Abstract

This study aimed to evaluate the scientific reliability of 3D-printed silicone boluses fabricated with patient-specific molds, focusing on fabrication-related uncertainties such as internal air bubbles, thickness variations, and density differences, thereby providing evidence for clinical quality assurance. Custom silicone boluses were fabricated using 3D-printed molds with varying vacuum degassing times (1, 5, and 10 min). Air bubble size and depth were quantified using scanner image analysis, while density and Hounsfield unit (HU) values were compared with a commercial bolus. Dosimetric evaluation was performed using a VitalBeam linear accelerator (6 MV photons, Varian Medical Systems, Palo Alto, CA, USA) and a MatriXX 2D detector (IBA Dosimetry, Schwarzenbruck, Germany), comparing treatment planning system (TPS) calculated doses with measured doses across a 3 × 3 grid. Surface dose distributions were further analyzed using EBT3 film. Results showed that bubble size increased with longer vacuum times, interpreted as coalescence due to limited degassing and silicone viscosity. The density of 3D boluses ranged from 0.980 to 1.104 g/cm3 (commercial: 0.988 g/cm3), with HU values of +240 to +250 (commercial: −110). In point-wise comparisons, mean dose differences were less than 1% for 1- and 5 min samples and approximately 1% for 10 min, with all conditions within |Δ| ≤ 3%. Film analysis confirmed equivalent surface dose distributions. These findings demonstrate, for the first time, that microscopic bubbles in 3D-printed silicone boluses have negligible clinical impact, supporting their safe adoption without requiring complex degassing procedures.

1. Introduction

In radiation therapy, the build-up effect of megavoltage photon beams leads to a dose deficit in the skin and superficial tissues; therefore, a bolus is used to compensate for this effect [1,2,3]. While commercial sheet-type boluses are standardized and convenient to use, they have limitations in regions with complex body contours, where the formation of air gaps between the bolus and the skin can result in dose reductions of approximately 3–17% [4,5].

To overcome these limitations, patient-specific silicone boluses fabricated using 3D-printing technology have been developed, providing optimized conformity to anatomical structures [6,7]. Among the early proposals for patient-specific boluses, Dubey et al. (2016) introduced a method of producing a soft silicone bolus using an optical scanner and a 3D printer, which was conformal to irregular contours and cost-effective [8]. This study represented an important turning point in terms of shape fidelity and minimizing air gaps in custom bolus fabrication. Subsequently, in 2018, Chiu et al. combined 3D-printed molds with silicone casting to create patient-specific boluses and presented a detailed process from computed tomography (CT)-based design to quality assurance (QA) [9]. These early reports demonstrated that patient-specific silicone boluses could serve as a practical alternative to reduce air gaps and improve the predictability of surface dose, thereby laying the foundation for further clinical applications.

Recent studies have demonstrated that the silicone casting method using 3D-printed molds is feasible for integration into clinical workflows, with systematic implementation cases reported that include commissioning and failure mode and effects analysis (FMEA) [10]. In addition, the clinical application process has been described, encompassing CT-based modeling, 3D-printed mold fabrication, silicone casting, QA, and in vivo dose verification, which collectively confirmed advantages such as reducing air gaps and improving the uniformity of surface dose compared with commercial boluses [11].

Furthermore, studies on patient-specific silicone boluses fabricated using the Life-Casting technique have evaluated both the physical properties of the material (Shore hardness, HU values, density) and the efficiency of the fabrication process, reporting improvements in reducing air gaps and enhancing conformity to the skin surface [12]. In addition, a comparative study of boluses made from polydimethylsiloxane (PDMS) and silicone elastomers reported that homogeneity, density, and dose delivery were stably maintained under various thickness conditions, thereby supporting the clinical stability of custom boluses [13].

Patient-specific silicone boluses are generally fabricated through the following process. First, CT images of the treatment site are acquired, and these images are used to perform three-dimensional modeling of the bolus shape. The model is then printed using a 3D printer to create a mold, into which mixed silicone is poured to obtain a bolus of the desired thickness and geometry. After curing is complete, the mold is removed, and the finished bolus is rescanned with CT to perform QA by verifying thickness uniformity, Hounsfield unit values, and conformity. This fabrication process has been reported to minimize the occurrence of air gaps and internal bubbles while achieving closer conformity to patient skin contours compared with commercial boluses [13].

Nevertheless, patient-specific boluses are not free from uncertainties that may arise during the fabrication process, such as thickness irregularities, residual air bubbles, and density variations. In particular, microscopic air bubbles may not be detected in CT-based treatment planning and therefore may not be accounted for in dose calculations. Previous studies have mainly focused on macroscopic air gaps between the bolus and the skin, whereas the dosimetric impact of microscopic air bubbles within the bolus has not been systematically evaluated.

Therefore, the present study aims to quantitatively analyze the effects of internal bubbles, thickness irregularities, and density variations arising in patient-specific silicone boluses fabricated using 3D-printed molds on radiation dose distribution, and to provide fundamental data for establishing QA standards to ensure the clinical safety and reliability of patient-specific boluses.

