Analysis of Internal Explosion Vibration Characteristics of Explosion-Proof Equipment in Coal Mines Using Laser Doppler

Abstract

1. Introduction

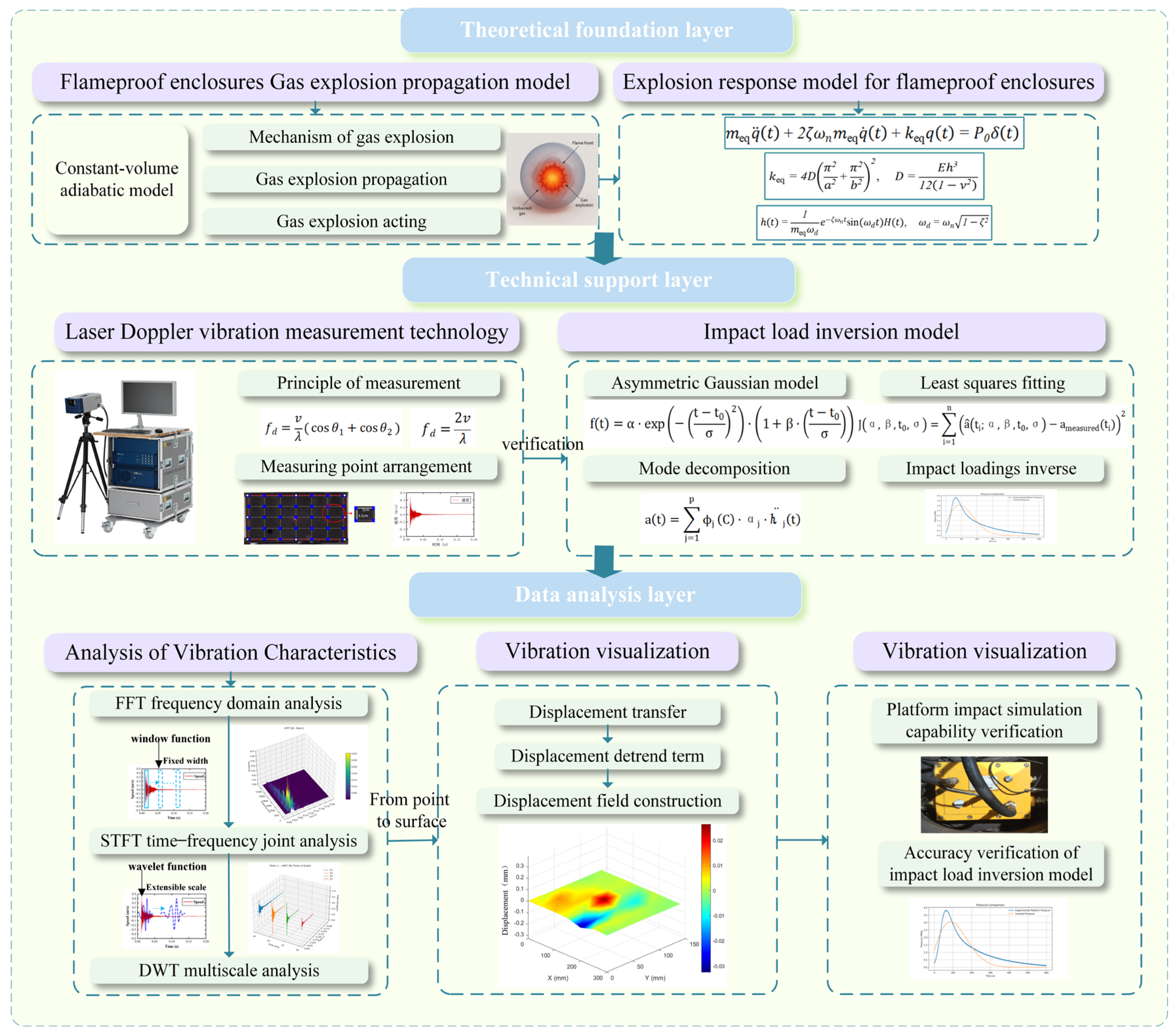

2. Principles of Measurement and Analysis of Vibration Characteristics of Coal Mine Flameproof Enclosures

3. Coal Mine Explosion-Prevention Equipment: Methane Explosion Transmission and Detonation Response Model

