing the flexural strength.

3.2. Load–Deflection Curves

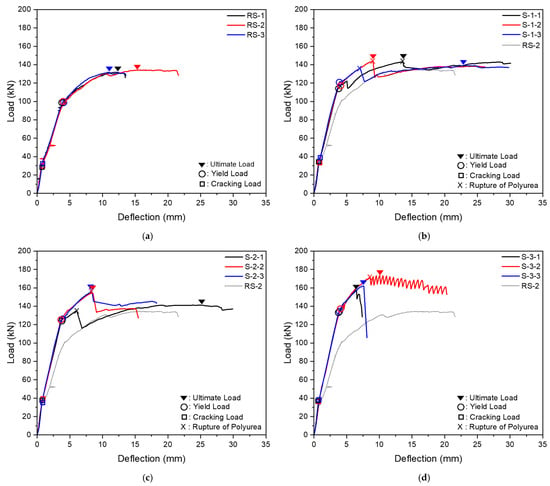

The load–deflection curves of the specimens are presented in Figure 4. As shown in Figure 4a, the load–deflection behavior of the unstrengthened specimens can generally be divided into three stages: pre-cracking, pre-yielding, and post-yielding. In contrast, for the HEPU-strengthened specimens (refer to Figure 4b–d), an additional stage is observed, resulting in four distinct phases: pre-cracking, pre-yielding, pre-HEPU rupture, and post-HEPU rupture.

Figure 4.

Load-deflection curves from flexural test: (a) RS specimens, unstrengthened; (b) S-1 specimens, strengthened with 1 mm HEPU; (c) S-2 specimens, strengthened with 2 mm HEPU; (d) S-3 specimens, strengthened with 3 mm HEPU.

In the pre-cracking stage, comparison of the load–deflection relationships indicates a slight increase in stiffness and cracking strength due to HEPU strengthening; however, the difference from the unstrengthened specimens is not significant. This can be attributed to the absence of cracks in the concrete at this stage, allowing the tensile-side concrete to primarily resist the bending moments induced by the applied load. Although the HEPU layer on the tensile face of the slab also contributes to load resistance, its cross-sectional area is relatively small compared to that of the concrete. Furthermore, the tensile strain remains minimal prior to cracking, which limits the observable effect of HEPU strengthening in this initial stage.

In the pre-yielding stage, comparison of the load–deflection relationships shows that the HEPU-strengthened specimens exhibited increased flexural stiffness after cracking compared to the unstrengthened specimens. This behavior can be attributed to the reduced tensile resistance of the cracked concrete, which enhances the relative contribution of the tensile force and second moment of inertia of the HEPU strengthening layer. Moreover, the strengthened slabs demonstrated higher yield loads than the unstrengthened specimens, indicating that HEPU effectively participates in resisting tensile forces alongside the steel reinforcement. The observed increases in yield strength and post-cracking flexural stiffness, reflected in the slope of the load–deflection curves, were found to correlate with the HEPU coating thickness.

In the unstrengthened specimens, following steel yielding, the tensile stress in the steel remains approximately constant at the yield level, while the flexural stiffness gradually decreases due to the upward shift in the neutral axis with increasing deformation. In contrast, in the HEPU-strengthened slab specimens, the flexural stiffness after yielding noticeably increases with thicker HEPU layers. This behavior can be attributed to the fact that HEPU remains in an elastic state after steel yielding, thereby restraining the upward movement of the neutral axis as deformation progresses. Furthermore, as the HEPU thickness increases, its tensile resistance also rises, resulting in a higher rupture load.

In the post-rupture stage, the load drops sharply following HEPU rupture due to the loss of its load-carrying capacity. Nevertheless, the slabs did not fail immediately upon HEPU rupture but maintained a certain level of residual strength, with their load-deflection curves converging toward those of the unstrengthened specimens. This observation suggests that the load previously resisted by HEPU is redistributed to the steel reinforcement, which remains in a yielded state. In specimen S-3-2, which had the thickest 3 mm HEPU layer, the post-peak load reduction occurred gradually and in several smaller steps as deformation increased, producing a fluctuating response. This behavior corresponds to the progressive rupture pattern of the polyurea layer, as shown in Figure 3d, where multiple branching fractures and partial tearing were observed near the mid-span. The sequential tearing and local load redistribution within the HEPU coating contributed to the stepped load-drop behavior observed after the initial rupture, indicating that the coating continued to carry tensile stresses even after the initial fracture of the polyurea layer.

