Abstract

Considering the complexity of the metro pit construction environment, the existing risk early-warning methods cannot ensure high-precision early warning. A high-accuracy metro pit collapse risk fusion early-warning method is proposed in present study. The main contributions include (1) presenting a new input to the fusion model by optimizing the machine learning model through a multi-step rolling method, and then using the basic probability assignment values obtained from the cloud model as input to the fusion model and (2) developing an improved methodology to address the paradoxical results of the fusion of traditional Dempster–Shafer evidence theory when there is a high level of conflict in multi-source risk prediction data. The proposed method is successfully applied to the Guangzhou Metro station project. By analyzing the early-warning results of 240 moments in 6 monitoring points, compared with the single information source method and the traditional D-S method, the early-warning accuracy of this method is increased by 15.8% and 10.8% respectively, the false alarm rate is reduced by 6.3% and 5.5%, respectively, and the missed alarm rate is reduced by 9.5% and 5.3%, respectively. The high-accuracy fusion early-warning method proposed in this paper has good universality and effectiveness in the early warning of subway foundation pit collapse risk.

1. Introduction

As a high-capacity, high-density rail system, the metro significantly alleviates urban surface traffic congestion. However, due to the complexity of the subway pit construction technology, the compactness of the operating site, and the sensitivity of the surrounding environment, there are unforeseen factors and huge safety risks. Due to its low cost and effective mitigation of impacts on adjacent buildings and structures, the open cut method is commonly used in subway pit excavation. However, numerous risk factors and complex construction procedures readily trigger foundation pit instability, causing collapses that result in schedule delays, economic losses, and casualties [1,2,3]. Thus, researching early-warning systems for collapse risks is crucial to ensure subway pit construction safety.

In the process of subway pit construction, its collapse often has a precursor. For example, excessive deformation leads to cracks in the supporting structure. Therefore, the deformation needs to be controlled within a reasonable range to ensure safe construction. Many scholars have studied the deformation, mainly through empirical methods [4,5,6], numerical simulations [7,8,9], and field tests [10,11,12]. In recent years, artificial intelligence methods have been heavily used in the subsurface space research. Many scholars have used artificial intelligence methods to predict deformation. Researchers [13,14,15] used neural network approach to study pit deformation, but it requires a large number of samples and is prone to overfitting. Therefore, some scholars [16,17] used small-sample machine learning algorithms for single-step prediction of deformation. However, because pit construction is dynamic, single-step prediction does not fully utilize the correlation between before and after monitoring data and does not provide sufficient response time for decision makers. Therefore, this paper intends to select three models suitable for small sample prediction for comparative analysis, which are decision tree regression model (DTR), support vector regression model (SVR), and Gaussian process regression model (GPR). The training set is also extended using a multi-step rolling prediction method with multiple steps to make greater use of the available monitoring data in order to increase the diversity of the training samples.

Since it is often difficult for individual monitoring data to reflect the actual situation of pit construction, scholars have proposed a multi-data fusion method to improve the accuracy of early warning. Due to the complex and sensitive environment of subway pit construction, there is a certain amount of fuzzy and random information in the monitoring data that is difficult to judge. Scholars [18,19,20] used cloud modeling to quantify the values of evaluation indicators to improve the certainty of information source data. Therefore, the cloud model can be used for the conversion of risk source data in the risk fusion early warning of subway pits. However, due to the different levels of data collection from different information sources, the data obtained are difficult to be harmonized and are prone to bias and even to greater conflict and mutual exclusion. The Dempster–Shafer (D-S) evidence theory can solve the problem of data discrepancy and uncertainty, and it is widely used in the fields of disaster identification and risk early warning [21,22,23,24]. While the traditional D-S evidence theory addresses reliability limitations of single-factor analysis through multi-source fusion [25,26], its vulnerability to high-evidence conflict causing fusion failure was overlooked. Although later scholars [27,28,29] significantly improved conflict resolution accuracy, their single-indicator methods demonstrate compromised interference resistance in diverse scenarios and lack generalizability for representing intense mutual exclusion [30,31].

D-S evidence theory can effectively fuse data from different evidence sources through Dempster’s synthesis rule, so that it can perform well in scenarios where multiple sources of information need to be integrated. However, the traditional DS evidence theory still has some limitations, which is more sensitive to high-conflict evidence. Different information sources can describe the risk state of foundation pit from different angles, so there may be great conflicts between them. In practical engineering, when two evidence pieces from different sources have high support for the same proposition, but due to the conflict between them, the fusion results may significantly reduce the support for the proposition, or even draw the opposite conclusion.

When dealing with the problem of high-conflict evidence fusion failure, it can be divided into two categories according to the source of conflict. The first type is the conflict between the evidence bodies, which is caused by the inconsistency or contradiction of the evidence itself. For example, different evidence sources have great differences in the distribution of trust in the same event. The solution can be described as follows: before evidence synthesis, the original evidence can be preprocessed to reduce conflicts. By discounting the evidence, that is, weighting according to the conflict degree and uncertainty of the evidence, the influence of unreliable evidence on the synthesis result is reduced. The second type is the defect of the evidence fusion rule, and the limitation of the fusion rule itself in high conflict scenarios, such as the DS rule magnifies the conflict due to normalization. The solution can be described as follows: by introducing fine-tuning items, weighted averages, etc., the synthesis rules are improved to improve the rationality and accuracy of the synthesis results.

Therefore, a fusion early-warning method for subway pit collapse risk based on machine learning and improved cloud D-S evidence theory is proposed. The prediction accuracy of three small sample machine learning models is compared using the multi-step rolling method to obtain the optimal prediction results, and the cloud model is used to transform them into basic probability assignment (BPA). A new evidence correction parameter is defined based on conflict degree and uncertain degree. A fusion early-warning model resolves high-conflict multi-data fusion failures, providing optimized methodologies for risk early-warning in subway foundation pit construction.

2. Methodology

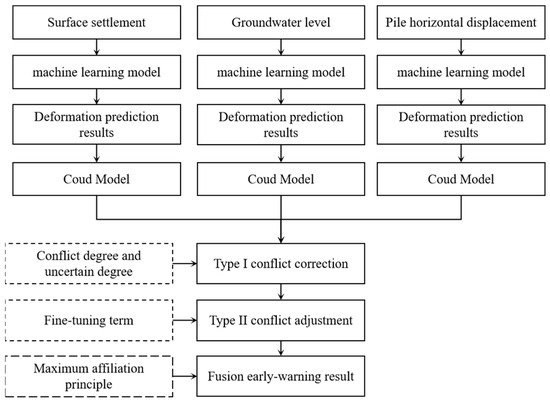

In order to improve the accuracy of early-warning of collapse risk in subway foundation pit construction, this paper proposes a multi-source data fusion early-warning method, as shown in Figure 1. Firstly, the risk evaluation system and evaluation set are constructed based on the engineering example, and the small sample machine learning prediction model is compared and analyzed to obtain the optimal prediction value. The cloud digital characteristics and membership function of the evaluation set are determined and transformed into the BPAs. The conflict degree and uncertain degree are introduced to obtain the credibility of the evidence and correct the evidence. Fine-tuning items are added and fusion rules are improved to adjust global conflicts. Finally, according to maximum affiliation principle, the early-warning results of the overall risk integration of the foundation pit are obtained.

