Infrared Drying of Banana Slices: Quality Evaluation Using Spectral and Microstructural Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

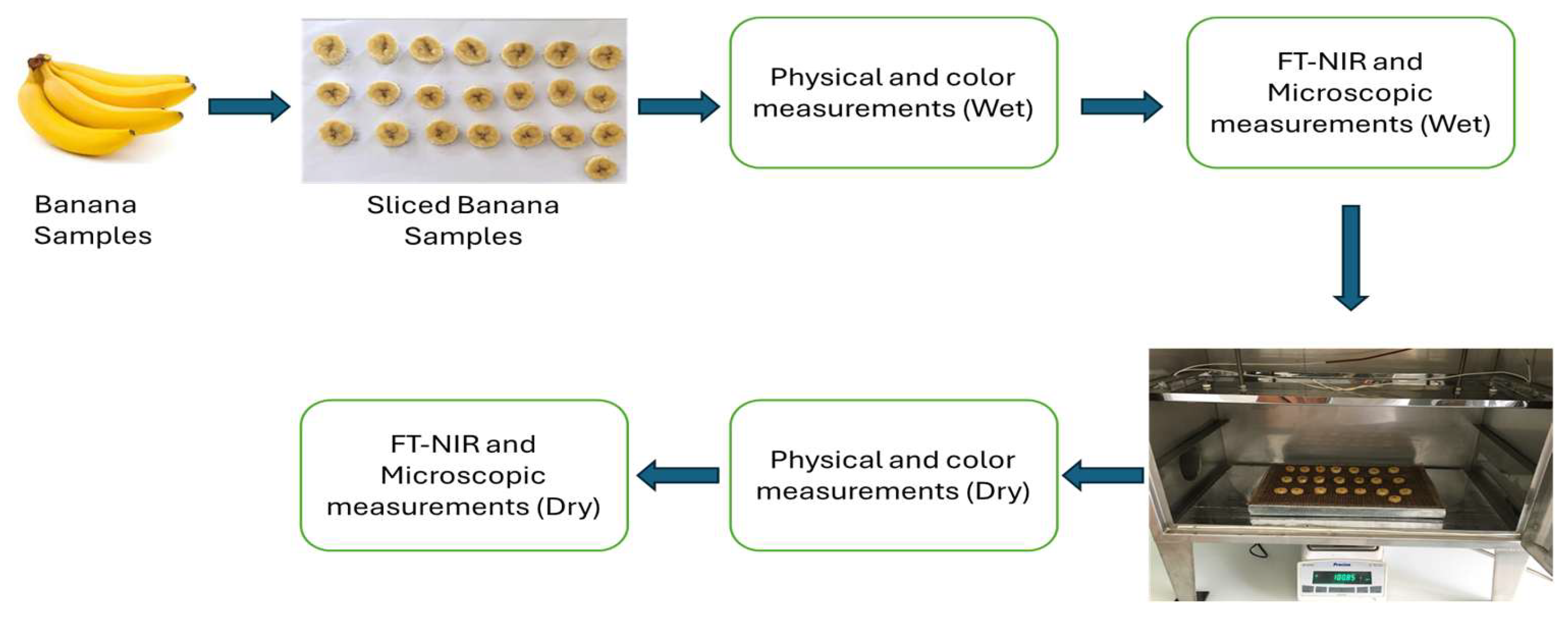

