Quantitative Evaluation of Paper Chromatography Spots in Correlation with Physicochemical Properties of Engine Oils

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Vehicles

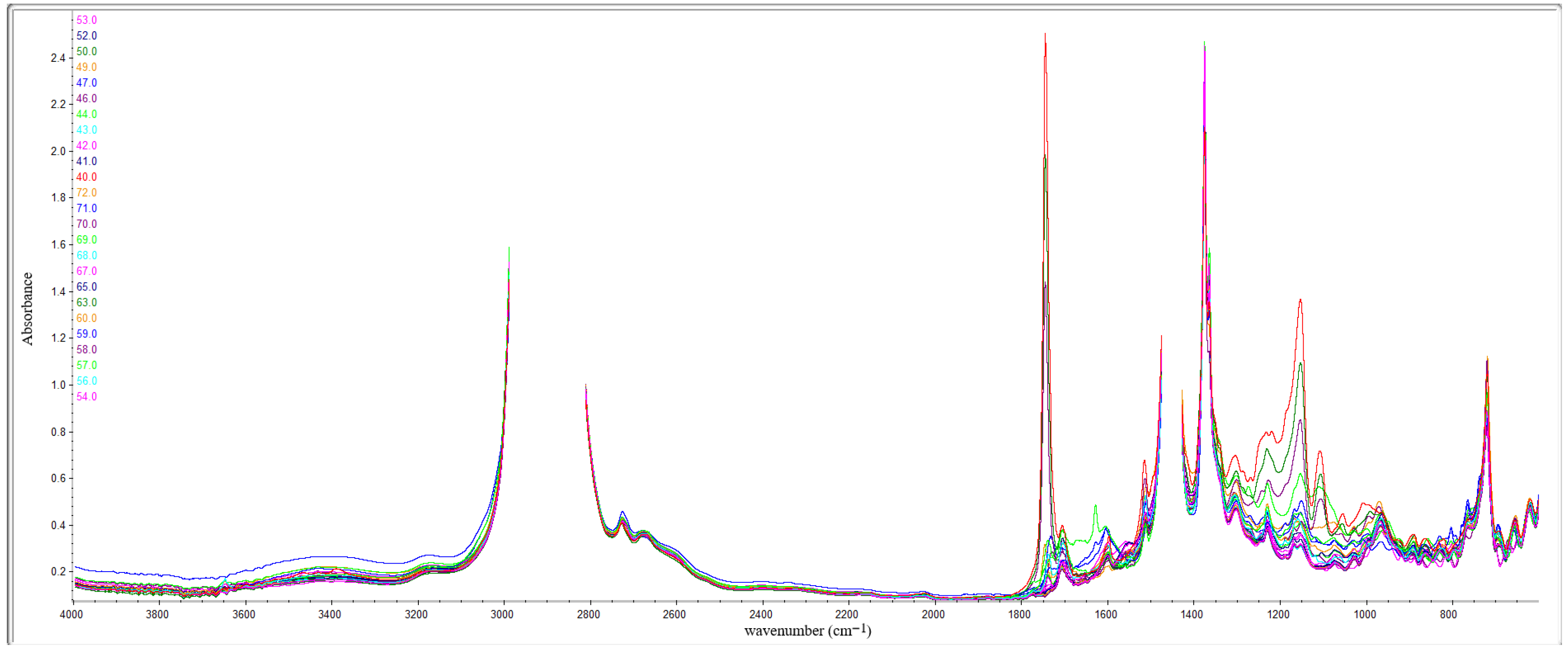

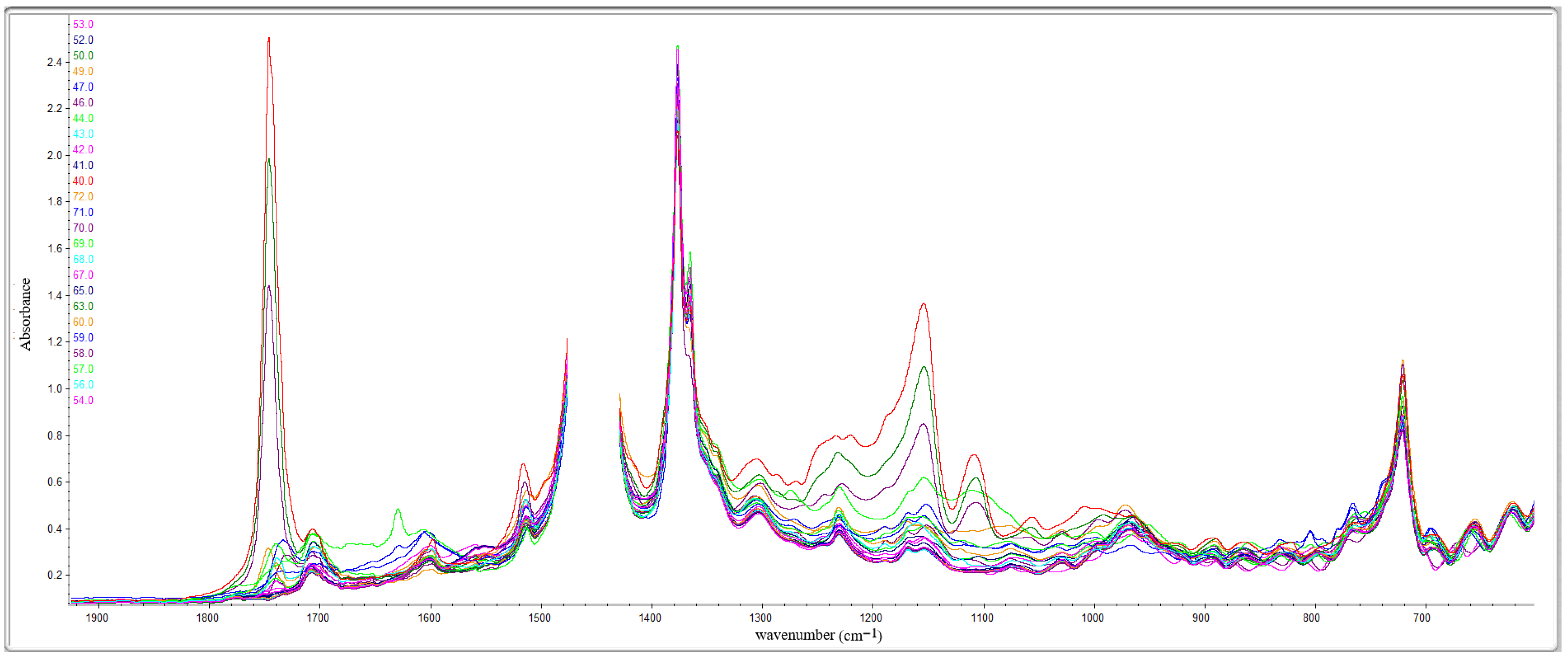

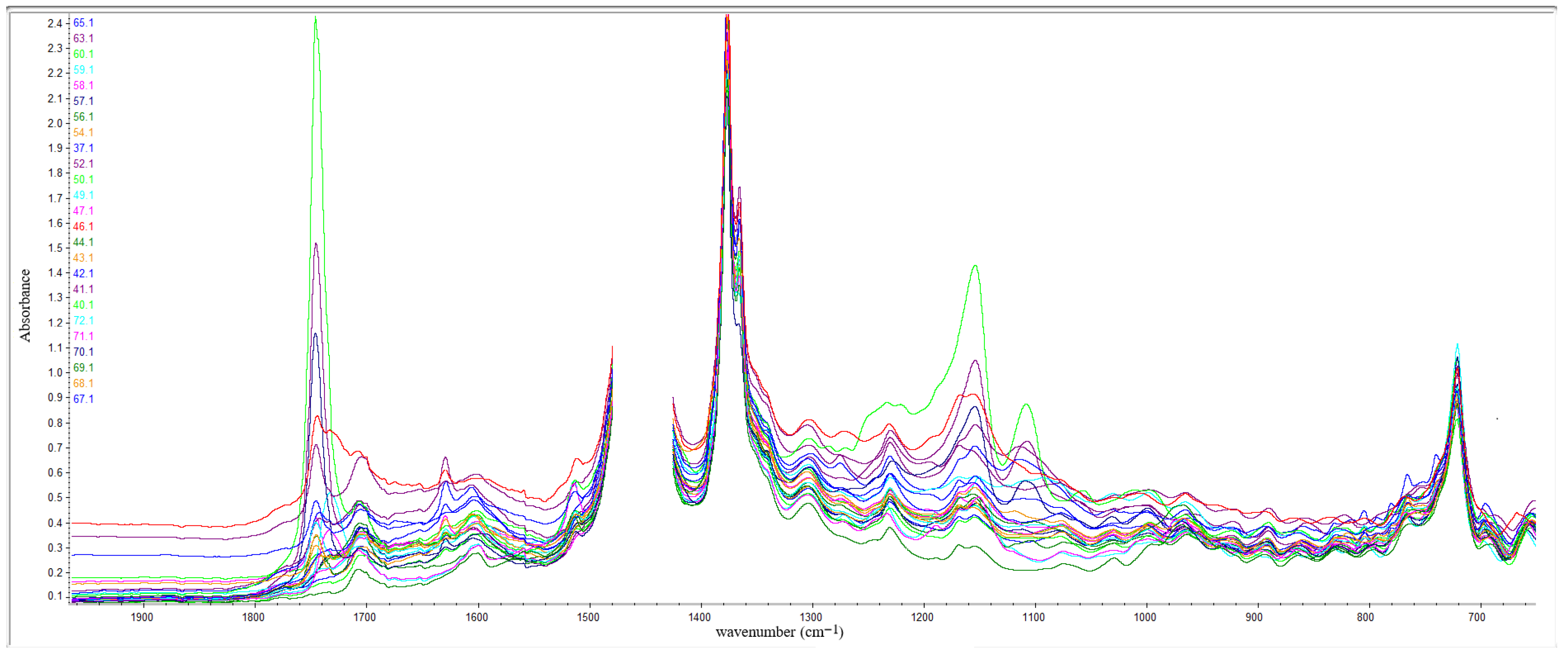

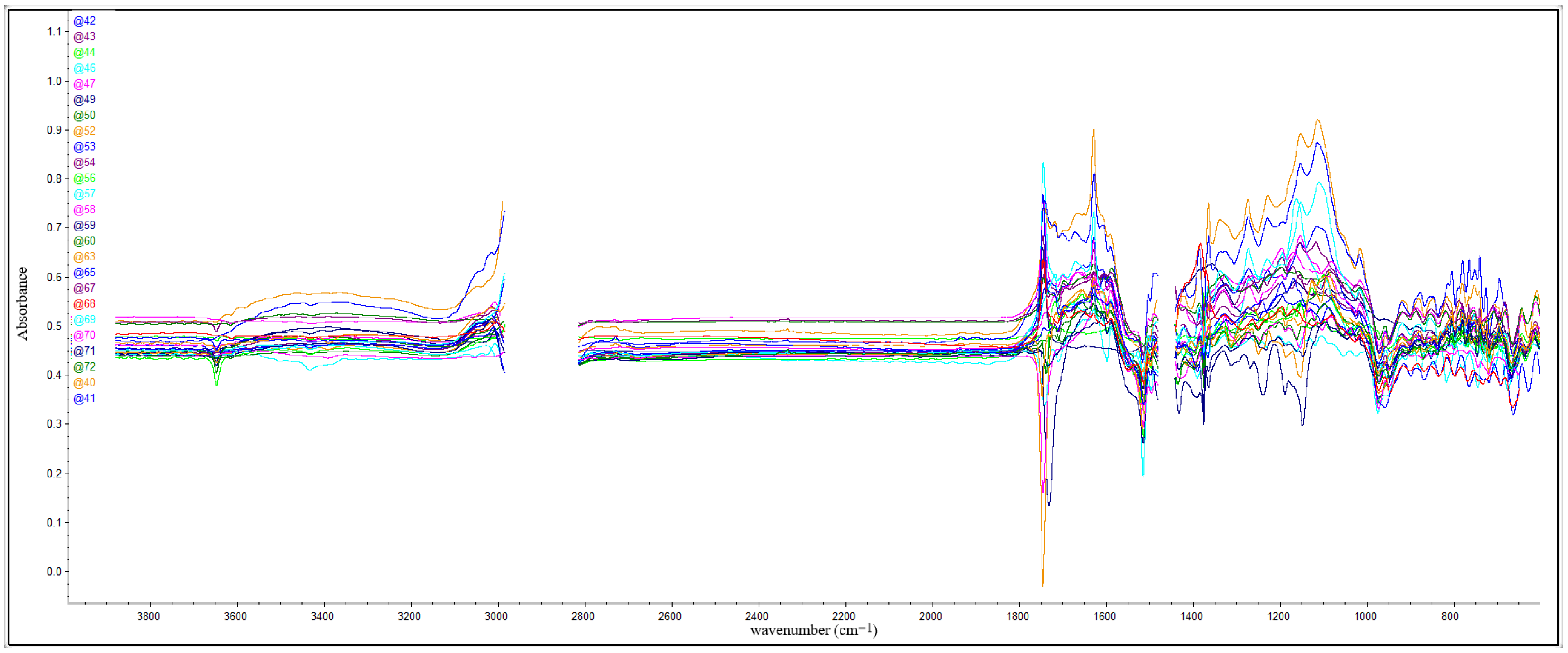

2.2. Research Equipment

2.3. Data Analysis Methods

2.4. Characteristics of Rapid Paper Tests

2.5. Procedure for an In-Depth Analysis of Chromatographic Separations on Paper Tests

3. Results

3.1. Results of Physico-Chemical Properties of Tested Oils

3.2. Results of Chromatographical Properties of Tested Oils

4. Statistical Analysis

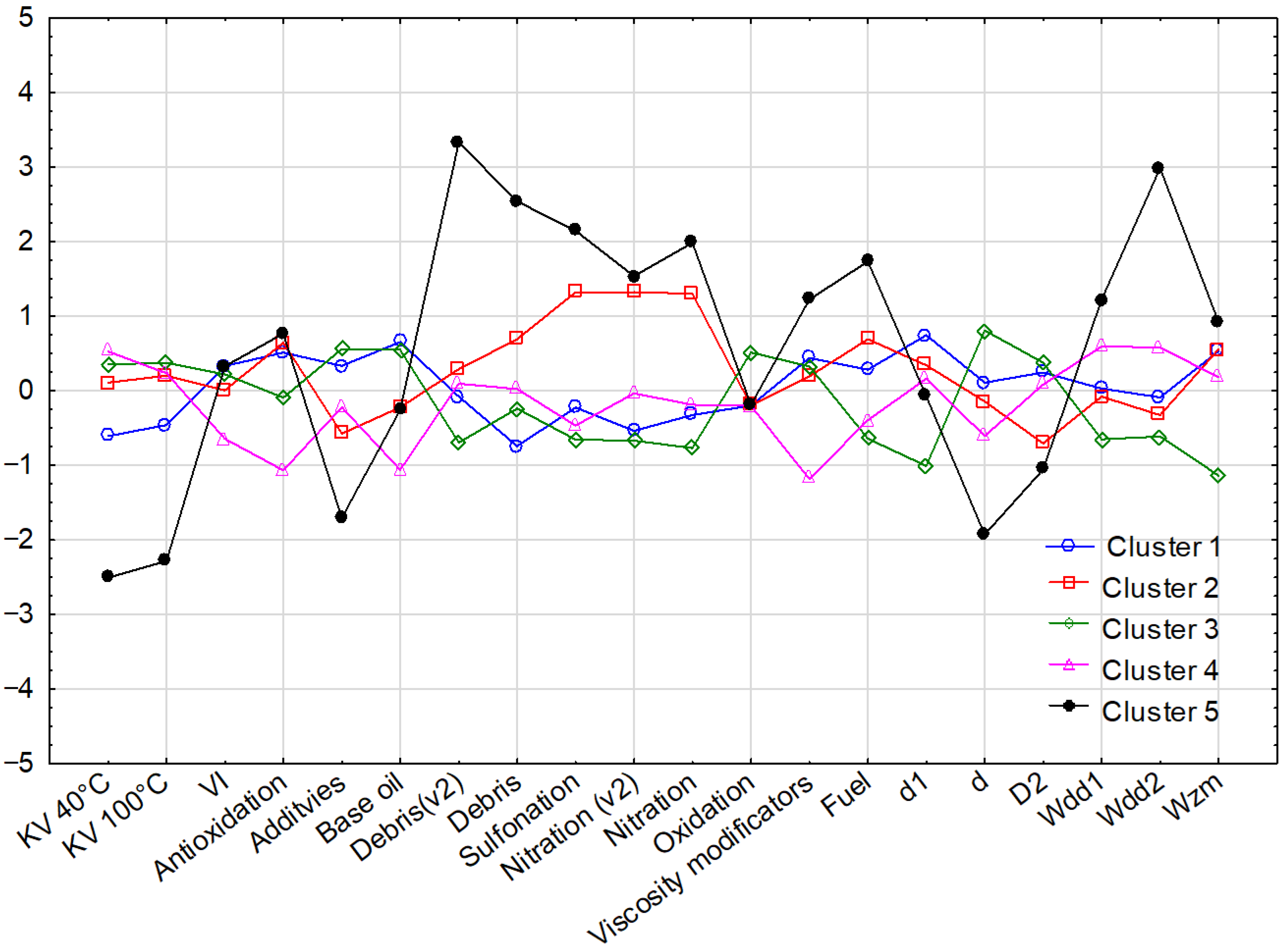

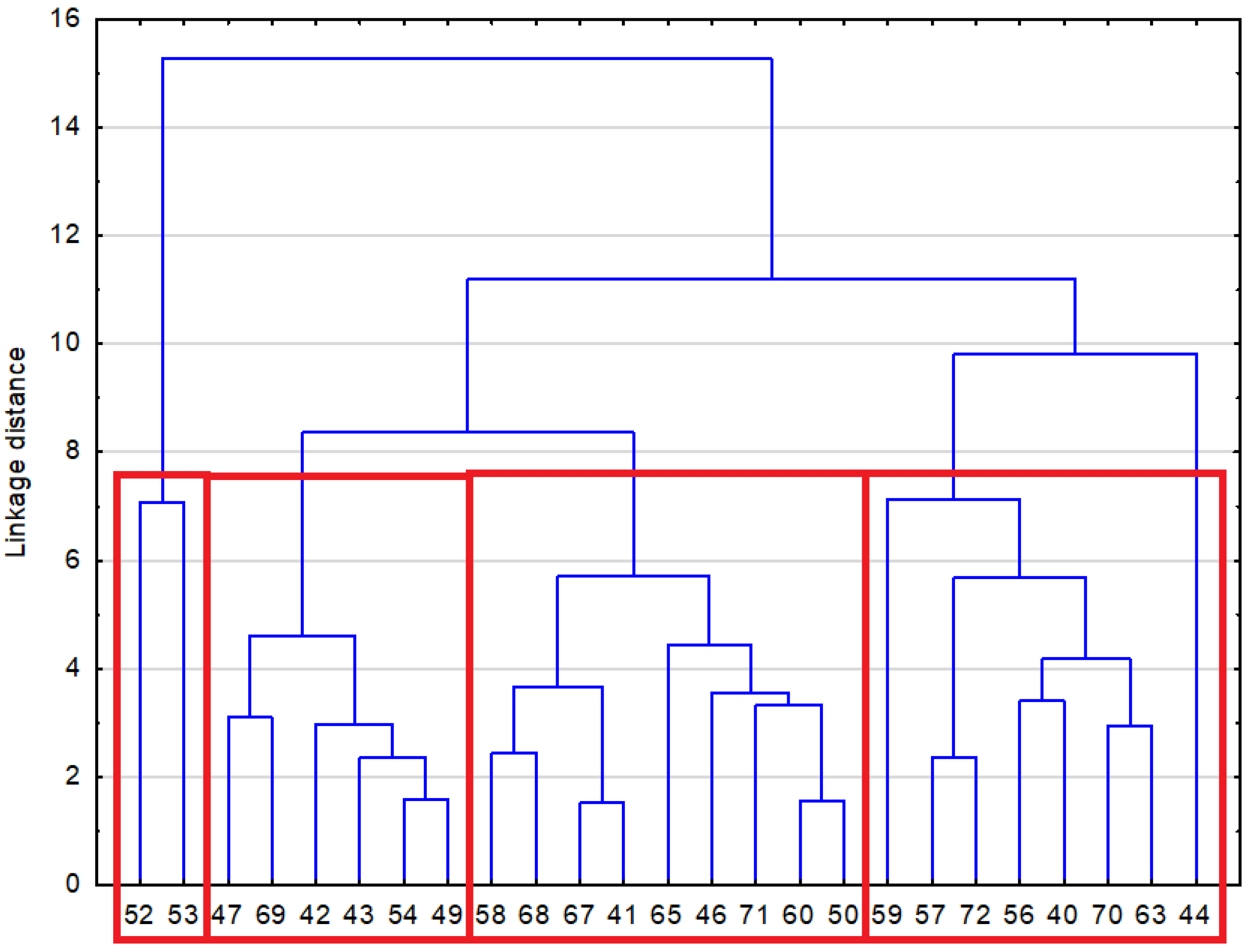

