The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions

Abstract

1. Introduction

2. Power System of Agricultural Machinery Chassis

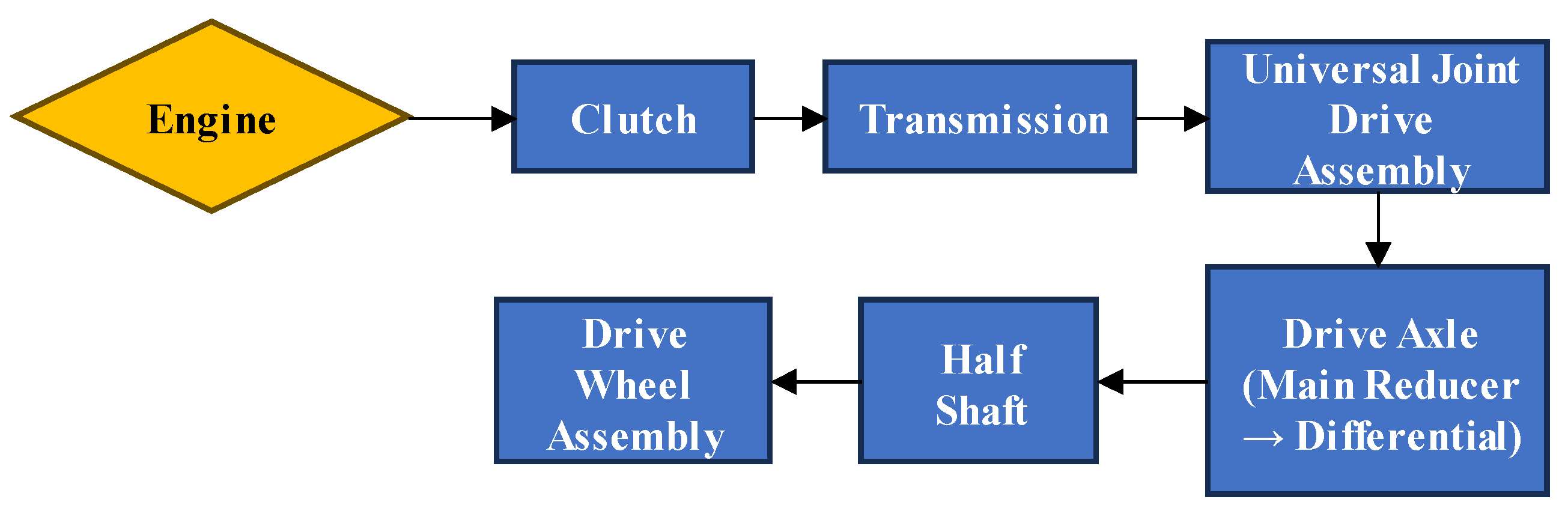

2.1. Mechanical Power System

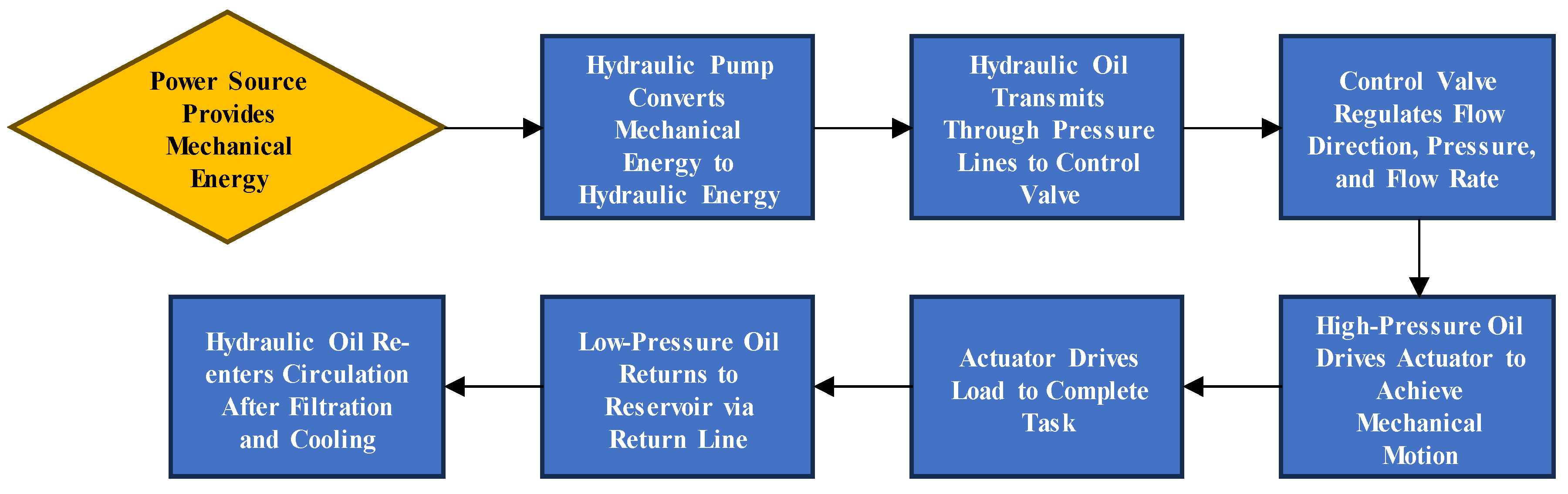

2.2. Hydraulic Power System

2.3. Electric Power System

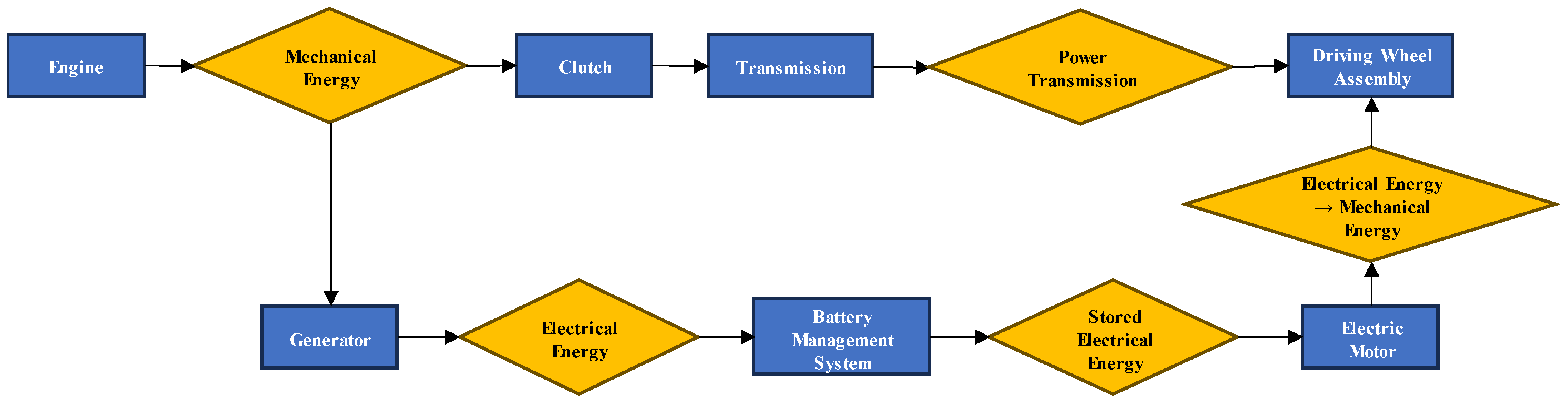

2.4. Hybrid Power System

3. Chassis Travel Mechanism System of Agricultural Machinery

3.1. Wheeled Travel Mechanism

3.2. Tracked Chassis Systems

4. Chassis Leveling Systems of Agricultural Machinery

