The Impact of Psyllium Mucilage as a Stabilizer on the Physical and Sensory Properties of Vegan Yogurt Ice Cream

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Oat Yogurt Preparation

2.3. Extraction of Mucilage from Psyllium Seed

2.4. Ice Cream Making

2.5. Overrun

2.6. Phase Separation

2.7. Melting Characteristics

2.8. Rheological Properties

2.9. Color

2.10. Texture

2.11. Consumer Acceptance

2.12. Statistical Analysis

3. Results

3.1. Extraction Yield

3.2. Rheological Analysis of Ice Cream Mixes

3.3. Overrun and Melting Parameters of Ice Cream Mixes

3.4. Color of Ice Cream

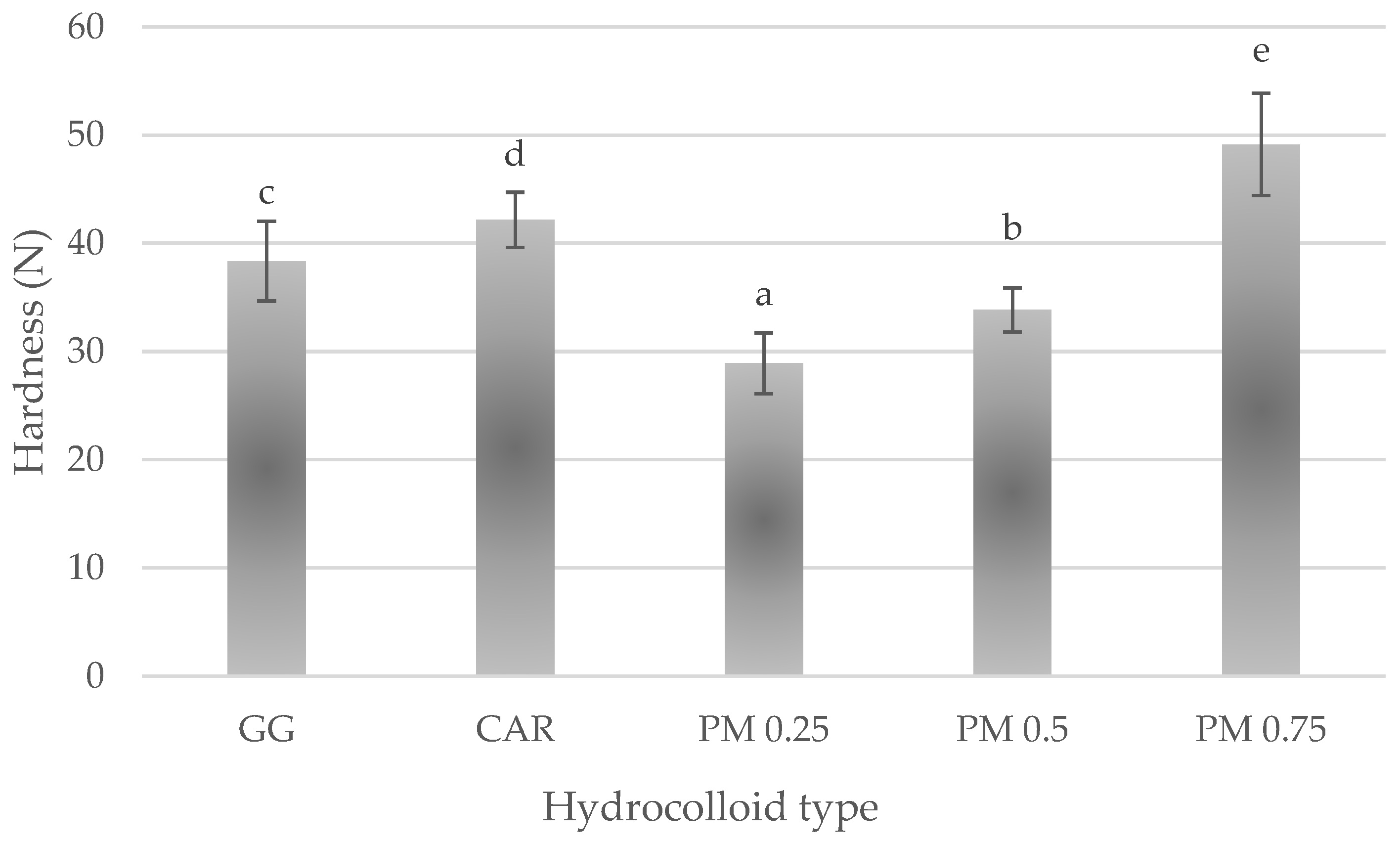

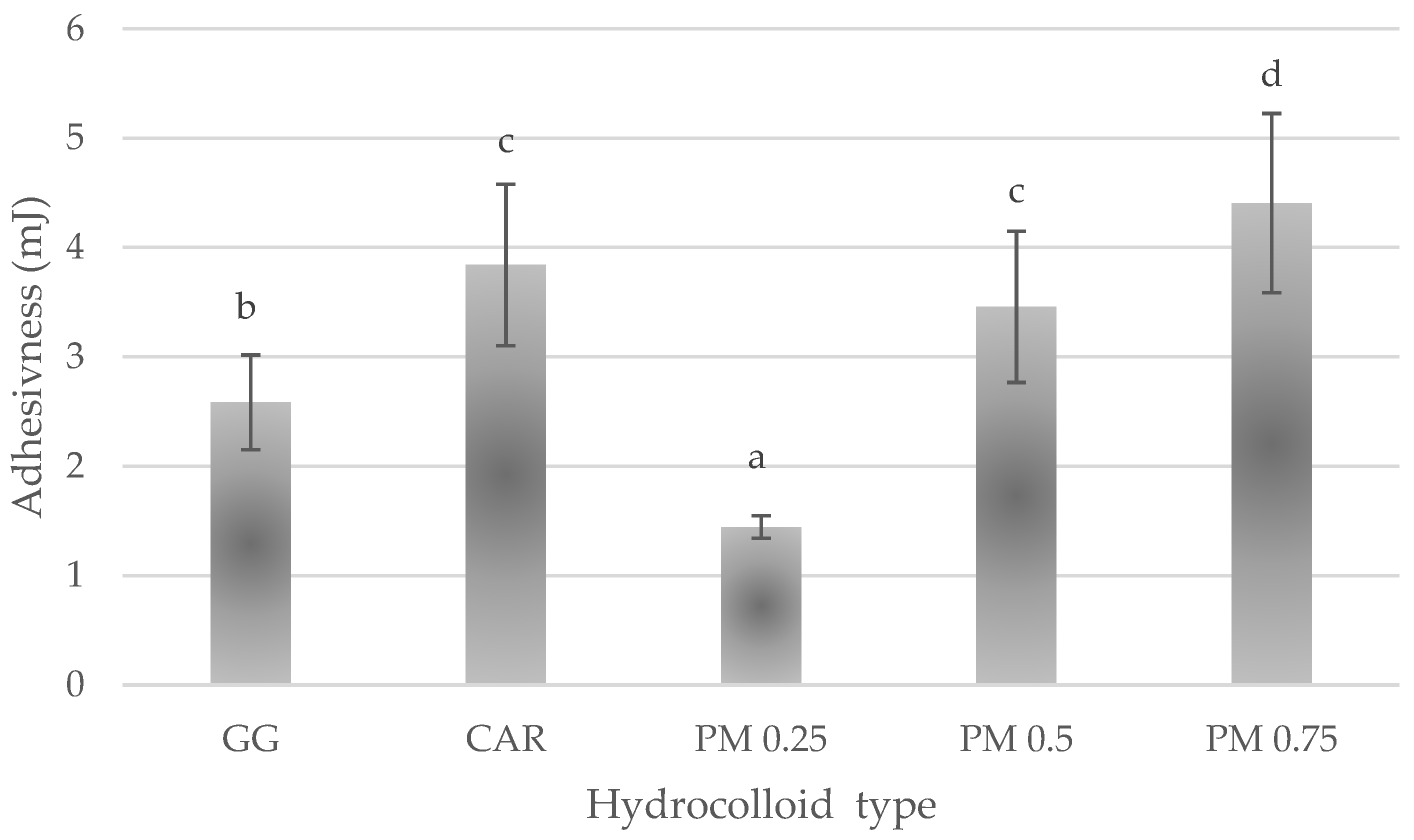

3.5. Textural Properties

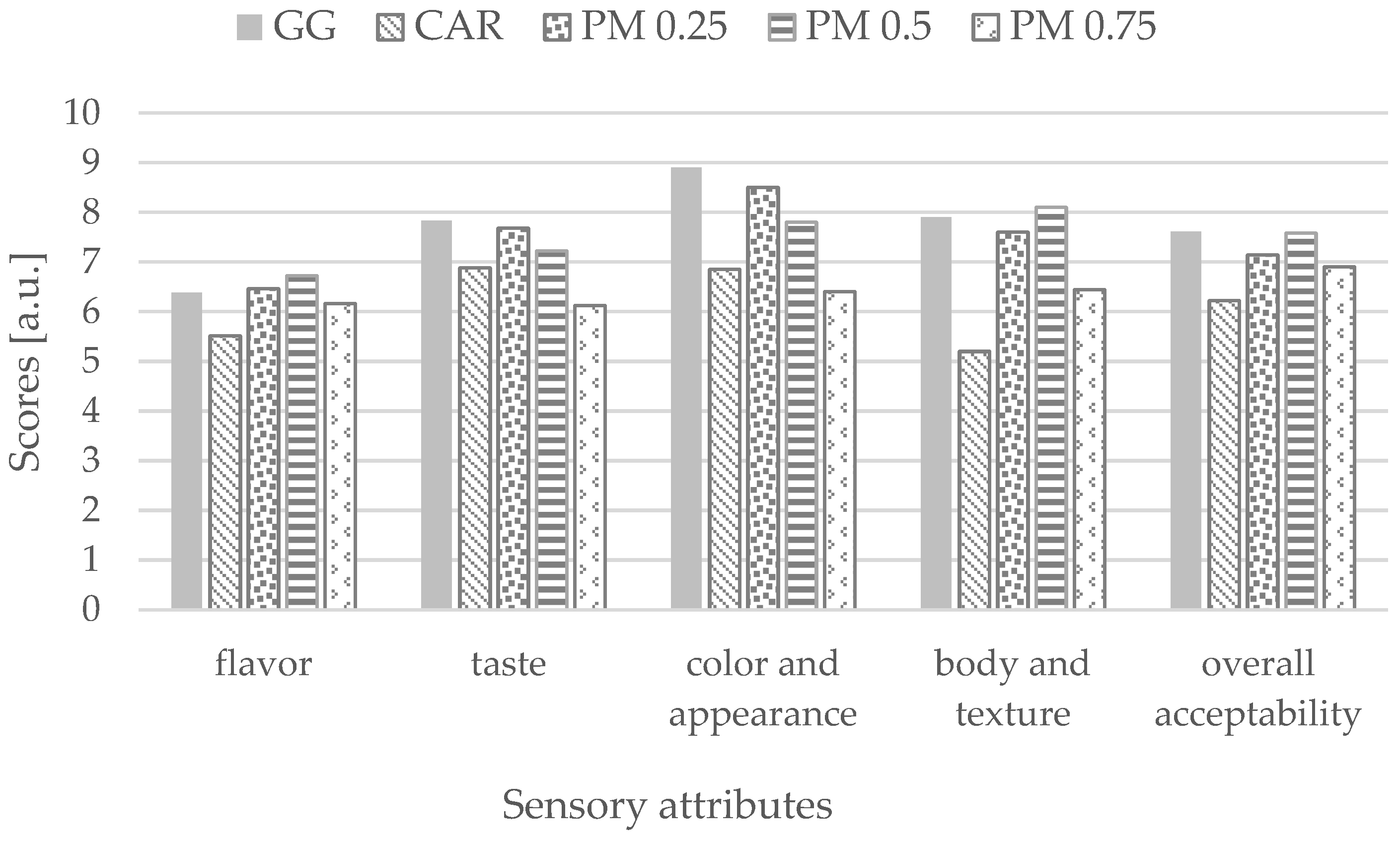

3.6. Consumer Acceptance Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Venter de Villiers, M.; Cheng, J.; Truter, L. The Shift Towards Plant-Based Lifestyles: Factors Driving Young Consumers’ Decisions to Choose Plant-Based Food Products. Sustainability 2024, 16, 9022. [Google Scholar] [CrossRef]

- Craig, W.J.; Messina, V.; Rowland, I.; Frankowska, A.; Bradbury, J.; Smetana, S.; Medici, E. Plant-Based Dairy Alternatives Contribute to a Healthy and Sustainable Diet. Nutrients 2023, 15, 3393. [Google Scholar] [CrossRef] [PubMed]