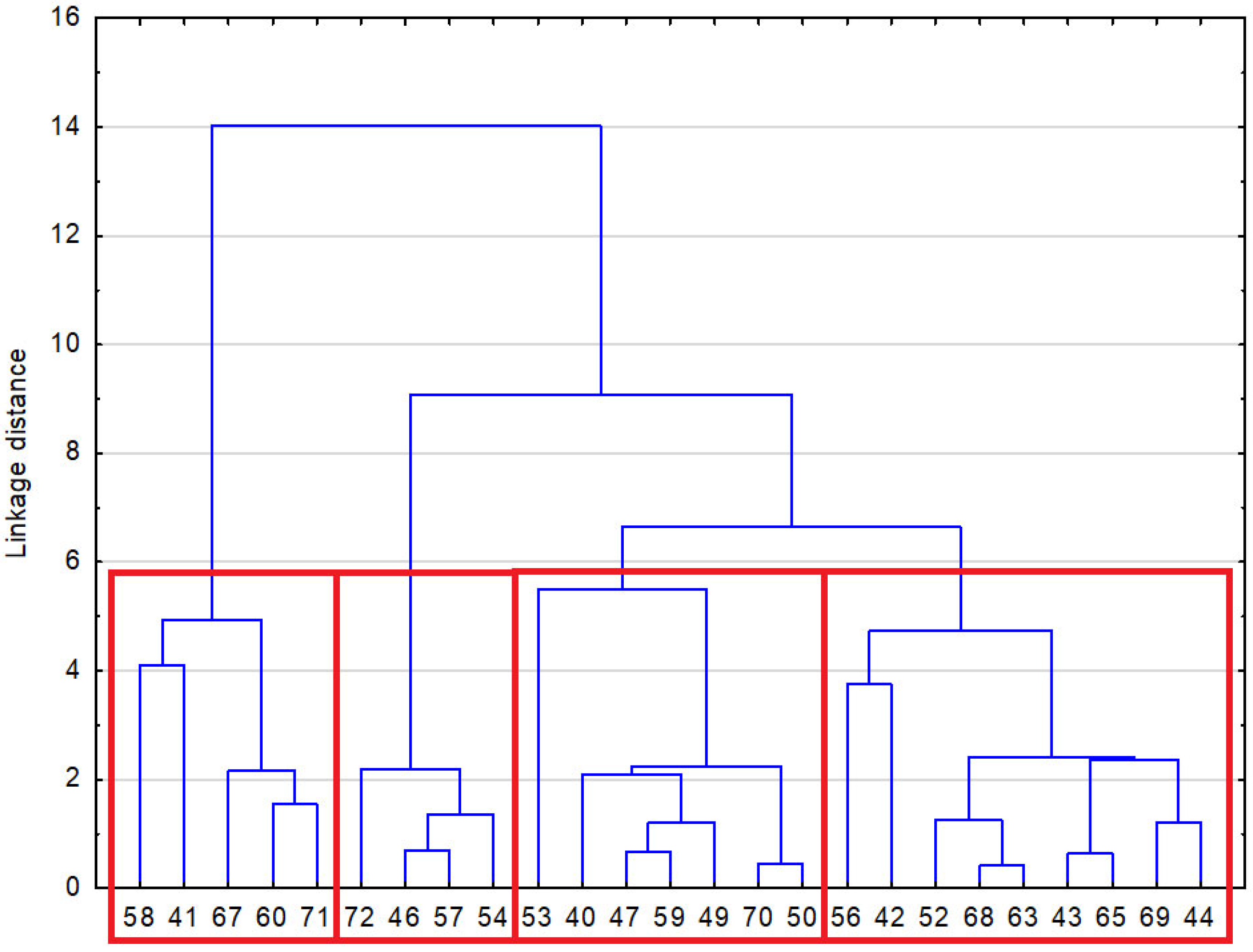

4.1. Results of Statistical Analysis—Clustering

4.2. Results of Statistical Analysis—Correlation

5. Discussion

6. Conclusions

7. Limitations

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Oil Sample No. | Car Brand | Car Model | Year of Production | Engine Displacement [cm3] | Engine Power [HP] | Fuel Type (Petrol/Diesel/LPG/Hybrid) | Particulate Filter (DPF/GPF)-YES/NO | Vehicle Mileage |

|---|---|---|---|---|---|---|---|---|

| 40 | Honda | Civic X. gen. | 2017 | 1500 | 182 | B | No | 60,600 |

| 41 | BMW | X3 E83 | 2007 | 2000 | 150 | D | Yes | 293,500 |

| 42 | Honda | Civic | 1998 | 1400 | 90 | B | No | 228,000 |

| 43 | Kia | Sportage | 2020 | 1600 | 132 | B | Yes | 14,100 |

| 44 | Mercedes-Benz | E W212 | 2011 | 3000 | 271 | D | No | 306,000 |