2.2. Experimental Method

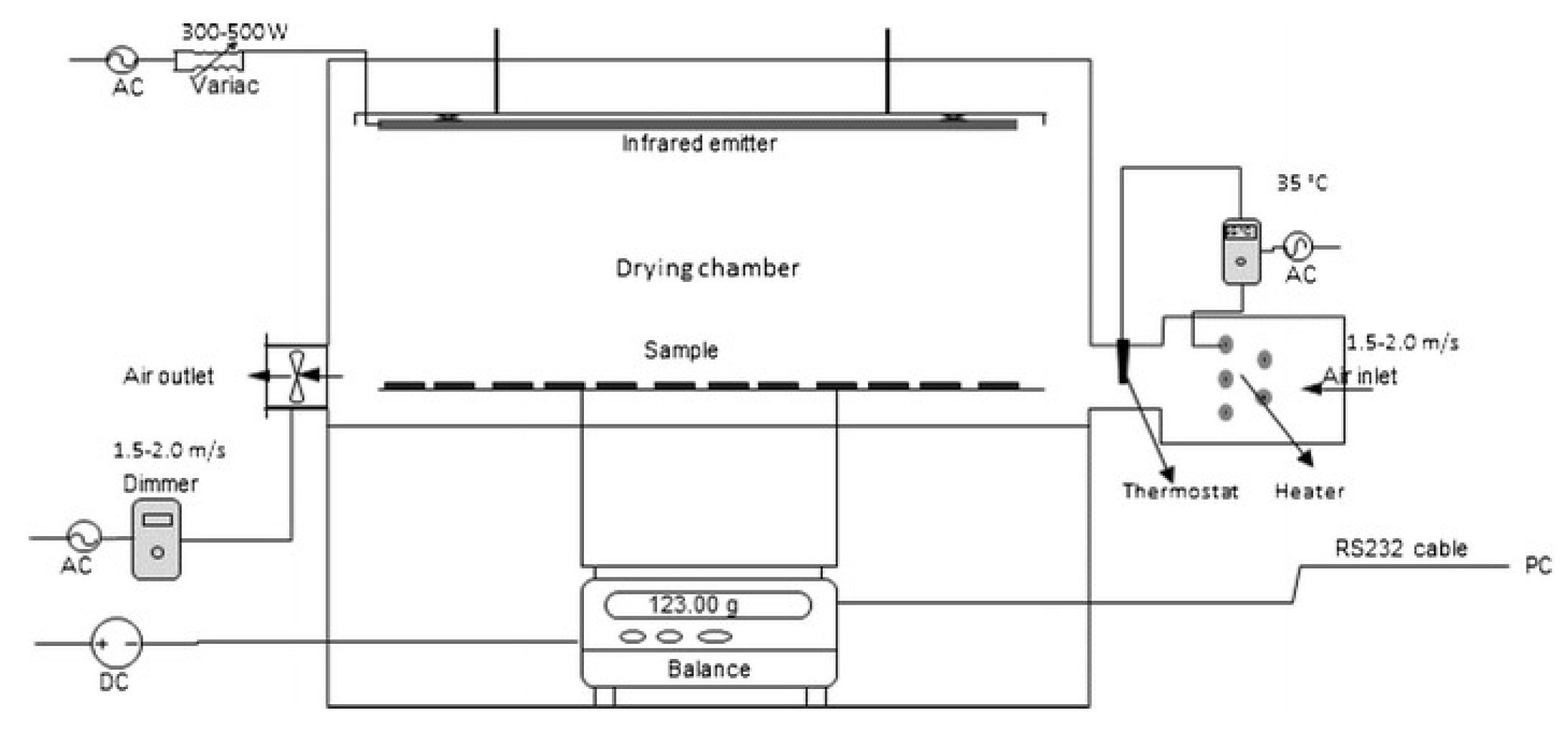

2.3. Drying Process

2.4. Color Measurements

2.5. Spectral and Microstructure Measurements

2.6. Shrinkage and Weight Loss

2.7. Statistical Methods

