Evaluation of Surface Roughness with Reduced Data of BRDF Pattern

Abstract

1. Introduction

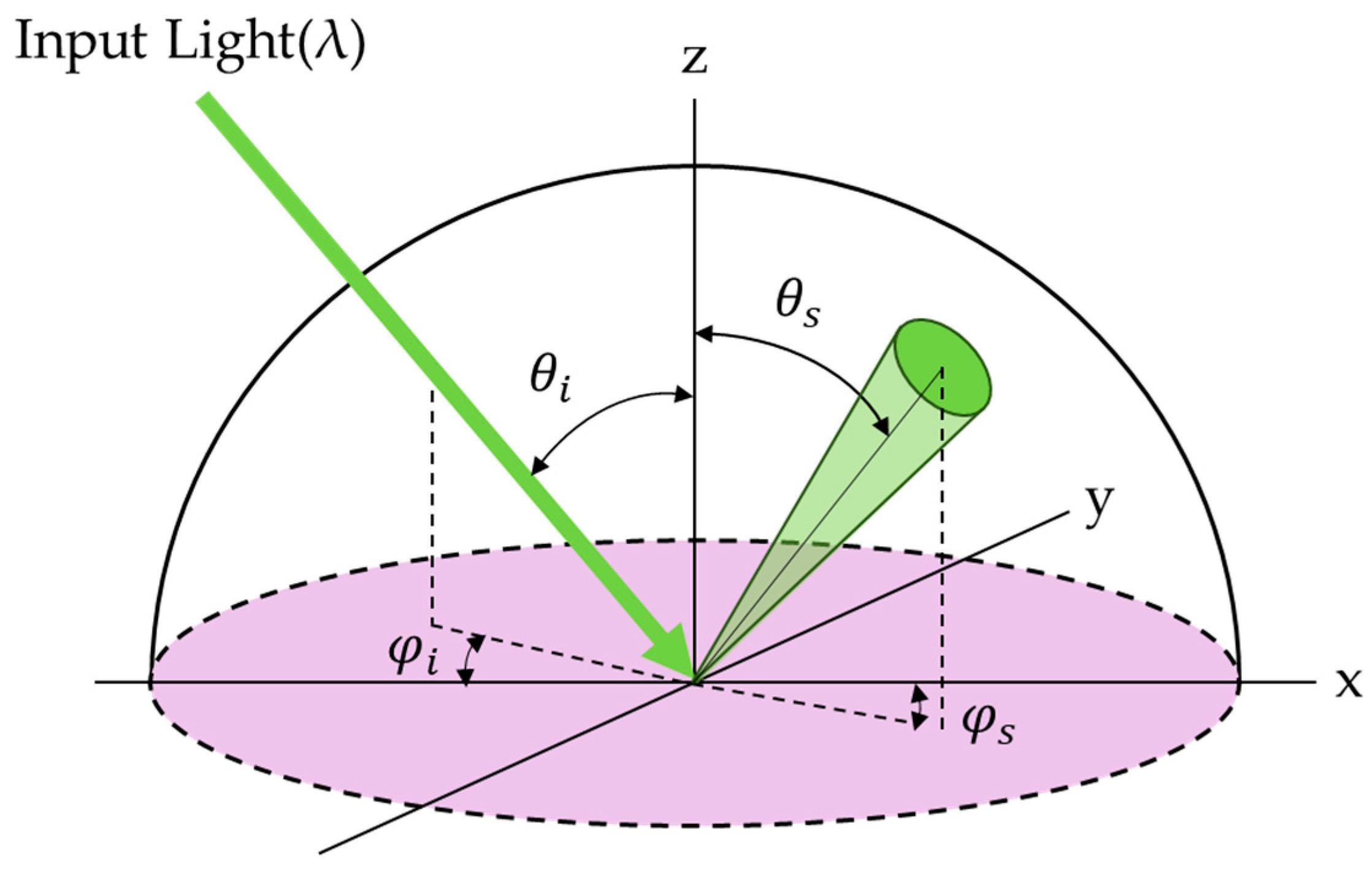

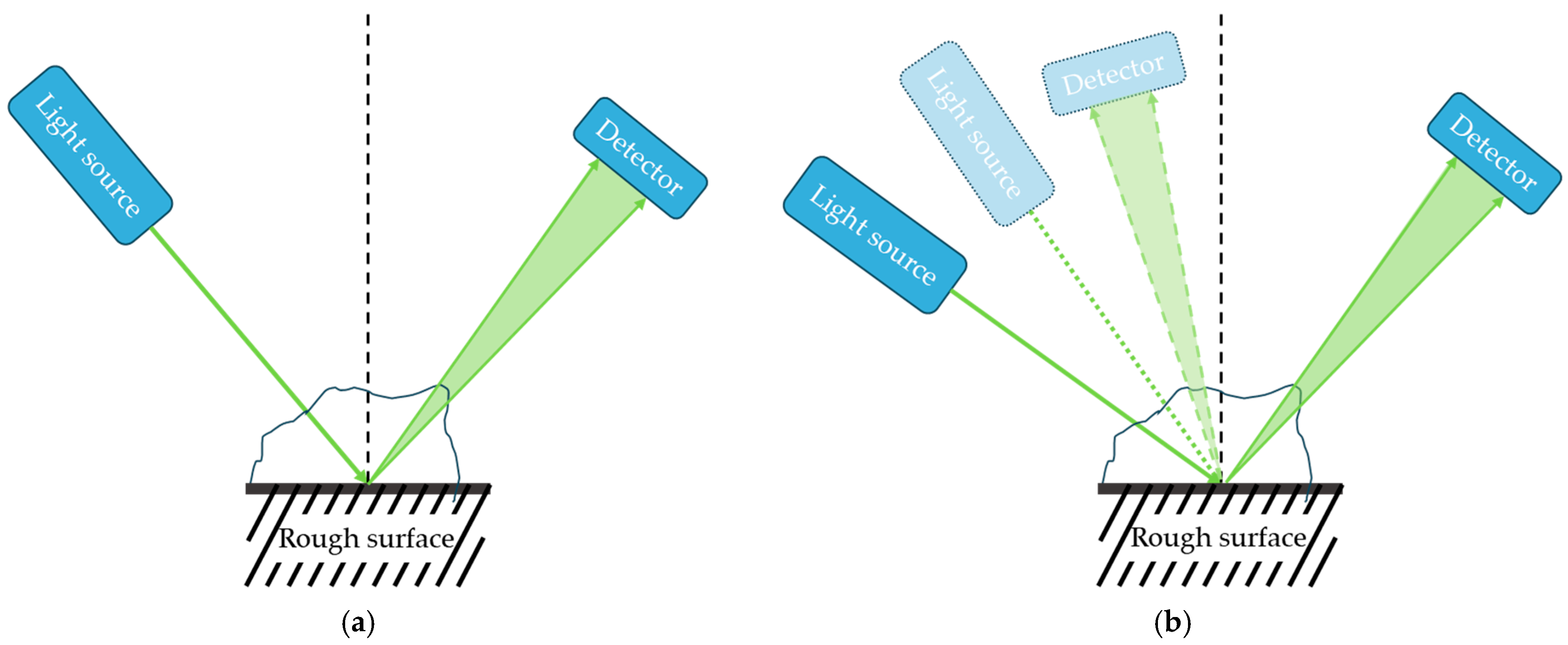