2. Materials and Methods

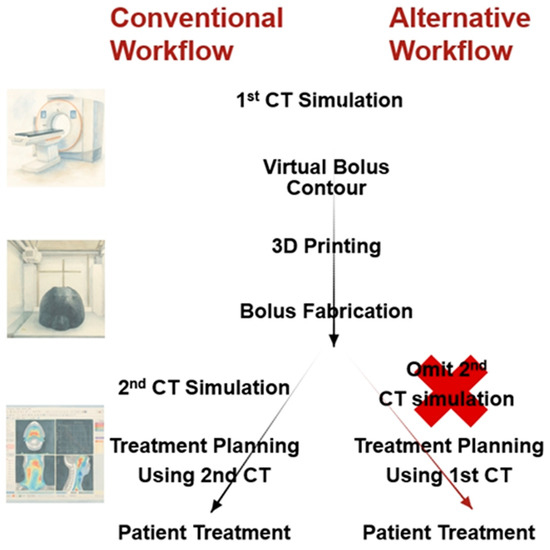

In order to apply a patient-specific silicone bolus, two CT simulations (CT-sims) are generally required (Figure 1). The first CT-sim is used for treatment planning, while the second CT-sim is acquired with the fabricated bolus applied to the patient, enabling dose recalculation that reflects fabrication-related variables such as thickness irregularities and residual air bubbles. This approach allows consideration of the physical characteristics of the bolus in the actual treatment dose distribution and provides the advantage of verifying patient setup reproducibility. However, this process requires three hospital visits in total (two CT-sims and one for treatment initiation) and extends the preparation period to an average of 7–8 days.

Figure 1.

Comparison of workflows for the fabrication of patient-specific boluses.

In this study, an alternative treatment planning process was proposed that omits the second CT-sim (Figure 1). This approach reduces the number of hospital visits and shortens the preparation period to 3–4 days. Furthermore, the present work quantitatively evaluated the impact of thickness irregularities and residual air bubbles in the fabricated patient-specific silicone bolus on dose distribution, in order to verify whether clinically reliable planning can be achieved with a single CT-sim. To assess the effect of this simplified workflow on treatment accuracy, phantom-based experiments were conducted to explore its feasibility.

2.1. Fabrication of Patient-Specific Silicone Bolus

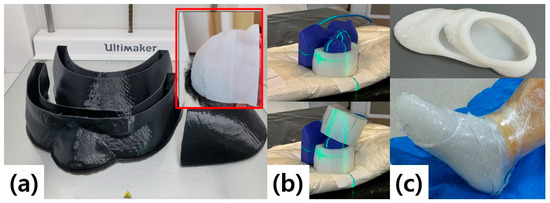

The fabrication process of the patient-specific silicone bolus is illustrated in Figure 2. CT images were imported into the treatment planning system (TPS) to define the target region and desired thickness, after which a virtual bolus was generated and exported in STereoLithography (STL) file format. The STL file was then converted into slicing data for 3D printing to create a plastic mold, into which liquid silicone was cast to form the final bolus [10,14,15].

Figure 2.

Examples of applying patient-specific silicone boluses fabricated with a 3D printer for different clinical cases. (a) A patient with systemic lymphoma treated to the facial region using Volumetric Modulated Arc Therapy (VMAT); a customized facial bolus was fabricated to ensure adequate dose coverage. (b) A cervix cancer patient with a vulvar tumor protruding externally; a conformal bolus was designed to precisely match the tumor surface, and treatment was delivered using 3D conformal radiotherapy. (c) A patient with lymphoma of the lower extremity; a foot-shaped bolus was created to enable VMAT delivery adapted to the contour of the limb.

The fabrication process begins by importing CT images into the TPS to define the region of interest and desired thickness, thereby generating a virtual bolus. This virtual bolus is converted into STL file format and further processed into slicing data for 3D printing. A plastic mold is then produced using the 3D printer, and liquid silicone is cast into the mold to form the final bolus (Figure 2b). Clinical reports have demonstrated that this 3D printing–based mold fabrication method can be applied even to irregular anatomical sites such as the ear or nose, providing superior conformity to the skin surface compared to commercial boluses and improving workflow efficiency [16,17].

A 3D printer (Ultimaker S5, Ultimaker B.V., Utrecht, The Netherlands) was used, with a maximum build volume of 330 × 240 × 300 mm and axis precision of 6.9, 6.9, and 2.5 μm for the X, Y, and Z axes, respectively. Molds were fabricated using a 0.4 mm nozzle and 2.85 mm diameter PLA filament, with a wall thickness of 0.8 mm. Each mold was designed in three separable parts with an open upper surface to facilitate silicone pouring.

To fabricate the boluses, a two-component addition-cure liquid silicone (Dragoskin NV 10%, Smooth-On Inc., Macungie, PA, USA) was employed. According to the manufacturer’s instructions, the material consists of a base and curing agent mixed at a 1:1 weight ratio. The mixture was stirred gently to minimize air entrapment and poured into the molds. Dragoskin NV is a platinum-catalyzed silicone elastomer commonly used in prosthetics and special effects applications, characterized by high flexibility and skin safety. Its reported density is approximately 1.08 g/cm3, which corresponds to a radiological electron density close to that of water, thereby supporting its suitability for dose calculation in treatment planning systems. The cured boluses were allowed to rest for 24 h at room temperature to ensure complete polymerization before experimental use [18].

Potential sources of error during the fabrication process included inaccuracies in mold geometry due to mechanical tolerances of the 3D printer and thickness irregularities of the bolus [19,20,21]. In addition, microbubbles could form during the mixing and casting of silicone, and shrinkage during curing could alter the size and location of the bubbles. Such bubbles may not be detectable in CT images and therefore might not be reflected in dose calculations, which motivated this study to evaluate their dosimetric impact.

