Novel Formulation of Low-Fat Milk Chocolate: Impact on Physicochemical and Sensory Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chocolate Production

2.3. Cocoa Butter Substitution Using WPI:IN

2.4. Rheological Analysis

2.5. Color Measurement

2.6. Differential Scanning Calorimetry (DSC)

2.7. Hardness Measurement

2.8. Caloric Value Determination

2.9. Sensory Evaluation Protocol

2.10. Effect of Emulsifiers on Chocolate Rheology

2.11. Emulsifier Optimization for High-Level Cocoa Butter Replacement

2.12. Statistical Analysis

3. Results and Discussion

3.1. Effects of Cocoa Butter Substitution on Chocolate Properties

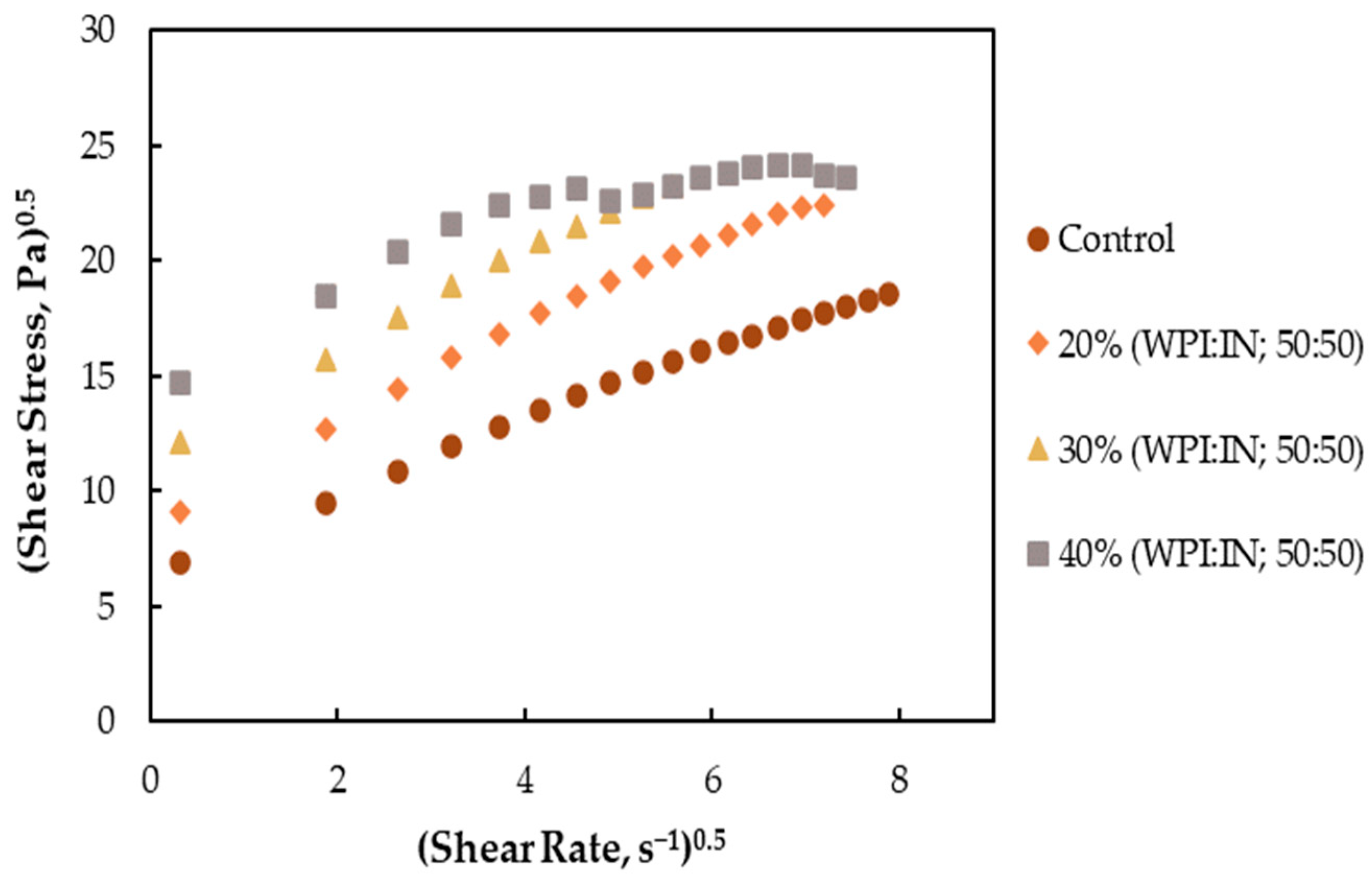

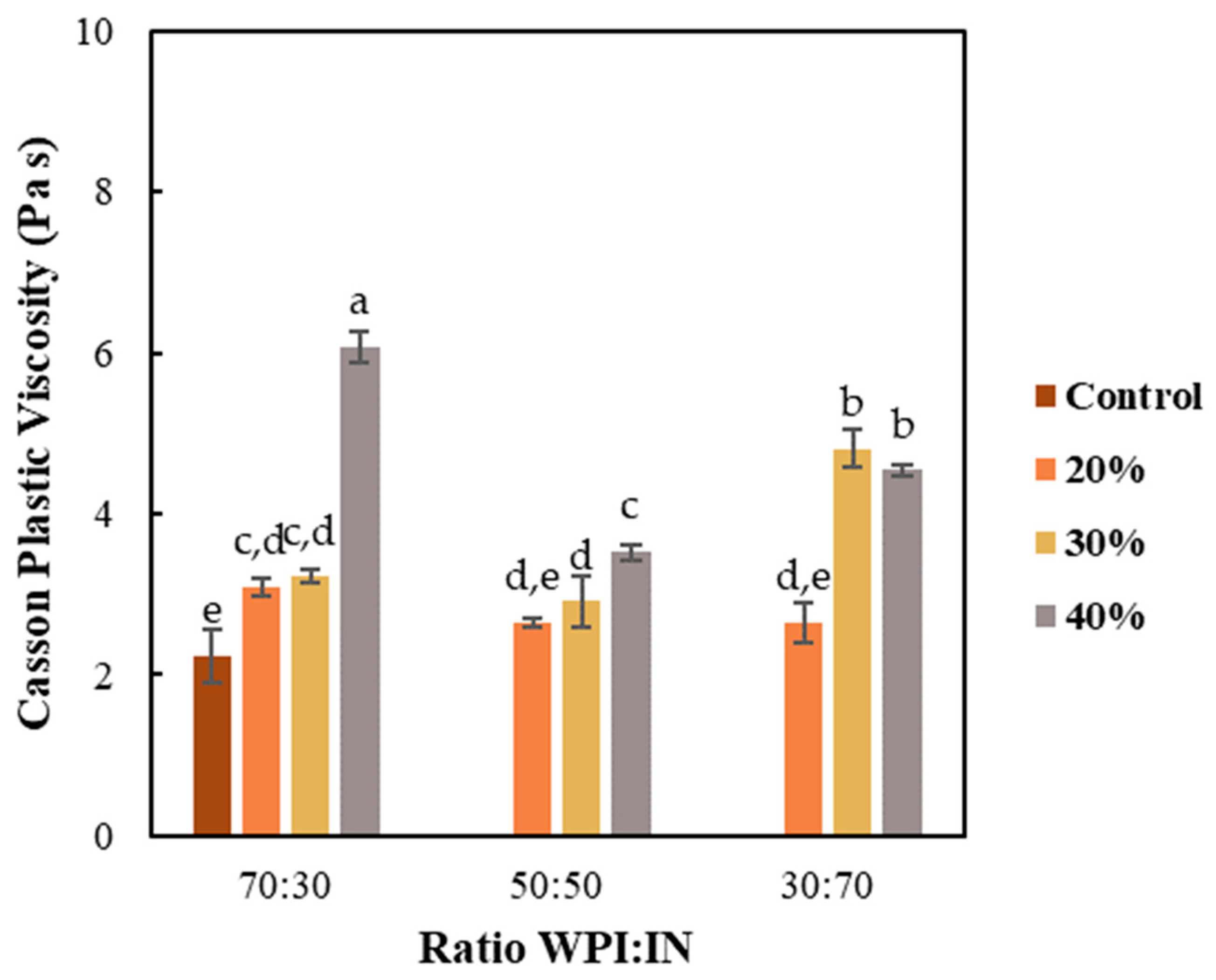

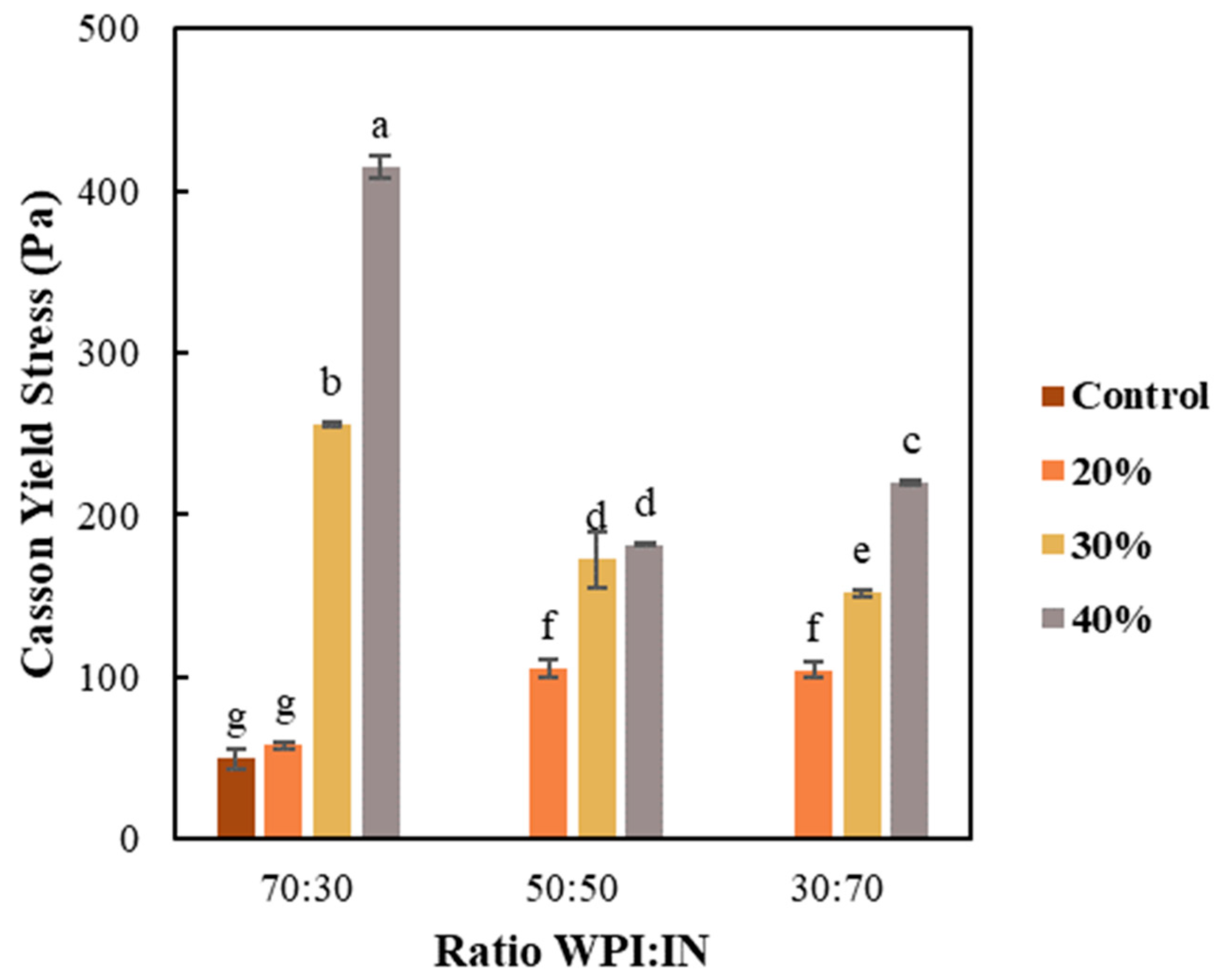