This behavior is likely attributed to the broader rupture area and the branch-shaped crack propagation path observed in the thicker HEPU layer. However, since other specimens in the S-3 series experienced shear failure prior to the rupture of the HEPU coating, further investigation is required to confirm whether this gradual post-rupture response is directly associated with the thickness of the HEPU layer.

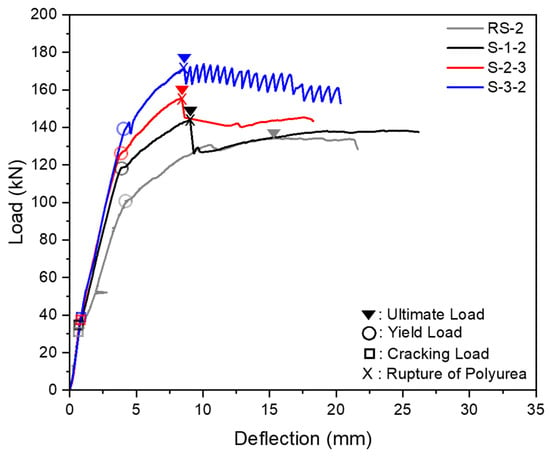

4. Influence of HEPU Coating Thickness on Strengthening Performance

The effect of HEPU coating thickness on the flexural performance of reinforced concrete slabs was systematically evaluated by comparing specimens with different HEPU thicknesses (S-1: 1 mm, S-2: 2 mm, S-3: 3 mm) to unstrengthened specimens (RS series). The results indicate that increasing the HEPU thickness enhances both flexural strength and stiffness. To evaluate the effect of HEPU coating thickness on strengthening performance, representative specimens that exhibited flexural failure rather than shear failure were selected from each test group, and their load–displacement curves were compared. (refer to Figure 5).

Figure 5.

Comparison of Load-deflection curves with different to HEPU coating thickness.

The results indicate that HEPU strengthening significantly improved flexural strength indicators (yield load, ultimate load) and flexural stiffness indicators (cracking stiffness) after cracking. Additionally, both flexural strength (yield load, ultimate load) and flexural stiffness (cracking stiffness) increased proportionally with HEPU coating thickness. These findings confirm the effectiveness of HEPU strengthening and suggest that increasing the coating thickness further enhances structural performance. However, since polyurea loses its strengthening effect after rupture, leading to a reduction in load resistance, this should be carefully considered in ductility-based strengthening design.

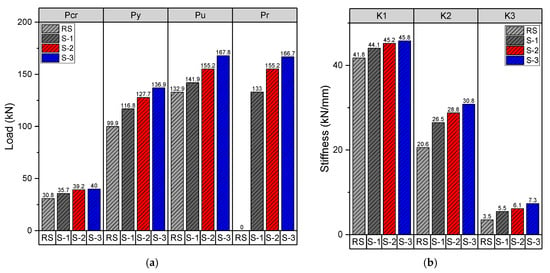

To quantitatively evaluate the strengthening effect, Table 5 summarizes the measured cracking load, yield load, ultimate load, HEPU rupture load, and flexural stiffness at each stage for all specimens. The yield load was determined based on strain gauge readings, identifying the point at which the rebar strain reached the yield strain, while cracking and ultimate loads were obtained directly from experimental measurements. Flexural stiffness at each stage was calculated from the slope of the load–deflection curve between respective load points using measured deflections at cracking and yield loads. Additionally, Figure 6 presents a comparison of the average values of flexural strength and flexural stiffness for each specimen group according to the HEPU strengthening thickness.

Table 5.

Summary of test results.

Figure 6.

Flexural performance comparison: (a) flexural strength index; (b) flexural stiffness index.

In the pre-cracking stage, the maximum tensile stress at the bottom of the slab remains below the flexural tensile strength of the concrete, preventing crack formation. Consequently, the entire cross-section, including the concrete, rebar, and HEPU, contributes to bending resistance in the elastic state. As shown in Table 5, the cracking load of HEPU-strengthened slabs was 15–30% higher than that of the unstrengthened slab, indicating that HEPU applied to the extreme tensile face helps delay crack initiation. Furthermore, the pre-cracking stiffness showed only a slight increase, ranging from 105% to 109% compared to the unstrengthened specimens, suggesting that the contribution of HEPU before cracking was relatively limited. However, as illustrated in Figure 6, the flexural performance indicators in the pre-cracking stage increased proportionally with HEPU thickness. These findings indicate that, although the overall strengthening effect of HEPU before cracking is modest, the influence of HEPU thickness on flexural performance cannot be entirely disregarded.