2.2. Fabrication of Sheet-Type Silicone Boluses

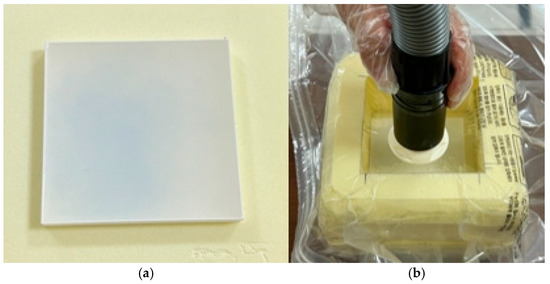

To quantitatively evaluate the effect of air bubbles on dose distribution, standardized silicone sheet specimens measuring 10 × 10 × 1 cm3 were fabricated (Figure 3). Three molds of identical dimensions were produced using a 3D printer, and liquid silicone was poured under identical conditions. The fabricated specimens were designed to simulate a range of air bubble conditions that may occur during the production of patient-specific boluses and were subsequently used to compare and analyze their dosimetric ef-fects, refer to Table 1.

Figure 3.

Fabrication process of sheet-type silicone boluses. (a) Preparation of a rectangular silicone mold (10 × 10 × 1 cm3) using 3D printing and pouring of silicone solution. (b) Vacuum sealing procedure to control the amount of entrapped air during curing.

Table 1.

Process parameters in bolus fabrication.

Vacuum degassing was applied to control the amount of entrapped air, with treatment times set to 1, 5, and 10 min, respectively, in order to produce samples with varying bubble densities. A household vacuum sealing system was employed to reflect a practical and clinically accessible method. By varying the degree of air removal during silicone curing, differences in the size and distribution of microbubbles were intentionally induced.

The fabricated specimens were designed to simulate a range of air bubble conditions that may occur during the production of patient-specific boluses and were subsequently used to compare and analyze their dosimetric effects.

2.3. Analysis of Air Bubble Size and Density

High-resolution cross-sectional images of each specimen were acquired using a flatbed scanner (Epson Expression 13000XL, Seiko Epson Corp., Nagano, Japan). Image analysis was performed with ImageJ version 1.53t (National Institutes of Health, Bethesda, MD, USA), and the diameter and depth (from the surface) of air bubbles were measured within ten systematically selected regions of interest (ROIs, 20 × 20 mm2) per sample. Up to four bubbles were extracted per ROI, resulting in a total of 40 measurements for each condition (1, 5, and 10 min). Due to the inherent limitations of cross-sectional image-based evaluation, some discrepancies from the true three-dimensional bubble geometry may exist. To ensure consistency, all measurements were performed by the same investigator.

For data analysis, the mean ± standard deviation, minimum–maximum values, coefficient of variation (CV%), and standard error (SE = SD/√n) were calculated for each condition. In addition, 95% confidence intervals were estimated using the t-distribution with 39 degrees of freedom.

To assess statistical differences among the three conditions, the Shapiro–Wilk test was first performed to test normality. If normality was satisfied, one-way analysis of variance (ANOVA) was conducted, and Tukey’s HSD post hoc test was applied when significant differences were observed. If normality was not met, the Kruskal–Wallis test was used instead. A p-value < 0.05 was considered statistically significant.

For density evaluation of the commercial bolus and the fabricated 3D-printed silicone boluses, the mass of each specimen was measured using an electronic balance (Mettler Toledo, Greifensee, Switzerland). Volumes were calculated from CT images (SOMATOM Definition AS, Siemens Healthineers, Erlangen, Germany) using segmentation, and density (g/cm3) was derived by dividing mass by volume. In addition, Hounsfield unit (HU) values of each bolus were extracted from CT images for comparison of physical properties.

2.4. Dosimetric Analysis

To evaluate the dose reproducibility of commercial boluses and 3D-printed patient-specific silicone boluses, two-dimensional dose distributions of the calculated dose from the TPS and the measured dose were compared. All experiments were performed using a VitalBeam linear accelerator (Varian Medical Systems, Palo Alto, CA, USA) with a 6 Megavoltage (MV) photon beam. Beam parameters were set to a 10 × 8 cm2 field size with 200 monitor units (MUs). For assessment of surface dose distribution, each bolus was placed on a cylindrical phantom with a radiochromic film (EBT3, Ashland Advanced Materials, Niagara Falls, NY, USA) positioned between the phantom and the bolus. Irradiation was delivered with a 3 × 3 cm2 field at 100 monitor units, and the resulting isodose distributions were analyzed (refer to Table 2).

Table 2.

Process parameters in dosimetric evaluation.

Dose measurements were performed using a MatriXX FFF 2D ionization chamber array detector (IBA Dosimetry, Schwarzenbruck, Germany). A 2 cm-thick RW3 phantom was placed above the detector, and the bolus under evaluation was positioned such that its center aligned with the isocenter. Corresponding calculated dose distributions for the same measurement plane were generated in the TPS.

Data analysis was conducted using an in-house Python (version 3.10.12, Google Colaboratory, Python Software Foundation, Wilmington, DE, USA)-based program. After registering both distributions to a common coordinate system, point-by-point dose differences were calculated at nine grid points (3 × 3 array within ±20 mm from the isocenter) using the formula Δ = (measured − planned)/planned × 100 (%). Evaluation metrics included mean, standard deviation, and root mean square (RMS) differences. Additionally, the proportion of points satisfying |Δ| ≤ 1% and |Δ| ≤ 2% was reported according to commonly applied clinical tolerance criteria.

For assessment of surface dose distribution, each bolus was placed on a cylindrical phantom with a radiochromic film (EBT3, Ashland Advanced Materials) positioned between the phantom and the bolus. Irradiation was delivered with a 3 × 3 cm2 field at 100 monitor units, and the resulting isodose distributions were analyzed.

