Abstract

Vibrations of the print head and structural components during 3D printing with FFF technology can significantly impact the quality of printed parts, resulting in defects such as ghosting, ringing, and geometric inaccuracies. These undesired effects are primarily caused by mechanical oscillations of the print head, build platform, and frame, induced by dynamic changes in movement speed and inertial forces within the printing mechanism. This study investigates the effectiveness of vibration compensation using an ADXL345 accelerometer to regulate the motion of the print head and build platform on the Ender 3 V2 Neo printer. The experiment consisted of three test series performed under two distinct conditions, without vibration compensation and with active compensation enabled. All tests were carried out using identical baseline printing parameters. The differences in output were evaluated through visual inspection and dimensional analysis of the printed samples. Efficient vibration monitoring and its active control, aimed at suppressing oscillatory phenomena, can enhance both geometric accuracy and surface uniformity. In FFF 3D printing, especially when utilizing increased layer heights such as 0.3 mm, surface roughness (Ra) values in the range of 18 to 25 µm are typically expected, even when optimal process parameters are applied. This study emphasizes the role of active vibration control strategies in additive manufacturing, particularly in enhancing surface quality and dimensional accuracy. The objective is not only to mitigate the adverse effects of dynamic mechanical vibrations but also to determine the extent to which surface roughness can be systematically reduced under defined conditions, such as layer height, print speed, and movement trajectory. The aim is to improve the final product quality without introducing significant compromises in process efficiency.

1. Introduction

In recent years, 3D printing has established itself as a key technology in industrial manufacturing, rapid prototyping, and scientific research. Among the most widespread methods is Fused Filament Fabrication (FFF), in which thermoplastic material is extruded through a heated nozzle and deposited layer by layer to form the final object. Continuous technological advancements have enabled higher print speeds and expanded the range of applicable materials. However, ensuring consistent print quality and repeatability remains one of the major challenges. Print quality is influenced by multiple factors, with one of the most critical being vibrations of the print head. These vibrations may lead to defects such as irregular edges, blurred details, or deviations in model geometry. The sources of vibrations vary and include dynamic motion of the print head, mechanical stability of the printer’s frame, and acceleration/deceleration settings of stepper motors. At higher print speeds, these factors become increasingly prominent, often resulting in process-induced defects and limiting the overall efficiency of the print process. Traditional mitigation strategies include reducing print speed, optimizing motion paths, or reinforcing the mechanical structure of the printer. However, such measures often result in increased production time or higher operational costs. A more advanced approach to vibration mitigation involves the use of accelerometric sensors, such as the ADXL345. This sensor enables real-time acceleration measurement, and the collected data can be used to adjust the motion trajectory of the print head to minimize unwanted oscillations.

FFF printing continues to evolve, with numerous studies focusing on improving the mechanical properties of printed parts, optimizing process parameters, and predicting potential print defects. Research efforts have explored the influence of factors such as temperature, print speed, cooling conditions, and material modifications. Recently, particular attention has been directed toward vibrations occurring during the printing process, as they may affect the internal structure and mechanical performance of the printed objects. Fuhui Ch. et al. studied the impact of print head vibrations on the mechanical properties of parts produced via FDM (Fused Deposition Modeling) technology. By developing a nozzle capable of vertical oscillations, they analyzed how varying vibration frequencies affected interlayer bonding strength. Their results indicated that appropriately controlled vibrations reduce material viscosity, influence porosity, and improve vertical tensile strength, while having no significant effect on horizontal strength [1]. Jensen N. J. et al. evaluated the influence of both environmental and operational vibrations on part quality in additive manufacturing. They found that environmental vibrations increased surface roughness by up to 85%, whereas machine-induced vibrations had a comparatively smaller effect. Passive vibration damping reduced the relative motion between print head and bed by 93% and improved surface uniformity by 16% [2]. Sohail Z. et al. analyzed the influence of induced vibrations on the mechanical properties of 3D-printed samples made of PLA, ABS, and PETG at frequencies of 2.4 Hz and 8.8 Hz, comparing them to samples printed without vibration. Visual inspection revealed tighter filament bonding at higher vibration frequencies, while porosity measurements showed up to 84.85% reduction in PLA samples at 8.8 Hz—a 32% improvement over the non-vibrated baseline [3]. Wolf J. et al. focused on analyzing the impact of drive type (stepper vs. servo motors) on the dynamic behavior of Cartesian 3D printers. Through circularity tests, repeatability measurements, and vibration analysis, they demonstrated that servo motors provide higher positioning accuracy and significantly lower operational vibrations. The study also highlights that while the choice of actuator influences path accuracy, the final print quality can still be affected by additional instabilities arising during motion execution [4]. Raza Mishra R. et al. analyzed the vibration behavior of four different 3D printers in five operating states (e.g., normal printing, clogged nozzle, filament runout) using an accelerometer placed near the nozzle. The results showed that each operating mode generates distinct vibration spectra, demonstrating that even small changes in system dynamics lead to specific vibrations. The study thus indirectly confirms the potential of using accelerometric data to assess mechanical stability [5]. Katarzyna B. et al. explored methods to reduce printer-induced vibrations caused by extruder movement during the FDM process. They achieved significant improvements in dimensional accuracy by modifying the structural design and integrating energy-dissipative components, with tests confirming that a 50–70% vibration amplitude reduction led to improved dimensional fidelity [6]. Fangkai X. et al. proposed a methodology for evaluating the influence of key process parameters—including raster angle, nozzle temperature, layer height, and deposition speed—on the vibration characteristics of FFF structures. Their application to PLA specimens demonstrated good reproducibility in both the printing and vibration testing phases. Notably, raster angle had the largest influence on resonance frequency (16.6%) and damping ratio (7.5%), while the impact of other parameters remained below 4% [7]. Yongxiang L. et al. developed a real-time monitoring and diagnostic method for the FFF process using vibration sensors and advanced machine learning algorithms. Employing LS-SVM (Least Squares Support Vector Machine) and BPNN (Backpropagation Neural Network), they accurately identified machine faults and print defects. LS-SVM effectively classified machine states, while BPNN predicted deformations and material buildup with high precision. The study further highlighted the role of feedrate in influencing vibration behavior and the importance of deeper understanding of defect generation mechanisms [8]. Muhammad F. W. et al. analyzed the impact of vibrations on print quality using FDM technology. Undesirable oscillations were shown to degrade part quality and damage machine components. Their study combined accelerometer and acoustic sensor data to detect failures, while demonstrating that machine learning can greatly enhance fault identification during print execution [9]. Alexander I. et al. used accelerometers to predict printer condition by analyzing vibration patterns. Applying Fourier transforms and machine learning models, they found that sensors placed closest to the nozzle yielded the highest sensitivity for fault detection. The findings confirm that vibration frequency data can support predictive maintenance and quality control in 3D printing [10]. These studies collectively demonstrate the substantial influence of vibrations on mechanical properties, dimensional accuracy, and surface quality in 3D printed parts. Various approaches to mitigating vibration—including process optimization, passive and active damping, and structural redesign—offer valuable pathways to improving this technology.

This research distinguishes itself from prior work by providing a comprehensive analysis of internal and external vibration sources that may compromise print stability and geometric precision in the FFF process. It not only examines mechanical vibrations stemming from the print head, build plate, and motion system, but also evaluates the role of external environmental factors—such as ambient vibrations, surrounding human activity, or equipment interference—in contributing to undesirable oscillatory behavior. The novelty of this study lies in its first systematic application of the ADXL345 accelerometer to monitor and partially compensate for vibrations in an open-frame FFF environment, without reliance on advanced control systems like PID or LQR. Unlike existing studies that use expensive piezoelectric sensors or closed commercial systems, this work demonstrates the feasibility of a practical sensor-based framework integrated directly into firmware-level compensation under real-world conditions. The study focuses on identifying dominant vibration components generated during head and bed movements and analyzes their correlation with surface roughness metrics. The main objective is to assess to what extent this affordable sensing approach can contribute to stabilizing the printing process under high dynamic loads, and to establish a foundation for developing lightweight, adaptive compensation strategies in open FFF systems. The insights gained are applicable to a wide range of low-cost 3D printers and potentially to other dynamic fabrication systems, supporting the development of vibration-aware, real-time control strategies without dependence on complex control architectures. As such, this research offers a novel, cost-effective, and practically implementable pathway to enhancing precision, repeatability, and reliability in high-speed FFF printing.

2. Materials and Methods

The research methodology focused on vibration compensation in 3D printing, specifically in the context of printing height-exposed geometries where vibrations can significantly impact print quality. The primary objective of the study was to validate a method for dynamically stabilizing the motion of the print head to minimize vibrations that lead to defects such as irregular edges, surface rippling, and geometric deviations.