In the pre-yielding stage, the tensile stress at the bottom of the strengthened slab exceeds the flexural tensile strength of the concrete, initiating crack formation in the bottom concrete. Once cracking occurs, the tensile-side concrete loses most of its resistance, and the tensile force is primarily carried by the steel reinforcement and HEPU strengthening layer. Since both materials remain in the elastic range at this stage, the load–deflection curve maintains a linear relationship. As shown in Table 5, the yield load of the HEPU-strengthened slabs was 17–37% higher than that of the unstrengthened specimen, indicating that HEPU applied to the extreme tensile surface effectively delays the onset of steel yielding. Furthermore, post-cracking stiffness increased by 28–49% compared to the unstrengthened specimens. As illustrated in Figure 6, the flexural performance indicators in the post-cracking stage also increased proportionally with HEPU thickness. These findings confirm that HEPU strengthening significantly enhances flexural performance after cracking, and that the degree of improvement becomes more pronounced with greater coating thickness.

In the post-yielding stage, assuming no strain hardening in the rebar, the stress in the steel remains constant at the yield level, leading to a significant reduction in flexural stiffness for the unstrengthened slab. In contrast, in the strengthened slabs, HEPU remains in the elastic range even after the tensile reinforcement yields, continuing to resist additional tensile forces as deformation progresses. As a result, the flexural stiffness of the strengthened slabs improves after yielding, and their load-carrying capacity continues to increase until HEPU rupture. As presented in Table 5, the maximum load of the HEPU-strengthened slabs was 6–26% higher than that of the unstrengthened specimen, demonstrating that HEPU applied to the extreme tensile surface effectively enhances the slab’s ultimate flexural strength. In addition, post-yielding stiffness increased by 56–110% compared to the unstrengthened specimens. However, since post-yielding stiffness in the strengthened specimens was calculated at the point of HEPU rupture—differing from the reference point used for unstrengthened specimens—a direct comparison is not entirely appropriate. Therefore, strengthening performance in this stage was primarily evaluated based on maximum flexural strength. As illustrated in Figure 6, the flexural performance indicators in the post-yielding stage increased proportionally with HEPU thickness. These findings confirm that HEPU strengthening significantly improves the ultimate flexural strength of slabs, with greater enhancement observed as coating thickness increases.

5. Conclusions

This study experimentally investigated the strengthening performance of High Elastic Modulus Polyurea (HEPU) coatings applied to reinforced concrete slabs. The results confirmed that HEPU strengthening substantially enhances both the flexural strength and stiffness of slabs, with the degree of improvement increasing proportionally to the coating thickness. Based on the experimental findings, the following key conclusions can be drawn:

- (1)

- The HEPU coating method significantly enhanced the flexural strength indicators of the slab, including cracking strength, yield strength, and ultimate strength, while also improving post-cracking flexural stiffness.

- (2)

- Although the strengthening effect of HEPU was not evident in the pre-cracking stage, observed crack patterns suggest that it may contribute to reducing crack propagation.

- (3)

- In the post-cracking to pre-yielding stage, HEPU strengthening increased the yield load of the slab by 17–37% compared to the unstrengthened reference slab and improved flexural stiffness by 28–49%. Additionally, strengthening performance was found to increase proportionally with HEPU coating thickness.

- (4)

- The maximum load of HEPU-strengthened slabs increased by 6–26% compared to the unstrengthened slab and improved flexural stiffness by 56–110%. Additionally, strengthening performance was found to increase proportionally with HEPU coating thickness.

- (5)

- While HEPU-strengthened slabs experienced a reduction in load resistance following HEPU rupture, they ultimately exhibited ductile failure behavior.

- (6)

- The enhancement in maximum flexural strength achieved with HEPU exceeded that of conventional polyurea strengthening methods, demonstrating HEPU’s effectiveness in improving the flexural performance of slabs.

- (7)

- Based on the experimental findings, applying HEPU, which has relatively low elongation, may not be suitable for enhancing the ultimate strength of slabs requiring high ductility. However, given its crack control capabilities and significant strengthening effect under service loads, HEPU may serve as an effective reinforcement technique for deteriorated slabs that have experienced a decline in structural performance and can no longer sustain service loads.