3. Results and Discussion

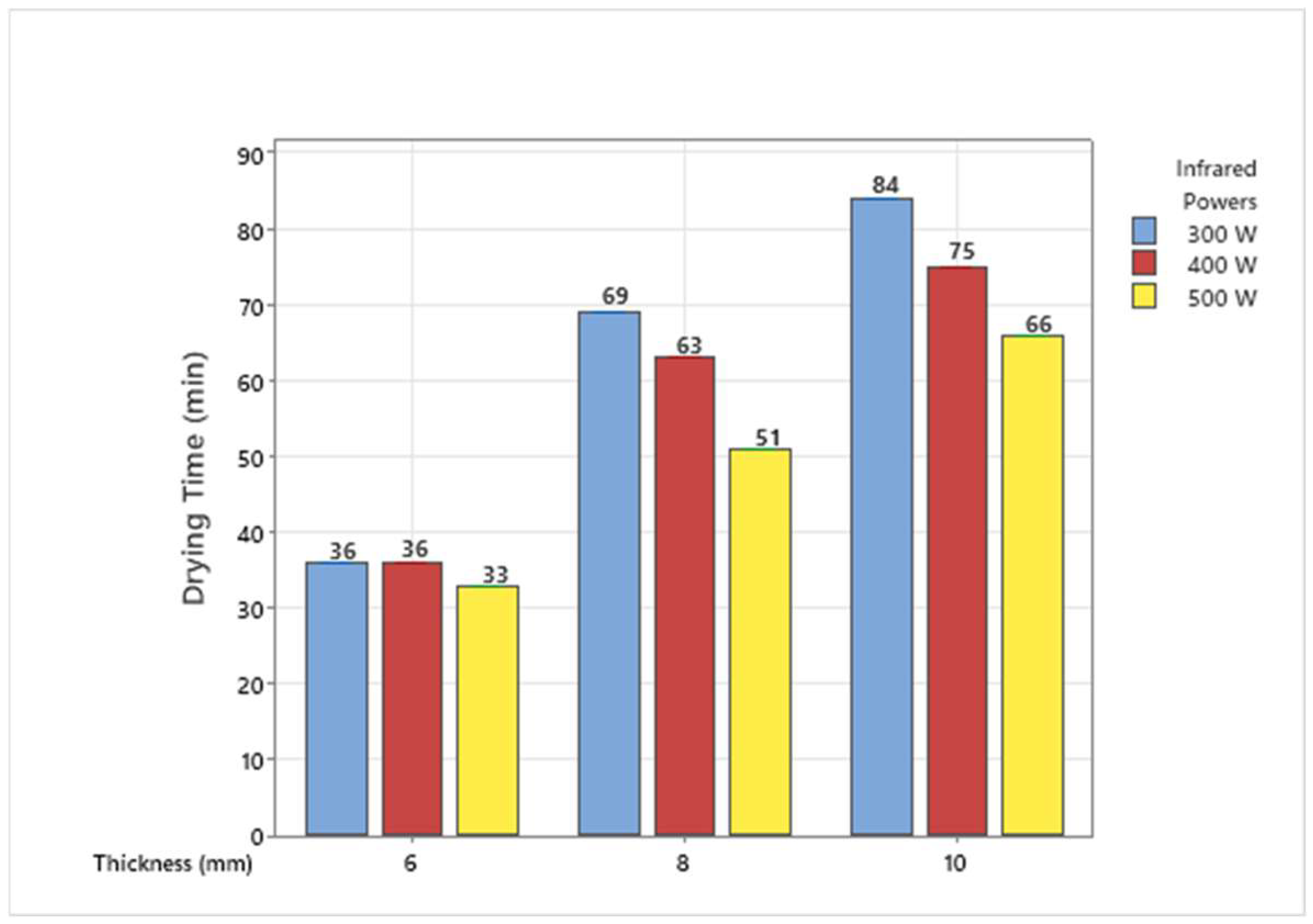

3.1. Changes in Drying Time

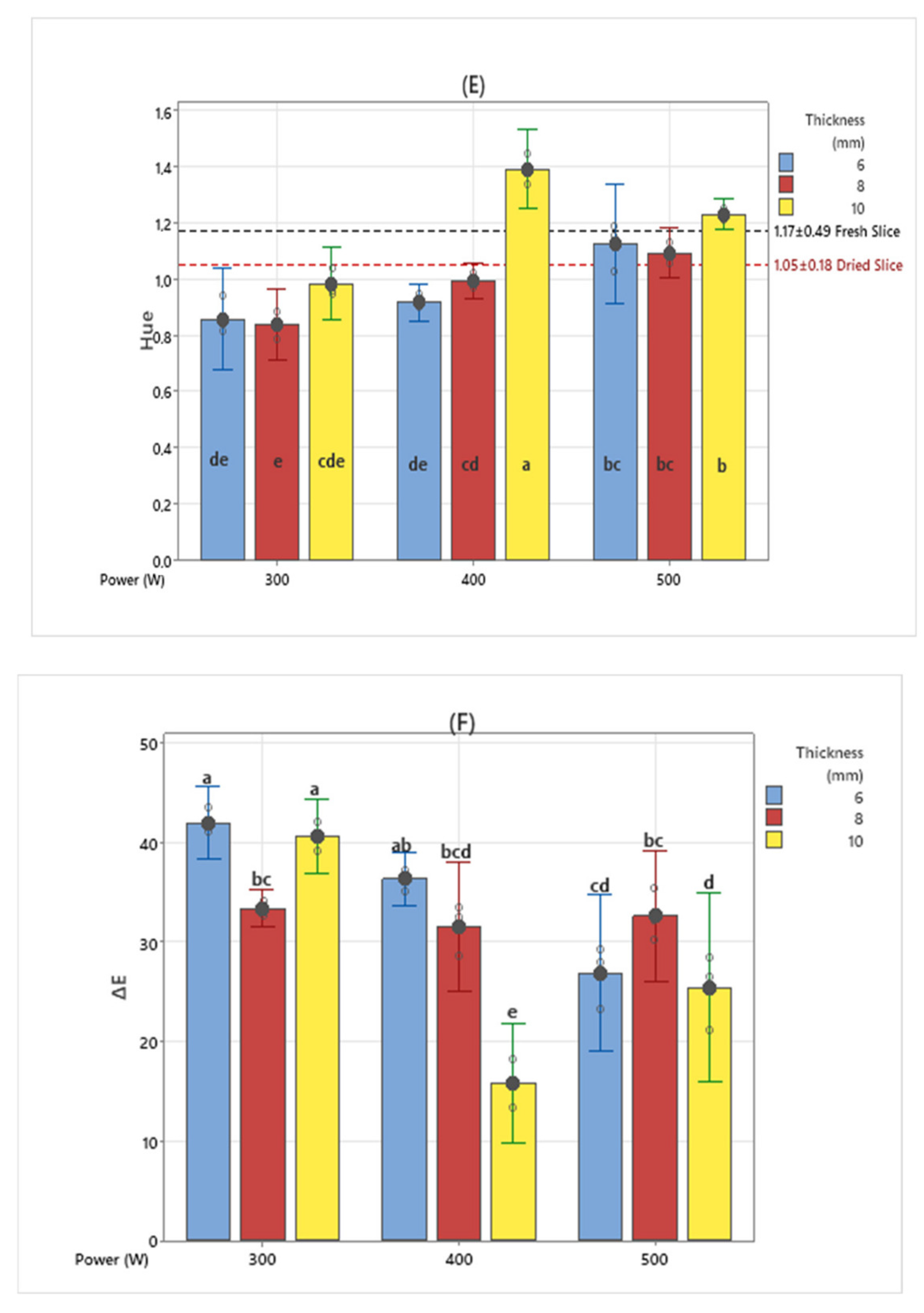

3.2. Color

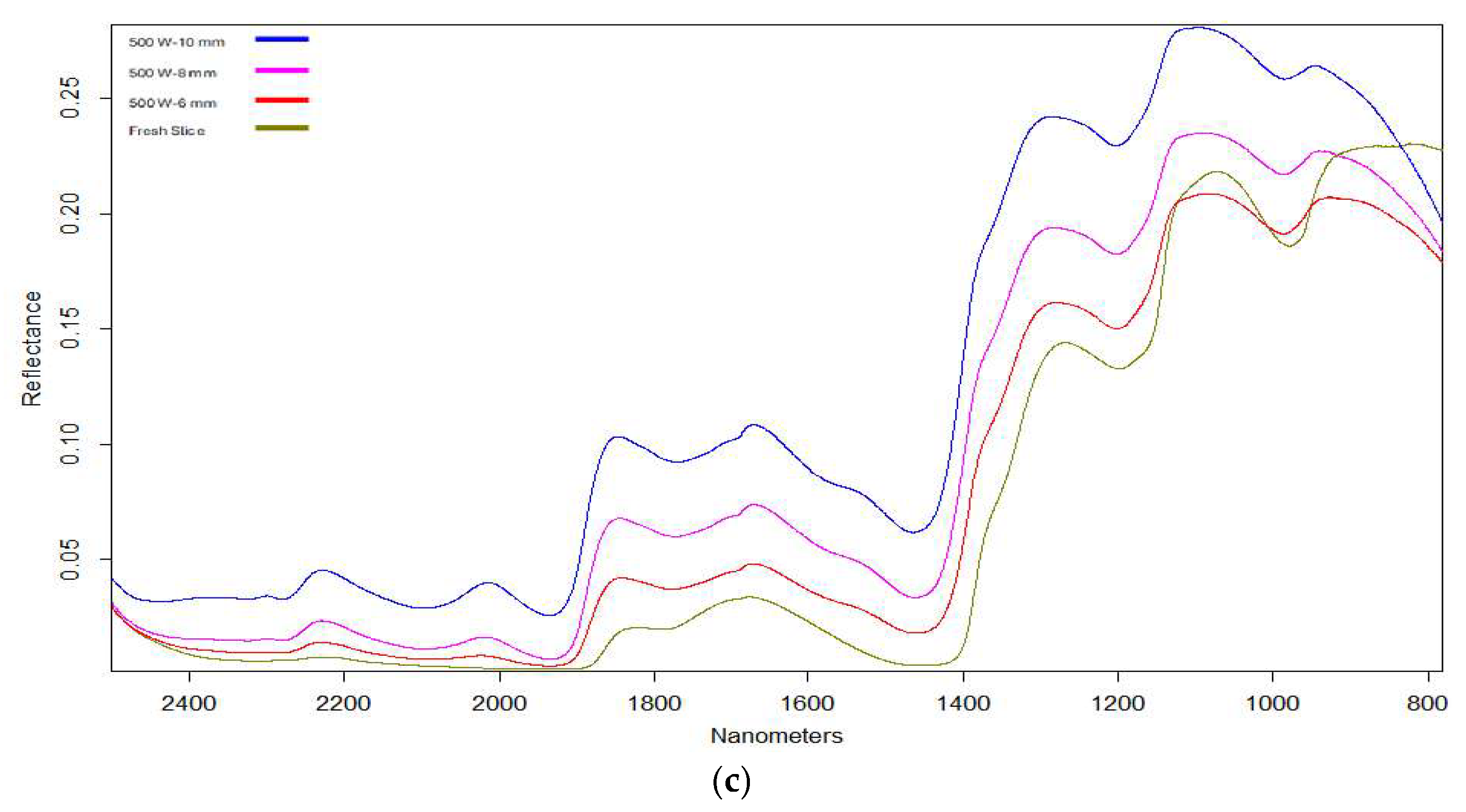

