Research on Distribution DSS Conceptual Framework of Textile Logistics in Textile Markets †

Abstract

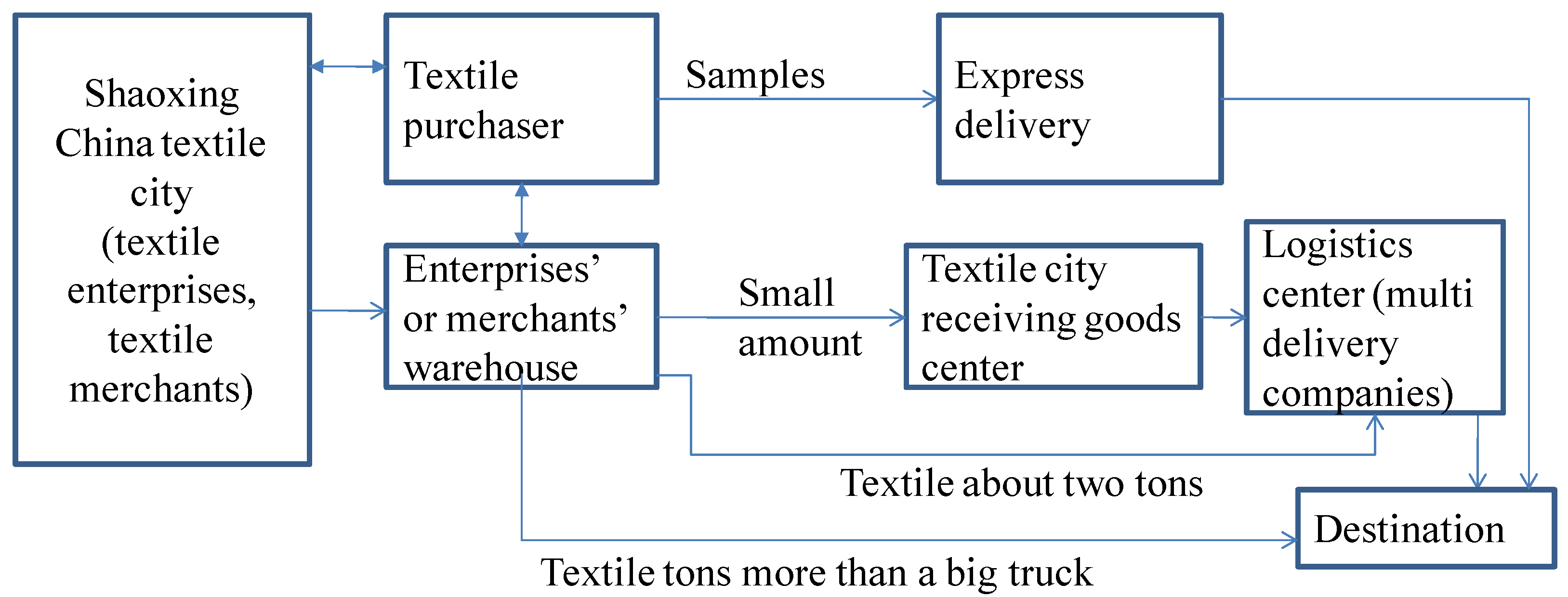

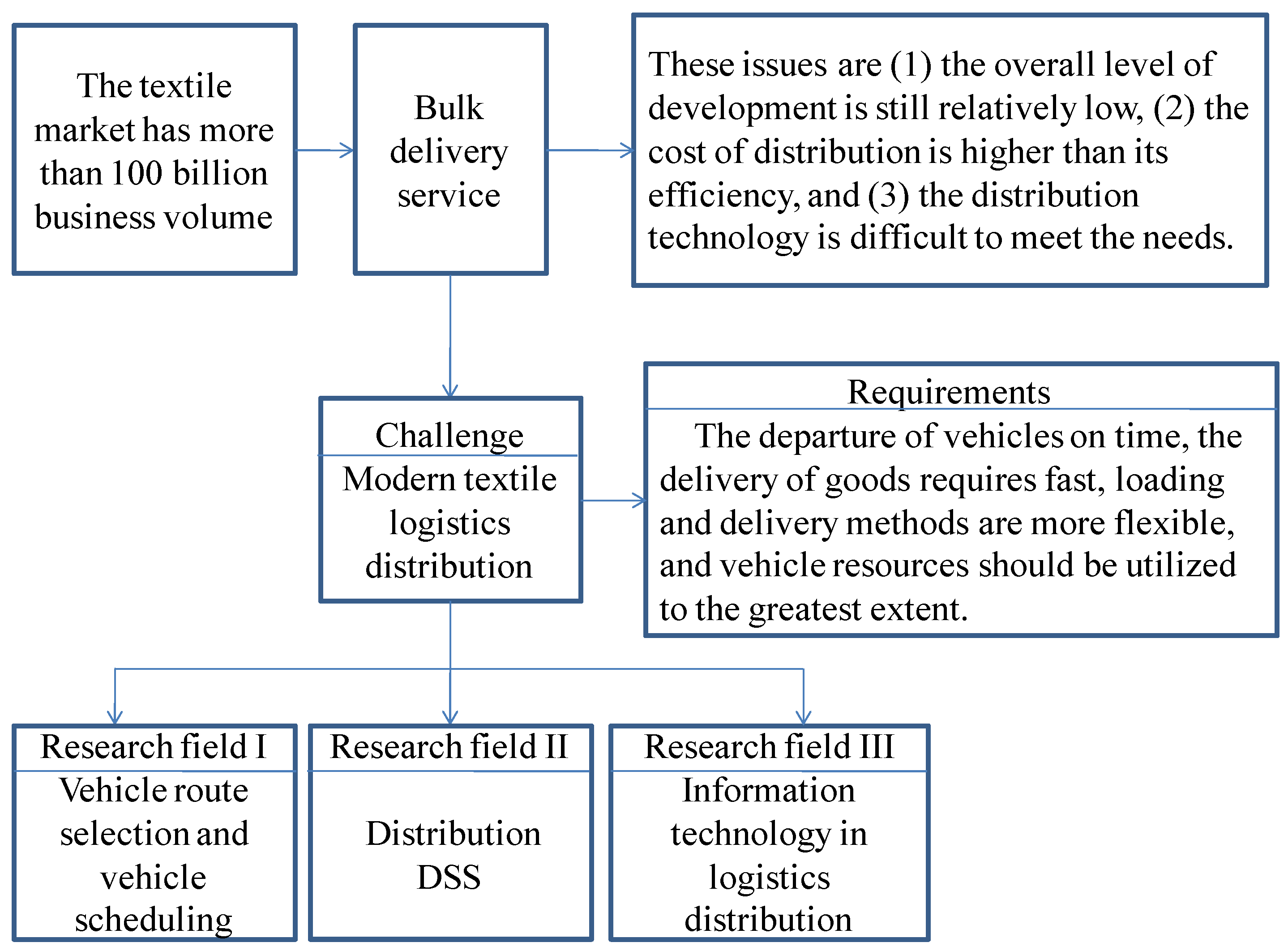

1. Introduction

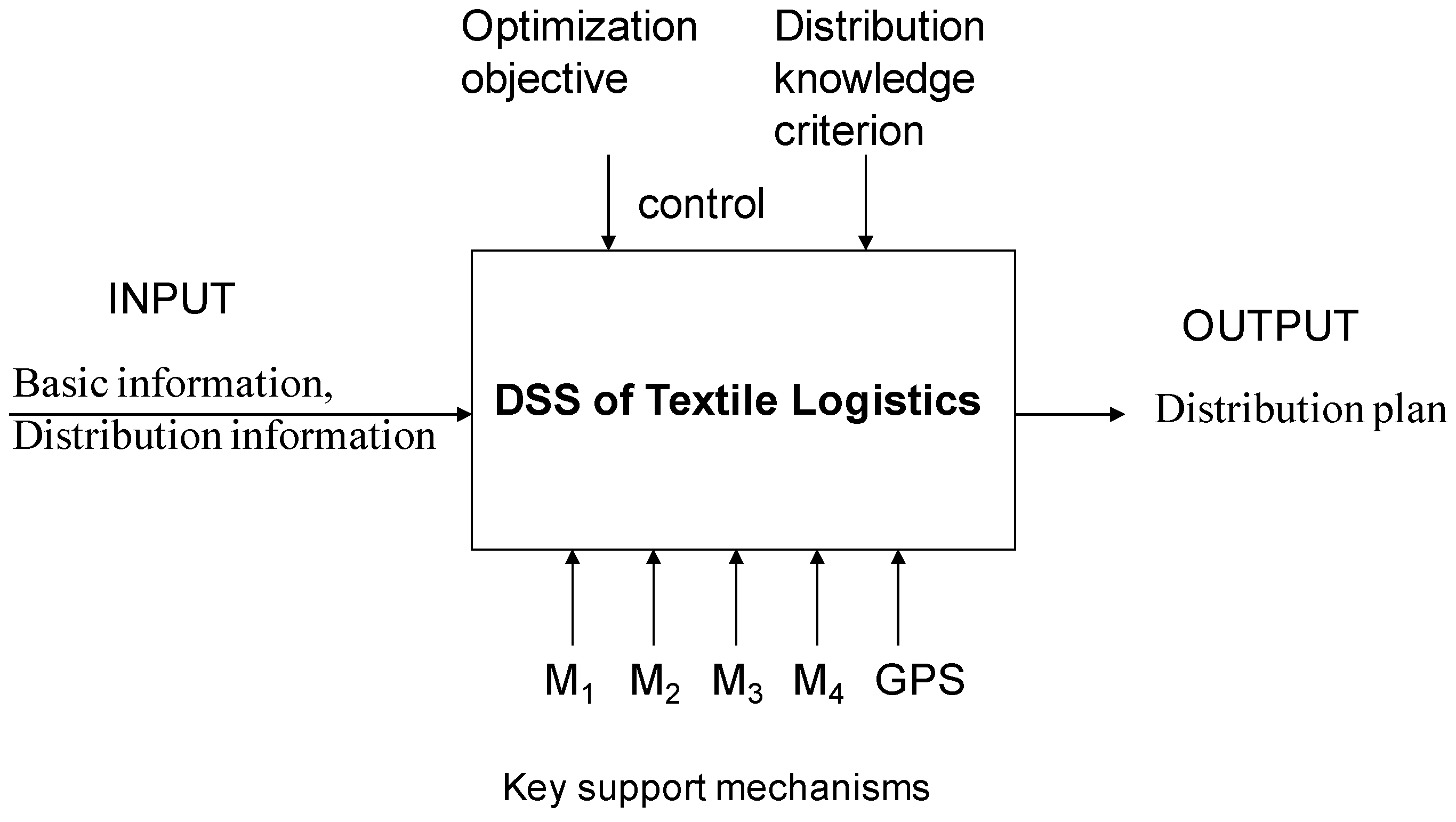

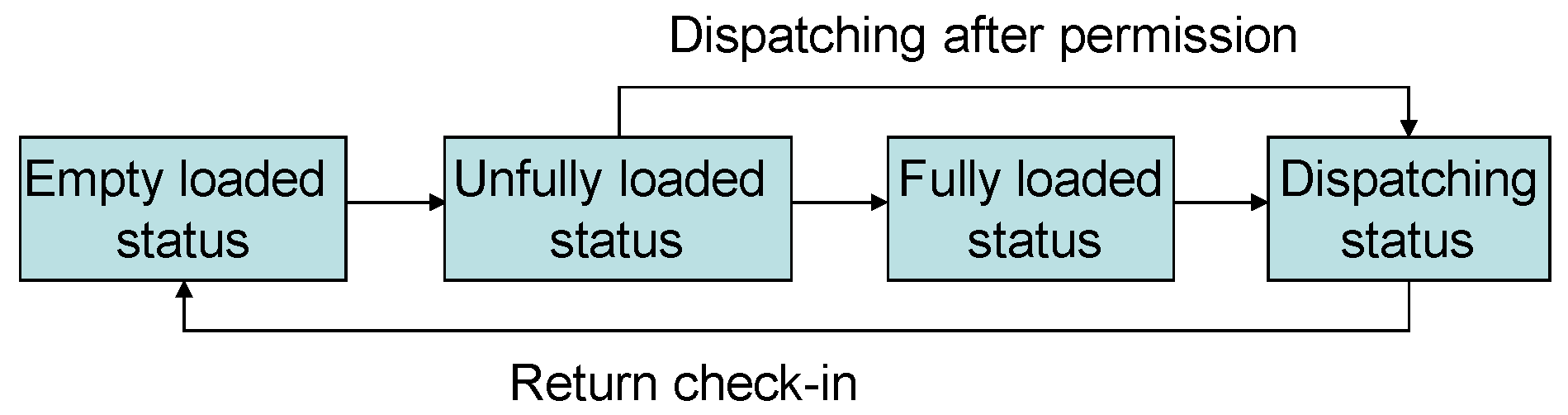

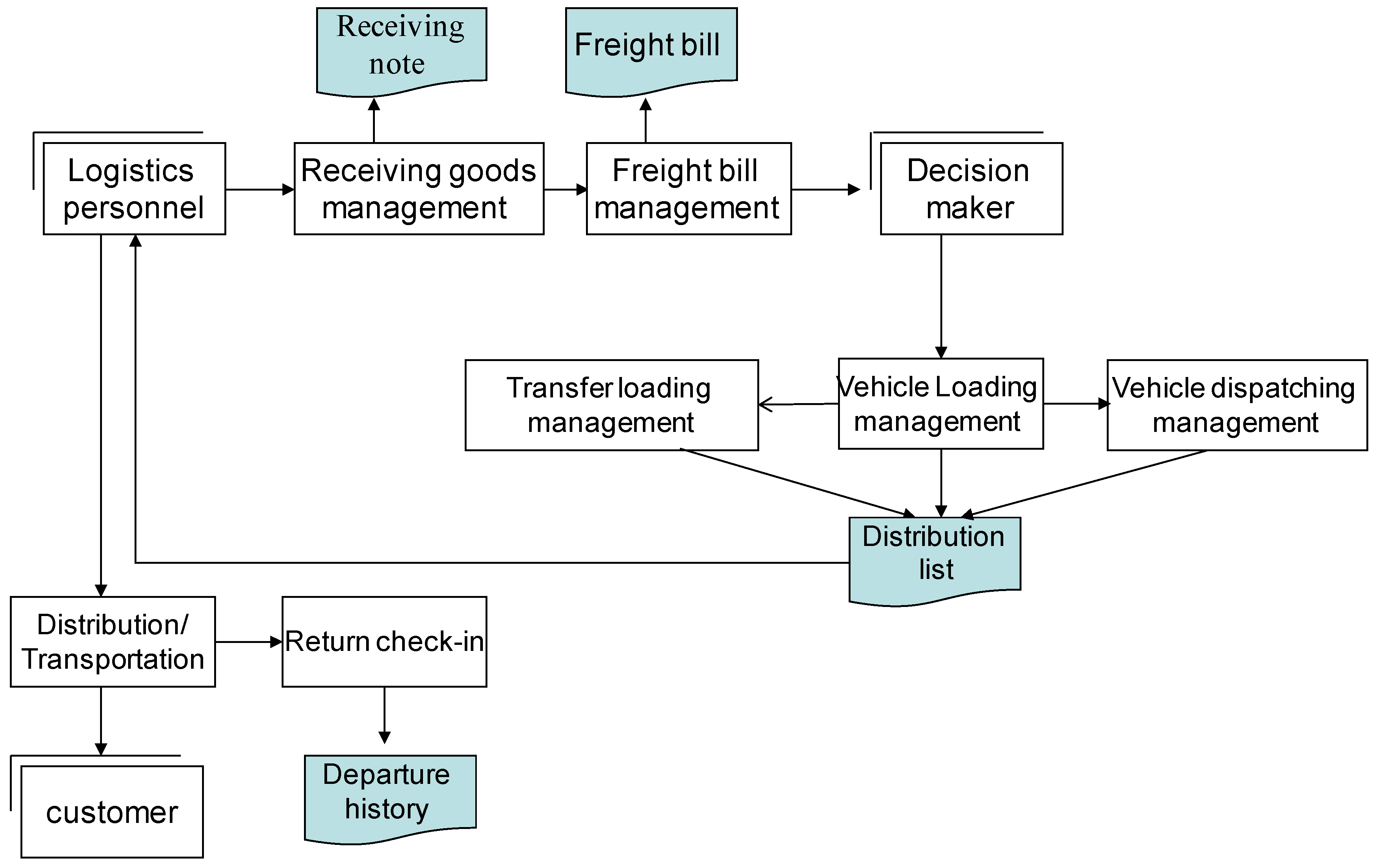

2. Theoretical Model of Distribution DSS Conceptual Framework of Textile Logistics

2.1. Input Link

2.2. Control Link