Funding

This research was supported by a Korean Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Korean government (MOLIT) (RS-2023–00250434).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Wu, Y.F.; Liu, T.; Oehlers, D.J. Fundamental principles that govern retrofitting of reinforced concrete columns by steel and FRP jacketing. Adv. Struct. Eng. 2016, 9, 507–532. [Google Scholar] [CrossRef]

- Adsam Gideon, D.S.; Alagusundaramoorthy, P. Flexural retrofit of RC beams using CFRP laminates. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 14th International Conference on Concrete Engineering and Technology, Kuala Lumpur, Malaysia, 8–9 August 2018; IOP Publishing: Bristol, UK, 2018; Volume 431, p. 072006. [Google Scholar]

- Brena, S.F.; Bramblett, R.M.; Wood, S.L.; Kreger, M.E. Increasing flexural capacity of reinforced concrete beams using carbon fiber-reinforced polymer composites. ACI Struct. J. 2003, 100, 36–46. [Google Scholar] [CrossRef]

- Brena, S.F.; Macri, B.M. Effect of carbon-fiber-reinforced polymer laminate configuration on the behavior of strengthened reinforced concrete beams. J. Compos. Constr. 2004, 8, 270–278. [Google Scholar] [CrossRef]

- Spadea, G.; Bencardino, F.; Swamy, R.N. Structural behavior of composite RC beams with externally bonded CFRP. J. Compos. Constr. 1998, 2, 132–137. [Google Scholar] [CrossRef]

- Carlos, T.B.; Rodrigues, J.P.C.; de Lima, R.C.A.; Dhima, D. Experimental analysis on flexural behaviour of RC beams strengthened with CFRP laminates and under fire conditions. Compos. Struct. 2018, 189, 516–528. [Google Scholar] [CrossRef]

- Habib, A.; Barakat, S.; Al-Toubat, S.; Junaid, M.T.; Maalej, M. Developing machine learning models for identifying the failure potential of fire-exposed FRP-strengthened concrete beams. Arab. J. Sci. Eng. 2024, 50, 8475–8490. [Google Scholar] [CrossRef]

- Kang, S.T.; Kim, J.K. The relation between fiber orientation and tensile behavior in an ultra high performance fiber reinforced cementitious composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Li, Q.H.; Xu, S.L. Experimental investigation and analysis on flexural performance of functionally graded composite beam crack-controlled by ultrahigh toughness cementitious composites. Sci. China Ser. E Technol. Sci. 2009, 52, 1648–1664. [Google Scholar] [CrossRef]

- Deng, M.K.; Pan, J.J.; Liang, X.W. Uniaxial compressive test of high ductile fiber-reinforced concrete and damage constitutive model. Adv. Civ. Eng. 2018, 2018, 4308084. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Practical design criteria for saturated pseudo strain hardening behavior in ECC. J. Adv. Concr. Technol. 2006, 4, 59–78. [Google Scholar] [CrossRef]

- Fisher, G.; Li, V.C. Influence of matrix ductility on the tension-stiffening behavior of steel reinforced ECC. ACI Struct. J. 2002, 99, 104–111. [Google Scholar]

- Wang, C.; Fu, P.; Liu, Z.L.; Wen, T.; Zhu, Y.Y.; Long, Y.H.; Jiang, J.H. Study of the durability damage of ultrahigh toughness fiber concrete based on grayscale prediction and the Weibull model. Buildings 2022, 12, 746. [Google Scholar] [CrossRef]

- Zheng, D.D.; Kou, J.L.; Wei, H.H.; Zhang, T.; Guo, H.C. Experimental study on flexural behavior of damaged concrete beams strengthened with high ductility concrete under repeated load. Eng. Struct. 2023, 274, 115203. [Google Scholar] [CrossRef]

- Wang, J.Y.; Wan, C.L.; Shen, L.H.; Zeng, Q.; Ji, X.H. Compressive behavior of masonry columns confined with basalt textile-reinforced concrete. J. Build. Eng. 2023, 75, 107019. [Google Scholar] [CrossRef]

- Wan, C.L.; Wang, J.Y.; Zeng, Q.; Shen, L.H.; Liu, C.B. Quasi-static cyclic loading tests of RAC brick masonry walls strengthened by basalt textile reinforced concrete. Compos. Struct. 2023, 321, 117238. [Google Scholar] [CrossRef]