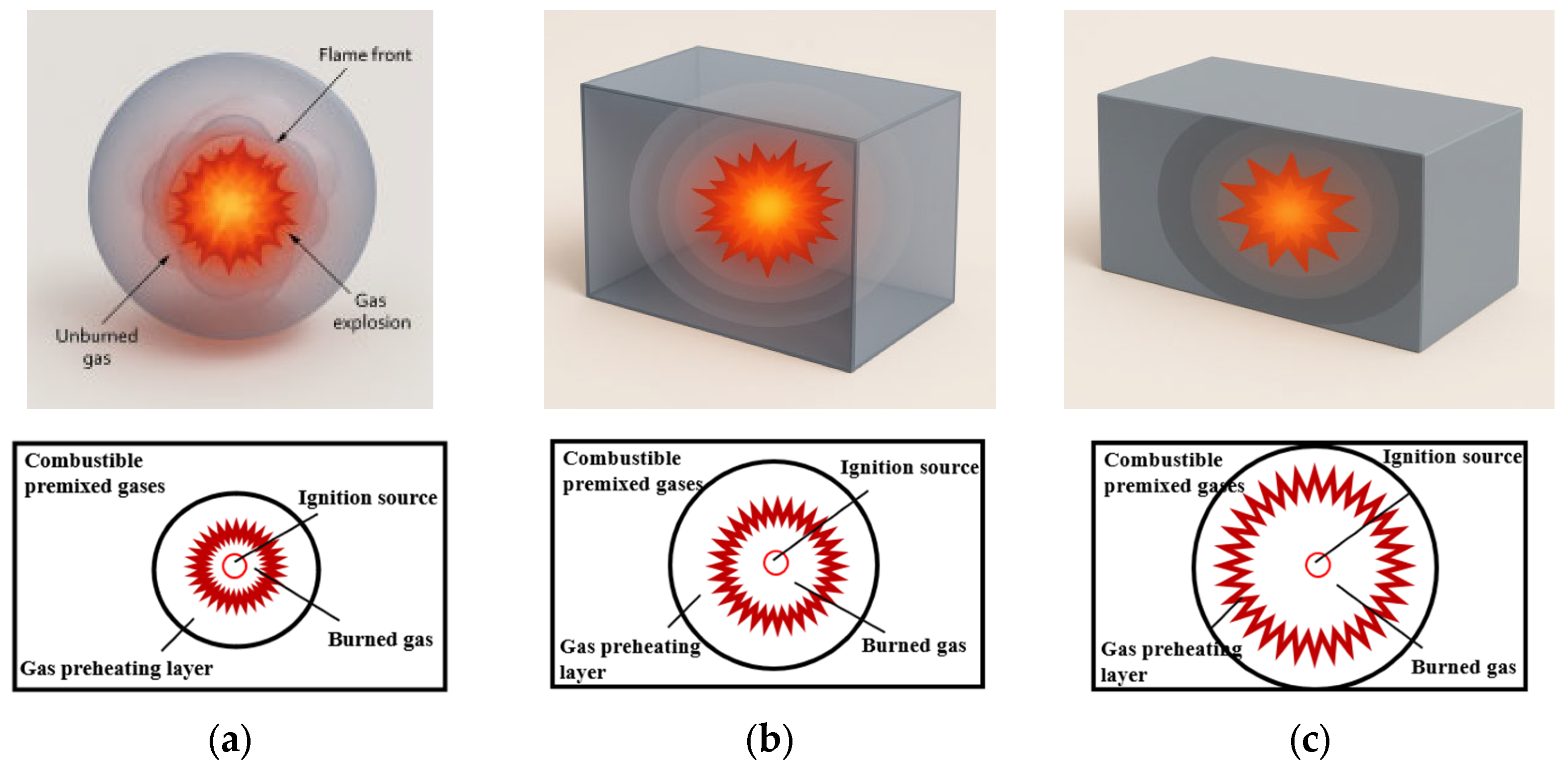

3.1. Gas Explosion Propagation Model

3.2. Detonation Transmission Response Model for Flameproof Enclosures

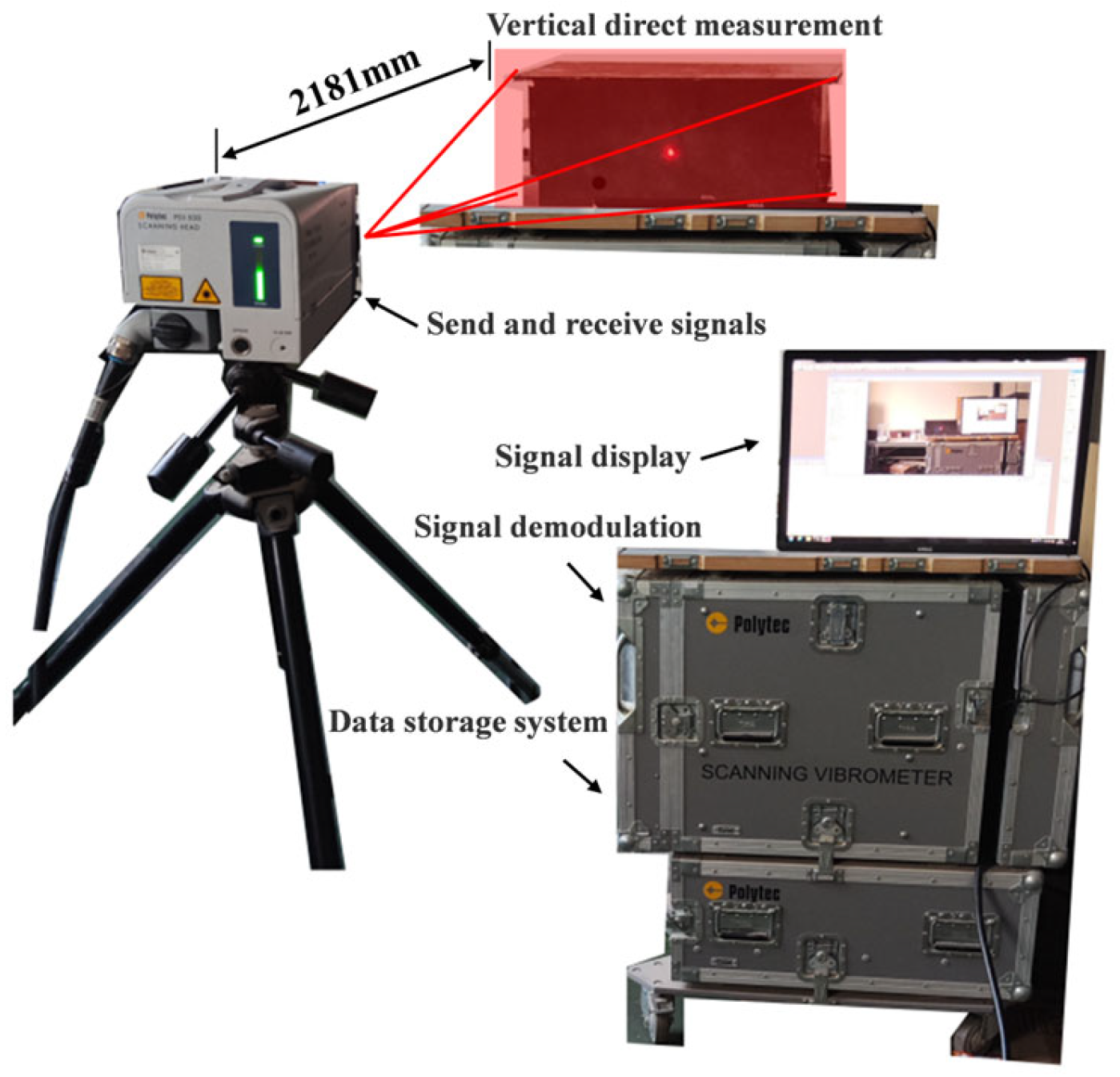

4. Principle of Explosion Shock Vibration Measurement Using Flameproof Enclosures with Laser Doppler

- (1)

- Direct measurement method

- (2)