Figure 1.

Flow chart of subway foundation pit collapse risk early warning. The solid line box represents the main flow. The dashed boxes represent the parameters used or the principles used. The black arrow represents the direction of the process.

2.1. Cloud Model

We let U be a quantitative thesis expressed numerically and C be a qualitative concept on the thesis U. The distribution of µ(x) over the domain U is called a cloud if there exists a quantitative value x∈U, x is a one-time random realization on C. The membership degree µ(x) exhibits stochasticity with distributional stability. Cloud models are characterized by three numerical parameters: expectation (Ex), entropy (En), and hyperentropy (He) [32,33,34]. Ex represents the centroid position of cloud droplets in the domain space. En represents the uncertainty of the qualitative concept and reflects the degree of discretization of the cloud droplets. He is the entropy uncertainty, which represents the degree of dispersion of the entropy.

where a+ and a− define the upper and lower bounds of the interval [a−, a+]. He is empirically assigned as 0.001 in this study.

We let Θ be the early-warning recognition framework (Θ = {safe, yellow early warning, orange early warning, alarm}). The cloud parameter for whether the early-warning level of a data source is A is [Ex, En, He], and the corresponding affiliation is µ(A). The affiliation is transformed into BPA (m(A)), and BPA of the global uncertainty is m(Θ).

where Enn is a normal random number with En as expectation and He as standard deviation. x is the value predicted by the machine learning model deformation.

2.2. Improved High-Conflict Evidence Fusion

Evidence conflicts can be categorized into Type I and Type II conflicts based on the fusion steps of the D-S evidence theory [35,36,37]. Type I are conflicts between bodies of evidence arising from the bodies of evidence themselves. Type II are conflicts arising from defects in the rules on fusion of evidence. To the above problems, the improvement process of this paper is as follows.

Step (1). Calculate the conflict degree: Based on the traditional DS evidence theory, the degree of conflict is represented by the conflict coefficient K, which describes the overall degree of conflict among the evidence bodies. The smaller the degree of conflict, the smaller the conflict. In construction risk early warning, for the evidence body composed of different information sources, we let αij be the degree of conflict between the ith information source and the ith information source.

where mi (A) and mj (A), respectively, represent the initial trust degree BPA corresponding to the ith information source and the jth information source when the early-warning level is A.

We suppose the initial trust degree of information source 1 is {m1 (safe), m1 (yellow), m1 (orange), m1 (alarm)} = {0.1, 0.7, 0.2, 0}, and the initial trust degree of information source 2 is {m2 (safe), m2 (yellow), m2 (orange), m2 (alarm)} = {0.2, 0.8, 0, 0}. So in the conflict degree calculation process for α12 = 0.1 × (0.8 + 0 + 0) + 0.7 × (0.2 + 0 + 0) + 0.2 × (0.2 + 0.8 + 0) + 0 × (0.2 + 0.8 + 0), the result is 0.42.

mi (A) and mj (A) denote the BPAs corresponding to the ith data source and the jth data source when the early-warning level is A, respectively.

Step (2). Calculate the uncertain degree: The focusing degree indicates the uncertainty of the data source itself: the smaller focusing degree, the smaller the uncertain degree. In order to keep the monotonicity of the conflict degree and uncertain degree consistent, the uncertain degree is represented by the focusing degree. We let θ denote the focusing degree of the ith data source, and the corresponding uncertain degree is β.

where |Θ| is the base of the subset Θ (the number of elements in the set Θ). The greater the uncertainty, the greater the conflict between the evidence, the more likely fusion failure to occur. The smaller the uncertainty, the smaller the conflict between evidences pieces, and the greater the possibility of fusion failure.

Step (3). Improve the conflict correction parameters: The distance from point (α, β) to (0, 0, 0) is defined as an improved evidence correction parameter. We let δ denote the credibility of the ith data source and adjust for the data source.

Step (4). Type I conflict correction: By applying the improved evidence correction parameter to the initial BPA, the BPA corrected for Type I conflict is obtained.

where mcorrected (A) represents the underlying probability assignment of the data source to early-warning Level A.

Step (5). Type II conflict adjustment: Type I conflict correction removes the differentiation between evidence pieces but does not resolve the global focal element allocation between evidences. Therefore, by adding the fine-tuning term L (A), the global conflict is decomposed into local conflicts to reduce the subjectivity of global focal element allocation. We let madjust (A) denote the adjusted BPA for the second type of conflict and mfusion (A) be the final fusion result.

where mi,corrected (B) and mj,corrected (C) denote the BPAs of the ith and jth data sources after Type I conflict adjustment.

3. Results

3.1. Engineering Background

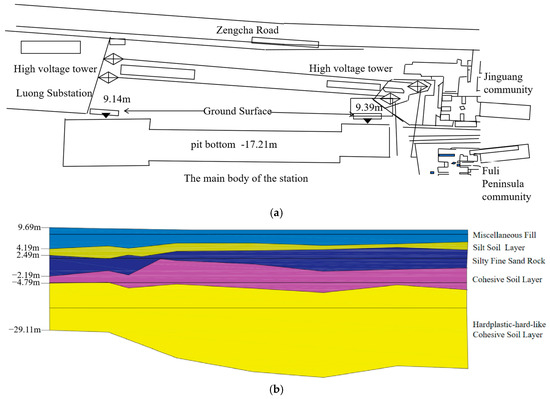

The station is an underground three-level side station with a total length of 220 m, a total construction area of 24,570 square meters, and a standard section width of 34 m. Open excavation is performed in the project at an excavation depth of approximately 24 m. The primary enclosure system employs a 1 m thick underground diaphragm wall with internal support. The station features environmentally complex surroundings, adverse geology including proximal fracture zones, and significant groundwater presence. Site configuration and structural cross-sections are depicted in Figure 2a,b, respectively. And its geotechnical parameters are shown in Table 1.

Figure 2.

(a) Station plan. (b) Section view of station.

Table 1.

Foundation pit geotechnical parameters.

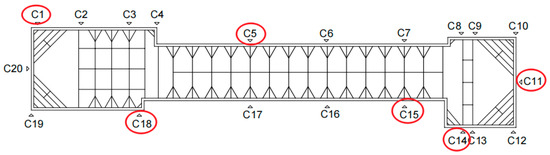

3.2. Early-Warning Indicator System

Instrumentation monitoring is a necessary part of underground construction. Different monitoring items have different impacts on pit safety. Analyzing all the monitoring data is not necessary and makes the calculation too complicated. Therefore, in accordance with the principle of indicator selection, the number of indicators is reasonably reduced on the premise of ensuring accuracy and comprehensiveness. The distribution of monitoring points is shown in Figure 3, with a total of 20 monitoring points. Given comparable deformation patterns and shared deployment principles across monitoring points, six representative locations (C1, C5, C11, C14, C15, C18) were selected for analysis. Items and related configuration are shown in Table 2.

Figure 3.