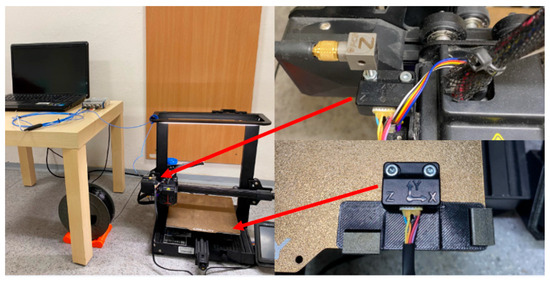

Vibrations during printing were measured externally using an ICP accelerometer, model 356A33 (PCB Piezotronics, Depew, NY, USA), which was mounted to the printer frame. The analog signal from the sensor was digitized using the NI USB-9162 (National Instruments, Austin, TX, USA), a high-speed USB data acquisition converter. Data collection and analysis were performed using LabVIEW SignalExpress 2012 (version S14X86761), which enabled time-domain signal recording, spectral analysis through Fast Fourier transform (FFT), and evaluation of vibrations along the X, Y, and Z axes. Measurements were carried out under different vibration compensation modes, both with and without active regulation, and the results were used to compare the effectiveness of each setting.

In both cases, the printing conditions were identical, which enabled a precise performance comparison of the ADXL345 accelerometer (Analog Devices, Inc., Wilmington, MA, USA). This approach was used to verify whether the ADXL345 could accurately detect vibrations and whether its data could be effectively utilized to control the print head trajectory and implement vibration control during printing.

To clearly present the research outcomes, visual evidence was employed to compare the results obtained under both operational modes, helping to illustrate differences in print quality and the effectiveness of vibration control. These images provided valuable insight into how regulation influences the final print and supported the experimental verification of the ADXL345 accelerometer’s functionality. Based on these visualizations, it was possible to clearly demonstrate the impact of vibrations on geometric accuracy and surface detail, thereby emphasizing the efficiency of the implemented motion stabilization system.

The research was conducted through the setup of the 3D printer, sensor installation, vibration measurements during the printing of geometrically demanding components, and analysis of the impact of regulation on print quality. The aim was not only to optimize the printing process but also to achieve high-quality and dimensionally accurate prints with minimal vibration. The study followed an experimental methodology consisting of several key phases and steps that enabled systematic testing and verification of vibration control effectiveness in the 3D printing of geometrically complex components. The research workflow included the following steps:

- Identification of the main problem, focusing on the influence and mitigation of vibrations during FFF printing, with the objective of improving dimensional accuracy and surface quality.

- Review of the current state of vibration control in FFF printing and assessment of the potential for regulation using accelerometric sensors.

- Analysis of the Ender 3 V2 printer (Shenzhen Creality 3D Technology Co., Ltd., Shenzhen, China), including identification of critical points generating vibrations, particularly along the X and Y axes, and proposal of optimal ADXL345 sensor placement to ensure effective detection and control.

- Integration of the ADXL345 sensor into the printer system, including proper physical mounting and the design of an appropriate support model.

- Preparation of test models with height-exposed features, considering increased layer height, to analyze the impact of vibrations on surface quality.

- Selection of consistent printing parameters for both unregulated and actively regulated printing modes.

- Execution of test prints without active vibration control, accompanied by external vibration measurement and evaluation of resulting visual defects.

- Execution of test prints with active vibration control in two configurations, with the sensor mounted either on the print head or on the print bed, including external vibration measurements in both cases and comparison of print quality between regulated and unregulated samples.

- Collection and analysis of data from test prints, including photo documentation, visual inspection of defects, surface structure analysis using a profilometer, and microscopic observation.

- Evaluation of the ADXL345 sensor’s effectiveness in suppressing vibrations, based on comparative analysis of print quality across different test conditions.

- Discussion of potential improvements to the system and methodology.

- Formulation of conclusions regarding the effectiveness of the ADXL345 sensor in vibration mitigation for 3D printing, along with process optimization strategies and recommendations for future research focused on dynamic stabilization of the print head and build platform.

2.1. Mechanistic Interaction Between Printer Framework and Operational Parameters in Vibration Generation

3D printing is a dynamic process influenced by the combined effects of various mechanical and process-related factors. One of the most critical issues affecting print quality and dimensional accuracy is the vibration of the print head and the print bed. These vibrations can significantly impact the final product, leading to geometric deviations, surface irregularities, and a reduction in detail quality.

The causes of such vibrations are diverse and include not only structural factors but also the printing parameters selected during the process. Table 1 demonstrates that vibrations in 3D printing arise not solely from the mechanical construction or the configured process settings, but primarily from their interaction. For example, even a robust and rigid printer frame does not guarantee high print quality if process parameters, such as excessive printing speed or abrupt acceleration profiles, are improperly configured. In contrast, systems with a moderately flexible frame can still achieve vibration reduction through precise optimization of the printing parameters [11,12,13,14,15].

Table 1.

Interaction between printer construction and print parameters in vibration generation.

2.2. Analysis of the Movement of 3D Printer Components Along the X, Y, and Z Axes and Their Influence on Vibration Generation During Printing

During the operation of the Creality Ender 3 V2 3D printer (Shenzhen Creality 3D Technology Co., Ltd., Shenzhen, China), multiple components move along different axes, and each of these movements can generate vibrations and affect the quality of the print. Analyzing motion in the X, Y, and Z axes is therefore essential for identifying instability sources and proposing effective measures for their elimination.

- Movement along the X-axis (component in motion): The print head (hotend) is the main component that moves along the X-axis during printing. This movement is fundamental for precise material deposition onto the build plate; therefore, it must be smooth and stable. Vibrations along this axis can significantly affect print quality, especially during fast movements where high positional accuracy is needed.

- Movement along the X-axis (mechanism in motion): A belt drive with a GT2 timing belt is commonly used in 3D printers to provide accurate movement of the print head in the X-axis. This mechanism uses synchronized belt motion connected to a stepper motor, which converts rotation into linear movement. While the GT2 belt is efficient and cost-effective, it can be sensitive to factors such as belt tension, friction, and wear.

The primary sources of vibrations in the X-axis are associated with mechanical and dynamic factors that influence print head movement. Wear on linear bearings or other moving components introduces mechanical tolerances, causing motion inaccuracies and vibration. Loose or improperly tensioned belt drives can cause slipping, leading to oscillations and reduced motion precision. Dynamic speed changes such as acceleration and deceleration generate short-term vibrations, especially at high speeds. Stepper motors may cause resonant frequencies that amplify vibrations and reduce movement stability, directly degrading print quality [16].

- Movement along the Y-axis (component in motion): The build plate is the main component that moves along the Y-axis. To ensure correct placement of the printed object, this movement must be stable and accurate. Vibrations along the Y-axis can cause visual defects such as ghosting, layer shifts, or model deformation, and must therefore be minimized.

- Movement along the Y-axis (mechanism in motion): The movement of the build plate along the Y-axis is ensured by a belt-driven mechanism utilizing a GT2 timing belt connected to a stepper motor, converting its rotational motion into linear displacement. Although effective and economical, this system is prone to mechanical issues like incorrect belt tension, friction in linear rails, or bearing wear, which all contribute to unwanted vibration.

Y-axis vibrations arise from several mechanical and dynamic factors affecting the movement of the build plate. Irregular behavior of linear bearings or rails can introduce micromovements, leading to instability and oscillations. Loose or improperly tensioned belts cause slippage and erratic plate motion, compromising layer precision. Dynamic forces during acceleration and deceleration of large plate movements can trigger impact-like vibrations, resulting in layer shifts and visual artifacts such as ghosting or wavy contours. Additionally, stepper motor resonance at specific frequencies can amplify vibrations and destabilize build plate motion, negatively affecting print quality.

- Movement along the Z-axis (component in motion): The entire print head assembly moves along the Z-axis, enabling the stepwise deposition of material layers during printing. Accurate and stable vertical motion is key to achieving consistent layer height and overall print quality.

- Movement along the Z-axis (mechanism in motion): Z-axis motion is driven by a threaded rod (leadscrew) mechanism, providing precise linear displacement of the print head in the vertical direction. This system employs a leadscrew coupled to a stepper motor for lifting or lowering the print head with high accuracy. Proper alignment and adequate lubrication are essential for smooth motion without mechanical distortion.

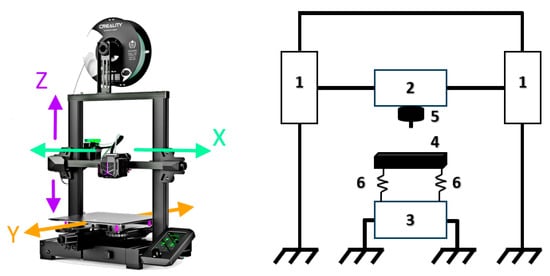

The main sources of vibrations in the Z-axis include backlash in the leadscrew, misalignment of the drive shaft, friction and wear in the screw mechanism, and stepper motor resonance. Backlash causes inconsistent motion when direction changes, leading to Z-banding and layer inaccuracies. Misalignment of the leadscrew can induce oscillations in the print head, affecting final print quality. Friction and wear result in jerky motion and inconsistent vertical movement. Stepper motor resonance at specific frequencies further amplifies vibrations, negatively impacting vertical accuracy and surface finish quality. Figure 1 shows a typical construction of an FFF Cartesian 3D printer (left) and its simplified mechanical model (right). The system consists of three basic linear axes—the X-axis (horizontal movement of the print head), the Y-axis (movement of the print bed forward and backward), and the Z-axis (vertical movement). In the schematic on the right, the individual components are labeled as follows:

Figure 1.

Schematic of the axis motion of an FFF printer and its corresponding dynamic model.

- Aluminum profile ensuring vertical (Z-axis) movement of the gantry,

- Horizontal aluminum profile enabling movement of the print head (X-axis),

- Aluminum frame of the bed for movement along the Y-axis,

- Print bed,

- Print head (extruder),

- Springs providing height adjustment and stabilization of the bed.

