Flexural Behavior of Reinforced Concrete Slabs Strengthened with High Elastic Modulus Polyurea

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

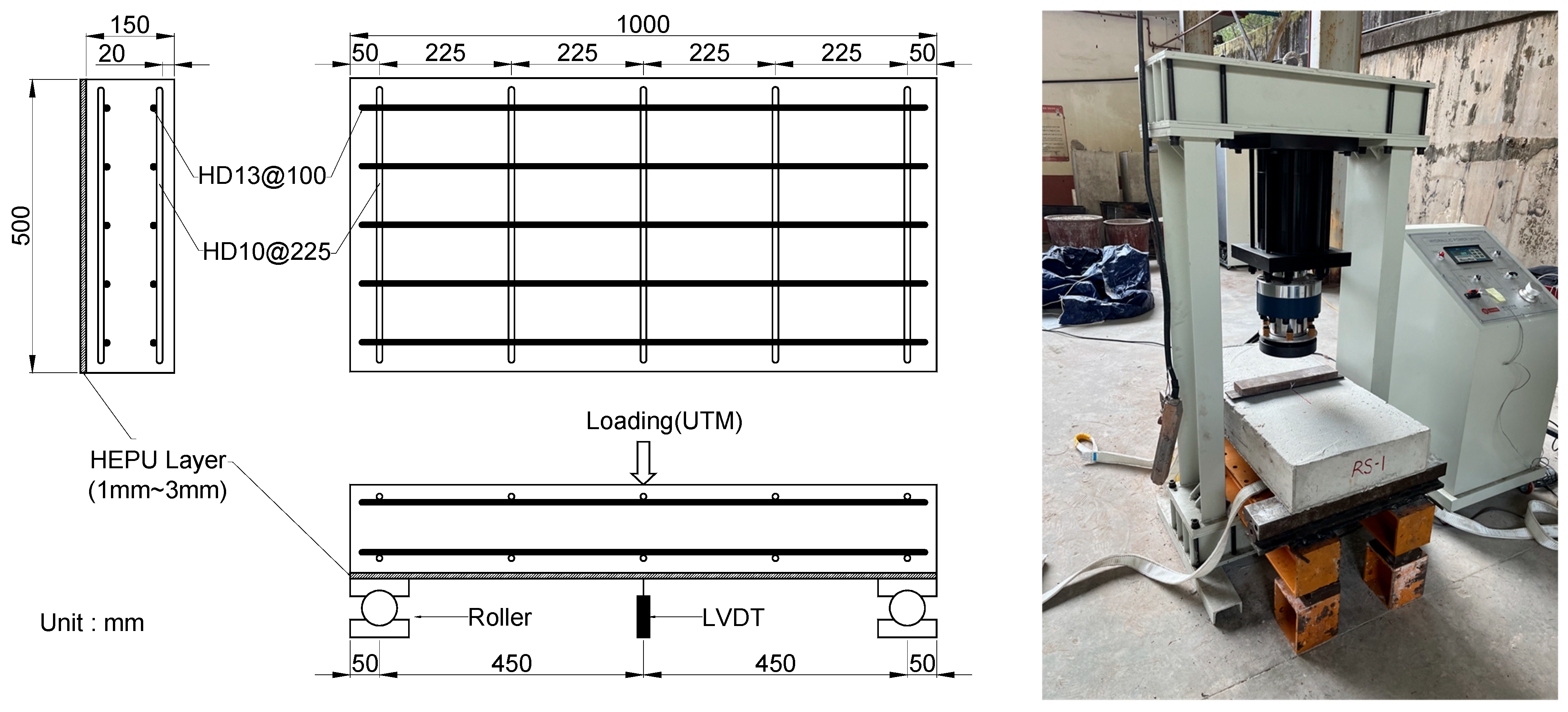

2.2. Specimen Design

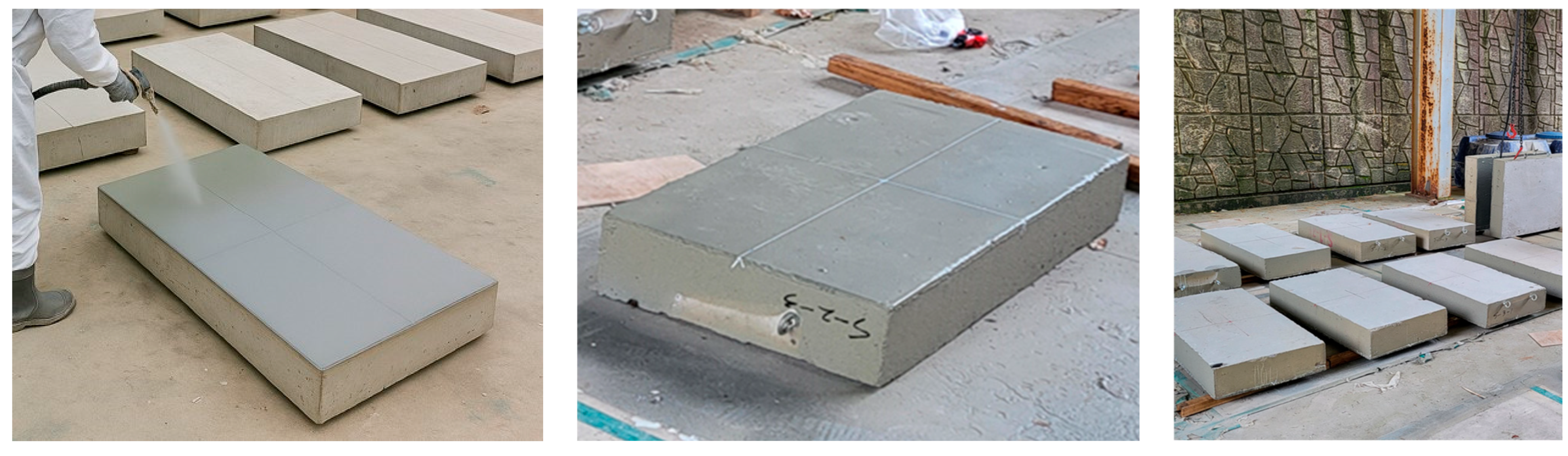

2.3. Specimen Fabrication and Test Method

3. Test Results of Strengthened Slabs