- Pua, A.; Tang, V.C.Y.; Goh, R.M.V.; Sun, J.; Lassabliere, B.; Liu, S.Q. Ingredients, Processing, and Fermentation: Addressing the Organoleptic Boundaries of Plant-Based Dairy Analogues. Foods 2022, 11, 875. [Google Scholar] [CrossRef] [PubMed]

- Montemurro, M.; Pontonio, E.; Coda, R.; Rizzello, C.G. Plant-Based Alternatives to Yogurt: State-of-the-Art and Perspectives of New Biotechnological Challenges. Foods 2021, 10, 316. [Google Scholar] [CrossRef]

- Aydar, E.F.; Tutuncu, S.; Ozcelik, B. Plant-Based Milk Substitutes: Bioactive Compounds, Conventional and Novel Processes, Bioavailability Studies, and Health Effects. J. Funct. Foods 2020, 70, 103975. [Google Scholar] [CrossRef]

- Moss, R.; LeBlanc, J.; Gorman, M.; Ritchie, C.; Duizer, L.; McSweeney, M.B. A Prospective Review of the Sensory Properties of Plant-Based Dairy and Meat Alternatives with a Focus on Texture. Foods 2023, 12, 1709. [Google Scholar] [CrossRef]

- Patil, A. Global Vegan Ice-Cream Market: Global Industry Analysis and Lucrative Growth Opportunities Worth US$1741.14 Million by 2032. Introsp. Mark. Res. 2024. [Google Scholar] [CrossRef]

- Greis, M.; Nolden, A.; Kinchla, A.; Puputti, S.; Seppä, L.; Sandell, M. What If Plant-Based Yogurts Were Like Dairy Yogurts? Texture Perception and Liking of Plant-Based Yogurts among US and Finnish Consumers. Food Qual. Prefer. 2023, 107, 104848. [Google Scholar] [CrossRef]

- Sipple, L.; Racette, C.M.; Schiano, A.N. Consumer Perception of Ice Cream and Frozen Desserts in the “Better-for-You” Category. J. Dairy Sci. 2022, 105, 21029. [Google Scholar] [CrossRef]

- Genovese, A.; Balivo, A.; Salvati, A.; Sacchi, R. Functional Ice Cream: Health Benefits and Sensory Implications. Food Res. Int. 2022, 161, 111858. [Google Scholar] [CrossRef]

- Hadjimbei, E.; Botsaris, G.; Chrysostomou, S. Beneficial Effects of Yoghurts and Probiotic Fermented Milks and Their Functional Food Potential. Foods 2022, 11, 2691. [Google Scholar] [CrossRef]

- Saadi, A.M.; Jafar, N.B.; Jassim, M.A. Effect of Some Types of Stabilizers on the Quality of Yogurt during Storage. J. Hyg. Eng. Des. 2022, 38, 125–130. [Google Scholar]

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-Based Milk Alternatives: An Emerging Segment of Functional Beverages—A Review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef]

- Henden, Y.; Gümüş, T.; Kamer, D.; Kaynarca, G.; Yücel, E. Optimizing Vegan Frozen Dessert: The Impact of Xanthan Gum and Oat-Based Milk Substitute on Rheological and Sensory Properties of Frozen Dessert. Food Chem. 2024, 460, 140787. [Google Scholar] [CrossRef]

- Akalın, H.; Kınık, Ö.; Şatır, G. Manufacturing Plant-Based Non-Dairy and Probiotic Frozen Desserts and Their Impact on Physicochemical, Sensory and Functional Aspects. J. Food Sci. Technol. 2024, 61, 1874–1883. [Google Scholar] [CrossRef]

- Zagorska, J.; Stamere, B.; Galoburda, R.; Ciprovica, I.; Strausa, E. Physical, Rheological and Nutritional Properties of Plant-Based Frozen Dessert. Rural Sustain. Res. 2024, 52, 31–43. [Google Scholar] [CrossRef]

- BahramParvar, M.; Tehrani, M.M. Application and Functions of Stabilizers in Ice Cream. Food Rev. Int. 2011, 27, 389–407. [Google Scholar] [CrossRef]