2.3. Internal and External Factors Causing Vibrations

Vibrations in 3D printers are a complex phenomenon arising from the interaction of various internal and external factors.

2.3.1. Internal Factors

Internal factors are directly related to the mechanisms and structural components of the printer itself. They originate from within the system and significantly affect the generation of vibrations during the printing process.

- Print head: The print head is a key component that moves along all three axes (X, Y, Z) during operation. If its movement is imprecise or unstable, vibrations can occur and be transferred to the printed material. Worn or loose drive mechanisms such as a poorly tensioned GT2 belt in the X-axis can result in slippage or inaccuracies in movement, which leads to unwanted oscillations.

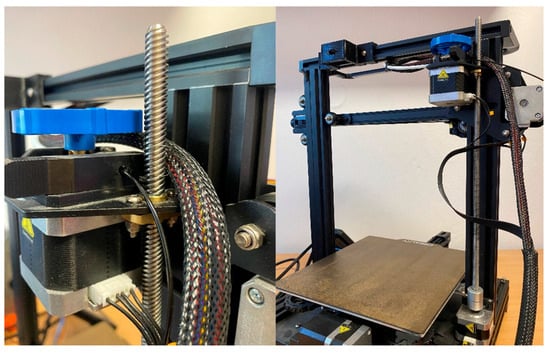

- Leadscrew drive: The Z-axis typically uses a leadscrew mechanism, which is particularly susceptible to backlash. Backlash refers to the small delay or shifts that occur when the direction of motion changes, often manifesting as Z-banding-visible layer irregularities that degrade print surface quality. Additionally, misaligned leadscrews can cause axial oscillations, resulting in nonlinear print head movement and uneven layer stacking (Figure 2).

Figure 2.

Location of the lead screw on the Creality Ender 3 V2.

- If the bearings are not properly maintained or are worn out, they may cause increased friction, resulting in sluggish movement or stalling. These stalls produce short-term but irregular vibrations that can affect extrusion accuracy.

- Wear on the lead screw or other motion components can cause interrupted movement and increase vibration generation. If these components are insufficiently lubricated or damaged, micro-oscillations may occur, compromising print stability.

- Stepper motor resonance: Stepper motors used for moving the print head and build plate can generate resonance at specific frequencies, which may transmit through the printer’s structure. These vibrations are amplified if the motors are operating at certain speeds or are subjected to excessive loads. Resonance can significantly reduce movement stability and precision, ultimately affecting print quality.

- Springs under the build plate are responsible for maintaining stability and uniform pressure. If the springs are unevenly adjusted or worn out, this may result in inconsistent pressure on the build plate, affecting its alignment. Consequently, print quality may deteriorate, leading to issues such as warped first layers or poor adhesion of the print material to the bed (Figure 3).

Figure 3.

Positioning screw placement for build plate leveling.

- High print speed and other parameters: At higher movement speeds of the print head or the build plate, the kinetic energy increases, resulting in greater stress on mechanical components and their stability. This intensified motion can lead to stronger vibrations that propagate through the printer’s structure and negatively affect print quality [17].

2.3.2. External Factors

External factors include influences originating from the environment surrounding the printer, which can indirectly affect its performance. These factors involve not only the physical space in which the printer is located but also the way it is positioned and its interaction with external objects. Key external factors include:

- Placing the printer on an unstable or lightweight table may increase its susceptibility to vibrations caused by external forces or movement. These vibrations can compromise print accuracy, particularly during high-speed movements of the print head.

- Proximity to external vibration sources (e.g., mechanical devices, fans, or air conditioning systems) may interfere with the motion of the print head and build plate, leading to unwanted artifacts in printed parts.

- Printers located in areas with high foot traffic (e.g., near doors, hallways, or production lines) can be exposed to floor-transmitted vibrations.

- Sudden impacts or shocks (e.g., bumping the table or handling objects nearby) can introduce vibrations that disrupt the precision and stability of the printing process.

- Temperature fluctuations and ambient humidity may affect the materials from which the 3D printer is built, leading to structural deformation. Sudden temperature changes can cause expansion or contraction of materials, altering the printer’s geometry. Inadequate humidity can change the elasticity and strength of printer components, contributing to vibrations that reduce print quality.

- Multiple 3D printers operating in the same room may generate mutual vibrations that negatively affect print quality. For instance, one printers movement can create shockwaves that propagate to others, especially when they are placed on the same surface.

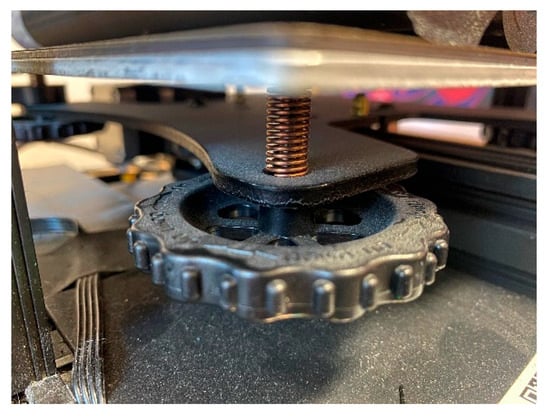

- Dust, dirt, or debris accumulation on wheels or bearings can cause uneven platform movement, impairing print accuracy (Figure 4). Such contamination may result in irregular bed movement, which leads to improper layer placement, deformation, and poor output quality [18].

Figure 4. Accumulation of wear particles and dust on the wheels beneath the build plate.

Figure 4. Accumulation of wear particles and dust on the wheels beneath the build plate.

2.4. Input Shaping for Vibration Suppression in 3D Printing

Input Shaping is a technique for shaping the input control signal with the aim of minimizing excitation effects on the natural frequencies of a mechanical system. In the context of 3D printing, it is used to suppress unwanted oscillations of components such as the print head, which mainly occur during sudden changes in velocity and direction (e.g., when printing sharp corners or complex geometries). The method consists of replacing the original input signal F (t) with a shaped signal Fshaped (t), which is composed of several time-delayed impulses with appropriately chosen amplitudes and delays. The principle can be illustrated by the example of a ZV (Zero Vibration) or ZVD (Zero Vibration Derivative) shaper as follows:

or for the extended ZVD shaper:

where

- δ(t) is the Dirac delta function,

- Ai are the amplitudes of the individual impulses,

- T is the delay between impulses, which depends on the natural frequency fn and damping ratio ζ of the system,

- The amplitudes and delays are designed to eliminate excitation effects on the dominant natural modes of the system.

For a mass-spring-damper system, the natural frequency is given by:

where

- k is the stiffness and m is the effective mass of the system (e.g., the moving parts of the X/Y/Z axis).

Implementation of Input Shaping in firmwares such as Klipper or Marlin enables dynamic trajectory optimization without the need for hardware modifications, thereby reducing effects such as ringing, ghosting, and geometric inaccuracies in printed parts. For the Input Shaping algorithm to be effective, it must be applied separately to each axis according to its own natural frequency. For example, in the Klipper firmware, it is possible to perform a resonance frequency test individually for each axis (X, Y, Z), which provides accurate data for designing shapers (e.g., ZV, ZVD). To perform a dynamic analysis of the motion of the printer’s moving components, individual axes (X—print head; Y—print bed; Z—gantry) can be approximated as mass-spring-damper systems. This model captures the fundamental physical phenomena such as the inertia of the moving mass, elastic deformation of the structure, and internal damping of vibrations. The general form of the differential equation for such a system is:

where m is the effective mass of the moving part of the system (e.g., the print head for the X-axis, the bed for the Y-axis, or the gantry for the Z-axis), c is the damping coefficient related to motion resistance and friction, k is the stiffness of the structure, x (t) is the instantaneous position, and F(t) represents the external force (e.g., the control signal to the motors). From this model, two key parameters are derived–the natural frequency of the system:

and the dimensionless damping ratio is

where ωn defines the undamped resonant frequency and ζ expresses the level of damping (e.g., 0—undamped; 1—critically damped). Once these parameters are identified, it is possible to design a specific input shaping filter (e.g., ZV, ZVD, EI) for each axis, which modifies the control signal F(t) to eliminate excitation components near ωn, thereby significantly reducing vibrations, improving accuracy, and enhancing print surface quality. This approach is applicable independently to all three axes, with the Y-axis typically being the most sensitive (due to the large moving mass of the print bed), followed by the X-axis (rapid movement of the print head), and finally the Z-axis, which, although moving slowly, is sensitive to vibrations transmitted from the other axes [19,20,21,22].

2.5. Mounting Design and Integration of the Vibration Sensor on the Print Bed

When designing the mounting solution for the ADXL345 vibration sensor on the printer’s print bed, several technical and practical aspects had to be considered. The sensor needed to be firmly and reliably attached directly to the moving bed to accurately capture real vibrations during Y-axis movement. The design accounted for thermal insulation from the heated surface, minimized the influence of additional weight on printing dynamics, ensured easy cable routing without restricting movement, and allowed for simple sensor installation and removal. The sensor was attached to the model using screws. Proper placement and securing of sensors are essential not only for their functionality but also for minimizing the impact of vibrations and collisions that may affect the experimental results. The key objective is to achieve reliable data comparison and verification of measurement accuracy, thereby contributing to the credibility and reproducibility of the results.