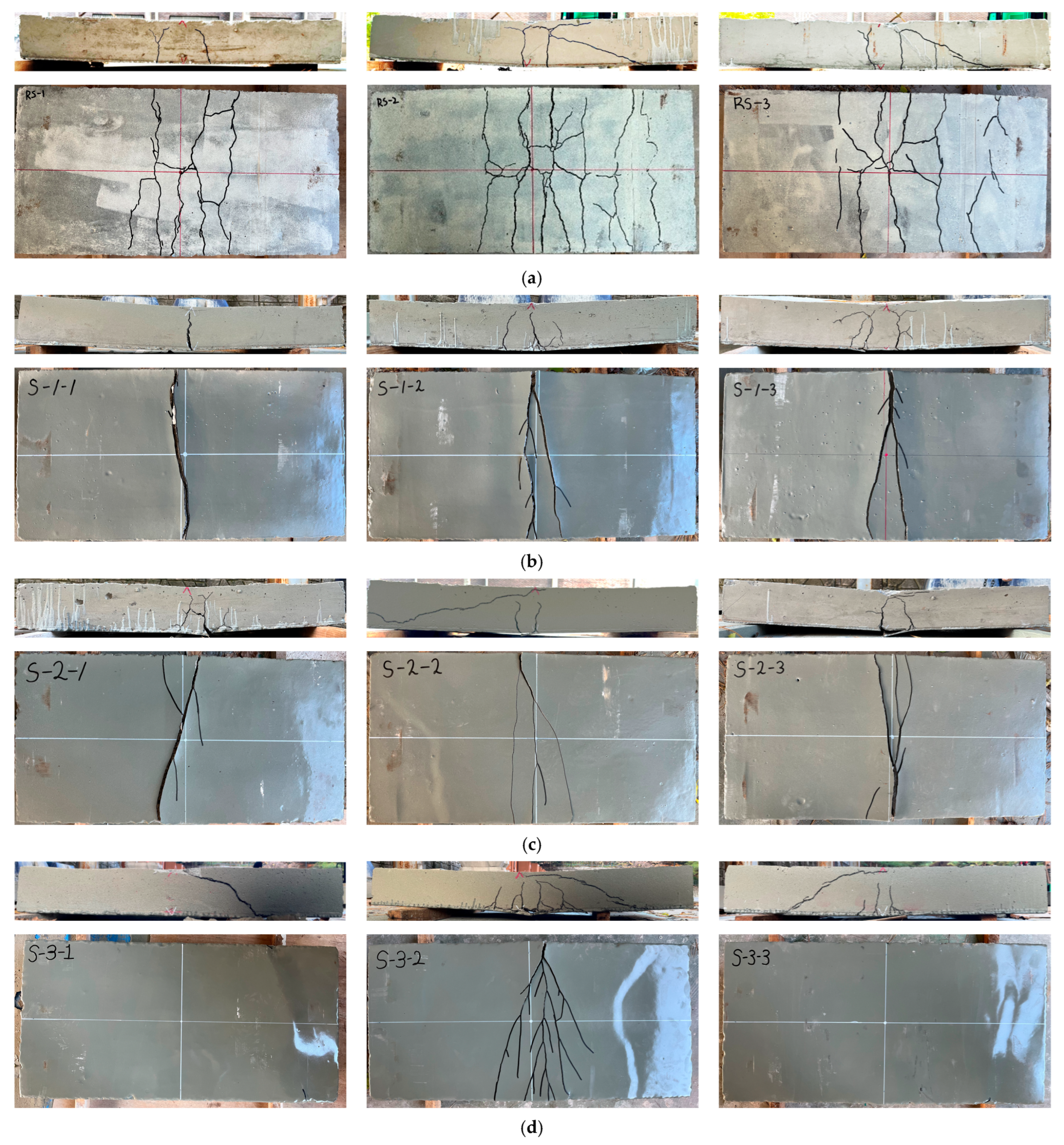

3.1. Crack Patterns and Failure Modes

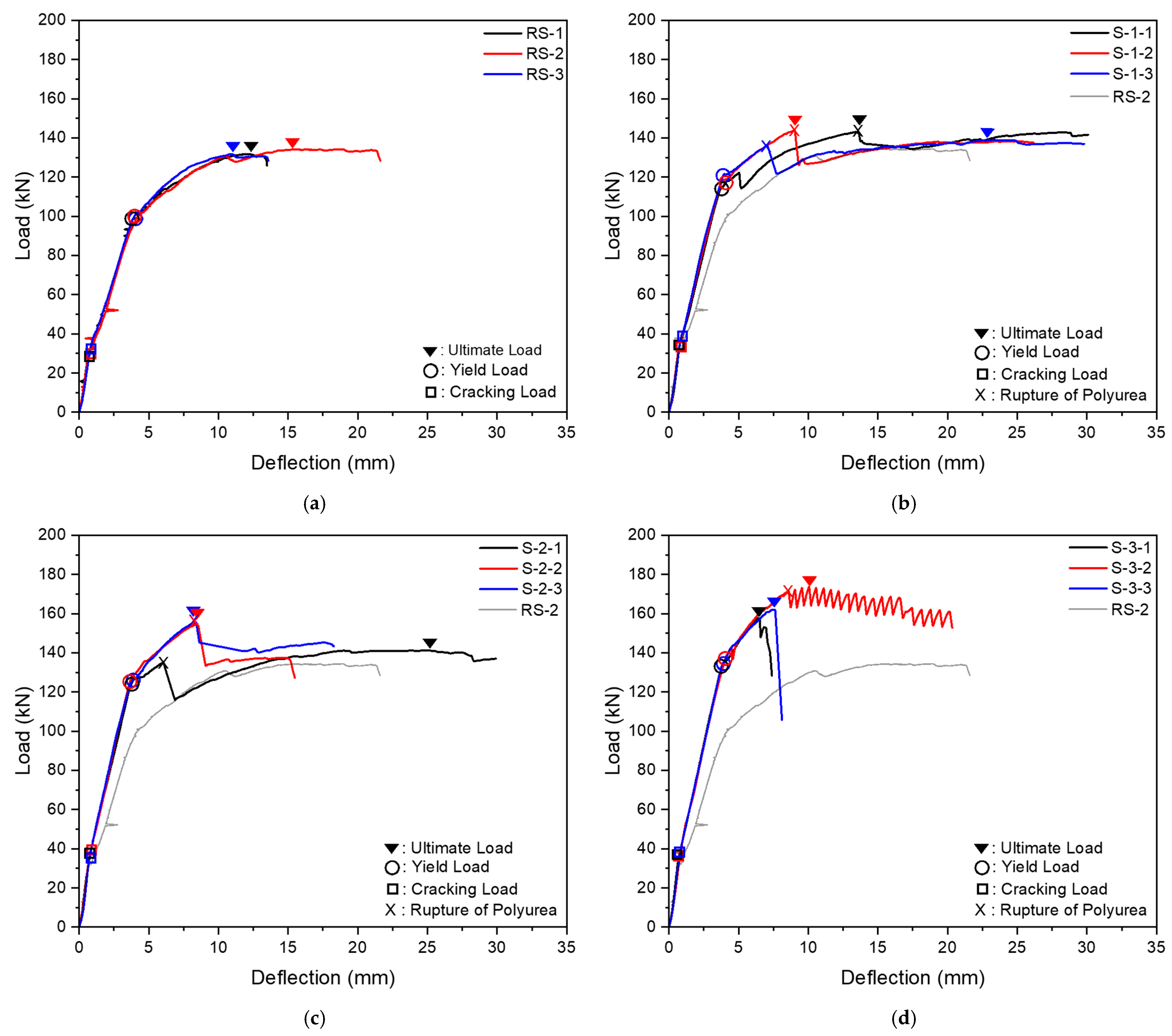

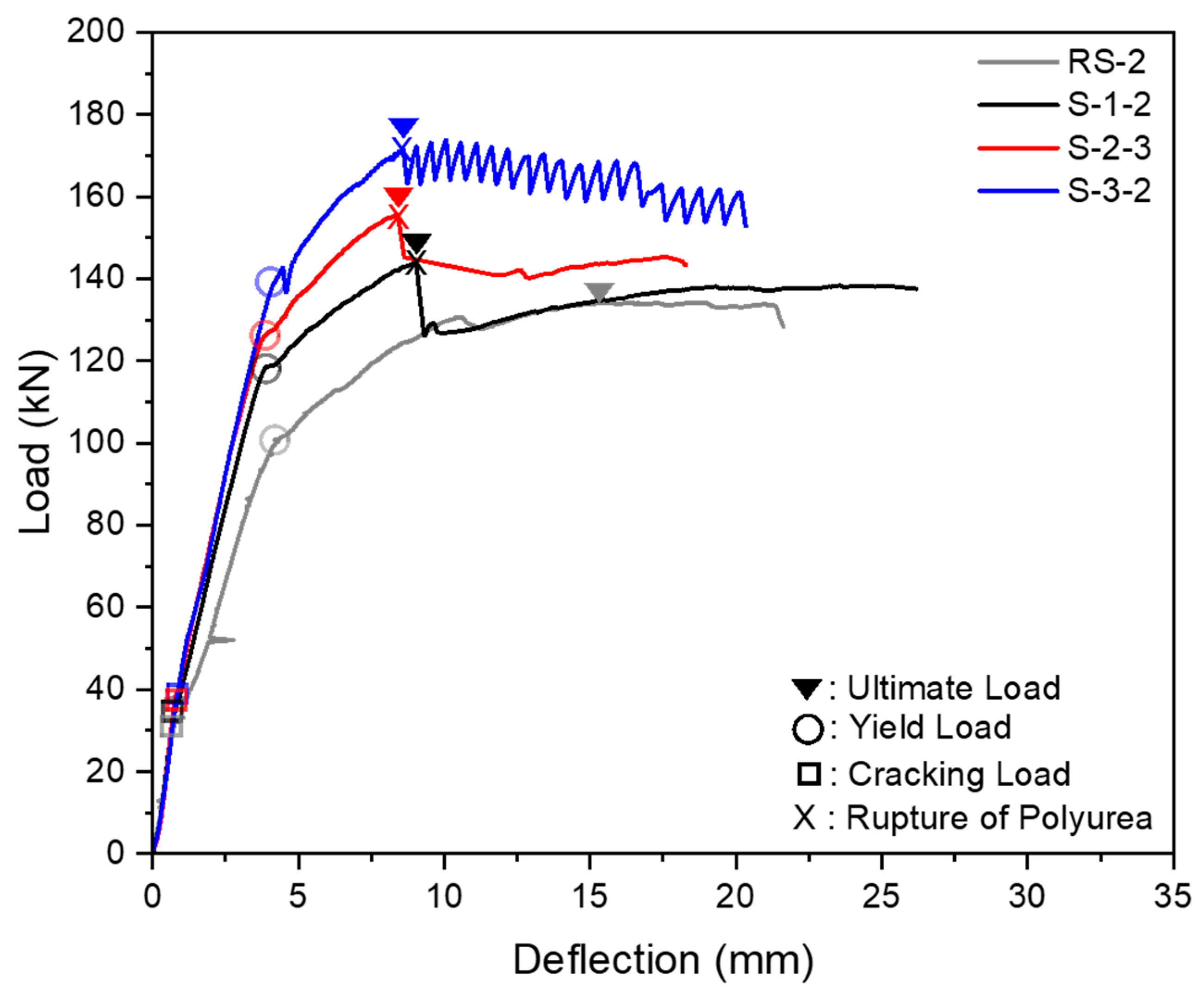

