Research on Preparation Process of Ultrafine Spherical WC-10Co-4Cr Spraying Powder Based on Spray Granulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Raw Materials and Powder

2.2. Viscosity and Stability of Pre-Sprayed Slurry

2.3. Performance and Characterization of Powder

3. Results

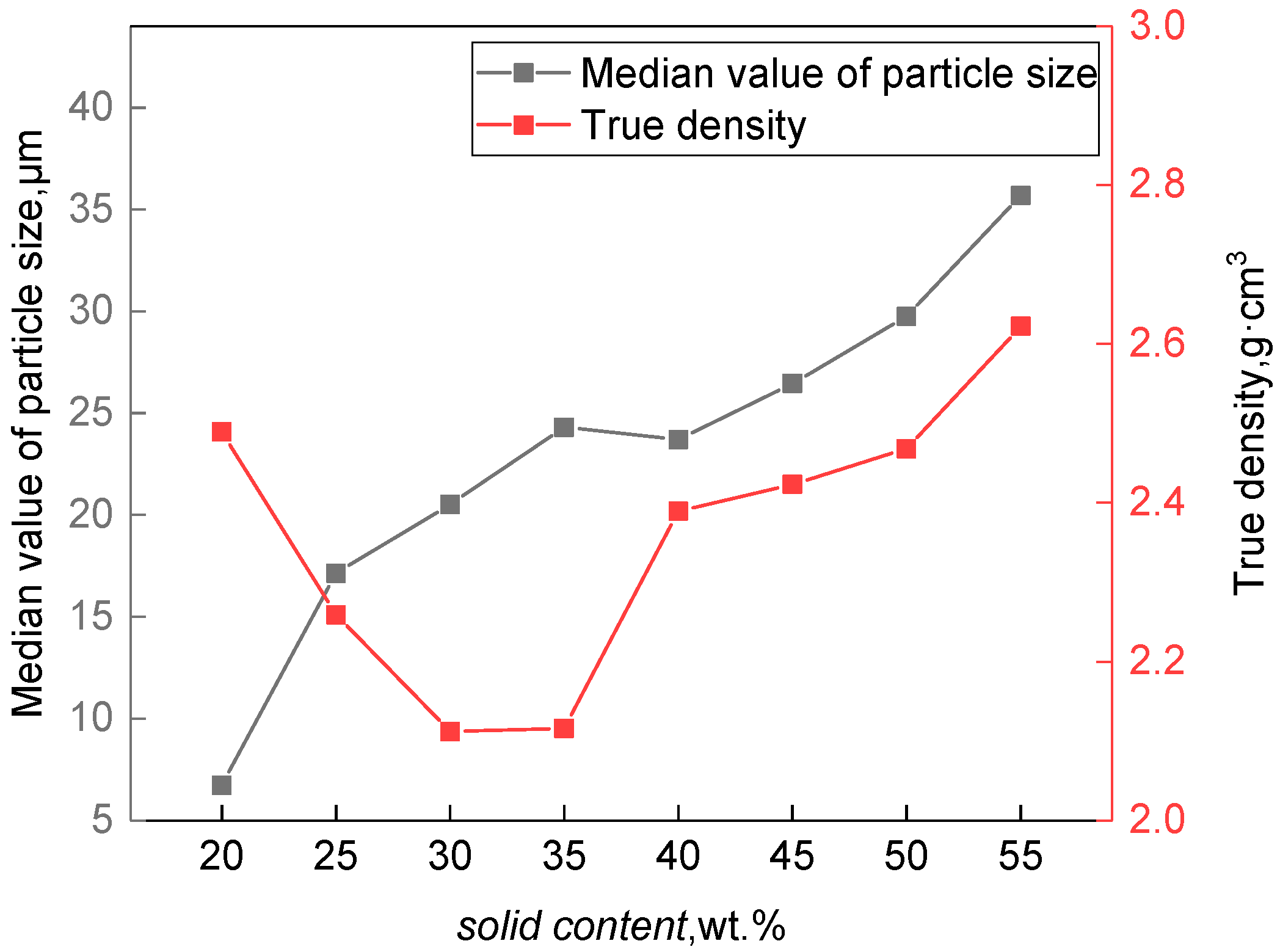

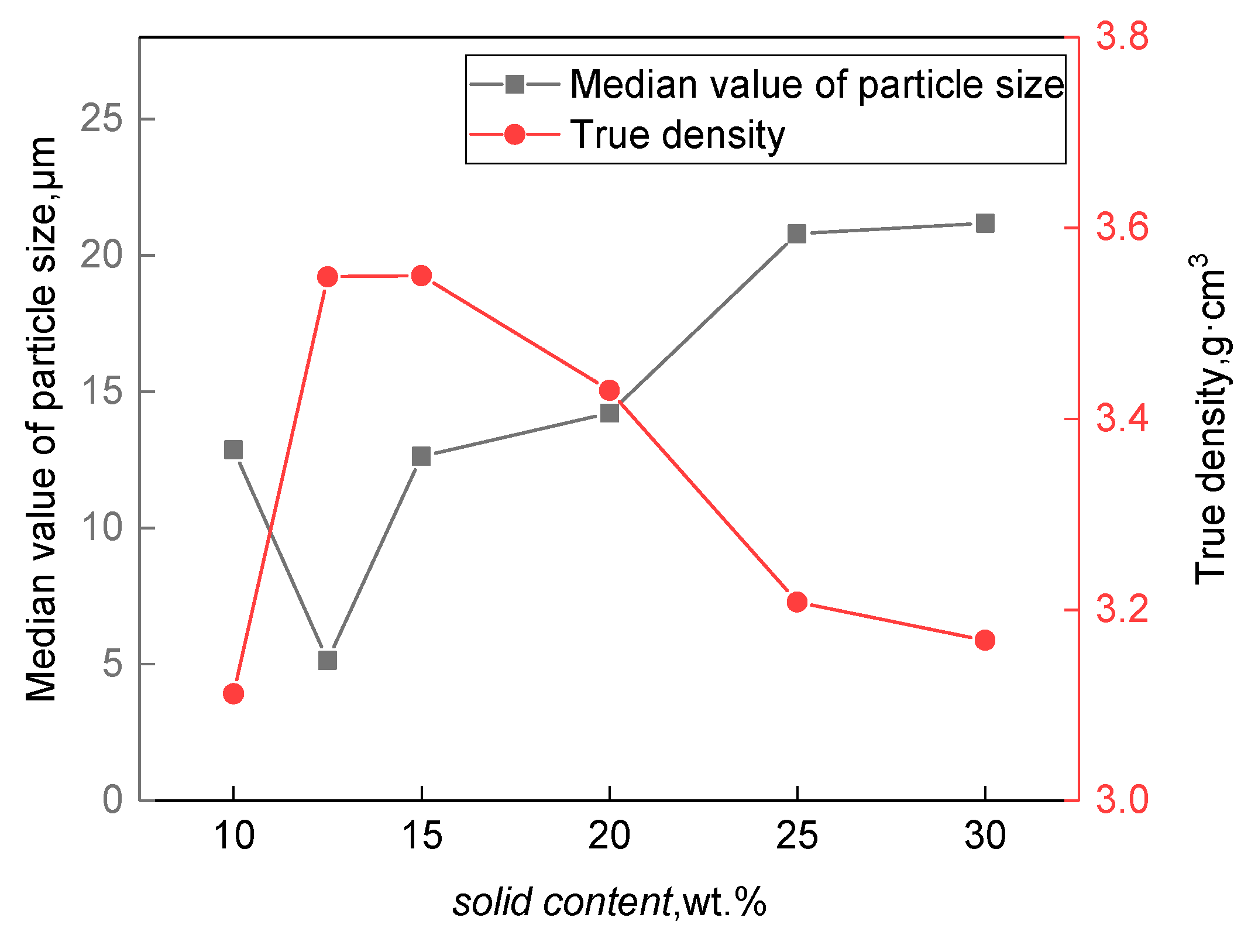

3.1. Effect of Solid Content of Pre-Sprayed Slurry on Powder

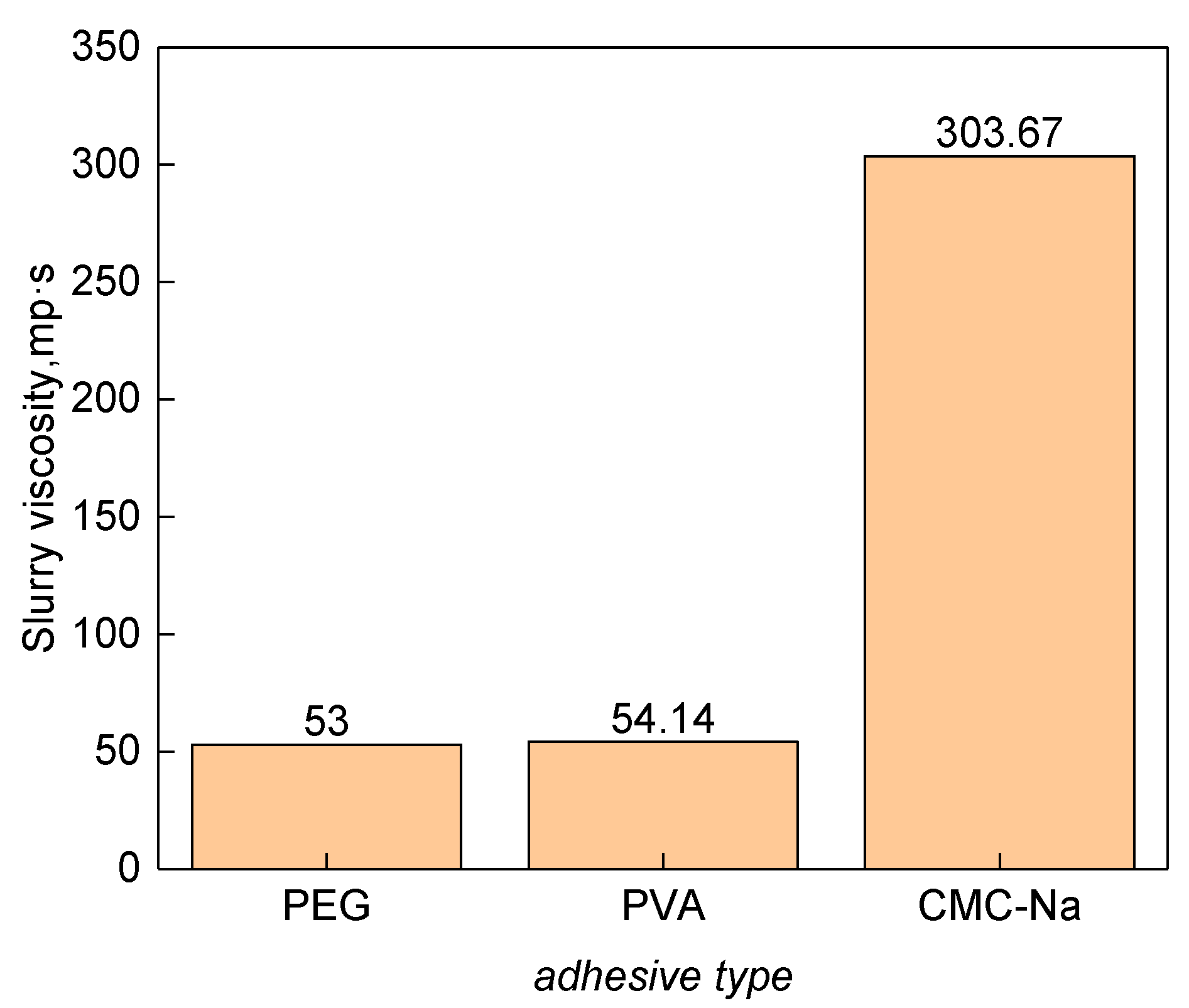

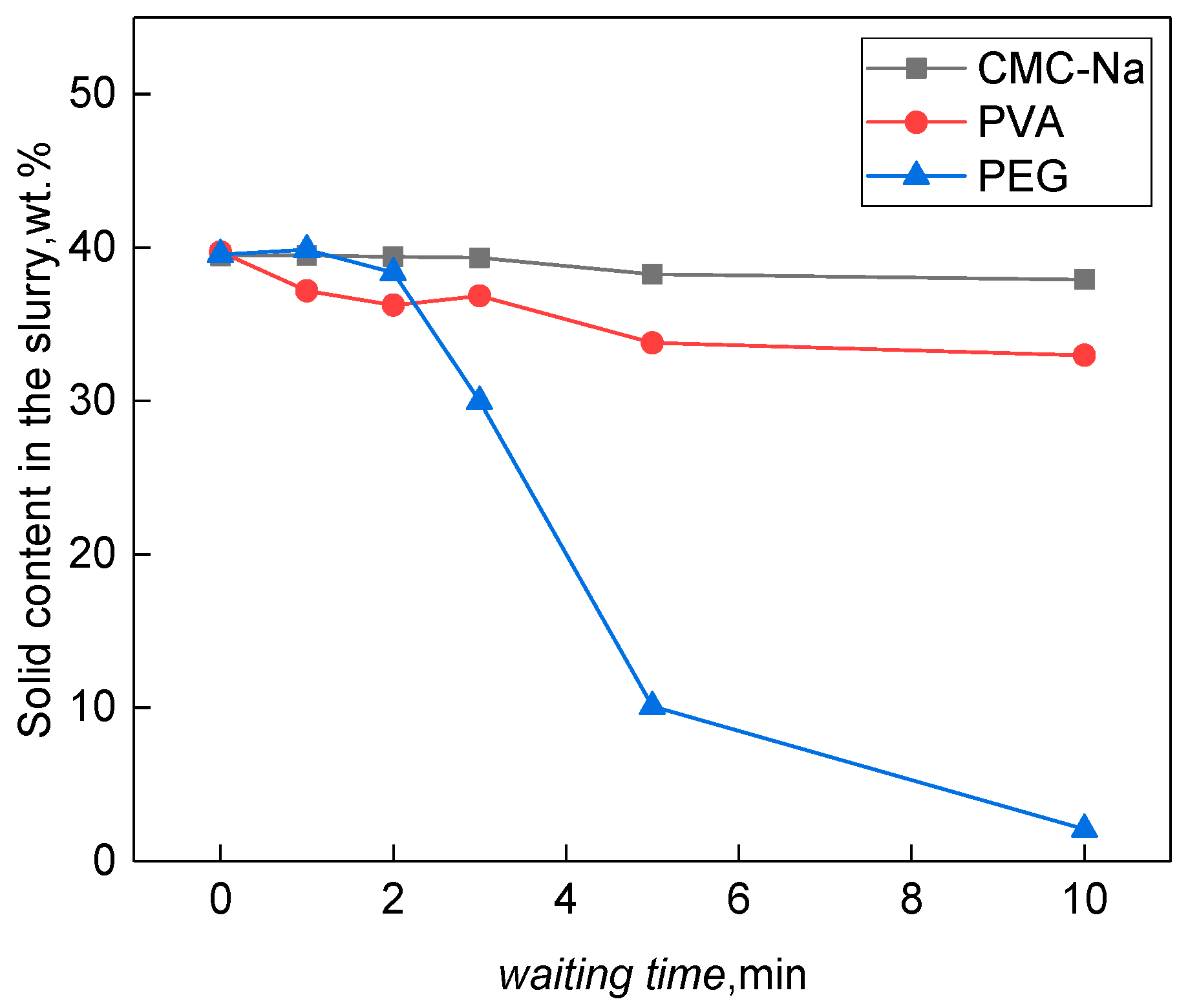

3.2. Properties of Pre-Sprayed Slurry with Different Binders