2.3. Mechanism Link

2.4. Output Link

3. Research on Database, Model Base, and Method Base

3.1. Research on Basic and Distribution Database

3.2. Research on Model Base and Method Base

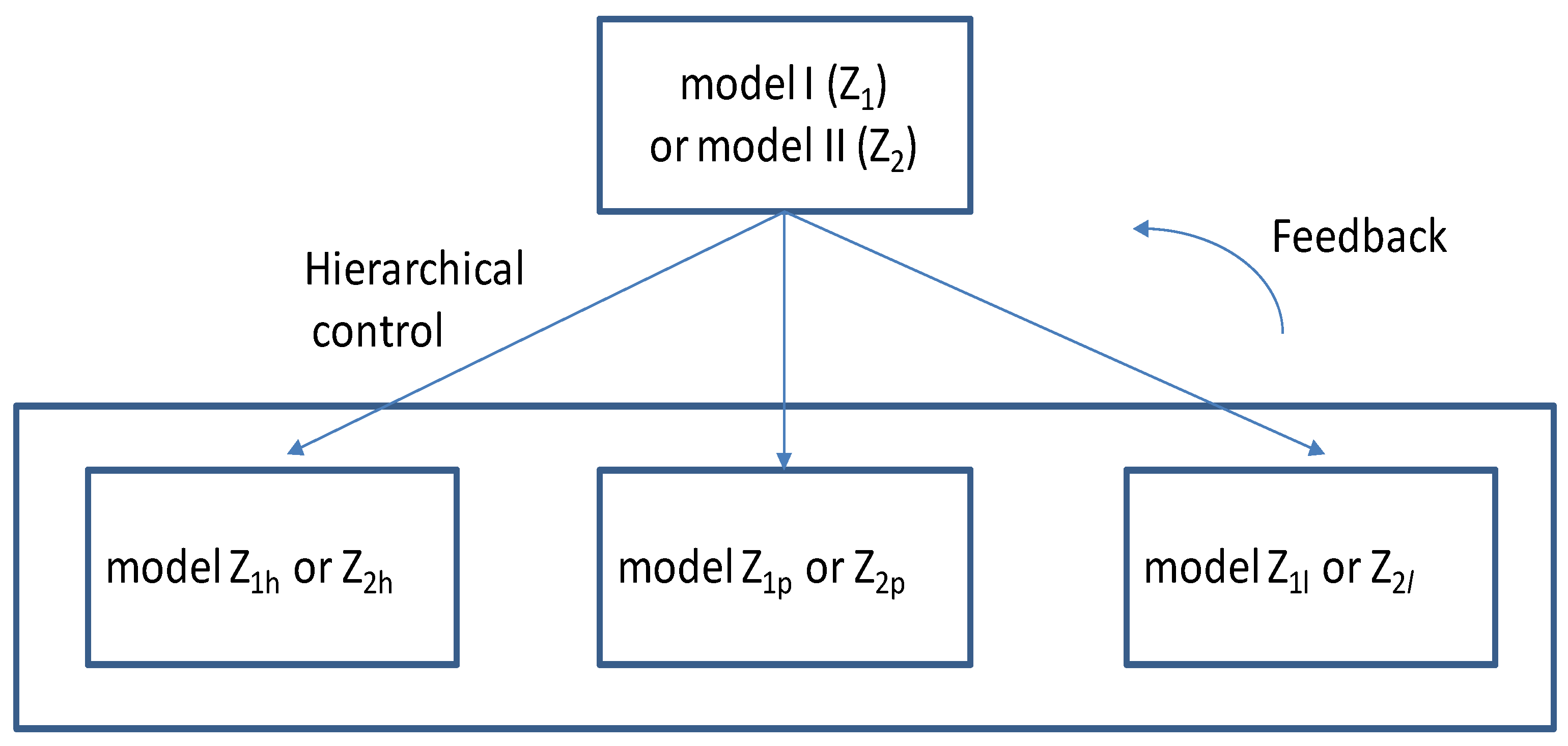

3.2.1. Construction of Model Base

3.2.2. Model-Solving Steps

3.2.3. Construction of Method Base

- (1)

- The Method of Surplus Vehicle Tonnage Utilization

- (2)

- The Method of Vehicle Priority Loading Order Selection