3.2. Load–Deflection Curves

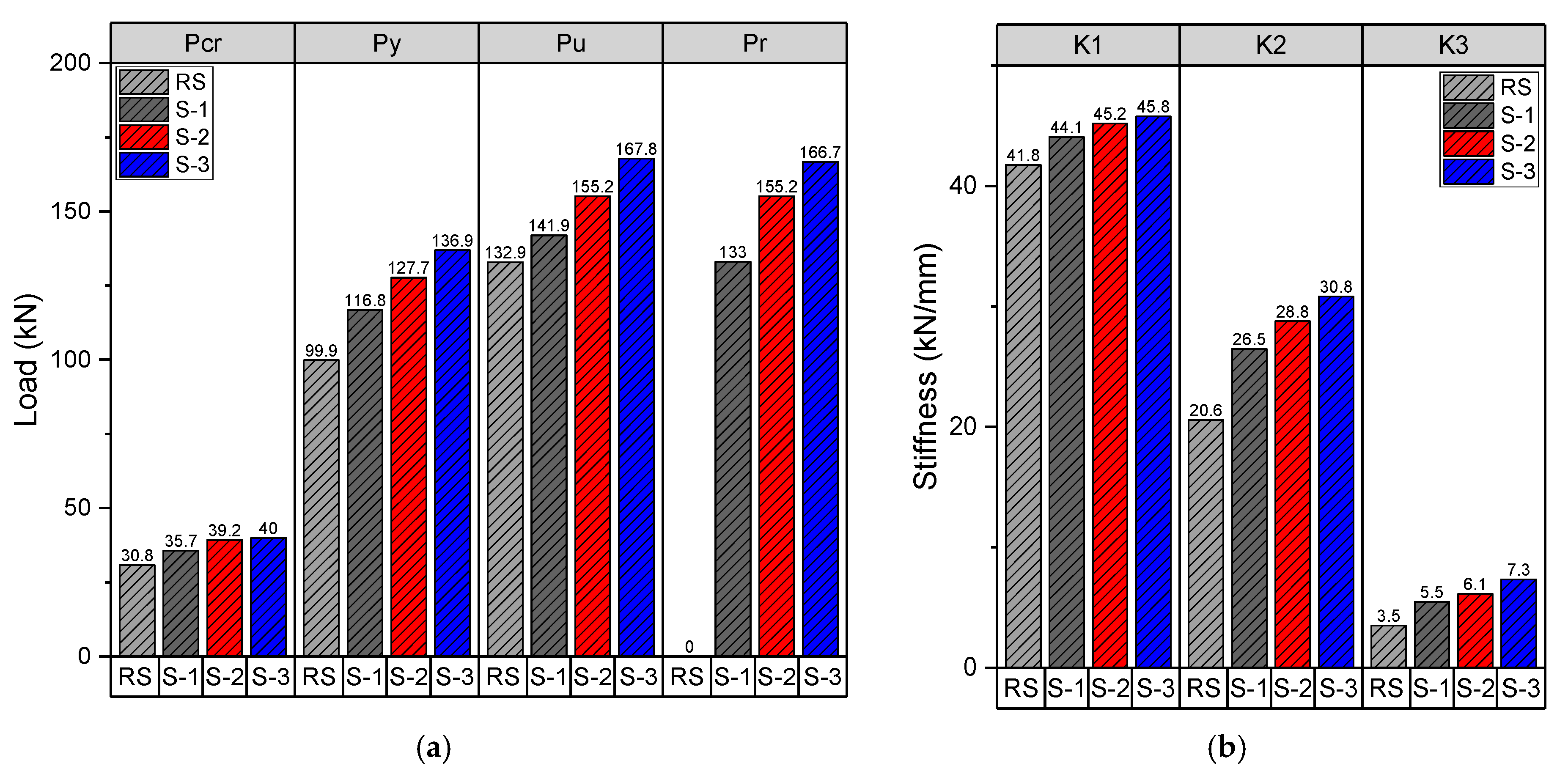

4. Influence of HEPU Coating Thickness on Strengthening Performance

5. Conclusions

- (1)

