Deformation of Existing Highway Induced by Close Undercrossing of Shield Tunnel with Steep Slope: A Case Study

Abstract

1. Introduction

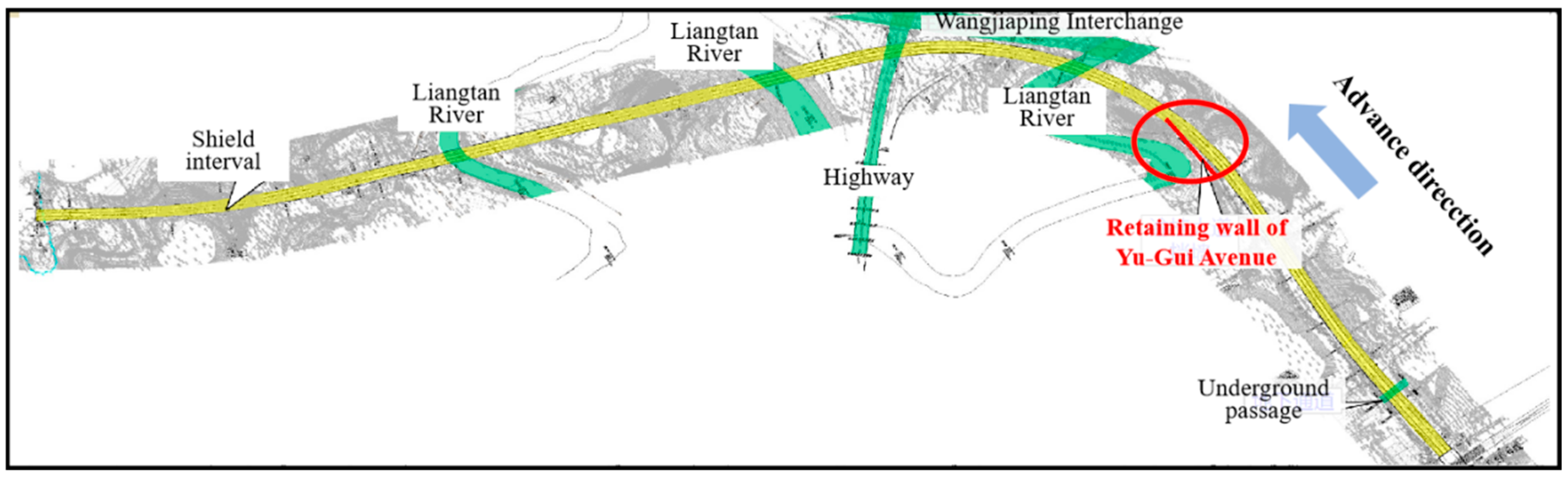

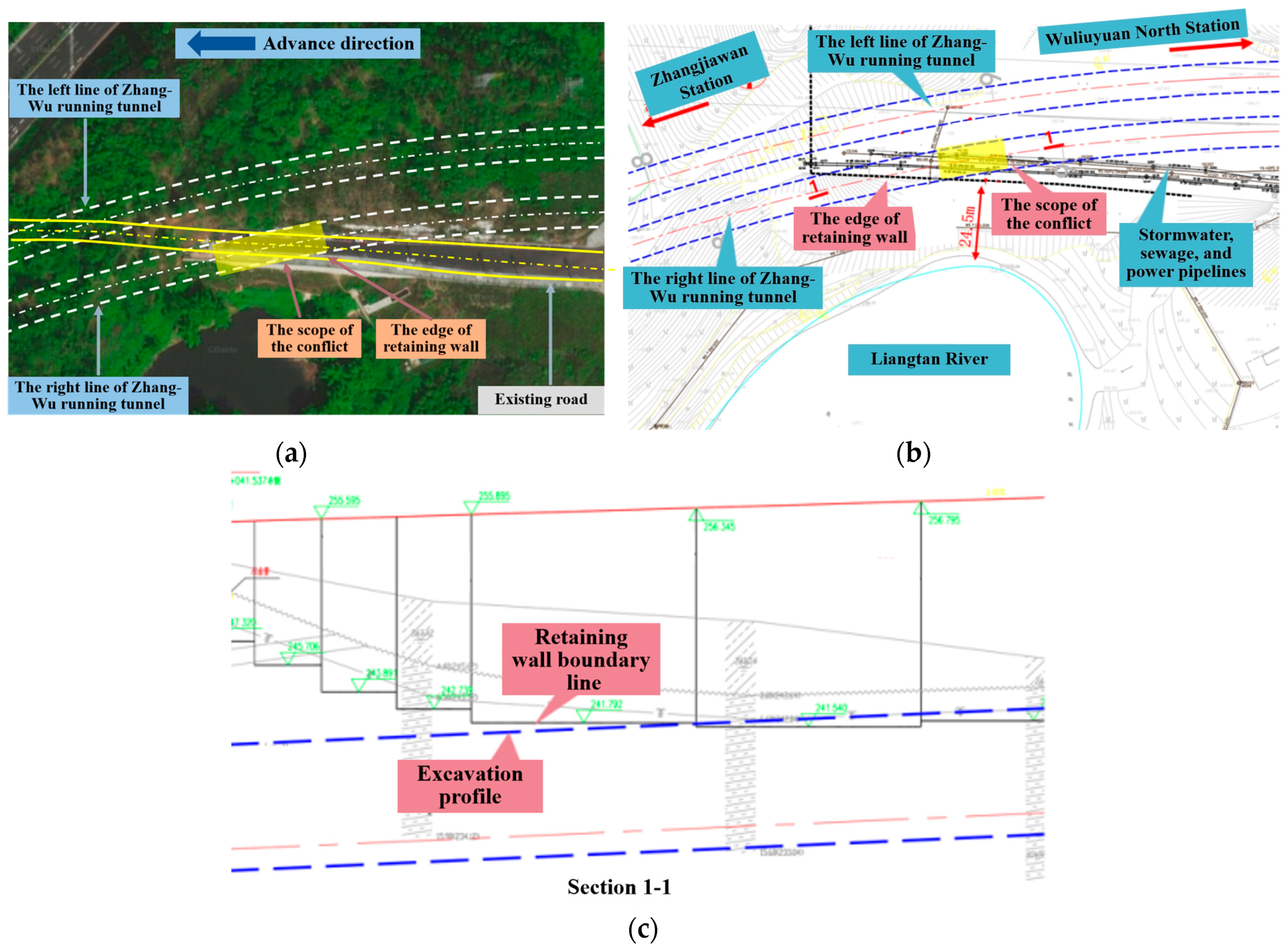

2. Project Background

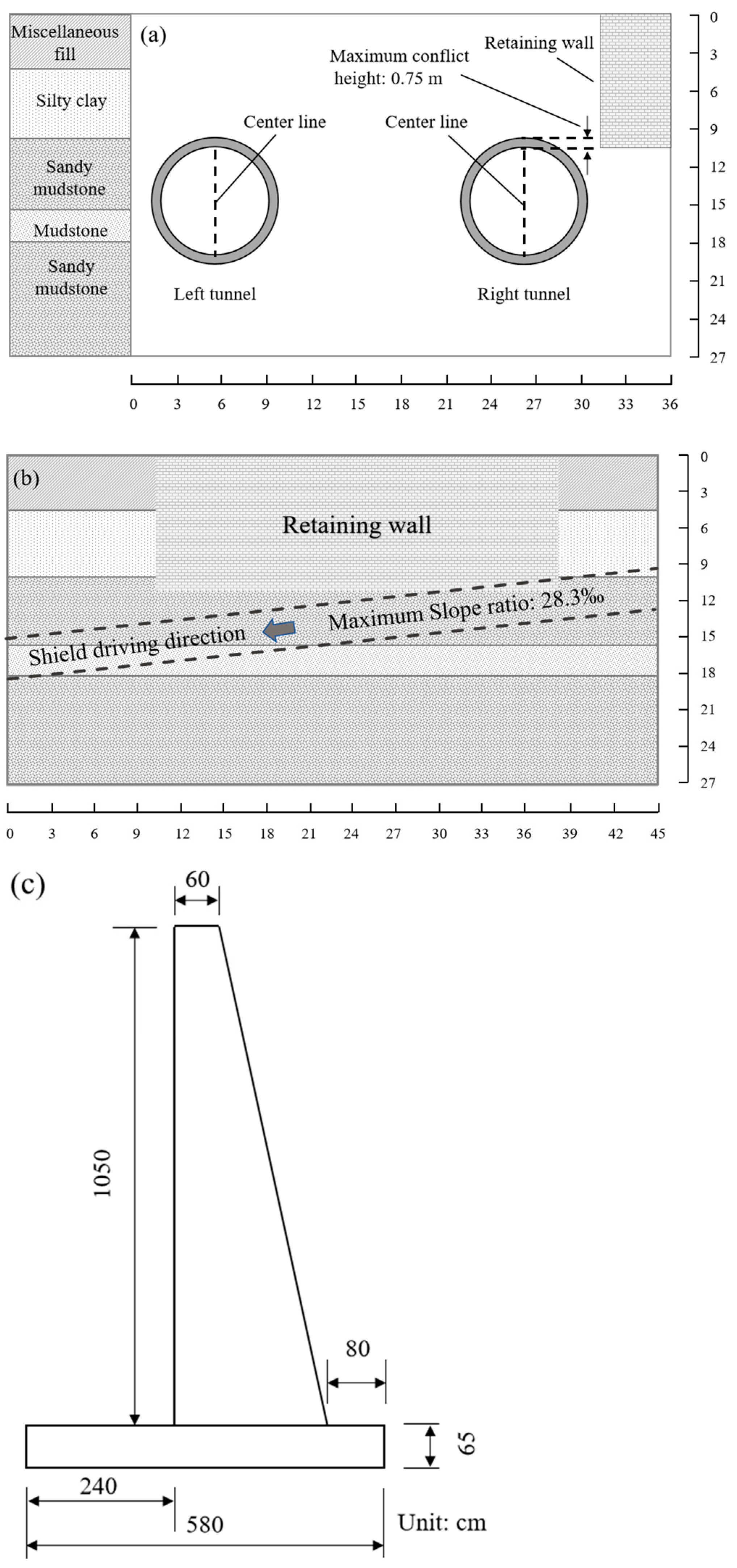

2.1. Project Introduction

2.2. Geological Condition

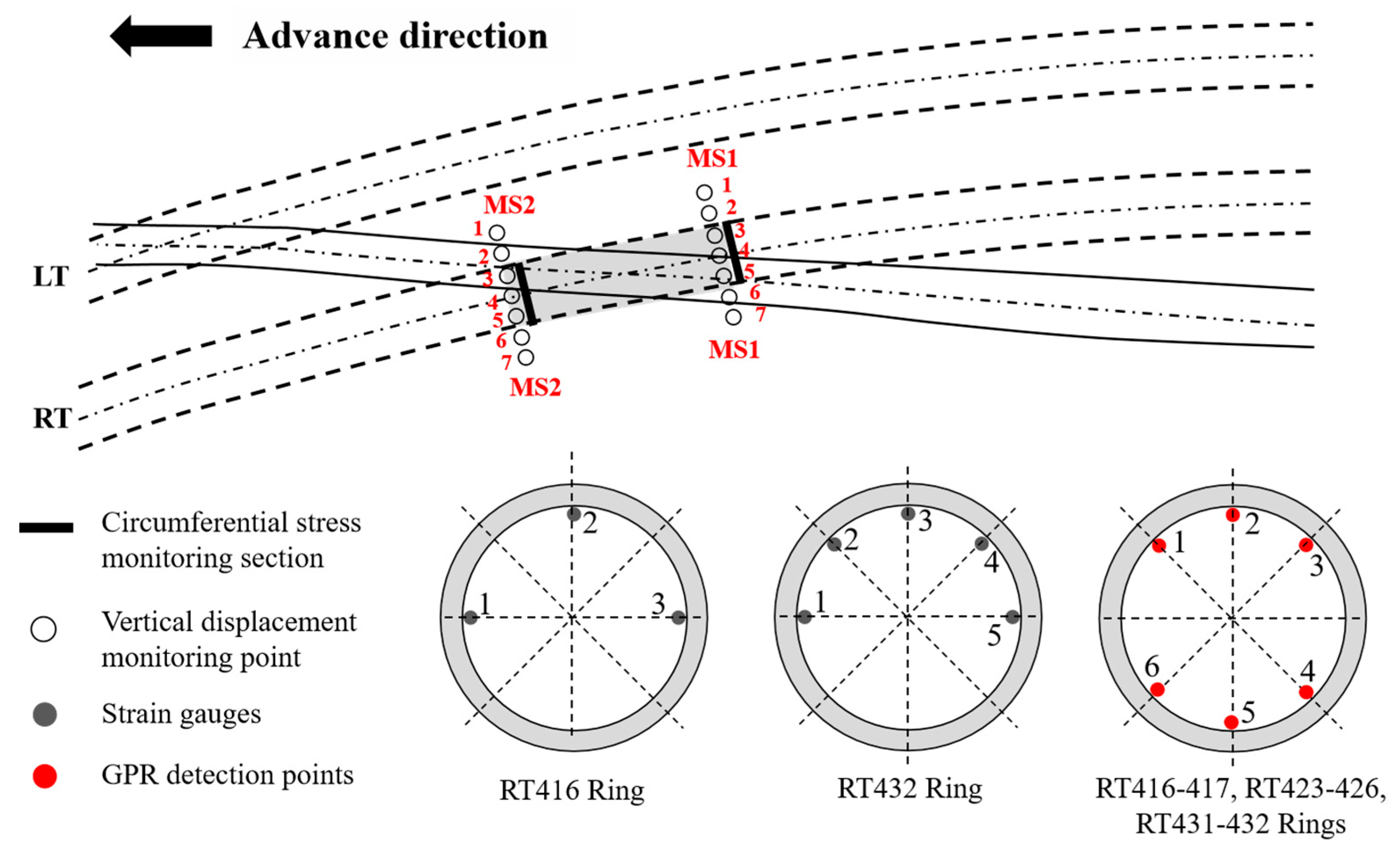

2.3. Monitoring Program

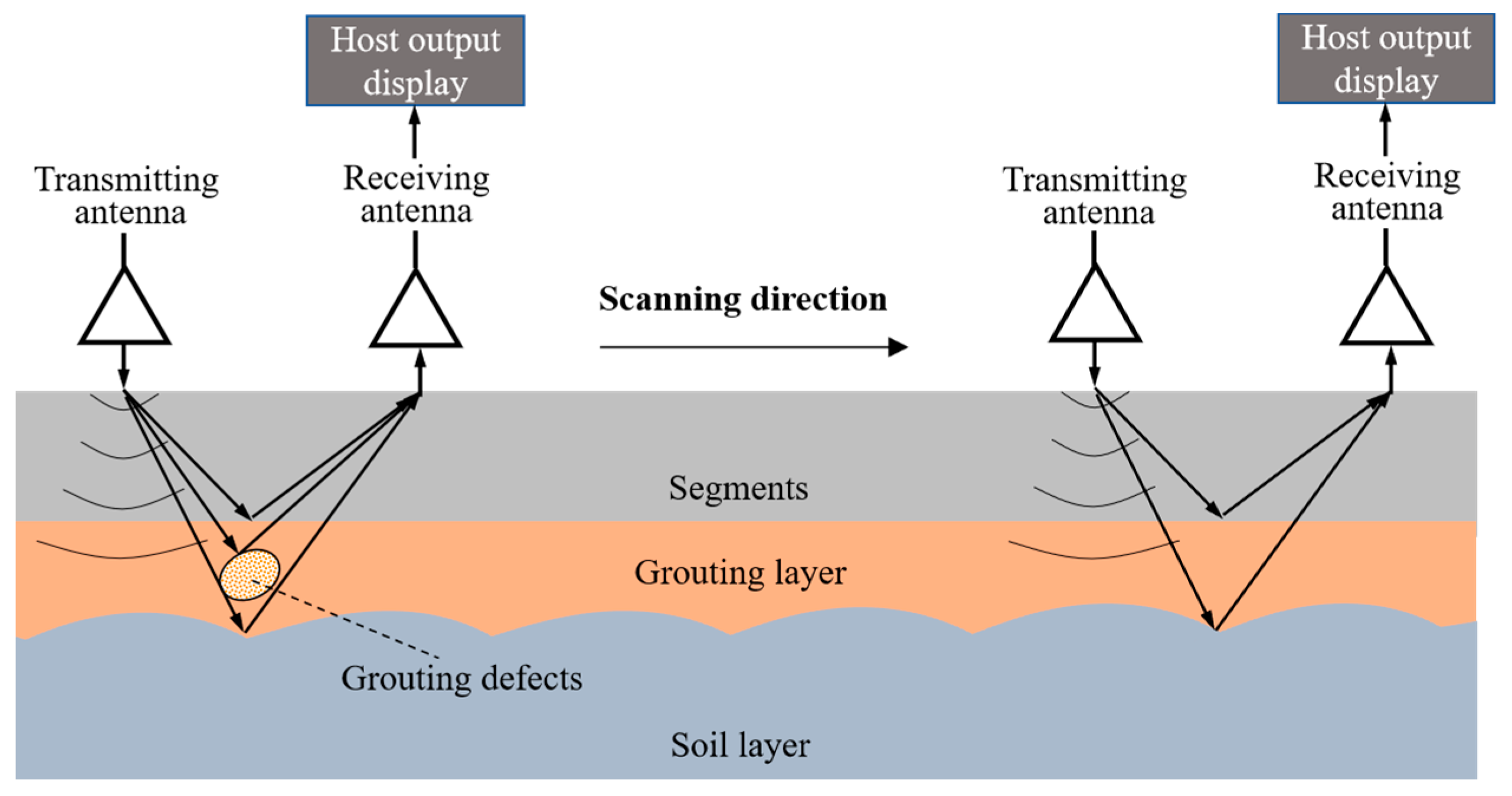

2.4. Detecting Principle of GPR in Grouting Quality Behind Tunnel Lining

3. Field Observations

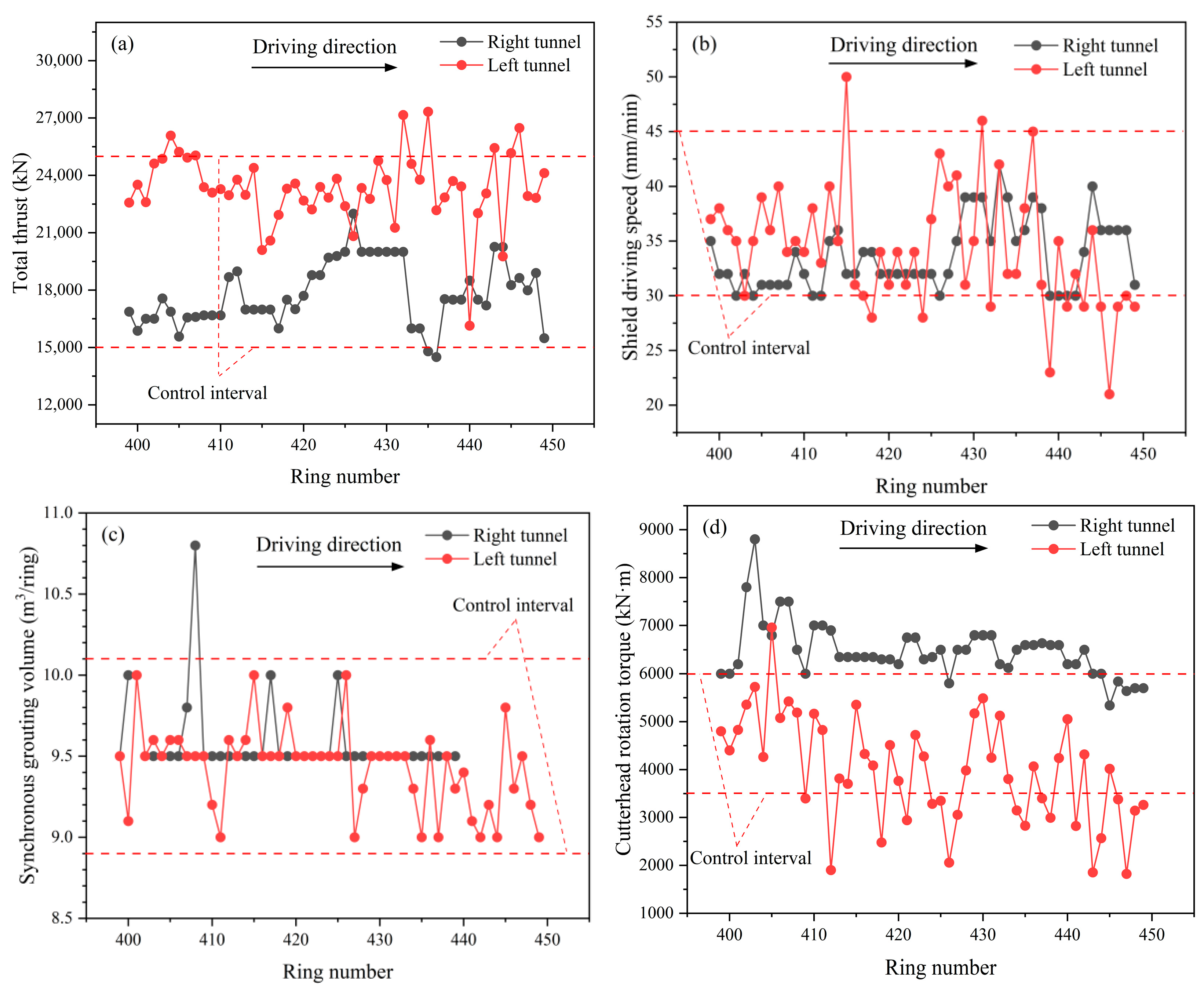

3.1. Shield Tunneling Parameters

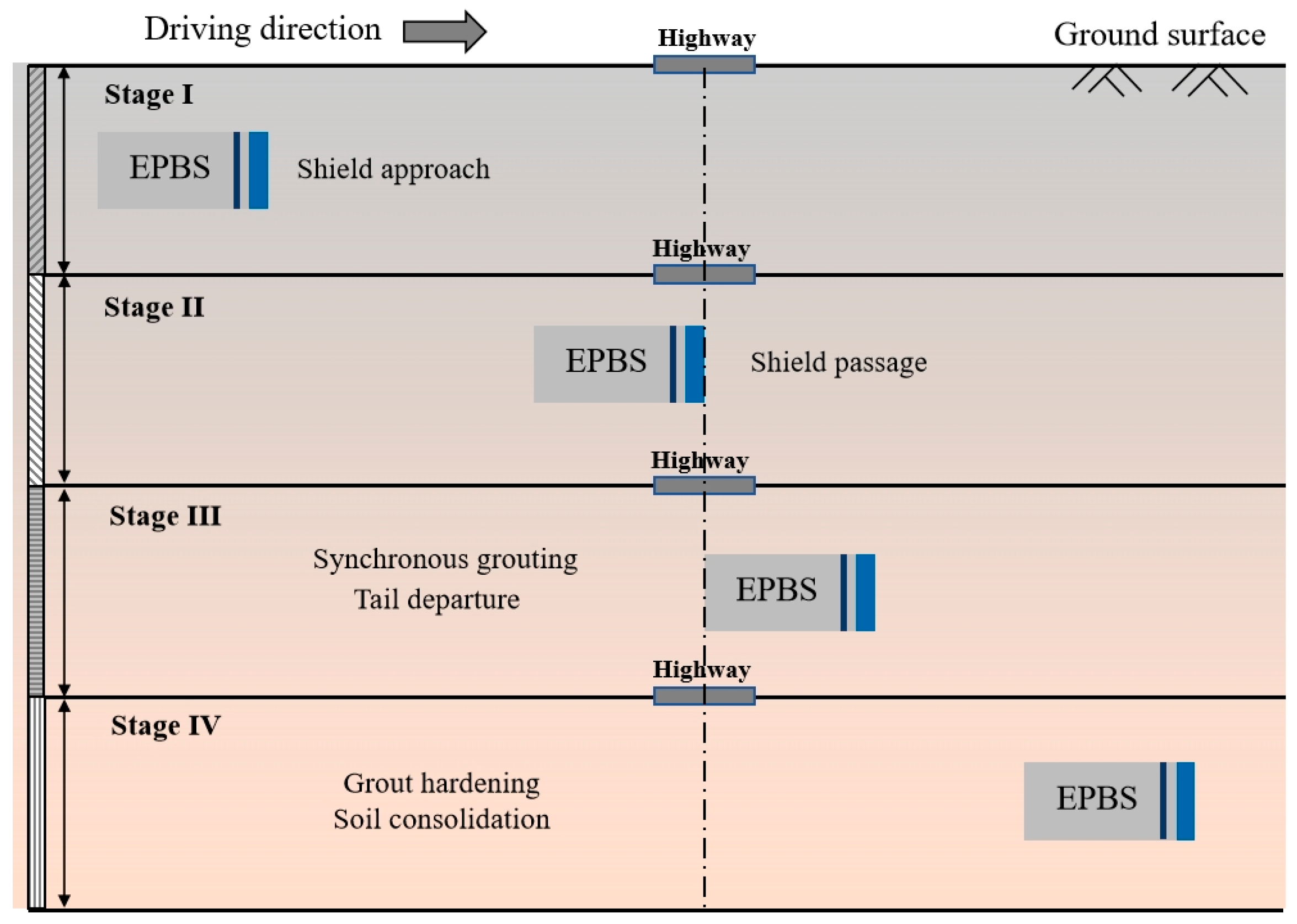

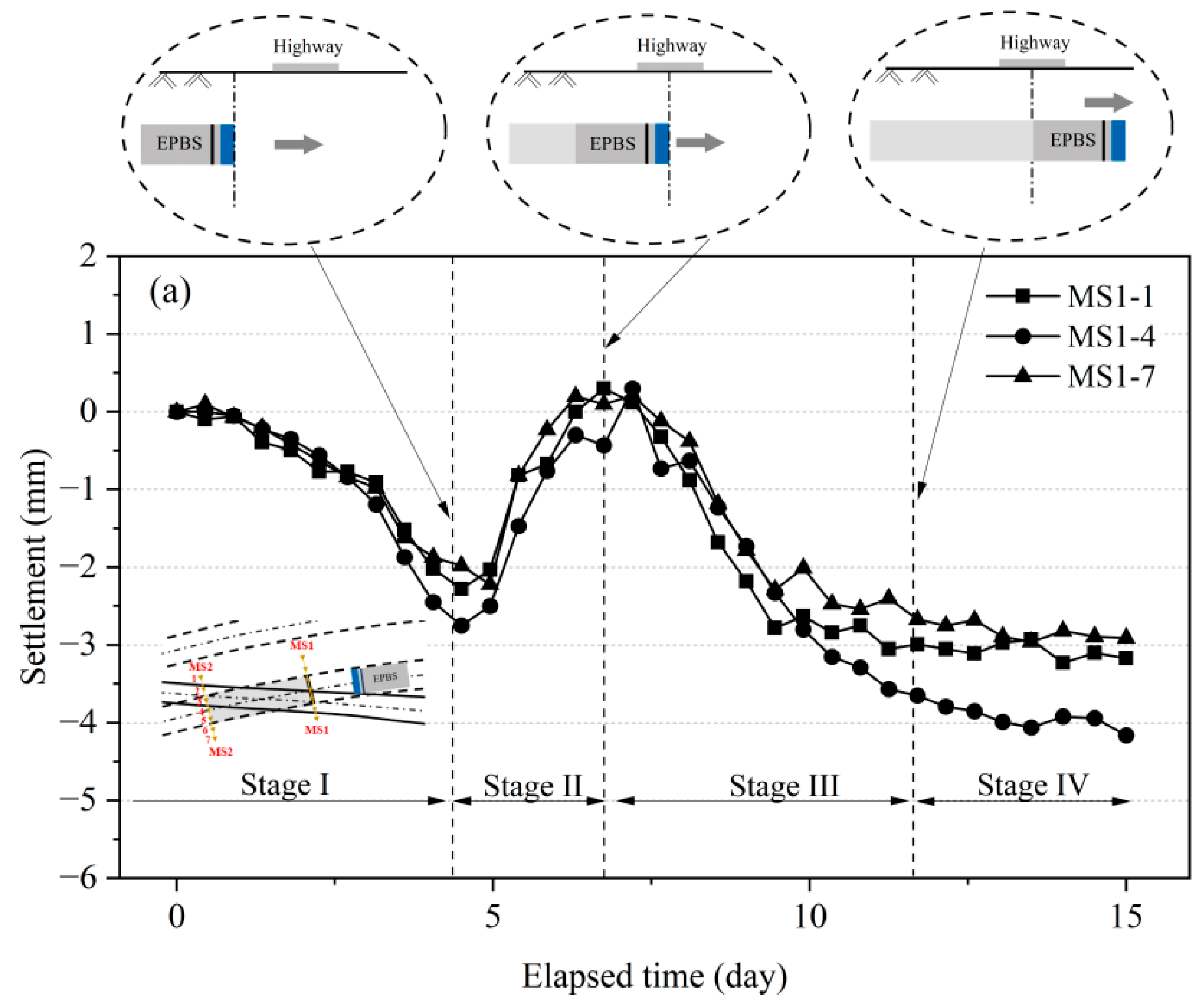

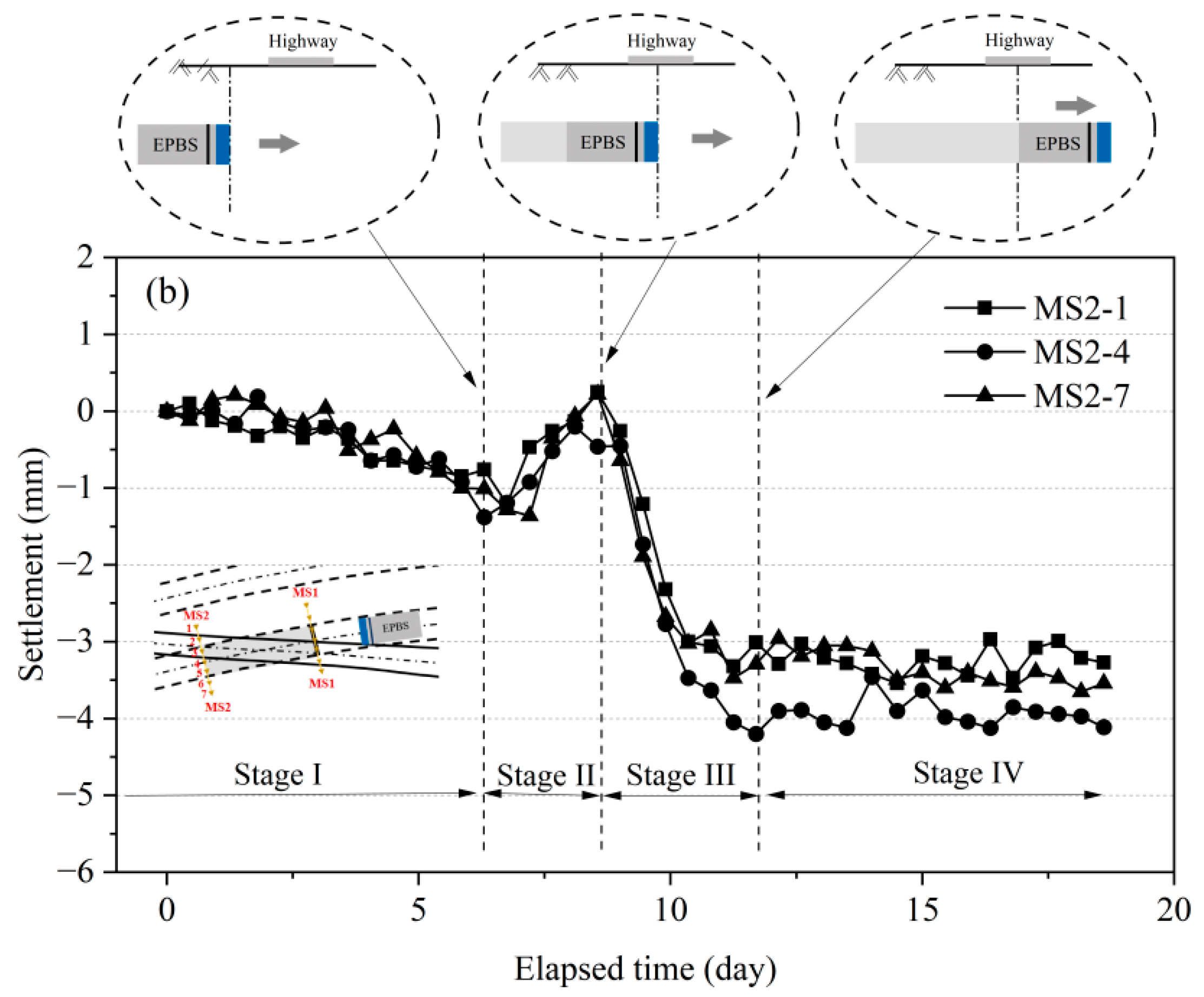

3.2. Deformation of the Existing Highway