3. Results

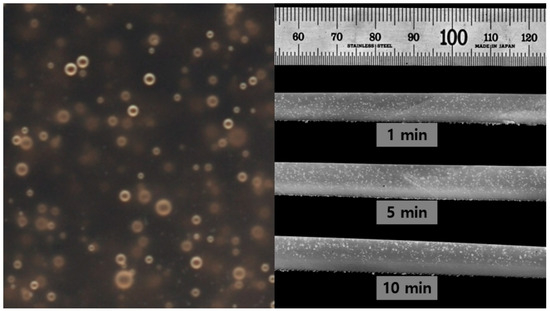

3.1. Measurement of Air Bubble Size

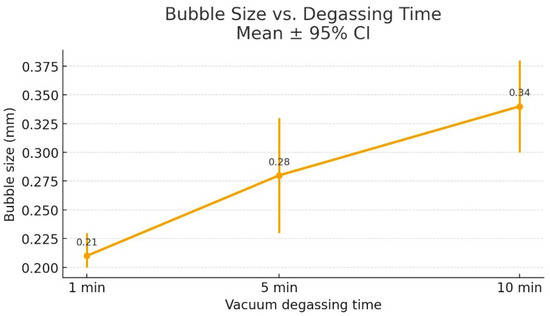

Based on the analysis of Figure 4 and Figure 5, bubble sizes were observed to increase with longer vacuum treatment times. This finding can be interpreted as incomplete removal of microbubbles under limited vacuum conditions, with smaller bubbles gradually coalescing over time to form larger bubbles. The high viscosity of silicone is also considered to contribute to the incomplete expulsion of bubbles. The mean bubble size was 0.21 ± 0.05 mm (95% CI: 0.20–0.23) at 1 min, 0.28 ± 0.16 mm (95% CI: 0.23–0.33) at 5 min, and 0.34 ± 0.12 mm (95% CI: 0.30–0.38) at 10 min. One-way ANOVA confirmed statistically significant differences among groups (F = 12.32, p < 0.001; Kruskal–Wallis, H = 32.56, p < 0.001). Post hoc analysis showed significant differences between 1 min and 5 min (p = 0.025) and between 1 min and 10 min (p < 0.001), whereas the difference between 5 min and 10 min was marginally significant (p = 0.059).

Figure 4.

Cross-sectional scans of silicone sheets fabricated with identical thickness and subjected to different vacuum treatment times (1, 5, and 10 min). Each sample was cut and scanned using a flatbed scanner. A ruler was included in the image to provide a reference for thickness measurement and to visualize the variation in entrapped microbubbles according to the vacuum duration.

Figure 5.

Mean air bubble size (mm) as a function of vacuum degassing time (1, 5, and 10 min). Data points represent the mean values, and error bars indicate 95% confidence intervals (CI).

For bubble depth, the mean value was greatest under the 5-min condition. The mean depth was 2.72 ± 1.84 mm (95% CI: 2.13–3.31) at 1 min, 3.38 ± 1.83 mm (95% CI: 2.79–3.97) at 5 min, and 1.71 ± 1.20 mm (95% CI: 1.32–2.09) at 10 min. In-tergroup differences were statistically significant (ANOVA, F = 10.42, p < 0.001; Kruskal–Wallis, H = 16.20, p = 0.0003). Post-hoc testing revealed significant differences between 1 min and 10 min (p = 0.019) and between 5 min and 10 min (p < 0.001), whereas the difference between 1 min and 5 min was not significant (p = 0.180) in Table 3.

Table 3.

Extended statistical summary of air bubble size and depth (mm) across three time conditions. Values are presented as mean ± SD [min–max], coefficient of variation (CV%), and 95% confidence interval (CI).

For bubble depth, the mean value was greatest under the 5 min condition. The mean depth was 2.72 ± 1.84 mm (95% CI: 2.13–3.31) at 1 min, 3.38 ± 1.83 mm (95% CI: 2.79–3.97) at 5 min, and 1.71 ± 1.20 mm (95% CI: 1.32–2.09) at 10 min. Intergroup differences were statistically significant (ANOVA, F = 10.42, p < 0.001; Kruskal–Wallis, H = 16.20, p = 0.0003). Post hoc testing revealed significant differences between 1 min and 10 min (p = 0.019) and between 5 min and 10 min (p < 0.001), whereas the difference between 1 min and 5 min was not significant (p = 0.180).

In summary, microbubble size tended to increase significantly with longer vacuum treatment, with a statistically significant difference observed at 10 min. In contrast, bubble depth was greatest under the 5 min condition but decreased significantly at 10 min.

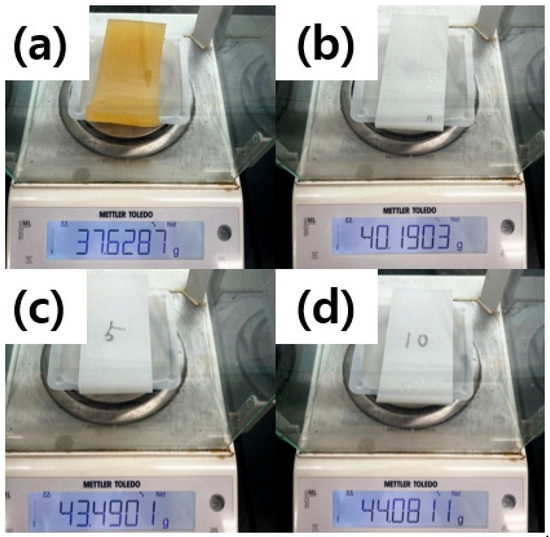

3.2. Measurement of Density and HU Values

The physical properties of the fabricated 3D-printed silicone boluses were compared with those of a commercial bolus used as a control. Density measurements showed that the commercial bolus had a density of 0.988 g/cm3, whereas the 3D-printed boluses exhibited a range of 0.980–1.104 g/cm3.