2.6. Overview of Technical Specifications of Equipment (Hardware/Software)

This section focuses on the technical specifications of the components used in the research, specifically the Creality Ender 3 V2 3D (Shenzhen Creality 3D Technology Co., Ltd., Shenzhen, China), printer and two sensors: the Creality ADXL345 (Shenzhen Creality 3D Technology Co., Ltd., Shenzhen, China), and the ICP accelerometer 356A33 (PCB Piezotronics, Inc., Depew, NY, USA). The purpose of this analysis is to provide detailed information about the parameters of these devices, which have a decisive impact on improving the efficiency of 3D printing, with particular focus on minimizing vibrations and achieving higher print quality. The Creality Ender 3 V2 is suitable for research purposes for several reasons, as outlined in Table 2. Thanks to its open construction and wide range of available upgrades, this printer can be adapted to specific research needs, such as the installation of sensors for vibration measurement, improvement of print stability, or modification of frame modules. In addition, the Ender 3 V2 has sufficient build volume, which allows for the printing of various types of prototypes and components for testing.

Table 2.

Default parameters of the Ender 3 V2 Neo device.

Minor vibrations can significantly affect print quality in 3D printing. An effective solution to this issue is the implementation of the ADXL345 sensor for vibration control, the parameters of which are presented in Table 3. This sensor is designed to measure the vibration frequencies of the printer’s X and Y axes, enabling efficient detection of unwanted movements during printing. Based on the gathered data, the operating system automatically adjusts the print parameters to eliminate the effects of vibrations. This helps compensate for resonance and minimize the “ghosting” effect caused by undesired movements of the print head. The result is improved print quality and greater process stability, leading to more precise and smoother printing.

Table 3.

Parameters of ADXL345 vibration compensation sensor.

The ICP accelerometer 356A33 is a high-sensitivity vibration sensor designed for precise monitoring of dynamic movements and structural vibrations in technical systems, as detailed in Table 4. It utilizes a piezoelectric measurement principle and integrated electronics, which ensures a stable and reliable output signal. Thanks to its compact design and low weight, it is ideal for applications where fine vibrations need to be monitored, such as during the analysis of print head movement in 3D printing or in technical diagnostics.

Table 4.

Parameters of ICP 356A33 Accelerometer.

2.7. Preparation of Test Models for Vibration Influence Analysis

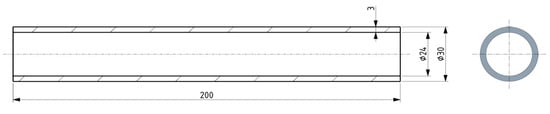

For effective analysis of the impact of vibrations on surface quality, it is essential to prepare test models with fine details that are sensitive to unwanted movements of the print head. Vibrations during printing can cause various defects, such as wavy patterns, layer shifts, deformations, or inconsistent surface texture, all of which negatively affect the final print quality. These undesirable phenomena may be caused by multiple factors, including print head movement speed, acceleration and deceleration, mechanical stability of the printer’s structure, stepper motor feedback, or even the properties of the material used. One of the most suitable models for vibration testing is a tall cylinder with a small diameter. This shape, as demonstrated in Figure 5, is ideal because any vibrations manifest significantly during printing, and the taller the cylinder, the more vibrations accumulate and result in surface irregularities. When printing taller objects, resonance can occur within specific frequency bands, leading to visible deformations. For this reason, the tall cylinder is one of the simplest and most effective test models for identifying vibrations in the printing system.

Figure 5.

Schematic representation of the model designed for testing.

In addition to the model’s shape, it is necessary to consider the following key test model parameters:

- Cylinder height: Taller models are more sensitive to vibrations and better reveal their effects. Minor deviations accumulate with height, becoming visible in the upper sections while remaining negligible in lower layers.

- Cylinder diameter: A smaller diameter accentuates lateral vibrations of the print head, which may result in irregular wavy surface defects.

- Wall thickness: Thinner walls are more prone to deformation due to vibrations. If the wall is too thin, undesired oscillations may occur, further highlighting the issue.

- Layer-by-layer analysis: Enables the comparison of deviations at different heights of the model. By analyzing individual segments, it is possible to precisely identify the critical areas where vibrations are most pronounced.

To achieve the most accurate results, various combinations of print parameters should be tested to observe their impact on the final quality. Factors that can be adjusted include print speed, acceleration, nozzle temperature, layer height, and bed type. A critical component of this process is recording data from the vibration sensor, which aids in visualizing the dynamic behavior of the print head. The proposed test model is ideal for the implementation of the ADXL345 sensor, which detects vibrations and their intensity in real time. This sensor provides feedback for adjusting the motion of the print head or bed to compensate for vibrations, ensuring consistent print quality.

This approach offers not only detailed insights into the effectiveness of compensation mechanisms but also helps evaluate the threshold of acceptable vibration levels that do not negatively impact the print. The combination of the ADXL345 sensor and external monitoring is therefore essential for optimizing the 3D printing process and achieving high print quality.

2.8. Definition of Parameters for Experimental Comparison

When printing 3D models, it is essential to set the correct parameters to ensure the desired print quality, as presented in Table 5. For comparing prints without vibration control and with vibration control, it is important to maintain consistent fundamental parameters, such as printhead movement speed, extruder temperature, and layer height. This ensures consistency across both testing modes. In the print mode without vibration control, these parameters are applied without any adjustments, which can result in undesirable vibrations that negatively affect the surface quality. In contrast, for the print mode with vibration control, the parameters are dynamically adjusted based on detected vibrations to minimize their impact on print quality.

Table 5.

Parameters used in individual printing processes.

This approach demonstrates the functionality of vibration regulation using the ADXL345 sensor and its capability to compensate for vibrations in real time. As a result, a more stable and accurate print is expected.

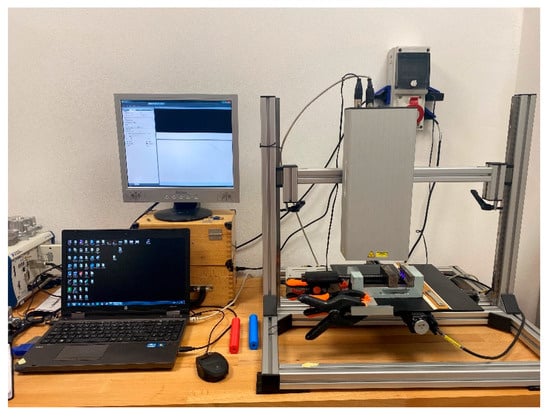

2.9. Strategic Positioning of the 3D Printer

To minimize environmental influences and vibrations originating from surrounding structures such as shelves, tables, or stands, the printer was placed on a solid and stable surface—ideally, a concrete floor covered with a thin rubber layer (Figure 6). This setup effectively absorbs unwanted vibrations and minimizes shocks that could negatively impact the accuracy and quality of the prints. The stable positioning of the printer allowed it to be isolated from external vibration sources, ensuring optimal conditions for objectively evaluating the impact of vibration compensation of the print head, build platform, and machine structure. This approach ensured that the experimental results were not affected by external factors, enabling more precise analysis of the efficiency of the stabilization mechanisms.

Figure 6.

Hardware equipment placement.

2.10. Comprehensive Experimental Analysis of FFF Printing with Various Vibration Compensation Modes

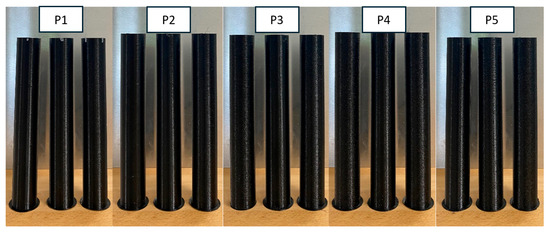

This part of the experiment involved a series of tests focused on monitoring the influence of vibrations during the FFF printing process under three modes: without active compensation, with active compensation of the printhead motion vibrations, and with active compensation of the print bed motion vibrations. The objective was to establish controlled conditions for the systematic observation of differences resulting from dynamic oscillations of the printer’s structural components during the printing process.

During each test series, both the operating conditions and the behavior of the printer’s motion mechanisms were recorded. Vibrations were monitored using the 356A33 sensor, which was integrated into the system for real-time acceleration detection. All tests were conducted under consistent technical parameters and identical ambient conditions to ensure the reproducibility of results. Each operating mode was tested separately to eliminate deviations caused by random factors and to ensure output comparability. The data obtained serves as a foundation for detailed interpretation in subsequent phases of the research, specifically aimed at correlating vibration compensation modes with overall printing stability. Numerous scientific studies have investigated the measurement of surface roughness (Ra) in FFF printing using various materials, including PETG, and have reported typical Ra values depending on layer height. At a layer height of 0.1 mm, Ra values typically range from 5 to 12 µm; at 0.2 mm, values are approximately 10 to 18 µm; and at 0.3 mm, Ra commonly ranges from 18 to 25 µm. However, in cases of poor printer calibration, incorrectly set parameters, or unmitigated vibrations, surface roughness Ra may exceed 30 µm.

When evaluating the resulting surface quality, it is essential to consider the full set of printing conditions, including material type, model geometry, printing speed, environmental factors (e.g., temperature and humidity), nozzle type, and the overall mechanical stability of the system [23,24].