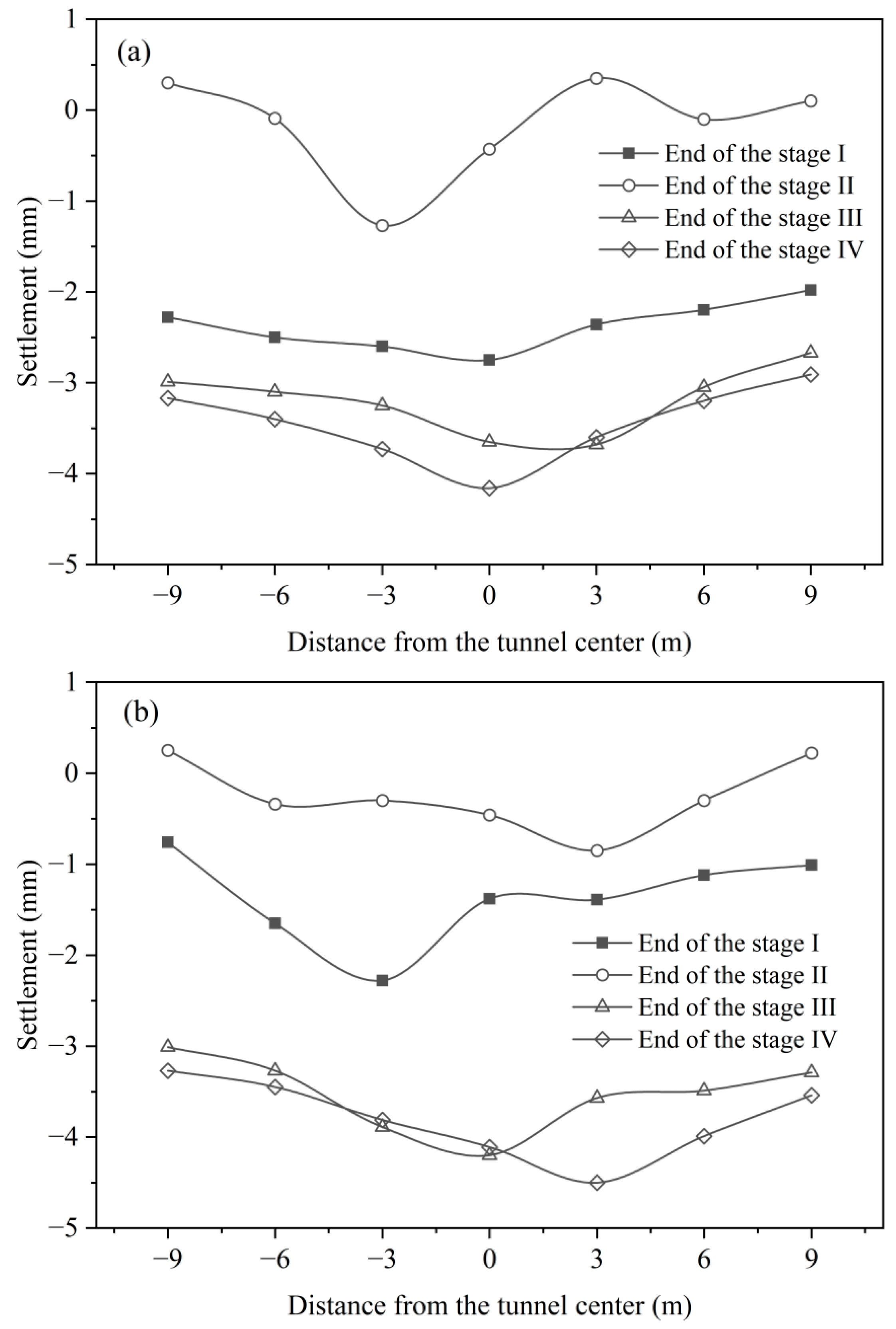

3.3. Settlement Trough of the Existing Highway

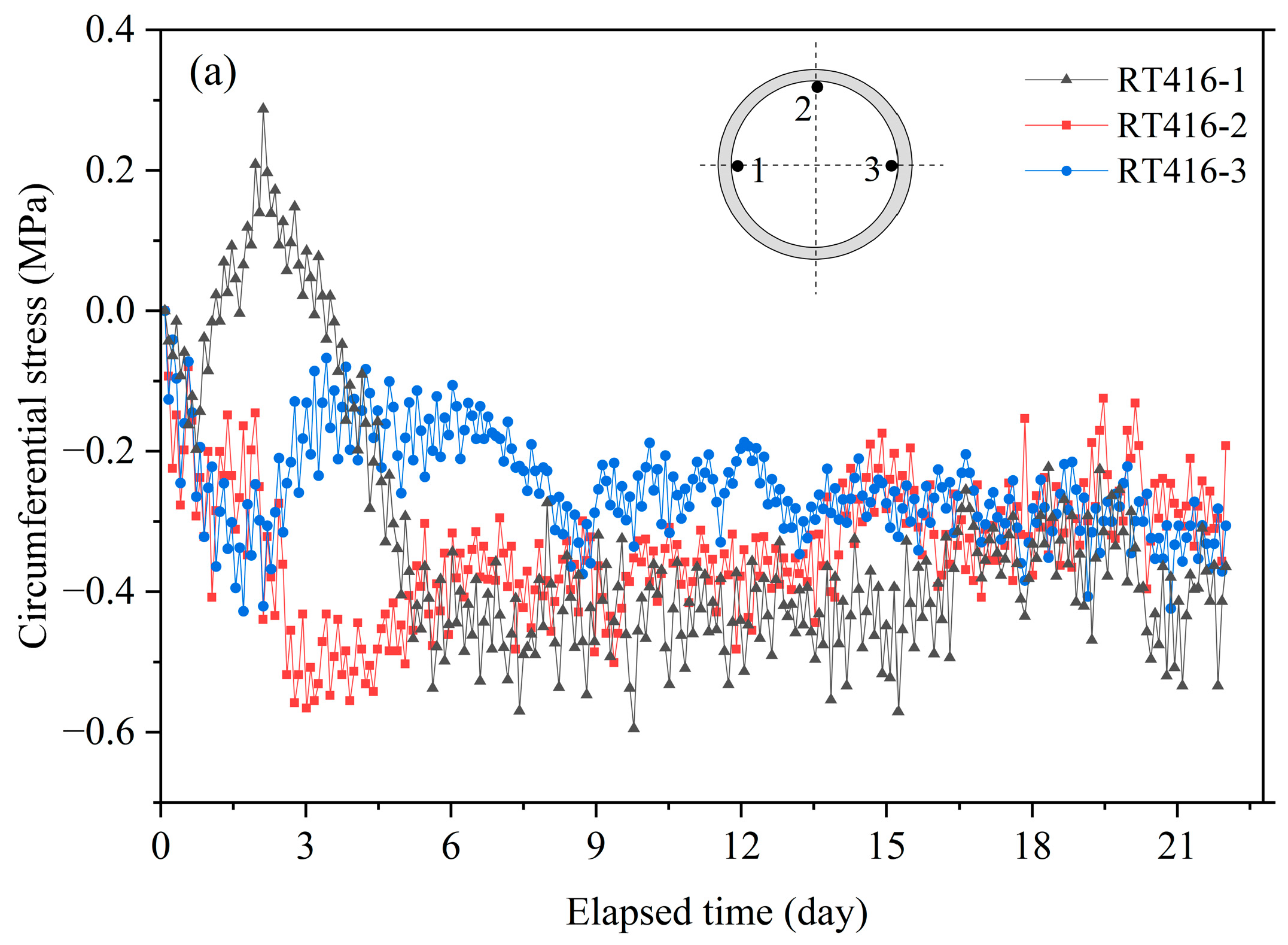

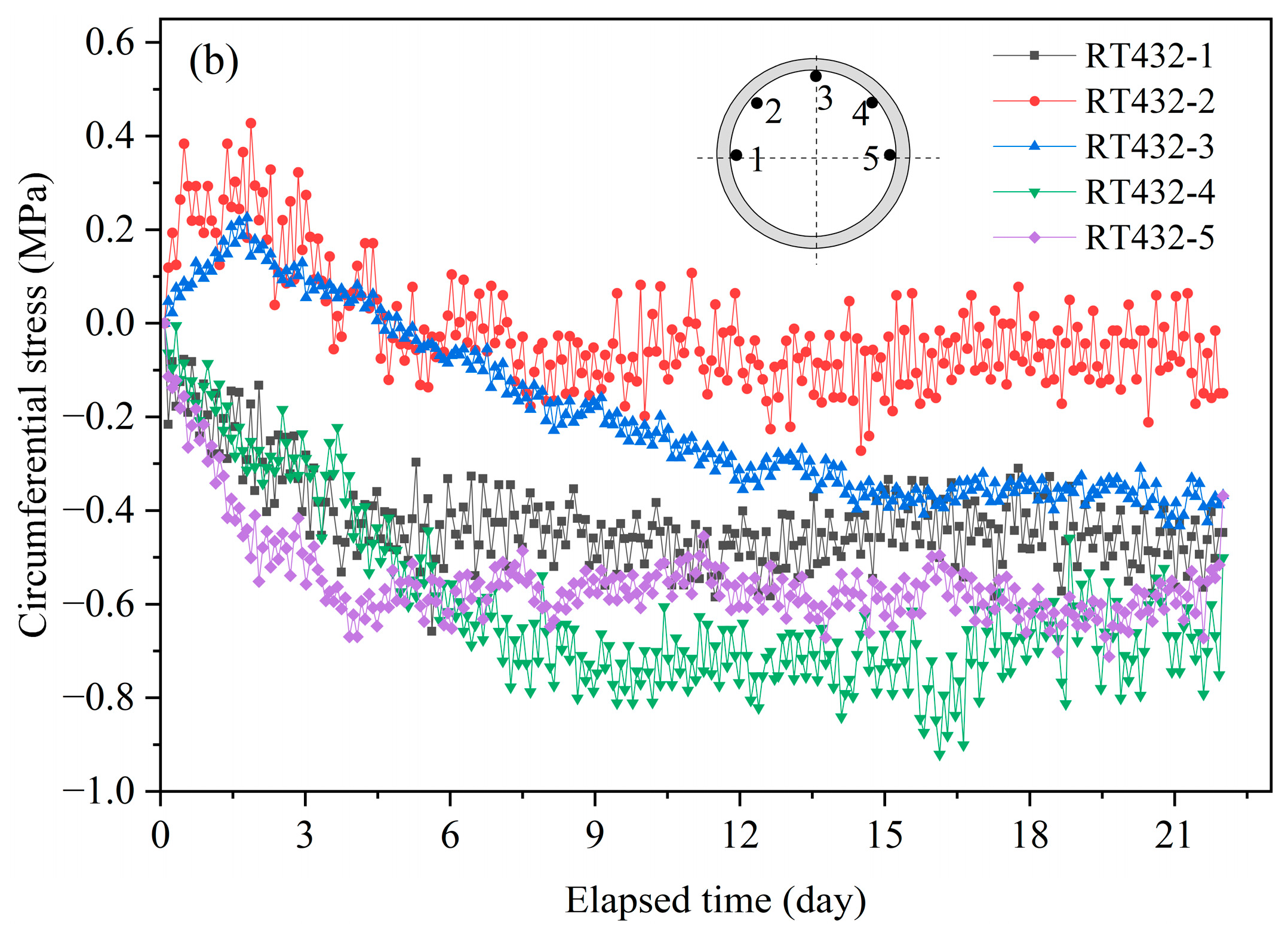

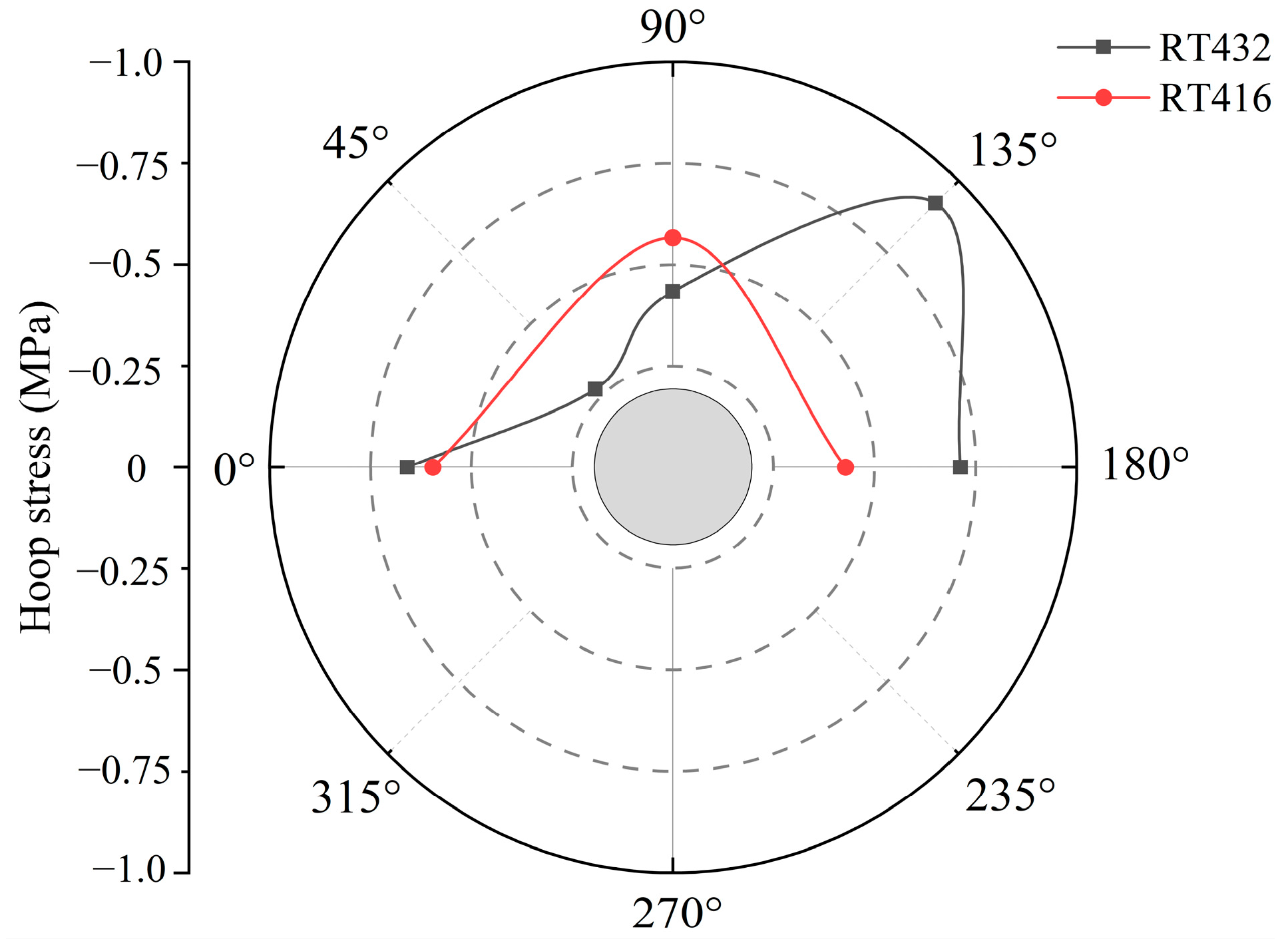

3.4. Circumferential Stresses of the New Tunnels

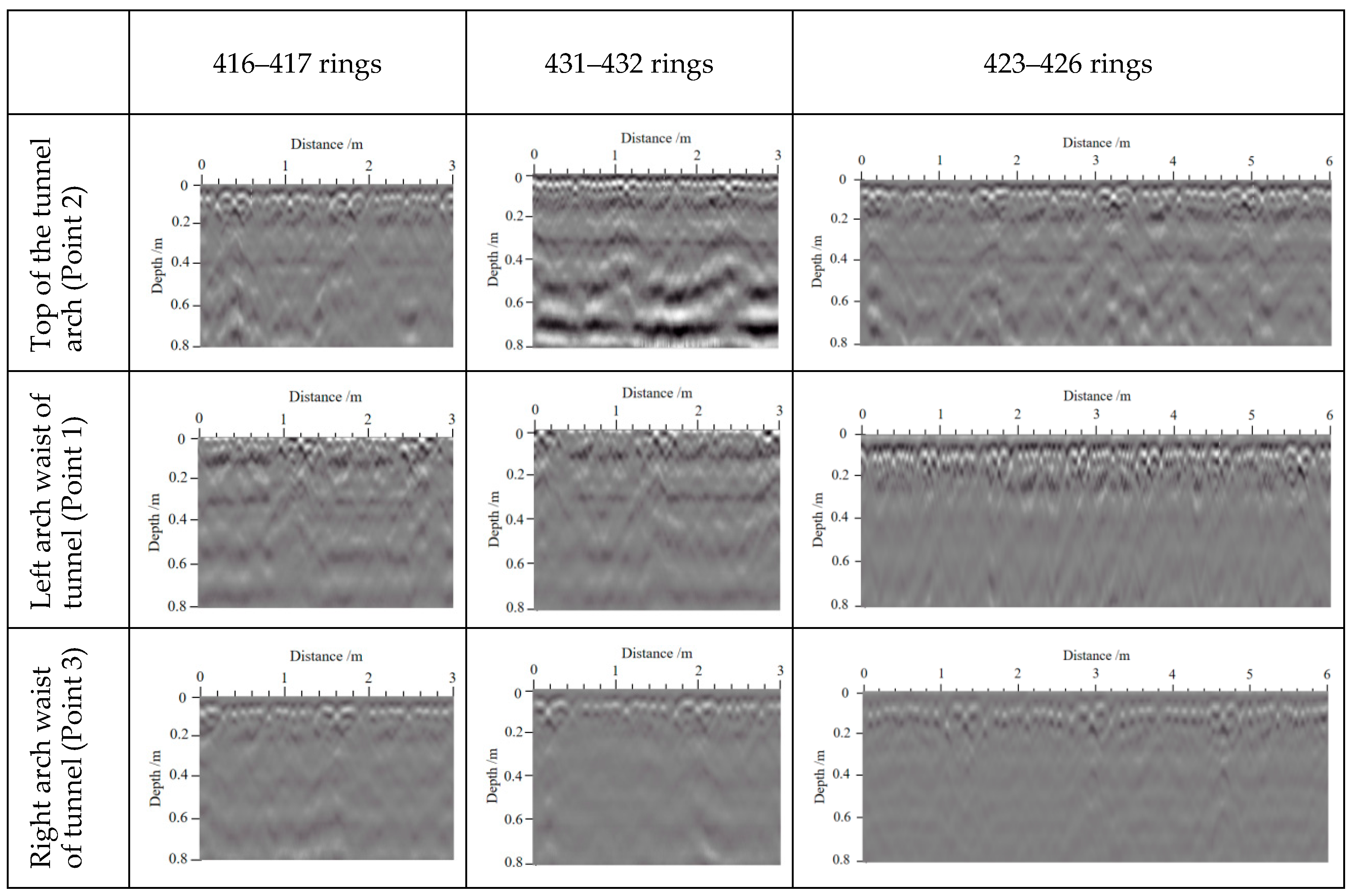

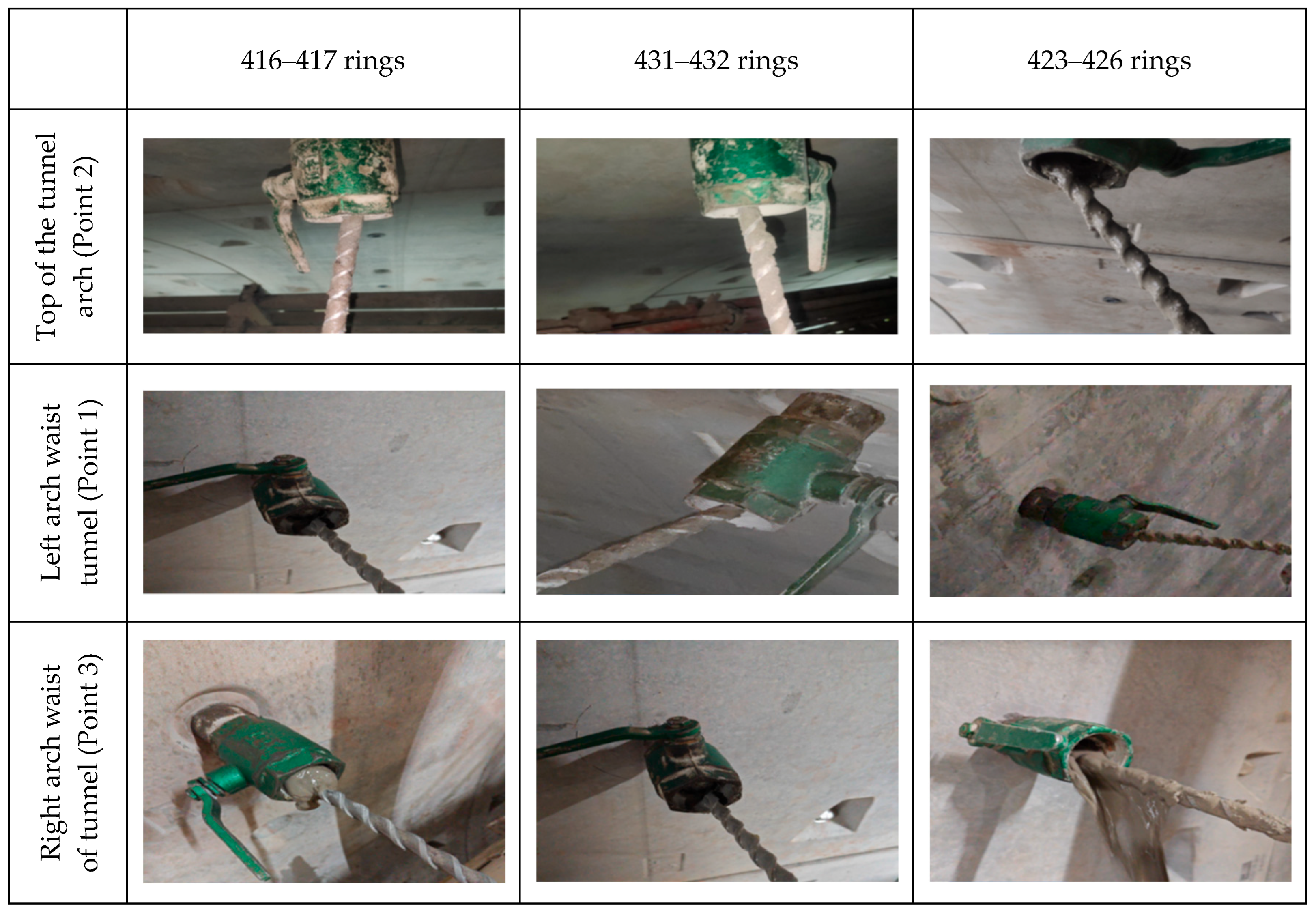

3.5. Evaluation of Backfill Grouting Quality Based on GPR Technology

4. Conclusions

- (1)

- Highway Settlement induced by the close-proximity undercrossing of the EPB shield can be divided into four phases: (I) initial settlement, primarily due to groundwater level drawdown caused by tunneling activities, (II) uplift, resulting from groundwater recharge and increased chamber pressure, (III) secondary settlement, induced by soil friction and tail void volume loss