Layout of monitoring points for the Luochongwei station project. Cx represents the location of the monitoring point, x = 1, 2, 3,…, 20.

Table 2.

Monitoring items and related configuration.

Combined with references [38,39] and the risk characteristics of this project, the surface settlement, groundwater level, and pile horizontal displacement are selected as the risk early-warning indicators. In the actual construction process, the control value is an important basis for judging the safety status of the project structure and the surrounding environment. According to the relevant specifications and the data provided by the relevant supervisory company, the control value of this metro pit project is controlled by the cumulative value and the rate of change, as shown in Table 3.

Table 3.

Early-warning indicators and corresponding control values.

Considering that the early-warning results and the actual monitoring values have trend uniformity, this paper takes the control value as the benchmark value and takes the ratio of the actual monitoring value to the control value (k = actual monitoring value/control value) as the standard, which is uniformly converted into a dimensionless quantity, in order to realize the uniformity of the early-warning indicator level. Using 70 percent, 85 percent, and 100 percent of the control value as the dividing criteria, the early-warning level indicators are divided into four levels [39], and the early-warning level from low to high is divided into four levels: safety, yellow early-warning, orange early-warning, and alarm, as shown in Table 4.

Table 4.

Early-warning classification criteria.

3.3. Analysis of Deformation Predictions

In view of the characteristics of the dataset studied in this paper, which is a small sample data, four machine learning models applicable to the prediction of small sample data are selected, namely decision tree regression model (DTR), support vector regression model (SVR), Gaussian process regression model (GPR), and stacked machine learning method (stacked ML) [40]. The prediction model is trained by rolling time series to find the optimal prediction model under the best time series. Considering the close proximity of Songxi Station and Luochongwei Station of Guangzhou Metro Line 13, the geological and hydrological conditions are similar. Therefore, the deformation data of Songxi station for a complete monitoring cycle are collected for model training, and then the trained model is used for deformation prediction at Luochongwei station. The data of 20 monitoring points in Songxi station are taken as the data set, 14 of which are selected as the training set, and the remaining 6 are the test set. The generalization ability of the model is evaluated by the average error of the test set.

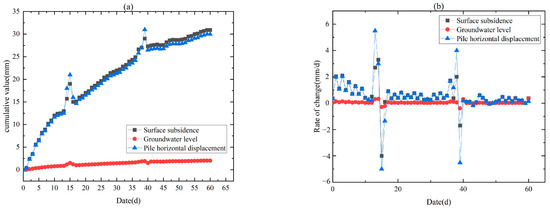

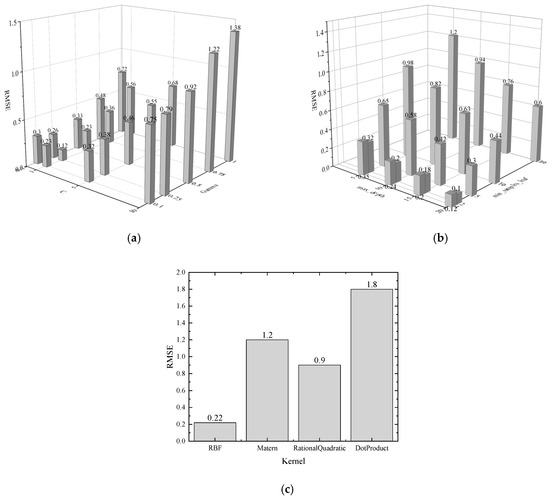

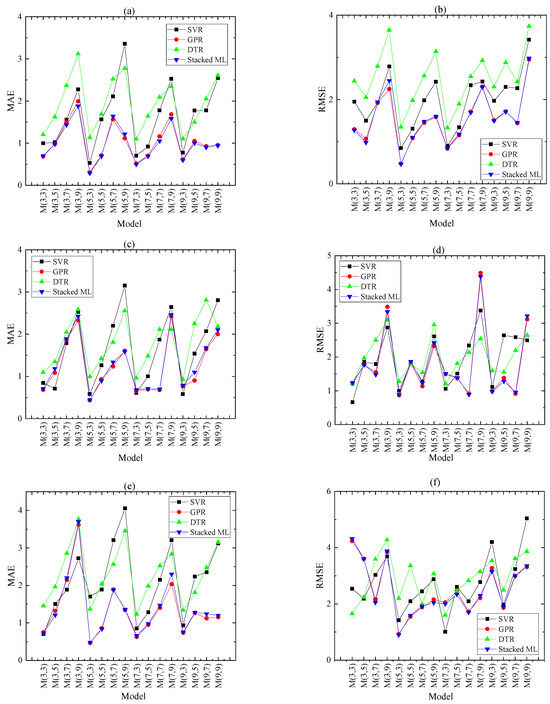

Firstly, monitoring data are collected from the Songxi station. Figure 4 displays the data of a monitoring point at Songxi station. Surface settlement, groundwater levels, and horizontal pile displacements tend to increase over time and fluctuate within a small range. And the corresponding rates of change shows an overall decreasing trend over time and fluctuate within a small range. The cumulative change and the rate of change have a similar pattern, both of which show a rise or fall before reaching a steady state. The prediction model has a uniformity, and the cumulative change is used to illustrate the model optimization process. Secondly, a five-fold cross-validation grid search method is used to find the optimal parameters of the model. As shown in Figure 5, the optimal parameters for DTR are {max_depth, min_samples_leaf} = {20, 2}, and the corresponding error value is 0.1. The optimal parameters SVM are {error term penalty parameter C, kernel function coefficient gamma} = (1, 0.25), and the corresponding error value is 0.12. The important parameter of GPR is the kernel function, the radial basis kernel function is chosen in this paper, and the corresponding error value is 0.22. The optimal parameters of the stacked ML are the data from reference. Finally, a rolling time series approach is used to construct the training model. If the input sequence is too short or the output sequence is too long, it is easy to produce under-fitting, and vice versa. Therefore, selecting the appropriate input and output sequence length directly affects the model effect. For subway foundation pit engineering, by predicting the data of the next 3 to 7 days, decision makers can have enough time to respond to emergencies. In this paper, the input sequence lengths are three, five, seven, nine, and the output sequence lengths are three, five, seven, nine, respectively. Therefore, there are 16 groups of input and output combinations, and the results are shown in Figure 6.

Figure 4.

Monitoring data from Songxi Station. (a) Cumulative value. (b) Rate of change.

Figure 5.

Parameter selection. (a) SVR. (b) DTR. (c) GPR.

Figure 6.

Comparison of different model errors at Songxi station. (a) Mean absolute error (MAE) of cumulative change in surface settlement. (b) Root mean square error (RMSE) of cumulative change in surface settlement. (c) MAE of cumulative change in groundwater level. (d) RMSE of cumulative change in groundwater level. (e) MAE of cumulative change in pile horizontal displacement. (f) RMSE of cumulative change in pile horizontal displacement.

