Simulation Study on the Magnetic Field Characteristics of a Permanent Magnet Motor for a Rim-Driven Device

Abstract

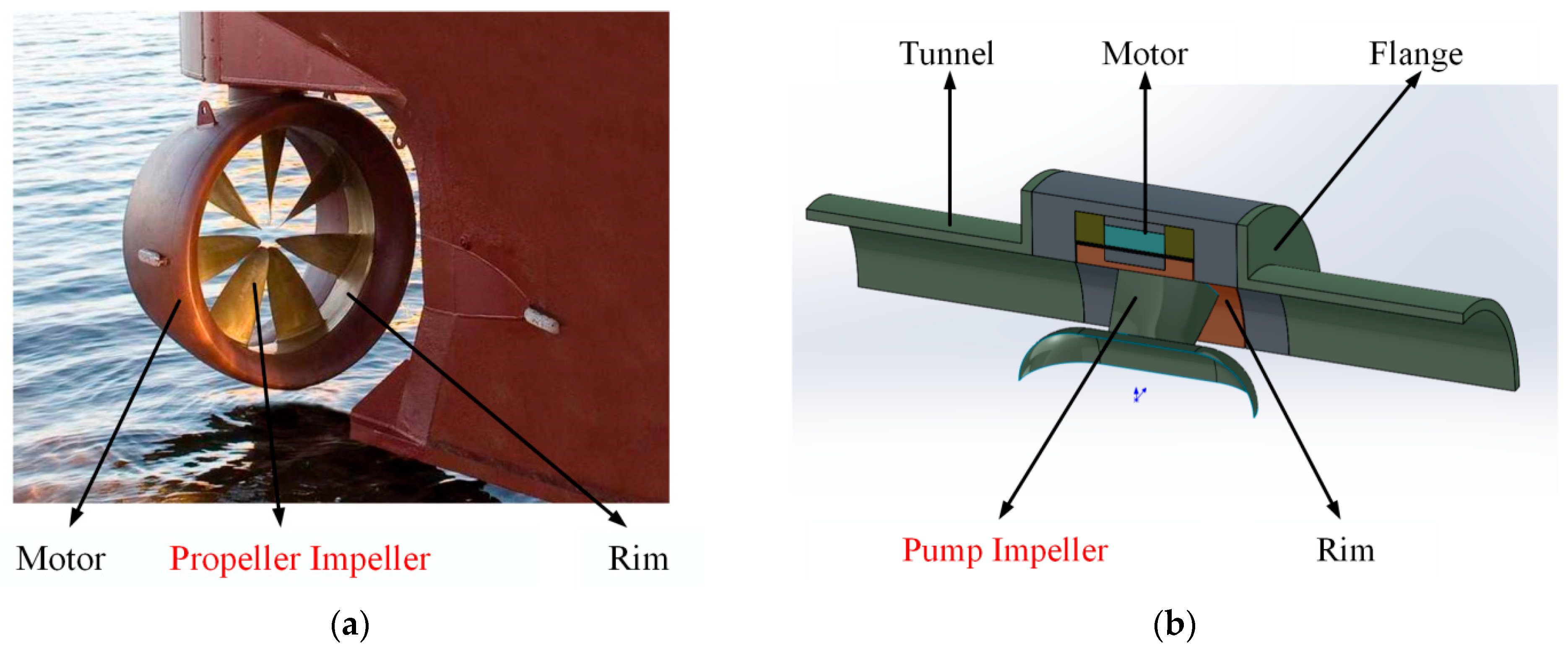

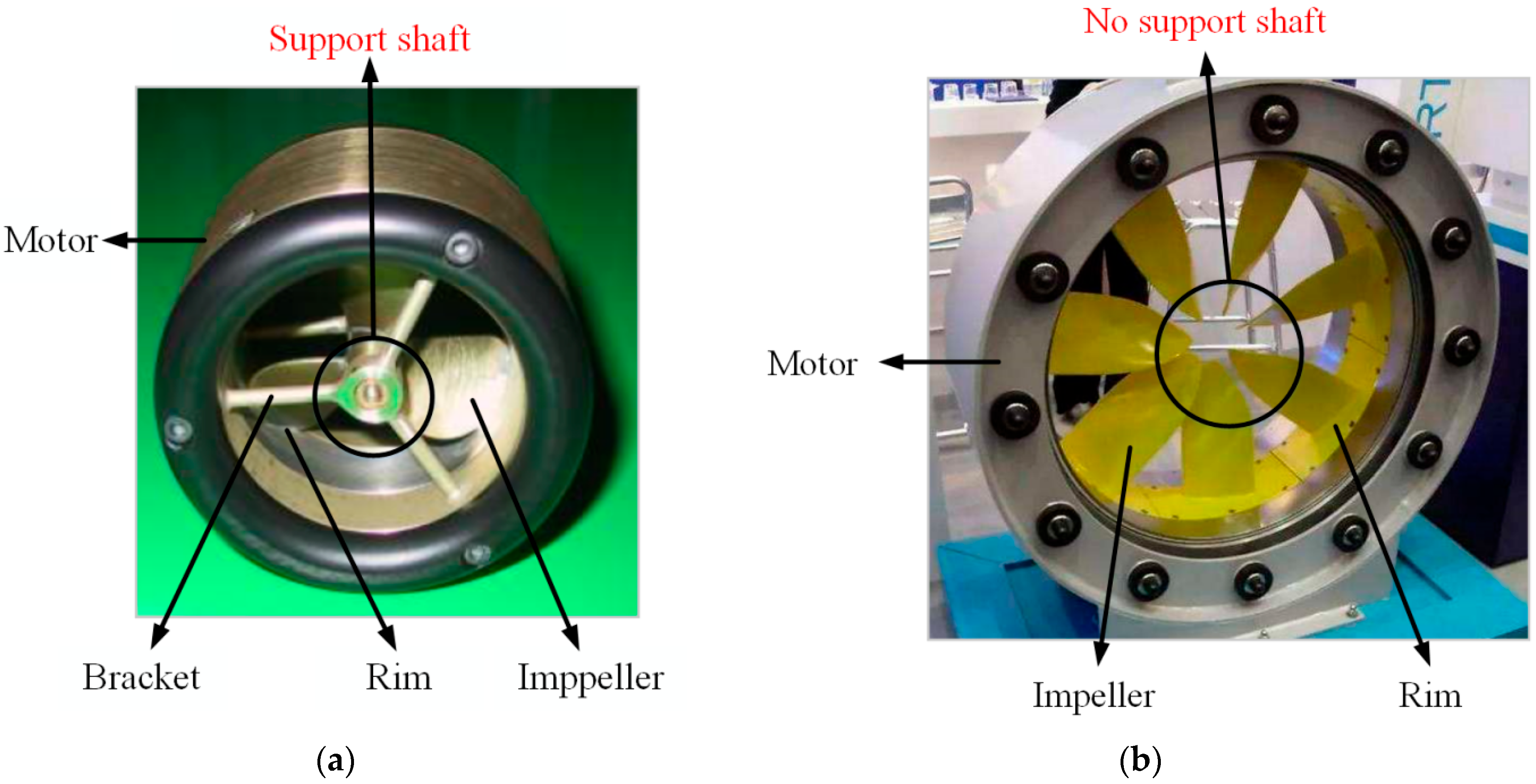

1. Introduction

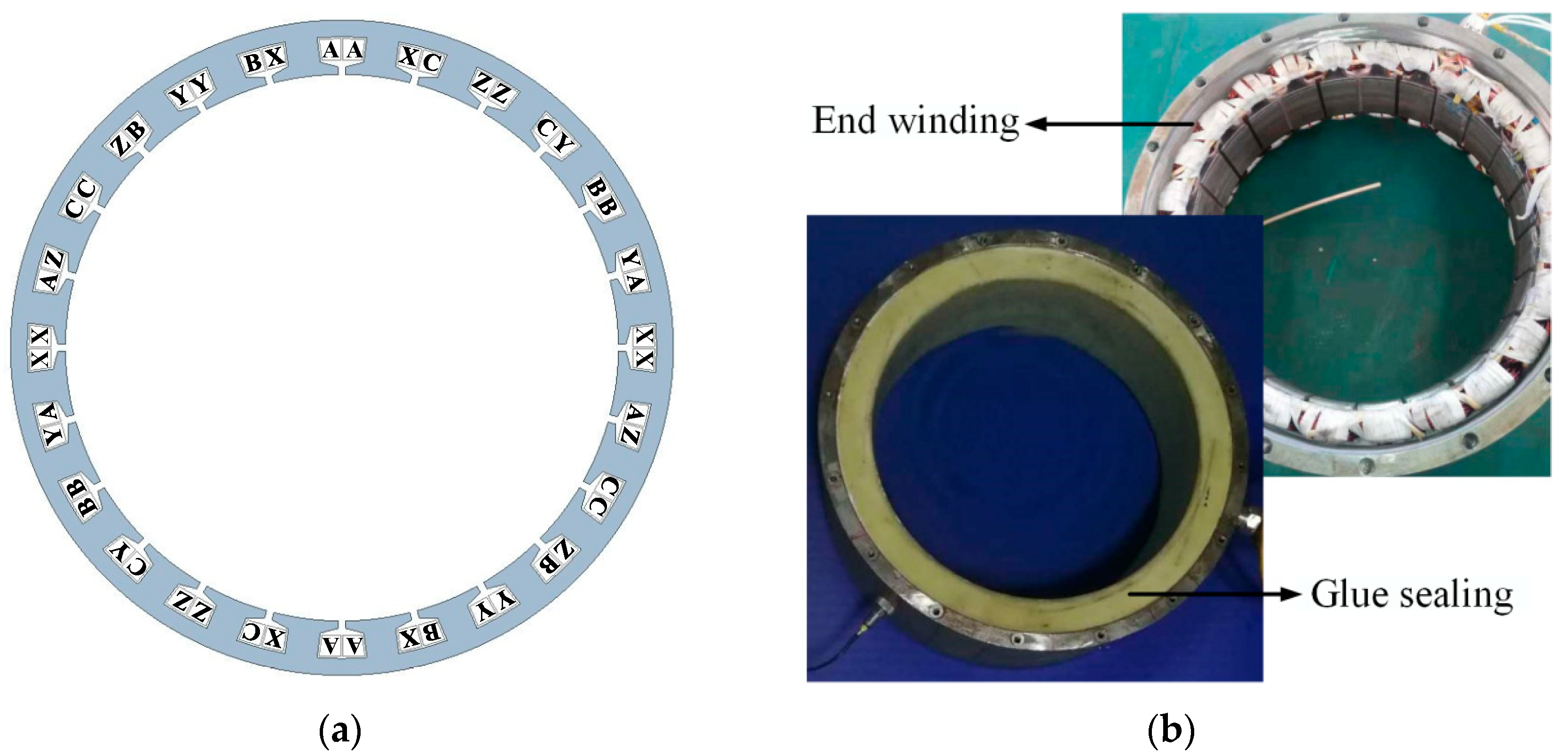

2. Design of Permanent Magnet Motor for RDD

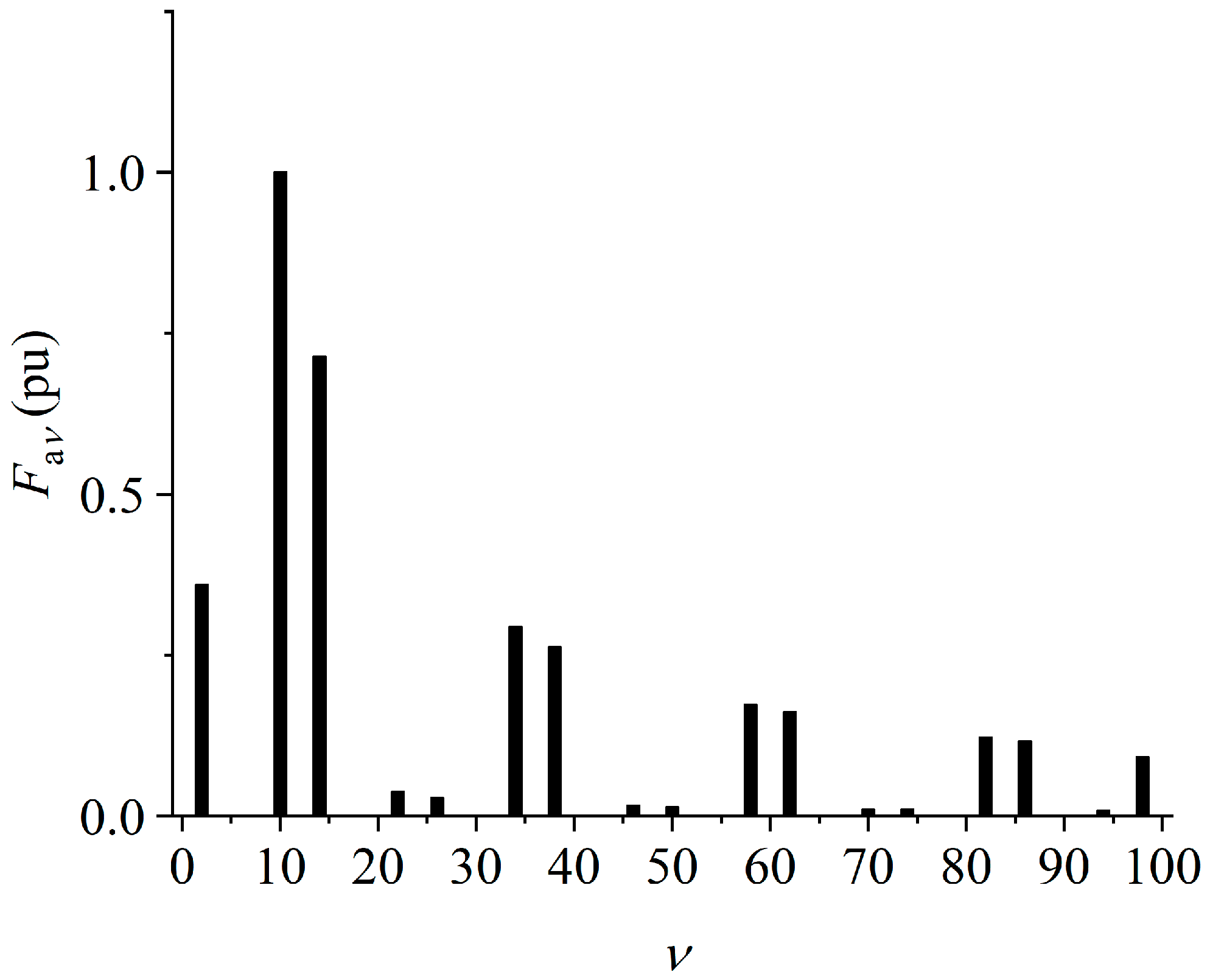

2.1. Thin-Yoke Wide-Tooth Fractional Slot Concentrated Winding Stator

2.2. Coreless Halbach Permanent Magnet Array Rotor

3. Harmonic Analysis of Air Gap Magnetic Field Based on One-Dimensional Magnetic Circuit Method