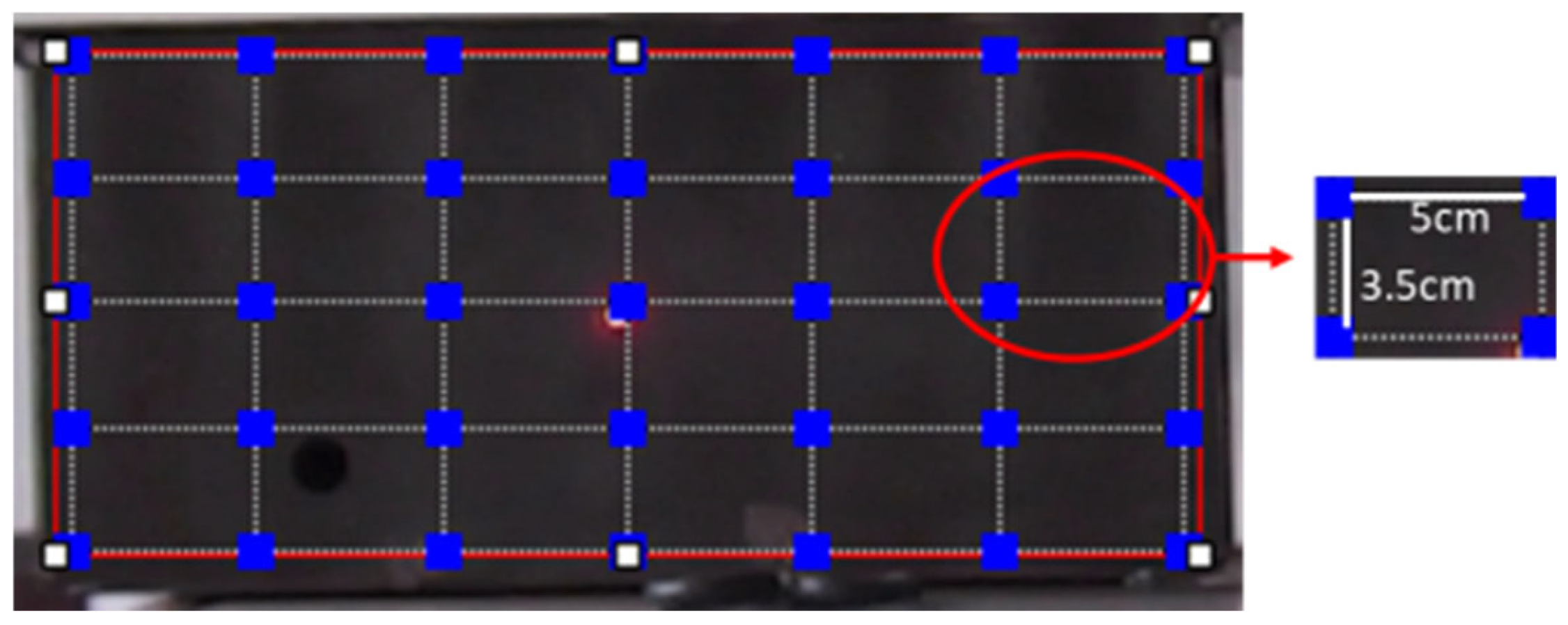

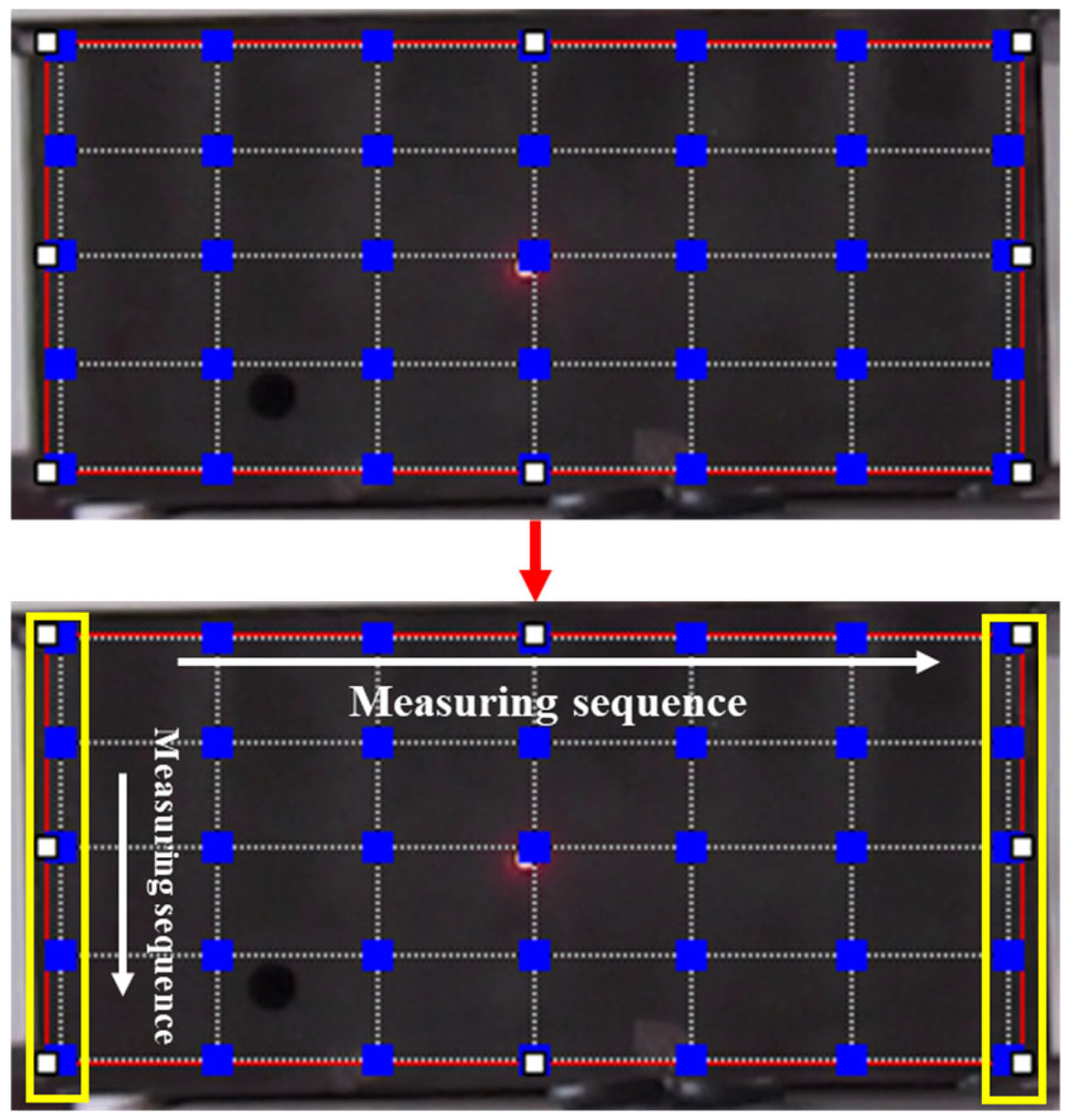

- Measurement point layout

5. Method for Analyzing Vibration Characteristics of Flameproof Enclosures

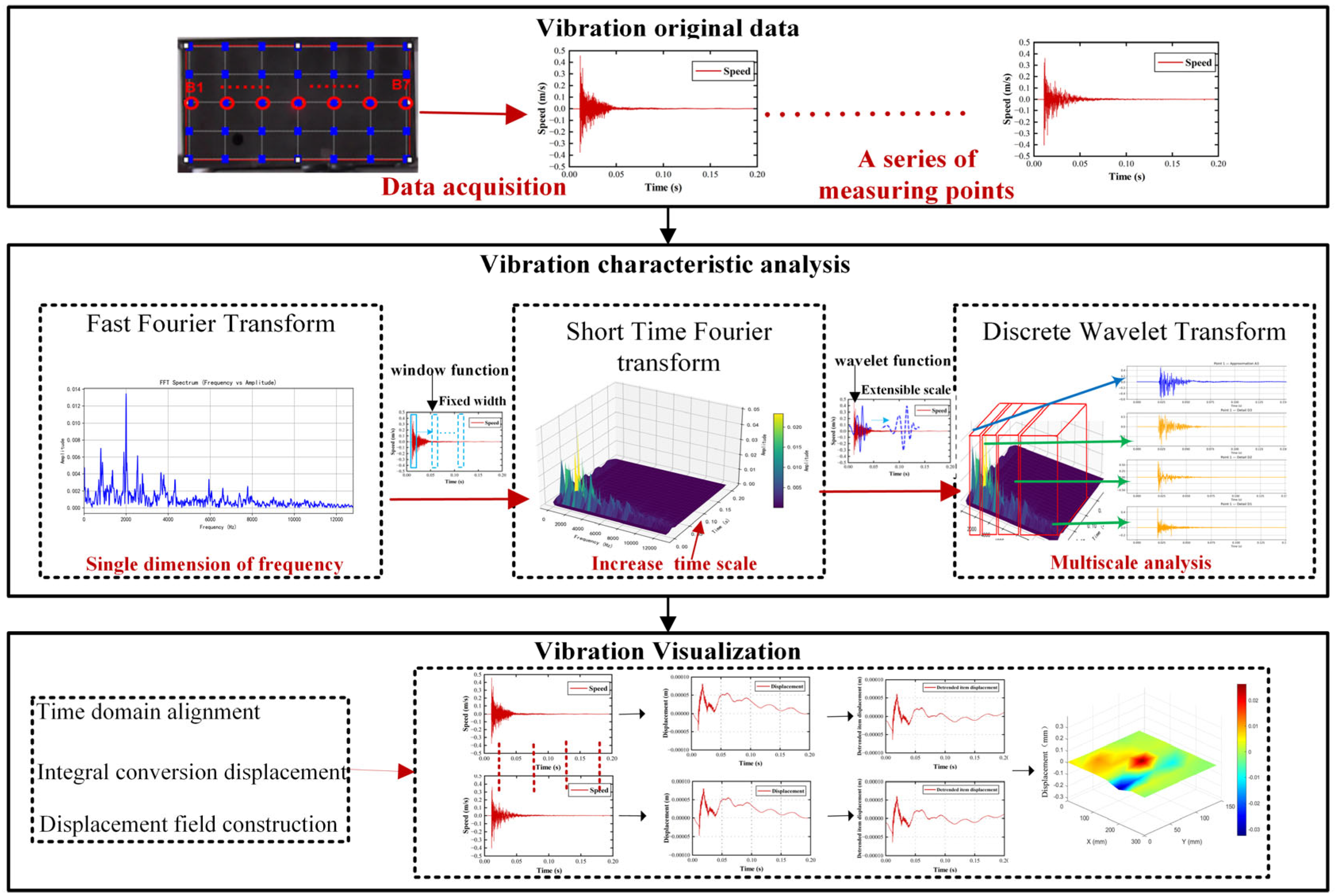

5.1. Time–Frequency Analysis Method for Vibration Characteristics of Flameproof Enclosures

- (1)

- Fourier transform method for analyzing vibration characteristics

- (2)

- Vibration characteristic analysis method of short-time Fourier transform

- (3)