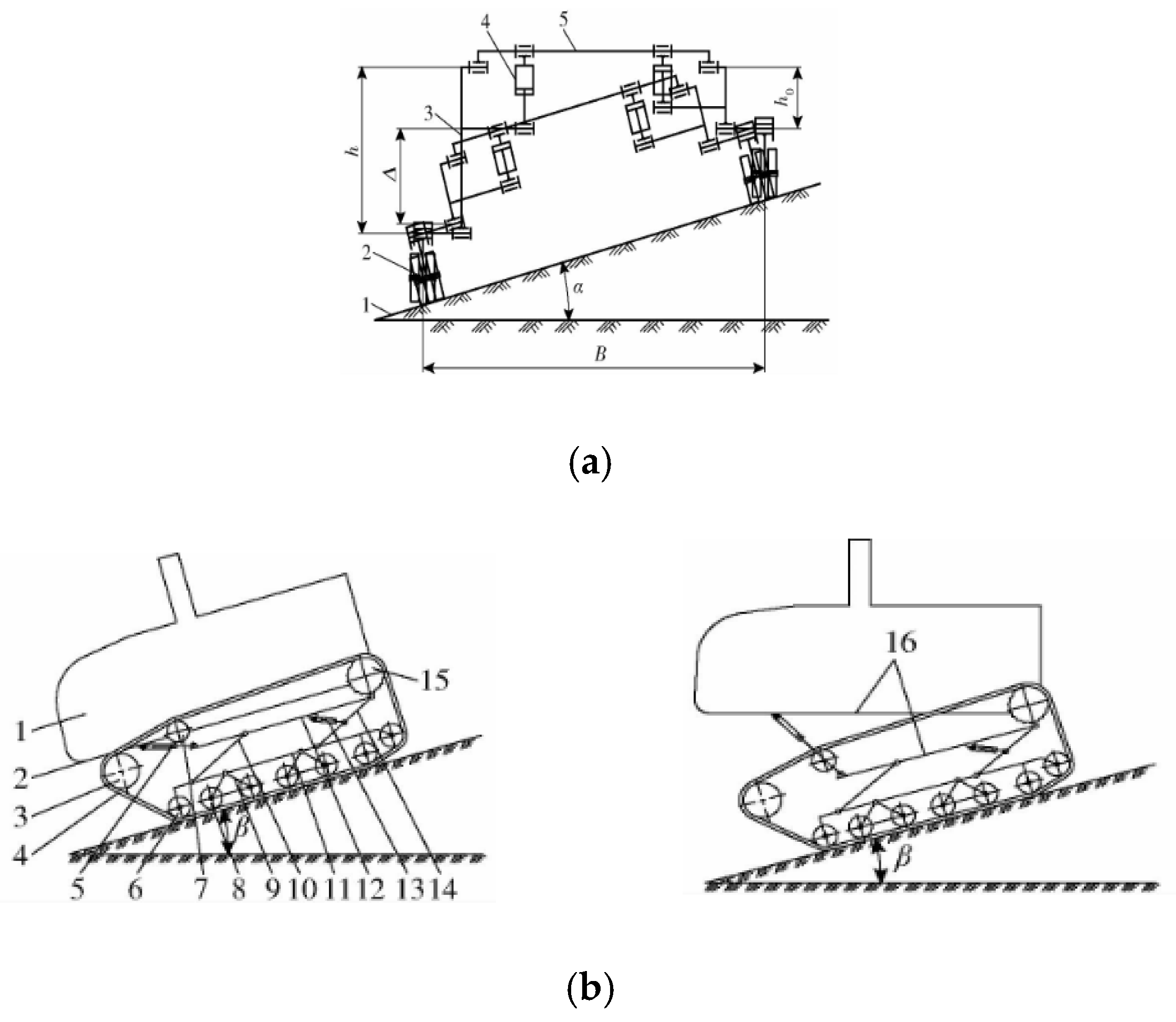

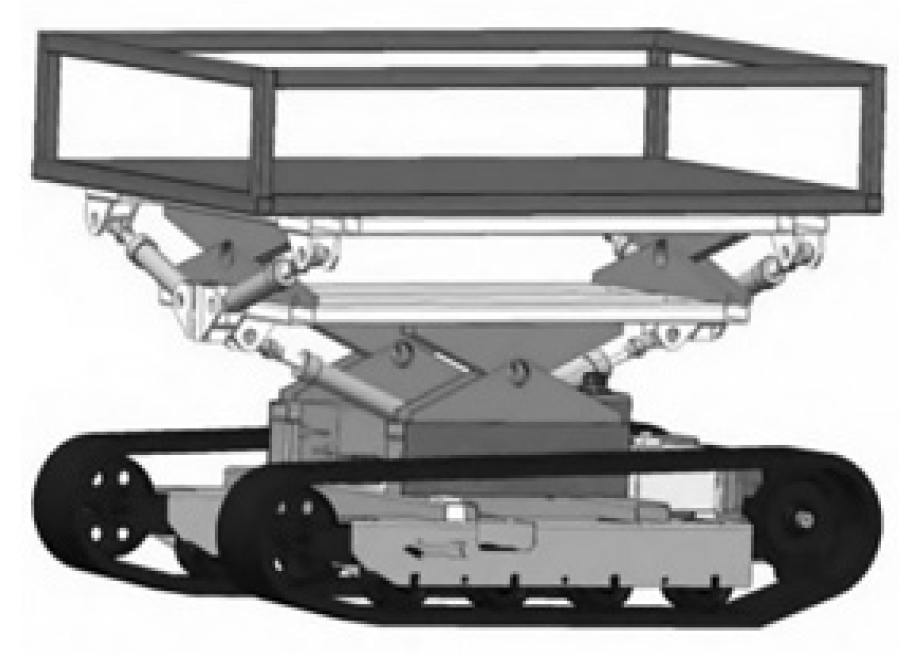

4.1. Mechanisms and Methods for Leveling

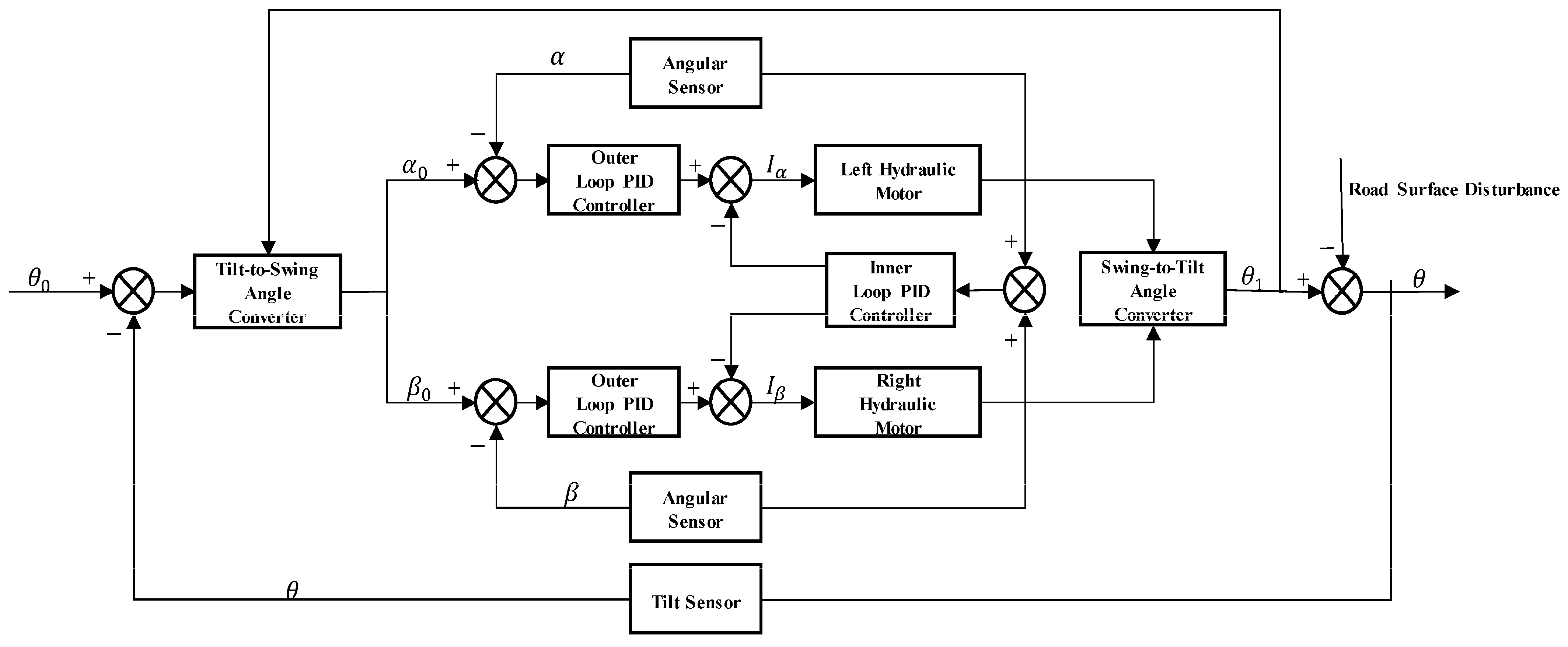

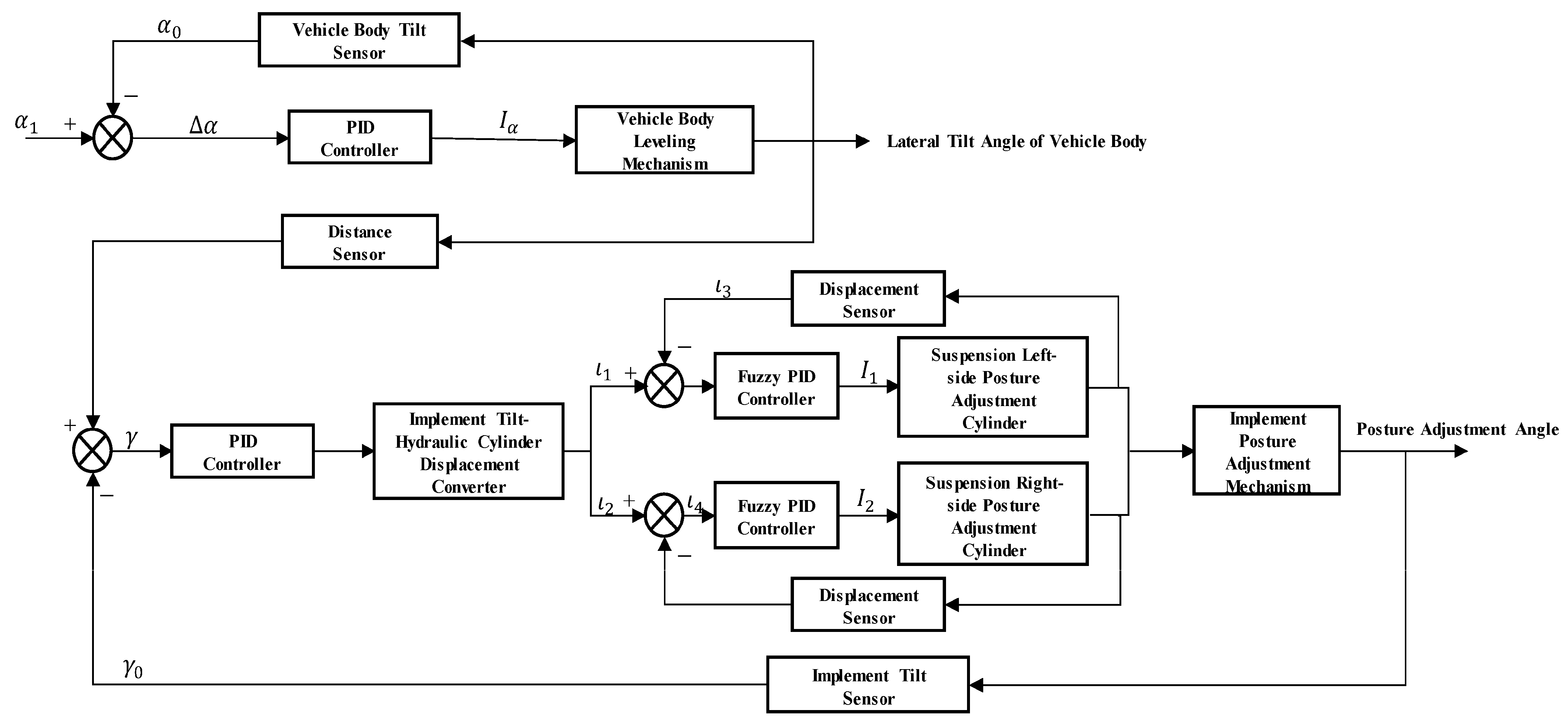

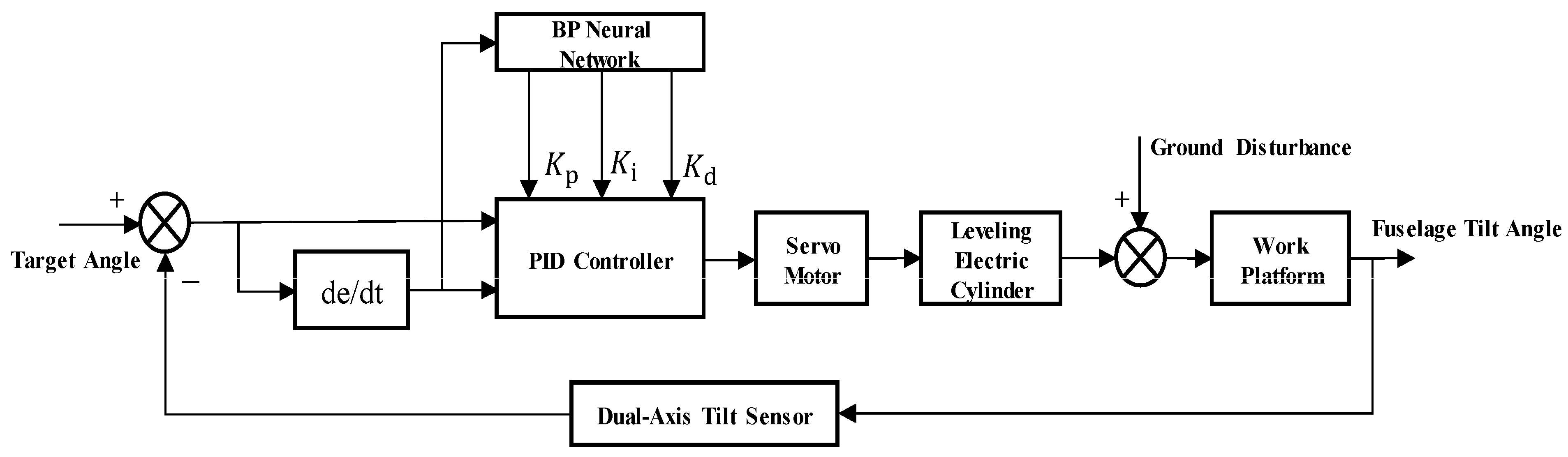

4.2. Control Systems of Leveling

5. Summary and Future Perspectives

- (1)

- Innovative Multi-Modal Mobility Mechanisms: Enhance adaptability to wet and cohesive soils through terrain-adaptive structural optimization coupled with soil-friendly mobility design.

- (2)

- Cooperative Control Algorithm Optimization: Improve power distribution efficiency by 15–20% through energy-driven approaches alongside energy efficiency optimization.

- (3)

- Integrated Intelligent Sensing Systems: Upgrade leveling systems utilizing dual-loop fuzzy PID controllers combined with sliding mode observer technologies to achieve high precision and adaptability; develop specialized MEMS tilt sensors along with multi-source fusion positioning modules specifically designed for hilly terrain; establish real-time mapping models of terrain–load–energy consumption aimed at mitigating chassis instability on slopes exceeding 25°.