- (3)

- The Simultaneous Loading Method of Multi-Freight Bills and Multi-Vehicles

- (4)

- The Method of Transfer Vehicle Loading

4. Test Data Example

4.1. Data

4.2. Running Result

4.3. Comparative Analysis

4.4. Challenges of Implementing the DSS

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jbili, S.; Chelbi, A.; Radhoui, M.; Kessentini, M. Integrated Strategy of Vehicle Routing and Maintenance. Reliab. Eng. Syst. Saf. 2018, 170, 202–214. [Google Scholar] [CrossRef]

- Hintsch, T.; Irnish, S. Large Multiple Neighborhood Search for the Clustered Vehicle-routing Problem. Eur. J. Oper. Res. 2018, 270, 118–131. [Google Scholar] [CrossRef]

- Kulkarni, S.; Patil, R.; Krishnamoorthy, M.; Ernst, A.; Ranade, A. A New Two-stage Heuristic for the Recreational Vehicle Scheduling Problem. Reliab. Eng. Syst. Saf. 2018, 170, 202–214. [Google Scholar] [CrossRef]

- Gansterer, M.; Hartl, R.F. Collaborative Vehicle Routing: A Survey. Eur. J. Oper. Res. 2018, 268, 1–12. [Google Scholar] [CrossRef]

- Noorizadegan, M.; Chen, B. Vehicle Routing With Probabilistic Capacity Constraints. Eur. J. Oper. Res. 2018, 270, 544–555. [Google Scholar] [CrossRef]

- Bruglieri, M.; Mancini, S.; Pezzella, F.; Pisacane, O.A. Path-based Solution Approach for the Green Vehicle Routing Problem. Comput. Oper. Res. 2019, 103, 109–122. [Google Scholar] [CrossRef]