- Dhakal, D.; Younas, T.; Bhusal, R.P.; Devkota, L.; Henry, C.J.; Dhital, S. Design Rules of Plant-Based Yoghurt-Mimic: Formulation, Functionality, Sensory Profile and Nutritional Value. Food Hydrocoll. 2023, 142, 108786. [Google Scholar] [CrossRef]

- Ge, Z.; Yin, D.; Li, Z.; Chen, X.; Dong, M. Effects of Commercial Polysaccharide Stabilizers with Different Charges on Textural, Rheological, and Microstructural Characteristics of Set Yoghurts. Foods 2022, 11, 1764. [Google Scholar] [CrossRef]

- Macit, E.; Karaoğlu, M.M.; Bakırcı, İ. Effects of Some Stabilizers on the Textural Properties of Set-Type Yogurt. Alinteri J. Agric. Sci. 2019, 34, 15–20. [Google Scholar] [CrossRef]

- Syed, Q.A.; Shah, M.S.U. Impact of Stabilizers on Ice Cream Quality Characteristics. MOJ Food Process Technol. 2016, 3, 246–252. [Google Scholar] [CrossRef]

- Petitjean, M.; Isasi, J.R. Locust Bean Gum, a Vegetable Hydrocolloid with Industrial and Biopharmaceutical Applications. Molecules 2022, 27, 8265. [Google Scholar] [CrossRef]

- Rana, M.R.; Babor, M.; Sabuz, A.A. Traceability of Sweeteners in Soy Yogurt Using Linear Discriminant Analysis of Physicochemical and Sensory Parameters. J. Agric. Food Res. 2021, 5, 100155. [Google Scholar] [CrossRef]

- Vanga, S.K.; Raghavan, V. How Well Do Plant Based Alternatives Fare Nutritionally Compared to Cow’s Milk? J. Food Sci. Technol. 2018, 55, 10–20. [Google Scholar] [CrossRef] [PubMed]

- Goksen, G.; Demir, D.; Dhama, K.; Kumar, M.; Shao, P.; Xie, F.; Echegaray, N.; Lorenzo, J.M. Mucilage Polysaccharide as a Plant Secretion: Potential Trends in Food and Biomedical Applications. Int. J. Biol. Macromol. 2023, 230, 123146. [Google Scholar] [CrossRef]

- Chinellato, M.M.; Berwig, K.; Monteiro, A. Properties of Mucilage Blends Using Psyllium Husk (Plantago psyllium L.) and Chia Seed (Salvia hispanica L.). Rev. Principia 2021, 1, 36–45. [Google Scholar] [CrossRef]

- Grant, K.; Gallardo, K.; McCluskey, J. Consumer Preferences for Foods with Clean Labels and New Food Technologies. Agribusiness 2021, 37, 764–781. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of Ingredients and Additives in Plant-Based Meat Analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Feizi, R.; Goh, K.; Mutukumira, A.N. Effect of Chia Seed Mucilage as Stabiliser in Ice Cream. Int. Dairy J. 2021, 120, 105087. [Google Scholar] [CrossRef]

- Bukhari, S.N.A.; Ali, A.; Hussain, M.A.; Tayyab, M.; Alotaibi, N.F.; Elsherif, M.A.; Junaid, K.; Ejaz, H. Extraction Optimization of Mucilage from Seeds of Mimosa pudica by Response Surface Methodology. Polymers 2022, 14, 1904. [Google Scholar] [CrossRef]

- BahramParvar, M.; Goff, H.D. Basil Seed Gum as a Novel Stabilizer for Structure Formation and Reduction of Ice Re-Crystallization in Ice Cream. Dairy Sci. Technol. 2013, 93, 273–285. [Google Scholar] [CrossRef]

- Hwang, S.-Y.; Yu, J.-C.; Shin, W.-S. Physicochemical and Sensory Properties of Vegan Ice Cream Using Upcycled Aquasoya Powder. Int. J. Food Sci. Technol. 2024, 59, e17388. [Google Scholar] [CrossRef]

- Javidi, F.; Razavi, S.M.A.; Behrouzian, F.; Alghooneh, A. The Influence of Basil Seed Gum, Guar Gum and Their Blend on the Rheological, Physical and Sensory Properties of Low-Fat Ice Cream. Food Hydrocoll. 2016, 52, 625–633. [Google Scholar] [CrossRef]