On CT imaging, the HU values were −110 HU for the commercial bolus and +240 to +250 HU for the 3D-printed silicone boluses. These differences in HU values are attributable to the inherent physical properties and density variations in the two bolus materials, reflecting their distinct radiation attenuation characteristics. The physical properties of the fabricated 3D-printed silicone boluses were compared with those of a commercial bolus used as a control. Density measurements showed that the commercial bolus had a density of 0.988 g/cm3, whereas the 3D-printed boluses exhibited densities of 0.984, 1.104, and 1.104 g/cm3, corresponding to a range of 0.980–1.104 g/cm3. These values indicate that the fabricated boluses were close to water-equivalent density, with only minor variations depending on the fabrication condition (Figure 6).

Figure 6.

Experimental setup for measuring the density of bolus samples. Each silicone sheet was placed on an electronic balance to determine its mass, and the measured values, combined with the sample dimensions, were used to cal-culate density. (a) Commercial bolus; (b) Silicone bolus fabricated with 1-min vacuum degassing; (c) Silicone bolus fabricated with 5-min vacuum degassing; (d) Silicone bolus fabricated with 10-min vacuum degassing.

3.3. Dosimetric Analysis

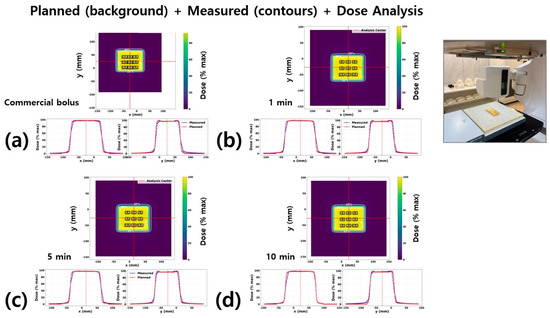

The quantitative results of the dose distribution comparison in Figure 7 are summarized in Table 4. For each condition (commercial bolus and 3D-printed silicone boluses fabricated with 1-, 5-, and 10 min vacuum treatments), the differences between measured and TPS-calculated doses were evaluated at nine grid points (3 × 3 array within ±20 mm of the isocenter).

Figure 7.

Comparison of two-dimensional dose distributions between TPS (Planned, background) and measurement with MatriXX FFF (contours) for a commercial bolus (a) and a custom 3D-printed silicone bolus under three delivery conditions (1, 5, and 10 min; (b–d)). Profiles along the central crosshairs and point-wise dose differences (3 × 3 grid at ±20 mm from isocenter) were extracted and analyzed using an in-house Python code. Each distribution is normalized to its maximum dose.

Table 4.

Point-wise dose differences (Measured − Planned, %) for a commercial bolus and custom 3D-printed silicone boluses fabricated with different vacuum degassing times (1, 5, and 10 min). Values are based on 9 points per case (3 × 3 grid within ±20 mm). RMS = √(mean(Δ2)) across the 9 points.

For the commercial bolus, the mean Δ was −0.34%, and all measurement points fell within |Δ| ≤ 2%, demonstrating excellent agreement with the planned dose. For the 3D-printed boluses, the mean Δ gradually increased with longer vacuum treatment times: +0.51% at 1 min, +0.67% at 5 min, and +0.95% at 10 min.

In particular, under the 10 min condition, the mean Δ rose to approximately +1%, and the RMS value increased to 1.22%. At this condition, two of the nine grid points exceeded |Δ| > 2% (7/9 points passed). Nevertheless, all bolus conditions satisfied the clinical tolerance of |Δ| ≤ 3%.

Overall, both the commercial and 3D-printed boluses showed agreement between TPS and measured dose distributions within the clinically acceptable error margin (±3%). However, in the case of 3D-printed boluses, a slight tendency was observed for the measured dose to exceed the planned dose as vacuum time increased, which may be associated with the characteristics of microbubbles generated during the fabrication process.

3.4. Surface Dose Distribution

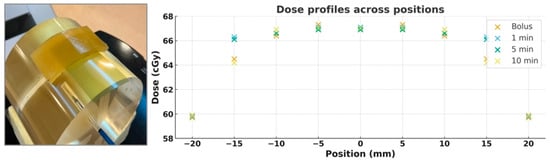

Figure 8 compares the measured dose profiles of a commercial bolus and custom 3D-printed silicone boluses fabricated with different vacuum treatment times (1, 5, and 10 min). Under all conditions, the dose near the isocenter (0 mm) was consistently observed at approximately 67 cGy, demonstrating excellent reproducibility of central dose delivery regardless of bolus type under identical irradiation conditions.

Figure 8.

Dose measurement using EBT3 film on a cylindrical phantom. A commercial bolus and a custom 3D-printed silicone bolus were individually placed on the phantom surface and irradiated under identical beam settings (3 × 3 cm2 field, 100 MU). The resulting film dose distributions were analyzed to evaluate the surface dose characteristics for each bolus.