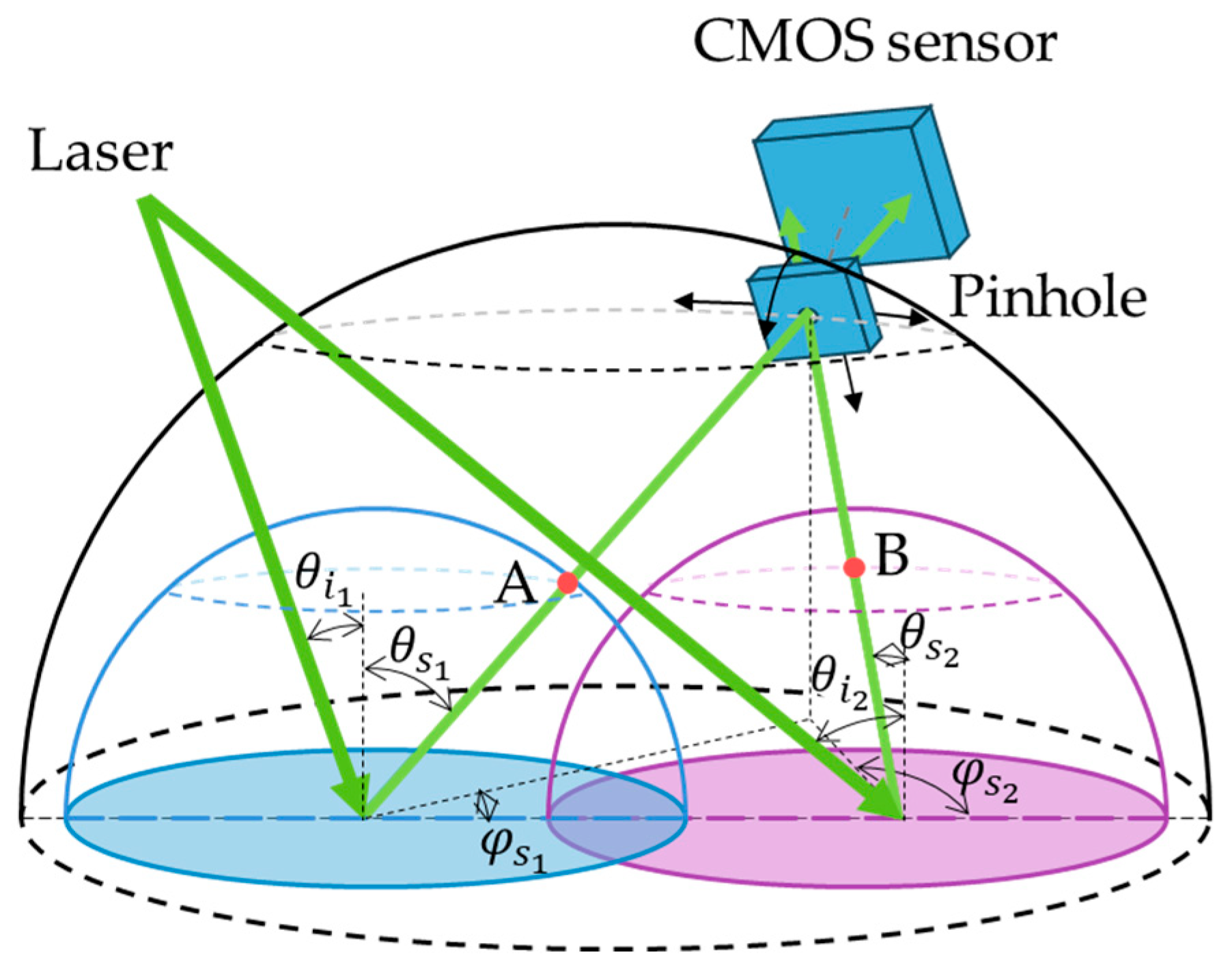

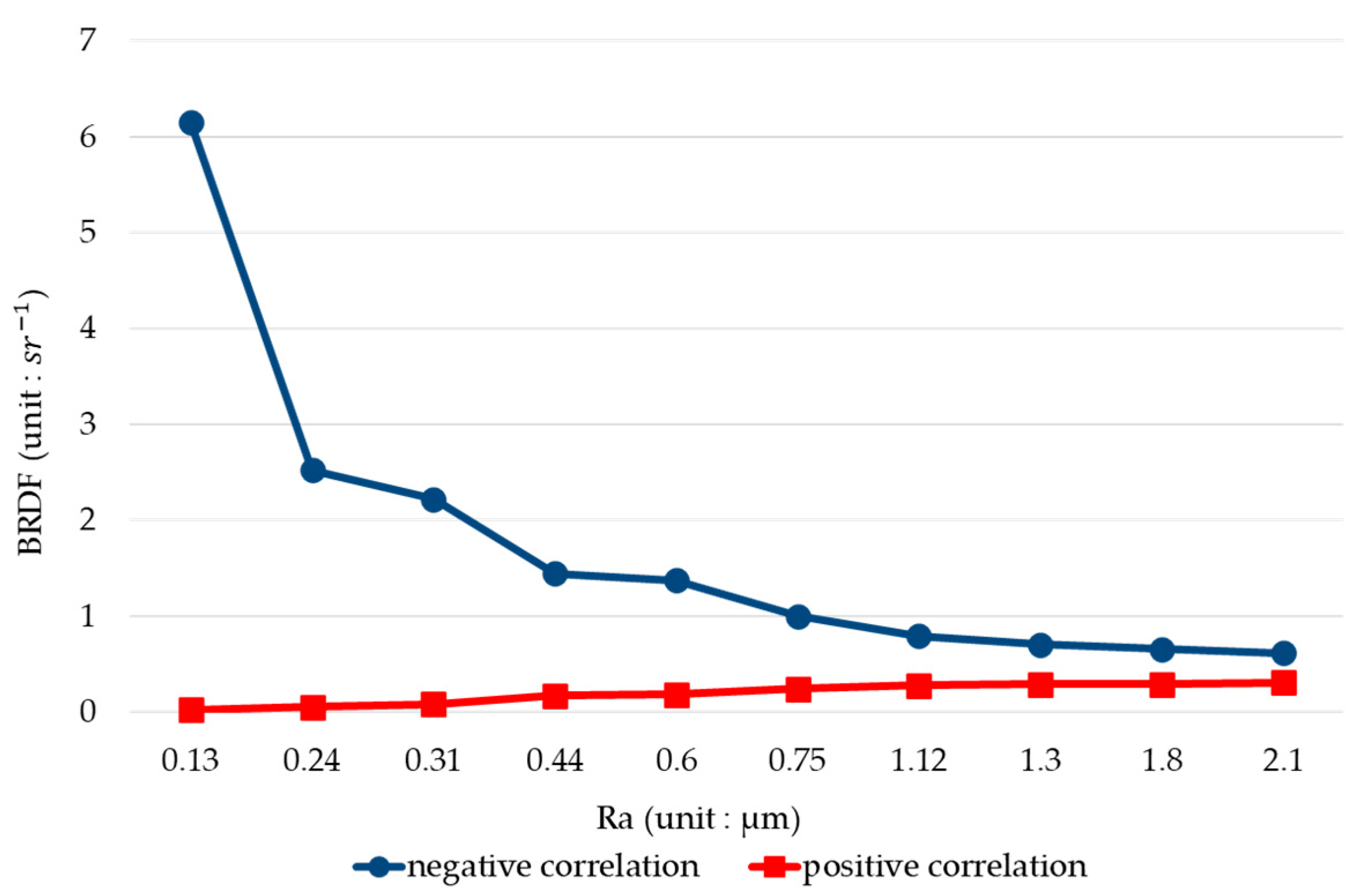

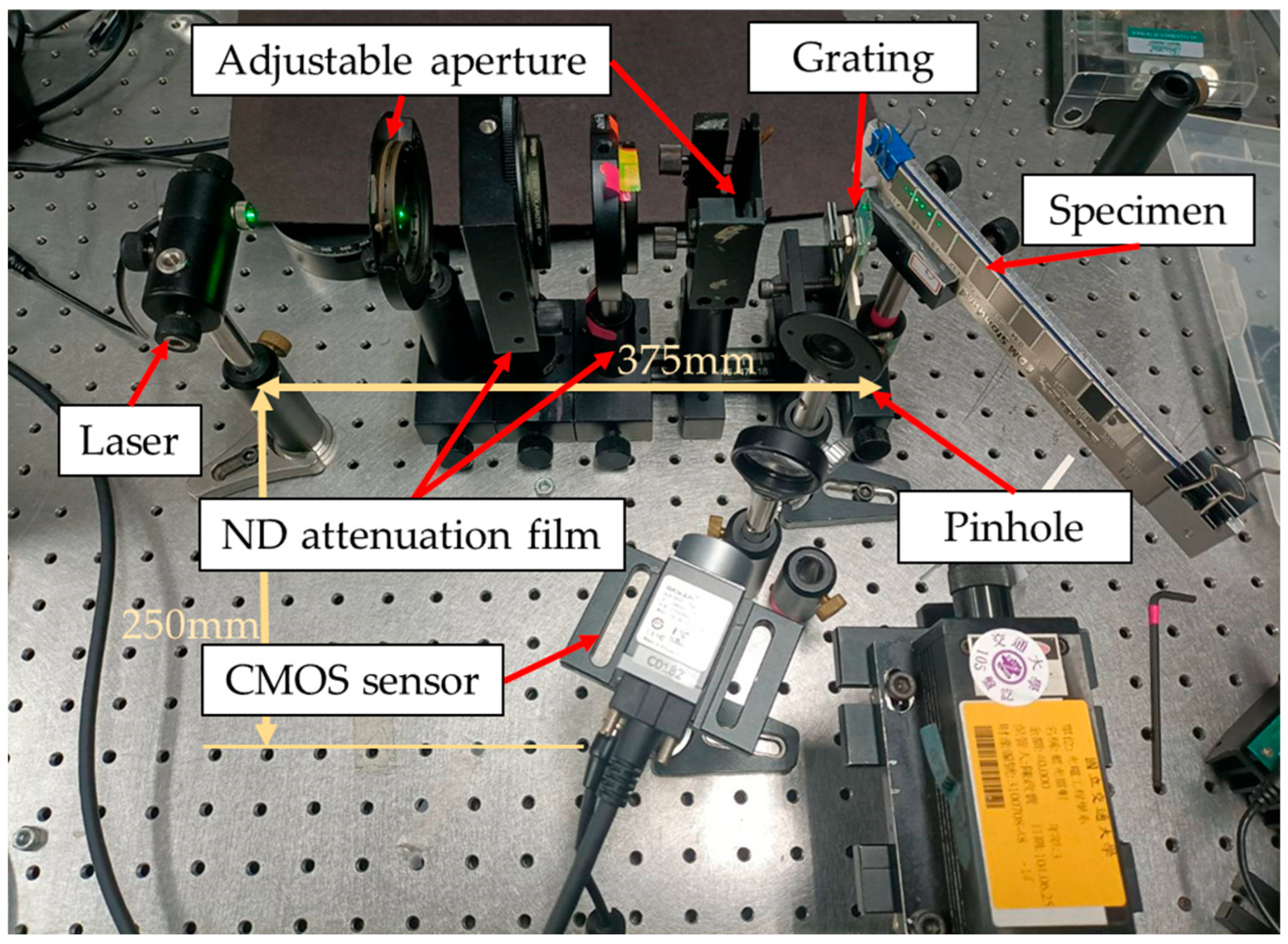

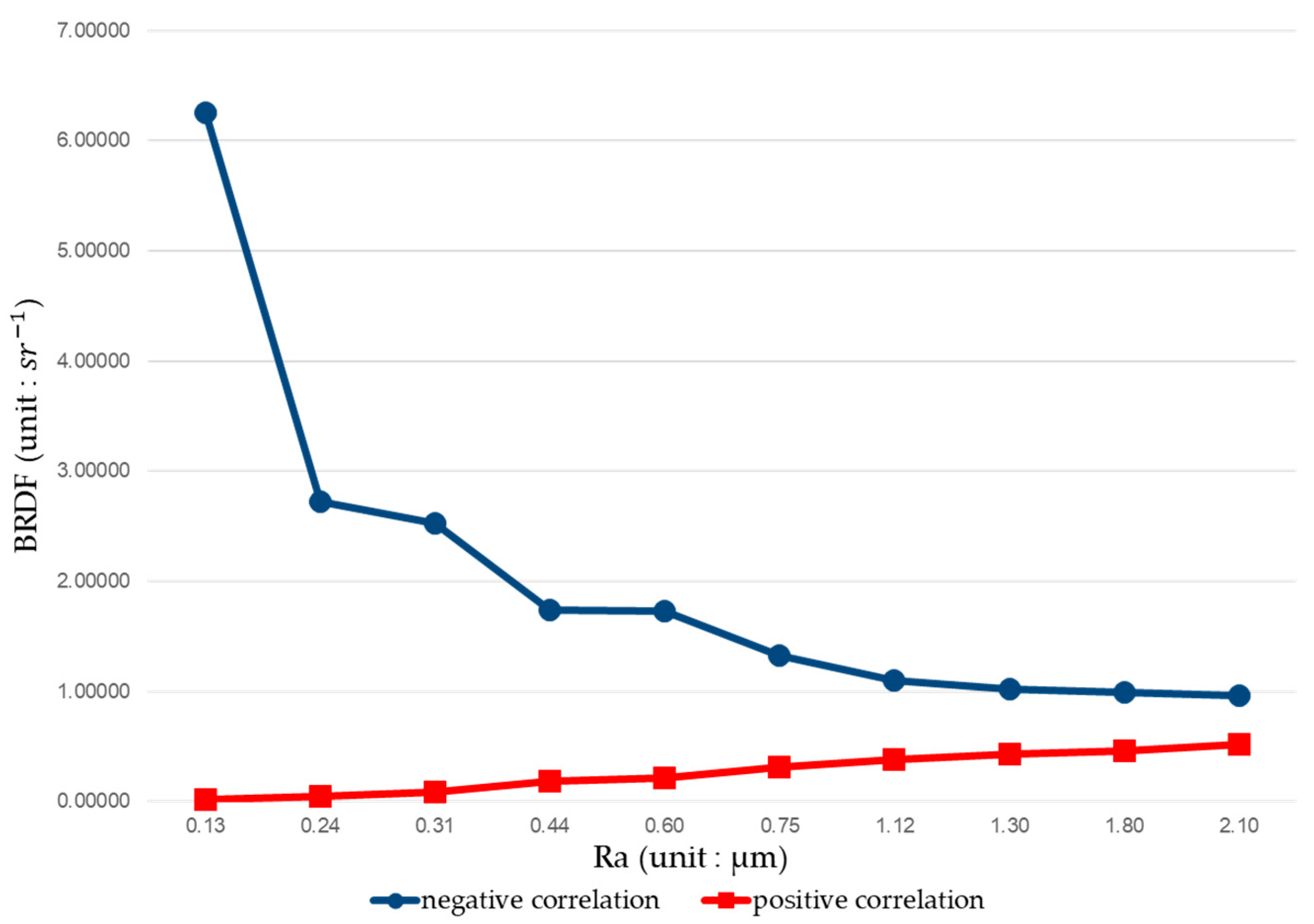