- Tsevdou, M.; Aprea, E.; Betta, E.; Khomenko, I.; Molitor, D.; Biasioli, F.; Gaiani, C.; Gasperi, F.; Taoukis, P.; Soukoulis, C. Rheological, Textural, Physicochemical and Sensory Profiling of a Novel Functional Ice Cream Enriched with Muscat de Hamburg (Vitis vinifera L.) Grape Pulp and Skins. Food Bioprocess Technol. 2019, 12, 665–680. [Google Scholar] [CrossRef]

- Devalekar, S.K.; Udachan, I.S. Process Optimization of Vegan Prebiotic Ice Cream by Response Surface Methodology. Discov. Food 2025, 5, 13. [Google Scholar] [CrossRef]

- PN-EN ISO 11136:2017-08; Analiza Sensoryczna. Metodyka. Ogólne Wytyczne Przeprowadzania Testów Hedonicznych z Konsumentami na Obszarze Kontrolowanym. Polish Committee for Standardization: Warszawa, Poland, 2017. (In Polish)

- PN-EN ISO 5492:2009; Analiza Sensoryczna. Terminologia. Polish Committee for Standardization: Warszawa, Poland, 2009. (In Polish)

- Chaves, M.A.; Piati, J.; Malacarne, L.T.; Gall, R.E.; Colla, E.; Bittencourt, P.R.S.; de Souza, A.H.P.; Gomes, S.T.M.; Matsushita, M. Extraction and Application of Chia Mucilage (Salvia hispanica L.) and Locust Bean Gum (Ceratonia siliqua L.) in Goat Milk Frozen Dessert. J. Food Sci. Technol. 2018, 55, 4148–4158. [Google Scholar] [CrossRef] [PubMed]

- Altaş, A.; Gursoy, O.; Güler Dal, H.Ö.; Yilmaz, Y. Use of chia (Salvia hispanica L.) seed mucilage powder as a stabilizer in the preparation of salep beverage. Food Sci. Nutr. 2024, 12, 5619–5631. [Google Scholar] [CrossRef]

- Caponio, G.R.; De Angelis, D.; Mansueto, L.; Vacca, M.; Silletti, R.; De Angelis, M.; Difonzo, G. Nutritional, rheological, and sensory effect of oat okara enrichment in plant-based ice cream. LWT 2025, 233, 118490. [Google Scholar] [CrossRef]

- Soukoulis, C.; Lebesi, D.; Tzia, C. Enrichment of Ice Cream with Dietary Fibre: Effects on Rheological Properties, Ice Crystallisation and Glass Transition Phenomena. Food Chem. 2009, 115, 665–671. [Google Scholar] [CrossRef]

- Erem, E.; Akdeniz, E.; Cayır, M.; Icyer, N.C.; Toker, O.S. Fruit-Based Vegan Ice Cream-Type Frozen Dessert with Aquafaba: Effect of Fruit Types on Quality Parameters. J. Food Sci. Technol. 2024, 61, 907–917. [Google Scholar] [CrossRef] [PubMed]

- Waleed, M.; Saeed, F.; Afzaal, M.; Niaz, B.; Raza, M.A.; Hussain, M.; Al Jbawi, E. Structural and Nutritional Properties of Psyllium Husk Arabinoxylans with Special Reference to Their Antioxidant Potential. Int. J. Food Prop. 2022, 25, 2505–2513. [Google Scholar] [CrossRef]

- Narala, V.; Orlovs, I.; Jugbarde, M.; Masin, M. Inulin as a Fat Replacer in Pea Protein Vegan Ice Cream and Its Influence on Textural Properties and Sensory Attributes. Appl. Food Res. 2022, 2, 100066. [Google Scholar] [CrossRef]

- Milliatti, M.; Lannes, S. Impact of Stabilizers on the Rheological Properties of Ice Creams. Food Sci. Technol. 2018, 38, 733–739. [Google Scholar] [CrossRef]

- Warren, M.M.; Hartel, R.W. Effects of Emulsifier, Overrun and Dasher Speed on Ice Cream Microstructure and Melting Properties: Ice Cream Microstructure and Melt Rate. J. Food Sci. 2018, 83, 639–647. [Google Scholar] [CrossRef]