| 46 | Peugeot | 308 SW T9 | 2016 | 2000 | 150 | D | Yes | 250,000 |

| 47 | BMW | E92 330i | 2009 | 3000 | 272 | B | No | 331,740 |

| 49 | Audi | A7 | 2014 | 3000 | 500 | B | No | 174,000 |

| 50 | Ford | Focus mk4 | 2018 | 1500 | 182 | B | No | 87,000 |

| 52 | Fiat | Punto II | 2009 | 1242 | 60 | B | No | 132,990 |

| 53 | Ford | Ka mk2 | 2009 | 1242 | 68 | B | No | 117,735 |

| 54 | Honda | CR-V | 2013 | 2000 | 155 | B | No | 65,000 |

| 56 | Skoda | Octavia | 2021 | 1498 | 150 | B | Yes | 16,700 |

| 57 | Toyota | Prius | 2012 | 1800 | 99 | B/H/LPG | No | 317,000 |

| 58 | BMW | E60 | 2004 | 2993 | 218 | D | Yes | 373,000 |

| 59 | Toyota | Corolla | 2019 | 1200 | 116 | B | No | 65,700 |

| 60 | Volkswagen | Passat B5 | 2000 | 1900 | 116 | D | No | 367,500 |

| 63 | Volkswagen | Passat B8 | 2016 | 1798 | 180 | B | No | 147,840 |

| 65 | Mazda | CX-3 | 2019 | 2000 | 120 | B | No | 33,600 |

| 67 | Skoda | Octavia | 2021 | 1968 | 150 | D | Yes | 37,660 |

| 68 | Volvo | V70 III | 2007 | 2400 | 220 | D | Yes | 375,407 |

| 69 | Fiat | Bravo | 2009 | 1368 | 150 | B | No | 160,000 |

| 70 | Subaru | Impreza | 2006 | 1998 | 160 | B/LPG | No | 207,800 |

| 71 | Toyota | Corolla TS | 2022 | 1987 | 152 | B/H | Yes | 19,500 |

| 72 | Skoda | Superb | 2021 | 1988 | 190 | B | Yes | 20,500 |

| Oil Sample No. | Viscosity at 40 °C [mm2/s] | Viscosity at 100 °C [mm2/s] | Viscosity Index [VI] | Viscosity at 40 °C [mm2/s] | Viscosity at 100 °C [mm2/s] | Viscosity Index [VI] | Viscosity at 40 °C [mm2/s] | Viscosity at 100 °C [mm2/s] | Viscosity Index [VI] |