5.1. Innovative Multi-Modal Mobility Mechanisms

5.1.1. Terrain-Adaptive Mechanism Optimization

5.1.2. Intelligent Mobility Mechanisms and Soil-Friendly Design

5.2. Cooperative Control Algorithm Optimization

5.2.1. Energy-Drive Cooperative Control

5.2.2. Deep Integration of Powertrains and Energy-Efficiency Optimization

5.3. Integrated Intelligent Perception Systems

- (1)

- Adaptive Leveling Systems: Employing model predictive control (MPC) algorithms to facilitate rapid responses and enhance leveling precision during operations on slopes;

- (2)

- Intelligent Navigation Systems: Integrating three-dimensional path planning to achieve centimeter-level operational accuracy on sloped terrains;

- (3)

- Load-Power Matching Systems: Optimizing fuel efficiency in hybrid machinery through adaptive adjustments.

5.3.1. High-Precision and Adaptive Upgrades for Leveling Systems

5.3.2. Construction of Multi-Modal Intelligent Operation Platforms

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Li, M.; Luo, X. 50 Years of Agricultural Mechanization in China. AMA Agric. Mech. Asia Afr. Lat. Am. 2020, 51, 86–92. [Google Scholar]

- Wang, B.; Du, X.; Wang, Y.; Mao, H. Multi-machine collaboration realization conditions and precise and efficient production mode of intelligent agricultural machinery. Int. J. Agric. Biol. Eng. 2024, 17, 27–36. [Google Scholar]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.; Zhang, T.; Zhang, P.; Yao, M.; Li, J.; Sun, Z.; Ma, G.; Chen, X.; Hu, J. Key Technologies in Intelligent Seeding Machinery for Cereals: Recent Advances and Future Perspectives. Agriculture 2025, 15, 8. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zhang, Z. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2023, 13, 51. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, S.; Jia, W. Current situation and development of agricultural mechanization in hilly and mountainous areas. J. Drain. Irrig. Mach. Eng. 2022, 40, 535–540. [Google Scholar]

- Zheng, Y.; Jiang, S.; Chen, B.; Lv, H.; Wan, C.; Kang, F. Review on Technology and Equipment of Mechanization in Hilly Orchard. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–20. [Google Scholar]

- Sun, J.; Liu, Z.; Yang, F.; Sun, Q.; Liu, Q.; Luo, P. Research Review of Agricultural Equipment and Slope Operation Key Technologies in Hilly and Mountains Region. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2023, 54, 1–18. [Google Scholar]

- Zhu, Y.; Cui, B.; Yu, Z.; Gao, Y.; Wei, X. Tillage Depth Detection and Control Based on Attitude Estimation and Online Calibration of Model Parameters. Agriculture 2024, 14, 2130. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, H.; Li, H.; Li, Y.; Ding, Z.; Chen, J. Developments of crawler steering gearbox for combine harvester straight forward and steering in situ. Int. J. Agric. Biol. Eng. 2020, 13, 120–126. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, B.; Pan, S.; Ye, Y.; Wang, E.; Mao, H. Task Allocation of Multi-Machine Collaborative Operation for Agricultural Machinery Based on the Improved Fireworks Algorithm. Agronomy 2024, 14, 710. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, W.; Leng, J.; Liu, X.; Xu, H.; Ding, H.; Zhou, J.; Cui, L. Review and Research Prospects on Additive Manufacturing Technology for Agricultural Man-ufacturing. Agriculture 2024, 14, 1207. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Jia, W.; Tai, K.; Wang, X.; Dong, X.; Ou, M. Design and Simulation of Intra-Row Obstacle Avoidance Shovel-Type Weeding Machine in Orchard. Agriculture 2024, 14, 1124. [Google Scholar] [CrossRef]

- Zhang, F.; Teng, S.; Wang, Y.; Guo, Z.; Wang, J.; Xu, R. Design of bionic goat quadruped robot mechanism and walking gait planning. Int. J. Agric. Biol. Eng. 2020, 13, 32–39. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Cheng, C. Development of multi-functional combine harvester with grain harvesting and straw baling. Span. J. Agric. Res. 2017, 15, e0202. [Google Scholar] [CrossRef]

- Han, J.; Yan, X.; Tang, H. Method of controlling tillage depth for agricultural tractors considering engine load characteristics. Biosyst. Eng. 2023, 227, 95–106. [Google Scholar] [CrossRef]

- Zheng, S.; Zhao, X.; Fu, H.; Tan, H.; Zhai, C.; Chen, L. Design and Experimental Evaluation of a Smart Intra-Row Weed Control System for Open-Field Cabbage. Agronomy 2025, 15, 112. [Google Scholar] [CrossRef]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting uniformity performance of motor-driven maize precision seeding systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Cui, B.; Cui, X.; Wei, X.; Zhu, Y.; Ma, Z.; Zhao, Y.; Liu, Y. Design and Testing of a Tractor Automatic Navigation System Based on Dynamic Path Search and a Fuzzy Stanley Model. Agriculture 2024, 14, 2136. [Google Scholar] [CrossRef]

- Dai, D.; Chen, D.; Wang, S.; Li, S.; Mao, X.; Zhang, B.; Wang, Z.; Ma, Z. Compilation and Extrapolation of Load Spectrum of Tractor Ground Vibration Load Based on CEEMDAN-POT Model. Agriculture 2023, 13, 125. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Fu, S.; Feng, K.; Han, X.; Hu, Y.; Zhu, Q.; Wei, X. Analysis of Vibration Characteristics of Tractor–Rotary Cultivator Combination Based on Time Domain and Frequency Domain. Agriculture 2024, 14, 1139. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, J.; Chai, X.; Liu, B.; Zhang, G.; Yao, W. Research status and development trend of key technology of agricultural machinery chassis in hilly and mountainous areas. Comput. Electron. Agric. 2024, 226, 109447. [Google Scholar] [CrossRef]

- Ahn, S.; Choi, J.; Kim, S.; Lee, J.; Choi, C.; Kim, H. Development of an integrated engine-hydro-mechanical transmission control algorithm for a tractor. Adv. Mech. Eng. 2015, 7, 1687814015593870. [Google Scholar] [CrossRef]

- Lu, K.; Liang, J.; Liu, M.; Lu, Z.; Shi, J.; Xing, P.; Wang, L. Research on Transmission Efficiency Prediction of Heavy-Duty Tractors HMCVT Based on VMD and PSO–BP. Agriculture 2024, 14, 539. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, D.; Qin, D.; Hou, W. Study on the Design Method of a New Hydro-Mechanical Continuously Variable Transmission System. IEEE Access 2020, 8, 195411–195424. [Google Scholar] [CrossRef]

- Neto, L.S.; Zimmermann, G.G.; Jasper, S.P.; Savi, D.; Sobenko, L.R. Energy Efficiency Of Agricultural Tractors Equipped with Continuously Variable And Full Powershift Transmission Systems. Eng. Agric. 2022, 42, e20210052. [Google Scholar] [CrossRef]

- Md-Tahir, H.; Zhang, J.; Xia, J.; Zhou, Y.; Zhou, H.; Du, J.; Sultan, M.; Mamona, H. Experimental Investigation of Traction Power Transfer Indices of Farm-Tractors for Effi-cient Energy Utilization in Soil Tillage and Cultivation Operations. Agronomy 2021, 11, 168. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, X.; Song, Y.; Wang, G.; Zhai, Z. Energy and Fuel Consumption of a New Concept of Hydro-Mechanical Tractor Transmis-sion. Sustainability 2023, 15, 10809. [Google Scholar] [CrossRef]

- Xiao, M.; Zhao, J.; Wang, Y.; Zhang, H.; Lu, Z.; Wei, W. Fuel economy of multiple conditions self-adaptive tractors with hydro-mechanical CVT. Int. J. Agric. Biol. Eng. 2018, 11, 102–109. [Google Scholar] [CrossRef]