The following conclusions can be drawn from Figure 6:

- (1)

- For the same risk source, the MAE and RMSE are similar. This indicates that the training data have no obvious outliers and can be better adapted to model training. From Figure 6a,b, the MAE of surface settlement ranges from 0 to 3.5 and the RMSE ranges from 0 to 4. From Figure 6c,d, the MAE of groundwater level ranges from 0 to 3.5 and the RMSE ranges from 0 to 4.5. From Figure 6e,f, the MAE of pile horizontal displacement ranges from 0 to 4.5 and the RMSE ranges from 0 to 5.5.

- (2)

- For the small sample of data in this paper, the GPR model and stacked ML gives the best prediction, followed by the SVR model and finally the DTR model. As can be seen from Figure 6, the “red circle position” is the lowest point of error. At the same time, considering the complexity of the model, the GPR model is simpler, easier to implement, and more difficult to overfit. Therefore, this paper chooses the GPR model as the prediction model.

- (3)

- The smaller the number of days of prediction, the better the model prediction. As can be seen in Figure 6a–f, the number of prediction days is set as three, five, seven and nine. When the number of prediction days is three, the model error is lower, the MAE is usually kept within 1.5, and the RMSE is kept within 2.5. But when the number of days of prediction is five, seven, and nine, the error value becomes higher in that order. Therefore, the forecasting model in this paper selects the number of forecasting days as three.

- (4)

- The GPR model performs best with a training sample length p of five when the number of prediction days is q of three. From the “red dots” in Figure 6a, it can be seen that when the number of prediction days is three, the training sample of five days has the smallest error value. Therefore, the prediction model in this paper chooses the GPR model with a training sample length of 5 days and 3 prediction days, denoted as GPR (5,3).

In summary, the GPR (5,3) model is the model with the best predictive performance in the small sample of data in this paper. Based on the rolling time series forecasting method, the number of forecasting days has a better forecasting effect when the number of forecasting days is 3 days. In addition to obtaining the predicted values of deformation, it is also possible to predict the trend of deformation. The model training sample length p, on the other hand, is related to the data themselves and needs to be adjusted according to the specific time series and test results. The optimal training sample length for this paper is five. Based on the above analyses, the GPR (5,3) is used in this paper. The indicators of the six monitoring points at Luochongwei station are selected for prediction, and the cumulative values for the next 3 days are predicted on a rolling basis using a training sample length of 5 days, and the results of the model predictions are used for fusion early warning of pit risk.

3.4. Multi-Source Data Fusion for Early Warning

Luochongwei Station of Guangzhou Metro Line 13 is used as the research object. A risk fusion early-warning study of multiple data sources based on machine learning and improved cloud D-S fusion models is performed. The frequency of data collection during pit excavation is once a day. The measured values are used in the deformation prediction model. The predicted values for a day after excavation are used as an example to illustrate the early-warning process of pit collapse risk fusion.

- (1)

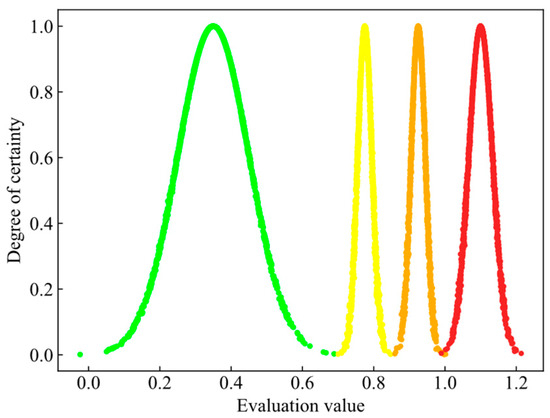

- Delineate evaluation intervals and determine cloud model parameters.

Following the interval classification in Table 4, the standard cloud parameters (Table 5) and corresponding cloud diagrams (Figure 7) are generated via Equation (1). Figure 7 demonstrates minimal intersection among rubric categories, confirming their suitability for multi-source data conversion.

Table 5.

Cloud numerical characteristics.

Figure 7.

Standard cloud for accuracy of target recognition. Green represents the cloud model corresponding to safe. Yellow represents the cloud model corresponding to the yellow early-warning. Orange represents the cloud model corresponding to the orange early-warning. Red represents the cloud model corresponding to the red early-warning.

- (2)

- BPA generation for different data sources

A total of six monitoring points are selected in this paper. Each monitoring point has three primary indicators (surface settlement, groundwater level, and pile horizontal displacement), each of which corresponds to two secondary indicators (cumulative value and rate of change). The set of early-warning levels is denoted as {safe, yellow early-warning, orange early-warning, alarm, Θ}, where Θ denotes the uncertainty about the global. That is, there is no prejudgment in the early-warning level pool to match to the unknown level.

The BPA generation process can be described as follows: According to Equation (1), the set of rubrics is converted into cloudy numerical features (Table 5), then the machine learning prediction results are substituted into Equation (2), then the numerical data is converted into affiliation, and finally the BPA is calculated. The input is the predicted value of the GPR model and the output is the BPA. Due to space constraints, only the BPA generated from the predicted values on day 21 is shown in the paper, and the results are shown in Table 6.

Table 6.

BPA for indicators at monitoring points on day 21.

Step (1). The predicted values for day 21 are obtained from the GPR (5,3) model trained above. For example, at monitoring point C1, the predicted result for the cumulative value of surface settlement is 29 mm.

Step (2). The cloud digital features (Table 5) can be obtained through Equation (1). Also, since Enn obeys NORMINV (p, En, 0.001) where p is rand (0,1) and En takes 0.001, Enn can be obtained as [0.279, 0.045, 0.045, 0.236].

Step (3). The predicted value of 29 mm is converted to k of 0.967. Substituting k into Equation (2), the degree of affiliation can be calculated. And BPA is [0.056, 0, 0.424, 0.23, 0.289].

In the process of multi-source information fusion, the information sources need to be converted into BPAs for early-warning levels. The cloud model combines fuzzy mathematics and probability theory to map quantitative data to probabilistic values, which has a huge advantage in describing the uncertainty in the BPA construction process. Thus, the cloud model outputs probability values for early-warning levels that can be used for subsequent multi-data fusion analyses.

- (3)

- Multi-source data fusion.

Due to data errors and other reasons, a single source of information early warning cannot fully reflect the actual situation on the site, resulting in a low rate of accuracy of early warning, and cannot provide accurate guidance for on-site construction. To the above problems, a feature-based information fusion model that learns new evidence correction parameters while reducing the effect of global uncertainty is proposed in this research. The predicted values of surface settlement, groundwater level, and pile horizontal displacement obtained from machine learning training are used as risk early-warning source, and the corresponding early-warning probability distributions can be obtained through the cloud model. Finally, the improved D-S evidence theory is used to fuse the multi-source data, which combines the characteristics of the three single information source, and the final early-warning result is given by fusing the judgements of each evidence.

In order to illustrate the fusion process, monitoring point C1 was taken as the object of study. The fusion results from a single data source, the traditional D-S method, and the proposed method of this paper are compared as shown in Table 7, where the bolded values are the maximum probability early-warning levels. The monitoring point C1 contains three primary indicators (surface settlement, groundwater level, and pile horizontal displacement), each of which corresponds to two secondary indicators (cumulative value and rate of change). So, there are a total of six evidences for monitoring point C1. For monitoring point C1, the fusion of the early-warning probabilities of the six evidence pieces at the same moment gives the final early-warning level. It can be described as follows.