2. System Architecture for Angular Intensity Measurement

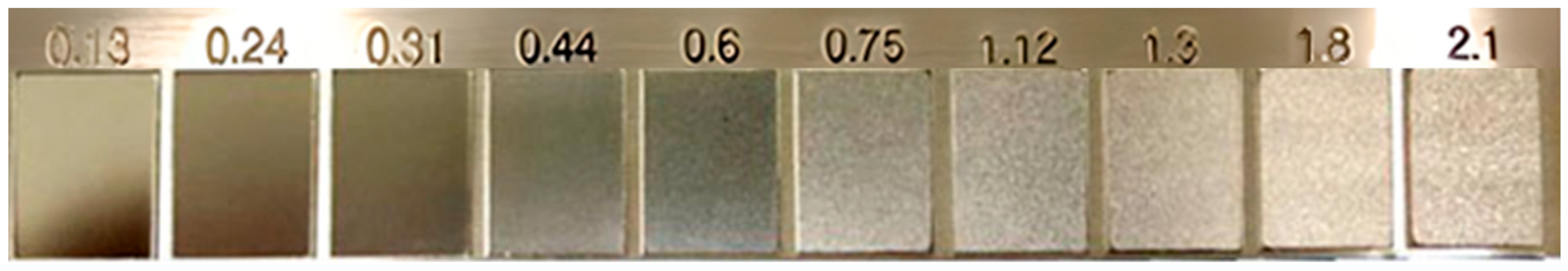

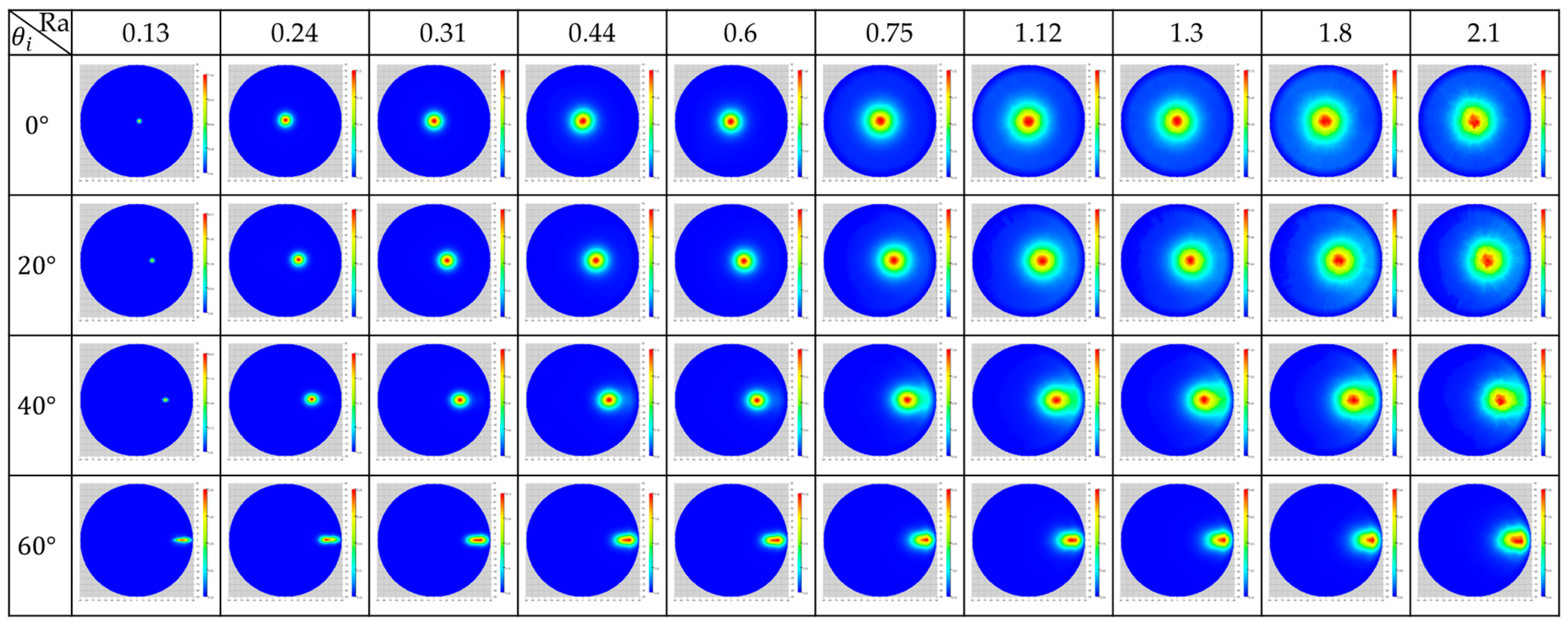