- Breunig, U.; Baldacci, R.; Hartl, R.F.; Vidal, T. The Electric Two-echelon Vehicle Routing Problem. Comput. Oper. Res. 2019, 103, 198–210. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Mardani, A. A novel two-echelon hierarchical location-allocation-routing optimization for green energy-efficient logistics systems. Ann. Oper. Res. 2023, 324, 795–823. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Faridnia, A.; Soltani, M.; Weber, G.-W. Multi-objective optimization for the reliable pollution-routing problem with cross-dock selection using Pareto-based algorithms. J. Clean. Prod. 2020, 276, 122927. [Google Scholar] [CrossRef]

- Guo, N.; Qian, B.; Shen, Q.Y.; Na, J.; Hu, R.; Geng, Y. Hyper-heuristic Ant Colony Optimization Algorithm for Green Two-echelon Multi-period Vehicle Routing Problem with Flexible Time Windows. Control. Decis. 2025, 40, 745–753. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, H.X.; Gou, M.Y.; Zhao, X.Q. Fresh Commodity Multi-compartment Loading Distribution Routing Optimization Problem Based on Vehicle Sharing. Packag. Eng. 2025, 46, 210–222. [Google Scholar] [CrossRef]

- Yao, L.J.; Wang, K.J. Reinforcement Learning Based Path Optimization for Multi-Trip Green Vehicles with Soft Time Window. Comput. Technol. Autom. 2024, 43, 153–160. [Google Scholar] [CrossRef]

- Guo, R.J.; Fan, C.R.; Liu, Y.; Jiang, K.N. Vehicle Path Selection for Distribution of Incompatible Emergency Materials Based on Demand Urgency. J. Saf. Sci. Technol. 2024, 12, 150–158. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, F.Y.; Lu, J.J.; Wang, Z.H.; Ma, B. Constrained Vehicle Routing Model for Emergency Relief Supplies Based on Demand Urgency. J. Tsinghua Univ. (Sci. Technol.) 2024, 64, 1082–1088. [Google Scholar] [CrossRef]

- Jiang, G.T.; Ji, J.Y.; Dong, J.W. Multi-vehicle Dynamic Vehicle Routing Optimization in Green Logistics Distribution. Syst. Eng.-Theory Pract. 2024, 44, 2362–2380. [Google Scholar] [CrossRef]

- Ge, F.; Min, S.; Qiu, H.; Dai, Z.Y.; Yang, Z.M. Research on an Algorithm for Solving Time-Dependent Green Vehicle Routing Problem. Comput. Eng. 2024, 50, 1–10. [Google Scholar] [CrossRef]

- Hua, Q.P.; Wang, X. Study on distribution model of clothing timeliness and modified ant colony algorithm. J. Text. Res. 2012, 33, 139–144. [Google Scholar] [CrossRef]

- Miao, Z.W.; Su, R.Z.; Zhang, J. An Adaptive Genetic Algorithm for the Truck Scheduling Problem in the CrossdockDistributionCenter. J. Ind. Eng./Eng. Manag. 2016, 30, 166–172. [Google Scholar] [CrossRef]

- Song, C.Y.; Wang, H.L.; Tian, Z.S.; Niu, X.Q. Review of demand-responsive transit vehicle scheduling models and algorithms. J. Beijing Jiaotong Univ. 2023, 47, 31–44. [Google Scholar] [CrossRef]

- Yang, K.; Wu, F.; Luo, W.Z. Research on Peak Hour Vehicle Scheduling Based on the Temporal and Spatial Distribution Law of Shared Electric Vehicles. J. Lanzhou Jiaotong Univ. 2023, 42, 32–38. [Google Scholar] [CrossRef]

- Kengpol, A. Design of a Decision Support System to Evaluate Logistics Distribution Network in Greater Mekong Subregion Countries. Int. J. Prod. Econ. 2008, 115, 388–399. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Maranesi, F. A Decision-support System for the Design and Management of Warehousing Systems. Comput. Ind. 2014, 65, 175–186. [Google Scholar] [CrossRef]

- Fikar, C. A Decision Support System to Investigate Food Losses in E-grocery Deliveries. Comput. Ind. Eng. 2018, 117, 282–290. [Google Scholar] [CrossRef]

- Wang, F.Z.; Pang, H.Y. Selecting optimal warehousing location and distribution combination decision for sales logistics of garment enterprise. J. Text. Res. 2014, 35, 139–143. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Lei, B.B.; Wang, X.F.; Zhu, X.J.; Song, J.H. Review of Metaheuristic Algorithms for Vehicle Routing Problem with Time Windows. Appl. Res. Comput. 2024, 42, 1–11. [Google Scholar] [CrossRef]