Table 7.

Fusion results for monitoring point C1.

Step (1). Early-warning results from a single source of information. Early-warning results for a single source of information can be obtained by grading the cumulative values and rates of change according to Table 4. We let the GPR (5,3) model predict the data of surface settlement. It can be seen that the predicted cumulative value and rate of change on day 21 are 26 mm and 2.84 mm/d, corresponding to k1 = 0.867, k2 = 0.947, respectively. From the early-warning classification criteria, the early-warning level for surface settlement (E1) is orange. Similarly, the early-warning levels for groundwater level (E2) and pile horizontal displacement (E3) are yellow and orange, respectively. However, the actual early-warning level is yellow. It indicates that when a single source of information is used for early warning, the results are often biased due to the uncertainty of the data.

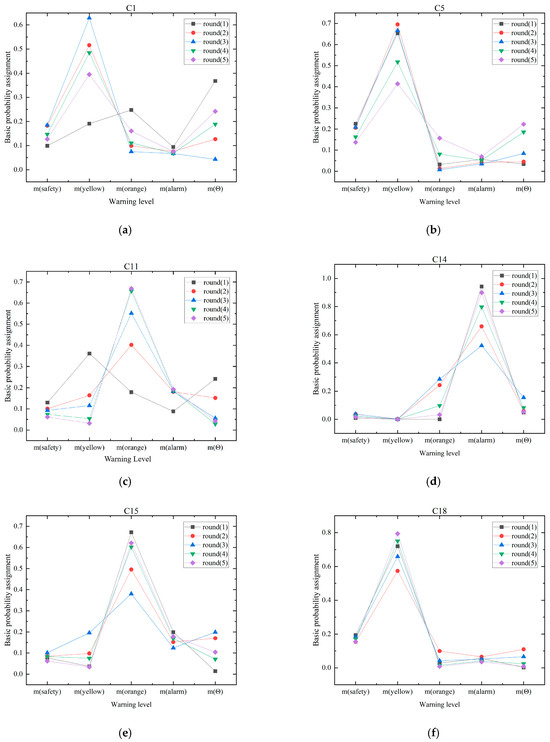

Step (2). Early-warning results from multi-source data fusion. The fusion process is shown in Figure 8. Each monitoring point corresponds to six indicators, which need to be fused five times in total. As the number of fusion rounds increases, the early-warning level gradually stabilizes. It is due to the fact that the fusion rule maintains the positive risk information, allowing the positive information to be superimposed one by one during the fusion process. For monitoring point C1, the final early-warning result is obtained by fusing the BPAs of the three information sources in turn. E1 si [0.065, 0.0243, 0.566, 0.233, 0.109]. E2 is [0.158, 0.515, 0.084, 0.078, 0.165]. E3 is [0.077, 0.062, 0.566, 0.186, 0.109]. E1 is the surface settlement, E2 is the groundwater level, and E3 is the pile horizontal displacement. The conflict degree α, the uncertain degree β, and the degree of credibility δ are as follows:

Figure 8.

Fusion early-warning process. (a) C1. (b) C5. (c) C11. (d) C14. (e) C15. (f) C18.

The three single model results are fused using the proposed method, and the fused probability distribution is [0.133, 0.537, 0.163, 0.075, 0.092]. The results show that the early-warning level for monitoring point C1 is yellow and the early-warning results are consistent with the facts.

The actual early-warning level for monitoring point C1 is yellow. As shown in Table 7, both E1 and E3 give incorrect results with low confidence, but E2 with higher confidence gives correct results. This demonstrates that the method proposed in this paper takes into account both the conflict and uncertainty of the model, such that the correct result of E2 corrects the incorrect results of E1 and E3 back to the correct result of the fusion model. In addition, the fact that the traditional D-S early-warning level is safe suggests that traditional D-S can produce erroneous or even completely opposite results when dealing with high-conflict evidence. However, the method proposed in this paper reduces the adversarial impact of high-conflict evidence by improving the fusion rule and employing adjustments to global conflicts to obtain more accurate results.

Firstly, single-source information early-warning models do not provide accurate decision-making advice for on-site construction. This is due to the fact that a single source of information does not fully consider the risk factors of pit collapse, and there are errors and uncertainties in the information, which ultimately leads to a slight deviation of the early-warning results from the actual data. Secondly, traditional D-S only accumulates consensus support; if a proposition is opposed by any evidence, it is rejected altogether, even though it receives support from other evidence. When the three single-information early-warning results are different, traditional D-S theory often gives fusion results that are the opposite of reality. However, the method proposed in this paper makes full use of the available information, including conflict information. It takes into account the data of three risk sources, namely surface settlement, groundwater level, and pile horizontal displacement, which makes the early-warning model closer to the actual situation and improves the accuracy of the early-warning results.

4. Discussion

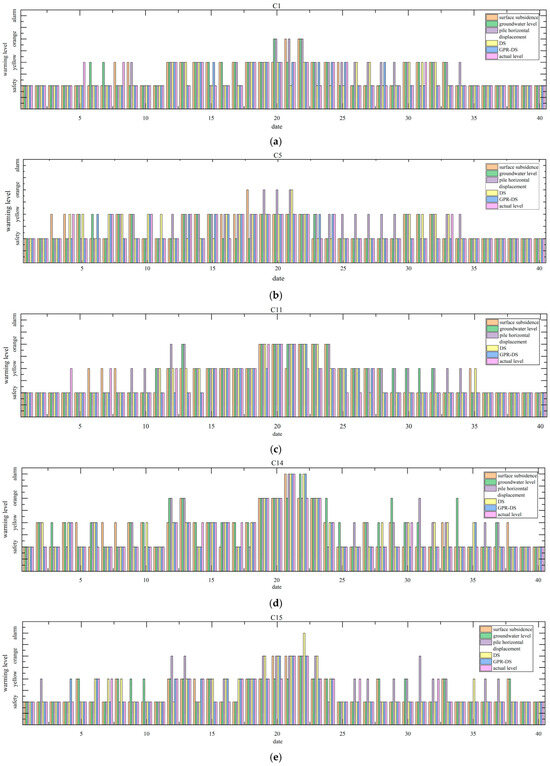

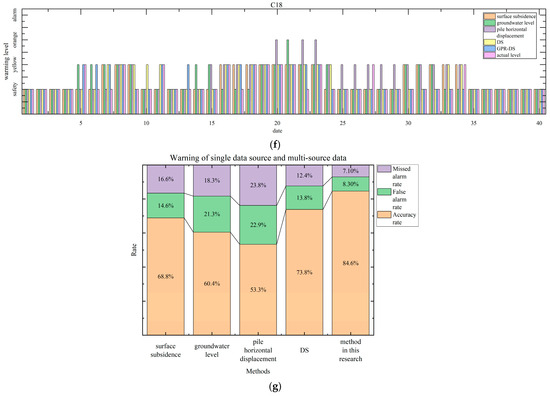

In order to gain sufficient risk response time for the decision makers, the GPR model was used during the construction of the Luochongwei station, and a time series length of 5 days was selected for rolling prediction of deformation for the next 3 days. And the deformation prediction results were used as an information source to be fused by the method proposed in this paper in order to realize the early warning of underground pit collapse risk. The results are shown in Figure 9.