- Markowska, J.; Tyfa, A.; Drabent, A.; Stępiak, A. The Physicochemical Properties and Melting Behavior of Ice Cream Fortified with Multimineral Preparation from Red Algae. Foods 2023, 12, 4481. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A.; Galus, S.; Jakubczyk, E. Effects of Different Ingredients and Stabilisers on Properties of Mixes Based on Almond Drink for Vegan Ice Cream Production. Sustainability 2021, 13, 12113. [Google Scholar] [CrossRef]

- Mokbel, S.; Blassy, K.; Abdeldaiem, A. Using Psyllium Husk Powder as Fat Replacer and Stabilizer to Improve Low Fat Ice Cream Properties. J. Food Dairy Sci. 2024, 15, 1–6. [Google Scholar] [CrossRef]

- Aydemir, L.Y.; Demir, H.; Erbay, Z.; Kılıçarslan, E.; Salum, P.; Ozdemir, M.B. Production of Vegan Ice Cream: Enrichment with Fermented Hazelnut Cake. Fermentation 2025, 11, 454. [Google Scholar] [CrossRef]

- Kulcan, A.; Zoua, U.; Aygün, M.; Kuzu, Ş.; Yıldız, D.; Kaya, N.; Hacıoğlu, A.; Karhan, M. Impact of Carob Extract Supplementation on Chemical and Sensory Properties of Yogurt and Ice Cream. Gida 2021, 46, 980–991. [Google Scholar] [CrossRef]

- Akin, M.B.; Goncu, B.; Musa, S.; Akin, S. Some Properties of Probiotic Yoghurt Ice Cream Supplemented with Carob Extract and Whey Powder. Adv. Microbiol. 2016, 6, 614095. [Google Scholar] [CrossRef]

- Souza, G.; Bergamasco, R.; Stafussa, A.; Madrona, G. Ultrasound-Assisted Extraction of Psyllium Mucilage: Evaluation of Functional and Technological Properties. Emir. J. Food Agric. 2020, 32, 238. [Google Scholar] [CrossRef]

- Soukoulis, C.; Chandrinos, I.; Tzia, C. Study of the Functionality of Selected Hydrocolloids and Their Blends with κ-Carrageenan on Storage Quality of Vanilla Ice Cream. LWT-Food Sci. Technol. 2008, 41, 1816–1827. [Google Scholar] [CrossRef]

- Góral, M.; Kaluza, F.; Wroniak, M.; Włodarczyk, P.; Domian, E. Impact of Stabilizers on the Freezing Process, and Physicochemical and Organoleptic Properties of Coconut Milk-Based Ice Cream. Lwt 2018, 92, 516–522. [Google Scholar] [CrossRef]

- Liu, X.; Sala, G.; Scholten, E. Role of Polysaccharide Structure in the Rheological, Physical and Sensory Properties of Low-Fat Ice Cream. Curr. Res. Food Sci. 2023, 7, 100531. [Google Scholar] [CrossRef]

- Akbari, M.; Eskandari, M.H.; Niakousari, M.; Bedeltavana, A. The Effect of Inulin on the Physicochemical Properties and Sensory Attributes of Low-Fat Ice Cream. Int. Dairy J. 2016, 57, 52–60. [Google Scholar] [CrossRef]

- Khan, A.; Khalid, W.; Safdar, S.; Usman, M.; Shakeel, M.; Jamal, N.; Jha, R.; Baig, M.; Shehzadi, S.; Khalid, M.Z.; et al. Nutritional and Therapeutic Benefits of Psyllium Husk (Plantago ovata). Acta Sci. Microbiol. 2021, 4, 43–50. [Google Scholar]

| GG | CAR | PM 0.25 | PM 0.5 | PM 0.75 | |

|---|---|---|---|---|---|

| Oat yogurt (g) | 500 | 500 | 500 | 500 | 500 |

| Oat drink (g) | 200 | 200 | 200 | 200 | 200 |

| Coconut oil (g) | 100 | 100 | 100 | 100 | 100 |

| Sucrose (g) | 170 | 170 | 170 | 170 | 170 |

| Emulsifier Glice (g) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Corn starch (g) | 25 | 25 | 25 | 25 | 25 |