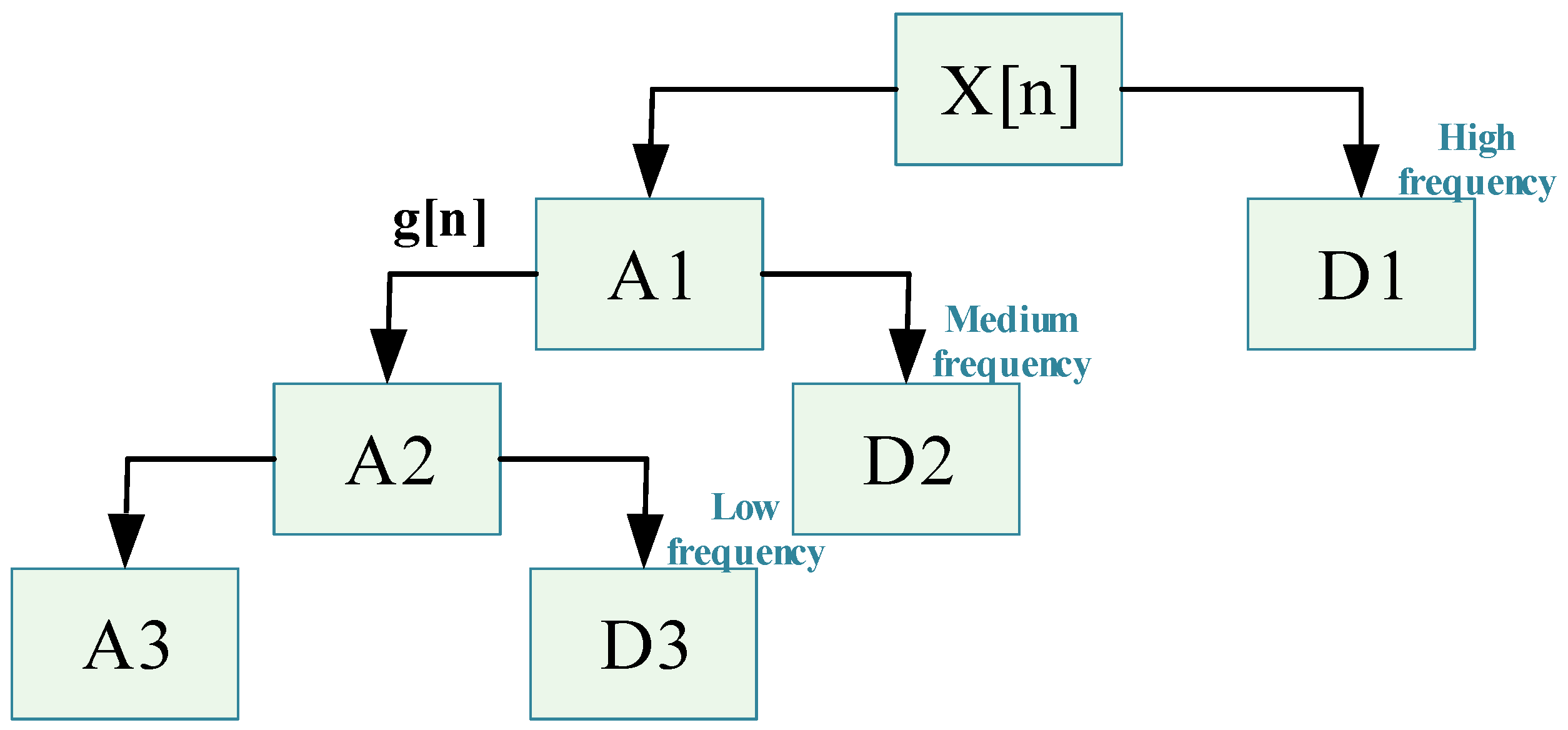

- Vibration characteristic analysis method of wavelet transform

5.2. Displacement Field Construction

6. Impact Load Inversion Model

7. Analysis

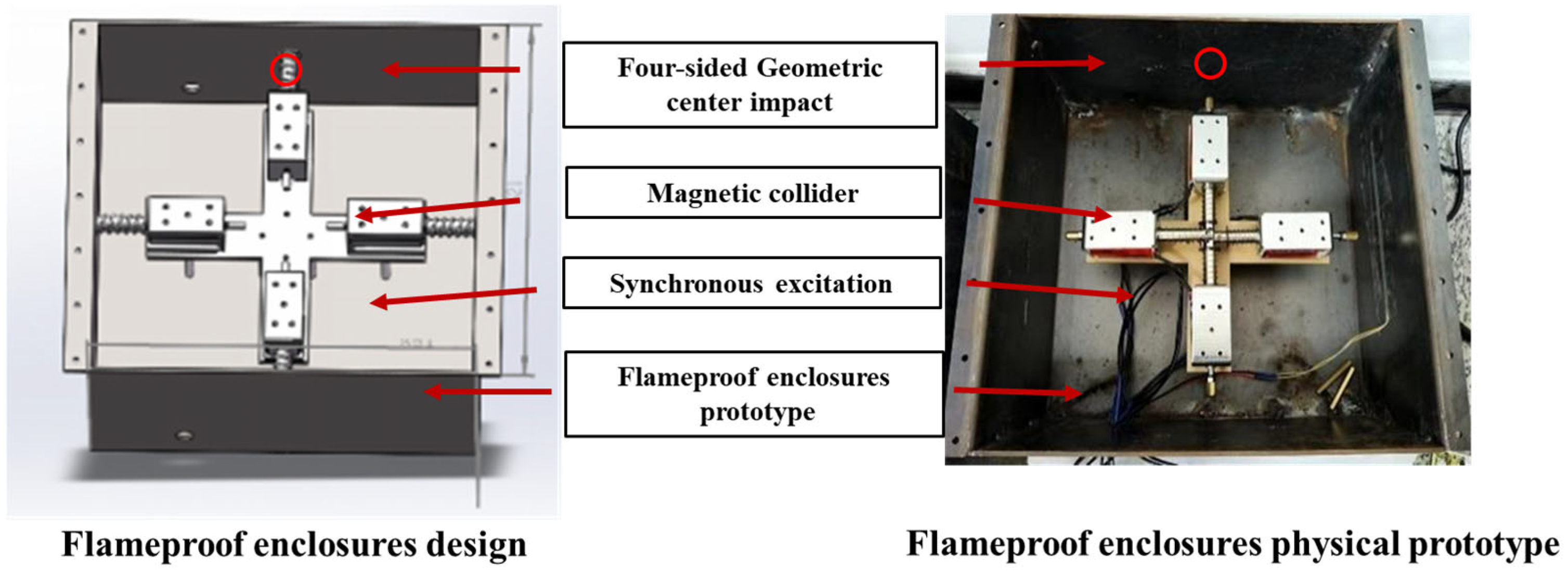

7.1. Experimental Design for Vibration Measurement of Flameproof Enclosures

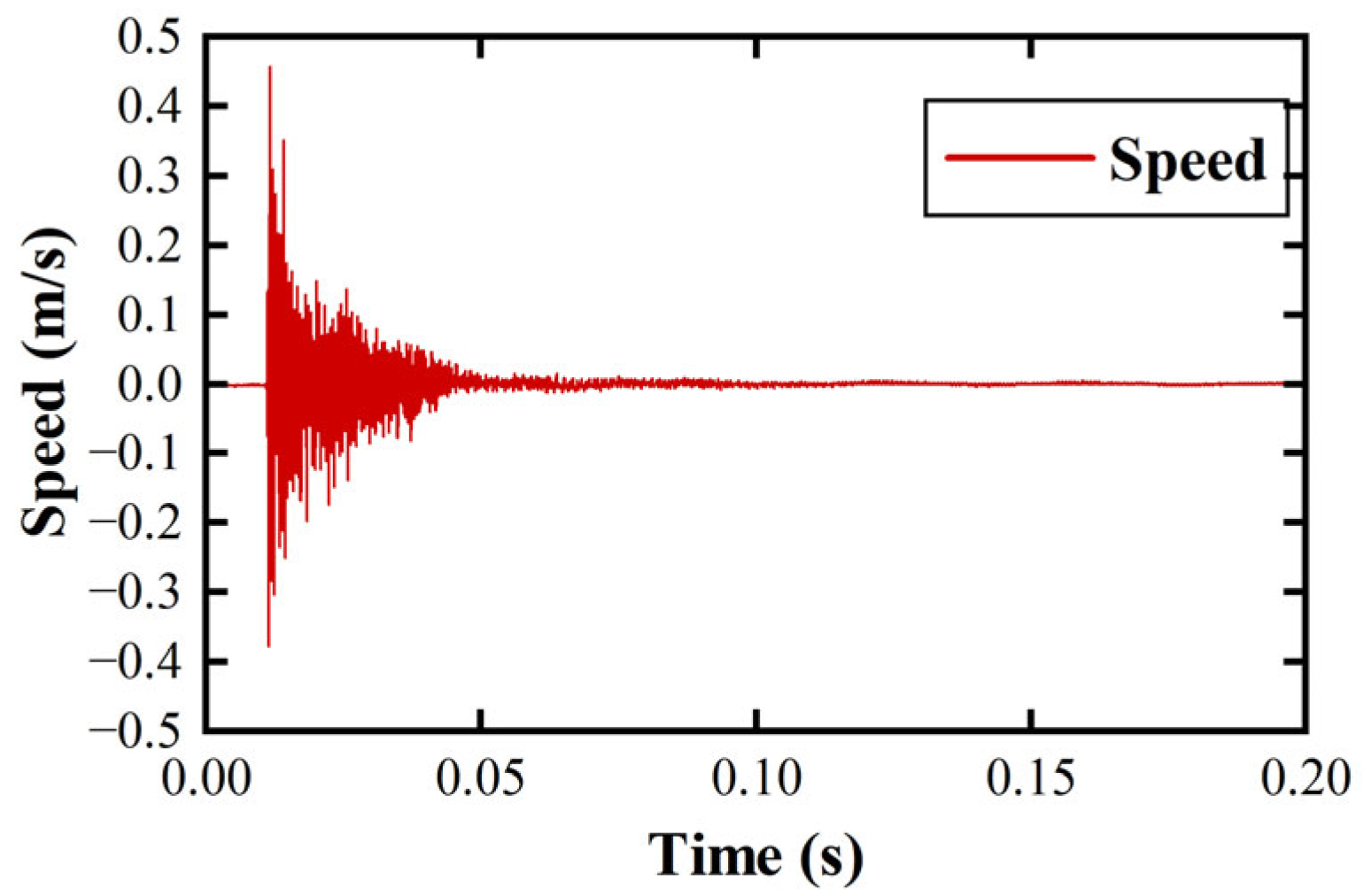

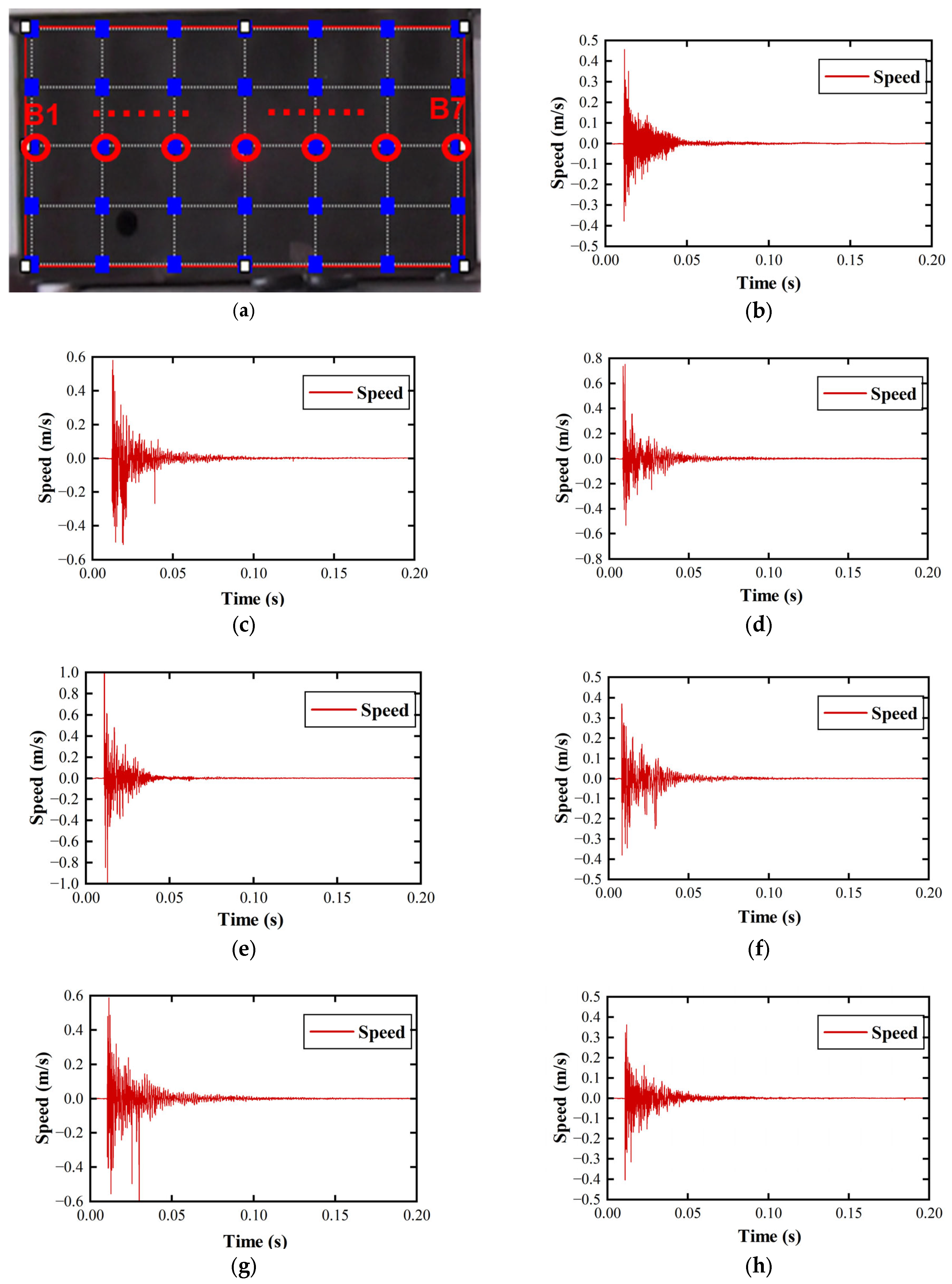