as the shield passed through the region, and (IV) stabilization stage, it was characterized by gradual settlement caused by grout hardening and soil consolidation. Notably, the secondary settlement caused by shield tail detachment was significantly greater than the initial settlement induced by distant shield construction.

- (2)

- The settlement trough of the existing highway exhibited distinct characteristics during the four stages of tunnel undercrossing. The maximum settlement point did not always lie on the tunnel centerline, but shifted towards one side, remaining within 3 m of the centerline. Approximately 12 d later, the settlement of the existing highway gradually stabilized, with the final settlement at the monitored sections controlled between 2.9 and 4.5 mm.

- (3)

- During the early stages of shield tail detachment, the circumferential stress of the tunnel changed rapidly. The circumferential stress was primarily compressive, with tensile stress observed at some monitoring points. Over time, the tensile stress at the monitoring points gradually transitioned to compressive stress. After the tunnel undercrossing, the circumferential stress gradually stabilized. The maximum circumferential stresses occurred at the tunnel crown and haunch, measuring −0.595 and −0.921 MPa, respectively.

- (4)

- GPR and borehole results indicated that in groundwater-rich strata, areas with poor grouting quality tended to occur at the tunnel crown, characterized by low-frequency strong reflections, discontinuities in signal phase axes, and chaotic lower reflection signals. Groundwater diluted