3.3. FT-NIR Spectra Features

3.4. Microstructure Features

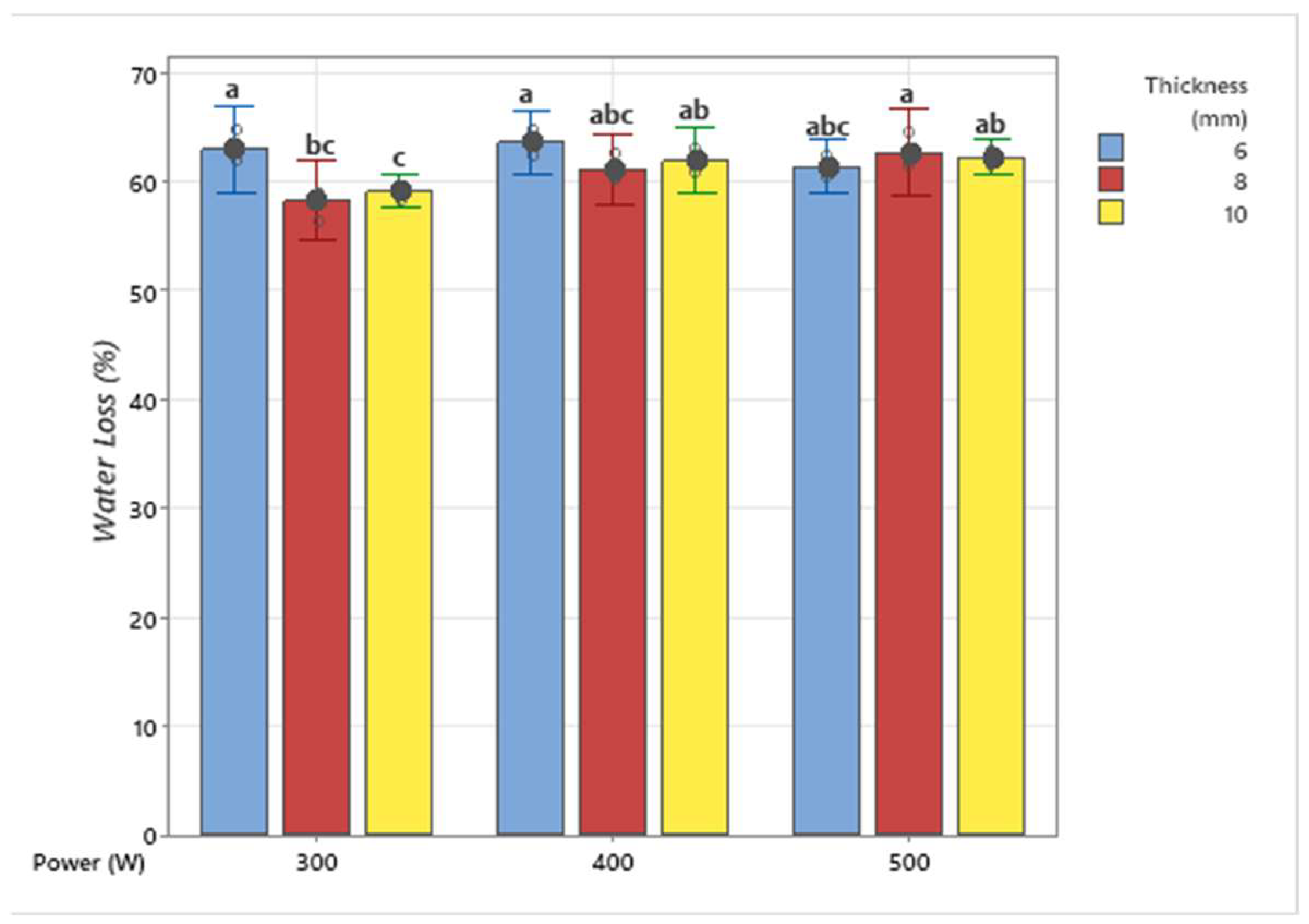

3.5. Water Loss and Shrinkage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atmaca, M.; Büyükcan, M.B. Kurutulmuş Muz Dilimlerinin Bazı Fiziksel ve Yapısal Kalite Karakteristiklerinin Belirlenmesi. ÇOMÜ Ziraat Fakültesi Derg. 2022, 10, 29–36. [Google Scholar] [CrossRef]