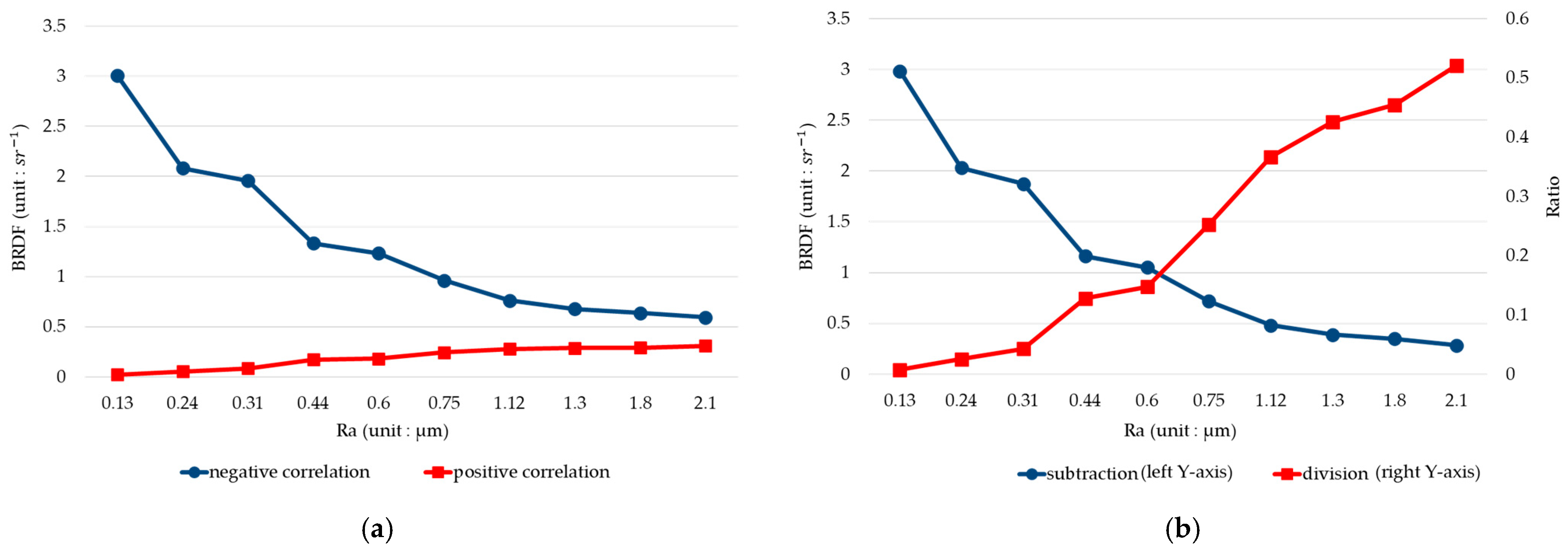

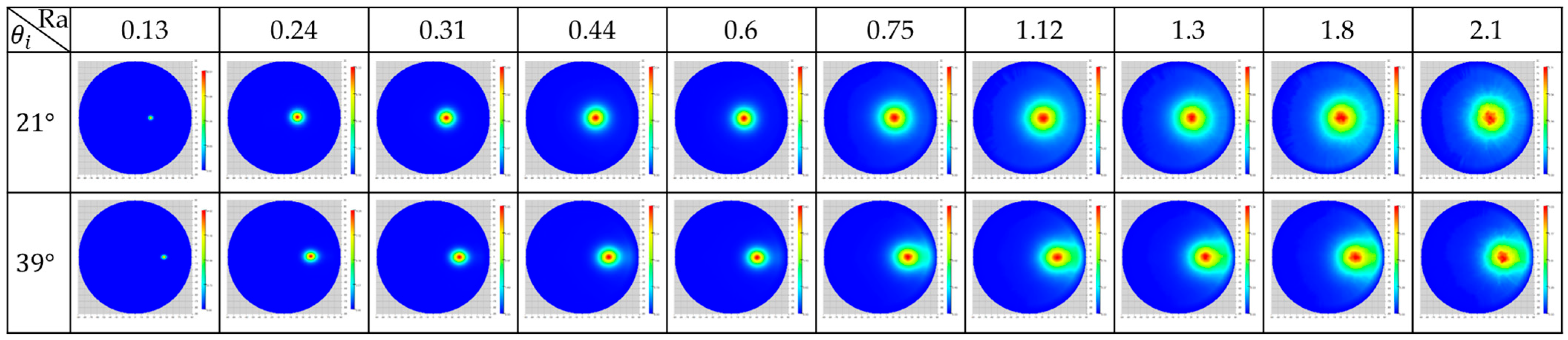

3. BRDF Measurement and Database Analysis

- 1.

- Build up BRDF database by sorting