- Tang, J.P.; Feng, R.; Quach, W.M.; Zeng, J.J. Evaluation of flexural performance on corrosion-damaged RC beams retrofitted with UHPFRCC under marine exposure. Eng. Struct. 2025, 333, 120193. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Fischer, G.; Lim, Y.M.; Li, V.C. Mechanical performance of sprayed engineered cementitious composite using wet-mix shotcreting process for repair applications. ACI Mater. J. 2004, 101, 42–49. [Google Scholar] [CrossRef]

- Wang, J.Y.; Yu, D.; Mu, F.J.; Ji, X.H.; Peng, Y. Toughening mechanism of directional fabric woven net and/or non-directional short-cut fiber-reinforced sprayed cement mortar thin-plates. Materials 2023, 16, 4418. [Google Scholar] [CrossRef]

- Awani, O.; El-Maaddawy, T.; Ismail, N. Fabric-reinforced cementitious matrix: A promising strengthening technique for concrete structures. Constr. Build. Mater. 2017, 132, 94–111. [Google Scholar] [CrossRef]

- Ombres, L. Flexural analysis of reinforced concrete beams strengthened with a cement based high strength composite material. Compos. Struct. 2012, 94, 143–155. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P.; Poggi, C. Long-term behavior of PBO FRCM and comparison with other inorganic-matrix composites. Materials 2022, 15, 3281. [Google Scholar] [CrossRef] [PubMed]

- Asghari, H.; Omeman, Z.; Noel, M.; Hajiloo, H. Tensile properties of carbon fabric-reinforced cementitious matrix (FRCM) at high temperatures. Structures 2023, 55, 85–96. [Google Scholar] [CrossRef]

- Mercedes, L.; Castellazzi, G.; Bernat-Maso, E.; Gil, L. Matrix and fabric contribution on the tensile behaviour of fabric reinforced cementitious matrix composites. Constr. Build. Mater. 2023, 363, 129693. [Google Scholar] [CrossRef]

- Ombres, L. Structural performances of PBO FRCM-strengthened RC beams. Proc. Inst. Civ. Eng.—Struct. Build. 2011, 164, 265–272. [Google Scholar] [CrossRef]

- Aljazaeri, Z.R.; Al-Jaberi, Z. Numerical study on flexural behavior of concrete beams strengthened with fiber reinforced cementitious matrix considering different concrete compressive strength and steel reinforcement ratio. Int. J. Eng. 2021, 34, 793–802. [Google Scholar] [CrossRef]

- Mandor, A.; El Refai, A. Flexural response of reinforced concrete continuous beams strengthened with fiber-reinforced cementitious matrix (FRCM). Eng. Struct. 2022, 251, 113557. [Google Scholar] [CrossRef]

- Feng, R.; Liu, Y.; Zhu, J.H.; Xing, F. Flexural behaviour of C-FRCM strengthened corroded RC continuous beams. Compos. Struct. 2020, 245, 112200. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Zhu, J.H.; Ueda, T.; Guo, G.P.; Xing, F. Combined impressed current cathodic protection and FRCM strengthening for corrosion-prone concrete structures. J. Compos. Constr. 2019, 23, 04019021. [Google Scholar] [CrossRef]

- Liu, P.; Tang, J.P.; Feng, R.; Fan, Y.; Zhu, J.H. Tensile behavior and flexural performance of polarized CFRCM-strengthened corroded RC continuous beams. Structures 2025, 76, 109022. [Google Scholar] [CrossRef]

- Su, M.N.; Zeng, C.Q.; Li, W.Q.; Zhu, J.H.; Lin, W.H.; Ueda, T.; Xing, F. Flexural performance of corroded continuous RC beams rehabilitated by ICCP-SS. Compos. Struct. 2020, 232, 111556. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Liang, H.S.; Zhu, J.H.; Ueda, T.; Xing, F. Fatigue behavior and design of corroded reinforced concrete beams intervened by ICCP-SS. Compos. Struct. 2021, 261, 113295. [Google Scholar] [CrossRef]

- Feng, R.; Tang, J.P.; Wang, F.Y.; Wang, S.; Zeng, J.J.; Zhu, J.H. Experiments on shear behavior of reinforced concrete continuous beams strengthened by C-FRCM. Struct. Concr. 2024, 25, 1052–1075. [Google Scholar] [CrossRef]

- Shojaei, B.; Najafi, M.; Yazdanbakhsh, A.; Abtahi, M.; Zhang, C. A review on the applications of polyurea in the construction industry. Polym. Adv. Technol. 2021, 32, 2797–2812. [Google Scholar] [CrossRef]