- Martínez, S.; Roman-Chipantiza, A.; Boubertakh, A.; Carballo, J. Banana Drying: A Review on Methods and Advances. Food Rev. Int. 2024, 40, 2188–2226. [Google Scholar] [CrossRef]

- Singh, R.; Gosewade, S.; Ravinder Singh, C.; Kaushik, R. Bananas as Underutilized Fruit Having Huge Potential as Raw Materials for Food and Non-Food Processing Industries: A Brief Review. Pharma Innov. J. 2018, 7, 574–580. [Google Scholar]

- Pu, Y.Y.; Zhao, M.; O’Donnell, C.; Sun, D.W. Nondestructive Quality Evaluation of Banana Slices during Microwave Vacuum Drying Using Spectral and Imaging Techniques. Dry. Technol. 2018, 36, 1542–1553. [Google Scholar] [CrossRef]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel Drying Techniques for the Food Industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Obajemihi, O.I.; Cheng, J.H.; Sun, D.W. Novel Sequential and Simultaneous Infrared-Accelerated Drying Technologies for the Food Industry: Principles, Applications and Challenges. Crit. Rev. Food Sci. Nutr. 2023, 63, 1465–1482. [Google Scholar] [CrossRef]

- Thuwapanichayanan, R.; Prachayawarakorn, S.; Kunwisawa, J.; Soponronnarit, S. Determination of Effective Moisture Diffusivity and Assessment of Quality Attributes of Banana Slices during Drying. LWT 2011, 44, 1502–1510. [Google Scholar] [CrossRef]

- Sabzevari, M.; Behroozi-Khazaei, N.; Darvishi, H. Real-Time Evaluation of Artificial Neural Network-Developed Model of Banana Slice Kinetics in Microwave-Hot Air Dryer. J. Food Process Eng. 2021, 44, e13796. [Google Scholar] [CrossRef]

- Sakare, P.; Prasad, N.; Thombare, N.; Singh, R.; Sharma, S.C. Infrared Drying of Food Materials: Recent Advances. Food Eng. Rev. 2020, 12, 381–398. [Google Scholar] [CrossRef]

- Sarsavadia, P.N.; Sawhney, R.L.; Pangavhane, D.R.; Singh, S.P. Drying Behaviour of Brined Onion Slices. J. Food Eng. 1999, 40, 219–226. [Google Scholar] [CrossRef]

- Abano, E.E.; Ma, H.; Qu, W. Influence of Air Temperature on the Drying Kinetics and Quality of Tomato Slices. J. Food Process Technol. 2011, 2, 123. [Google Scholar] [CrossRef]

- Yadollahinia, A.; Jahangiri, M. Shrinkage of Potato Slice during Drying. J. Food Eng. 2009, 94, 52–58. [Google Scholar] [CrossRef]

- Nowak, D.; Lewicki, P.P. Infrared Drying of Apple Slices. Innov. Food Sci. Emerg. Technol. 2004, 5, 353–360. [Google Scholar] [CrossRef]

- Akoy, E.O.M. Experimental Characterization and Modeling of Thin-Layer Drying of Mango Slices. Int. Food Res. J. 2014, 21, 1911–1917. [Google Scholar]

- Seremet, L.; Botez, E.; Nistor, O.V.; Andronoiu, D.G.; Mocanu, G.D. Effect of Different Drying Methods on Moisture Ratio and Rehydration of Pumpkin Slices. Food Chem. 2016, 195, 104–109. [Google Scholar] [CrossRef]

- Kocabiyik, H.; Tezer, D. Drying of Carrot Slices Using Infrared Radiation. Int. J. Food Sci. Technol. 2009, 44, 953–959. [Google Scholar] [CrossRef]

- Tao, T.; Wang, Y.; Gao, J.; Yan, W.; Liu, Q.; Zhang, Z.; Ding, C. Impact of Infrared Heating on Drying Properties and Flavor Components of Carmine Radish (Raphanus sativus L.). Slices. Food Bioeng. 2023, 2, 164–174. [Google Scholar] [CrossRef]

- Huang, D.; Yang, P.; Tang, X.; Luo, L.; Sunden, B. Application of Infrared Radiation in the Drying of Food Products. Trends Food Sci. Technol. 2021, 110, 765–777. [Google Scholar] [CrossRef]

- Pekke, M.A.; Pan, Z.L.; Atungulu, G.G.; Smith, G.; Thompson, J.F. Drying Characteristics and Quality of Bananas under Infrared Radiation Heating. Int. J. Agric. Biol. Eng. 2013, 6, 58–70. [Google Scholar] [CrossRef]