- Ye, B.; Zhao, Y.; Yu, G.; Li, G. Multi-objective reliability optimization design of tractor’s NGW type planetary gear final trans-mission. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2008, 24, 89–94. [Google Scholar]

- Liang, L.; Li, Q.; Tan, Y.; Yang, Z. Multi-parameter optimization of HMCVT fuel economy using parameter cyclic algorithm. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 48–55. [Google Scholar]

- Wu, C.; Wen, L.; Chen, Z.; Wu, X.; Zhao, X.; Tang, X.; Yang, W. Minimum-jerk velocity planning and control for CVT tractorvelocity regulation. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 28–35. [Google Scholar]

- Fu, S.; Zhang, Y.; Zhang, W.; Mao, E.; Wang, G.; Du, Y. PST Shift Strategy and Hardware in Loop Test Considering Adaptive Compensation of Random Load. Trans. Chin. Soc. Agric. Mach. 2022, 53, 408–416. [Google Scholar]

- Fu, S.; Li, Z.; Du, Y.; Mao, E.; Zhu, Z. Matching Optimization for Tractor Powertrain Based on Improved NSGA-II; Algorithm. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 349–357. [Google Scholar]

- Xiao, M.; Zhao, Y.; Wang, H.; Xu, X.; Bartos, P.; Zhu, Y. Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder. Agriculture 2024, 14, 595. [Google Scholar] [CrossRef]

- Yang, F.; Du, Y.; Wen, C.; Li, Z.; Mao, E.; Zhu, Z. Optimization design of the hydro-pneumatic suspension system for high clearance self-propelled sprayer using improved MOPSO algorithm. Int. J. Agric. Biol. Eng. 2024, 17, 109–122. [Google Scholar]

- Zhang, C.; Li, C.; Zhao, C.; Li, L.; Gao, G.; Chen, X. Design of Hydrostatic Chassis Drive System for Large Plant Protection Machine. Agriculture 2022, 12, 1118. [Google Scholar] [CrossRef]

- Hu, K.; Zhang, W. Design and simulation for driving system and steering system of hydraulic chassis of rice transplanter. Adv. Mech. Eng. 2018, 10, 1687814018808901. [Google Scholar] [CrossRef]

- Sun, T.; Mao, E.; Fu, L.; Song, Z.; Li, Z.; Li, P. Design and Experiment of Spray Machine Drive Anti-skid System Based on Variable Motor Control. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2024, 55, 158–166. [Google Scholar]

- Chen, S.; Du, Y.; Xie, B.; Song, Z.; Mao, E.; Chen, Y. Design and performance analysis of drive system for high clearance self-propelled corn detasseling machine. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 10–17. [Google Scholar]

- Li, S.; Chen, H.; Peng, J.; Meng, L.; Zhang, K.; Li, M. Design and Test of Hydraulic Remote Control Crawler Power Chassis for Hilly and Mountainous Orchards. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2024, 55, 119–127. [Google Scholar]

- Zhang, H.; Zheng, J. Comparison of straight line driving synchronous control methods and validation of 4WD sprayer chassis with hydraulic power. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 43–50. [Google Scholar]

- Moreda, G.; Muñoz-García, M.; Barreiro, P. High voltage electrification of tractor and agricultural machinery—A review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Liu, H.; Shen, C.; Hu, L.; Chang, C.; Cao, G. Research progress and development trend of electric agricultural equipments. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 39–51. [Google Scholar]

- Baek, S.; Baek, S.; Jeon, H.; Kim, W.; Kim, Y.; Sim, T.; Choi, K.; Hong, S.; Kim, H.; Kim, Y. Traction Performance Evaluation of the Electric All-Wheel-Drive Tractor. Sensors 2022, 22, 785. [Google Scholar] [CrossRef]

- Mao, Y.; Wu, Y.; Yan, X.; Liu, M.; Xu, L.; Zhang, L. Simulation and experimental research of electric tractor drive system based on Modelica. PLoS ONE 2022, 17, e0276231. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, M.; He, Y.; Chen, L.; Shen, J.; Xu, L. Distributed Drive Control Method of Electric Harvester Based on BLF Multi-constraint Inversion Control. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2024, 55, 212–220. [Google Scholar]

- Deng, X.; Sun, H.; Lu, Z.; Cheng, Z.; An, Y.; Chen, H. Research on Dynamic Analysis and Experimental Study of the Distributed Drive Electric Tractor. Agriculture 2023, 13, 40. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- An, Y.; Wang, L.; Deng, X.; Chen, H.; Lu, Z.; Wang, T. Research on Differential Steering Dynamics Control of Four-Wheel Independent Drive Electric Tractor. Agriculture 2023, 13, 1758. [Google Scholar] [CrossRef]

- Xie, B.; Wang, S.; Wu, X.; Wen, C.; Zhang, S.; Zhao, X. Design and hardware-in-the-loop test of a coupled drive system for electric tractor. Biosyst. Eng. 2022, 216, 165–185. [Google Scholar] [CrossRef]

- Wen, C.-K.; Zhang, S.-L.; Xie, B.; Song, Z.-H.; Li, T.-H.; Jia, F.; Han, J.-G. Design and verification innovative approach of dual-motor power coupling drive systems for electric tractors. Energy 2022, 247, 123538. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Du, Y.; Mao, E. Powertrain parameter matching and optimal design of dual-motor driven electric tractor. Int. J. Agric. Biol. Eng. 2019, 12, 33–41. [Google Scholar] [CrossRef]

- Du, Y.; Sun, X.; Sun, Y.; Xiao, F.; Zhu, X.; Mao, Y.; Yan, X. Electronic pole-changing strategy and analysis for PC-DSPM motor in electric tractors. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 44–53. [Google Scholar]

- Wu, Y.; Zhou, X.; Zhang, L.; Yang, X. Compensation control strategy for complex disturbance in VLF-PM motor of electric tractors with PTO system. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 92–103. [Google Scholar]

- Li, T.; Xie, B.; Wang, D.; Zhang, S.; Li, L. Real-time Adaptive Energy Management Strategy for Dual-motor-driven Electric Tractors. Trans. Chin. Soc. Agric. Mach. 2020, 51, 530–543. [Google Scholar]

- Li, L.; Ran, G.; Gao, Z.; Liu, Y.; Nie, J. Adaptive energy management and capacity configuration for electric tractor power supply sys-tem. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 82–91. [Google Scholar]

- He, X.; Yu, Q.; Jiang, Z.; Tan, Y.; Chen, Y.; Xie, B.; Wen, C. Dual-layer adaptive power management strategy for E-tractor incorporating operating infor-mation and deep reinforcement learning. Energy 2025, 319, 134942. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Zhao, X.; Wang, S.; Xie, B.; Song, Z.; Wang, D. Co-optimization energy management strategy for a novel dual-motor drive system of electric tractor considering efficiency and stability. Energy 2023, 281, 128074. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, C.; Han, J. Research on Energy Management of Fuel-Cell Electric Tractor Based on Quadratic Utility Function. J. Energy Eng. 2023, 149, 04022044. [Google Scholar] [CrossRef]

- de Melo, R.R.; Tofoli, F.L.; Daher, S.; Antunes, F.L.M. Wheel Slip Control Applied to an Electric Tractor for Improving Tractive Efficiency and Reducing Energy Consumption. Sensors 2022, 22, 4527. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Z.; Jiang, Y.; Leng, Y.; Tang, J.; Wang, R.; Lv, X. Simulation and Experiment of the Smoothness Performance of an Electric Four-Wheeled Chassis in Hilly and Mountainous Areas. Sustainability 2023, 15, 16868. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Sun, Y. Development and Testing of the Power Transmission System of a Crawler Electric Tractor for Greenhouses. Appl. Eng. Agric. 2020, 36, 797–805. [Google Scholar] [CrossRef]

- Han, J.; Wang, F. Design and Testing of a Small Orchard Tractor Driven by a Power Battery. Eng. Agrícola 2023, 43, e20220195. [Google Scholar]