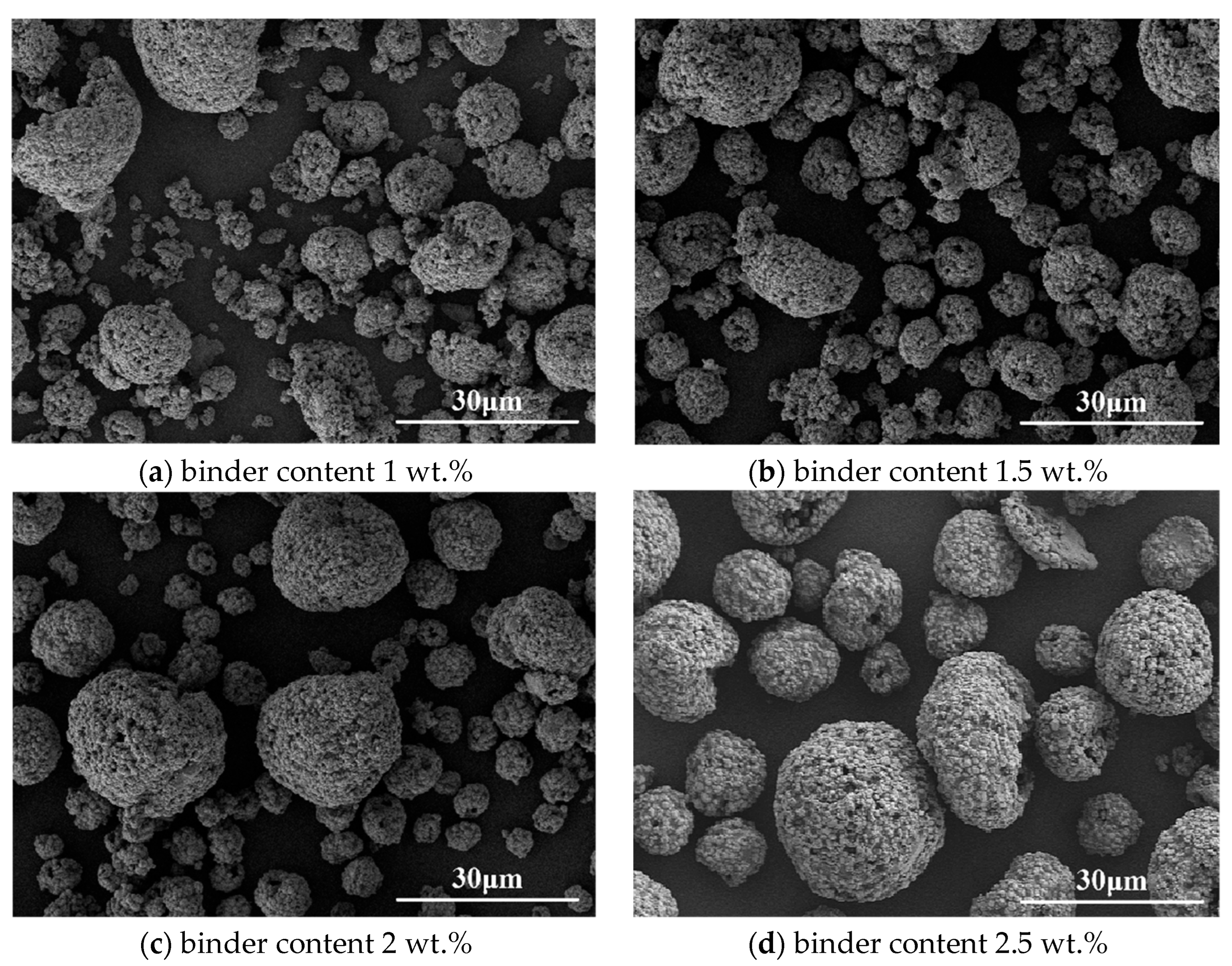

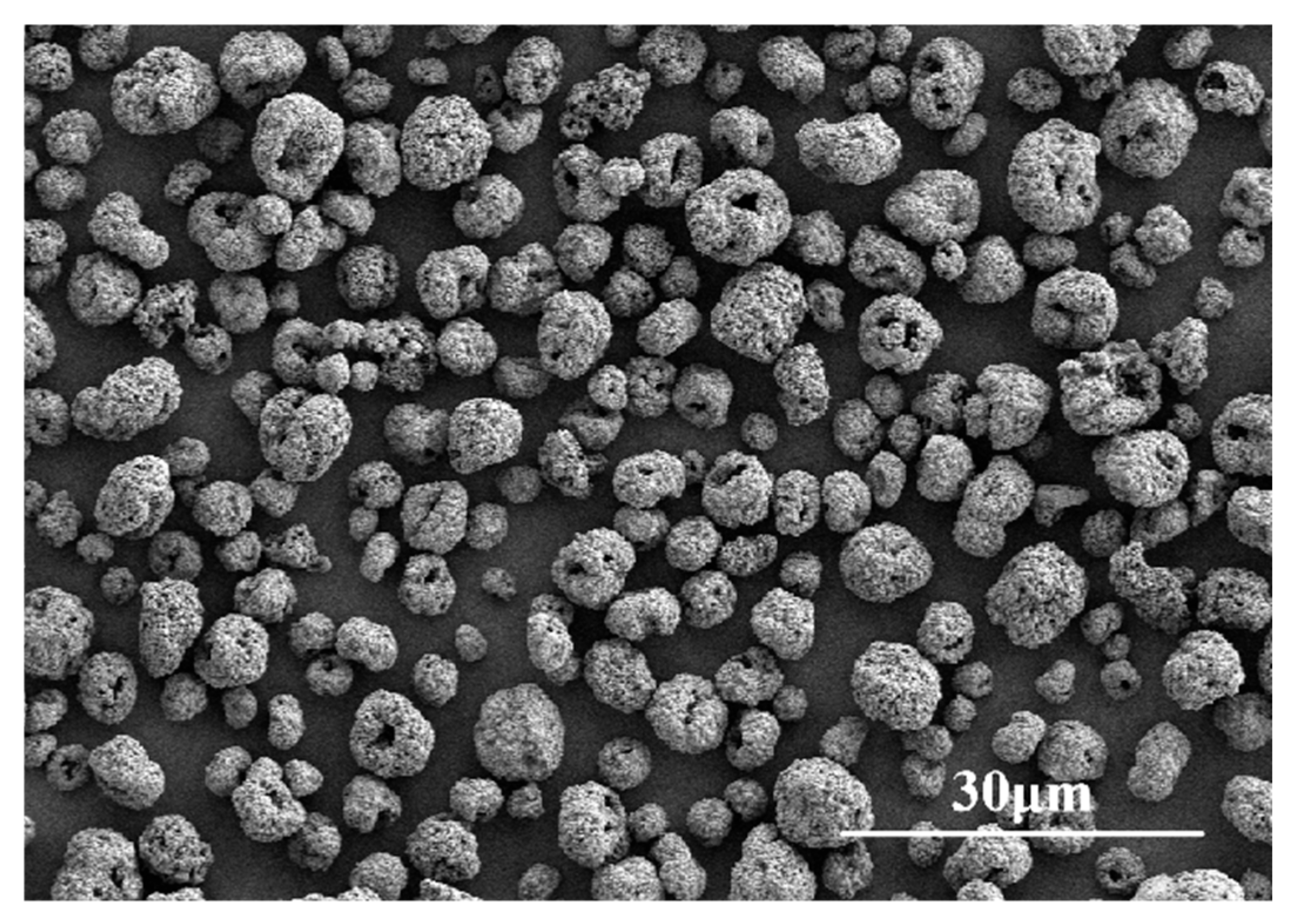

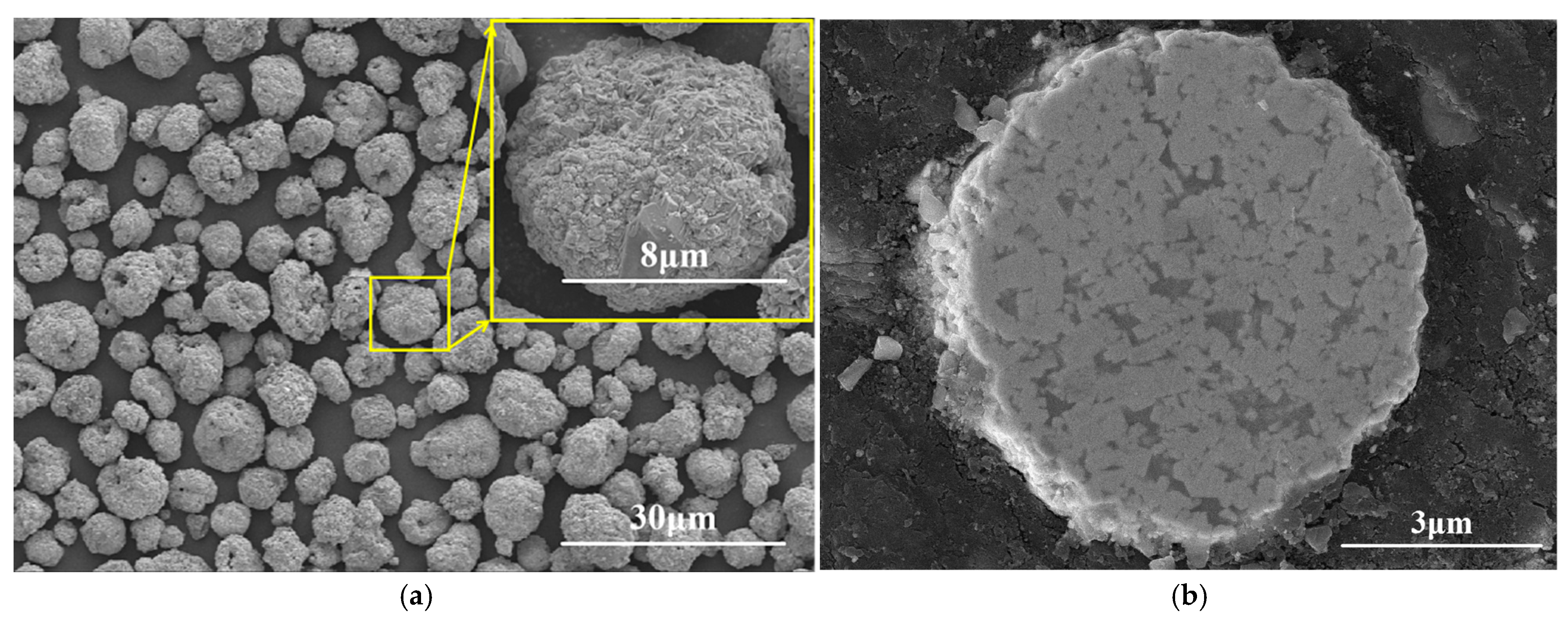

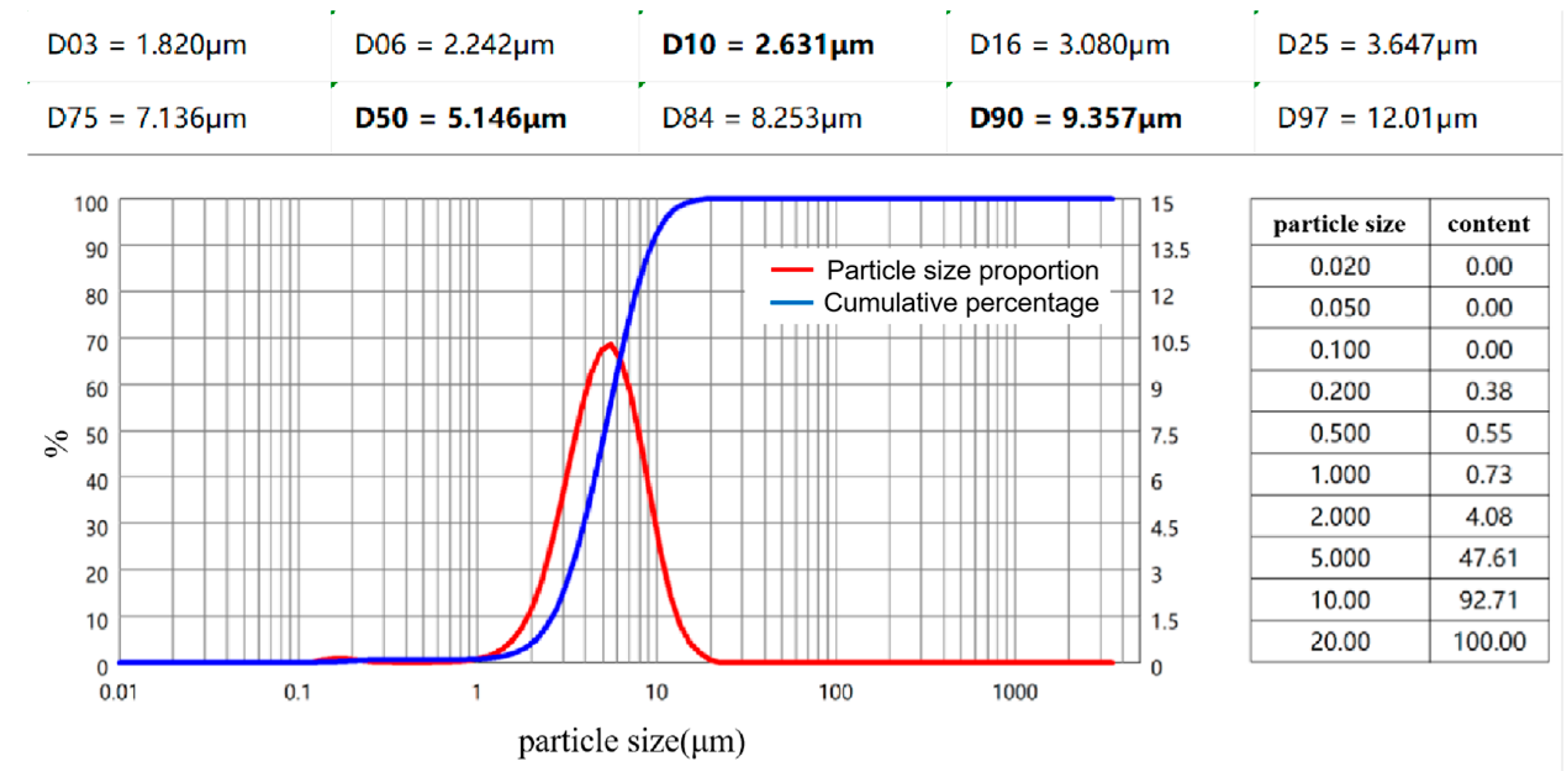

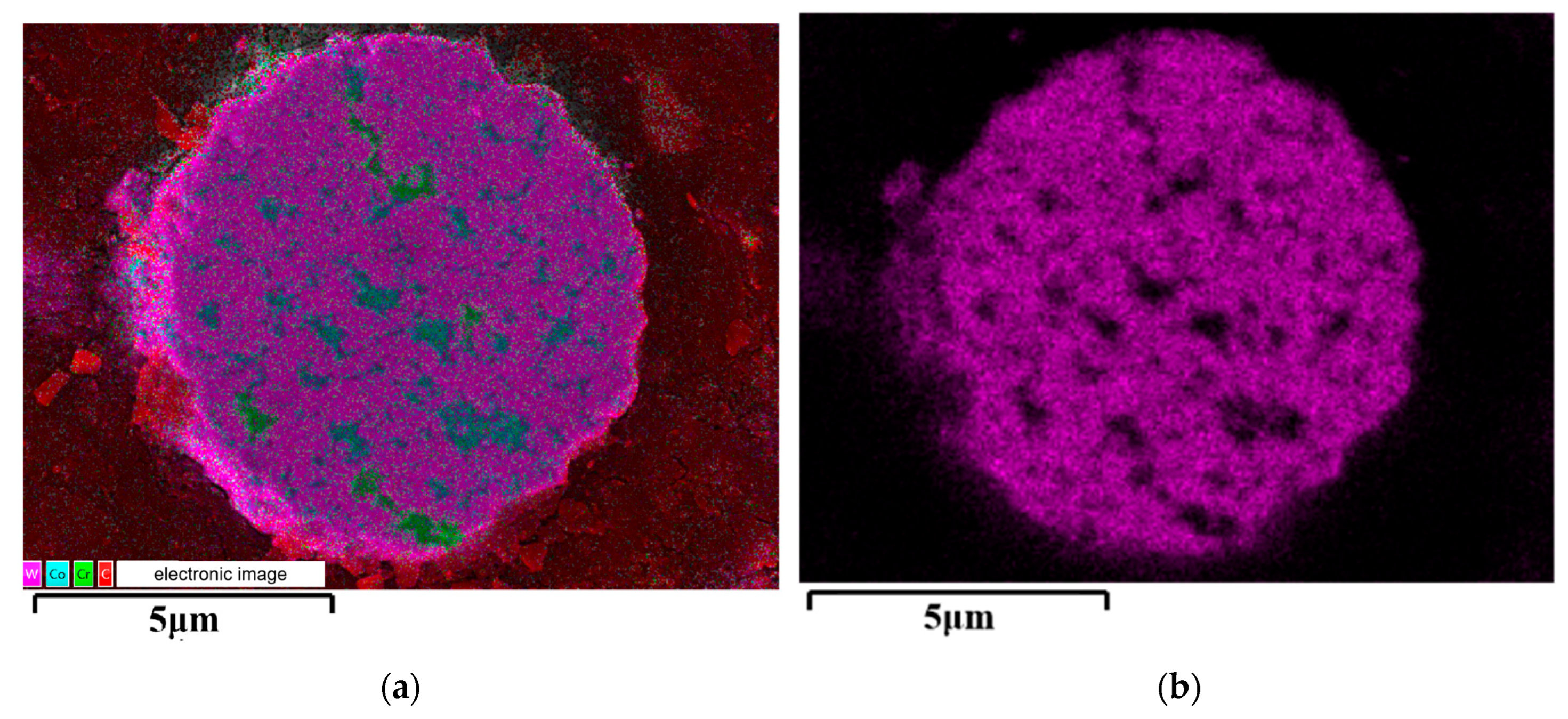

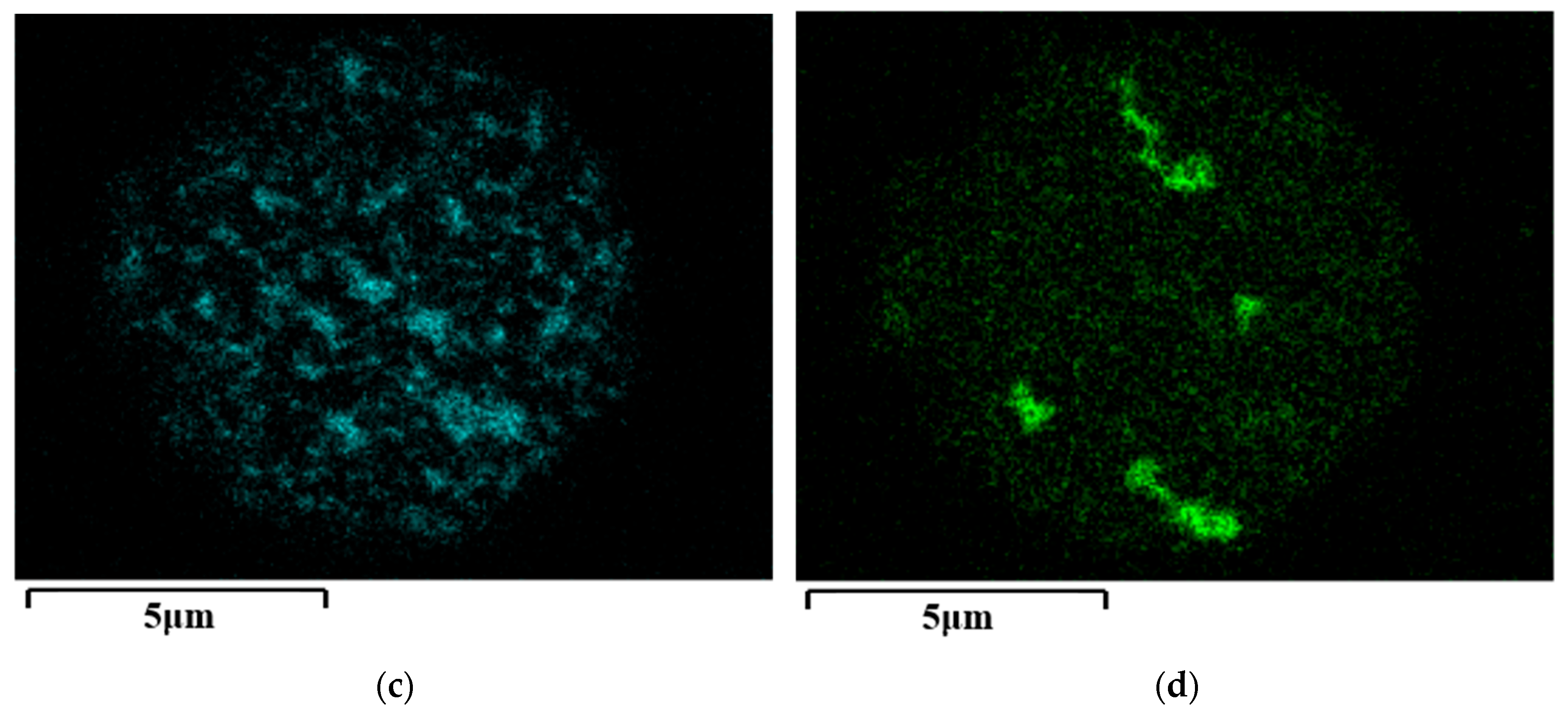