- The HEPU coating method significantly enhanced the flexural strength indicators of the slab, including cracking strength, yield strength, and ultimate strength, while also improving post-cracking flexural stiffness.

- (2)

- Although the strengthening effect of HEPU was not evident in the pre-cracking stage, observed crack patterns suggest that it may contribute to reducing crack propagation.

- (3)

- In the post-cracking to pre-yielding stage, HEPU strengthening increased the yield load of the slab by 17–37% compared to the unstrengthened reference slab and improved flexural stiffness by 28–49%. Additionally, strengthening performance was found to increase proportionally with HEPU coating thickness.

- (4)

- The maximum load of HEPU-strengthened slabs increased by 6–26% compared to the unstrengthened slab and improved flexural stiffness by 56–110%. Additionally, strengthening performance was found to increase proportionally with HEPU coating thickness.

- (5)

- While HEPU-strengthened slabs experienced a reduction in load resistance following HEPU rupture, they ultimately exhibited ductile failure behavior.

- (6)

- The enhancement in maximum flexural strength achieved with HEPU exceeded that of conventional polyurea strengthening methods, demonstrating HEPU’s effectiveness in improving the flexural performance of slabs.

- (7)

- Based on the experimental findings, applying HEPU, which has relatively low elongation, may not be suitable for enhancing the ultimate strength of slabs requiring high ductility. However, given its crack control capabilities and significant strengthening effect under service loads, HEPU may serve as an effective reinforcement technique for deteriorated slabs that have experienced a decline in structural performance and can no longer sustain service loads.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.F.; Liu, T.; Oehlers, D.J. Fundamental principles that govern retrofitting of reinforced concrete columns by steel and FRP jacketing. Adv. Struct. Eng. 2016, 9, 507–532. [Google Scholar] [CrossRef]

- Adsam Gideon, D.S.; Alagusundaramoorthy, P. Flexural retrofit of RC beams using CFRP laminates. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 14th International Conference on Concrete Engineering and Technology, Kuala Lumpur, Malaysia, 8–9 August 2018; IOP Publishing: Bristol, UK, 2018; Volume 431, p. 072006. [Google Scholar]

- Brena, S.F.; Bramblett, R.M.; Wood, S.L.; Kreger, M.E. Increasing flexural capacity of reinforced concrete beams using carbon fiber-reinforced polymer composites. ACI Struct. J. 2003, 100, 36–46. [Google Scholar] [CrossRef]

- Brena, S.F.; Macri, B.M. Effect of carbon-fiber-reinforced polymer laminate configuration on the behavior of strengthened reinforced concrete beams. J. Compos. Constr. 2004, 8, 270–278. [Google Scholar] [CrossRef]

- Spadea, G.; Bencardino, F.; Swamy, R.N. Structural behavior of composite RC beams with externally bonded CFRP. J. Compos. Constr. 1998, 2, 132–137. [Google Scholar] [CrossRef]

- Carlos, T.B.; Rodrigues, J.P.C.; de Lima, R.C.A.; Dhima, D. Experimental analysis on flexural behaviour of RC beams strengthened with CFRP laminates and under fire conditions. Compos. Struct. 2018, 189, 516–528. [Google Scholar] [CrossRef]

- Habib, A.; Barakat, S.; Al-Toubat, S.; Junaid, M.T.; Maalej, M. Developing machine learning models for identifying the failure potential of fire-exposed FRP-strengthened concrete beams. Arab. J. Sci. Eng. 2024, 50, 8475–8490. [Google Scholar] [CrossRef]

- Kang, S.T.; Kim, J.K. The relation between fiber orientation and tensile behavior in an ultra high performance fiber reinforced cementitious composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Li, Q.H.; Xu, S.L. Experimental investigation and analysis on flexural performance of functionally graded composite beam crack-controlled by ultrahigh toughness cementitious composites. Sci. China Ser. E Technol. Sci. 2009, 52, 1648–1664. [Google Scholar] [CrossRef]

- Deng, M.K.; Pan, J.J.; Liang, X.W. Uniaxial compressive test of high ductile fiber-reinforced concrete and damage constitutive model. Adv. Civ. Eng. 2018, 2018, 4308084. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Practical design criteria for saturated pseudo strain hardening behavior in ECC. J. Adv. Concr. Technol. 2006, 4, 59–78. [Google Scholar] [CrossRef]

- Fisher, G.; Li, V.C. Influence of matrix ductility on the tension-stiffening behavior of steel reinforced ECC. ACI Struct. J. 2002, 99, 104–111. [Google Scholar]

- Wang, C.; Fu, P.; Liu, Z.L.; Wen, T.; Zhu, Y.Y.; Long, Y.H.; Jiang, J.H. Study of the durability damage of ultrahigh toughness fiber concrete based on grayscale prediction and the Weibull model. Buildings 2022, 12, 746. [Google Scholar] [CrossRef]