|---|---|---|---|---|---|---|---|---|---|

| Fresh Oil | Used Oil | Percentage Changes | |||||||

| 40 | 59.8 | 10.5 | 165.4 | 51.7 | 9.5 | 169.1 | −13% | −9% | 2% |

| 41 | 67.4 | 11.8 | 172.5 | 58.1 | 11.1 | 187.5 | −14% | −6% | 9% |

| 42 | 77.2 | 12.9 | 168.0 | 69.4 | 12.3 | 176.2 | −10% | −5% | 5% |

| 43 | 58.4 | 10.5 | 171.2 | 45.5 | 8.9 | 180.8 | −22% | −15% | 6% |

| 44 | 60.4 | 11.8 | 195.8 | 61.5 | 12.1 | 199.1 | 2% | 3% | 2% |

| 46 | 53.1 | 10.5 | 191.0 | 49.3 | 9.8 | 191.0 | −7% | −6% | 0% |

| 47 | 85.6 | 14.2 | 171.8 | 74.2 | 12.6 | 169.5 | −13% | −11% | −1% |

| 49 | 88.7 | 14.2 | 166.4 | 70.6 | 12.2 | 172.2 | −20% | −14% | 3% |

| 50 | 46.9 | 8.5 | 160.5 | 41.2 | 7.8 | 164.0 | −12% | −8% | 2% |

| 52 | 80.7 | 13.4 | 169.4 | 83.7 | 14.4 | 166.9 | 4% | 7% | −1% |

| 53 | 88.5 | 14.6 | 172.6 | 58.0 | 10.7 | 177.8 | −34% | −27% | 3% |

| 54 | 56.5 | 10.5 | 178.7 | 47.7 | 9.3 | 182.9 | −16% | −11% | 2% |

| 56 | 67.2 | 11.9 | 175.4 | 63.7 | 11.5 | 176.5 | −5% | −4% | 1% |

| 57 | 41.9 | 8.0 | 165.7 | 38.9 | 7.8 | 177.3 | −7% | −2% | 7% |

| 58 | 88.6 | 14.4 | 169.6 | 65.7 | 11.7 | 175.5 | −26% | −19% | 3% |

| 59 | 36.8 | 8.6 | 222.4 | 30.5 | 6.8 | 189.3 | −17% | −21% | −15% |

| 60 | 88.3 | 14.5 | 171.3 | 76.4 | 12.9 | 170.3 | −14% | −11% | −1% |

| 63 | 65.1 | 11.7 | 176.4 | 59.7 | 10.9 | 176.4 | −8% | −7% | 0% |

| 65 | 57.0 | 10.2 | 167.7 | 44.7 | 8.6 | 172.2 | −21% | −16% | 3% |

| 67 | 39.8 | 7.9 | 176.0 | 34.2 | 7.3 | 187.9 | −14% | −7% | 7% |

| 68 | 67.4 | 11.1 | 156.9 | 58.1 | 10.1 | 163.2 | −14% | −9% | 4% |

| 69 | 84.5 | 13.8 | 168.2 | 68.7 | 11.8 | 168.0 | −19% | −15% | 0% |

| 70 | 79.2 | 12.9 | 164.5 | 74.8 | 12.4 | 163.7 | −6% | −5% | 0% |

| 71 | 31.0 | 6.9 | 193.3 | 25.9 | 5.9 | 181.6 | −16% | −15% | −6% |

| 72 | 43.7 | 8.2 | 164.6 | 43.1 | 8.2 | 170.1 | −2% | 1% | 3% |

| Oil Sample No. | Antioxidation Degradation | EP Degradation | Additives/Base Oil~1520 | Debris ~3000–3100 | Debris ~3150–3700 | Sulfonation Level | Nitration Level | Oxidation Level | Viscosity Modificators ~1747 | Fuel ~1590 |

|---|---|---|---|---|---|---|---|---|---|---|

| abs/0.1mm | Integrated Area (abs·cm−1) | abs/0.1mm | ||||||||

| 40 | −0.02 | −0.08 | −0.17 | 4.12 | 3.39 | 0.13 | 0.12 | 0.07 | −0.12 | 0.08 |

| 41 | −0.02 | −0.12 | −0.08 | 2.00 | 0.00 | 0.17 | 0.14 | 0.00 | 0.32 | 0.11 |

| 42 | −0.01 | −0.06 | −0.09 | 3.40 | 3.12 | 0.24 | 0.22 | 0.14 | 0.00 | 0.14 |

| 43 | 0.00 | −0.13 | −0.09 | 4.46 | 7.85 | 0.20 | 0.20 | 0.13 | 0.15 | 0.14 |

| 44 | −0.01 | −0.03 | −0.01 | 0.00 | 0.00 | 0.07 | 0.01 | 0.00 | 0.16 | 0.02 |

| 46 | 0.00 | −0.01 | −0.03 | 0.36 | 2.61 | 0.04 | 0.05 | 0.03 | 0.11 | 0.02 |

| 47 | 0.00 | −0.13 | −0.10 | 0.84 | 4.20 | 0.22 | 0.22 | 0.12 | 0.00 | 0.09 |

| 49 | 0.00 | −0.10 | −0.08 | 3.59 | 0.00 | 0.15 | 0.17 | 0.08 | 0.08 | 0.16 |

| 50 | 0.00 | −0.09 | −0.05 | 2.80 | 3.66 | 0.12 | 0.10 | 0.04 | 0.03 | 0.09 |

| 52 | 0.00 | −0.17 | −0.07 | 5.55 | 16.33 | 0.43 | 0.41 | 0.23 | 0.26 | 0.20 |

| 53 | 0.00 | −0.16 | −0.09 | 11.84 | 17.59 | 0.37 | 0.33 | 0.21 | 0.27 | 0.18 |

| 54 | 0.00 | −0.07 | −0.07 | 3.85 | 5.54 | 0.15 | 0.16 | 0.08 | 0.18 | 0.15 |

| 56 | −0.05 | −0.14 | −0.14 | 2.67 | 4.40 | 0.14 | 0.15 | 0.11 | −0.11 | 0.07 |

| 57 | −0.03 | −0.06 | −0.06 | 1.18 | 4.55 | 0.03 | 0.09 | −0.02 | −0.11 | 0.05 |

| 58 | −0.01 | −0.05 | −0.06 | 2.38 | −1.10 | 0.14 | 0.09 | 0.09 | 0.25 | 0.08 |

| 59 | −0.03 | −0.10 | −0.13 | 5.98 | 10.74 | 0.04 | 0.12 | −0.30 | 0.00 | 0.06 |

| 60 | 0.00 | −0.08 | −0.05 | 0.00 | 6.32 | 0.10 | 0.12 | 0.08 | 0.09 | 0.11 |

| 63 | −0.02 | −0.12 | −0.09 | 4.15 | 4.13 | 0.15 | 0.16 | 0.08 | −0.53 | 0.11 |

| 65 | −0.01 | −0.07 | 0.05 | 4.77 | 2.61 | 0.10 | 0.14 | 0.08 | 0.04 | 0.15 |

| 67 | −0.02 | −0.11 | −0.08 | 1.23 | 3.75 | 0.11 | 0.10 | 0.07 | 0.17 | 0.10 |

| 68 | −0.01 | −0.09 | −0.07 | 0.21 | −4.94 | 0.11 | 0.08 | 0.08 | 0.18 | 0.07 |

| 69 | 0.00 | −0.07 | −0.08 | 5.23 | 9.62 | 0.33 | 0.28 | 0.15 | 0.00 | 0.10 |

| 70 | 0.00 | −0.09 | −0.11 | 0.00 | 0.00 | 0.10 | 0.16 | 0.00 | −0.29 | 0.14 |

| 71 | −0.02 | −0.05 | −0.06 | 4.46 | 7.39 | 0.06 | 0.07 | 0.00 | 0.00 | 0.09 |

| 72 | −0.05 | −0.06 | −0.07 | 3.39 | 6.35 | 0.07 | 0.10 | 0.05 | 0.00 | 0.05 |

References

- Furch, J.; Konečný, V.; Krobot, Z. Modelling of Life Cycle Cost of Conventional and Alternative Vehicles. Sci. Rep. 2022, 12, 10661. [Google Scholar] [CrossRef] [PubMed]