3.3. Ultrafine Powder

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.R.; Chang, Q.M.; Li, C.Y. Performance of Plasma Sprayed WC-12Co Coating and Its Application in Aeroengine. Hot Work. Technol. 2021, 50, 102–104. [Google Scholar]

- Xu, F.; Cao, C.J.; Zhao, Y.X. Research on the Tribological Properties of WC-Co Coatings for Aircraft Engine Variable Stator Vane. Lubr. Eng. 2024, 49, 106–113. [Google Scholar]

- Wang, C.G. Research on High-Performance WC-Co-Ni-Based Cemented Carbides for Corrosive Service Condition. Master’s Thesis, Central South University, Changsha, China, 2023. [Google Scholar]

- Fan, S.Y.; Kuang, T.C.; Lin, S.S. Research Progress on Cutting Tools Made from WC-Co Cemented Carbide Substrates and Coated with CVD Diamond. Mater. Rep. 2023, 37, 28–37. [Google Scholar]

- Wang, B.X. Research on Preparation Process and Application of Ultrafine WC-Co Cemented Carbide Solid End Mill. Ph.D. Thesis, Nanjing University, Nanjing, China, 2022. [Google Scholar]

- Gong, B.R.; Wang, X.S.; Wang, T.W. Summary of Lightweight Application in Artillery Design. J. Gun Launch Control 2023, 44, 94–98. [Google Scholar]