In this experiment, samples were printed under three distinct vibration compensation modes. For each mode, three identical samples were produced, forming a complete series (e.g., P1, P2, P3, P4, P5). Specifically, in Figure 7, the samples of series P1 are displayed. The first sample from the left corresponds to printing without any compensation, the second was produced with active compensation of printhead vibrations, and the third with compensation applied to the motion of the print bed. This order is consistent across series P2 through P5, with each set of samples illustrating the effect of individual compensation modes on the quality and stability of the printed parts.

Figure 7.

Experimental samples for testing.

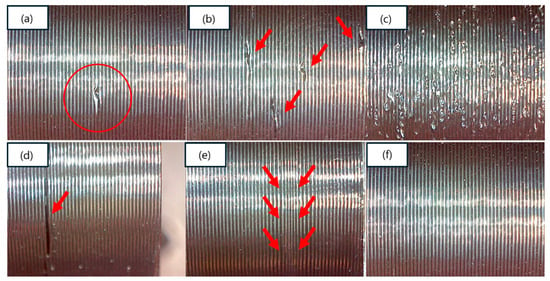

2.11. Comparative Analysis of Print Quality Before and After Using the Vibration Sensor—Visual Evaluation Using a Microscope

In this part of the experiment, a visual microscopic surface and geometric analysis was conducted on the test prints produced under different compensation modes. The objective was to identify and classify common FFF printing defects, compare their occurrence in prints made without and with active compensation, and visually substantiate the qualitative differences between the printing conditions.

- Local surface defect—with compensation (Figure 8a): A concentrated irregularity with a disturbed surface structure was observed in the selected section, likely caused by a sudden change in speed or a transitional phase in the movement trajectory of the print head. This type of defect indicates an undesired oscillation—probably a short-term resonance phenomenon that occurred during acceleration or deceleration in a specific movement direction. Despite the active vibration compensation, this case revealed a limitation of the control system, particularly during extreme or nonlinear dynamic changes that may exceed the effective correction range.

Figure 8. Overview of inspected samples., (a) local surface defect; (b) repeated occurrence of defects in various areas; (c) defects caused by moisture absorption; (d) layer separation–delamination; (e) ringing artifacts (ghosting/ringing); (f) representative flawless sample.

Figure 8. Overview of inspected samples., (a) local surface defect; (b) repeated occurrence of defects in various areas; (c) defects caused by moisture absorption; (d) layer separation–delamination; (e) ringing artifacts (ghosting/ringing); (f) representative flawless sample. - Repeated occurrence of defects in various areas—without compensation (Figure 8b): The observation of multiple similar defects at different height levels of the print suggests a periodic nature of the disturbance. It is likely caused by uncompensated vibrations generated by repeated acceleration and deceleration in the X/Y axis, with amplitudes exceeding the acceptable stability threshold of the system.

- Defects caused by moisture absorption—without compensation (Figure 8c): Small craters and inhomogeneities were present on the print surface, resulting from steam escaping the material during extrusion. This phenomenon is typical of hygroscopic materials (e.g., PETG, PLA, etc.) that were insufficiently dried prior to printing, leading to micro-explosions and disruption of layer integrity.

- Layer separation–delamination—without compensation (Figure 8d): The analyzed cross-section clearly shows layer separation, likely caused by vibrations along the Z-axis during the transition between layers. The resulting loss of adhesion caused a discontinuity in the structure, which may lead to a decrease in the overall strength of the print.

- Ringing artifacts (ghosting/ringing)—without compensation (Figure 8e): Repeated parallel patterns—so-called ringing artifacts—are observed along the model. This phenomenon arises as a mechanical response to the sudden deceleration of the print head, where inertial forces induce residual frame and system oscillations that are then transferred into the extruded path.

- Representative flawless sample—with compensation (Figure 8f): The sample printed under optimized parameters with active vibration compensation exhibited a homogeneous surface structure, precise contours, and no visible defects. This sample represents the ideal output achieved under stable and properly regulated conditions.

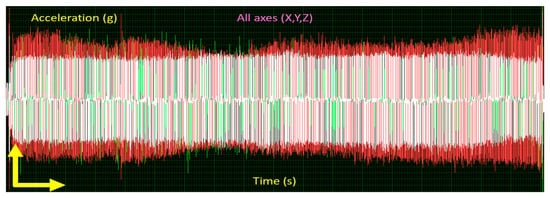

2.12. Monitoring of FFF Printing Using an External Accelerometer

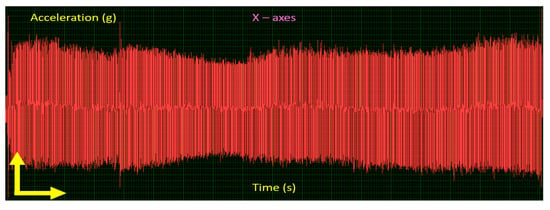

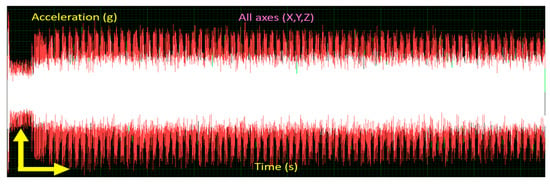

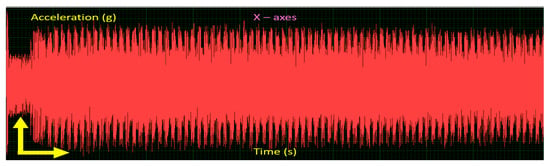

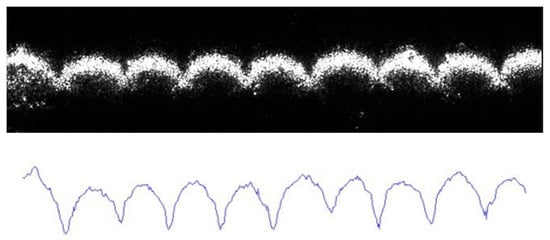

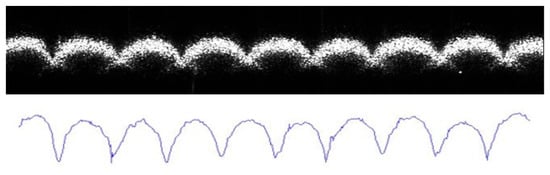

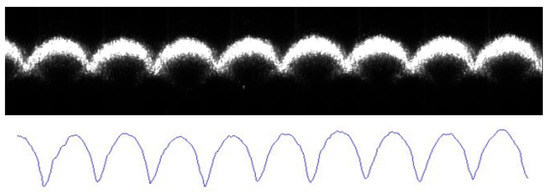

For the purpose of observing dynamic phenomena during the FFF printing process, monitoring was conducted using an external three-axis accelerometer mounted on the frame of the Creality Ender 3 V2 Neo device. The objective of this monitoring was to record the accelerations acting on each axis (X, Y, Z) during printing and to gain a more detailed insight into the system behavior under different compensation modes. Accelerations were recorded in real time across all three axes—X, Y, and Z. The output consisted of graphs, where the X-axis represents time (s) and the Y-axis indicates the acceleration value in multiples of gravitational acceleration (g). The monitoring was performed on samples with parameter set P1 (without compensation and with printhead compensation) [25]. Figure 9, shows the vibration patterns recorded in all three axes during printing without active compensation. A high level of dynamic oscillations and irregular fluctuations is clearly visible, which may negatively affect the print quality. The vibration patterns in Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16 are recorded within a ±1.5 g range; however, due to limited resolution of the graphs, it is not possible to display the numerical scale directly within the individual visualizations.

Figure 9.

Comprehensive acceleration record in all axes (X, Y, Z) during printing without vibration compensation.

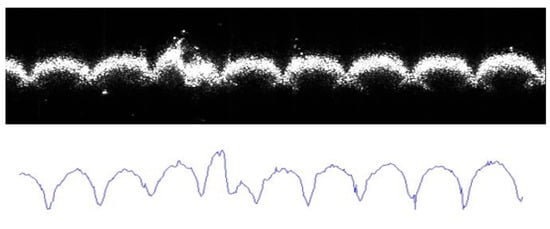

In the mode without motion compensation, noticeable oscillations and irregularities in the curve were observed along the X-axis, indicating an unstable motion profile of the printhead in the horizontal direction. This phenomenon may be caused by resonances induced by sudden speed changes during specific printing segments. The result is an irregular acceleration trace with higher amplitude and frequent deviations from the average value (Figure 10).

Figure 10.

Acceleration profile in the X-axis during FFF printing without active vibration compensation.