Figure 9.

The results of single data early warning and multi-data fusion early warning. (a) Early-warning results of monitoring point C1. (b) Early-warning results of monitoring point C5. (c) Early-warning results of monitoring point C11. (d) Early-warning results of monitoring point C14. (e) Early-warning results of monitoring point C15. (f) Early-warning results of monitoring point C18. (g) Early-warning results for single and multiple data sources.

(1) Analysis of actual early-warning results. Figure 9a–f represent the changes in early-warning results over time for different monitoring points. The pink bar indicates the actual early-warning level. The highest actual early-warning level of C1, C5, and C18 is yellow, the highest actual early-warning level of C11 and C15 is orange, and the highest actual early-warning level of C14 is alarm. This shows that the collapse risk of monitoring point C14 is the highest, followed by C11 and C15, and the collapse risk of C1, C5, and C18 is lower. For C14, it can be seen that from day 1 to day 11, the monitoring point is basically in a safe state, indicating that the risk at this point is in a controllable range and no early warning has occurred. From day 12 to day 18, the yellow early-warning status occurs, which indicates that the pit is beginning to have the possibility of unsafe deformation, and the operator should start to pay attention to the deformation situation and communicate it in a timely manner in the daily meeting. The actual early-warning level on day 19 to day 20 is orange, the alarm is triggered on day 21 and eliminated on day 22 to day 23 but is still in the orange early-warning state, indicating that there is a large potential risk of collapse and that immediate measures should be taken until the risk is reduced to a safe state before construction can continue. It is essentially in a safe condition from day 24 to day 40, indicating that the measures taken had a positive effect and that no deformation collapses occurred.

After confirmation by the expert on-site inspection, it was found that the occurrence of the above early-warning status was due to the unloading of the pit excavation leading to a large bulge near the monitoring point C14, and there was a high probability of deformation of the supporting structure or a small-scale collapse, which was undesired and required immediate measures to be taken. Firstly, site operators should be evacuated immediately, as well as those in neighbouring units or dwellings that may be affected. Secondly, excavation should be stopped immediately and additional settlement monitoring points outside the pit should be installed. In addition, immediately after, backfilling with grout or backfilling until the settlement trend outside the pit converges should be performed, before it can be stopped, and then the rotary sprayer should be used and cement should be equipped to reinforce the soil. It can be seen that the early-warning level was reduced to safe on day 25, indicating the effectiveness of the response measures taken.

For C11 and C15, there is a short time of orange. The C15 monitoring point was at a safe or yellow level from the 1stday to the 20th day. Orange early-warning appeared on the 21st day and the 22nd day, and it finally reduced to a safe level after on-site disposal. The C11 monitoring point was at a safe or yellow level from the 1st day to the 18th day. The orange early-warning appeared on the 19th day and the 21st day, and finally reduced to a safe level after on-site disposal. C11 and C15 were deformed due to excavation and unloading near the C14 measuring point. It can be seen from Figure 9c,e that they were quickly reduced to the safety level after on-site treatment.

For C1, C5, and C18, there are only two early-warning levels of safety and yellow. Safety shows that the risk of each location is in a controllable state, there are no obvious early-warning signs, and the monitoring data are also in the normal range. Yellow indicates that there is a possibility of unsafe distortion, and only on-site operation is required to pay attention to the changes at all times, and the changes are notified at daily meetings.

(2) Analysis of single data source early-warning results and multi-data source fusion early-warning results. From Figure 9a–f, the differently colored bars represent the different methods of obtaining early-warning results. The average early-warning accuracy can be obtained by averaging the early-warning accuracies of different monitoring points. Similarly, the average false alarm rate and the average missed alarm rate can be obtained as in Figure 9g. It can be seen that a single source of information has a missed alarm rate of up to 23.8%, a false alarm rate of up to 22.9%, and an accuracy rate of no more than 68.8%. Traditional D-S has a missed alarm rate of 12.4%, a false alarm rate of 13.8%, and an accuracy rate of 73.8%. The improved method in this paper has a missed alarm rate of 7.1%, a false alarm rate of 8.3%, and a correct rate of 84.6%. It is clear that the method proposed in this paper has the highest accuracy rate and the lowest missed alarm rate and false alarm rate. The next best performing method is the traditional D-S method, followed by the single source of information method. It can be seen that the fusion of multi-source information for early warning has a higher accuracy rate compared to a single data source.

It can be seen from Figure g that among the single information sources, the early-warning accuracy of the surface subsidence information source is the highest, which is 68.8%. The early-warning accuracy of groundwater level information source is the second, which is 60.4%. The early-warning accuracy of pile horizontal displacement information source is the lowest, which is 53.3%. The reason is that the horizontal displacement of the pile is often the result of deeper reasons such as soil instability, support failure, and groundwater action. When the displacement increases significantly, these deep problems may have developed to a more serious degree. Therefore, there is a certain lag in the early warning through the horizontal displacement of the pile.

The accuracy of multi-source information fusion early-warning method is higher than that of single information source. In the early warning of multi-source information fusion, the early-warning accuracy of the improved method is 84.6%, which is 10.8% higher than that of the traditional DS method. This is due to the fact that the traditional method does not process the high conflict evidence, while the improved method performs the first type of conflict adjustment and the second type of conflict correction on the conflict evidence, thus reducing the contradiction between the evidence and improving the accuracy after fusion.

As the pit excavation process involves many risk factors, a single data source, although it realizes risk early-warning to a certain extent, often fails to reflect the actual situation of the whole pit excavation. However, the multi-source data fusion method takes into account the characterization information from multiple data sources and provides a more comprehensive understanding of pit deformation, which can reduce the uncertainty and ambiguity associated with a single data source, thus improving the early-warning accuracy. However, traditional D-S performs poorly when dealing with multi-source high-conflict evidence, and it can even produce the exact opposite result. Therefore, the improved fusion early-warning method proposed in this paper can better solve the problems of low credibility of a single information source and the failure of fusion of highly conflicting evidence from multiple sources. For actual engineering, the early-warning accuracy of single information source methods or traditional D-S methods is low, which can easily cause collapse accidents. The fusion early-warning method proposed in this paper has high accuracy and credibility, which can better provide sufficient response time for engineering decision makers to reduce the occurrence of collapse accidents in time.

5. Conclusions

A fusion early-warning method for subway pit collapse risk based on deformation prediction and improved cloud D-S evidence theory is proposed in this research. Combining GPR for rolling prediction of deformations, then using cloud models for basic probability assignment transformation, and applying the improved D-S evidence theory for fusion early-warning, the final risk early-warning level is obtained. Deformation prediction value as an information source for multi-data fusion can predict the future collapse situation in advance, so that decision makers have enough time to understand the construction site situation and grasp the main factors leading to the risk of collapse so as to target the corresponding measures to reduce the probability of engineering accidents. The proposed method is applied to the Luochongwei station and the following conclusions can be obtained:

- (1)

- Limited to the variability of the geological conditions of the pit and the uncertainty of the construction process, it is difficult to judge the early-warning level by the environmental conditions and structural conditions of the pit. Since all kinds of monitoring data are the visual embodiment of the integrated effect of environmental conditions, construction conditions, etc., it is of great significance to study the early warning of pit risk based on monitoring data.