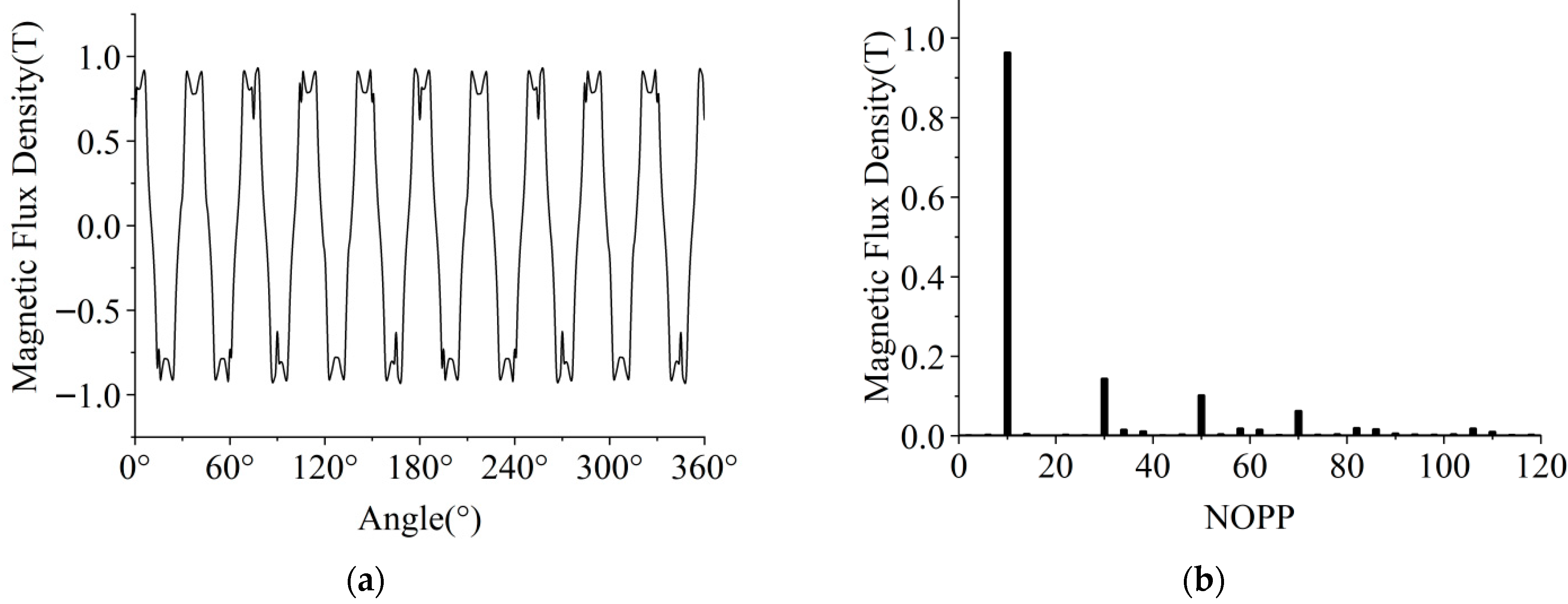

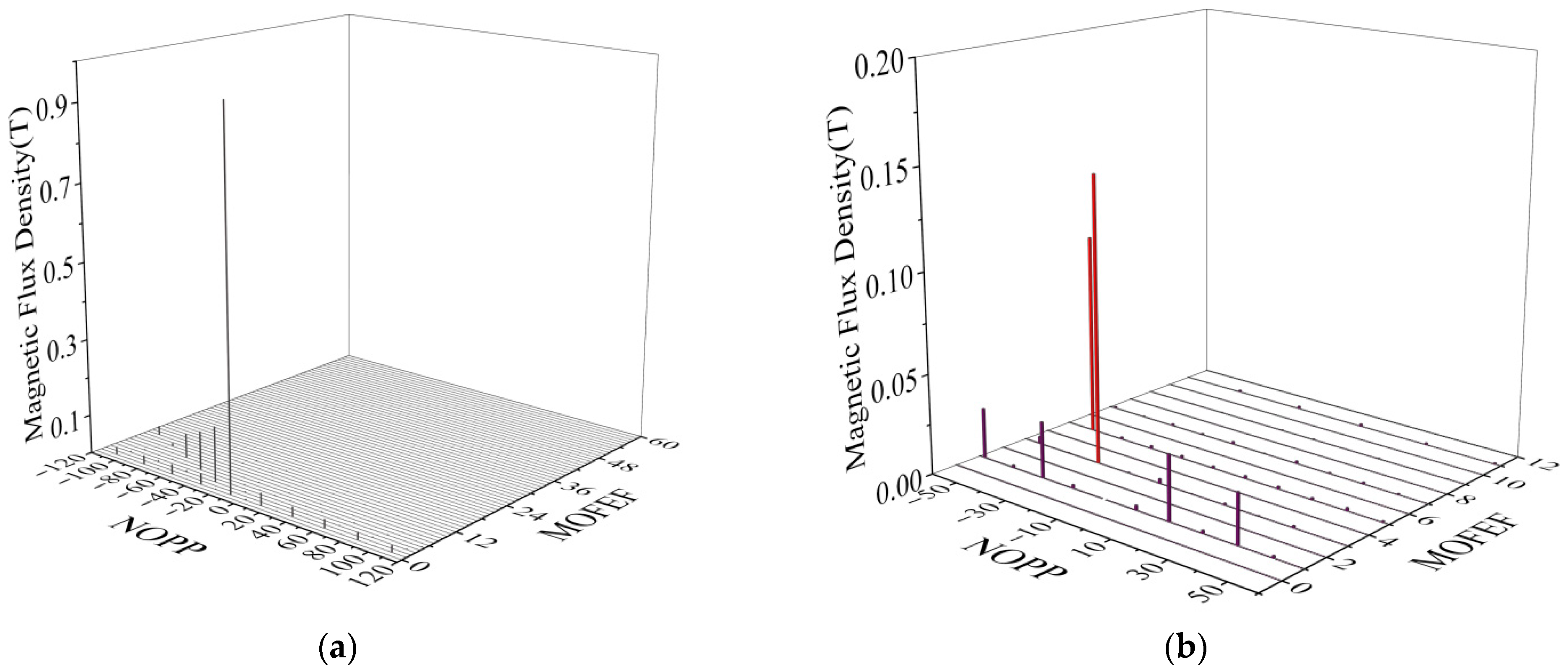

3.1. Radial Air Gap Magnetic Flux Density

3.2. Tangential Air Gap Magnetic Flux Density

4. Simulation Analysis of Air Gap Magnetic Field Based on Two-Dimensional Finite Element Method

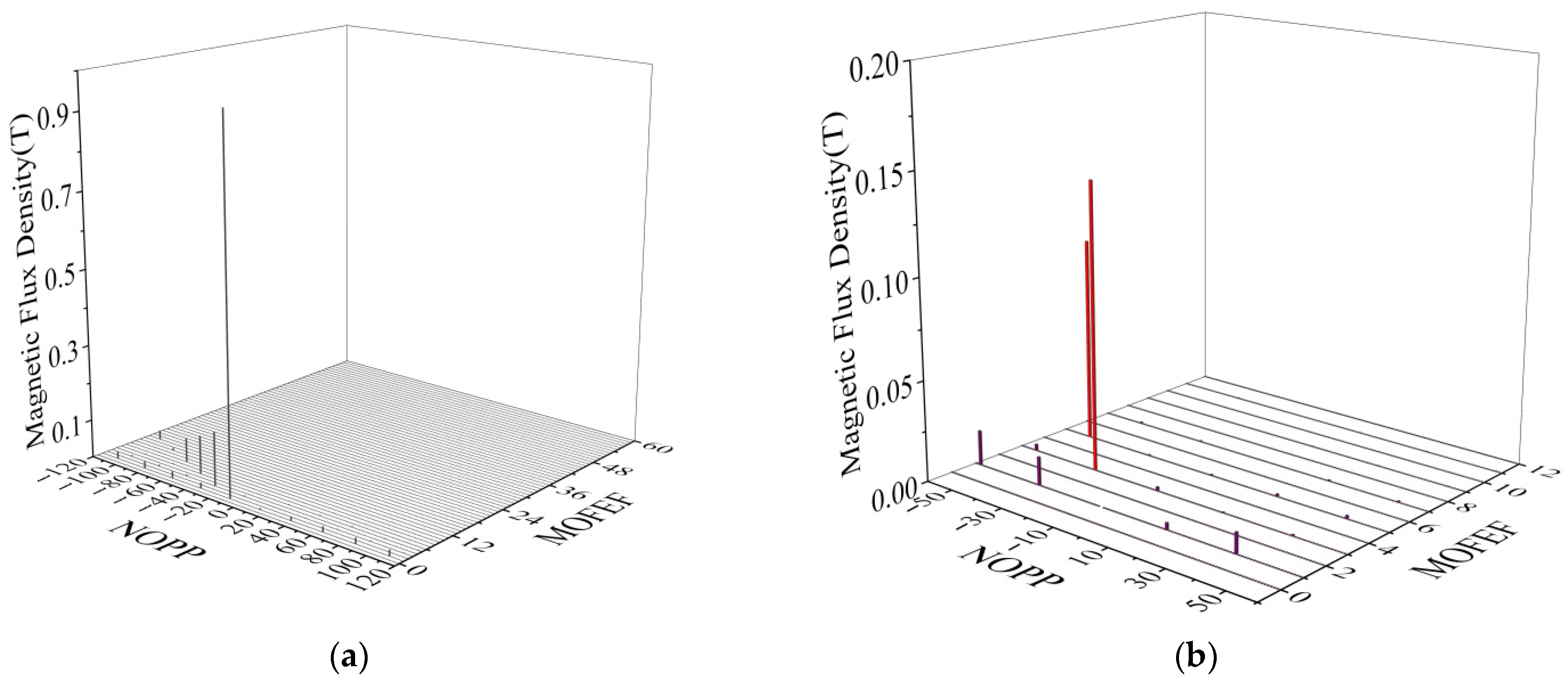

4.1. No-Load

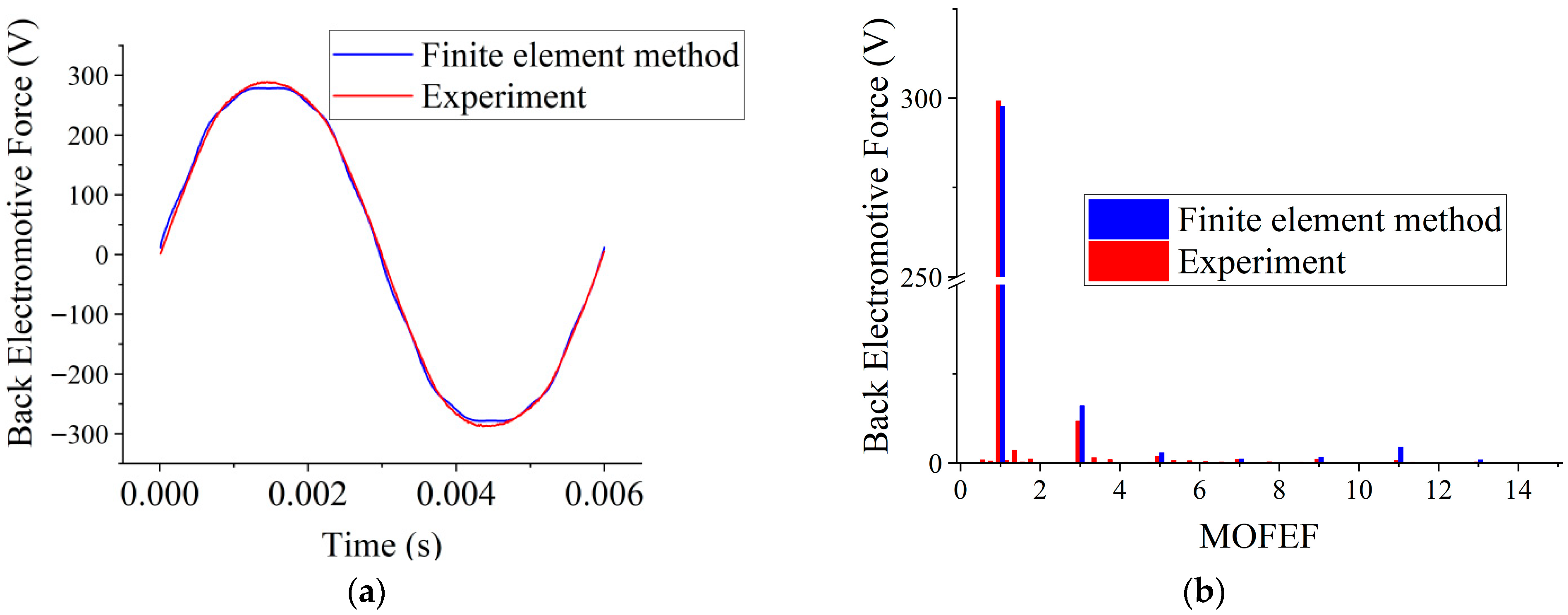

4.2. Contains Only Fundamental Current

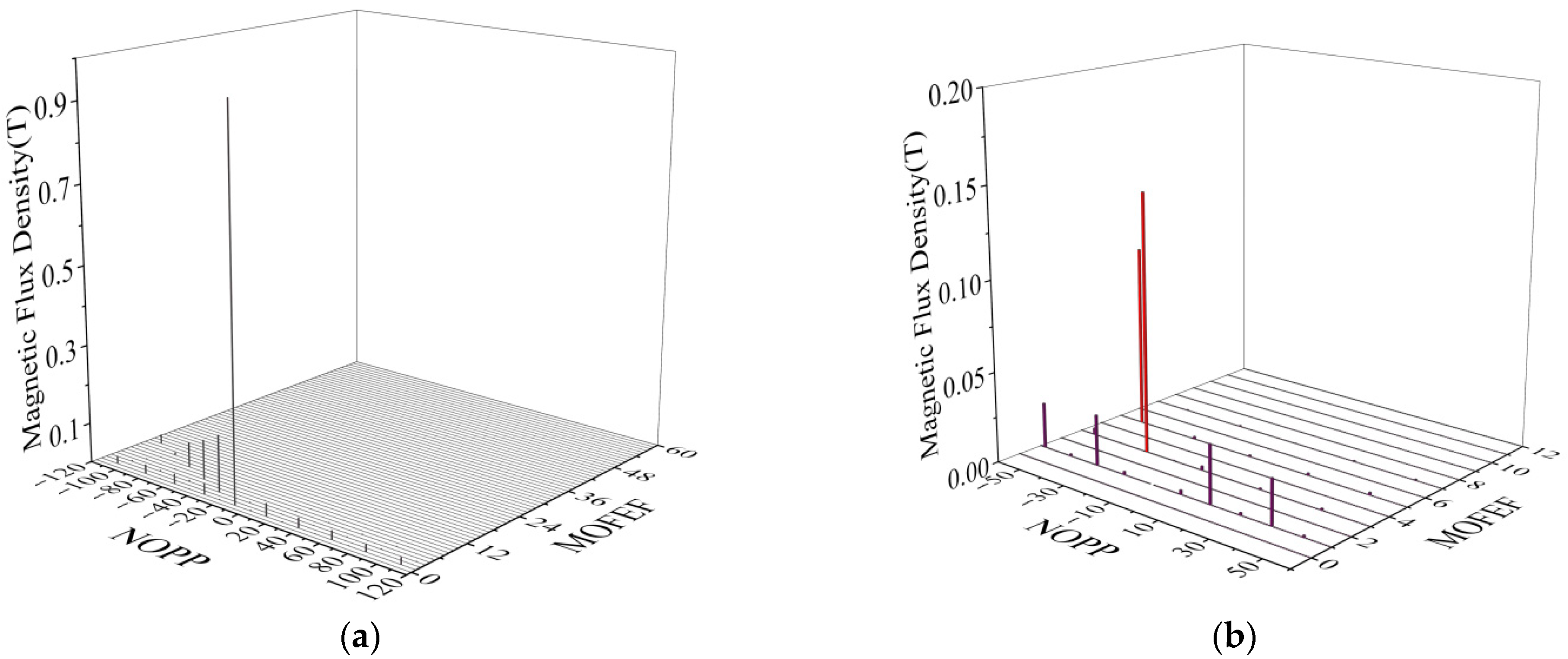

4.3. Contains Harmonic Currents

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NOPP | number of pole pairs |