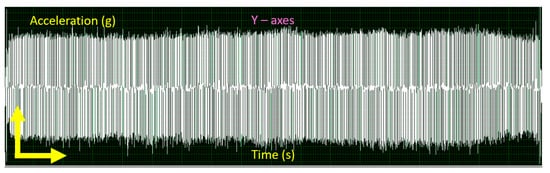

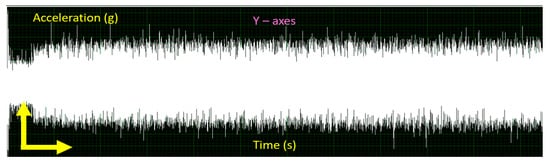

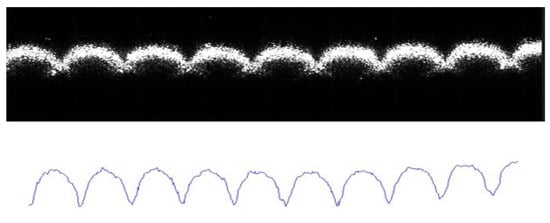

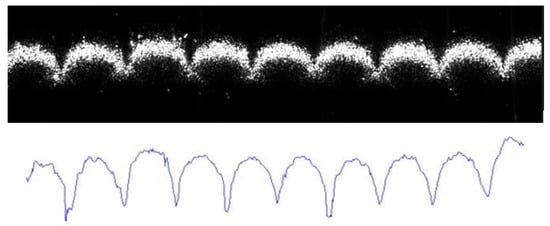

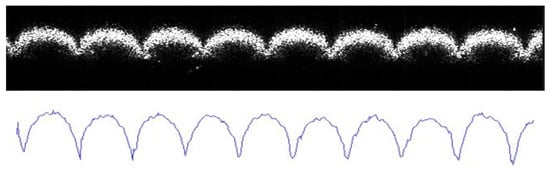

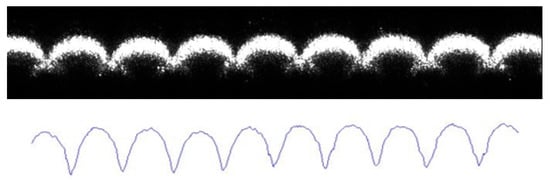

The curve along the Y-axis was slightly more stable, yet minor fluctuations were still observable. These deviations are less pronounced than those in the X-axis; however, they still indicate mechanical backlash effects, particularly during abrupt stops and directional changes in movement (Figure 11).

Figure 11.

Acceleration profile in the Y-axis during FFF printing without active vibration compensation.

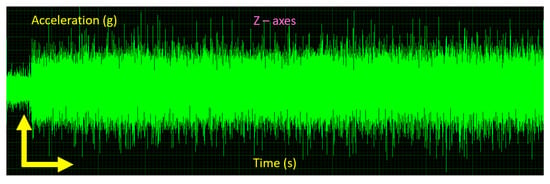

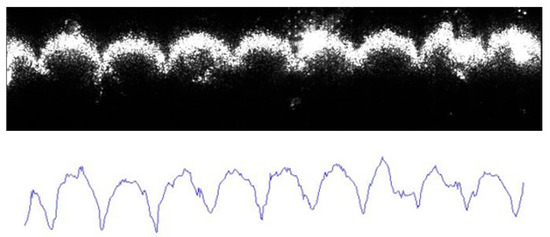

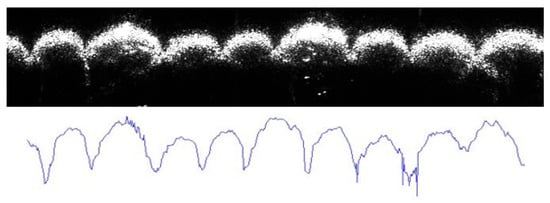

The largest deviations were recorded along the Z-axis. The curve appeared chaotic, with several sharp peaks and sudden jumps in acceleration. These fluctuations indicate vertical vibrations of the frame or the print bed, which can directly affect layer flatness and thus the surface quality of the final print (Figure 12).

Figure 12.

Acceleration profile in the Z-axis during FFF printing without active vibration compensation.

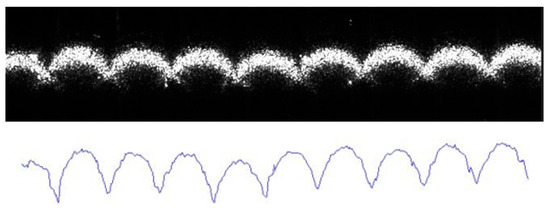

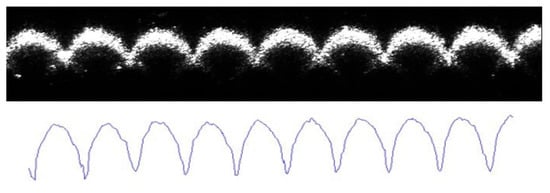

After enabling compensation mode, the vibrations in all axes are significantly dampened. The curves are smoother and more stable, indicating improved motion control and potentially higher print quality (Figure 13).

Figure 13.

Combined acceleration record in all axes (X, Y, Z) during printing with active vibration compensation.

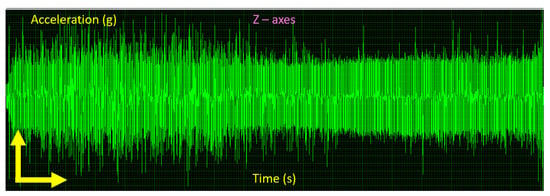

After activating the print head motion compensation, the signal in the X-axis improved significantly. The curve appeared smooth and without major deviations, demonstrating effective suppression of oscillations in this axis. Vibrations were substantially reduced, and the acceleration profile exhibited a stable characteristic, which positively affects the accuracy of material deposition (Figure 14).

Figure 14.

Acceleration profile in the X-axis during FFF printing with active vibration compensation of the printhead movement.

The Y-axis also showed a clear stabilization of the motion profile. The curve became smoother, the amplitude of fluctuations decreased, and the recorded acceleration pattern was consistent and predictable. This stability is particularly important during diagonal movements, where motions in the X and Y axes are combined (Figure 15).

Figure 15.

Acceleration profile in the Y-axis during FFF printing with active vibration compensation of the printhead movement.

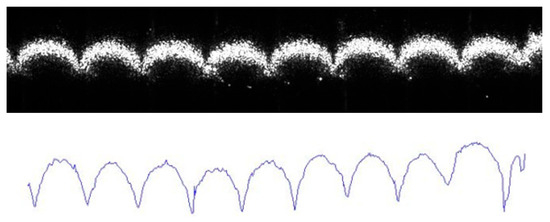

In the Z-axis, the highest level of improvement was achieved after activating the compensation. The curve was nearly completely flattened, without sudden changes, indicating a significant suppression of vertical vibrations. This enhances the likelihood of accurate layer height control, thereby reducing the risk of defects and improving surface quality (Figure 16).

Figure 16.

Acceleration profile in the Z-axis during FFF printing with active vibration compensation of the printhead movement.

3. Results

The surface profile of a 200 mm long sample was measured using a profilometer at three distinct points distributed evenly along the length of the sample, dividing the total distance into three equal segments (1/3, 2/3, 3/3). These points are referred to as point 1, point 2, and point 3, with each representing the center of the corresponding third of the surface (Figure 17). To ensure representative results, the measurements were repeated after rotating the sample by 45 degrees around its longitudinal axis. This procedure enabled the capture of potential anisotropic surface structures that may be oriented at different angles. Thus, a total of 9 measurements were performed on a single sample.

Figure 17.

Illustrative division of the sample for measurement.

During the measurement process, the sample was fixed in a prismatic vise, ensuring firm and accurate clamping to eliminate vibrations and unwanted movements, thereby enhancing measurement accuracy. The seam line, which typically forms at the start and end of extrusion in each layer during FFF printing, was deliberately excluded from the measurement zones. This feature is considered a technological imperfection and not representative of the overall printed surface. The length of the measured path using the laser profilometer was consistently set to 2.84 mm (2840 µm) for each measurement point and orientation. This ensured uniformity and comparability across all measured data.

The arithmetic mean deviation (Ra) was chosen as the representative parameter for surface texture evaluation. This selection is since Ra is one of the most used and widely accepted parameters for assessing surface finish quality. Moreover, in the context of comparative experiments, such as evaluating the impact of vibrations on the surface quality of 3D-printed parts, Ra is particularly suitable because it enables the quantitative comparison of surface roughness levels under different vibration conditions during printing.

Therefore, Ra was selected as the primary metrological characteristic for assessing print quality based on the selected regime (with or without vibration compensation). Figure 18 presents the specialized profilometry workstation. The laser profilometer consists of a support frame with vertically adjustable measuring head, a programmable sample translation system in the X and Y axes, a laser source, a lens, and a CMOS AVT Marlin 131B camera (Allied vision technologies GmBH, Stadtroda, Germany) equipped with a Tamron lens. The translation is driven by standard stepper motors with a maximum travel of 300 mm and a positioning accuracy of 2.5 µm per step. The system supports sample weights up to 8 kg, with a resolution of 0.02 mm/pixel, and includes dedicated software for data evaluation [26].

Figure 18.

Profilometer with the remaining hardware equipment.

As part of the data processing, the Apply Shape Filter function was used in the software, employing the principle of linear approximation. This filter was activated for each individual measurement, allowing automatic compensation for sample tilting or inclination caused by slight deviations in orientation or positioning during the measurement process.

The main reason for using this function was to eliminate systematic errors resulting from imperfect sample alignment, which could otherwise significantly distort the final surface quality analysis. Surface inclination relative to the reference plane can artificially increase or decrease the evaluated parameters and complicate the interpretation of surface morphology details.