and dispersed the grouting material, resulting in insufficient density of the grouting layer at the tunnel crown. In contrast, grouting quality was generally good along other survey lines and within the detection depth range.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, Q.; Zhang, D.; Wong, L.N.Y. Shallow tunnelling method (STM) for subway station construction in soft ground. Tunn. Undergr. Space Technol. 2012, 29, 10–30. [Google Scholar] [CrossRef]

- Fang, Q.; Liu, X.; Zhang, D.; Lou, H. Shallow tunnel construction with irregular surface topography using cross diaphragm method. Tunn. Undergr. Space Technol. 2017, 68, 11–21. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, D.; Fang, Q.; Cao, L.; Xu, T.; Li, Q. Surface settlement of subway station construction using pile-beam-arch approach. Tunn. Undergr. Space Technol. 2019, 90, 340–356. [Google Scholar] [CrossRef]

- Yang, H.; Shi, H.; Jiang, X.; Liu, C.; Yu, L. Study on influence of construction process of double-line shield tunnels on frame structure. Geotech. Geol. Eng. 2021, 39, 1465–1484. [Google Scholar] [CrossRef]

- Zheng, G.; Fan, Q.; Zhang, T.; Zheng, W.; Sun, J.; Zhou, H.; Diao, Y. Multistage regulation strategy as a tool to control the vertical displacement of railway tracks placed over the building site of two overlapped shield tunnels. Tunn. Undergr. Space Technol. 2019, 83, 282–290. [Google Scholar] [CrossRef]

- Di, H.; He, P.; Li, X.; Xiao, F.; Chen, H. Influence of large-diameter shield tunneling on deformation of adjacent high-speed railway subgrade in soft soils and effectiveness of protective measures. Tunn. Undergr. Space Technol. 2025, 156, 106260. [Google Scholar] [CrossRef]

- Lin, X.; Chen, R.; Wu, H.; Cheng, H. Deformation behaviors of existing tunnels caused by shield tunneling undercrossing with oblique angle. Tunn. Undergr. Space Technol. 2019, 89, 78–90. [Google Scholar] [CrossRef]

- Lai, H.; Zheng, H.; Chen, R.; Kang, Z.; Liu, Y. Settlement behaviors of existing tunnel caused by obliquely under-crossing shield tunneling in close proximity with small intersection angle. Tunn. Undergr. Space Technol. 2020, 97, 103258. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.; Yang, Y.; Jiang, Y.; Xu, X.; Hu, Q. Deformation characteristics of existing tunnels induced by above-crossing quasi-rectangular shield tunnel. Transp. Geotech. 2024, 45, 101227. [Google Scholar] [CrossRef]