- Tang, Z.; Wang, H.; Liu, S.; Lu, D.; Tang, Y. Development of Structure and Control System of Self-Propelled Small Green Vegetables Combine Harvester. J. Agric. Sci. Technol. 2023, 25, 1045–1058. [Google Scholar]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Soma, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Trac-tors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical Performance Investigation of a Hybrid eCVT Specialized Agricultural Tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Zhang, X.; Song, Z.; Li, W. Design of distributed hybrid electric tractor based on axiomatic design and Extenics. Adv. Eng. Inform. 2022, 54, 101765. [Google Scholar] [CrossRef]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Sun, L.; Liu, M.; Wang, Z.; Wang, C.; Luo, F. Research on Load Spectrum Reconstruction Method of Exhaust System Mounting Bracket of a Hybrid Tractor Based on MOPSO-Wavelet Decomposition Technique. Agriculture 2023, 13, 1919. [Google Scholar] [CrossRef]

- Zhu, Z.; Lai, L.; Wang, D.; Chen, L.; Cai, Y. Energy saving characteristics of the mechanical hydraulic tractor power system with oil electric hybrid power. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 52–60. [Google Scholar]

- Zhu, Z.; Yang, Y.; Wang, D.; Cai, Y.; Lai, L. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Mul-ti-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Radrizzani, S.; Panzani, G.; Trezza, L.; Pizzocaro, S.; Savaresi, S.M. An Add-On Model Predictive Control Strategy for the Energy Management of Hybrid Electric Tractors. IEEE Trans. Veh. Technol. 2024, 73, 1918–1930. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, M.; Liu, M.; Li, H.; Zhao, B.; Yan, X. Dual-Source Cooperative Optimized Energy Management Strategy for Fuel Cell Tractor Considering Drive Efficiency and Power Allocation. Agriculture 2024, 14, 1455. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, J.; Liu, M.; Zhou, Z.; Liu, C. Control algorithm and energy management strategy for extended range electric tractors. Int. J. Agric. Biol. Eng. 2017, 10, 35–44. [Google Scholar]

- Wu, Z.; Wang, J.; Xing, Y.; Li, S.; Yi, J.; Zhao, C. Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules. Agriculture 2023, 13, 1303. [Google Scholar] [CrossRef]

- Han, M.; Xu, K.; Liao, Y.; Li, M.; Yu, K. Co-simulation and Test of Electro-Hydraulic System of Novel Hybrid Track. Trans. Chin. Soc. Agric. Mach. 2024, 55, 396–408,418. [Google Scholar]

- Wang, Z.; Zhou, J.; Wang, J. Research on Energy Management Model for Extended-range Electric Rotary-tilling Tractor. Trans. Chin. Soc. Agric. Mach. 2022, 54, 428–438. [Google Scholar]

- Han, L.; Mao, H.; Hu, J.; Kumi, F. Development of a riding-type fully automatic transplanter for vegetable plug seedlings. Span. J. Agric. Res. 2019, 17, e0205. [Google Scholar] [CrossRef]

- Liu, S.; Tang, Z.; Zhang, B.; Liang, Y.; Gu, X. Ergonomic Design of Cab Structure for Wheeled Combine Harvester. Eng. Agric. 2022, 42, e20220023. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Lu, E.; Ma, Z.; Li, Y.; Xu, L.; Tang, Z. Adaptive backstepping control of tracked robot running trajectory based on real-time slip parameter estimation. Int. J. Agric. Biol. Eng. 2020, 13, 178–187. [Google Scholar] [CrossRef]

- Xu, L.; Chai, X.; Gao, Z.; Li, Y.; Wang, Y. Experimental study on driver seat vibration characteristics of crawler-type combine harvester. Int. J. Agric. Biol. Eng. 2019, 12, 90–97. [Google Scholar] [CrossRef]

- Ben Hazem, Z.; Fotuhi, M.J.; Bingul, Z. A Comparative Study of the Joint Neuro-Fuzzy Friction Models for a Triple Link Rotary Inverted Pendulum. IEEE Access 2020, 8, 49066–49078. [Google Scholar] [CrossRef]

- Ahmadi, I. Dynamics of tractor lateral overturn on slopes under the influence of position disturbances (model development). J. Terramechanics 2011, 48, 339–346. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V.; Capacci, E. Lateral Stability Performance of Articulated Narrow-Track Tractors. Agronomy 2021, 11, 2512. [Google Scholar] [CrossRef]

- Li, Z.; Mitsuoka, M.; Inoue, E.; Okayasu, T.; Hirai, Y. Development of stability indicators for dynamic Phase I overturn of conventional farm tractors with front axle pivot. Biosyst. Eng. 2015, 134, 55–67. [Google Scholar] [CrossRef]

- Li, Z.; Mitsuoka, M.; Inoue, E.; Okayasu, T.; Hirai, Y. Effect of Geometric Configuration on Tractor Stability Characteristics. J. Fac. Agric. Kyushu Univ. 2016, 61, 153–156. [Google Scholar] [CrossRef]

- Li, Z.; Mitsuoka, M.; Inoue, E.; Okayasu, T.; Hirai, Y.; Zhu, Z. Parameter sensitivity for tractor lateral stability against Phase I overturn on random road surfaces. Biosyst. Eng. 2016, 150, 10–23. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Z.; Qin, J.; Mao, E.; Mitsuoka, M.; Inoue, E.; Shin, S. Factorial significance on tractor stability under variation of terrain roughness employing the Taguchi method. Int. J. Agric. Biol. Eng. 2018, 11, 88–94. [Google Scholar] [CrossRef]

- Qin, J.; Zhu, Z.; Ji, H.; Zhu, Z.; Li, Z.; Du, Y.; Song, Z.; Mao, E. Simulation of active steering control for the prevention of tractor dynamic rollover on random road surfaces. Biosyst. Eng. 2019, 185, 135–149. [Google Scholar] [CrossRef]

- Qin, J.; Wu, A.; Song, Z.; He, Z.; Suh, C.S.; Zhu, Z.; Li, Z. Recovering tractor stability from an intensive rollover with a momentum flywheel and active steering: System formulation and scale-model verification. Comput. Electron. Agric. 2021, 190, 106458. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, J.; Liu, F.; He, Z.; Lai, Q.; Zhu, Z.; Song, Z.; Li, Z. Algorithm and scale experiment of gyro-based tractor rollover control towards hilly farmland application. Comput. Electron. Agric. 2024, 220, 108925. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Song, Z.; Ni, Y.; He, Z.; Zhai, Z.; Zhu, Z.; Zhou, Q.; Song, Z.; Li, Z. Advances in tractor rollover and stability control: Implications for off-road driving safety. Comput. Electron. Agric. 2024, 226, 109483. [Google Scholar] [CrossRef]

- He, Z.; Song, Z.; Wang, L.; Zhou, X.; Gao, J.; Wang, K.; Yang, M.; Li, Z. Fasting the stabilization response for prevention of tractor rollover using active steering: Controller parameter optimization and real-vehicle dynamic tests. Comput. Electron. Agric. 2022, 204, 107525. [Google Scholar] [CrossRef]

- Song, Z.; Wang, L.; Liu, Y.; Wang, K.; He, Z.; Zhu, Z.; Qin, J.; Li, Z. Actively steering a wheeled tractor against potential rollover using a sliding-mode control algorithm: Scaled physical test. Biosyst. Eng. 2022, 213, 13–29. [Google Scholar] [CrossRef]

- Yuan, L.; Tang, Z.; Liu, S.; Wang, T.; Ding, Z. Design for Copying Grouser and Bionic Convex Hull Patterns on Track Surfaces of Crawler Combine Harvesters. Agriculture 2024, 14, 1079. [Google Scholar] [CrossRef]

- Inoue, E.; Mitsuoka, M.; Rabbani, M. Investigation of Nonlinear Vibration Characteristics of Agricultural Rubber Crawler Vehicles. AMA Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 89–93. [Google Scholar]