As presented in Table 6, in the first section of the measurement (1/3 of the sample length), the surface roughness values (Ra) ranged from approximately 18.6 to 24.7 µm. The highest value was recorded the print without compensation (24.746 µm), as presented in Figure 19, indicating a significant influence of vibrations on surface quality. Upon activating print head motion compensation, the irregularities decreased to 23.022 µm, while the lowest value of 18.841 µm was achieved with print bed motion compensation, as presented in Figure 20. These results confirm the effectiveness of the implemented measures, particularly in stabilizing the bed motion, which yielded the most notable improvement in surface quality.

Table 6.

Comparison of surface roughness (Ra) of sample P1 in individual measurement sections under different vibration compensation modes.

Figure 19.

Selection from the sample measurement without compensation—parameter Ra (1/3)—measurement 2 (24.746 µm).

Figure 20.

Selection from the sample measurement with bed compensation—parameter Ra (1/3)—measurement 2 (18.841 µm).

In the second section of the sample (2/3), similar trends were observed, but with slightly higher variability. The highest Ra value (24.726 µm) was again measured in the absence of compensation. With print head compensation applied, surface irregularity decreased to 21.462 µm, and for print bed compensation, a value of 20.643 µm was achieved. In some measurements (e.g., without compensation—18.341 µm), surface quality appeared to be better, which may be attributed to local process fluctuations. Overall, however, the results confirm the beneficial effect of compensation in reducing surface roughness.

In the final section of the sample (3/3), the differences between individual compensation modes stabilized. Without compensation, Ra values remained higher (e.g., 21.426 µm), while with active print head motion compensation, the lowest value of 17.780 µm was obtained. In the print bed compensation mode, the results were similar to those of the head compensation (e.g., 18.769 µm). The average values across all three measurements show that both compensation modes positively impact surface quality and help reduce irregularities caused by vibrations during the printing process.

At the beginning of the measurement for sample P2, Ra values during printing without compensation ranged from 19.193 to 23.910 µm. Surprisingly, when print head motion compensation was applied, Ra increased to 25.308 µm, which may have been caused by resonance effects related to the specific geometry or interactions with the selected print parameters. The highest surface roughness was observed with print bed compensation (27.126 µm), suggesting that this compensation mode may not be suitable for the given profile or movement speeds. Contrary to expectations, no significant surface quality improvement was observed in this section; instead, a slight deterioration was noted. In the middle section of the sample, Ra values again differed between compensation modes. The lowest surface roughness was recorded using print head compensation (18.697 µm), indicating its positive effect under the given dynamic printing conditions. Without compensation, Ra values were around 22.2 µm, while print bed compensation did not yield a clear improvement (max. 24.195 µm). These results indicate that print head compensation is the most effective strategy for this section, contributing to reduced oscillations and a more uniform surface texture.

The final section of sample P2 shows a slight improvement in surface quality with both compensation modes. Without compensation, the highest Ra value reached 24.633 µm (measurement 1), as presented in Figure 21, which also corresponds with the visually observed surface pattern. Print head compensation reduced this value to 20.661 µm, while bed compensation lowered it slightly further to 22.212 µm (also measurement 1), as presented in Figure 22. Overall, the results show a stabilization of surface quality with reduced variability between individual measurements, confirming the positive impact of active compensation on the prints dynamic behavior.

Figure 21.

Selection from the sample measurement without compensation—parameter Ra (3/3)—measurement 1 (24.633 µm).

Figure 22.

Selection from the sample measurement with bed compensation—parameter Ra (3/3)—measurement 1 (22.212 µm).

The Ra value of 27.126 µm (measurement 2), as presented in Table 7, under bed-leveling compensation was identified because of PETG material instability due to elevated extrusion temperature and moisture exposure. PETG is hygroscopic, and during Test P2, it was exposed to approximately 50% humidity without prior drying. Microscopic analysis (Figure 8c) revealed vapor-induced microdefects, supporting the hypothesis of material degradation independent of compensation.

Table 7.

Comparison of surface roughness (Ra) of sample P2 in individual measurement sections under different vibration compensation modes.

In the first third of the P3 sample, the Ra values were relatively consistent across all modes. The lowest value (18.186 µm) was achieved with printhead motion compensation, indicating a stabilized movement profile in this area. The mode without compensation yielded values around 19.5–21.1 µm, while bed motion compensation produced slightly higher values, up to 22.7 µm. These results suggest that active compensation of the printhead motion may slightly improve surface quality in the initial section, although the differences are not significant, indicating relatively stable printing conditions even without intervention.

The middle section of the P3 sample confirms continued process stability. The lowest Ra values were recorded with bed compensation (e.g., 18.863 µm), while the results without compensation were within a comparable range (e.g., 19.643 µm—as shown in measurement 3, Figure 23). Compensation of the printhead resulted in a slight increase in Ra (e.g., 21.456 µm), as presented in Figure 24.

Figure 23.

Selection from the sample measurement without compensation—parameter Ra (2/3)—measurement 3 (19.643 µm).

Figure 24.

Selection from the sample measurement with head compensation—parameter Ra (2/3)—measurement 3 (21.456 µm).

This section does not reveal a clear benefit of one compensation mode over the other; rather, a balanced performance is observed across all modes. Possible variations may be influenced by print speed settings or minor deviations in the geometric configuration of the layers.

In the final third of the sample, greater variability in Ra values was observed, particularly with printhead compensation (e.g., 26.772 µm). This anomaly may result from resonance effects or a mismatch between the compensation algorithm and the motion trajectory in this section. The other modes (without compensation and with bed compensation as presented in Table 8) showed more stable values (ranging from 19.5 to 21.9 µm), suggesting that in this case, printhead compensation was not effective. The results indicate that the effectiveness of compensation may depend on the specific motion profile and part geometry.

Table 8.

Comparison of surface roughness (Ra) of sample P3 in individual measurement sections under different vibration compensation modes.

In the first third of sample P4, the surface roughness values (Ra) were relatively consistent across all measurement modes. The values ranged approximately from 19.4 to 23.6 µm. Slightly lower averages were recorded in the measurement without compensation, whereas higher values appeared with bed motion compensation (e.g., 23.597 µm). This section did not reveal a significant positive effect of any specific mode, which may indicate that vibrations do not play a major role in the initial layers or are already well dampened by the printer’s mechanical configuration.

In the middle section of the sample, a slight increase in variability between the modes was observed. The highest Ra values were again measured with bed motion compensation (up to 24.613 µm), which suggests a possible deterioration in surface quality due to overcompensation. Conversely, head motion compensation yielded slightly better results, with values dropping below 20 µm (e.g., 19.750 µm). From the perspective of balancing stability and surface quality, this mode appears to be more effective during this stage of printing.

In the final third of sample P4, the most significant differences between the modes were clearly observed. The measurement without compensation showed the highest Ra value in the entire dataset (25.565 µm, as illustrated in Figure 25), clearly indicating the negative impact of uncontrolled vibrations toward the end of the print. In contrast, bed motion compensation recorded the lowest value (18.244 µm, as illustrated in Figure 26).

Figure 25.

Selection from the sample measurement without compensation—parameter Ra (3/3)—measurement 1 (25.565 µm).

Figure 26.

Selection from the sample measurement with bed compensation—parameter Ra (3/3)—measurement 1 (18.244 µm).

This contrast, as detailed in Table 9, suggests that active bed motion compensation can be highly effective in suppressing vibrations and improving surface quality during the final phase of printing.

Table 9.

Comparison of surface roughness (Ra) of sample P4 in individual measurement sections under different vibration compensation modes.

In the initial third of sample P5, a higher variability of Ra values between the different modes can be observed. In the measurement without compensation, values ranged from 18.88 to 23.39 µm, which represents a slightly lower average compared to the modes with compensation. Both printhead and bed motion compensation showed increased Ra values, which may indicate an undesired effect of the vibration compensation algorithm during the initial layers. This outcome may be related to interference between the compensation control system and the unstable dynamic behavior at the beginning of the print.

The middle section of sample P5 shows consistent behavior across all modes. The lowest Ra value was measured without compensation (18.717 µm, as illustrated in Figure 27), suggesting that in this particular case, the mechanical system may have been sufficiently stable even without assistance. Printhead motion compensation slightly increased the surface roughness (20.521 µm, as illustrated in Figure 28), while bed motion compensation showed similarly high values (up to 24.871 µm). This section suggests that active correction may sometimes lead to undesired oscillations if not optimally configured.

Figure 27.

Selection from the sample measurement without compensation—parameter Ra (2/3)—measurement 1 (18.717 µm).

Figure 28.

Selection from the sample measurement with head compensation—parameter Ra (2/3)—measurement 1 (20.521 µm).

In the final third of the sample also detailed in Table 10, the significance of active compensation became apparent. Ra values under head and bed compensation were noticeably lower (around 18.9–21.8 µm) compared to the mode without compensation, where the highest value reached 24.169 µm. These results confirm the effectiveness of the compensation mechanisms in the final printing stage, when motion system vibrations are often the most pronounced. Optimized correction has a positive impact on the final surface quality, especially during more dynamic structural movements.

Table 10.

Comparison of surface roughness (Ra) of sample P5 in individual measurement sections under different vibration compensation modes.