- Zheng, D.D.; Kou, J.L.; Wei, H.H.; Zhang, T.; Guo, H.C. Experimental study on flexural behavior of damaged concrete beams strengthened with high ductility concrete under repeated load. Eng. Struct. 2023, 274, 115203. [Google Scholar] [CrossRef]

- Wang, J.Y.; Wan, C.L.; Shen, L.H.; Zeng, Q.; Ji, X.H. Compressive behavior of masonry columns confined with basalt textile-reinforced concrete. J. Build. Eng. 2023, 75, 107019. [Google Scholar] [CrossRef]

- Wan, C.L.; Wang, J.Y.; Zeng, Q.; Shen, L.H.; Liu, C.B. Quasi-static cyclic loading tests of RAC brick masonry walls strengthened by basalt textile reinforced concrete. Compos. Struct. 2023, 321, 117238. [Google Scholar] [CrossRef]

- Tang, J.P.; Feng, R.; Quach, W.M.; Zeng, J.J. Evaluation of flexural performance on corrosion-damaged RC beams retrofitted with UHPFRCC under marine exposure. Eng. Struct. 2025, 333, 120193. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Fischer, G.; Lim, Y.M.; Li, V.C. Mechanical performance of sprayed engineered cementitious composite using wet-mix shotcreting process for repair applications. ACI Mater. J. 2004, 101, 42–49. [Google Scholar] [CrossRef]

- Wang, J.Y.; Yu, D.; Mu, F.J.; Ji, X.H.; Peng, Y. Toughening mechanism of directional fabric woven net and/or non-directional short-cut fiber-reinforced sprayed cement mortar thin-plates. Materials 2023, 16, 4418. [Google Scholar] [CrossRef]

- Awani, O.; El-Maaddawy, T.; Ismail, N. Fabric-reinforced cementitious matrix: A promising strengthening technique for concrete structures. Constr. Build. Mater. 2017, 132, 94–111. [Google Scholar] [CrossRef]

- Ombres, L. Flexural analysis of reinforced concrete beams strengthened with a cement based high strength composite material. Compos. Struct. 2012, 94, 143–155. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P.; Poggi, C. Long-term behavior of PBO FRCM and comparison with other inorganic-matrix composites. Materials 2022, 15, 3281. [Google Scholar] [CrossRef] [PubMed]

- Asghari, H.; Omeman, Z.; Noel, M.; Hajiloo, H. Tensile properties of carbon fabric-reinforced cementitious matrix (FRCM) at high temperatures. Structures 2023, 55, 85–96. [Google Scholar] [CrossRef]

- Mercedes, L.; Castellazzi, G.; Bernat-Maso, E.; Gil, L. Matrix and fabric contribution on the tensile behaviour of fabric reinforced cementitious matrix composites. Constr. Build. Mater. 2023, 363, 129693. [Google Scholar] [CrossRef]

- Ombres, L. Structural performances of PBO FRCM-strengthened RC beams. Proc. Inst. Civ. Eng.—Struct. Build. 2011, 164, 265–272. [Google Scholar] [CrossRef]

- Aljazaeri, Z.R.; Al-Jaberi, Z. Numerical study on flexural behavior of concrete beams strengthened with fiber reinforced cementitious matrix considering different concrete compressive strength and steel reinforcement ratio. Int. J. Eng. 2021, 34, 793–802. [Google Scholar] [CrossRef]

- Mandor, A.; El Refai, A. Flexural response of reinforced concrete continuous beams strengthened with fiber-reinforced cementitious matrix (FRCM). Eng. Struct. 2022, 251, 113557. [Google Scholar] [CrossRef]

- Feng, R.; Liu, Y.; Zhu, J.H.; Xing, F. Flexural behaviour of C-FRCM strengthened corroded RC continuous beams. Compos. Struct. 2020, 245, 112200. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Zhu, J.H.; Ueda, T.; Guo, G.P.; Xing, F. Combined impressed current cathodic protection and FRCM strengthening for corrosion-prone concrete structures. J. Compos. Constr. 2019, 23, 04019021. [Google Scholar] [CrossRef]

- Liu, P.; Tang, J.P.; Feng, R.; Fan, Y.; Zhu, J.H. Tensile behavior and flexural performance of polarized CFRCM-strengthened corroded RC continuous beams. Structures 2025, 76, 109022. [Google Scholar] [CrossRef]

- Su, M.N.; Zeng, C.Q.; Li, W.Q.; Zhu, J.H.; Lin, W.H.; Ueda, T.; Xing, F. Flexural performance of corroded continuous RC beams rehabilitated by ICCP-SS. Compos. Struct. 2020, 232, 111556. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Liang, H.S.; Zhu, J.H.; Ueda, T.; Xing, F. Fatigue behavior and design of corroded reinforced concrete beams intervened by ICCP-SS. Compos. Struct. 2021, 261, 113295. [Google Scholar] [CrossRef]

- Feng, R.; Tang, J.P.; Wang, F.Y.; Wang, S.; Zeng, J.J.; Zhu, J.H. Experiments on shear behavior of reinforced concrete continuous beams strengthened by C-FRCM. Struct. Concr. 2024, 25, 1052–1075. [Google Scholar] [CrossRef]