| MOFEF | multiples of fundamental electrical frequency |

References

- Dubas, A.J.; Bressloff, N.W.; Sharkh, S.M. Numerical modelling of rotor–stator interaction in rim driven thrusters. Ocean Eng. 2015, 106, 281–288. [Google Scholar] [CrossRef]

- Hassannia, A.; Darabi, A. Design and performance analysis of superconducting rim-driven synchronous motors for marine propulsion. IEEE Trans. Appl. Suppercon. 2014, 24, 5200207. [Google Scholar] [CrossRef]

- Tuohy, P.M.; Smith, A.C.; Husband, M.; Hopewell, P. Rim-drive marine thruster using a multiple-can induction motor. IET Electr. Power Appl. 2013, 7, 557–565. [Google Scholar] [CrossRef]

- Lai, S.H. Design Optimisation of a Slotless Brushless Permanent Magnet dc Motor with Helically-Wound Laminations for Underwater Rim-Driven Thrusters. Ph.D. Thesis, University of Southampton, Southampton, UK, 2006. [Google Scholar] [CrossRef]

- Piet, V.D. Manufacture of a Prototype Advanced Permanent Magnet Motor Pod. J. Ship Prod. 2003, 19, 91–97. [Google Scholar] [CrossRef]

- Liu, B.; Vanierschot, M.; Buysschaert, F. Numerical study of scale effects on the open water performance of a rim-driven thruster. Appl. Ocean Res. 2023, 138, 103667. [Google Scholar] [CrossRef]