Test Under Optimized Printing Settings

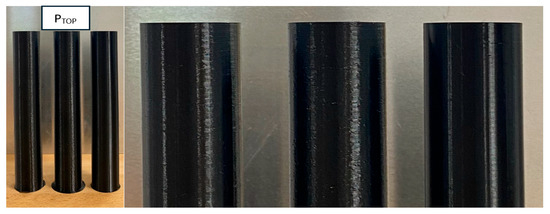

Testing was also carried out under optimized process parameters (marked as PTOP, Table 11), which were established based on previous analysis as the most suitable for ensuring stable printing performance and achieving high-quality printouts. After applying these parameters, a separate series of tests was conducted in two modes: with active vibration compensation and without it, using the same methodology as in previous cases.

Table 11.

Parameters used for PTOP samples.

In the first third of the PTOP sample, as presented in Figure 29, the Ra surface roughness values are uniform, ranging from 19.10 to 20.98 µm. The lowest values were recorded with print head motion compensation (e.g., 19.672 µm), indicating that active correction of the print head can contribute to improved surface quality even in the initial stages of printing. The values without compensation and with bed compensation were slightly higher, though the differences are not significant, suggesting a relatively stable printing process in this segment.

Figure 29.

Experimental samples for testing—top version.

In the middle section of the sample, Ra values were observed in the range of approximately 19.4 to 21.1 µm. Again, the positive effect of head compensation is evident, with Ra values remaining lower and more consistent (around 19.4 to 20.5 µm). Bed compensation yielded slightly higher values, though still better than the no-compensation mode. This section highlights that correction algorithms can effectively reduce vibrations during more stable parts of the printing process.

In the final third of the sample, improvements with compensation modes are clearly noticeable. Ra values with both head and bed compensation are lower (approximately 19.1 to 20.9 µm) compared to the uncompensated mode, which reached up to 20.8 µm. This confirms that active vibration correction is especially important during the final phase of the printing process, when mechanical vibrations and the dynamic motion of the system can have the most impact on surface quality. The Ra results of all three sections are presented in Table 12 and in the subsequent Figure 30, Figure 31 and Figure 32.

Table 12.

Comparison of surface roughness (Ra) of sample PTOP in individual measurement sections under different vibration compensation modes.

Figure 30.

Selection from the measurement of the sample without compensation—parameter Ra (3/3)—measurement 1 (20.150 µm).

Figure 31.

Selection from the measurement of the sample with head compensation—parameter Ra (3/3)—measurement 1 (19.447 µm).

Figure 32.

Selection from the measurement of the sample with bed compensation—parameter Ra (3/3)—measurement 1 (20.827 µm).

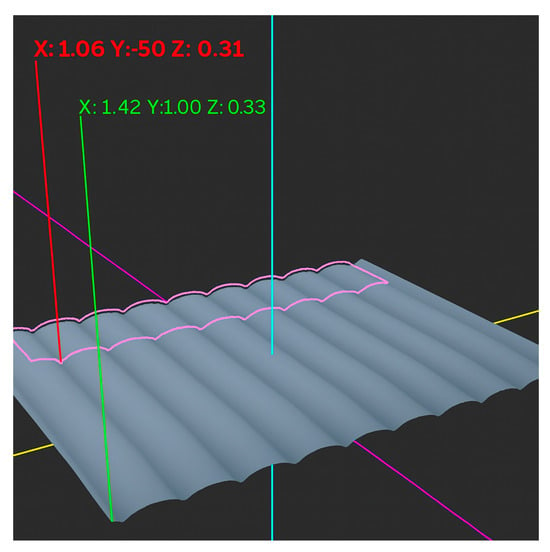

For a detailed surface quality analysis of the sample, 3D visualization of the profilometric data was performed using specialized software. This program enables the rendering and quantification of the surface microgeometry at high resolution, considering various parameters such as the primary profile (Ra). The resulting 3D surface map provides a comprehensive overview of surface irregularities, defects, and the overall homogeneity of the printed layers. Such visualization helps to better understand the impact of individual print parameters and compensation algorithms on the final product quality.

When analyzing the 3D surface model of the sample obtained from the profilometer, it is important to identify the minimum and maximum coordinate values in the X, Y, and Z axes. The X and Y coordinates represent the distribution of measured points in the sample’s plane, with the range of these values defining the size of the analyzed area. The Z axis displays the vertical deviations of the surface, representing the peaks and troughs of the sample surface, as presented in Figure 33.

Figure 33.

Surface visualization of the sample using a profilometer.

4. Discussion

In general, it can be concluded that the accuracy and quality of components produced by FFF technology are significantly influenced by the complex interaction between the structural elements of the 3D printer, printing parameters, and both internal and external vibrations. The experimental study confirmed that oscillations occurring during the movement of the print head or the build platform can notably affect the surface structure of printed parts. The presence of vibrations manifested primarily in the form of fine surface irregularities, which were clearly reflected in the measured surface roughness (Ra) values of the samples. In this experiment, a vertically oriented cylinder with a height of 200 mm proved to be an appropriate test model. This geometry allowed for improved detection of vertical deviations along the Z-axis caused by vibrations, as well as transverse deformations resulting from dynamic movement along the X and Y axes. The selected model represents a typical structure where resonance effects are more pronounced, making it particularly suitable for analyzing the influence of kinematic vibrations on final print quality.

The ADXL345 accelerometer demonstrated good capability in capturing detailed acceleration data along all three axes. Specific frequency patterns corresponding to the characteristic speeds of stepper motor movements were identified during measurements. The collected data were subsequently used for active vibration suppression through printer firmware via input shaping. This intervention had a measurable impact on surface quality, as demonstrated especially by comparing test samples P1 through P5 and PTOP. The results clearly indicate that activating input shaping, whether applied to the print head or to the build platform, significantly reduces the amplitude of mechanical oscillations. These improvements were quantified by surface roughness measurements (Ra) taken at three locations along the printed models to ensure consistent evaluation. When comparing the modes without control, with print head control, and with bed control, the most positive effect was observed in the bed compensation mode, particularly in the lower sections of the print, where residual vibrations tend to accumulate. From a structural point of view, the primary source of generated vibrations can be attributed to the motion mechanism of the Creality Ender 3 V2 printer. This printer uses a kinematic system in which the print head moves along the X and Z axes while the build platform moves along the Y-axis. Although this design simplifies construction, it introduces considerable inertial forces that are transferred to the frame and ultimately affect the printing process. These forces result in micro-deformations within the printed object, which are difficult to eliminate without proper compensation. In terms of print parameters, both speed and acceleration play a critical role. Although high values reduce printing time, they simultaneously increase vibration amplitude. The study confirmed that optimizing these parameters in combination with input shaping provides a synergistic effect in reducing unwanted oscillations. A major advantage is that such improvements can be achieved without requiring mechanical modifications to the printer itself, enabling software-based upgrades for existing devices. Another factor affecting surface quality was the filament’s moisture content. In samples P1 through P5, higher humidity led to increased microporosity and surface irregularities. Moist filament may produce vapor bubbles during extrusion, resulting in uneven material flow and rougher surfaces. This effect is particularly significant with fine layer heights, where micropores are more problematic. For future studies, it is recommended to include material humidity monitoring through sensors and to pre-condition the filament by drying, as was done in the preparation of sample PTOP.

One limitation of this study is the restricted scope of input shaping techniques. Some high-frequency vibrations caused by structural resonances in the printer frame or by improperly tensioned belts were not fully eliminated by this method. Therefore, in the long term, it is advisable to combine input shaping with passive vibration reduction strategies, such as anti-vibration pads, increased frame mass, or improved linear guide arrangements. Another important finding is that surface quality differences in the lower layers (first 20 to 30 mm) were less pronounced, likely due to stronger adhesion to the print bed and lower movement acceleration. The most significant deviations were observed in the middle and upper sections of the printed models, where mechanical resonance effects tend to accumulate. This experimental study clearly demonstrates that vibrations are a key factor influencing FFF print quality. Their active control through input shaping represents an effective and broadly applicable method, although it has certain limitations that must be addressed through complementary approaches.

Recommendations for Further Research

Considering the complexity of dynamic phenomena and their impact on product quality in the FFF process, it is essential to continuously improve methods for detecting and eliminating unwanted vibrations. The results of this study confirmed that the integration of sensor technologies and the optimization of control algorithms hold significant potential for enhancing the accuracy and reliability of printing processes.

Nevertheless, from both technical and material perspectives, several challenges remain that require a multidisciplinary approach and continued research efforts. The following recommendations outline key directions for the further development and implementation of innovative solutions in the areas of active and passive vibration control, print parameter optimization, and material preparation:

- Combination of active and passive measures—to improve vibration reduction efficiency, it is advisable to combine software-based motion control with mechanical anti-vibration elements such as damping pads, reinforced frames, or optimized placement of linear guides.

- Material control and preparation—implementing sensors for real-time monitoring of filament moisture during the printing process, combined with automated material drying processes, could significantly improve surface quality and consistency of printed parts.

- Optimization of print parameters regarding machine dynamics—research should continue in identifying ideal movement speeds and accelerations of the print head and build platform that minimize unwanted oscillations without significantly increasing print time.

- Expansion of test models—in addition to vertical cylinders, more complex geometries should be used to more accurately simulate practical applications and dynamic effects across different areas of printing.

- Design innovations in motion systems—the development of new mechanical concepts with lower inertia and better vibration absorption may result in substantial improvements in print quality without the need for complex software interventions.

- Implementation and advancement of adaptive control algorithms—future systems should utilize machine learning and adaptive algorithms capable of evaluating and compensating for dynamic deviations in the printing process in real time.

5. Conclusions