- Davidson, J.; Porter, J.R.; Dinan, R.; Hammons, M.; Connell, J.D. Explosive testing of polymer retrofit masonry walls. J. Perform. Constr. Facil. 2004, 18, 100–106. [Google Scholar] [CrossRef]

- Santos, A.P.; Chiquito, M.; Castedo, R.; López, L.; Gomes, G.; Mota, C.; Fangueiro, R.; Mingote, J. Experimental and numerical study of polyurea coating systems for blast mitigation of concrete masonry walls. Eng. Struct. 2023, 284, 116006. [Google Scholar] [CrossRef]

- Yue, Z.Y.; Zhou, J.N.; Wang, P.; Kong, X.-L.; Zhou, Y.-Z.; Chen, Y.-S.; Song, X.-Y.; Feng, F. Experimental study on the anti-blast performance of polyurea reinforced concrete arch structures. J. Build. Eng. 2023, 77, 107483. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, B.; Zhang, B.; Zheng, Q.; Zhou, J.; Jin, F.; Fan, H. Polyurea coating for foamed concrete panel: An efficient way to resist explosion. Def. Technol. 2020, 16, 136–149. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, R.; Wang, X.; Lyu, P.; Ju, J.; Gao, F.; Yan, S. Study of blast mitigation performance and fracture mechanism of polyurea under contact explosion. Polymers 2022, 14, 3458. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Wu, J.; Jia, P.; Li, S.; Yan, Q.; Xu, S. Experimental and numerical investigation of the polyurea-coated ultra-high-performance concrete (UHPC) column under lateral impact loading. Int. J. Struct. Stab. Dyn. 2022, 22, 2250037. [Google Scholar] [CrossRef]

- Ji, L.; Wang, P.; Cai, Y.; Shang, W.; Zu, X. Blast resistance of 240 mm building wall coated with polyurea elastomer. Materials 2022, 15, 850. [Google Scholar] [CrossRef] [PubMed]

- Gu, M.; Wang, H.; Yu, A.; Wang, H.; Ling, X.; Chen, G. Research on dynamic behavior and gas explosion resistance of polyurea. Mater. Today Commun. 2022, 33, 104826. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Fang, Q.; Chen, W.; Hao, H.; Zhu, R.; Zheng, K. Experimental and numerical study on CFRP strip strengthened clay brick masonry walls subjected to vented gas explosions. Int. J. Impact Eng. 2019, 129, 66–79. [Google Scholar] [CrossRef]

- Greene, C.E.; Myers, J.J. Flexural and shear behavior of reinforced concrete members strengthened with a discrete fiber-reinforced polyurea system. J. Compos. Constr. 2013, 17, 108–116. [Google Scholar] [CrossRef]

- Marawan, A.E.; Debaiky, A.S.; Khalil, N.N. Shear and flexural behavior of RC beams strengthened with polyurea spray. Int. J. Adv. Res. Sci. Eng. 2015, 4, 12–26. [Google Scholar]

- Parniani, S.; Toutanji, H. Monotonic and fatigue performance of RC beams strengthened with a polyurea coating system. Constr. Build. Mater. 2015, 101, 22–29. [Google Scholar] [CrossRef]

- Rizwan, M.; Khaleequzzaman, S.; Uz Zaman, U.K.; Fida, S.A.; Shahzad, A.; Rehman, M.; Sulaiman, M.O. Tensile strength improvement of concrete slabs using polyurea spray. Pract. Period. Struct. Des. Constr. 2021, 26, 4020048. [Google Scholar] [CrossRef]

- Song, J.H.; Lee, E.T.; Eun, H.C. A study on the improvement of structural performance by glass fiber-reinforced polyurea (GFRPU) reinforcement. Adv. Civ. Eng. 2019, 2019, 2818219. [Google Scholar] [CrossRef]

- Kim, S.B.; Kim, J.H.; Choi, H.S.; Heo, G. Development and applicability evaluation of high performance polyurea for RC construction reinforcement. J. Korean Soc. Civ. Eng. 2009, 30, 169–176. [Google Scholar]

- Park, J.C.; Lee, S.W.; Kim, S.B.; Kim, J.H. Development and applicability evaluation of stiff-type polyurea for RC construction reinforcement. J. Korean Soc. Civ. Eng. 2010, 31, 457–464. [Google Scholar]

- KS F 2405:2010; Standard Test Method for Compressive Strength of Concrete. Korea Standard Association: Seoul, Republic of Korea, 2010.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).