- Liang, X.; Yan, X.; Ouyang, W.; Liu, Z. Experimental research on tribological and vibration performance of water-lubricated hydrodynamic thrust bearings used in marine shaft-less rim driven thrusters. Wear 2019, 426–427, 778–791. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, X.; Qiao, M.; Zhu, P.; Cai, W.; Xia, Y.; Li, G. Optimal design and multifield coupling analysis of propelling motor used in a novel integrated motor propeller. IEEE Trans. Magn. 2013, 49, 5742–5748. [Google Scholar] [CrossRef]

- Yang, Z.; Yan, X.; Ouyang, W.; Bai, H.; Xiao, J. Multi-Parameter Fuzzy-Based Neural Network Sensorless PMSM Iterative Learning Control Algorithm for Vibration Suppression of Ship Rim-Driven Thruster. J. Mar. Sci. Eng. 2024, 12, 396. [Google Scholar] [CrossRef]

- Brown, D.W.; Repp, J.R.; Taylor, O.S. Submersible outboard electric motor/propulsor. Nav. Eng. J. 1989, 101, 44–52. [Google Scholar] [CrossRef]

- Richardson, K.M.; Pollock, C.; Flower, J.O. Design of a switched reluctance sector motor for an integrated motor/propeller unit. In Proceedings of the Seventh International Conference on Electrical Machines and Drives, Durham, UK, 11–13 September 1995; pp. 271–275. [Google Scholar] [CrossRef]

- Sharkh, S.M.A.; Lai, S.H.; Turnock, S.R. A structurally integrated brushless PM motor for miniature propeller thrusters. IEE Proc.-Electr. Power Appl. 2004, 151, 513–519. [Google Scholar] [CrossRef]

- Shen, Y.; Hu, P.; Jin, S.; Wei, Y.; Lan, R.; Zhuang, S.; Zhu, H.; Cheng, S.; Chen, J.; Wang, D.; et al. Design of novel shaftless pump-jet propulsor for multi-purpose long range and high speed autonomous underwater vehicle. IEEE Trans. Magn. 2016, 52, 7403304. [Google Scholar] [CrossRef]