- Ye, C.S.; Wang, X.X.; Shi, Z.M.; Huang, C.C. Research on Optimization of Distribution Network under Artificial Intelligence Background. J. Chongqing Technol. Bus. Univ. (Nat. Sci. Ed.) 2018, 35, 22–26. [Google Scholar] [CrossRef]

- Han, J.D.; Du, Q.G. Research on the Internet of Things Application in Fresh Agricultural Product Distribution. China Bus. Mark. 2015, 12, 54–60. [Google Scholar] [CrossRef]

- Li, C.B.; Wang, E.J.; Yuan, J.B. Research on the Optimization of Logistics Distribution Route of Fresh Agricultural Produce under Internet of Things. Commer. Res. 2017, 4, 1–9. [Google Scholar] [CrossRef]

- Lu, J.C. Scheduling Distribution Vehicles in Internet of Things Based on Perturbation Contraction Particle Swarm Optimization. J. Highw. Transp. Res. Dev. 2020, 37, 111–117. [Google Scholar]

- Li, L.W. Construction of logistics distribution information sharing platform based on the Internet of Things technology. Mod. Electron. Tech. 2021, 44, 78–82. [Google Scholar] [CrossRef]

| Table Name | Description | Related Criterion |

|---|---|---|

| Cuser | It is a login user table, which is used to verify the system login | None |

| Client | It is a customer information data table, which is used to record the basic information of each customer | None |

| Product | It is a textile fabric information data table, which is used to manage the receiving information of each customer’s textile fabrics | None |

| Vehicle | It is a vehicle information data table, which is used to manage the basic information and operating status of the vehicle (empty, not fully loaded, fully loaded, dispatching) | Vehicle status management criterion, vehicle-loading criterion |

| TransRecord | It is a departure history data table, which is used to manage departure history and return check-in. The status of the vehicle after the return check-in will be empty | Vehicle status management criterion |

| Bill | It is a freight bill information data table. It is used to generate the freight bill number for each customer’s textile fabric and record whether the goods in each freight bill are arranged to be loaded | Freight bill service criterion |

| BillDeco | It is a vehicle loading information data table. It is used to record the loading time and quantity of each freight bill on each vehicle | Freight bill service criterion, vehicle-loading criterion |

| Variable | Description |

|---|---|

| the path number is j, and J represents the path sequence set, , which is obtained by the vehicle navigation system | |

| the maximum number of distribution places for one service is , | |

| the vehicle serial number is represented as , the available vehicle set is | |

| the maximum number of customers for one service is , | |

| the maximum quantity of goods types in one service is , | |

| is a 0–1 variable, which is also a decision variable, if means that vehicle is selected, means that vehicle is not selected | |

| is the approved deadweight tonnage of vehicle | |

| represents the total amount of one delivery demand at all distribution points in a service cycle (such as the next 48 h) | |

| represents the distance of vehicle on route | |

| represents the loading number of the vehicle running on the route j, which is also the decision variable | |

| For the specified path by GPS, let the simplified be the quantity of the vehicle and the customer at the distribution place | |

| For the specified path by GPS, let the simplified be the quantity of the vehicle and the customer and the goods at the distribution place |

| Module | Data Table for Each Module | Model Running of the Model Base | Method Running of the Method Base |

|---|---|---|---|

| Login | Cuser | None | None |

| Customer management | Client | None | None |

| Vehicle management (maintenance, departure, departure history) | Vehicle, TransRecord | None | None |

| Receiving goods management (maintenance, generation of freight bill) | Product, Client, Bill | None | None |

| Vehicle loading management (multi-freight bill and multi-vehicle loading method) | Vehicle, Bill, BillDesc | Model I or model II | The method of vehicle surplus tonnage utilization; The method of vehicle priority loading order selection; The simultaneous loading method of multi-freight bills and multi-vehicles |

| Transfer loading management (one-to-one transfer) | Vehicle, Bill, BillDesc | Model II | The method of vehicle surplus tonnage utilization; The method of transfer vehicle loading |

| Loading list view and output | TransRecord, BillDesc | None | None |

| Client i | Delivery Amount (Unit: Ton) | Destination | Delivery Time | Client i | Delivery Amount (Unit: Ton) | Destination | Delivery Time | Client i | Delivery Amount (Unit: Ton) | Destination | Delivery Time |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.9 | Ganzhou | Within 36 h | 11 | 1.5 | Nanjing | Within 48 h | 19 | 2.3 | Wuhan | Within 72 h |

| 2 | 6.3 | Ganzhou | Within 36 h | 12 | 4.2 | Nanjing | Within 48 h | 20 | 3.4 | Wuhan | Within 72 h |

| 3 | 7.9 | Ganzhou | Within 36 h | 13 | 3.8 | Nanjing | Within 48 h | 21 | 3.1 | Wuhan | Within 72 h |