out the data with surface roughness Ra, incident angle and observation angle . The database can be expressed as

- 2.

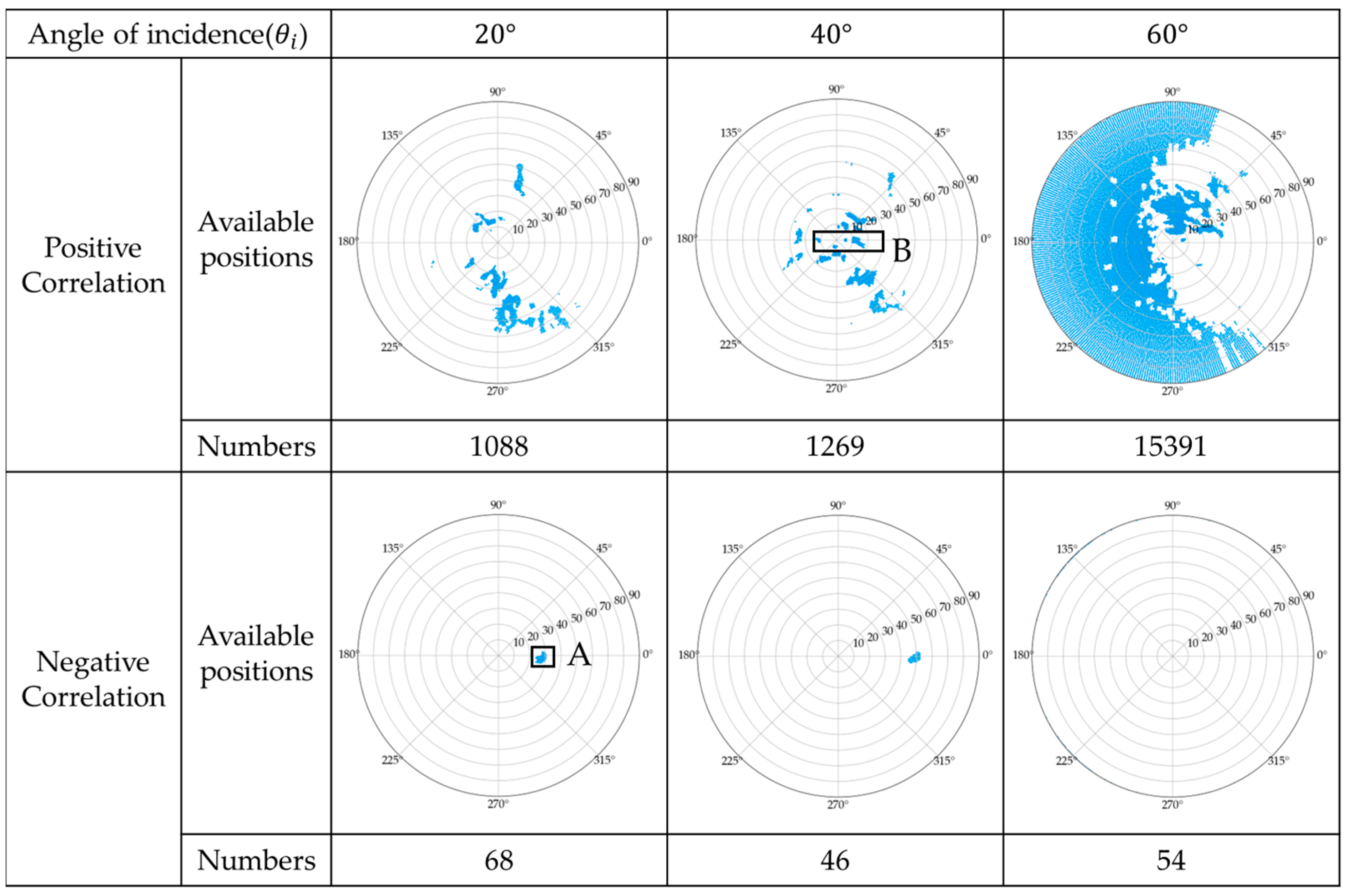

- Funding the combination of incident angle and observation angle , for which BRDF value changes monotonically with surface roughness. The algorithm is expressed as