- EL-Refaie, A.M. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines: Opportunities and Challenges. IEEE Trans. Ind. Electron. 2009, 57, 107–121. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.M.; Koo, D.H.; Woo, B.C.; Hong, D.K.; Lee, J.Y. Fractional slot concentrated winding permanent magnet synchronous machine with consequent pole rotor for low speed direct drive. IEEE Trans. Magn. 2012, 48, 2965–2968. [Google Scholar] [CrossRef]

- Markovic, M.; Perriard, Y. Optimization Design of a Segmented Halbach Permanent-Magnet Motor Using an Analytical Mode. IEEE Trans. Magn. 2009, 45, 2955–2960. [Google Scholar] [CrossRef]

- Sadeghi, S.; Parsa, L. Multiobjective design optimization of five-phase halbach array permanent-magnet machine. IEEE Trans. Magn. 2011, 47, 1658–1666. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J. A simple method for performance prediction of permanent magnet eddy current couplings using a new magnetic equivalent circuit model. IEEE Trans. Ind. Electron. 2018, 65, 2487–2495. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D.; Bolte, E. Instantaneous magnetic field distribution in brushless permanent magnet DC motors. I. Open-circuit field. IEEE Trans. Magn. 1993, 29, 124–135. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Instantaneous magnetic field distribution in brushless permanent magnet DC motors. II. Armature-reaction field. IEEE Trans. Magn. 1993, 29, 136–142. [Google Scholar] [CrossRef]

- Zarko, D.; Ban, D.; Lipo, T.A. Analytical calculation of magnetic field distribution in the slotted air gap of a surface permanent-magnet motor using complex relative air gap permeance. IEEE Trans. Magn. 2006, 42, 1828–1837. [Google Scholar] [CrossRef]

- Li, J.; Choi, D.; Cho, Y. Analysis of rotor eccentricity in switched reluctance motor with parallel winding using fem. IEEE Trans. Magn. 2009, 45, 2851–2854. [Google Scholar] [CrossRef]

| Design Parameter | Value (Unit) |

|---|---|

| Phase number | 3 |

| Rated power | 11 kW |

| Rated (line) voltage | 380 V |

| Rated speed | 1000 r/min |

| Number of slots | 24 |

| Number of poles | 20 |

| Rated frequency | 166.67 Hz |

| Outer diameter of the stator core | 350 mm |

| Inner diameter of the stator core | 286 mm |

| Thickness of the stator epoxy resin sheath | 1 mm |

| Physical air gap | 1 mm |

| Thickness of the stainless steel sheath of the rotor | 1 mm |

| Thickness of the permanent magnet | 12 mm |

| Flange thickness | 6 mm |

| Outer diameter of the impeller | 250 mm |

| Effective axial length | 56 mm |

| Source | NOPP | MOFEF |

|---|---|---|

| Fundamental magnetomotive force of the magnetic pole and constant specific magnetic permeability | 1 | |

| Harmonic magnetomotive force of the magnetic pole and constant specific magnetic permeability | ||

| Fundamental magnetomotive force of the magnetic pole and fundamental specific magnetic permeability | 1 | |

| Harmonic magnetomotive force of the magnetic pole and fundamental specific magnetic permeability |

| Source | NOPP | MOFEF |

|---|---|---|

| Harmonic magnetomotive force of the armature with fundamental current and constant specific magnetic permeability | 1 | |

| Harmonic magnetomotive force of the armature with fundamental current and fundamental specific magnetic permeability | 1 |

| Source | NOPP | MOFEF |

|---|---|---|

| Fundamental magnetomotive force of the armature with harmonic current and constant specific magnetic permeability | ||

| Harmonic magnetomotive force of the armature with harmonic current and constant specific magnetic permeability | ||

| Fundamental magnetomotive force of the armature with harmonic current and fundamental specific magnetic permeability | ||

| Harmonic magnetomotive force of the armature with harmonic current and fundamental specific magnetic permeability |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Shuai, C.; Qiao, M. Simulation Study on the Magnetic Field Characteristics of a Permanent Magnet Motor for a Rim-Driven Device. Appl. Sci. 2025, 15, 11129. https://doi.org/10.3390/app152011129

Jiang C, Shuai C, Qiao M. Simulation Study on the Magnetic Field Characteristics of a Permanent Magnet Motor for a Rim-Driven Device. Applied Sciences. 2025; 15(20):11129. https://doi.org/10.3390/app152011129

Chicago/Turabian StyleJiang, Chao, Changgeng Shuai, and Mingzhong Qiao. 2025. "Simulation Study on the Magnetic Field Characteristics of a Permanent Magnet Motor for a Rim-Driven Device" Applied Sciences 15, no. 20: 11129. https://doi.org/10.3390/app152011129

APA StyleJiang, C., Shuai, C., & Qiao, M. (2025). Simulation Study on the Magnetic Field Characteristics of a Permanent Magnet Motor for a Rim-Driven Device. Applied Sciences, 15(20), 11129. https://doi.org/10.3390/app152011129