- Wang, J.M.; Zhong, X.F.; Wang, W.P. The Technique of Weapon‘s Light Weight Design. J. Ordnance Equip. Eng. 2017, 38, 131–134. [Google Scholar]

- Chen, J.S.; Sun, B.S.; An, K. Titanium Alloys for Ordnance Equipment Applications. J. Ordnance Equip. Eng. 2020, 41, 14–20. [Google Scholar]

- Ren, Q.H.; Zhang, L.J.; Xue, X.Y. The Application of Titanium Alloy in Lightweight Ground Weapon Equipment. World Nonferr. Met. 2017, 20, 1–4. [Google Scholar]

- Dai, B.; Wang, J.A.; Wang, H.F. The Lightweight Research on the Airborne Rocket Launcher Weapon System. J. Gun Launch Control 2021, 42, 106–112. [Google Scholar]

- Song, J.B.; Liu, M. Characterization of WC-CoCr coating by HVAF. Mater. Res. Appl. 2011, 5, 271–274. [Google Scholar]

- Wang, Q.; Zhang, S.Y.; Cheng, Y.L. Wear and corrosion performance of WC-10Co4Cr coatings deposited by different HVOF and HVAF spraying processes. Surf. Coat. Technol. 2013, 218, 127–136. [Google Scholar] [CrossRef]

- Myalska, H.; Moskal, G.; Szymański, K. Microstructure and properties of WC-Co coatings, modified by sub-microcrystalline carbides, obtained by different methods of high velocity spray processes. Surf. Coat. Technol. 2014, 260, 303–309. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Yang, Y.; Lu, T. Effect of High Velocity Oxygen Fuel Sprayed WC-10Co4Cr Coating on Resistance to Wear and Corrostion of TC11 Titanium Alloy. Corros. Prot. 2024, 45, 68–74. [Google Scholar]

- Torkashvand, K.; Gupta, M.; Björklund, S. Influence of nozzle configuration and particle size on characteristics and sliding wear behaviour of HVAF-sprayed WC-CoCr coatings. Surf. Coat. Technol. 2021, 423, 127585. [Google Scholar] [CrossRef]

- Torkashvand, K.; Gupta, M.; Björklund, S. Tribological Performance of Thin HVAF-Sprayed WC-CoCr Coatings Fabricated Employing Fine Powder Feedstock. J. Therm. Spray Technol. 2023, 32, 1033–1046. [Google Scholar] [CrossRef]

- Torkashvand, K.; Selpol, V.K.; Gupta, M. Influence of Test Conditions on Sliding Wear Performance of High Velocity Air Fuel-Sprayed WC-CoCr Coatings. Materials 2021, 14, 3074. [Google Scholar] [CrossRef]

- Wang, H.B.; Qiu, Q.F.; Mark, G. Wear resistance enhancement of HVOF-sprayed WC-Co coating by complete densification of starting powder. Mater. Des. 2020, 191, 108586. [Google Scholar] [CrossRef]

- Wang, H.B.; Song, X.Y.; Liu, X.M. Spray granulation of WC-Co composite powders and influencing factors of apparent density. Chin. J. Nonferrous Met. 2012, 22, 3241–3248. [Google Scholar]

- Wang, H.B.; Song, X.Y.; Liu, X.M. Effect of heat-treatment of spray-dried powder on properties of ultrafine-structured WC-Co coating. Surf. Coat. Technol. 2020, 207, 117–122. [Google Scholar] [CrossRef]

- Xu, B.S.; Guo, D.H.; Zhou, F.F. A Nanostructured Lutetium Disilicate Feedstock and its Preparation Method and Application. China Patent 202310145214.7, 15 August 2023. [Google Scholar]

- Xu, B.S.; He, J.H. A Kind of Anti-Reflection and Wear-Resistant Metal Ceramic Coating Feedstock, Its Preparation Method and Anti-Reflection and Wear-Resistant Metal Ceramic Coating. China Patent 202411288522.6, 13 December 2024. [Google Scholar]

- Wang, X.Y.; Yang, Y.; Li, K.R. Influence of graphite additive on microstructure and mechanical characteristics of plasma sprayed TiB2-TiC composite coating. J. Mat. Sci. 2023, 58, 10005–10022. [Google Scholar] [CrossRef]

- Li, M.L.; Yu, Q.; Liu, J.H. Study on particle gradation to improve the tap density of spherical silver powder. Ordnance Mater. Sci. Eng. 2020, 43, 33–35. [Google Scholar]

- Yang, C.P.; Zhang, M.X.; Lin, L.Y. Effect of Graphite Particle Size on Tap Bulk Density. Non-Met. Met. Mines 2015, 38, 21–23. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Ding, Q.; Xu, B. Research on Preparation Process of Ultrafine Spherical WC-10Co-4Cr Spraying Powder Based on Spray Granulation. Appl. Sci. 2025, 15, 10213. https://doi.org/10.3390/app151810213

He J, Ding Q, Xu B. Research on Preparation Process of Ultrafine Spherical WC-10Co-4Cr Spraying Powder Based on Spray Granulation. Applied Sciences. 2025; 15(18):10213. https://doi.org/10.3390/app151810213

Chicago/Turabian StyleHe, Jianhua, Qihua Ding, and Baosheng Xu. 2025. "Research on Preparation Process of Ultrafine Spherical WC-10Co-4Cr Spraying Powder Based on Spray Granulation" Applied Sciences 15, no. 18: 10213. https://doi.org/10.3390/app151810213

APA StyleHe, J., Ding, Q., & Xu, B. (2025). Research on Preparation Process of Ultrafine Spherical WC-10Co-4Cr Spraying Powder Based on Spray Granulation. Applied Sciences, 15(18), 10213. https://doi.org/10.3390/app151810213