- Apicella, B.; Catapano, F.; Di Iorio, S.; Magno, A.; Russo, C.; Sementa, P.; Tregrossi, A.; Vaglieco, B.M. Comprehensive Analysis on the Effect of Lube Oil on Particle Emissions through Gas Exhaust Measurement and Chemical Characterization of Condensed Exhaust from a DI SI Engine Fueled with Hydrogen. Part 2: Effect of Operating Conditions. Int. J. Hydrogen Energy 2024, 48, 22277–22287. [Google Scholar] [CrossRef]

- Nassar, A.M.; Ahmed, N.S.; Abdel-Hameed, H.S.; El-Kafrawy, A.F. Synthesis and Utilization of Non-Metallic Detergent/Dispersant and Antioxidant Additives for Lubricating Engine Oil. Tribol. Int. 2016, 93, 297–305. [Google Scholar] [CrossRef]

- Leonor, F.; Borda, G.; Jos, S.; Oliveira, D.; Maria, L.; Monteiro, S.; Jose, A.; Kalab, L. Experimental Investigation of the Tribological Behavior of Lubricants with Additive Containing Copper Nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Dörr, N.; Brenner, J.; Ristić, A.; Ronai, B.; Besser, C.; Pejaković, V.; Frauscher, M. Correlation Between Engine Oil Degradation, Tribochemistry, and Tribological Behavior with Focus on ZDDP Deterioration. Tribol. Lett. 2019, 67, 62. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Ristic, A.; Tabakov, Z.M.; Raffai, P.; Besser, C.; Frauscher, M. Oil Degradation Patterns in Diesel and Petrol Engines Observed in the Field—An Approach Applying Mass Spectrometry. Lubricants 2023, 11, 404. [Google Scholar] [CrossRef]

- Nguele, R.; Al-Salim, H.S.; Mohammad, K. Modeling and Forecasting of Depletion of Additives in Car Engine Oils Using Attenuated Total Reflectance Fast Transform Infrared Spectroscopy. Lubricants 2014, 2, 206–222. [Google Scholar] [CrossRef]

- Zając, G.; Gołębiowski, W.; Szczepanik, M.; Wolak, A.; Sejkorová, M. Analysis of Changes in Soot Content in Engine Oils under Operating Conditions. Lubricants 2023, 11, 89. [Google Scholar] [CrossRef]

- Al Sheikh Omar, A.; Motamen Salehi, F.; Farooq, U.; Morina, A.; Neville, A. Chemical and Physical Assessment of Engine Oils Degradation and Additive Depletion by Soot. Tribol. Int. 2021, 160, 107054. [Google Scholar] [CrossRef]

- Johnson, M.D.; McCabe, R.W.; Hubbard, C.P.; Riley, M.J.; Kirby, C.W.; Ball, D.J.; Tripp, G.; McDonnell, T.F.; Lam, W.Y. Effects of Engine Oil Formulation Variables on Exhaust Emissions in Taxi Fleet Service; In Proceedings of the SAE Technical Papers; SAE International: Troy, Turkey, 2002. [Google Scholar]

- Macián, V.; Tormos, B.; Olmeda, P.; Gómez, Y.A. Findings from a Fleet Test on the Performance of Two Engine Oil Formulations in Automotive CNG Engines. Lubr. Sci. 2015, 27, 15–28. [Google Scholar] [CrossRef]

- Wolak, A.; Krasodomski, W.; Zając, G. FTIR Analysis and Monitoring of Used Synthetic Oils Operated under Similar Driving Conditions. Friction 2019, 8, 995–1006. [Google Scholar] [CrossRef]

- Shinde, H.M.; Bewoor, A.K. Evaluating Petrol Engine Oil Deterioration through Oxidation and Nitration Parameters by Low-Cost IR Sensor. Appl. Petrochemical Res. 2020, 10, 83–94. [Google Scholar] [CrossRef]

- Shalygin, M.; Vashchishin, S.; Vashchishina, A. Study of Physico-Chemical and anti-wear properties of motor oils at the end of operation. Transp. Eng. 2024, 12–19. [Google Scholar] [CrossRef]

- Dörr, N.; Agocs, A.; Besser, C.; Ristić, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Tribol. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive Assessment of Oil Degradation Patterns in Petrol and Diesel Engines Observed in a Field Test with Passenger Cars—Conventional Oil Analysis and Fuel Dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Gołębiowski, W.; Wolak, A.; Zając, G. Definition of Oil Change Intervals Based on the Analysis of Selected Physicochemical Properties of Used Engine Oils. Combust. Engines 2018, 172, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Amrani, M.A.; Haddad, Y.; Abdulhameed, M.; Hyder, O.S.; Saif, A.; Ghaleb, A.M.; Mejjaouli, S. A Lubricating Oil-Based Maintenance for Diesel Engines at the End-User: An Effective Predictive Approach. Jordan J. Mech. Ind. Eng. 2022, 16, 689–700. [Google Scholar]

- Buses, U.; Raposo, H.; Farinha, T.; Ferreira, L.A. Condition Monitoring with Prediction Based on Diesel Engine Oil Analysis: A Case Study for urban buses. Actuators 2019, 8, 14. [Google Scholar] [CrossRef]

- Rodrigues, J.; Costa, I.; Farinha, J.T.; Mendes, M.; Margalho, L. Predicting Motor Oil Condition Using Artificial Neural Networks and Principal Component Analysis. Eksploat. I Niezawodn. 2020, 22, 440–448. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating Oil Conditioning Sensors for Online Machine Health Monitoring—A Review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Vasanthan, B.; Devaradjane, G.; Shanmugam, V. Online Condition Monitoring of Lubricating Oil on Test Bench Diesel Engine & Vehicle. J. Chem. Pharm. Sci. 2015, 4, 315–320. [Google Scholar]

- Zhang, R.; Howard, K.; Kirkman, P.; Browne, D.; Lu, Z.; He, S.; Boger, T. A Study into the Impact of Engine Oil on Gasoline Particulate Filter Performance through a Real-World Fleet Test; In Proceedings of the SAE Technical Papers; SAE International: Troy, Turkey, 2019. [Google Scholar]

- Molenda, J.; Wolak, A.; Zając, G.; Cieloch, P.; Chudy, D. Assessment of the Suitability of Paper Chromatography for Quick Diagnostics of the Operating Condition of Engine Oil. Eksploat. I Niezawodn. 2023, 25, 162912. [Google Scholar] [CrossRef]