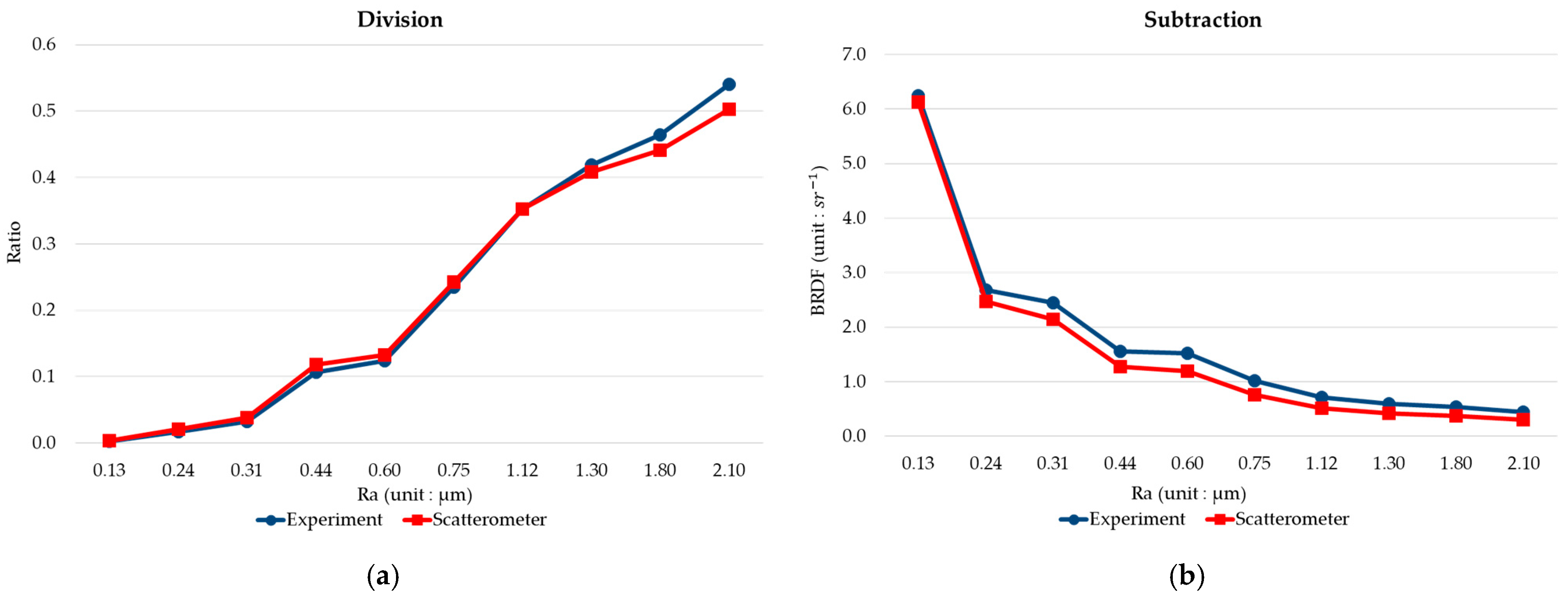

4. Prototype and Experiment

5. Discussions

6. Conclusions

- Proposes a compact system using a single light source and a single CMOS sensor for BRDF-based roughness detection;

- Requires only two angular intensities, enabling high-speed acquisition (<100 ms) with low processing overhead;

- The configuration offers potential for in-line integration using beam-splitting optical elements such as Dammann gratings, which generate uniform multi-beam patterns with customizable diffraction angles;

- Validates the method on EDM-processed specimens with Ra from 0.13 µm to 2.1 µm, showing strong correlation with commercial BRDF results;

- Acknowledges limitations such as material dependency, angular sensitivity, and limited Ra range;

- Plans future work to address broader material compatibility, uncertainty analysis, and model retraining for extended roughness ranges.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, W.; Kim, W.-C.; Park, N.-C. A Novel Approach to Surface Roughness Quantification in Semiconductor Packaging Using Quantitative Metrics Based on BRDF Analysis. Opt. Laser Technol. 2025, 185, 112578. [Google Scholar] [CrossRef]

- Peterson, G.L. A BRDF model for scratches and digs. In Proc. SPIE 8495, Reflection, Scattering, and Diffraction from Surfaces III; 84950G, 15 October 2012; SPIE: Bellingham, WA, USA, 2012. [Google Scholar] [CrossRef]

- ISO 4288: 1996; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. Edition DIN EN ISO 4288. European Committee for Standardization: Brussels, Belgium, April 1998.

- ISO 4287:1997; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters, 1st ed. International Organization for Standardization: Geneve, Switzerland, 1 April 1997.

- ISO 25178-600:2019; Geometrical Product Specification (GPS)—Surface Texture: Areal—Metrological Characteristics for Areal Topography Measuring Methods. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/67651.html (accessed on 20 February 2025).

- Whitehouse, D.J. Handbook of Surface Metrology; IOP Publishing Ltd.: Bristol, UK, 1994. [Google Scholar]

- Degarmo, E.P.; Black, J.T.; Kohser, R.A. Materials and Processes in Manufacturing, 9th ed.; Wiley: Hoboken, NJ, USA, 2003; ISBN 0-471-65653-4. [Google Scholar]

- Williams, H. Influence of Curved Surface Roughness on White Light Interferometer Microscopy. Phys. Educ. 2022, 57, 015001. [Google Scholar] [CrossRef]

- Hariharan, P. Basics of Interferometry, 2nd ed.; Academic Press: New York, NY, USA, 2007. [Google Scholar]

- Wyant, J.C. White Light Interferometry. Proc. SPIE 2002, 4737, 103. [Google Scholar] [CrossRef]

- Udupa, G.; Singaperumal, M.; Sirohi, R.S.; Kothiyal, M.P. Characterization of Surface Topography by Confocal Microscopy: I. Principles and the Measurement System. Meas. Sci. Technol. 2000, 11, 305–314. [Google Scholar] [CrossRef]

- Mauch, F.; Osten, W. Model-Based Approach for Planning and Evaluation of Confocal Measurements of Rough Surfaces. Meas. Sci. Technol. 2014, 25, 105002. [Google Scholar] [CrossRef]

- Jordan, H.-J.; Wegner, M.; Tiziani, H. Highly Accurate Non-Contact Characterization of Engineering Surfaces Using Confocal Microscopy. Meas. Sci. Technol. 1999, 9, 1142–1151. [Google Scholar] [CrossRef]