3.1.1. Rheological Properties

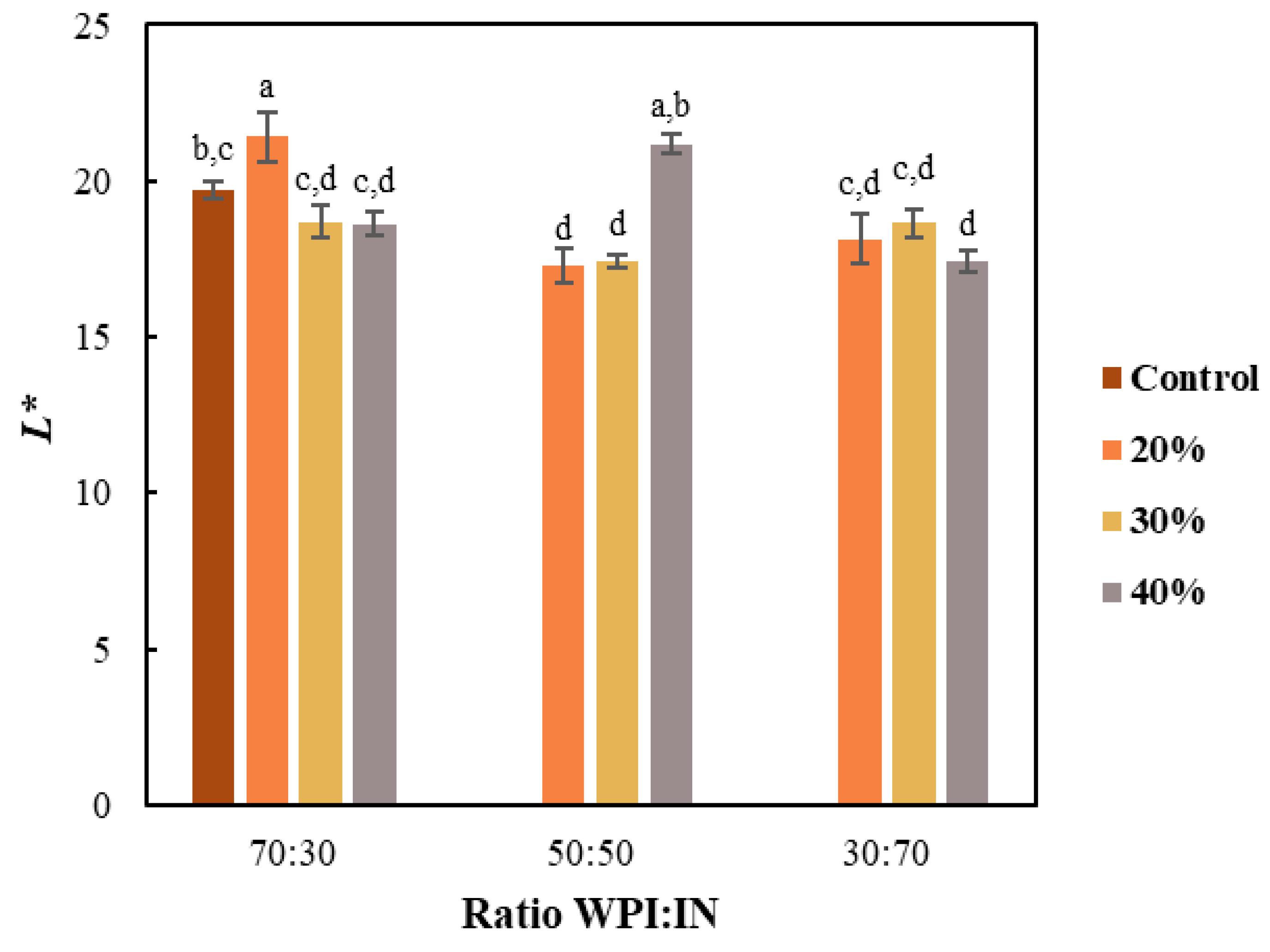

3.1.2. Color Attributes

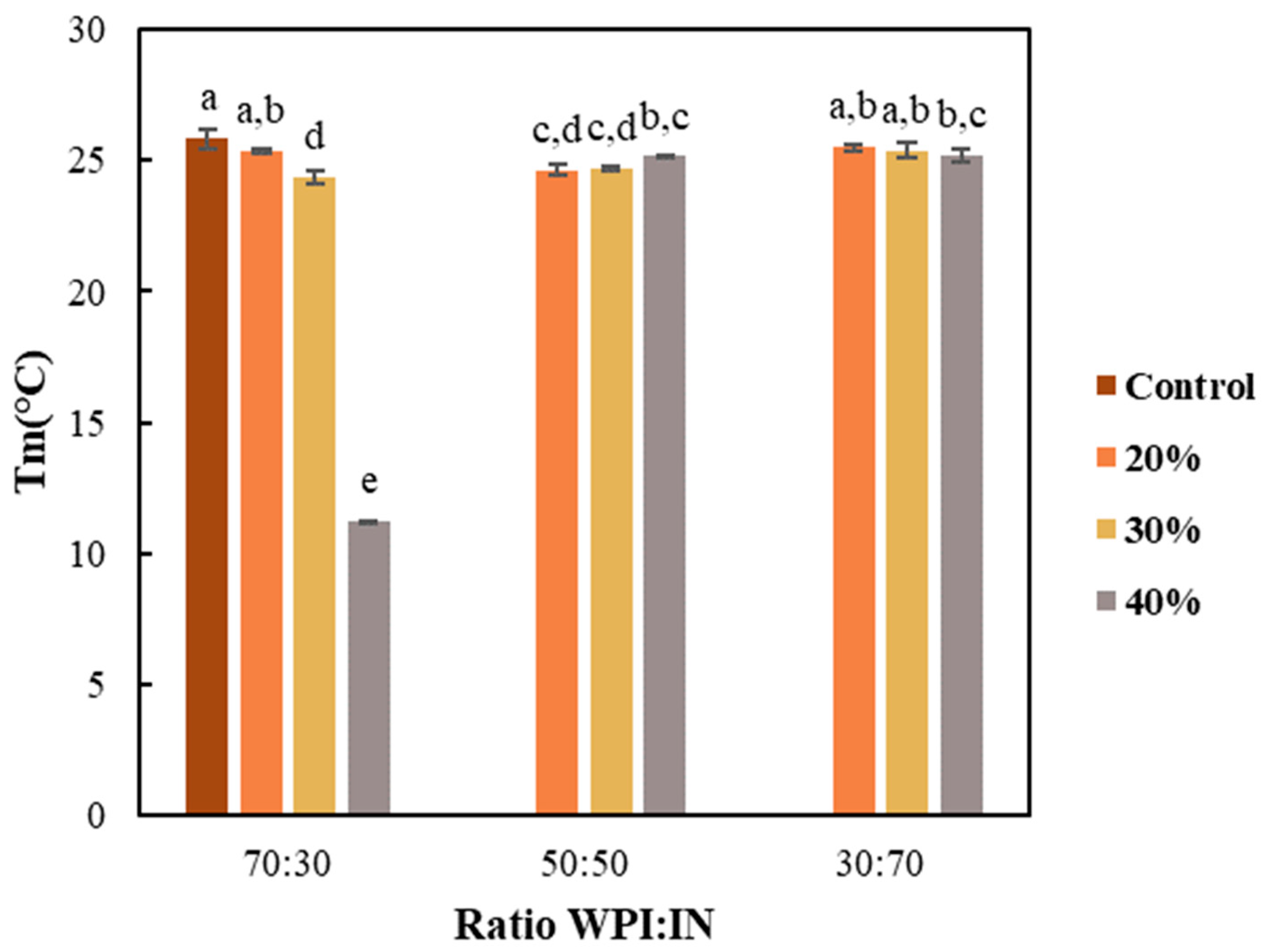

3.1.3. Melting Behavior (Tm, °C)

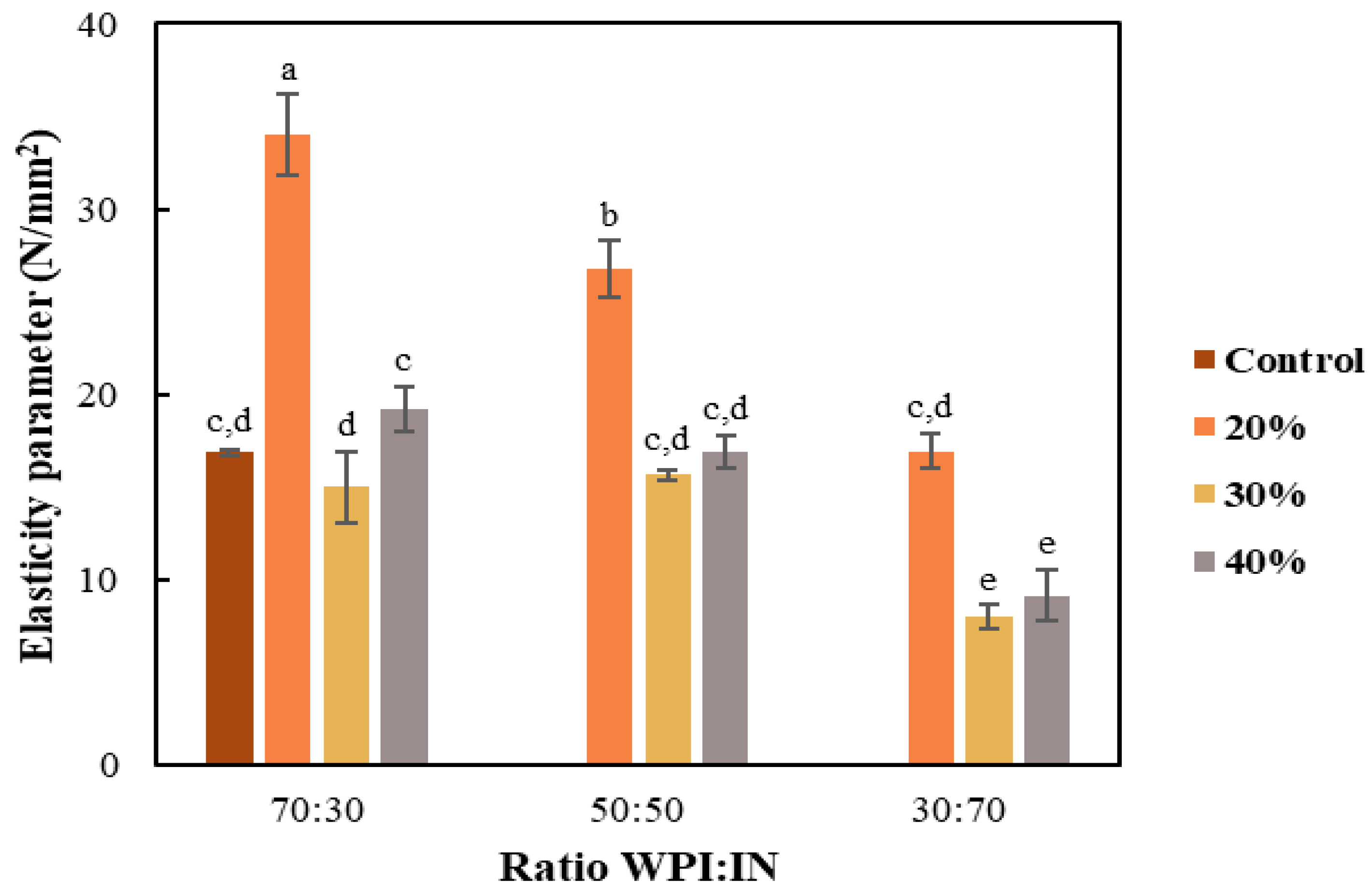

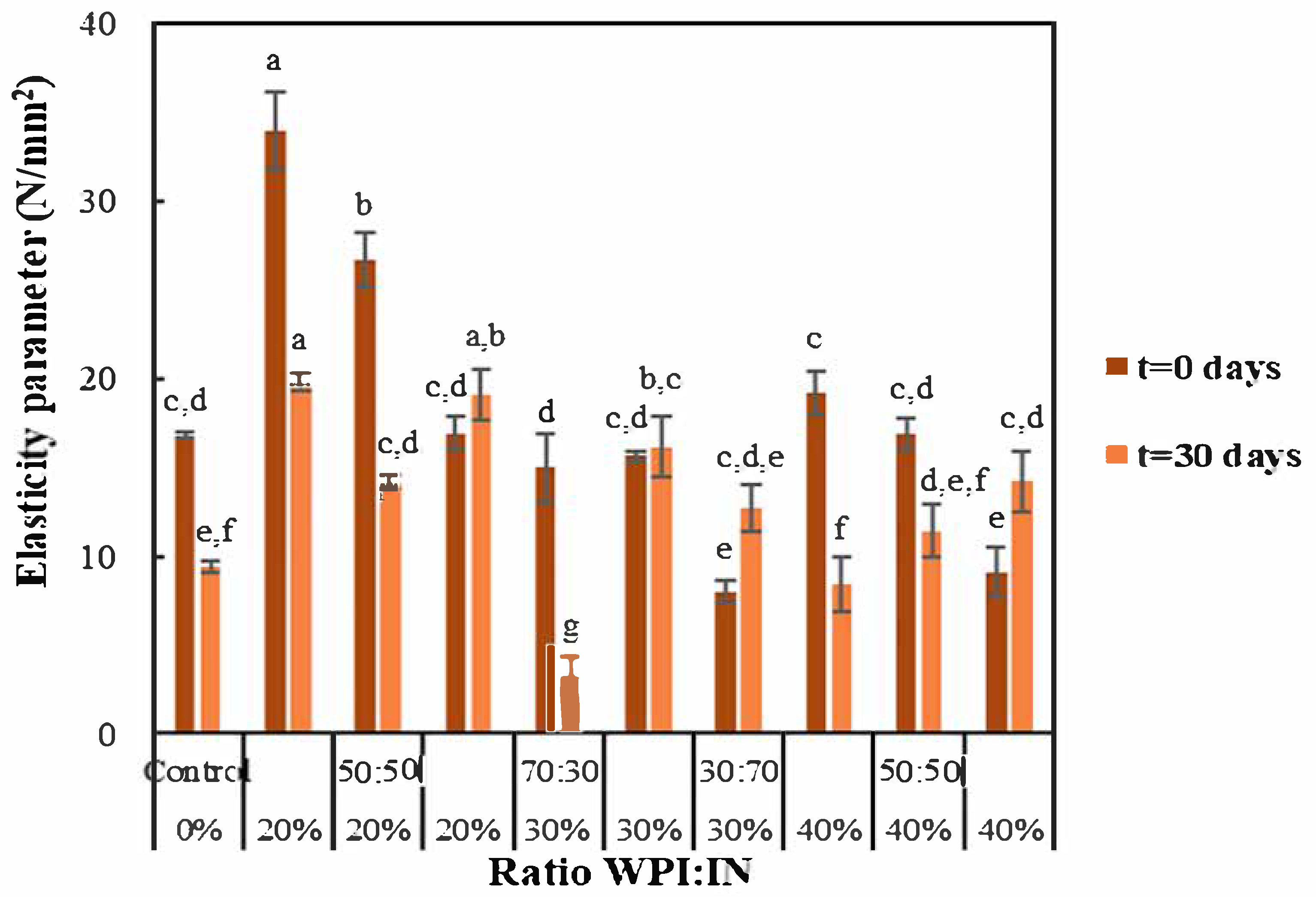

3.1.4. Textural Properties: Hardness

3.1.5. Caloric Content

3.1.6. Sensory Evaluation Results

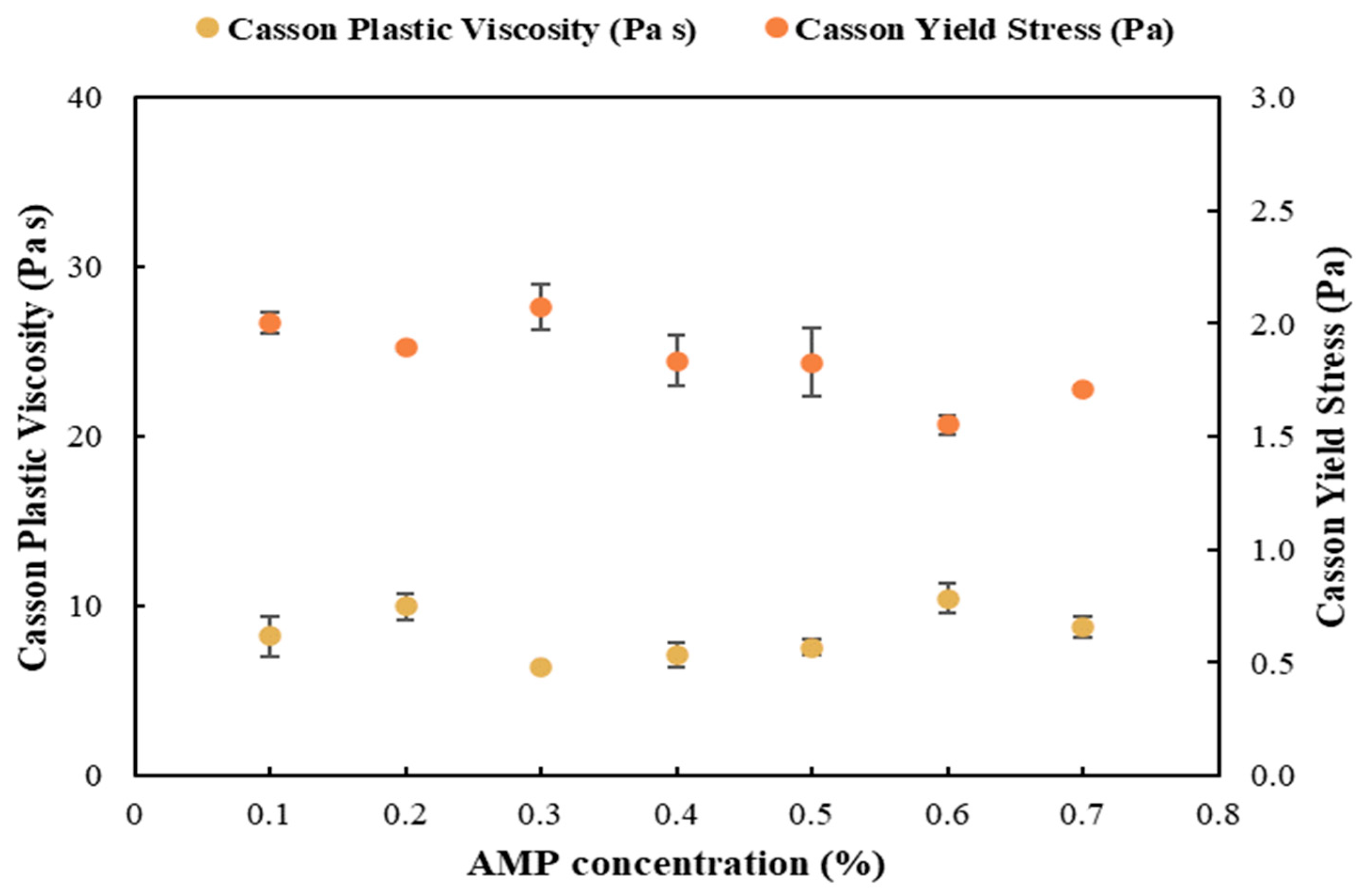

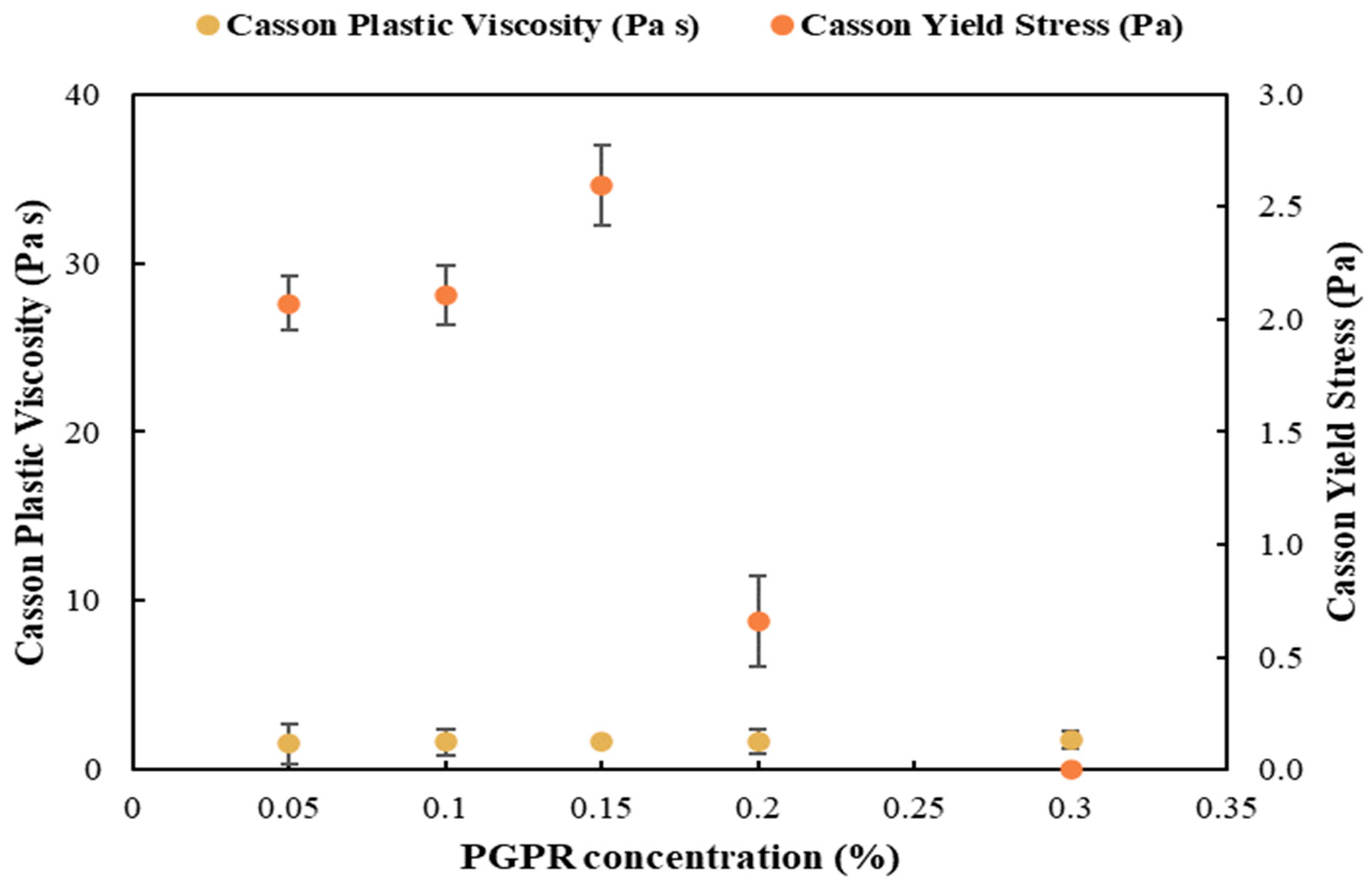

3.2. Emulsifier Effect on Chocolate Rheology

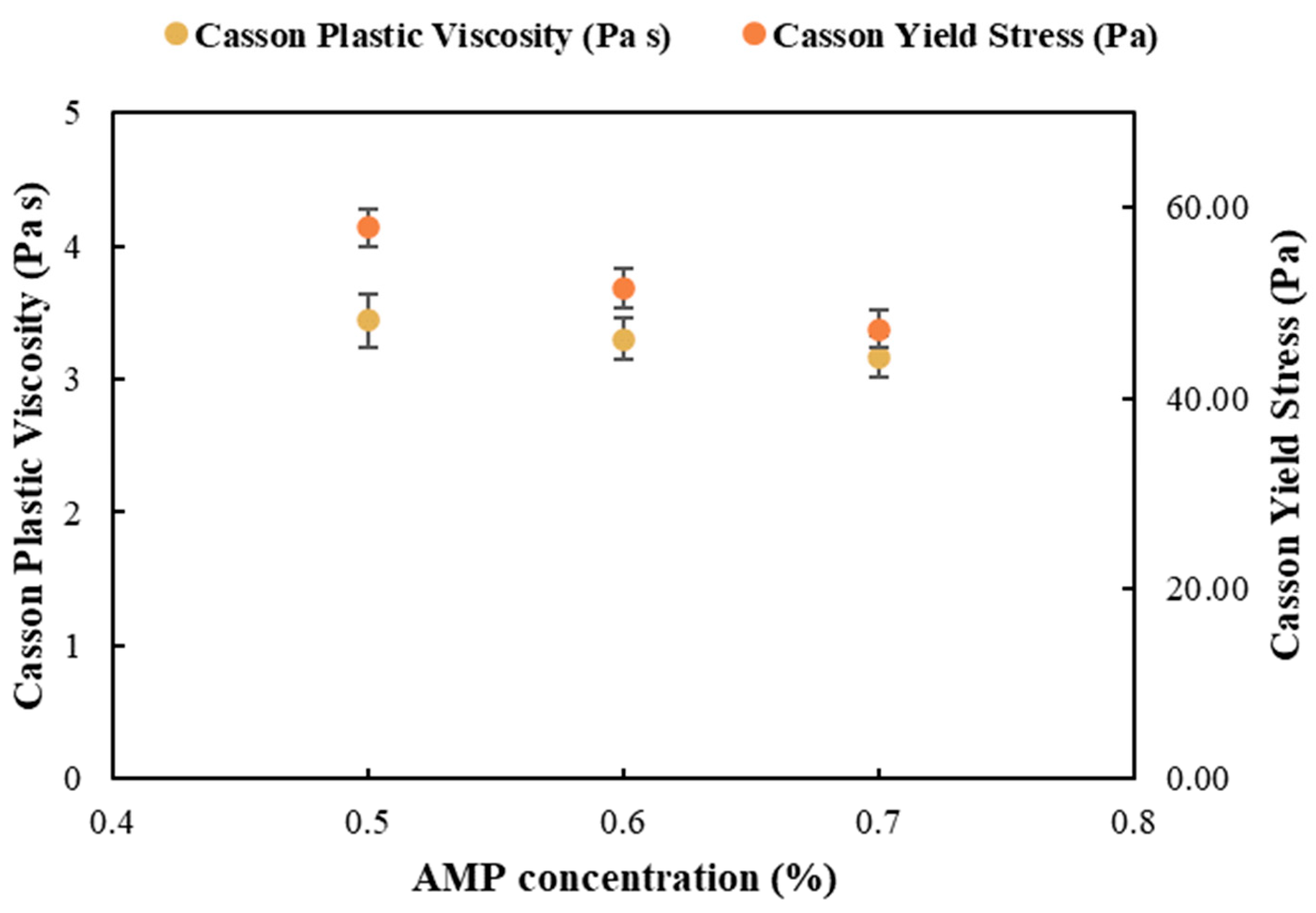

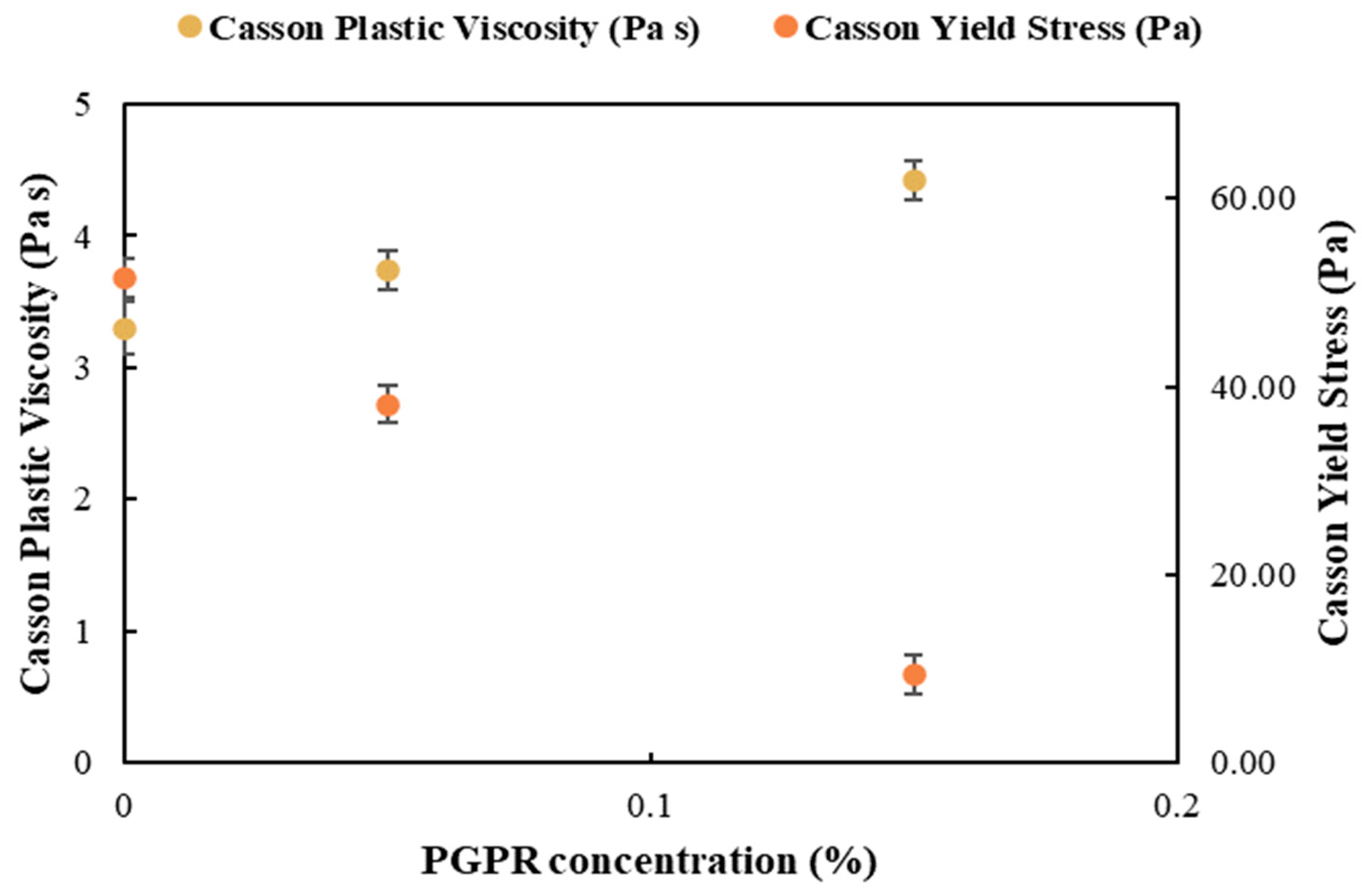

3.3. Optimization of Rheology in High Cocoa Butter Replacement Samples

3.3.1. Rheological Optimization of the 40% CB-Substituted Chocolate Sample

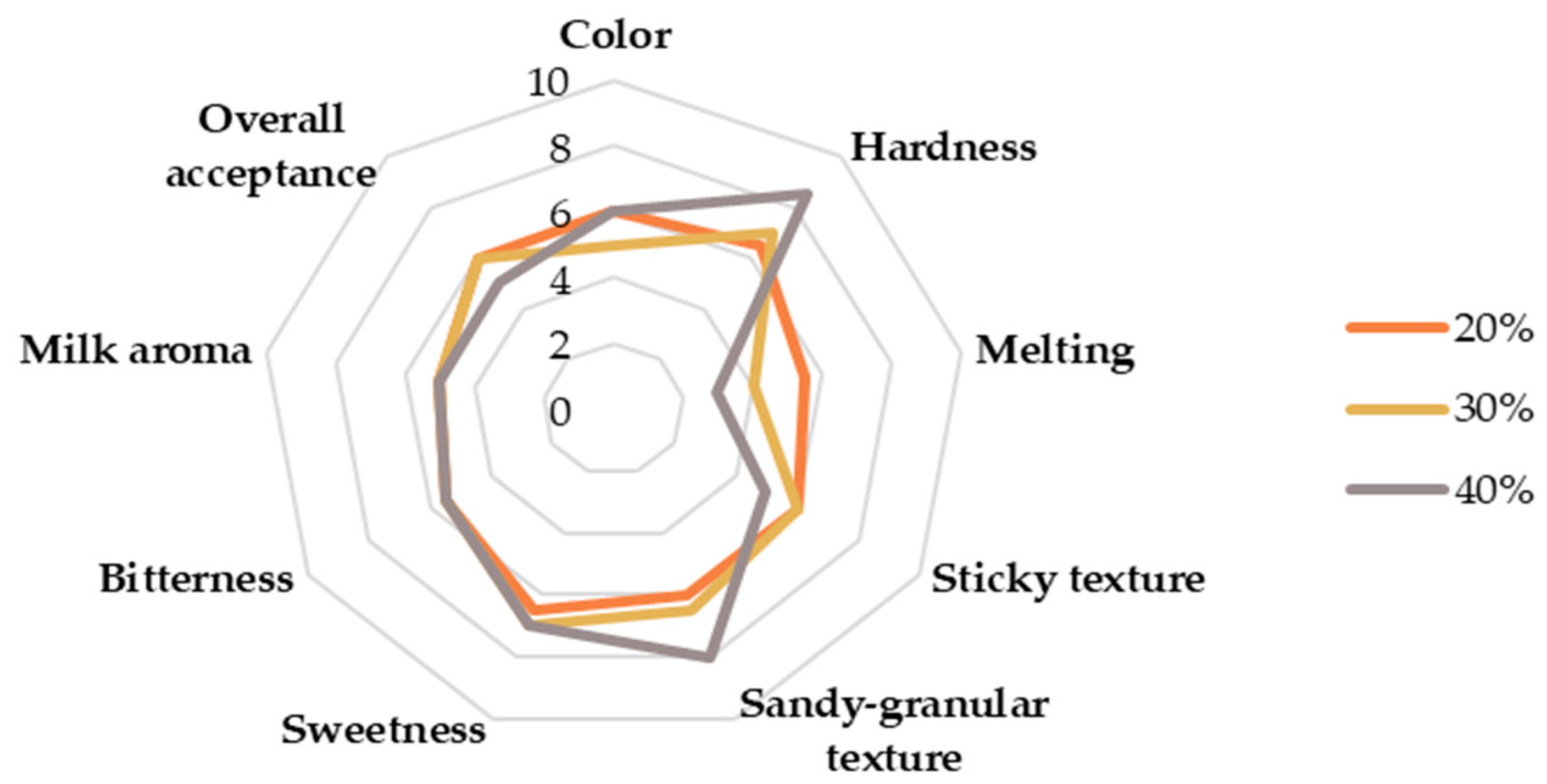