- Swasdisevi, T.; Devahastin, S.; Sa-Adchom, P.; Soponronnarit, S. Mathematical Modeling of Combined Far-Infrared and Vacuum Drying Banana Slice. J. Food Eng. 2009, 92, 100–106. [Google Scholar] [CrossRef]

- Shi, X.; Yang, Y.; Li, Z.; Wang, X.; Liu, Y. Moisture Transfer and Microstructure Change of Banana Slices during Contact Ultrasound Strengthened Far-Infrared Radiation Drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102537. [Google Scholar] [CrossRef]

- Kocabiyik, H.; Yilmaz, N.; Tuncel, N.B.; Sumer, S.K.; Buyukcan, M.B. Drying, Energy, and Some Physical and Nutritional Quality Properties of Tomatoes Dried with Short-Infrared Radiation. Food Bioprocess Tech. 2015, 8, 516–525. [Google Scholar] [CrossRef]

- Buyukcan, M.B.; Kavdir, I. Prediction of Some Internal Quality Parameters of Apricot Using FT-NIR Spectroscopy. J. Food Meas. Charact. 2017, 11, 651–659. [Google Scholar] [CrossRef]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Lu, L.; Tang, J.; Ran, X. Temperature and Moisture Changes during Microwave Drying of Sliced Food. Dry. Technol. 1999, 17, 414–431. [Google Scholar] [CrossRef]

- Swasdisevi, T.; Devahastin, S.; Ngamchum, R.; Soponronnarit, S. Optimization of a Drying Process Using Infrared-Vacuum Drying of Cavendish Banana Slices. Songklanakarin J. Sci. Technol. 2007, 29, 809–816. [Google Scholar]

- Tunckal, C.; Doymaz, İ. Performance Analysis and Mathematical Modelling of Banana Slices in a Heat Pump Drying System. Renew. Energy 2020, 150, 918–923. [Google Scholar] [CrossRef]

- Karabulut, I.; Topcu, A.; Duran, A.; Turan, S.; Ozturk, B. Effect of Hot Air Drying and Sun Drying on Color Values and β-Carotene Content of Apricot (Prunus armenica L.). LWT—Food Sci. Technol. 2007, 40, 753–758. [Google Scholar] [CrossRef]

- Nagvanshi, S.; Goswami, T.K. Development of a System to Measure Color in Fresh and Microwave Dried Banana Slices. J. Food Sci. Technol. 2021, 58, 1673–1681. [Google Scholar] [CrossRef]

- Cevoli, C.; Iaccheri, E.; Fabbri, A.; Ragni, L. Data Fusion of FT-NIR Spectroscopy and Vis/NIR Hyperspectral Imaging to Predict Quality Parameters of Yellow Flesh “Jintao” Kiwifruit. Biosyst. Eng. 2024, 237, 157–169. [Google Scholar] [CrossRef]

- Rambo, M.K.D.; Amorim, E.P.; Ferreira, M.M.C. Potential of Visible-near Infrared Spectroscopy Combined with Chemometrics for Analysis of Some Constituents of Coffee and Banana Residues. Anal. Chim. Acta 2013, 775, 41–49. [Google Scholar] [CrossRef]

- Arendse, E.; Fawole, O.A.; Magwaza, L.S.; Nieuwoudt, H.; Opara, U.L. Evaluation of Biochemical Markers Associated with the Development of Husk Scald and the Use of Diffuse Reflectance NIR Spectroscopy to Predict Husk Scald in Pomegranate Fruit. Sci. Hortic. 2018, 232, 240–249. [Google Scholar] [CrossRef]

- El Hosry, L.; Elias, V.; Chamoun, V.; Halawi, M.; Cayot, P.; Nehme, A.; Bou-Maroun, E. Maillard Reaction: Mechanism, Influencing Parameters, Advantages, Disadvantages, and Food Industrial Applications: A Review. Foods 2025, 14, 1881. [Google Scholar] [CrossRef] [PubMed]

- Hemmler, D.; Roullier-Gall, C.; Marshall, J.W.; Rychlik, M.; Taylor, A.J.; Schmitt-Kopplin, P. Evolution of Complex Maillard Chemical Reactions, Resolved in Time. Sci. Rep. 2017, 7, 3227. [Google Scholar] [CrossRef] [PubMed]

- Starowicz, M.; Zieliński, H. How Maillard Reaction Influences Sensorial Properties (Color, Flavor and Texture) of Food Products? Food Rev. Int. 2019, 35, 707–725. [Google Scholar] [CrossRef]

- Jafary, S.U.H.; Ahmad, R.S.; Hussain, M.B.; Ur Rehman, T.; Majeed, M.; Khan, M.U.; Shariati, M.A. Investigation of Changes in Antioxidant Activities of Caramelization Products Under Various Time Regimes and Ph Ranges. Carpathian J. Food Sci. Technol. 2018, 10, 116–128. [Google Scholar]