| 4 | 3.8 | Ganzhou | Within 36 h | 14 | 6.7 | Nanjing | Within 48 h | 22 | 2.2 | Wuhan | Within 72 h |

| 5 | 6.8 | Ganzhou | Within 72 h | 15 | 8 | Nanjing | Within 48 h | 23 | 1.6 | Wuhan | Within 72 h |

| 6 | 5.0 | Ganzhou | Within 72 h | 16 | 4.6 | Nanjing | Within 48 h | ||||

| 7 | 2.6 | Ganzhou | Within 72 h | 17 | 5.0 | Nanjing | Within 48 h | ||||

| 8 | 5.5 | Ganzhou | Within 72 h | 18 | 2.2 | Nanjing | Within 48 h | ||||

| 9 | 3.6 | Ganzhou | Within 72 h | ||||||||

| 10 | 1.9 | Ganzhou | Within 72 h |

| Vehicle Serial Number | Ton | Loading Quantity | Vehicle Status | Destination | Vehicle Status | Loading Quantity | Destination |

|---|---|---|---|---|---|---|---|

| 1 | 17 | 10 | Not fully loaded status | Shanghai | Not fully loaded status | 10 | Shanghai |

| 2 | 17 | Empty status | Empty status | ||||

| 3 | 13 | 12 | Dispatching status | Hangzhou | Empty status | ||

| 4 | 13 | Empty status | Dispatching status | 13 | Ganzhou | ||

| 5 | 8 | Empty status | Dispatching status | 7.9 | Ganzhou | ||

| 6 | 8 | 7 | Dispatching status | Jinan | Empty status | Return | |

| 7 | 8 | 8 | Dispatching status | Nanning | Empty status | Return | |

| 8 | 8 | 7.9 | Dispatching status | Shanghai | Empty status | Return | |

| Remarks | The 0th delivery (before new delivery) | The new 1st delivery |

| Vehicle Serial Number | Vehicle Status | Loading Quantity | Destination | Vehicle Status | Loading Quantity | Destination | Vehicle Status | Loading Quantity | Destination |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Dispatching status | 16 | Shanghai, Nanning | Dispatching status | 16 | Return | Dispatching status | 17 | Ganzhou |

| 2 | Dispatching status | 17 | Nanning | Dispatching status | 17 | Return | Empty status | Ganzhou | |

| 3 | Dispatching status | 13 | Nanning | Dispatching status | 13 | Return | Not fully loaded status | 8.4 | Ganzhou |

| 4 | Dispatching status | Return | Dispatching status | 12.6 | Return | Dispatching status | 12.6 | Wuhan | |

| 5 | Dispatching status | Return | Empty status | Empty status | |||||

| 6 | Empty status | Empty status | Empty status | ||||||

| 7 | Empty status | Empty status | Empty status | ||||||

| 8 | Empty status | Empty status | Empty status | ||||||

| Remarks | The new 2nd delivery | The new 3rd delivery | The new 4th delivery |

| Items | Logistics Business Applications | Future Application of DSS |

|---|---|---|

| Number of contract transport enterprises | More than 100 | Lessen |

| Goods receipt | Single enterprise conducts operation independently manually or by Excel or ordinary applications | Multi-enterprise cooperation |

| Freight bill management | Single enterprise conducts operation independently or several enterprises cooperate manually or by Excel or ordinary applications | |

| Loading plan | ||

| Vehicle dispatching | ||

| Transfer loading plan | One-to-one vehicle transfer loading | One-to-one vehicle transfer loading |

| Vehicle status management | Managed by general experience for each enterprise | Record all vehicles |

| Vehicle return check-in | Managed manually or by Excel or parking management system | Record all vehicles |

| Vehicle departure history | Managed manually or by Excel or ordinary applications | Record all vehicles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Li, C. Research on Distribution DSS Conceptual Framework of Textile Logistics in Textile Markets. Appl. Sci. 2025, 15, 9755. https://doi.org/10.3390/app15179755

Wang F, Li C. Research on Distribution DSS Conceptual Framework of Textile Logistics in Textile Markets. Applied Sciences. 2025; 15(17):9755. https://doi.org/10.3390/app15179755

Chicago/Turabian StyleWang, Fuzhong, and Chongyan Li. 2025. "Research on Distribution DSS Conceptual Framework of Textile Logistics in Textile Markets" Applied Sciences 15, no. 17: 9755. https://doi.org/10.3390/app15179755

APA StyleWang, F., & Li, C. (2025). Research on Distribution DSS Conceptual Framework of Textile Logistics in Textile Markets. Applied Sciences, 15(17), 9755. https://doi.org/10.3390/app15179755