Toward the lateral edges of the profile (±20 mm), the dose gradually decreased to about 59–60 cGy, consistent with the expected dose fall-off at the beam field boundary. The dose profiles for the commercial bolus and the 1- and 5 min silicone boluses were nearly superimposed across the entire curve, confirming the consistency of dose delivery. In contrast, the 10 min condition showed a slightly lower dose pattern in the ±15–20 mm region; however, the difference was within 2 cGy, which remains clinically acceptable.

4. Discussion

In this study, the effects of residual air bubbles, thickness irregularities, and differences in density and HU values arising during the fabrication of 3D-printed silicone boluses on radiation dose distribution were evaluated. The analysis confirmed the presence of some air bubbles (maximum diameter approximately 1 mm, depth up to 7 mm) and thickness variations; however, the differences between planned and measured doses remained within clinically acceptable limits (±3–5%) (Table 4, Figure 7). These results comply with the commonly applied quality assurance (QA) tolerance in radiotherapy of a 3% dose error and 3 mm spatial error. Furthermore, film-based surface dose analysis demonstrated that the 3D-printed boluses achieved an equivalent performance level to that of commercial boluses (Figure 8).

Previous studies have primarily evaluated the effect of air gaps between the bolus and the skin on surface dose. Butson et al. [4] reported that a 10 mm air gap under 6 MV photon irradiation could reduce the surface dose by approximately 10%. Boman et al. [5] found that in VMAT, a 10 mm air gap resulted in a 13.6% reduction, whereas the decrease was limited to ≤2.6% when using the field-in-field technique. Dilson et al. [1] reported that uniform air gaps of 5–15 mm caused a 5–18% dose reduction, while non-uniform air gaps led to smaller reductions of around 3–3.5%. In addition, Khan et al. [22] demonstrated that significant dose reduction (~10%) occurred when air gaps exceeded 5 mm. Collectively, these studies highlight the negative impact of air gaps on treatment accuracy.

Meanwhile, recent studies have highlighted the advantages of patient-specific or 3D-printed boluses. Wang et al. [6] reported that silicone custom boluses significantly reduced the air gap volume and the discrepancy between planned and measured doses compared with commercial boluses. Kim et al. [23] demonstrated that patient-specific boluses reduced the air gap volume by more than 77% and improved both the mean dose error and standard deviation in 3D-CRT and VMAT. In addition, Chatchumnan et al. [24] reported that silicone boluses fabricated for head and neck treatments exhibited HU values, density, and thickness characteristics equivalent to those of commercial boluses, and showed comparable or even superior results in dose profiles and gamma analysis.

In contrast, the present study quantitatively analyzed the impact of air bubbles located within the bolus on dose distribution. While previous reports have only mentioned the possibility of bubble formation, few studies have systematically correlated the actual size and depth distribution of bubbles with corresponding dose variations. This study addresses that gap and demonstrates that microbubbles generated during the fabrication of custom boluses have only a limited effect on delivered dose. To our knowledge, this is the first study to systematically evaluate microbubble dimensions inside silicone boluses and correlate them with dosimetric outcomes, which clearly distinguishes it from previous investigations that mainly addressed macroscopic air gaps between the bolus and the skin.

At the same time, several practical techniques to minimize bubble formation during fabrication have been reported in the literature. For instance, Wang et al. showed that optimized mold design combined with 3D-printed casting significantly reduced air gap volume and improved the predictability of delivered doses, with smaller gaps correlating with reduced deviations between planned and measured values [6]. Yu et al. demonstrated that the Life-Casting method using EcoFlex silicone decreased the air gap volume by approximately 77% compared with commercial boluses, while reducing both mean and maximum dose errors in 3D-CRT and VMAT [12]. Boopathi et al. reported that the homogeneity and density of silicone elastomer boluses remained stable under different mixing and thickness conditions, indirectly supporting the role of material properties in reducing bubble occurrence [13]. Moreover, pouring silicone from the lowest point of the mold in a thin stream and incorporating upper vents has been described as an effective way to allow trapped air to escape, thereby reducing bubble size and frequency [9,11]. Similarly, studies have reported that self-adhesive or soft hydrogel-based silicone boluses improved conformity to the skin surface, which in turn reduced the likelihood of air entrapment [6,11,13]. Taken together, these findings suggest that although the bubble levels observed in this study were clinically acceptable, adopting optimized fabrication strategies—including mold and pouring design, material selection, and mixing protocols—could further enhance reproducibility and reliability in clinical workflows.

Several clinical considerations should be noted. First, the study was conducted using a homogeneous phantom, which cannot fully replicate the complex anatomical structures and tissue heterogeneity of actual patients. Nevertheless, the implications of our findings are directly relevant to clinical settings, particularly in cases with complex anatomy or advanced delivery techniques such as IMRT and SBRT. Future validation using patient datasets will be essential to confirm the translatability of these results. Second, the detection of air bubbles may be underestimated due to the spatial resolution limitations of CT imaging, particularly for bubbles smaller than 1 mm in diameter. In addition, bubble characterization in this study relied on 2D scanning, which was sufficient for initial quantification; however, three-dimensional imaging methods such as micro-CT could provide a more comprehensive evaluation and will be considered in future investigations. Third, in advanced techniques such as Intensity-Modulated Radiation Therapy (IMRT), VMAT, and Stereotactic Body Radiation Therapy (SBRT), small fields and high dose rates are employed; under these conditions, repeated beam intersections with bolus-entrapped bubbles could induce local dose inhomogeneities (hotspots). This effect may be particularly significant in SBRT, where cumulative errors could have clinically meaningful consequences. Therefore, extended validation with diverse treatment techniques and patient datasets is required before these findings can be generalized to clinical practice. Such follow-up investigations will support both the optimization of bolus fabrication processes and the establishment of clinical reliability.