3.3.2. Sensory Profile of Optimized Formulations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CB | Cocoa Butter |

| WPI | Whey Protein Isolate |

| IN | Inulin |

| AMP | Ammonium Phosphatide |

| PGPR | Polyglycerol Polyricinoleate |

| Tm | Melting Temperature |

| DSC | Differential Scanning Calorimetry |

| σ | Stress (Pa) |

| ε or εn | Strain |

| E_mod | Modulus of Elasticity |

| τ | Shear Stress (Pa) |

| γ or γ̇ | Shear Rate (1/s) |

| τ0 | Yield Stress (Pa) |

| k | Plastic Viscosity (Pa·s) |

| WHO | World Health Organization |

| CIELAB | Commission Internationale de l’Eclairage Lab* (Color space) |

References

- Lim, H.J.; Xue, H.; Wang, Y. Global Trends in Obesity. In Handbook of Eating and Drinking; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–20. [Google Scholar]

- Memon, M.A. Bariatric Surgery Focused Issue. Ann. Transl. Med. 2020, 8 (Suppl. S1), S1. [Google Scholar] [CrossRef]

- Blüher, M.; Stumvoll, M. Diabetes and Obesity. In Diabetes. Epidemiology, Genetics, Pathogenesis, Diagnosis, Prevention, and Treatment; Springer Nature: Berlin/Heidelberg, Germany, 2018; pp. 1–49. [Google Scholar]

- WHO. 2023. Available online: https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 30 June 2025).

- Drewnowski, A.; Darmon, N. The Economics of Obesity: Dietary Energy Density and Energy Cost. Am. J. Clin. Nutr. 2005, 82, 265S–273S. [Google Scholar] [CrossRef] [PubMed]

- Joseph, C.; Batra, R.; Selvasekaran, P.; Chidambaram, R. Low Calorie Cocoa-Based Products: A Short Review. J. Food Sci. Technol. 2022, 59, 2931–2939. [Google Scholar] [CrossRef] [PubMed]