- Shojaei, B.; Najafi, M.; Yazdanbakhsh, A.; Abtahi, M.; Zhang, C. A review on the applications of polyurea in the construction industry. Polym. Adv. Technol. 2021, 32, 2797–2812. [Google Scholar] [CrossRef]

- Davidson, J.; Porter, J.R.; Dinan, R.; Hammons, M.; Connell, J.D. Explosive testing of polymer retrofit masonry walls. J. Perform. Constr. Facil. 2004, 18, 100–106. [Google Scholar] [CrossRef]

- Santos, A.P.; Chiquito, M.; Castedo, R.; López, L.; Gomes, G.; Mota, C.; Fangueiro, R.; Mingote, J. Experimental and numerical study of polyurea coating systems for blast mitigation of concrete masonry walls. Eng. Struct. 2023, 284, 116006. [Google Scholar] [CrossRef]

- Yue, Z.Y.; Zhou, J.N.; Wang, P.; Kong, X.-L.; Zhou, Y.-Z.; Chen, Y.-S.; Song, X.-Y.; Feng, F. Experimental study on the anti-blast performance of polyurea reinforced concrete arch structures. J. Build. Eng. 2023, 77, 107483. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, B.; Zhang, B.; Zheng, Q.; Zhou, J.; Jin, F.; Fan, H. Polyurea coating for foamed concrete panel: An efficient way to resist explosion. Def. Technol. 2020, 16, 136–149. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, R.; Wang, X.; Lyu, P.; Ju, J.; Gao, F.; Yan, S. Study of blast mitigation performance and fracture mechanism of polyurea under contact explosion. Polymers 2022, 14, 3458. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Wu, J.; Jia, P.; Li, S.; Yan, Q.; Xu, S. Experimental and numerical investigation of the polyurea-coated ultra-high-performance concrete (UHPC) column under lateral impact loading. Int. J. Struct. Stab. Dyn. 2022, 22, 2250037. [Google Scholar] [CrossRef]

- Ji, L.; Wang, P.; Cai, Y.; Shang, W.; Zu, X. Blast resistance of 240 mm building wall coated with polyurea elastomer. Materials 2022, 15, 850. [Google Scholar] [CrossRef] [PubMed]

- Gu, M.; Wang, H.; Yu, A.; Wang, H.; Ling, X.; Chen, G. Research on dynamic behavior and gas explosion resistance of polyurea. Mater. Today Commun. 2022, 33, 104826. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Fang, Q.; Chen, W.; Hao, H.; Zhu, R.; Zheng, K. Experimental and numerical study on CFRP strip strengthened clay brick masonry walls subjected to vented gas explosions. Int. J. Impact Eng. 2019, 129, 66–79. [Google Scholar] [CrossRef]

- Greene, C.E.; Myers, J.J. Flexural and shear behavior of reinforced concrete members strengthened with a discrete fiber-reinforced polyurea system. J. Compos. Constr. 2013, 17, 108–116. [Google Scholar] [CrossRef]

- Marawan, A.E.; Debaiky, A.S.; Khalil, N.N. Shear and flexural behavior of RC beams strengthened with polyurea spray. Int. J. Adv. Res. Sci. Eng. 2015, 4, 12–26. [Google Scholar]

- Parniani, S.; Toutanji, H. Monotonic and fatigue performance of RC beams strengthened with a polyurea coating system. Constr. Build. Mater. 2015, 101, 22–29. [Google Scholar] [CrossRef]

- Rizwan, M.; Khaleequzzaman, S.; Uz Zaman, U.K.; Fida, S.A.; Shahzad, A.; Rehman, M.; Sulaiman, M.O. Tensile strength improvement of concrete slabs using polyurea spray. Pract. Period. Struct. Des. Constr. 2021, 26, 4020048. [Google Scholar] [CrossRef]

- Song, J.H.; Lee, E.T.; Eun, H.C. A study on the improvement of structural performance by glass fiber-reinforced polyurea (GFRPU) reinforcement. Adv. Civ. Eng. 2019, 2019, 2818219. [Google Scholar] [CrossRef]

- Kim, S.B.; Kim, J.H.; Choi, H.S.; Heo, G. Development and applicability evaluation of high performance polyurea for RC construction reinforcement. J. Korean Soc. Civ. Eng. 2009, 30, 169–176. [Google Scholar]

- Park, J.C.; Lee, S.W.; Kim, S.B.; Kim, J.H. Development and applicability evaluation of stiff-type polyurea for RC construction reinforcement. J. Korean Soc. Civ. Eng. 2010, 31, 457–464. [Google Scholar]

- KS F 2405:2010; Standard Test Method for Compressive Strength of Concrete. Korea Standard Association: Seoul, Republic of Korea, 2010.