- (2)

- Multi-step rolling prediction of deformation trends is performed using a small-sample machine learning approach. The predictions are transformed into basic probability distributions through cloud modelling, providing multiple sources of input information for the fusion early-warning model. The small-sample prediction results in this paper are consistent with the construction site monitoring results, which can provide decision makers with an over-advanced risk prediction signal so that construction workers have sufficient risk emergency response time to reduce the probability of collapse accidents.

- (3)

- In order to solve the problems of low credibility of a single source of information and the failure of fusion of highly conflicting evidence from multiple sources, an improved multi-source information fusion early-warning method is proposed. The three sources of information, namely surface settlement, groundwater level, and pile horizontal displacement, are considered together, and the predicted values of multiple monitoring items are fused for early warning based on the newly defined evidence correction parameters and optimized fusion rules. The results show that the method proposed in this paper outperforms the single information source method and the traditional D-S method. The proposed method has high accuracy and effectiveness.

The research in this paper can provide a new idea for the construction risk early warning of subway foundation pit engineering. This method can reflect the construction risk state through multiple indicators and multiple angles. At the same time, the predicted displacement is used as an information source for multi-data fusion, which can predict the collapse failure after a few days and provide sufficient reaction time for the construction personnel. The decision makers should fully understand the on-site construction situation, have a preliminary understanding of the main risk factors causing the collapse, and take corresponding measures for specific problems to achieve the right remedy, greatly improving the efficiency of construction. This method solves the blind area of construction risk caused by the one-sidedness of a single information source, and can win the disposal time for on-site emergencies.

However, the research method in this paper is based on the linear relationship between the fusion failure level and the increase in the monitoring value, which is more suitable for the urban underground space. For the risk of underground space construction in harsh environments, such as mine environment, the linear hypothesis cannot well describe the risk acceleration effect near the critical state. In addition, the data in this paper are derived from instrument monitoring, mainly based on sensor monitoring. The data acquisition depends on the device itself, such as the aging problem of long-term monitoring, and the construction environment of underground space engineering is more complicated. Therefore, in future research, we will further focus on the exploration of creep-aging coupling mechanism, alternative reinforcement technology for the whole life cycle, and new long-term monitoring technology so as to more accurately capture the collapse failure level, perceive the on-site construction status, and reduce the losses caused by construction risk accidents.

Author Contributions

Conceptualization, J.Z.; Methodology, J.Z.; software, C.L.; validation, J.Z.; writing—original draft preparation, J.Z.; writing—review and editing, B.W. and C.L.; project administration, B.W. and C.L.; funding acquisition, B.W. and C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of China (Grant Nos.: 52168055, 52278397), the Natural Science Foundation of Jiangxi Province (Grant Nos.: 20212ACB204001, 20224BAB204058), “Double Thousand Plan” Innovation Leading Talent Project of Jiangxi Province (Grant No.: jxsq2020101001), China Postdoctoral Science Foundation (Grant No.: 2022M711429), and Jiangxi Province Graduate Innovation Special Fund Project (Grant No.: YC2022-B179).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, H.; Zhang, K.; Jiang, Y.B.; Cao, M.H. Research on Axial Force Prediction and Safety Warning Model of Steel Bracing System in Deep Foundation Pit of Subway Station. J. Disaster Prev. Mitig. Eng. 2023, 43, 576–587. [Google Scholar]

- Yan, M. Research on Safety Monitoring and Prediction and Early Warning of Ultra-large and Ultra-deep Foundation Pit for Large Water Purification Plant; Kunming University of Science and Technology: Kunming, China, 2023. [Google Scholar]

- Li, L. Research on Intelligent Warning of Safety Risk Based on BIM and Multi-Source Monitoring During the Subway Construction; China University of Mining and Technology: Xuzhou, China, 2022. [Google Scholar]

- Clough, G.W.; O’Rourke, T.D. Construction induced movements of in situ walls. In Design and Performance of Earth Retaining Structures; Geotechnical Special Publication: Reston, VA, USA, 1990; Available online: https://www.researchgate.net/publication/279565072_Construction_induced_movements_of_in_situ_wall (accessed on 1 July 2025).

- Long, M. Database for retaining wall and ground movements due to deep excavations. J. Geotech. Geoenviron. Eng. 2001, 127, 203–224. [Google Scholar] [CrossRef]

- Moormann, C. Analysis of Wall and Ground Movements Due to Deep Excavations in Soft Soil Based on a New Worldwide Database. Soils Found. 2004, 44, 87–98. [Google Scholar] [CrossRef]

- Yin, L.J.; Li, Y.J.; Zhu, Y.P. Monitoring and numerical simulation of support for foundation pit at Yanyuan Road Station of Lanzhou Metro. Chin. J. Geotech. Eng. 2021, 43, 111–116. [Google Scholar] [CrossRef]

- Wang, W.D. Analytical methods and controlling techniques for deformation and environmental influence of deep excavations in soft soils. Chin. J. Geotech. Eng. 2024, 46, 1–25. [Google Scholar] [CrossRef]

- Huang, H.; Ruan, B.; Wu, X.G.; Qin, Y.W. Parameterized modeling and safety simulation of shield tunnel based on BIM-FEM automation framework. Autom. Constr. 2024, 162, 105362. [Google Scholar] [CrossRef]

- Zhang, L.F.; Chen, Z.H.; Nian, G.Q.; Bao, M.; Zhou, Z.H. Base friction testing methodology for the deformation of rock masses caused by mining in an open-pit slope. Measurement 2023, 206, 112235. [Google Scholar] [CrossRef]

- Chen, S.J.; Gu, X.Q.; Gao, G.Y. Comparison and application of small strain shear moduli from field and laboratory measurements. Chin. J. Geotech. Eng. 2019, 41, 133–136. [Google Scholar] [CrossRef]

- An, Z.Z.; Liu, T.Y.; Zhang, Q.L.; Zhang, Z.S.; Huangfu, Z.H.; Li, Q.B. Vibration compaction process model for rockfill materials considering viscoelastic-plastic deformation. Autom. Constr. 2021, 131, 103889. [Google Scholar] [CrossRef]

- Shan, J.Z.; Zhang, X.; Liu, Y.W.; Zhang, C.B.; Zhou, J.H. Deformation prediction of large-scale civil structures using spatiotemporal clustering and empirical mode decomposition-based long short-term memory network. Autom. Constr. 2024, 158, 105222. [Google Scholar] [CrossRef]

- Xue, Y.J. Time Series Prediction of Deep Foundation Pit Deformation in Soil-rock Composite Stratum Based on Machine Learning Algorithm. Mod. Tunn. Technol. 2022, 59, 77–85. [Google Scholar]