- Ma, S.; Shao, Y.; Liu, Y.; Jiang, J.; Fan, X. Responses of pipeline to side-by-side twin tunnelling at different depths: 3D centrifuge tests and numerical modelling. Tunn. Undergr. Space Technol. 2017, 66, 157–173. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, R.; Jiang, A.; Fang, Q.; Ma, X. Mechanical behaviors and soil gap formation of existing pipeline based on large-deformation theory. Int. J. Geomech. 2023, 23, 04023098. [Google Scholar] [CrossRef]

- Zhao, Q.; Li, K.; Cao, P.; Liu, Y.; Pang, Y.; Liu, J. A study on the influence of double tunnel excavations on the settlement deformation of flood control dikes. Sustainability 2023, 15, 12461. [Google Scholar] [CrossRef]

- Lin, Q.; Cao, P.; Dong, T.; Liu, J.; Zhao, Q.; Zhu, W. Numerical Simulation of Flood Control Levee Deformation by Shield Tunnel Excavation through the Liuyang River: A Case Study. Geofluids 2023, 2023, 8925891. [Google Scholar] [CrossRef]

- Xu, Q.; Zhu, H.; Ma, X.; Ma, Z.; Li, X.; Tang, Z.; Zhuo, K. A case history of shield tunnel crossing through group pile foundation of a road bridge with pile underpinning technologies in Shanghai. Tunn. Undergr. Space Technol. 2015, 45, 20–33. [Google Scholar] [CrossRef]

- Simic-Silva, P.T.; Martínez-Bacas, B.; Galindo-Aires, R.; Simic, D. 3D simulation for tunnelling effects on existing piles. Comput. Geotech. 2020, 124, 103625. [Google Scholar] [CrossRef]

- Liu, W.; Wang, M.; Luo, G.; Lu, W.; Xiao, H. Horizontal response of existing pile induced by adjacent shield tunnelling with large longitudinal slope. Tunn. Undergr. Space Technol. 2024, 153, 106036. [Google Scholar] [CrossRef]

- Gokuldas, S.; Banerjee, S.; Nimbalkar, S.S. Effects of tunneling-induced ground movements on stability of piled raft foundation: Three-dimensional finite-element approach. Int. J. Geomech. 2020, 20, 04020104. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, Y. Analysis of stratum settlement laws caused by the construction of shallow-buried expressway tunnels with large span and small spacing. Geotech. Geol. Eng. 2021, 39, 1485–1495. [Google Scholar] [CrossRef]

- Qian, W.; Qi, T.; Zhao, Y.; Le, Y.; Yi, H. Deformation characteristics and safety assessment of a high-speed railway induced by undercutting metro tunnel excavation. J. Rock Mech. Geotech. Eng. 2019, 11, 88–98. [Google Scholar] [CrossRef]

- Wang, G.; Shan, Y.; Detmann, B.; Lin, W. Physics-Informed Neural Network (PINN) model for predicting subgrade settlement induced by shield tunnelling beneath an existing railway subgrade. Transp. Geotech. 2024, 49, 101409. [Google Scholar] [CrossRef]

- Song, M.; Liu, J.; Wang, X.; Lou, H.; Lin, X. Study on railway subgrade settlement induced by an ultra-large-diameter shield tunnel crossing under railway subgrade. Symmetry 2022, 15, 75. [Google Scholar] [CrossRef]

- Zhang, Q.; Xia, T.; Ding, Z.; Huang, X.; Lin, C. Effect of nearby undercrossing tunneling on the deformation of existing metro tunnel and construction control. Rock Soil Mech. 2016, 37, 3561–3568. [Google Scholar]

- Zheng, Y.; Wu, K.; Sun, J.; Chen, R.; Li, Y.; Yang, S. Study on the influence of close distance construction of urban tunnel on the existing station. Geotech. Geol. Eng. 2021, 39, 4765–4780. [Google Scholar] [CrossRef]

- Li, P.; Dai, Z.; Huang, D.; Cai, W.; Fang, T. Impact analysis for safety prevention and control of special-shaped shield construction closely crossing multiple operational metro tunnels in shallow overburden. Geotech. Geol. Eng. 2022, 40, 2127–2144. [Google Scholar] [CrossRef]

- Peng, F.; Ma, S. Analysis of experimental data on the effect of double-line parallel shield tunneling on the deformation of adjacent buildings. Alex. Eng. J. 2021, 60, 3957–3963. [Google Scholar] [CrossRef]

- Li, X.; Yuan, D. Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels. Tunn. Undergr. Space Technol. 2012, 28, 18–30. [Google Scholar] [CrossRef]

- Liu, H.; Yue, Y.; Lai, S.; Meng, X.; Du, Y.; Cui, J.; Spencer, B.F. Evaluation of the antenna parameters for inspection of hidden defects behind a reinforced shield tunnel using GPR. Tunn. Undergr. Space Technol. 2023, 140, 105265. [Google Scholar] [CrossRef]

- Li, T.; Liu, B.; Han, Y.; Fu, C.; Sun, Y. Structural analysis of shield machine cutting monopile using py curve based finite element method. Comput. Geotech. 2023, 161, 105605. [Google Scholar] [CrossRef]

- Standing, J.R.; Selemetas, D. Greenfield ground response to EPBM tunnelling in London Clay. Géotechnique 2013, 63, 989–1007. [Google Scholar] [CrossRef]

- Komiya, K.; Soga, K.; Akagi, H.; Jafari, M.R.; Bolton, M.D. Soil consolidation associated with grouting during shield tunnelling in soft clayey ground. Geotechnique 2001, 51, 835–846. [Google Scholar] [CrossRef]

- Kravitz, B.; Mooney, M.; Karlovsek, J.; Danielson, I.; Hedayat, A. Void detection in two-component annulus grout behind a pre-cast segmental tunnel liner using Ground Penetrating Radar. Tunn. Undergr. Space Technol. 2019, 83, 381–392. [Google Scholar] [CrossRef]

- Zeng, L.; Zhang, X.; Xie, X.; Zhou, B.; Xu, C.; Lambot, S. Measuring annular thickness of backfill grouting behind shield tunnel lining based on GPR monitoring and data mining. Autom. Constr. 2023, 150, 104811. [Google Scholar] [CrossRef]

- Zeng, H.; Wang, J.; Wang, J.; Du, Y.; Li, F. Evaluation of steel mesh impact on GPR detection of voids behind lining in railway tunnels. Constr. Build. Mater. 2025, 466, 140316. [Google Scholar] [CrossRef]

| Geotechnical Parameter | Sandstone | Mudstone | |

|---|---|---|---|

| Unit weight (kN/m3) | 24–25.6 | 23–24.9 | |

| Cohesion (kPa) | 50–538 | 70–2101 | |

| Angle of internal friction ψ (°) | 28–32 | 30–40 | |

| Compressive strength (MPa) | saturated value | 4.7 | 27.5 |

| natural value | 8.2 | 37 | |

| Tensile strength (kPa) | 110 | 500 | |

| Modulus of deformation (MPa) | 944 | 3971 | |

| Modulus of elasticity (MPa) | 1235 | 4753 | |

| Poisson’s ratio µ | 0.38 | 0.12 | |

| Standardized value of ultimate bond strength between geotechnical body and anchors (kPa) | 0.4 | 1.2 | |

| Substrate friction coefficient | 0.50 | 0.65 | |

| Static side pressure coefficient | 0.4–0.55 | 0.3–0.5 | |

| Cement (kg) | Fly Ash (kg) | Bentonite (kg) | Sand (kg) | Water (kg) |

|---|---|---|---|---|

| 80 | 300 | 50 | 900 | 237 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, C.; Wang, Q.; Wang, J.; Sha, F.; Yao, H.; Liu, F. Deformation of Existing Highway Induced by Close Undercrossing of Shield Tunnel with Steep Slope: A Case Study. Appl. Sci. 2025, 15, 10884. https://doi.org/10.3390/app152010884

Mao C, Wang Q, Wang J, Sha F, Yao H, Liu F. Deformation of Existing Highway Induced by Close Undercrossing of Shield Tunnel with Steep Slope: A Case Study. Applied Sciences. 2025; 15(20):10884. https://doi.org/10.3390/app152010884

Chicago/Turabian StyleMao, Chaojun, Quanfeng Wang, Jinlong Wang, Fei Sha, Hui Yao, and Fanghao Liu. 2025. "Deformation of Existing Highway Induced by Close Undercrossing of Shield Tunnel with Steep Slope: A Case Study" Applied Sciences 15, no. 20: 10884. https://doi.org/10.3390/app152010884

APA StyleMao, C., Wang, Q., Wang, J., Sha, F., Yao, H., & Liu, F. (2025). Deformation of Existing Highway Induced by Close Undercrossing of Shield Tunnel with Steep Slope: A Case Study. Applied Sciences, 15(20), 10884. https://doi.org/10.3390/app152010884