- Tang, Z.; Ren, H.; Li, X.; Liu, X.; Zhang, B. Structure Design and Bearing Capacity Analysis for Crawler Chassis of Rice Combine Harvester. Complexity 2020, 2020, 7610767. [Google Scholar] [CrossRef]

- Keller, T.; Arvidsson, J. A model for prediction of vertical stress distribution near the soil surface below rubber-tracked un-dercarriage systems fitted on agricultural vehicles. Soil Tillage Res. 2016, 155, 116–123. [Google Scholar] [CrossRef]

- Kormanek, M.; Dvořák, J. Ground Pressure Changes Caused by MHT 8002HV Crawler Harvester Chassis. Croat. J. For. Eng. 2021, 42, 201–211. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Zhou, Y.; Zhang, H.; Zappino, E. Inertial Vibration Characteristics of Track Chassis Caused by Reciprocating Motion of Crank Slider. Shock. Vib. 2019, 2019, 4378138. [Google Scholar] [CrossRef]

- Liu, S.; Tang, Z.; Shen, C.; Wang, T.; Liang, Y. Effect of Rice Stubble on Soil Compaction Properties of a Crawler Undergoing Combine Har-vester Harvesting. Eng. Agrícola 2023, 43, e20230057. [Google Scholar] [CrossRef]

- Jing, T.; Tang, Z.; Ding, Z.; Liang, Y.; Fang, M.; Wang, T. Paddy Soil Compaction Effect Undergoing Multi-Dimensional Dynamic Load of Combine Harvester Crawler. Agriculture 2024, 14, 202. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, C.; Yang, T.; Wang, T.; Ni, Y. Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis. Agriculture 2024, 14, 65. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tang, Z.; Cao, Y.; Zhao, Y. Structural Form and Field Operation Effect of Crawler Type Broccoli Harvester. Eng. Agric. 2023, 43, e20230132. [Google Scholar] [CrossRef]

- Neto, L.S.; Kmiecik, L.L.; Jasper, S.P.; Zimmermann, G.G.; Savi, D. Operational and energy performance of 250 kw double wheeled versus rubber half-tracked tractors in the soybean sowing. Eng. Agric. 2020, 40, 617–623. [Google Scholar] [CrossRef]

- Grazioso, A.; di Maria, E.; Giannoccaro, N.I.; Ishii, K. Multibody Modeling of a New Wheel/Track Reconfigurable Locomotion System for a Small Farming Vehicle. Machines 2022, 10, 1117. [Google Scholar] [CrossRef]

- Zhou, B.; Chen, S.; Hu, J.; You, Y.; Wang, D.; Zhang, Q. Multi-body dynamics modeling and test of an articulated steering half-track tractor. Int. J. Agric. Biol. Eng. 2023, 16, 124–133. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy Control Strategy for the Forward Speed of a Combine Harvester Based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Cui, L.; Mao, H.; Xue, X. Hydraulic-drive roll movement control of a spray boom using adaptive robust control strategy. Adv. Mech. Eng. 2019, 11, 1687814018825012. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.; Jing, T.; Liu, S.; Shen, C. Centroid Swinging Property of a Machine Body Undergoing Longitudinal Excitation in a Straw Compression Baler. Eng. Agric. 2024, 44, e20230109. [Google Scholar] [CrossRef]

- Bałchanowski, J. Modelling and Simulation Studies of a Mobile Robot with Self-Leveling Chassis System. J. Theo-Retical Appl. Mech. 2016, 54, 149–161. [Google Scholar] [CrossRef]

- Dettù, F.; Corno, M.; D’aMbrosio, D.; Acquistapace, A.; Taroni, F.; Savaresi, S.M. Modeling, control design and experimental automatic calibration of a leveling system for combine harvesters. Control. Eng. Pr. 2023, 132, 105411. [Google Scholar] [CrossRef]

- Pijuan, J.; Comellas, M.; Nogués, M.; Roca, J.; Potau, X. Active bogies and chassis levelling for a vehicle operating in rough terrain. J. Terramechanics 2012, 49, 161–171. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Li, Z.; Yin, Y.; Liu, X.; Zhao, X. Design and Test of Twisting and Swinging Attitude Adjustment Device of Wheel Hilly Tractor. Trans. Chin. Soc. Agric. Mach. 2021, 53, 425–433. [Google Scholar]

- Sun, J.; Chu, G.; Pan, G.; Meng, C.; Liu, Z.; Yang, F. Design and Performance Test of Remote Control Omnidirectional Leveling Hillside Crawler Tractor. Trans. Chin. Soc. Agric. Mach. 2021, 52, 358–369. [Google Scholar]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, L.; Jing, B.; Chai, X.; Li, Y. Development of a four-point adjustable lifting crawler chassis and experiments in a combine harvester. Comput. Electron. Agric. 2020, 173, 105416. [Google Scholar] [CrossRef]

- Chai, X.; Hu, J.; Ma, T.; Liu, P.; Shi, M.; Zhu, L.; Zhang, M.; Xu, L. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude-Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar] [CrossRef]

- Tan, H.; Wang, G.; Zhou, S.; Jia, H.; Zou, Z.; Qu, M. Development of a crawler chassis attitude adjustment device for a self-propelled maize harvester and experiment of fuselage leveling. Int. J. Agric. Biol. Eng. 2024, 17, 111–120. [Google Scholar]

- Sun, J.; Meng, C.; Zhang, Y.; Chu, G.; Zhang, Y.; Yang, F.; Liu, Z. Design and physical model experiment of an attitude adjustment device for a crawler tractor in hilly and mountainous regions. Inf. Process. Agric. 2020, 7, 466–478. [Google Scholar] [CrossRef]

- Gao, Q.; Gao, F.; Tian, L.; Li, L.; Ding, N.; Xu, G.; Jiang, D. Design and development of a variable ground clearance, variable wheel track self-leveling hillside vehicle power chassis (V2-HVPC). J. Terramechanics 2014, 56, 77–90. [Google Scholar] [CrossRef]

- Denis, D.; Thuilot, B.; Lenain, R. Online adaptive observer for rollover avoidance of reconfigurable agricultural vehicles. Comput. Electron. Agric. 2016, 126, 32–43. [Google Scholar] [CrossRef]

- Gonzalez, D.O.; Martin-Gorriz, B.; Berrocal, I.I.; Hernandez, B.M.; Garcia, F.C.; Sanchez, P.M. Development of an automatically deployable roll over protective structure for agricultural tractors based on hydraulic power: Prototype and first tests. Comput. Electron. Agric. 2016, 124, 46–54. [Google Scholar] [CrossRef]

- Qi, W.; Li, Y.; Zhang, J.; Tan, C.; Liu, C.; Yin, Y. Double Closed Loop Fuzzy PID Control Method of Tractor Body Leveling on Hilly and Moun-tainous Areas. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 17–23, 34. [Google Scholar]

- Yang, F.; Niu, H.; Sun, J.; Liu, Z.; Li, Y.; Zhu, H. Design and Experiment of Attitude Cooperative Control System of Mountain Crawler Tractor and Farm Tools. Trans. Chin. Soc. Agric. Mach. 2022, 53, 414–422. [Google Scholar]

- Jiang, Y.; Sun, Z.; Wang, R.; Ding, R.; Ye, Q. Design and control of a new omnidirectional levelling system for hilly crawler work ma-chines. Comput. Electron. Agric. 2024, 218, 108661. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

- Wang, R.; Jiang, Y.; Ding, R.; Sun, Z.; Xu, K. Omnidirectional levelling control of electromechanical machine using BP neural network PID. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 52–62. [Google Scholar]