7.2. Vibration Characteristics Analysis of Flameproof Enclosures

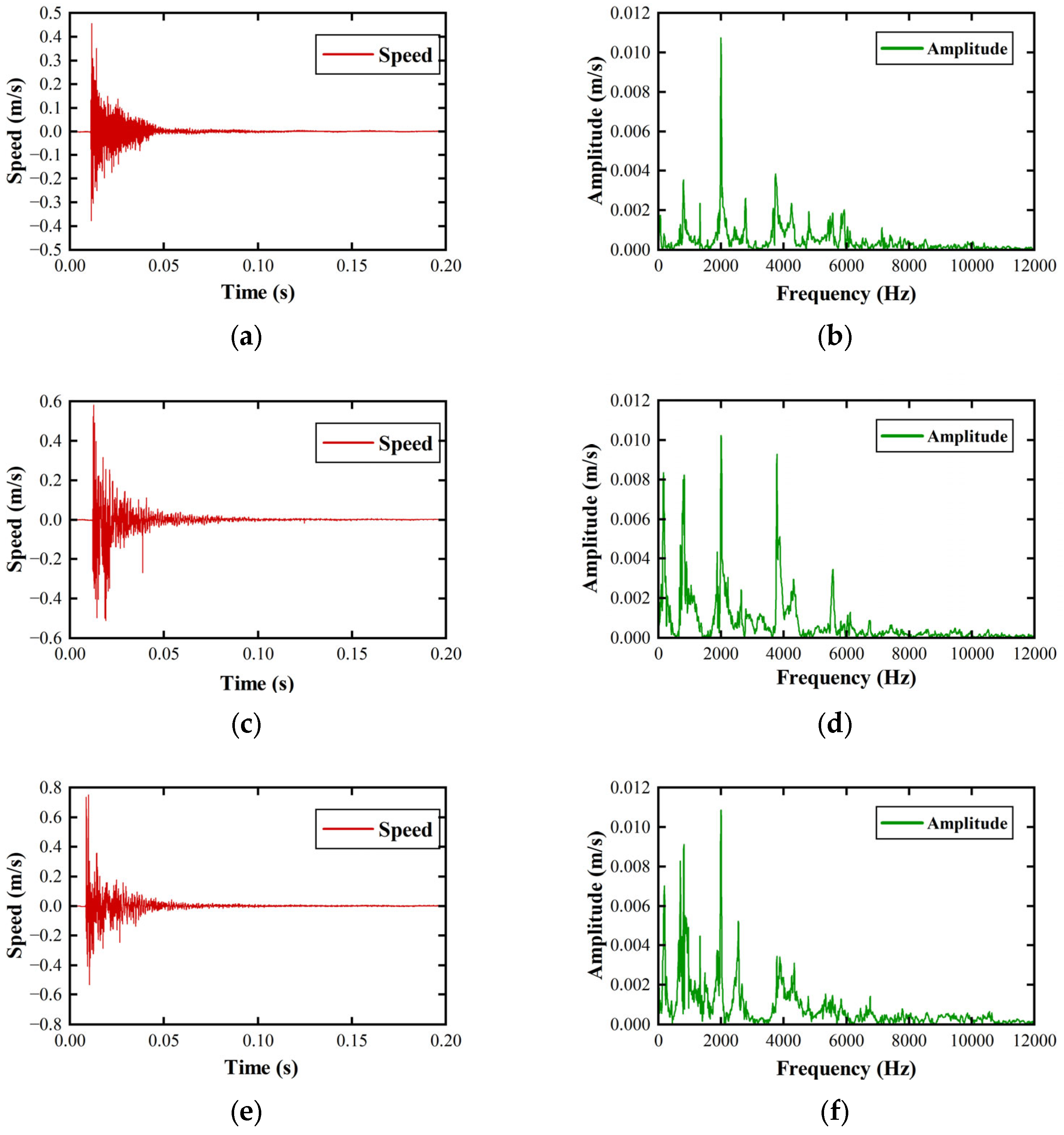

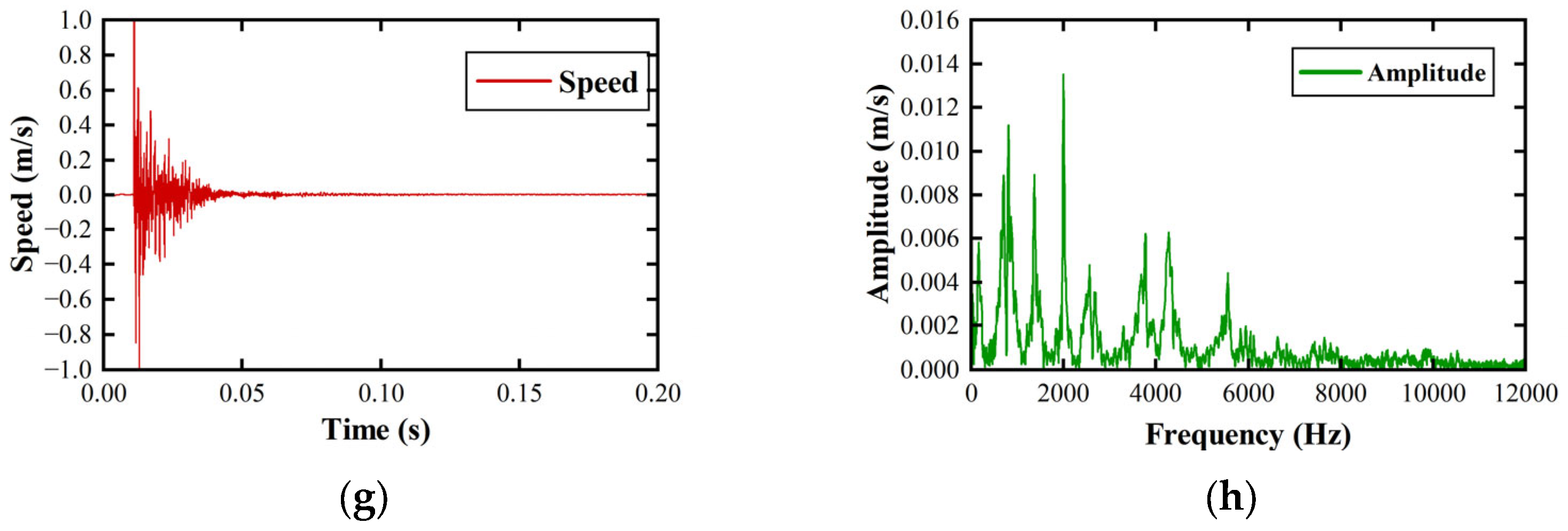

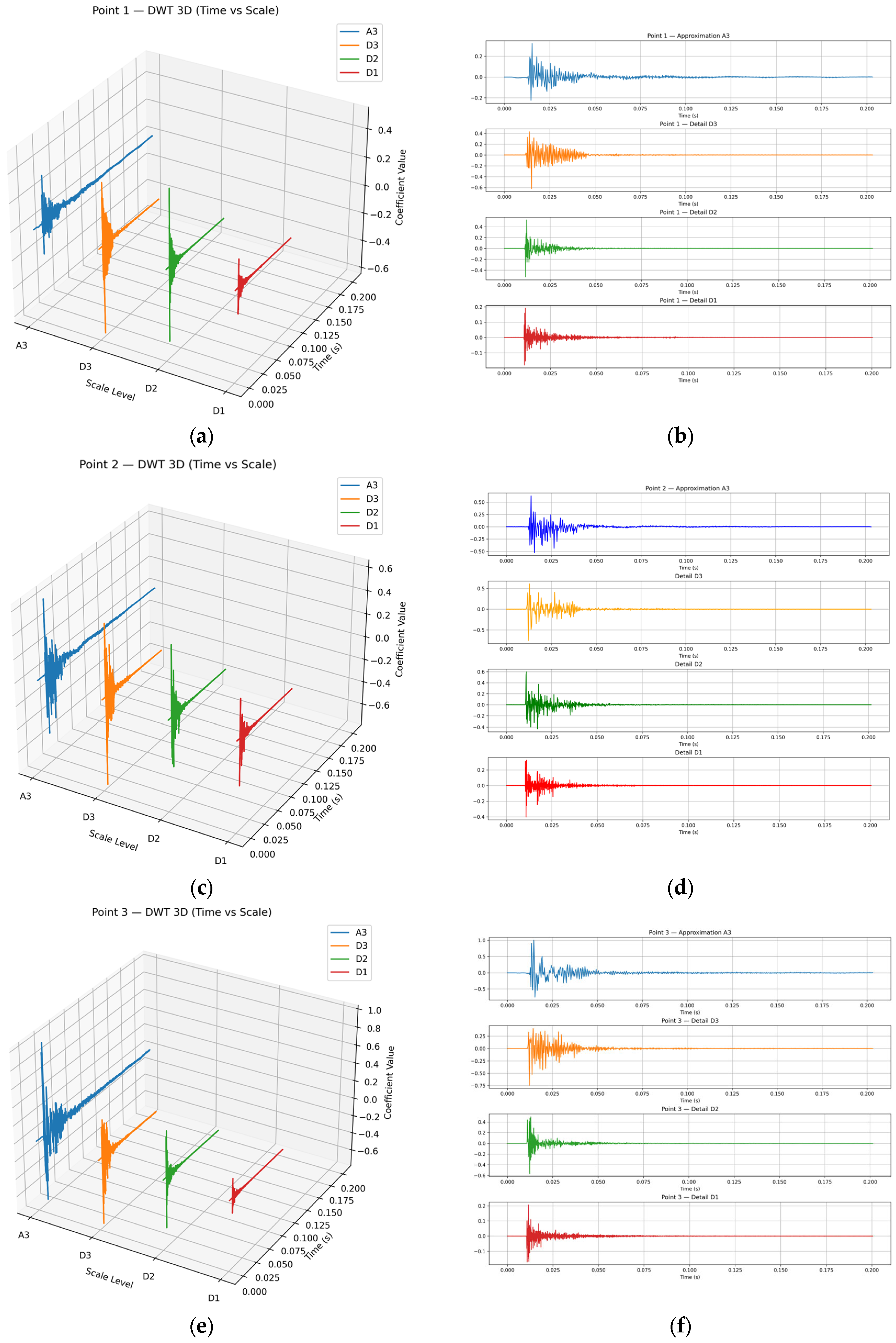

7.2.1. Time–Frequency Domain Analysis of Flameproof Enclosures Under Vibration

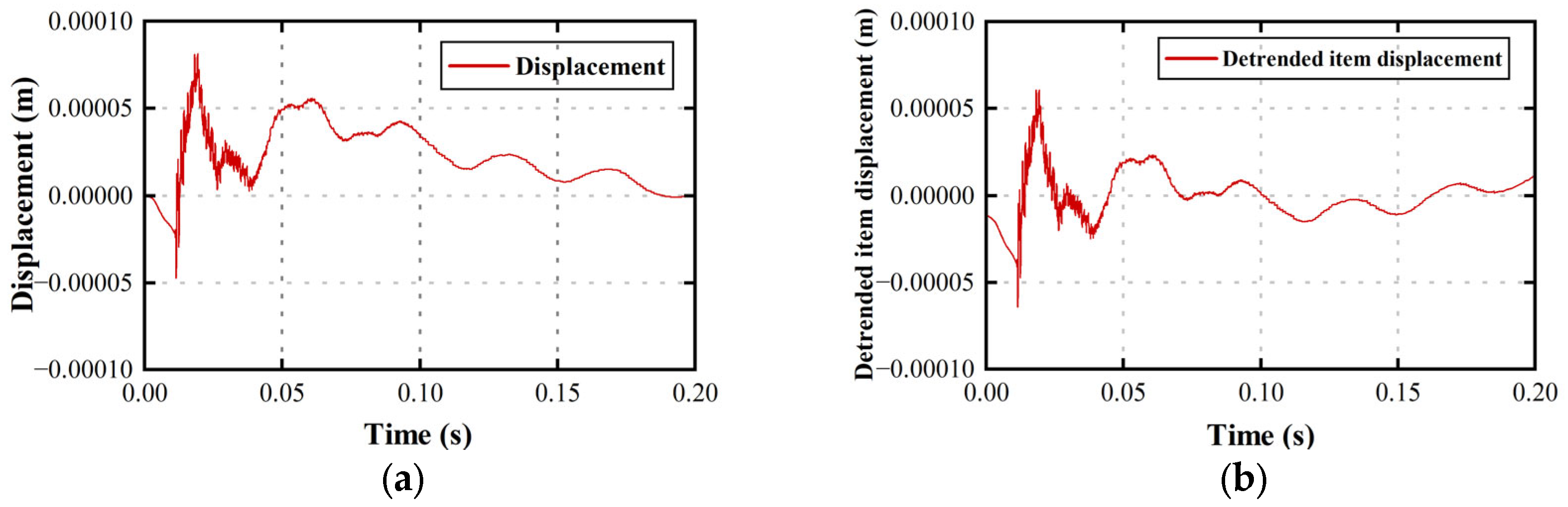

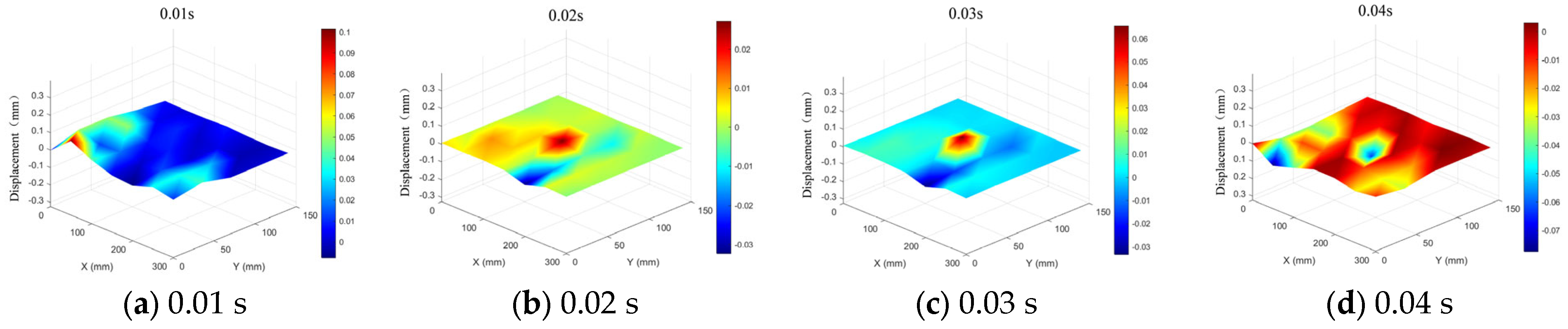

7.2.2. Visualization of Vibration in Flameproof Enclosures