From a QA perspective, setting fabrication conditions to minimize bubble formation and implementing CT-based verification procedures may be beneficial. Although complete elimination of bubbles through vacuum or pressurization could be ideal (An et al., 2019; Hobbis et al., 2024) [10,25], the present findings indicate that the observed level of bubbles did not produce clinically significant dose deviations. Thus, custom boluses fabricated under appropriate QA can provide clinically acceptable reliability without requiring complex additional procedures.

In conclusion, this study systematically evaluated the effect of internal air bubbles within patient-specific silicone boluses on dose delivery in radiotherapy. The observed levels of bubbles resulted in dose reproducibility within clinically acceptable limits in the phantom setting. Nevertheless, further prospective clinical validation and expanded assessments across different treatment modalities are necessary for clinical translation. Such efforts will contribute not only to the optimization of fabrication processes but also to potential workflow simplification in the future.

5. Conclusions

This study represents one of the first attempts to quantitatively verify the impact of internal air bubbles within patient-specific silicone boluses on radiation dose delivery, highlighting its clinical significance. The levels of bubbles observed in this study demonstrated dose reproducibility largely within clinically acceptable limits; however, it would be more appropriate to interpret this as conditional safety rather than concluding that bubble removal processes are unnecessary.

Several limitations should be noted. First, this work was conducted using a homogeneous phantom, which does not fully represent the anatomical complexity of actual patients. Second, only limited fabrication and evaluation conditions were investigated (e.g., vacuum degassing times, a single irradiation energy), which restricts the generalizability of the findings.

For clinical implementation, it is essential to establish individualized QA criteria that take into account each institution’s equipment environment, treatment objectives, and patient characteristics. Continuous monitoring and verification are required to ensure safety. In the future, multicenter validation studies including real patient data and diverse fabrication parameters are expected to facilitate workflow optimization and the establishment of standardized clinical guidelines.

Author Contributions

Conceptualization, M.K. and Y.S.S.; methodology, Y.S.S.; software, B.K.; validation, S.J.B. and Y.S.S.; formal analysis, B.K.; investigation, Y.S.S.; resources, S.J.B.; data curation, B.K.; writing—original draft preparation, Y.S.S.; writing—review and editing, M.K.; visualization, B.K.; supervision, M.K.; project administration, M.K.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the Department of Radiation Oncology at Keimyung University Dongsan Medical Center for supporting this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dilson, L.; Challapalli, S.; Sourjya, B.; Athiyamaan, M.S.; Ramamoorthy, R.; Johan, S.; Abhishek, K. Estimation of surface dose in the presence of unwanted air gaps under the bolus in postmastectomy radiation therapy: A phantom dosimetric study. Asian Pac. J. Cancer Prev. 2022, 23, 2973–2981. [Google Scholar] [CrossRef]

- Vyas, V.; Palmer, L.; Mudge, R.; Jiang, R.; Fleck, A.; Schaly, B.; Osei, E.; Charland, P. On bolus for megavoltage photon and electron radiation therapy. Med. Dosim. 2013, 38, 268–273. [Google Scholar] [CrossRef]

- Li, F.; Hu, W.; Li, H.; Li, B.; Wang, Y. Bolus use in postmastectomy radiation therapy for breast cancer: A systematic literature review. Technol. Cancer Res. Treat. 2025, 24, 15330338251344521. [Google Scholar] [CrossRef]

- Butson, M.J.; Cheung, T.; Yu, P.K.N.; Metcalfe, P. Effects on skin dose from unwanted air gaps under bolus in photon beam radiotherapy. Radiat. Meas. 2000, 32, 201–204. [Google Scholar] [CrossRef]

- Boman, E.; Ojala, J.; Rossi, M.; Kapanen, M. Monte Carlo investigation on the effect of air gap under bolus in post-mastectomy radiotherapy. Phys. Med. 2018, 55, 82–87. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.M.; Rickards, A.J.; Bingham, T.; Tward, J.D.; Price, R.G. Technical note: Evaluation of a silicone-based custom bolus for radiation therapy of a superficial pelvic tumor. J. Appl. Clin. Med. Phys. 2022, 23, e13538. [Google Scholar] [CrossRef]

- Gugliandolo, S.G.; Pillai, S.P.; Rajendran, S.; Vincini, M.G.; Pepa, M.; Pansini, F.; Zaffaroni, M.; Marvaso, G.; Alterio, D.; Vavassori, A.; et al. 3D-printed boluses for radiotherapy: Influence of geometrical and printing parameters on dosimetric characterization and air gap evaluation. Radiol. Phys. Technol. 2024, 17, 347–359. [Google Scholar] [CrossRef]

- Dubey, A.; Johnson, K.; Sasaki, D.; Rickey, D.; Harris, C.; Boyer, T.; Butler, J.; Leylek, A.; Sharma, A.; Koul, R. Innovative Approach for Generating Soft Silicone Bolus Using 3-Dimensional Printing for Electron Treatment of Skin Cancers in Areas with Irregular Contours. Int. J. Radiat. Oncol. Biol. Phys. 2016, 96 (Suppl. S2), E606–E607. [Google Scholar] [CrossRef]

- Chiu, T.; Tan, J.; Brenner, M.; Gu, X.; Yang, M.; Westover, K.; Strom, T.; Sher, D.; Jiang, S.; Zhao, B. Development and clinical implementation of 3D printed bolus in radiation therapy. Pract. Radiat. Oncol. 2018, 8, e167–e174. [Google Scholar] [CrossRef]