- Meng, G.W.; Liu, J.L.; Huang, J.S.; Wu, B.; Ou, Q. Automatic Prediction of the Deformation of a Retaining Structure in a Deep Foundation Pit Construction Based on a BP Artificial Neural Network. Urban Rapid Rail Transit 2022, 35, 80–88. [Google Scholar]

- Feng, T.G.; Wang, C.R.; Zhang, J.; Wang, B.; Jin, Y.F. An improved artificial bee colony-random forest (IABC-RF) model for predicting the tunnel deformation due to an adjacent foundation pit excavation. Undergr. Space 2022, 7, 514–527. [Google Scholar] [CrossRef]

- Cao, J.; Li, W.Y.; Zhao, D.S.; Song, Z.G.; Ding, W.Y. Forecast of building inclination around foundation pit based on PSO-LSSVM model. Comput. Eng. Appl. 2016, 52, 254–259. [Google Scholar]

- Chen, H.Y.; Shen, Q.P.; Feng, Z.B.; Liu, Y. Vulnerability assessment in urban metro systems based on an improved cloud model and a Bayesian network. Sustain. Cities Soc. 2023, 98, 104823. [Google Scholar] [CrossRef]

- Wang, M.W.; Wang, X.; Liu, Q.Y.; Shen, F.Q.; Jin, J.L. A novel multi-dimensional cloud model coupled with connection numbers theory for evaluation of slope stability. Appl. Math. Model. 2020, 77, 426–438. [Google Scholar] [CrossRef]

- Xie, B.; Liu, Y.; Cui, L.B. High Altitude Railway Construction Risk Warning Based on Improved Game Theory-2D Cloud Model. Railw. Stand. Des. 2025, 69, 144–152. [Google Scholar]

- Zhang, Q.Y.; Babanajad, S.; Sun, H.R.; Braley, J.; Alavi, A.H. Multi-resource fusion of nondestructive evaluation data for bridge deck assessment using discrete wavelet transform and Dempster-Shafer theory. Measurement 2023, 220, 113303. [Google Scholar] [CrossRef]

- Chen, X.D.; Xu, Y.; Guo, H.D.; Hu, S.W.; Gu, C.S.; Hu, J.; Que, H.; Guo, J. Comprehensive evaluation of dam seepage safety combining deep learning with Dempster-Shafer evidence theory. Measurement 2024, 226, 114172. [Google Scholar] [CrossRef]

- Fei, L.G.; Feng, Y.Q.; Wang, H.L. Modeling heterogeneous multi-attribute emergency decision-making with Dempster-Shafer theory. Comput. Ind. Eng. 2021, 161, 107633. [Google Scholar] [CrossRef]

- Belmahdi, F.; Lazri, M.; Ouallouche, F.; Labadi, K.; Absi, R.; Ameur, S. Application of Dempster-Shafer theory for optimization of precipitation classification and estimation results from remote sensing data using machine learning. Remote Sens. Appl. Soc. Environ. 2023, 29, 100906. [Google Scholar] [CrossRef]

- Luo, Z.Q.; Li, Y.Y.; Qin, Y.G.; Wen, L. A method developed for early warning of under ground rock mass instability in mining area based on Cusp catastrophe model and D-S fusion evidence theory. Chin. J. Geol. Hazard Control 2020, 31, 60–69. [Google Scholar]

- Huang, J.; Weng, C.P.; Ding, W.Q. Study on the Early-warning Index of Deflection of Deep Foundation Excavation Group in Coastal Under-consolidated Stratum. Constr. Technol. 2021, 50, 95–98+108. [Google Scholar] [CrossRef]

- Wang, T.; Shi, B. Study on safety level and deformation control index of transit foundation pit works in Jiangsu Province. Mod. Uransit 2019, 07, 89–92. [Google Scholar] [CrossRef]

- Wang, Y.S.; Zhang, W.J.; Zeng, G.D. Study on Deformation Law and Early Warning Monitoring Index of Deep Foundation Pit at Water-rich Sandy Stratum. Bull. Sci. Technol. 2018, 34, 227–231. [Google Scholar] [CrossRef]

- Yan, X.; Liu, H.S.; Tu, N.W.; Shu, S.W. Study on Early-warning of Coal and Gas Outburst in Mines Based on Image Recognition. Control. Eng. China 2023, 30, 1935–1942. [Google Scholar] [CrossRef]

- Qiu, W.X.; Zhao, L.H.; Wu, B. A Multi-source Information Fusion Assessment for the Tunneling Collapse Disaster Based on Evidential Reasoning. J. Hunan Univ. (Nat. Sci.) 2024, 51, 190–200. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, W.X.; Xu, S.X. A Method for Assessing Probability of Tunnel Collapse Based on Artificial Intelligence Deformation Prediction. Earth Sci. 2024, 49, 4204–4215. [Google Scholar] [CrossRef]

- Ma, Q.; Lu, L.F.; Li, Q.F.; Wang, Z.P. Green Construction Grade Evaluation of Large Channels Based on Uncertain AHP-Multidimensional Cloud Model. Sustainability 2022, 14, 6143. [Google Scholar] [CrossRef]

- Li, P.Y.; Han, H.D.; Wang, D.H.; Wang, C.S. Current situation and development trends of suitability evaluation of urban underground space resources. Sediment. Geol. Tethyan Geol. 2021, 41, 121–128. [Google Scholar] [CrossRef]

- Xu, X.B.; Guo, H.H.; Zhang, Z.H.; Yu, S.N.; Chang, L.L.; Steyskal, F.; Brunauer, G. A cloud model-based interval-valued evidence fusion method and its application in fault diagnosis. Inf. Sci. 2024, 658, 119995. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, S.L.; Xiang, J.W.; Sun, R.X. A conflict evidence fusion method based on the composite discount factor and the game theory. Inf. Fusion 2023, 94, 1–16. [Google Scholar] [CrossRef]

- Xue, P.Y.; Fei, L.G.; Ding, W.P. A volunteer allocation optimization model in response to major natural disasters based on improved Dempster-Shafer theory. Expert Syst. Appl. 2024, 236, 121285. [Google Scholar] [CrossRef]

- Kavya, R.; Jabez, C.; Subhrakanta, P. A new belief interval-based total uncertainty measure for Dempster-Shafer theory. Inf. Sci. 2023, 642, 119150. [Google Scholar] [CrossRef]

- Li, S.L.; Liang, W.Q.; Chen, X.B.; Xie, Q.Y.; Xiao, Y.Z.; Sun, Q.F. Safety Monitoring and Early Warning Indexes of Urban Underground Space. Geol. Explor. 2024, 60, 95–104. [Google Scholar] [CrossRef]

- Zeng, Y.S. Monitoring and Analysis of Ultra-deep Foundation Pit of Shield Working Well. Subgrade Eng. 2024, 2, 228–234. [Google Scholar]

- Kazemi, F.; Asgarkhani, N.; Jankowski, R. Optimization-based stacked machine-learning method for seismic probability and risk assessment of reinforced concrete shear walls. Expert Syst. Appl. 2024, 255, 124897. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).