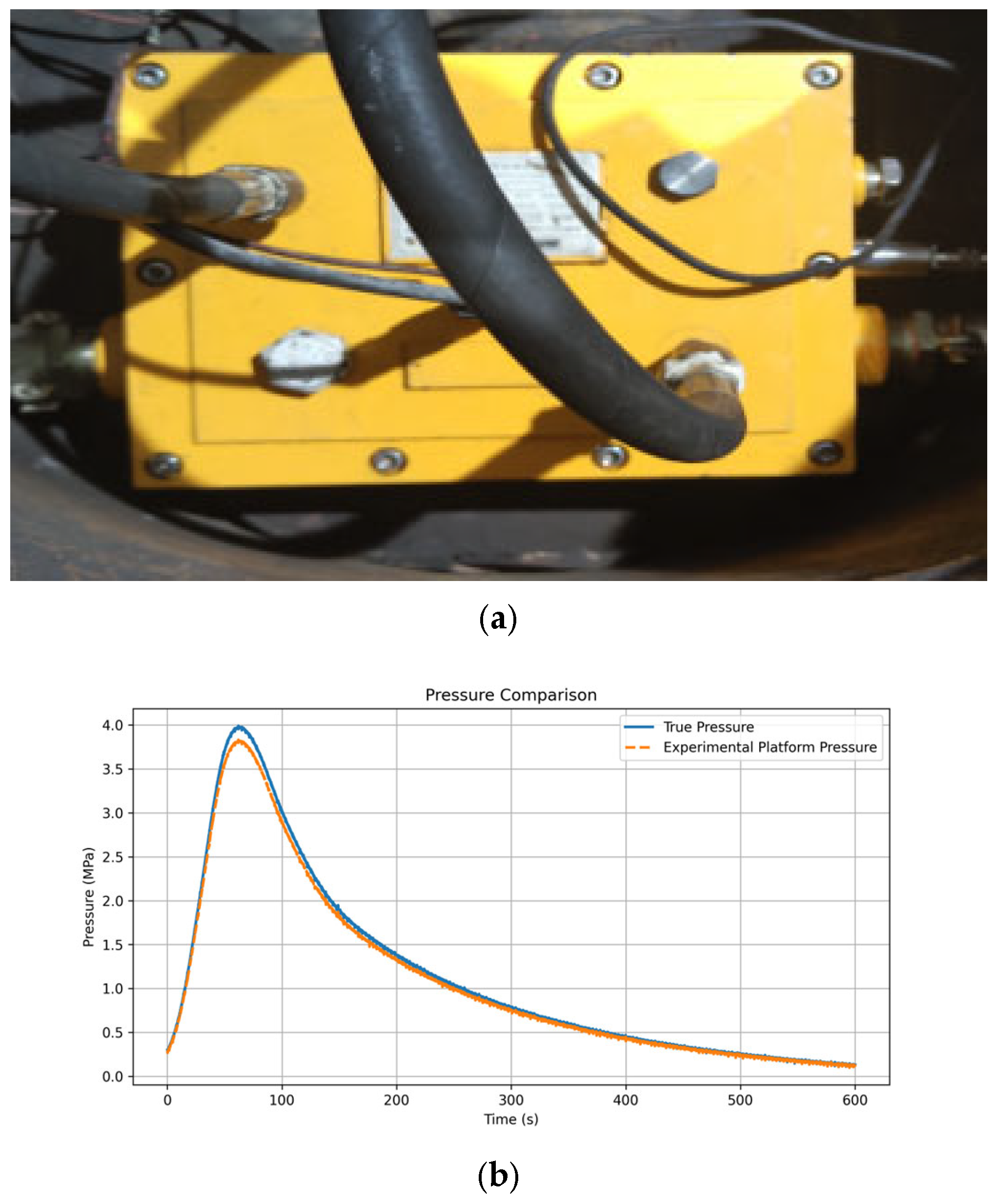

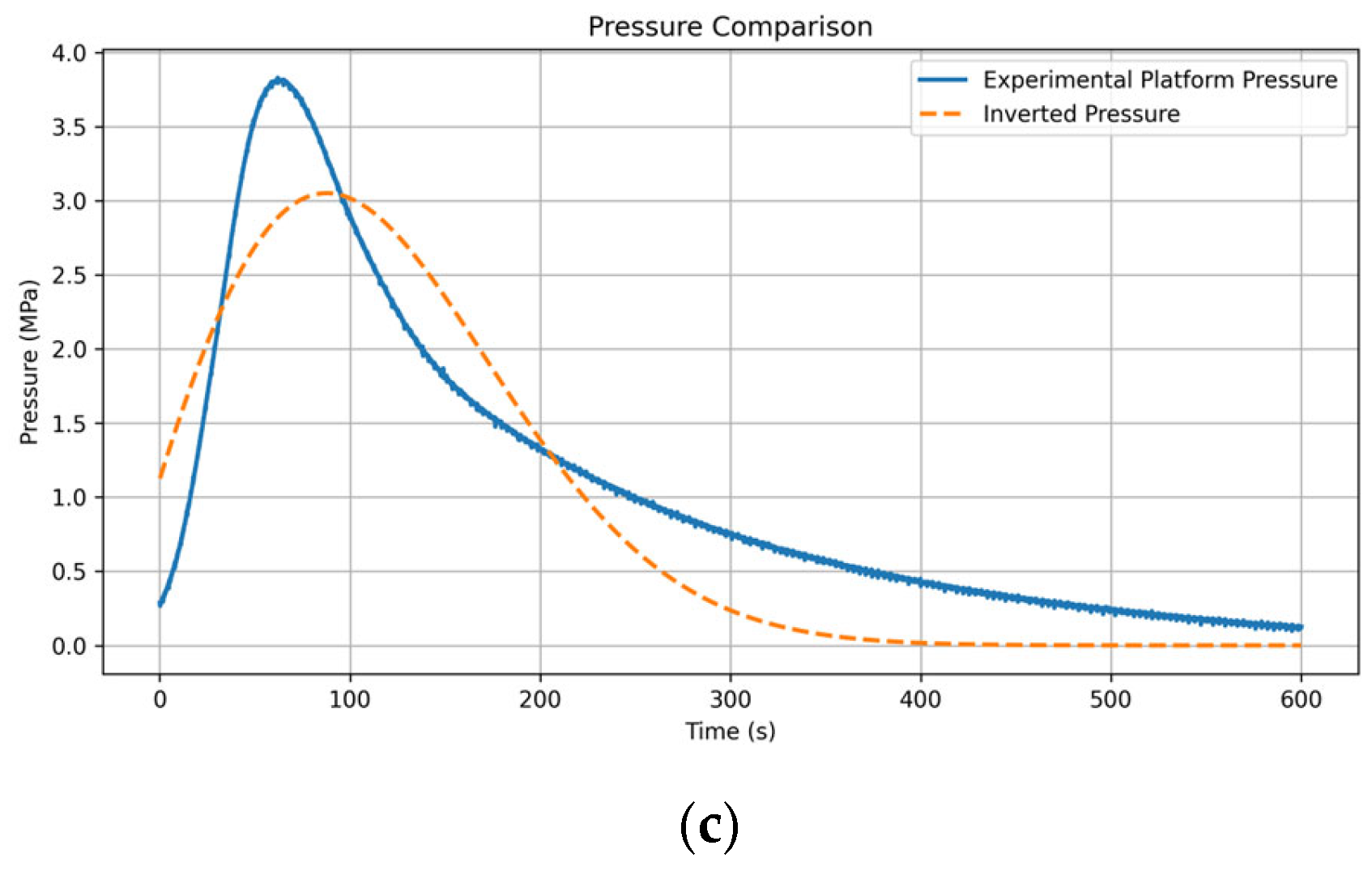

7.3. Impact Load Inversion Verification

- (1)

- Platform impact simulation capability verification

- (2)

- Verification of the accuracy of the impact load inversion model

8. Conclusions

- (1)

- A model for gas explosion propagation inside flameproof enclosures was established. The single pulse response function was improved by introducing the material and structural characteristics of flameproof enclosures, and a detonation transmission response model for flameproof enclosures was established, providing a theoretical basis for the propagation laws and detonation transmission characteristics of gas explosion shock waves in coal mine flameproof equipment.