- Hobbis, D.; Armstrong, M.D.; Patel, S.H.; Tegtmeier, R.C.; Laughlin, B.S.; Chitsazzadeh, S.; Clouser, E.L.; Smetanick, J.L.; Pettit, J.; Gagneur, J.D.; et al. Comprehensive clinical implementation, workflow, and FMEA of bespoke silicone bolus cast from 3D printed molds using open-source resources. J. Appl. Clin. Med. Phys. 2024, 25, e14498. [Google Scholar] [CrossRef] [PubMed]

- Son, J.; Kang, S.; Jin, J.; Park, H.; Lee, I.; Huh, Y.; Choi, C.H.; Kim, J.-I.; Wu, H.-G. Clinical application of patient-specific bolus based on molding and casting method in radiotherapy. J. Clin. Med. 2025, 14, 3796. [Google Scholar] [CrossRef]

- Yu, G.B.; Kwon, J.; Chae, S.; Lee, S.Y.; Jung, S. Evaluations of patient-specific bolus fabricated by mold-and-cast method using computer numerical control machine tools. J. Radiat. Res. 2023, 64, 973–981. [Google Scholar] [CrossRef]

- Boopathi, M.; Khanna, D.; Venkatraman, P.; Varshini, R.; Sureka, C.S.; Pooja, S. Fabrication and dosimetric characteristics of silicon elastomer-based bolus using external beam radiotherapy. Asian Pac. J. Cancer Prev. 2023, 24, 141–147. [Google Scholar] [CrossRef]

- Yu, S.; Ahn, S.H.; Choi, S.H.; Ahn, W.S.; Jung, I.H. Clinical application of a customized 3D-printed bolus in radiation therapy for distal extremities. Life 2023, 13, 362. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, X.; Xiang, Z.; Zeng, Y.; Liu, F.; Shao, B.; He, T.; Ma, J.; Yu, S.; Liu, L. The clinical application of 3D-printed boluses in superficial tumor radiotherapy. Front. Oncol. 2021, 11, 698773. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-Y.; Yang, B.; Lam, W.W.; Tang, K.K.; Li, T.C.; Law, W.K.; Cheung, K.Y.; Yu, S.K. Effects on skin dose from unwanted air gaps under bolus in an MR-guided linear accelerator (MR-linac) system. Phys. Med. Biol. 2021, 66, 065021. [Google Scholar] [CrossRef]

- Bochyńska, A.; Zawadzka, A.; Kukolowicz, P.; Spalek, M.J. Application of 3D printing for personalized boluses in radiotherapy: A systematic review. Rep. Pract. Oncol. Radiother. 2025, 30, 100–113. [Google Scholar] [CrossRef]

- Smooth-On Inc. Dragon Skin™ 10 NV: Technical Bulletin [Internet]; Smooth-On, Inc.: Macungie, PA, USA, 2025; Available online: https://www.smooth-on.com/tb/files/DRAGON_SKIN_10NV_TB.pdf (accessed on 22 September 2025).

- Robar, J.L.; Moran, K.; Allan, J.; Clancey, J.; Joseph, T.; Chytyk-Praznik, K.; MacDonald, R.L.; Lincoln, J.; Sadeghi, P.; Rutledge, R. Intrapatient study comparing 3D printed bolus versus standard vinyl gel sheet bolus for postmastectomy chest wall radiation therapy. Pract. Radiat. Oncol. 2018, 8, 221–229. [Google Scholar] [CrossRef]

- Kairn, T.; Talkhani, S.; Charles, P.H.; Chua, B.; Lin, C.Y.; Livingstone, A.G.; Maxwell, S.K.; Poroa, T.; Simpson-Page, E.; Spelleken, E.; et al. Determining tolerance levels for quality assurance of 3D printed bolus for modulated arc radiotherapy of the nose. Phys. Eng. Sci. Med. 2021, 44, 1187–1199. [Google Scholar] [CrossRef] [PubMed]

- Wake, J.R.; Chen, F.Q.; Ashworth, S.; Byth, K.; Wang, W.; Stuart, K.E. Verification using in vivo optically stimulated luminescent dosimetry of the predicted skin surface dose in patients receiving postmastectomy radiotherapy. Med. Dosim. 2021, 46, e1–e6. [Google Scholar] [CrossRef]

- Khan, Y.; Villarreal-Barajas, J.E.; Udowicz, M.; Sinha, R.; Muhammad, W.; Abbasi, A.N.; Hussain, A. Clinical and dosimetric implications of air gaps between bolus and skin surface during radiation therapy. J. Cancer Ther. 2013, 4, 1251–1255. [Google Scholar] [CrossRef]

- Kim, J.; Park, J.; Park, B.; Park, B.; Kim, T.G. Feasibility of a patient-specific bolus using the life-casting method for radiation therapy. Appl. Sci. 2023, 13, 9977. [Google Scholar] [CrossRef]

- Chatchumnan, N.; Kingkaew, S.; Aumnate, C.; Sanghangthum, T. Development and dosimetric verification of 3D customized bolus in head and neck radiotherapy. J. Radiat. Res. 2022, 63, 428–434. [Google Scholar] [CrossRef]

- An, H.J.; Kim, M.S.; Kim, J.; Son, J.; Choi, C.H.; Park, J.M.; Kim, J.-I. Geometric evaluation of patient-specific 3D bolus from 3D printed mold and casting method for radiation therapy. Prog. Med. Phys. 2019, 30, 24–30. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).