- Yamada, K.; Ibuki, M.; McBrayer, T. Cocoa Butter, Cocoa Butter Equivalents, and Cocoa Butter Replacers. In Healthful Lipids; AOCS Publishing: Champaign, IL, USA, 2005. [Google Scholar]

- Fukami, Y.; Iwaoka, E.; Kuriyama, M.; Sato, K. Physical Properties of Bloom-resistant Chocolate Using Palm-based No- Trans. Cocoa Butter Replacers. J. Am. Oil Chem. Soc. 2025, 102, 311–322. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, W.-W.; Ni, Z.-J.; Thakur, K.; Zhang, J.-G.; Hu, F.; Wei, Z.-J. Development and Characterization of Novel Lycium Barbarum Seed Oil-Based Oleogels and Their Application in Functional Chocolate. Food Biosci. 2023, 56, 103155. [Google Scholar] [CrossRef]

- Espert, M.; Hernández, M.J.; Sanz, T.; Salvador, A. Reduction of Saturated Fat in Chocolate by Using Sunflower Oil-Hydroxypropyl Methylcellulose Based Oleogels. Food Hydrocoll. 2021, 120, 106917. [Google Scholar] [CrossRef]

- Medina-Mendoza, M.; Rodriguez-Pérez, R.J.; Rojas-Ocampo, E.; Torrejón-Valqui, L.; Fernández-Jeri, A.B.; Idrogo-Vásquez, G.; Cayo-Colca, I.S.; Castro-Alayo, E.M. Rheological, Bioactive Properties and Sensory Preferences of Dark Chocolates with Partial Incorporation of Sacha Inchi (Plukenetia volubilis L.) Oil. Heliyon 2021, 7, e06154. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Cofrades, S.; Espert, M.; Sanz, T.; Salvador, A. Development of Chocolates with Improved Lipid Profile by Replacing Cocoa Butter with an Oleogel. Gels 2021, 7, 220. [Google Scholar] [CrossRef]