| Guar gum (g) | 2.5 | - | - | - | - |

| Carob (g) | - | 2.5 | - | - | - |

| PM powder (g) | 2.5 | 5 | 7.5 |

| Hydrocolloid Type | AV * (mPa·s) at 100 s−1 | k (Pa sn) | n (-) | τ0 (Pa) | R2 | TI (%) |

|---|---|---|---|---|---|---|

| GG | 208.7 ± 4.8 c | 2.905 ± 0.386 d | 0.479 ± 0.091 b | 1.415 ± 0.497 a | 0.998 | 3.82 ± 0.24 b |

| CAR | 41.8 ± 4.6 a | 0.198 ± 0.011 a | 0.328 ± 0.087 a | 1.923 ± 0.098 b | 0.994 | 2.12 ± 0.32 a |

| PM 0.25 | 181.5 ± 16.1 b | 0.252 ± 0.027 b | 0.523 ± 0.037 c | 2.261 ± 0.154 c | 0.995 | 39.20 ± 0.85 d |

| PM 0.5 | 494.8 ± 69.5 d | 0.420 ± 0.074 c | 0.853 ± 0.049 d | 5.005 ± 0.474 d | 0.998 | 30.15 ± 7.42 c |

| PM 0.75 | 585.3 ± 52.3 e | 0.509 ± 0.153 c | 0.875 ± 0.049 d | 8.055 ± 0.662 e | 0.993 | 56.56 ± 4.46 e |

| Hydrocolloid Type | Ov (%) | PS (%) | FDT (min) | EM (g/g) |

|---|---|---|---|---|

| GG | 39.32 ± 1.87 d | 19.54 ± 2.28 b | 42.22 ± 3.12 c | 2.22 ± 0.08 c |

| CAR | 25.48 ± 2.14 b | 32.22 ± 1.52 c | 28.31 ± 2.42 a | 3.09 ± 0.15 d |

| PM 0.25 | 34.27 ± 1.86 c | 15.49 ± 2.11 a | 35.27 ± 3.31 b | 1.71 ± 0.11 b |

| PM 0.5 | 32.73 ± 1.53 c | 21.16 ± 2.24 b | 52.13 ± 2.74 d | 1.39 ± 0.21 a |

| PM 0.75 | 19.38 ± 0.98 a | 35.02 ± 3.38 c | 67.22 ± 3.48 e | 1.20 ± 0.07 a |

| Hydrocolloid Type | L* | a* | b* | ΔE |

|---|---|---|---|---|

| GG | 84.58 ± 3.39 c | 3.73 ± 0.19 a | 6.94 ± 0.87 b | - |

| CAR | 74.85 ± 1.84 a | 7.87 ± 0.12 e | 8.22 ± 0.38 c | 10.24 ± 0.85 c |

| PM 0.25 | 81.60 ± 1.96 b | 4.16 ± 0.10 b | 5.21 ± 0.64 a | 3.48 ± 0.49 a |

| PM 0.5 | 79.33 ± 1.27 b | 4.71 ± 0.05 c | 5.41 ± 0.46 a | 5.56 ± 0.71 b |

| PM 0.75 | 75.27 ± 3.00 a | 5.40 ± 0.09 d | 5.32 ± 0.53 a | 9.59 ± 0.89 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wyrwisz, J.; Pokorski, P. The Impact of Psyllium Mucilage as a Stabilizer on the Physical and Sensory Properties of Vegan Yogurt Ice Cream. Appl. Sci. 2025, 15, 11190. https://doi.org/10.3390/app152011190

Wyrwisz J, Pokorski P. The Impact of Psyllium Mucilage as a Stabilizer on the Physical and Sensory Properties of Vegan Yogurt Ice Cream. Applied Sciences. 2025; 15(20):11190. https://doi.org/10.3390/app152011190

Chicago/Turabian StyleWyrwisz, Jarosław, and Patryk Pokorski. 2025. "The Impact of Psyllium Mucilage as a Stabilizer on the Physical and Sensory Properties of Vegan Yogurt Ice Cream" Applied Sciences 15, no. 20: 11190. https://doi.org/10.3390/app152011190

APA StyleWyrwisz, J., & Pokorski, P. (2025). The Impact of Psyllium Mucilage as a Stabilizer on the Physical and Sensory Properties of Vegan Yogurt Ice Cream. Applied Sciences, 15(20), 11190. https://doi.org/10.3390/app152011190