- Ajandouz, E.H.; Tchiakpe, L.S.; Dalle Ore, F.; Benajiba, A.; Puigserver, A. Effects of PH on Caramelization and Maillard Reaction Kinetics in Fructose-Lysine Model Systems. J. Food Sci. 2001, 66, 926–931. [Google Scholar] [CrossRef]

- Sarpong, F.; Yu, X.; Zhou, C.; Oteng-Darko, P.; Amenorfe, L.P.; Wu, B.; Bai, J.; Ma, H. Drying Characteristic, Enzyme Inactivation and Browning Pigmentation Kinetics of Controlled Humidity-Convective Drying of Banana Slices. Heat. Mass. Transf./Waerme-Und Stoffuebertragung 2018, 54, 3117–3130. [Google Scholar] [CrossRef]

- Siyum, Z.H.; Pham, T.T.; Vozáry, E.; Kaszab, T.; Nguyen, L.L.P.; Baranyai, L. Monitoring of Banana’s Optical Properties by Laser Light Backscattering Imaging Technique during Drying. J. Food Meas. Charact. 2023, 17, 5268–5287. [Google Scholar] [CrossRef]

- Kadam, D.M.; Dhingra, D. Mass Transfer Kinetics of Banana Slices during Osmo-Convective Drying. J. Food Process Eng. 2011, 34, 511–532. [Google Scholar] [CrossRef]

- Alaei, B.; Amiri Chayjan, R. Drying Characteristics of Pomegranate Arils Under Near Infrared-Vacuum Conditions. J. Food Process Preserv. 2015, 39, 469–479. [Google Scholar] [CrossRef]

- Salehi, F.; Kashaninejad, M. Modeling of Moisture Loss Kinetics and Color Changes in the Surface of Lemon Slice during the Combined Infrared-Vacuum Drying. Inf. Process. Agric. 2018, 5, 516–523. [Google Scholar] [CrossRef]

- Yagua, C.V.; Moreira, R.G. Physical and Thermal Properties of Potato Chips during Vacuum Frying. J. Food Eng. 2011, 104, 272–283. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Ariyapuchai, T.; Prasertsit, K. Effects of Vacuum Frying on Structural Changes of Bananas. J. Food Eng. 2011, 106, 298–305. [Google Scholar] [CrossRef]

| Weight (g) | Width (mm) | Diameter (mm) | ||||

|---|---|---|---|---|---|---|

| Wet | Dried | Wet | Dried | Wet | Dried | |

| n | 198 | 198 | 198 | 198 | 198 | 198 |

| Minimum | 2.57 | 0.83 | 27.17 | 21.40 | 17.29 | 13.26 |

| Maximum | 8.56 | 3.66 | 41.33 | 39.87 | 32.57 | 32.27 |

| Averages | 5.37 | 2.09 | 3.96 | 27.30 | 27.70 | 23.90 |

| Standard error | 1.49 | 0.68 | 2.78 | 2.56 | 2.57 | 2.76 |

| Infrared Powers | 6 mm | 8 mm | 10 mm | Average |

|---|---|---|---|---|

| 300 W | 0.5637 ± 0.0577 | 0.5759 ± 0.0200 | 0.6243 ± 0.0550 | 0.5880 ± 0.0496 B |

| 400 W | 0.6291 ± 0.0281 | 0.5894 ± 0.0611 | 0.6229 ± 0.0272 | 0.6138 ± 0.0407 AB |

| 500 W | 0.6596 ± 0.0787 | 0.6029 ± 0.0502 | 0.6976 ± 0.0248 | 0.6534 ± 0.0635 A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atmaca, M.; Büyükcan, M.B. Infrared Drying of Banana Slices: Quality Evaluation Using Spectral and Microstructural Analysis. Appl. Sci. 2025, 15, 9632. https://doi.org/10.3390/app15179632

Atmaca M, Büyükcan MB. Infrared Drying of Banana Slices: Quality Evaluation Using Spectral and Microstructural Analysis. Applied Sciences. 2025; 15(17):9632. https://doi.org/10.3390/app15179632

Chicago/Turabian StyleAtmaca, Melih, and Mehmet Burak Büyükcan. 2025. "Infrared Drying of Banana Slices: Quality Evaluation Using Spectral and Microstructural Analysis" Applied Sciences 15, no. 17: 9632. https://doi.org/10.3390/app15179632

APA StyleAtmaca, M., & Büyükcan, M. B. (2025). Infrared Drying of Banana Slices: Quality Evaluation Using Spectral and Microstructural Analysis. Applied Sciences, 15(17), 9632. https://doi.org/10.3390/app15179632