- Zhao, X.; Yang, J.; Zhong, Y.; Zhang, C.; Gao, Y. Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot. Agronomy 2024, 14, 1765. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

| Type | Working Principle | Core Characteristics and Performance Metrics | Typical Agricultural Application Scenarios |

|---|---|---|---|

| Mechanical | Gear/chain direct power transmission | Max climbing gradient: 25–30° Energy consumption per unit mass: 2.8–3.5 kJ/kg·km Torque density: ≈50 N·m/kg System efficiency: 60–75% | Small tractors (<50 HP), threshers, conventional harvesters, and other low-complexity equipment |

| Hydraulic | Pump–valve–cylinder energy conversion | Max climbing gradient: 35–40° Energy consumption per unit mass: 2.0–2.5 kJ/kg·km Torque density: >120 N·m/kg System efficiency: 70–80% | Large combine harvesters (e.g., CLAAS LEXION), sugarcane harvesters, orchard lifting platforms, and other high-torque/precision control scenario |

| Electric | Battery–motor direct drive | Max climbing gradient: 40°+ Energy consumption per unit mass: 0.9–1.4 kJ/kg·km Torque density: >200 N·m/kg System efficiency: >90% | Greenhouse operation robots, electric plant protection UAVs, and small electric tractors (e.g., Kubota X tractor) |

| Hybrid | Internal combustion engine + electric motor coordination | Max climbing gradient: 38–42° Energy consumption per unit mass: 1.6–2.0 kJ/kg·km Torque density: ≈150 N·m/kg System efficiency: 80–88% | Large intelligent tractors (e.g., John Deere 6R), silage harvesters, and hilly–mountainous multi-functional platforms |

| Type | Working Principle | Structural Features | Key Parameters | Performance Indicators | Typical Agricultural Application Scenarios |

|---|---|---|---|---|---|

| Wheeled | Frictional drive through tire–ground interaction with steering mechanism for directional control | Simple structure; diverse tire configurations; optional independent suspension | Ground pressure: 50–150 kPa; minimum turning radius: 3–5 m; speed range: 0–40 km/h | Max climbing angle: 25–32; energy consumption per unit mass: 2.5–3.8 kJ/kg·km; traction efficiency: 60–75%; slip rate: 15–30% | Dryland farming in plains (e.g., John Deere 8R tractor), transport vehicles, and orchard management machines (narrow wheelbase design) |

| Tracked | Continuous ground contact via driven sprockets and track plates for pressure distribution | Multi-material track systems; Bogie wheel load-bearing; tension adjustment device | Ground pressure: 15–30 kPa; minimum turning radius: 1.5–3 m; speed range: 0–15 km/h | Max climbing angle: 35–42°; energy consumption per unit mass: 1.8–2.5 kJ/kg·km; traction efficiency: 75–88%; slip rate: 5–15% | Paddy field operations (e.g., Kubota PRO988Q harvester), wetland farming, and slope orchards (slip resistance > 85%) |

| Half-track | Electro-hydraulic coupling system combining front-wheel steering and rear-track drive | Articulated chassis; hydraulic speed regulation; modular configuration switching | Ground pressure: 30–50 kPa; minimum turning radius: 2–4 m; speed range: 0–25 km/h | Max climbing angle: 32–38°; energy consumption per unit mass: 2.0–3.0 kJ/kg·km; traction efficiency: 68–82%; slip rate: 8–20% | Muddy terrain operations (e.g., Case Steiger Quadtrac), hilly/mountainous transport, and silage harvesting (40% traction enhancement) |

| Leveling Mechanism | Core Advantages | Performance Limitations | Performance Indicators | Suitable Application Scenarios |

|---|---|---|---|---|

| Hydraulic Differential Height Type | Excellent contour operation performance; simple structural principle; good slope adaptability | Poor lateral stability on uphill slopes; ground adhesion loss > 15% | Maximum climbing angle: 20–25°; energy consumption per unit mass: 3.2–4.0 kJ/kg·km; leveling error: <1.5°; response time: 0.8–1.2 s | Sloping terrain with gentle undulations; contouring on sloping terrain |

| Parallel Four-Bar Linkage Type | Simple structure; low failure rate | Limited leveling freedom (single axis); slow dynamic response | Maximum climbing angle: 15–20°; energy consumption per unit mass: 2.5–3.2 kJ/kg·km; leveling error: 2–3°; response time: >2 s; | Sloping terrain with gentle undulations; contouring on sloping terrain |

| Adjustable Center of Gravity Type | High traction efficiency; good uphill stability; excellent slope adaptability | Complex structure; requires multi-layer chassis | maximum climbing angle: 35–40°; energy consumption per unit mass: 2.0–2.8 kJ/kg·km; leveling error: <0.8°; response time: 0.5–0.9 s | Steep slope ascent/descent operations; steep slope surface undulations |

| Articulated-Torsion Type | High adaptability to rugged terrain; small turning radius; high flexibility; compact structure | Unsuitable for large-gradient slopes; high cost; complex structure; requires skilled operators | Maximum climbing angle: 25–30°; energy consumption per unit mass: 2.8–3.5 kJ/kg·km; leveling error: 1.2–2°; response time: 0.4–0.7 s | Rugged slope surfaces; small fragmented plots; gentle slope surface undulations |

| Omnidirectional Leveling Type | High traction efficiency; superior uphill stability; outstanding slope adaptability | High cost; complex maintenance; | Maximum climbing angle: 40°+; energy consumption per unit mass: 1.8–2.4 kJ/kg·km; leveling error: <0.5°; response time: <0.3 s | Steep slope ascent/descent operations; steep slope surface undulations; rugged slope surfaces |

| Control Strategy | Core Advantages | Performance Defects | Performance Indicators |

|---|---|---|---|

| Classic PID Control | Simple implementation; flexible adjustment | Poor nonlinear adaptability; weak disturbance rejection | Max slope: 20–25°; energy consumption: 3.0–4.2 kJ/kg·km; response time: 300–500 ms; overshoot: 15–25% |

| Incremental PID Control | Strong anti-interference ability; easy to switch between automatic and manual modes | Poor adaptability to time-varying systems; high computational burden | Maximum slope: 22–27°; energy consumption per unit mass: 2.8–3.8 kJ/kg·km; response time: 250–400 ms; overshoot: 10–20% |

| Fuzzy PID Control | Strong adaptability; good robustness; high control accuracy | Complex rule-based design; limited real-time performance | Maximum slope: 28–33°; energy consumption per unit mass: 2.3–3.0 kJ/kg·km; response time: 150–250 ms; overshoot: 5–12% |

| Dual-Loop Fuzzy PID Control | Excellent stability; rapid response speed | Difficult to design parameters; over-regulation problem; steady-state error problem | Maximum slope: 30–35°; energy consumption per unit mass: 2.0–2.7 kJ/kg·km; response time: 80–150 ms; overshoot: 3–8% |

| Model Predictive Control (MPC) | Multi-objective optimization; strong constraint handling | High computational complexity; sensitive to model | Maximum slope: 35–40°; energy consumption per unit mass: 1.7–2.3 kJ/kg·km; response time: 200–350 ms; overshoot: 1–5% |

| Sliding Mode Control (SMC) | Fast response; strong robustness; strong anti-interference ability | High-frequency chattering | Maximum slope: 38°+; energy consumption per unit mass: 1.8–2.5 kJ/kg·km; response time: 40–100 ms; overshoot: 0–3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, R.; Qi, X.; Chen, X.; Mei, Y.; Li, A. The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions. Appl. Sci. 2025, 15, 7505. https://doi.org/10.3390/app15137505

Ding R, Qi X, Chen X, Mei Y, Li A. The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions. Applied Sciences. 2025; 15(13):7505. https://doi.org/10.3390/app15137505

Chicago/Turabian StyleDing, Renkai, Xiangyuan Qi, Xuwen Chen, Yixin Mei, and Anze Li. 2025. "The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions" Applied Sciences 15, no. 13: 7505. https://doi.org/10.3390/app15137505

APA StyleDing, R., Qi, X., Chen, X., Mei, Y., & Li, A. (2025). The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions. Applied Sciences, 15(13), 7505. https://doi.org/10.3390/app15137505