- Prosapio, V.; Norton, I.T. Development of Fat-Reduced Chocolate by Using Water-in-Cocoa Butter Emulsions. J. Food Eng. 2019, 261, 165–170. [Google Scholar] [CrossRef]

- Rezende, N.V.; Benassi, M.T.; Vissotto, F.Z.; Augusto, P.P.C.; Grossmann, M.V.E. Mixture Design Applied for the Partial Replacement of Fat with Fibre in Sucrose-Free Chocolates. LWT—Food Sci. Technol. 2015, 62, 598–604. [Google Scholar] [CrossRef]

- Saentaweesuk, S.; Chaikham, P. Effect of Whey Protein Isolate Incorporated with Various Carbohydrate-Based Fat Replacers on Physicochemical and Sensorial Properties of Low-Fat Chocolate Ice Cream. Food Res. 2023, 7, 167–176. [Google Scholar] [CrossRef]

- Drosou, C.; Krokida, M. Enrichment of White Chocolate with Microencapsulated β-Carotene: Impact on Quality Characteristics and β-Carotene Stability during Storage. Foods 2024, 13, 2699. [Google Scholar] [CrossRef]

- Stanciu, I.; Ouerfelli, N. An Extended Casson Equation for Rheological Properties of Soybean Oil at Different Temperatures and Atmospheric Pressure. J. Biochem. Technol. 2020, 11, 52–57. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.-J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Laina, K.T.; Drosou, C.; Giannenas, I.; Krokida, M. Formulation of Novel Functional Extrudates Containing Natural Bioactive Compounds. Dry. Technol. 2024, 42, 1778–1790. [Google Scholar] [CrossRef]

- Lee, S.; Biresaw, G.; Kinney, M.P.; Inglett, G.E. Effect of Cocoa Butter Replacement with a Β-glucan-rich Hydrocolloid (C-trim30) on the Rheological and Tribological Properties of Chocolates. J. Sci. Food Agric. 2009, 89, 163–167. [Google Scholar] [CrossRef]

- Syafiq, A.; Amir, I.Z.; Sharon, W.X.R. Mixture Experiment on Rheological Properties of Dark Chocolate as Influenced by Cocoa Butter Substitution with Xanthan Gum/Corn Starch/Glycerin Blends. Int. Food Res. J. 2014, 21, 1887–1892. [Google Scholar]

- Ghorbel, D.; Saïdi, I.; Ben Slema, M.; Gharsallah, M. Adjusting flow properties of molten milk chocolate by means of emulsifiers and fat. J. Food Process Eng. 2011, 34, 317–331. [Google Scholar] [CrossRef]

- Lim, P.Y.; Wong, K.Y.; Thoo, Y.Y.; Siow, L.F. Effect of Inulin, Fructo-Oligosaccharide, Trehalose or Maltodextrin (M10 and M30) on the Physicochemical and Sensory Properties of Dark Compound Chocolate. LWT 2021, 149, 111964. [Google Scholar] [CrossRef]

- Aidoo, R.P.; Appah, E.; Van Dewalle, D.; Afoakwa, E.O.; Dewettinck, K. Functionality of Inulin and Polydextrose as Sucrose Replacers in Sugar-free Dark Chocolate Manufacture—Effect of Fat Content and Bulk Mixture Concentration on Rheological, Mechanical and Melting Properties. Int. J. Food Sci. Technol. 2017, 52, 282–290. [Google Scholar] [CrossRef]

- Longoria-García, S.; Cruz-Hernández, M.; Flores-Verástegui, M.; Martínez-Vázquez, G.; Contreras-Esquivel, J.; Jiménez-Regalado, E.; Belmares-Cerda, R. Rheological Effects of High Substitution Levels of Fats by Inulin in Whole Cassava Dough: Chemical and Physical Characterization of Produced Biscuits. J. Food Sci. Technol. 2020, 57, 1517–1522. [Google Scholar] [CrossRef] [PubMed]

- Soleiman, A.H.F. Optimization of the Formulation of Prebiotic Milk Chocolate Based on Rheological Properties. Food Technol. Biotechnol. 2009, 47, 396–403. [Google Scholar]

- Shah, A.B.; Jones, G.P.; Vasiljevic, T. Sucrose-Free Chocolate Sweetened with Stevia Rebaudiana Extract and Containing Different Bulking Agents—Effects on Physicochemical and Sensory Properties. Int. J. Food Sci. Technol. 2010, 45, 1426–1435. [Google Scholar] [CrossRef]

- Zarić, D.B.; Rakin, M.B.; Bulatović, M.L.; Dimitrijević, I.D.; Ostojin, V.D.; Lončarević, I.S.; Stožinić, M.V. Rheological, Thermal, and Textural Characteristics of White, Milk, Dark, and Ruby Chocolate. Processes 2024, 12, 2810. [Google Scholar] [CrossRef]

- Konar, N. Influence of Conching Temperature and Some Bulk Sweeteners on Physical and Rheological Properties of Prebiotic Milk Chocolate Containing Inulin. Eur. Food Res. Technol. 2013, 236, 135–143. [Google Scholar] [CrossRef]

- Kiumarsi, M.; Majchrzak, D.; Jäger, H.; Song, J.; Lieleg, O.; Shahbazi, M. Comparative Study of Instrumental Properties and Sensory Profiling of Low-Calorie Chocolate Containing Hydrophobically Modified Inulin. Part II: Proton Mobility, Topological, Tribological and Dynamic Sensory Properties. Food Hydrocoll. 2021, 110, 106144. [Google Scholar] [CrossRef]

- Rodriguez Furlán, L.T.; Baracco, Y.; Lecot, J.; Zaritzky, N.; Campderrós, M.E. Influence of Hydrogenated Oil as Cocoa Butter Replacers in the Development of Sugar-Free Compound Chocolates: Use of Inulin as Stabilizing Agent. Food Chem. 2017, 217, 637–647. [Google Scholar] [CrossRef]

- Aidoo, R.P.; Afoakwa, E.O.; Dewettinck, K. Rheological Properties, Melting Behaviours and Physical Quality Characteristics of Sugar-Free Chocolates Processed Using Inulin/Polydextrose Bulking Mixtures Sweetened with Stevia and Thaumatin Extracts. LWT—Food Sci. Technol. 2015, 62, 592–597. [Google Scholar] [CrossRef]

- Sarfarazi, M.; Mohebbi, M. An Investigation into the Crystalline Structure, and the Rheological, Thermal, Textural and Sensory Properties of Sugar-Free Milk Chocolate: Effect of Inulin and Maltodextrin. J. Food Meas. Charact. 2020, 14, 1568–1581. [Google Scholar] [CrossRef]

- Selvasekaran, P.; Chidambaram, R. Pea Protein Isolate-Kappa-Carrageenan Complex Coacervate as a Lecithin Substitute and Their Effect on Physical Properties, Polymorphism, and Melting Behaviour of Dark Chocolates. Food Hydrocoll. 2024, 157, 110404. [Google Scholar] [CrossRef]

- Kiumarsi, M.; Majchrzak, D.; Yeganehzad, S.; Jäger, H.; Shahbazi, M. Comparative Study of Instrumental Properties and Sensory Profiling of Low-Calorie Chocolate Containing Hydrophobically Modified Inulin. Part 1: Rheological, Thermal, Structural and External Preference Mapping. Food Hydrocoll. 2020, 104, 105698. [Google Scholar] [CrossRef]

- Tatar, H.D.; Glicerina, V.T.; Foligni, R.; Zeppa, G. Microstructural and Rheological Influence of Different Strategies to Mitigate Oil Migration in Chocolate Pralines during Storage in Limiting Conditions. LWT 2024, 208, 116672. [Google Scholar] [CrossRef]

- Zhao, H.; Li, B.; James, B.J. Structure-Fracture Relationships in Chocolate Systems. LWT 2018, 96, 281–287. [Google Scholar] [CrossRef]

- Konar, N.; Palabiyik, I.; Toker, Ö.S.; Saputro, A.D.; Pirouzian, H.R. Improving Functionality of Chocolate. In Trends in Sustainable Chocolate Production; Springer International Publishing: Cham, Switzerland, 2022; pp. 75–112. [Google Scholar]