- Bulauka, Y.; Mialeshka, A. Analysis of the Efficiency of Rapid-Tests to Determine the Time to Replace Used Engine oil. Her. Polotsk State Univ. Ser. B Ind. Appl. Sci. 2023, 1, 100–107. [Google Scholar] [CrossRef]

- Gryazin, V.; Bagautdinov, I.; Kozlov, K.; Belogusev, V. Tool for Quality Control of Lubricants. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018. [Google Scholar]

- Fygueroa, S.; Serrano, M.; Moreno, G. Engine Predictive Maintenance Thru Oil Analisys. Rev. Colomb. Tecnol. Av. 2009, 1, 91–96. [Google Scholar]

- ASTM E2412; Standard Practice for Condition Monitoring of Used Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D7042; Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D7899-19; Standard Test Method for Measuring the Merit of Dispersancy of In-Service Engine Oils with Blotter Spot Method. ASTM International: West Conshohocken, PA, USA, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

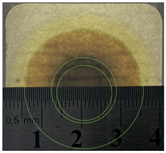

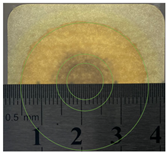

| Type of Engine Oil Contamination | Example of a Paper Chromatography Test After An Oil Test | Description of the Observation |

|---|---|---|

| Fuel |  | A pale ring will form around the outermost edge that can be observed after just 1 min from the application of oil to the test paper. |

| Soot and/or solids |  | The particles will form a black stain marking the deposition site (in the center). If the dispersing additives are working properly, fine soot particles will easily penetrate toward the outside of the applied droplet, blurring the boundaries between individual fraction areas. |

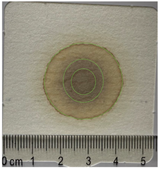

| Water |  | Ragged edges form on one of the inner circles. |

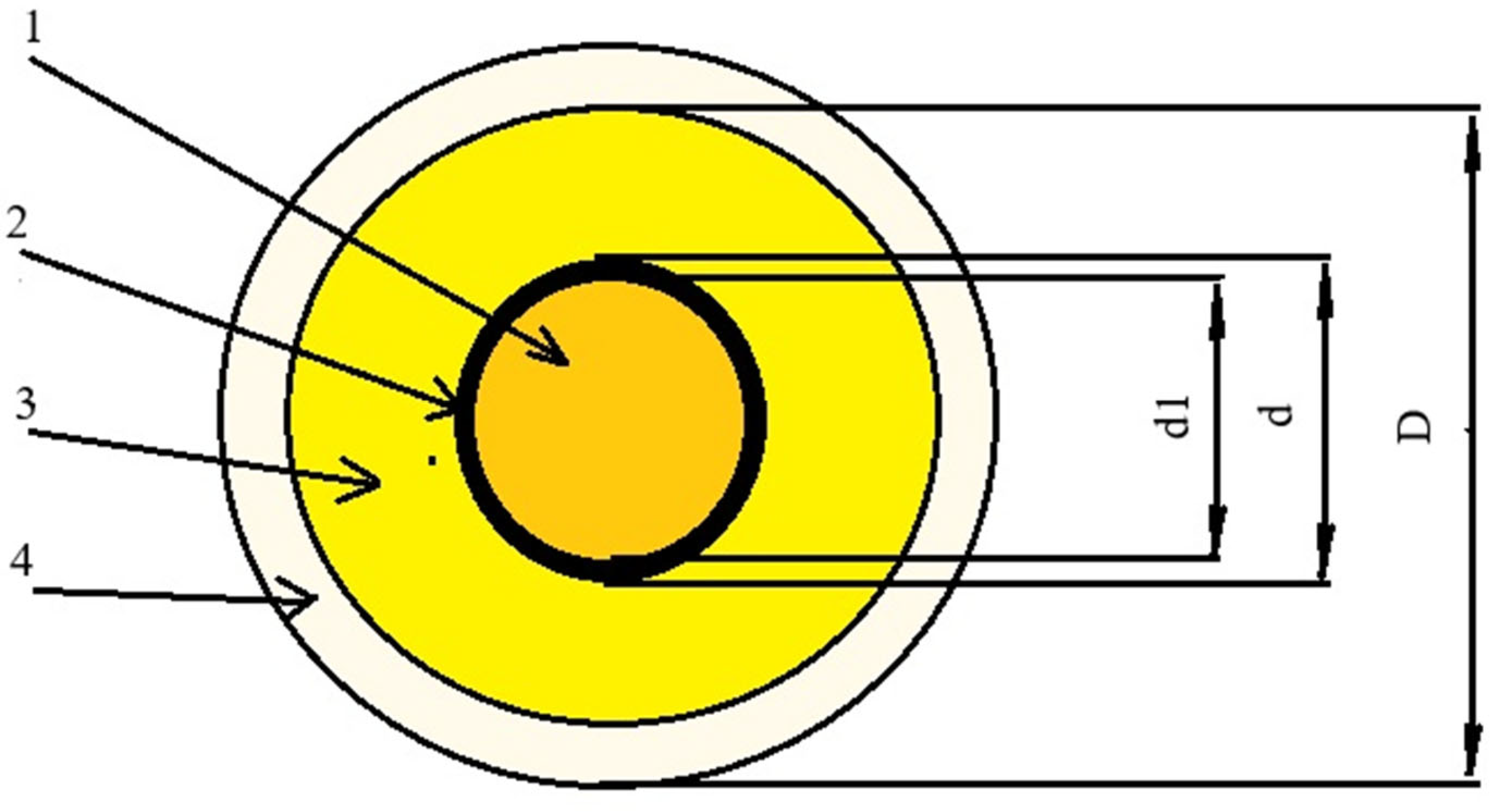

| Designation | Description |

|---|---|

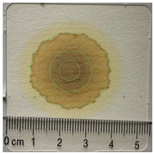

| 1, d1 (core zone) | The central part of the stain, referred to as the core, contains heavy contaminants that are poorly soluble in the oil. It is characterized by the smallest diameter (d1) and typically appears as the darkest and most concentrated area. |

| 2, d (marginal zone) | The marginal zone surrounds the core and has a larger diameter (d). As oil additives degrade during engine operation, an increasing amount of insoluble deposits forms, causing the marginal zone to expand outward. The diameter of this zone (d) is always greater than that of the core (d1), and its presence is indicative of the accumulation of suspended impurities that are no longer effectively dispersed. |

| 3, D diffusion (or dispersion) zone | This zone contains contaminants that are easily soluble in the oil and migrate further outward due to capillary action. It is characterized by a lighter coloration and represents the widest distinct ring of the stain, typically forming a smooth gradient from the center. |

| 4 (clean oil zone) | In some cases, an additional outer zone may be visible, corresponding to clean oil. However, this zone is not always present. When fuel contamination occurs, the visual signal of clean oil may overlap with that of fuel presence, or a separate, most external ring may emerge, indicating fuel dilution within the sample. |

| Oil Sample No. | Viscosity at 40 °C [mm2/s] | Viscosity at 100 °C [mm2/s] | Viscosity Index [VI] |