| Cylinder Strength | Design Strength | W/C | S/a | Unit Weight [kg/m3] | ||||

|---|---|---|---|---|---|---|---|---|

| [MPa] | [MPa] | [%] | [%] | W | C | S | G | Admixture |

| 42.5 | 40 | 45.1 | 39.0 | 148 | 328 | 791 | 1238 | 4.5 |

| Rebar Type | Nominal Strength | Yield Strength | Yield Strain | Tensile Strength | Elongation | Elastic Modulus |

|---|---|---|---|---|---|---|

| [MPa] | [MPa] | [%] | [MPa] | [%] | [GPa] | |

| D10 | 400 | 469 | 0.23 | 648 | 17.4 | 196.1 |

| D13 | 400 | 473 | 0.24 | 665 | 18.2 | 194.3 |

| Nominal Strength | Tensile Strength | Elongation | Elastic Modulus | Density |

|---|---|---|---|---|

| [MPa] | [MPa] | [%] | [GPa] | [g/cm3] |

| 56 | 52 | 3.8 | 1608 | 3.8 |

| Group ID | Specimen | Length × Width × Height | Effective Depth | Top Rebar | Bottom Rebar | HEPU Thickness | ||

|---|---|---|---|---|---|---|---|---|

| [mm] | [mm] | [MPa] | [MPa] | [mm] | ||||

| RS | RS-1 | 1000 × 500 × 150 | 113.5 | 40 | 400 | 5-D10 | 5-D13 | - |

| RS-2 | ||||||||

| RS-3 | ||||||||

| S-1 | S-1-1 | 1 | ||||||

| S-1-2 | ||||||||

| S-1-3 | ||||||||

| S-2 | S-2-1 | 2 | ||||||

| S-2-2 | ||||||||

| S-2-3 | ||||||||

| S-3 | S-3-1 | 3 | ||||||

| S-3-2 | ||||||||

| S-3-3 |

| Specimen | Pcr | Py | Pu | Pr | Failure Mode | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [kN] | [mm] | [kN] | [mm] | [kN] | [mm] | [kN] | [mm] | [kN/mm] | ||||

| RS-1 | 29.9 | 0.7 | 98.7 | 3.9 | 131.7 | 12.0 | - | - | 41.5 | 21.8 | 4.1 | F |

| RS-2 | 31.7 | 0.8 | 101.0 | 4.3 | 134.2 | 15.7 | - | - | 42.0 | 19.3 | 2.9 | F |

| RS-3 | 34.7 | 0.9 | 100.5 | 4.0 | 131.8 | 10.9 | - | - | 40.1 | 20.9 | 4.5 | F |

| Average | 30.8 | 0.7 | 99.9 | 4.1 | 132.9 | 13.8 | - | - | 41.8 | 20.6 | 3.5 | - |

| S-1-1 | 35.9 | 0.8 | 115.1 | 3.8 | 143.1 | 13.4 | 122.2 | 5.0 | 44.0 | 26.1 | 6.0 | F+R |

| S-1-2 | 35.5 | 0.8 | 118.6 | 3.9 | 143.8 | 9.0 | 143.8 | 9.0 | 44.1 | 26.8 | 4.9 | F+R |

| S-1-3 | 40.4 | 0.9 | 120.6 | 3.9 | 139.0 | 23.4 | 136.5 | 7.1 | 43.0 | 27.4 | 5.0 | F+R |

| Average | 35.7 | 0.8 | 116.8 | 3.9 | 141.9 | 11.2 | 133.0 | 7.0 | 44.1 | 26.5 | 5.5 | - |

| S-2-1 | 39.2 | 0.8 | 126.6 | 3.9 | 141.2 | 25.0 | 135.0 | 6.1 | 46.8 | 28.1 | 4.0 | F+R |

| S-2-2 | 40.4 | 0.9 | 127.9 | 3.8 | 154.7 | 8.5 | 154.7 | 8.5 | 45.8 | 29.8 | 5.7 | F+R |

| S-2-3 | 37.9 | 0.9 | 127.5 | 4.1 | 155.6 | 8.4 | 155.6 | 8.4 | 44.6 | 27.7 | 6.5 | F+R |

| Average | 39.2 | 0.9 | 127.7 | 3.9 | 155.2 | 8.5 | 155.2 | 8.5 | 45.2 | 28.8 | 6.1 | |

| S-3-1 | 39.6 | 0.8 | 135.0 | 3.9 | 157.6 | 6.5 | 157.6 | 6.5 | 48.7 | 31.1 | 8.6 | S |

| S-3-2 | 39.8 | 0.9 | 139.1 | 4.2 | 173.8 | 10.1 | 171.6 | 8.6 | 45.2 | 30.3 | 7.3 | F+R |

| S-3-3 | 40.1 | 0.9 | 134.8 | 3.9 | 161.9 | 7.6 | 161.9 | 7.6 | 46.3 | 31.4 | 7.3 | S |

| Average | 40.0 | 0.9 | 136.9 | 4.0 | 167.8 | 8.8 | 166.7 | 8.1 | 45.8 | 30.8 | 7.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, J.-H. Flexural Behavior of Reinforced Concrete Slabs Strengthened with High Elastic Modulus Polyurea. Appl. Sci. 2025, 15, 11347. https://doi.org/10.3390/app152111347

Chung J-H. Flexural Behavior of Reinforced Concrete Slabs Strengthened with High Elastic Modulus Polyurea. Applied Sciences. 2025; 15(21):11347. https://doi.org/10.3390/app152111347

Chicago/Turabian StyleChung, Joo-Hong. 2025. "Flexural Behavior of Reinforced Concrete Slabs Strengthened with High Elastic Modulus Polyurea" Applied Sciences 15, no. 21: 11347. https://doi.org/10.3390/app152111347

APA StyleChung, J.-H. (2025). Flexural Behavior of Reinforced Concrete Slabs Strengthened with High Elastic Modulus Polyurea. Applied Sciences, 15(21), 11347. https://doi.org/10.3390/app152111347