- Pombal, M.; Marcet, I.; Rendueles, M.; Diaz, M. Emulsifiers: Their Influence on the Rheological and Texture Properties in an Industrial Chocolate. Molecules 2024, 29, 5185. [Google Scholar] [CrossRef]

- Podchong, P.; Rousseau, D. Quantification of Emulsifier Adsorption onto Sugar Crystals Dispersed in Vegetable Oil and Associated Effects on Flow Behaviour. Food Res. Int. 2025, 199, 115377. [Google Scholar] [CrossRef]

- Toker, O.S.; Ozonuk, S.; Gunes, R.; Icyer, N.C.; Rasouli, H.P.; Konar, N.; Palabiyik, I.; Altop, C. Importance of Emulsifiers in Chocolate Industry: Effect on Structure, Machinability, and Quality of Intermediate and Final Products. J. Am. Oil Chem. Soc. 2024, 101, 721–733. [Google Scholar] [CrossRef]

- Sözeri Atik, D.; Bölük, E.; Toker, O.S.; Palabiyik, I.; Konar, N. Investigating the Effects of Lecithin-PGPR Mixture on Physical Properties of Milk Chocolate. LWT 2020, 129, 109548. [Google Scholar] [CrossRef]

- Gallery, C.; Bourge, S.; Agoda-Tandjawa, G. Flow Behaviors of Multiple Molten Chocolate Matrices: Appropriate Curve Fitting Models and Impact of Different Types of Surfactants. J. Food Eng. 2024, 363, 111780. [Google Scholar] [CrossRef]

- Hussain, N.; Wong, P.E.; Rajentran, K. Effects of Polyglycerol Polyriconoleate (PGPR) as Partial Substitute of Cocoa Butter and Lecithin on Rheology and Shelf Life of Chocolate Glaze. J. Biochem. Microbiol. Biotechnol. 2024, 12, 35–38. [Google Scholar] [CrossRef]

- Simoes, S.; Lelaj, E.; Rousseau, D. The Presence of Crystalline Sugar Limits the Influence of Emulsifiers on Cocoa Butter Crystallization. Food Chem. 2021, 346, 128848. [Google Scholar] [CrossRef]

- Ashkezary, M.R.; Yeganehzad, S.; Vatankhah, H.; Todaro, A.; Maghsoudlou, Y. Effects of different emulsifiers and refining time on rheological and textural characteristics of compound chocolate. Ital. J. Food Sci. 2018, 30, 26–36. [Google Scholar]

- Ibadullah, W.Z.W.; Han, T.Z.; Xuan, C.Y.; Ahmad, N.F.N.; Ishak, I.; Khaironi, J.; Mustapha, N.A.; Ismail-Fitry, M.R.; Sukor, R.; Abedin, N.H.Z.; et al. Effect of Different Types of Emulsifiers on the Physical Characteristics and Fat Bloom Stability of Dark Chocolate with Cocoa Butter Alternatives. J. Biochem. Microbiol. Biotechnol. 2024, 12, 27–30. [Google Scholar] [CrossRef]

- Toczek, K.; Glibowski, P.; Kordowska-Wiater, M.; Iłowiecka, K. Rheological and Textural Properties of Emulsion Spreads Based on Milk Fat and Inulin with the Addition of Probiotic Bacteria. Int. Dairy J. 2022, 124, 105217. [Google Scholar] [CrossRef]

- Icyer, N.C.; Ozmen, D.; Sener, D.; Kokyar, N.; Toker, O.S. Structural and Sensory Impact of Various Emulsifiers in Cocoa Hazelnut Spread Formulations. J. Food Sci. 2024, 89, 6590–6600. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Akhter, R.; Maktedar, S.S. Advancements in Sustainable Food Packaging: From Eco-Friendly Materials to Innovative Technologies. Sustain. Food Technol. 2024, 2, 1297–1364. [Google Scholar] [CrossRef]

- Ertural, G.I.; Gunes, R.; Toker, O.S.; Palabiyik, I.; Konar, N.; Sagdic, O. Importance of Rheological Properties in Enrobing Efficiency of Dark Chocolate: Application in Wafer Products. Int. J. Food Sci. Technol. 2023, 58, 5938–5946. [Google Scholar] [CrossRef]

- Kissiedu, K.O.; Agbenorhevi, J.K.; Datsomor, D.N. Optimization of Sensory Acceptability of Milk Chocolate Containing Okra Pectin as Emulsifier. Int. J. Food Prop. 2020, 23, 1310–1323. [Google Scholar] [CrossRef]

- Li, Y.; James, B. Oral Processing Preference Affects Flavor Perception in Dark Chocolate with Added Ingredients. J. Food Sci. 2021, 86, 177–183. [Google Scholar] [CrossRef]

- Abdul Halim, H.S.; Selamat, J.; Mirhosseini, S.H.; Hussain, N. Sensory Preference and Bloom Stability of Chocolate Containing Cocoa Butter Substitute from Coconut Oil. J. Saudi Soc. Agric. Sci. 2019, 18, 443–448. [Google Scholar] [CrossRef]

| Ingredient | Amount (g/100 g Chocolate) |

|---|---|

| Cocoa mass | 17.50 |

| Sugar | 38.35 |

| Skimmed milk powder | 23.55 |

| CB * | 20.00 |

| Lecithin | 0.30 |

| PGPR ** | 0.22 |

| Vanilla | 0.08 |

| Substitution Level | WPI:IN Ratio | CB * | WPI ** | IN *** |

|---|---|---|---|---|

| 0% | - | 20 | 0 | 0.0 |

| 20% | 70:30 | 16 | 2.8 | 1.2 |

| 50:50 | 16 | 2.0 | 2.0 | |

| 30:70 | 16 | 1.2 | 2.8 | |

| 30% | 70:30 | 14 | 4.2 | 1.8 |

| 50:50 | 14 | 3.0 | 3.0 | |

| 30:70 | 14 | 1.8 | 4.2 | |

| 40% | 70:30 | 12 | 5.6 | 2.4 |

| 50:50 | 12 | 4.0 | 4.0 | |

| 30:70 | 12 | 2.4 | 5.6 |

| Ingredient | Energy Value (kcal/g) |

|---|---|

| Cocoa mass | 6.40 |

| CB * | 8.84 |

| Sucrose | 3.87 |

| Skimmed milk powder | 3.57 |

| IN ** | 2.50 |

| WPI *** | 3.70 |

| Lecithin | 6.00 |

| Vanilla | 2.88 |

| AMP * Concentration (%) | PGPR ** Concentration (%) |

|---|---|

| 0.5 | 0 |

| 0.6 | 0 |

| 0.7 | 0 |

| 0.6 | 0 |

| 0.6 | 0.05 |

| 0.6 | 0.15 |

| Fat Substitution | Ratio | Calories (kcal) Per 100 g Chocolate | Caloric Value Reduction Percentage |

|---|---|---|---|

| 0% | Control | 523.32 | - |

| 20% | 70:30 | 499.4 | 4.57% |

| 20% | 50:50 | 500.36 | 4.39% |

| 20% | 30:70 | 501.32 | 4.20% |

| 30% | 70:30 | 487.44 | 6.86% |

| 30% | 50:50 | 488.88 | 6.58% |

| 30% | 30:70 | 490.32 | 6.31% |

| 40% | 70:30 | 475.48 | 9.14% |

| 40% | 50:50 | 477.4 | 8.77% |

| 40% | 30:70 | 479.32 | 8.41% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drosou, C.; Argyriou, I.; Laina, K.T.; Mari, A.; Krokida, M. Novel Formulation of Low-Fat Milk Chocolate: Impact on Physicochemical and Sensory Properties. Appl. Sci. 2025, 15, 10338. https://doi.org/10.3390/app151910338

Drosou C, Argyriou I, Laina KT, Mari A, Krokida M. Novel Formulation of Low-Fat Milk Chocolate: Impact on Physicochemical and Sensory Properties. Applied Sciences. 2025; 15(19):10338. https://doi.org/10.3390/app151910338

Chicago/Turabian StyleDrosou, Christina, Ioanna Argyriou, Konstantina Theodora Laina, Alexandra Mari, and Magdalini Krokida. 2025. "Novel Formulation of Low-Fat Milk Chocolate: Impact on Physicochemical and Sensory Properties" Applied Sciences 15, no. 19: 10338. https://doi.org/10.3390/app151910338

APA StyleDrosou, C., Argyriou, I., Laina, K. T., Mari, A., & Krokida, M. (2025). Novel Formulation of Low-Fat Milk Chocolate: Impact on Physicochemical and Sensory Properties. Applied Sciences, 15(19), 10338. https://doi.org/10.3390/app151910338