- (2)

- Laser Doppler replaces traditional explosion test pressure measurement, using direct measurement and global measurement point layout to accurately capture the dynamic response of flameproof enclosures, solving the installation difficulties of traditional contact measurement.

- (3)

- FFT, STFT, and DWT were used to analyze the vibration characteristics of the surface of flameproof enclosures. The experimental results show that the FFT method can be used to obtain the global time-domain distribution of vibrations, while the STFT can be used to further analyze the changes in the main frequency and other significant frequencies over time. The DWT can be used to further analyze each frequency band’s amplitude to a specific time through multi-scale analysis, gradually revealing the vibration characteristics of flameproof enclosures in multiple dimensions and scales.

- (4)

- The measured values of the experimental platform and the actual explosion test impact pressure error index are both less than 5%, and the inversion load errors are all within 15%, which verifies the feasibility of the experimental platform, the accuracy of the model inversion, and the good substitutability of the laser Doppler measurement method.

- (5)

- Vibration analysis and comparison with traditional explosion test data solved the problem of traditional pressure measurement data being single and unable to characterize the dynamic response of the enclosure. The laser Doppler measurement method provided new technical support for measuring and analyzing flameproof enclosure failure modes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H. Laying a solid foundation and taking multiple measures to shape a new trend of safe development in mines. China Coal Ind. 2025, 56–57. [Google Scholar]

- Zhang, Y. Analysis of Explosion Pressure and Its Influencing Factors of Flameproof Shell. Colliery Mech. Electr. Technol. 2023, 44, 67–70. [Google Scholar]

- Chen, F. Influence Factors of Reference Pressure Measurement in Pressure Test of Flameproof Shell. Saf. Coal Mines 2019, 232–234. [Google Scholar] [CrossRef]

- Deffet, L.; Brinkley, S.R.; Laderman, A.J.; Urtiew, P.A.; Oppenheim, A.K. On the Generation of a Shock Wave by Flame in an Explosive Gas. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1963; pp. 265–274. [Google Scholar]

- Kundu, S.; Zanganeh, J.; Moghtaderi, B. A review on understanding explosions from methane–air mixture. J. Loss Prev. Process Ind. 2016, 40, 507–523. [Google Scholar] [CrossRef]

- Ogle, R.A. Explosion hazard analysis for an enclosure partially filled with a flammable gas. Process Saf. Prog. 1999, 18, 170–177. [Google Scholar] [CrossRef]

- Ma, H.; Long, Y.; Li, X.; Zhong, M.; Wu, J.; Zhou, Y. Study on Vibration Characteristics of Natural Gas Pipeline Explosion Based on Improved MP-WVD Algorithm. Shock. Vib. 2018, 2018, 8969675. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, L.; Luo, H.; Fen, W.; Tian, F. Computational model of reaction kinetic for gas explosion in constant volume combustion reactor. J. China Coal Soc. 2015, 40, 1853–1858. [Google Scholar]

- Li, H. Pressure Test System of Flameproof Enclosure and Analysis of Influencing Factors. Electr. Explos. Prot. 2020, 36–38. [Google Scholar] [CrossRef]

- Zhou, W. Method to Test Explosion Pressure of Flameproof Enclosure and Analysis on Influence Factors. Coal Sci. Technol. 2012, 40, 91–94. [Google Scholar]

- An, P. Pressure Testing method on Flameproof Enclosure of Electrical Equipment. Electr. Explos. Prot. 2010, 38–40. [Google Scholar] [CrossRef]

- Liu, H.L.; Shao, L.; Zuo, H.B.; Liu, N. Application of Laser Doppler Technique in Measurement of Explosive Container Based on Frequency Correction. Appl. Mech. Mater. 2013, 391, 497–500. [Google Scholar] [CrossRef]

- Li, M. Discussion on the Main Problems and Precautions in the Processing of Mining Flameproof Enclosure. Electr. Explos. 2025, 20–23. [Google Scholar] [CrossRef]

- Xiao, T.; Shi, F.; Yi, X.; Chen, X. Research on vibration characteristics of electric spindle of milling machine based on laser vibration measurement technology. Chin. J. Constr. Mach. 2024, 22, 191–195. [Google Scholar]

- Bai, X.; Guo, P.; Chen, S.; Zhang, Y.; Chen, H.; Bu, Z. Simulation in the Time Domain and Time-Frequency Analysis for Coherent Doppler Wind Lidar. Chin. J. Laser 2015, 42, 0114003. [Google Scholar]

- Labelle, L.; Roozen, N.B.; Vandenbroeck, J.; Akasaka, S.; Glorieux, C. Elastic characterization of polymer fibers by laser Doppler vibrometry. Opt. Lasers Eng. 2017, 99, 88–97. [Google Scholar] [CrossRef]

- Taylor, G.I. The formation of a blast wave by a very intense explosion I. Theoretical discussion. Proc. R. Soc. Lond. A 1950, 201, 159–174. [Google Scholar]

- Zhang, W.; Zou, Y.; Jia, Y. Influence of filling ratio on gas explosion in flameproof chamber. Saf. Coal Mines 2023, 54, 229–233. [Google Scholar]

- Briggs, M.E.; Hill, L.; Hull, L.; Shimas, M. Application and Principles of Photon-Doppler Velocimetry for Explosives Testing (No. LA-UR-10-01427; LA-UR-10-1427); Los Alamos National Laboratory (LANL): Los Alamos, NM, USA, 2010. [Google Scholar]

- Nian, G.; Gu, X.; Cheng, F.; Zeng, X. The Research on Vibration Characteristic of Cylindrical Explosive Vessel with Flat End Plat. J. Proj. Rocket. Missiles Guid. 2011, 31, 105–108. [Google Scholar]

- Wang, K.; Pan, H.; Zhang, T.; Wang, H. Experimental study on the radial vibration characteristics of a coal briquette in each stage of its life cycle under the action of CO2 gas explosion. Fuel 2022, 320, 123922. [Google Scholar] [CrossRef]

- Huang, D.; Cui, S.; Li, X. Wavelet packet analysis of blasting vibration signal of mountain tunnel. Soil Dyn. Earthq. Eng. 2019, 117, 72–80. [Google Scholar] [CrossRef]

- Goutaudier, D.; Gendre, D.; Kehr-Candille, V.; Ohayon, R. Single-sensor approach for impact localization and force reconstruction by using discriminating vibration modes. Mech. Syst. Signal Process. 2020, 138, 106534. [Google Scholar] [CrossRef]

- Li, S. On Explosion Pressure in Explosion-Proof Enclosures and Its Influencing Factors. Saf. Coal Mines 2003, 101–103. [Google Scholar] [CrossRef]

| Measurement Range | Resolution | Sampling Frequency | Speed Range | Laser Wavelength | Number of Channels |

|---|---|---|---|---|---|

| 0–15 m | µm level | 0–50 MHz | ±10 m/s | 633 nm He-Ne | single channel |

| Frequency Band | D1 | D2 | D3 | A3 |

|---|---|---|---|---|

| Frequency | ||||

| Explanation | High-frequency details | Mid–high frequency details | Midrange details | Low-frequency trend |

| Indicator Name | MSE | Peak Error | Ascent Rate Error | Attenuation Rate Error |

|---|---|---|---|---|

| Error | 0.039 | 1.5% | 4.1% | 3.9% |

| Indicator Name | MSE | Peak Error | Ascent Rate Error | Attenuation Rate Error |

|---|---|---|---|---|

| Error | 0.183 | 11.33% | 13.12% | 13.89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Qiu, J.; Zhang, H.; Yang, W.; Wan, H.; Chen, F. Analysis of Internal Explosion Vibration Characteristics of Explosion-Proof Equipment in Coal Mines Using Laser Doppler. Appl. Sci. 2025, 15, 9255. https://doi.org/10.3390/app15179255

Xue X, Qiu J, Zhang H, Yang W, Wan H, Chen F. Analysis of Internal Explosion Vibration Characteristics of Explosion-Proof Equipment in Coal Mines Using Laser Doppler. Applied Sciences. 2025; 15(17):9255. https://doi.org/10.3390/app15179255

Chicago/Turabian StyleXue, Xusheng, Junbiao Qiu, Hongkui Zhang, Wenjuan Yang, Huahao Wan, and Fandong Chen. 2025. "Analysis of Internal Explosion Vibration Characteristics of Explosion-Proof Equipment in Coal Mines Using Laser Doppler" Applied Sciences 15, no. 17: 9255. https://doi.org/10.3390/app15179255

APA StyleXue, X., Qiu, J., Zhang, H., Yang, W., Wan, H., & Chen, F. (2025). Analysis of Internal Explosion Vibration Characteristics of Explosion-Proof Equipment in Coal Mines Using Laser Doppler. Applied Sciences, 15(17), 9255. https://doi.org/10.3390/app15179255