- Stover, J.C. Optical Scattering Measurement and Analysis; SPIE Press: Bellingham, WA, USA, 2012. [Google Scholar]

- Bihan, Q.K.-L. From BRDF to Roughness: Defining the Link between Two Key Parameters for Optical Design. In Optical Systems Design 2015: Illumination Optics IV; SPIE: Bellingham, WA, USA, 2015; Volume 9629. [Google Scholar] [CrossRef]

- Ali, A.; Nishino, K.; Ikeuchi, K. Efficient Modeling of Objects BRDF with Planned Sampling. IPSJ Trans. Comput. Vis. Appl. 2013, 5, 114–118. [Google Scholar] [CrossRef]

- Prabhakar, D.V.N.; Gopala Krishna, A.; Sreenivasa Kumar, M. Analysis on Significance of Various Statistical Texture Features in Vision-Based Surface Roughness Prediction in End Milling Process. Int. J. Interact. Des. Manuf. 2023, 17, 1563–1577. [Google Scholar] [CrossRef]

- Persson, U. In-Process Measurement of Surface Roughness Using Light Scattering. Wear 1998, 215, 54–58. [Google Scholar] [CrossRef]

- Feidenhans’l, N.A.; Hansen, P.-E.; Pilný, L.; Madsen, M.H.; Bissacco, G.; Petersen, J.C.; Taboryski, R. Comparison of Optical Methods for Surface Roughness Characterization. Meas. Sci. Technol. 2015, 26, 085208. [Google Scholar] [CrossRef]

- Lu, R.-S.; Tian, G.Y. On-Line Measurement of Surface Roughness by Laser Light Scattering. Meas. Sci. Technol. 2006, 17, 1496–1502. [Google Scholar] [CrossRef]

- Masaki, T.; Kawata, K.; Masuzawa, T. Micro Electro-Dsicharge Machining and Its Applications; IEEE: New York, NY, USA, 1990. [Google Scholar]

- Nicodemus, F.E. Directional reflectance and emissivity of an opaque surface. Appl. Opt. 1965, 4, 767–775. [Google Scholar] [CrossRef]

- Luan, C.; Li, Y.; Guo, H.; Sun, H.; Zhang, L.; Zheng, H.; Zhang, X. Modified Model of Polarized Bidirectional Reflectance Distribution Function Used for Light Detection and Ranging (LiDAR). Photonics 2023, 10, 1119. [Google Scholar] [CrossRef]

- Schröder, S.; Duparré, A.; Coriand, L.; Tünnermann, A.; Penalver, D.H.; Harvey, J.E. Modeling of light scattering in different regimes of surface roughness. Opt. Exp. 2011, 19, 9820–9835. [Google Scholar] [CrossRef] [PubMed]

- Georgiev, G.T.; Speck, D.R.; Johnson, D.D. Scatter Light Measurements in Support of Optical Instruments Development. In Proceedings of the 24th Annual Mirror Technology SBIR/STTR Workshop, Greenbelt, MD, USA, 18–21 November 2024; NASA: Washington, DC, USA, 2024. [Google Scholar]

- Younis, M.A. On Line Surface Roughness Measurements Using Image Processing towards an Adaptive Control. Computers 1998, 35, 49–52. [Google Scholar] [CrossRef]

- Aulbach, L.; Salazar Bloise, F.; Lu, M.; Koch, A.W. Non-Contact Surface Roughness Measurement by Implementation of a Spatial Light Modulator. Sensors 2017, 17, 596. [Google Scholar] [CrossRef] [PubMed]

- Shang, S.; Wang, C.; Liang, X.; Cheung, C.F.; Zheng, P. Surface Roughness Prediction in Ultra-Precision Milling: An Extreme Learning Machine Method with Data Fusion. Micromachines 2023, 14, 2016. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Wei, Y.; Terpenny, J. Surface roughness prediction in additive manufacturing using machine learning. In Proceedings of the International Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers, College Station, TX, USA, 18–22 June 2018; Volume 51371, p. V003T02A018. [Google Scholar]

- Guo, M.; Wei, S.; Han, C.; Xia, W.; Luo, C.; Lin, Z. Prediction of Surface Roughness Using Deep Learning and Data Augmentation. J. Intell. Manuf. Spec. Equip. 2024, 5, 221–241. [Google Scholar] [CrossRef]

- Krackhardt, U.; Streibl, N. Design of Dammann-Gratings for Array Generation. Opt. Commun. 1989, 74, 31–36. [Google Scholar] [CrossRef]

- Jahns, J.; Downs, M.M.; Prise, M.E.; Streibl, N.; Walker, S.J. Dammann Gratings for Laser Beam Shaping. Opt. Eng. 1989, 28, 281267. [Google Scholar] [CrossRef]

- Jia, J.; Zhou, C.; Liu, L. Circular Dammann Grating and Its Applications. In Nano-Optics and Nano-Structures; Zhu, X., Chou, S.Y., Arakawa, Y., Eds.; International Society for Optics and Photonics (SPIE): Bellingham, WA, USA, 2002; Volume 4923, pp. 119–126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yen, J.-H.; Fang, Z.-Y.; Chen, C.-H. Evaluation of Surface Roughness with Reduced Data of BRDF Pattern. Appl. Sci. 2025, 15, 9850. https://doi.org/10.3390/app15179850

Yen J-H, Fang Z-Y, Chen C-H. Evaluation of Surface Roughness with Reduced Data of BRDF Pattern. Applied Sciences. 2025; 15(17):9850. https://doi.org/10.3390/app15179850

Chicago/Turabian StyleYen, Jui-Hsiang, Zih-Ying Fang, and Cheng-Huan Chen. 2025. "Evaluation of Surface Roughness with Reduced Data of BRDF Pattern" Applied Sciences 15, no. 17: 9850. https://doi.org/10.3390/app15179850

APA StyleYen, J.-H., Fang, Z.-Y., & Chen, C.-H. (2025). Evaluation of Surface Roughness with Reduced Data of BRDF Pattern. Applied Sciences, 15(17), 9850. https://doi.org/10.3390/app15179850