|---|---|---|---|

| Used Oil | |||

| 40 | 51.7 | 9.5 | 169.1 |

| 41 | 58.1 | 11.1 | 187.5 |

| 42 | 69.4 | 12.3 | 176.2 |

| 43 | 45.5 | 8.9 | 180.8 |

| 44 | 61.5 | 12.1 | 199.1 |

| 46 | 49.3 | 9.8 | 191.0 |

| 47 | 74.2 | 12.6 | 169.5 |

| 49 | 70.6 | 12.2 | 172.2 |

| 50 | 41.2 | 7.8 | 164.0 |

| 52 | 83.7 | 14.4 | 166.9 |

| 53 | 58.0 | 10.7 | 177.8 |

| 54 | 47.7 | 9.3 | 182.9 |

| 56 | 63.7 | 11.5 | 176.5 |

| 57 | 38.9 | 7.8 | 177.3 |

| 58 | 65.7 | 11.7 | 175.5 |

| 59 | 30.5 | 6.8 | 189.3 |

| 60 | 76.4 | 12.9 | 170.3 |

| 63 | 59.7 | 10.9 | 176.4 |

| 65 | 44.7 | 8.6 | 172.2 |

| 67 | 34.2 | 7.3 | 187.9 |

| 68 | 58.1 | 10.1 | 163.2 |

| 69 | 68.7 | 11.8 | 168.0 |

| 70 | 74.8 | 12.4 | 163.7 |

| 71 | 25.9 | 5.9 | 181.6 |

| 72 | 43.1 | 8.2 | 170.1 |

| Oil Sample No. | Oxidation Level | Nitration Level | Sulfonation Level | |||

|---|---|---|---|---|---|---|

| cm−1 | abs/0.1 mm | cm−1 | abs/0.1 mm | cm−1 | abs/0.1 mm | |

| 40 | ~1720 | 0.07 | ~1630 | 0.12 | ~1150 | 0.13 |

| 41 | 0.00 | 0.14 | 0.17 | |||

| 42 | 0.14 | 0.22 | 0.24 | |||

| 43 | 0.13 | 0.20 | 0.20 | |||

| 44 | 0.00 | 0.01 | 0.07 | |||

| 46 | 0.03 | 0.05 | 0.04 | |||

| 47 | 0.12 | 0.22 | 0.22 | |||

| 49 | 0.08 | 0.17 | 0.15 | |||

| 50 | 0.04 | 0.10 | 0.12 | |||

| 52 | 0.23 | 0.41 | 0.43 | |||

| 53 | 0.21 | 0.33 | 0.37 | |||

| 54 | 0.08 | 0.16 | 0.15 | |||

| 56 | 0.11 | 0.15 | 0.14 | |||

| 57 | −0.02 | 0.09 | 0.03 | |||

| 58 | 0.09 | 0.09 | 0.14 | |||

| 59 | −0.30 | 0.12 | 0.04 | |||

| 60 | 0.08 | 0.12 | 0.10 | |||

| 63 | 0.08 | 0.16 | 0.15 | |||

| 65 | 0.08 | 0.14 | 0.10 | |||

| 67 | 0.07 | 0.10 | 0.11 | |||

| 68 | 0.08 | 0.08 | 0.11 | |||

| 69 | 0.15 | 0.28 | 0.33 | |||

| 70 | 0.00 | 0.16 | 0.10 | |||

| 71 | 0.00 | 0.07 | 0.06 | |||

| 72 | 0.05 | 0.10 | 0.07 | |||

| Oil Sample No. | d1 | d | D2 | Wdd1 | Wdd2 | Wzm |

|---|---|---|---|---|---|---|

| 40 | 1.35 | 1.35 | 3.25 | 0.83 | 2.41 | 1.00 |

| 41 | 0.00 | 2.90 | 2.90 | 0.00 | 1.00 | 0.00 |

| 42 | 1.00 | 1.65 | 2.20 | 0.44 | 1.33 | 0.61 |

| 43 | 0.70 | 1.35 | 2.70 | 0.75 | 2.00 | 0.52 |

| 44 | 0.40 | 1.55 | 2.85 | 0.70 | 1.84 | 0.26 |

| 46 | 0.00 | 1.75 | 3.45 | 0.74 | 1.97 | 0.00 |

| 47 | 1.15 | 1.60 | 3.10 | 0.73 | 1.94 | 0.72 |

| 49 | 1.35 | 1.65 | 2.95 | 0.69 | 1.79 | 0.82 |

| 50 | 0.90 | 1.45 | 3.20 | 0.79 | 2.21 | 0.62 |

| 52 | 1.00 | 1.85 | 3.00 | 0.62 | 1.62 | 0.54 |

| 53 | 0.55 | 0.80 | 2.70 | 0.91 | 3.38 | 0.69 |

| 54 | 0.35 | 1.50 | 3.40 | 0.81 | 2.27 | 0.23 |

| 56 | 0.00 | 1.15 | 2.40 | 0.77 | 2.09 | 0.00 |

| 57 | 0.00 | 1.55 | 3.35 | 0.79 | 2.16 | 0.00 |

| 58 | 1.60 | 2.60 | 3.15 | 0.32 | 1.21 | 0.62 |

| 59 | 1.15 | 1.65 | 3.30 | 0.75 | 2.00 | 0.70 |

| 60 | 0.00 | 2.40 | 3.25 | 0.45 | 1.35 | 0.00 |

| 63 | 0.75 | 1.60 | 3.05 | 0.72 | 1.91 | 0.47 |

| 65 | 0.90 | 1.45 | 2.80 | 0.73 | 1.93 | 0.62 |

| 67 | 0.00 | 2.10 | 2.80 | 0.44 | 1.33 | 0.00 |

| 68 | 0.80 | 1.70 | 3.15 | 0.71 | 1.85 | 0.47 |

| 69 | 0.00 | 1.60 | 3.05 | 0.72 | 1.91 | 0.47 |

| 70 | 0.80 | 1.45 | 3.30 | 0.81 | 2.28 | 0.55 |

| 71 | 0.00 | 2.05 | 3.45 | 0.65 | 1.68 | 0.00 |

| 72 | 0.00 | 1.20 | 3.05 | 0.85 | 2.54 | 0.00 |

#40 |  #41 |  #42 |  #43 |  #44 |

#46 |  #47 |  #49 |  #50 |  #52 |

#53 |  #54 |  #56 |  #57 |  #58 |

#59 |  #60 |  #63 |  #65 |  #67 |

#68 |  #69 |  #70 |  #71 |  #72 |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolak, A. Quantitative Evaluation of Paper Chromatography Spots in Correlation with Physicochemical Properties of Engine Oils. Appl. Sci. 2025, 15, 11023. https://doi.org/10.3390/app152011023

Wolak A. Quantitative Evaluation of Paper Chromatography Spots in Correlation with Physicochemical Properties of Engine Oils. Applied Sciences. 2025; 15(20):11023. https://doi.org/10.3390/app152011023

Chicago/Turabian StyleWolak, Artur. 2025. "Quantitative Evaluation of Paper Chromatography Spots in Correlation with Physicochemical Properties of Engine Oils" Applied Sciences 15, no. 20: 11023. https://doi.org/10.3390/app152011023

APA StyleWolak, A. (2025). Quantitative Evaluation of Paper Chromatography Spots in Correlation with Physicochemical Properties of Engine Oils. Applied Sciences, 15(20), 11023. https://doi.org/10.3390/app152011023