Hybrid Grey–Fuzzy Approach for Optimizing Circular Quality Responses in Plasma Jet Manufacturing of Aluminum Alloy

Abstract

1. Introduction

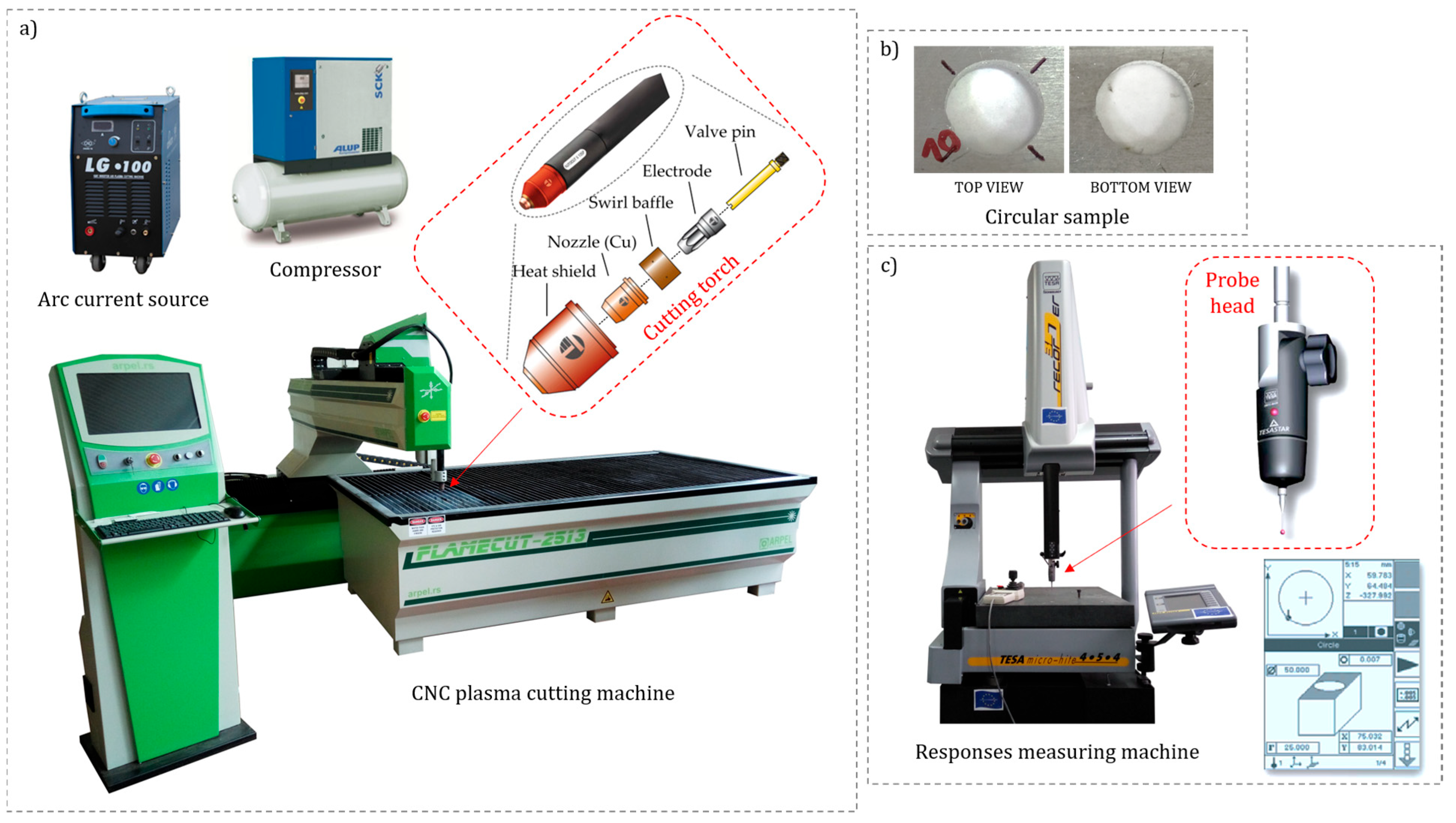

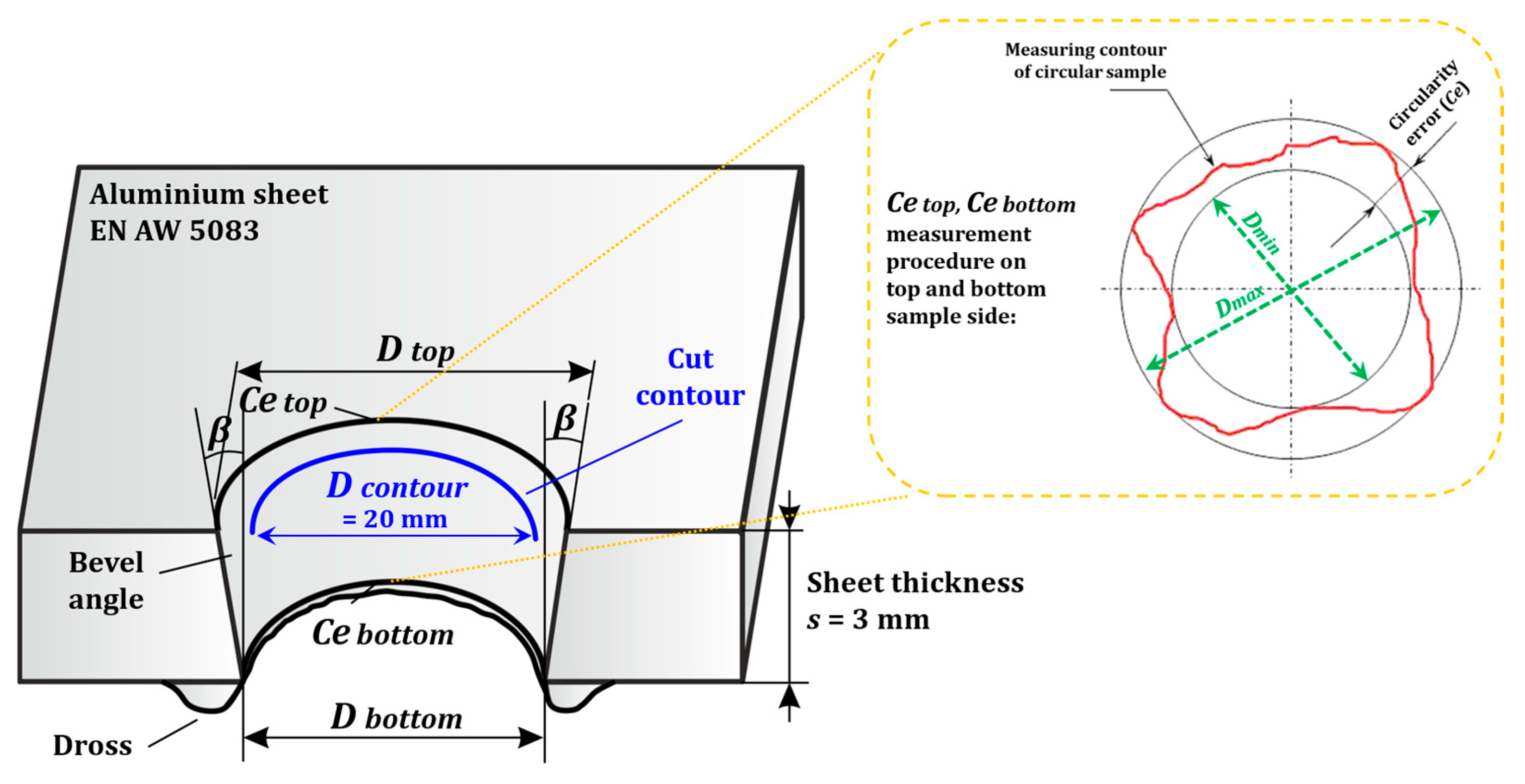

2. Experimental Research

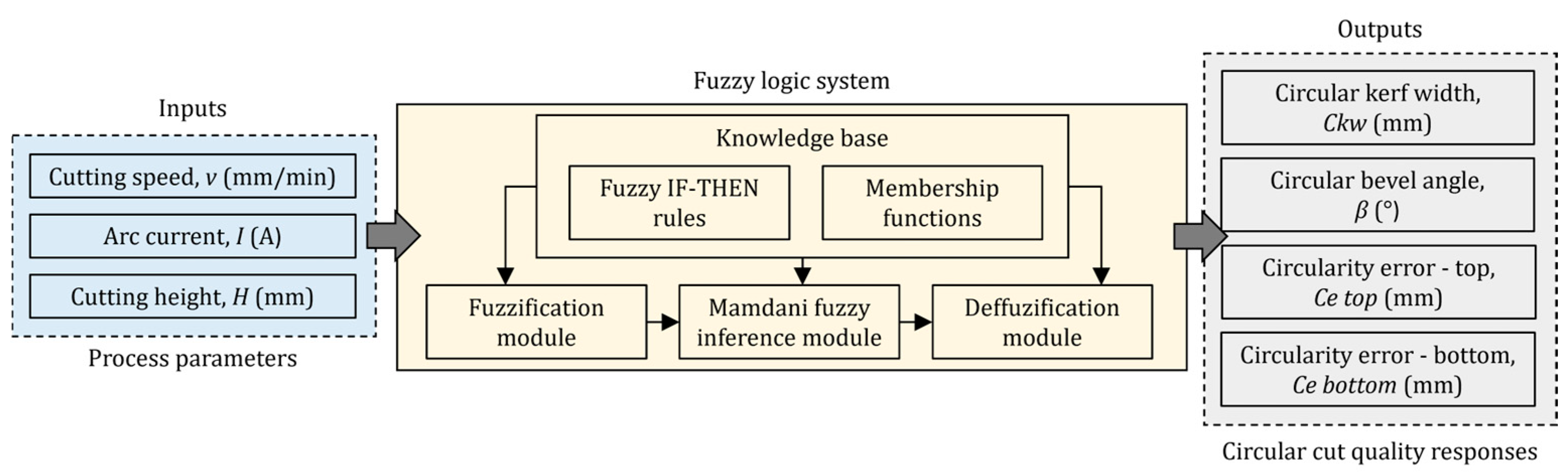

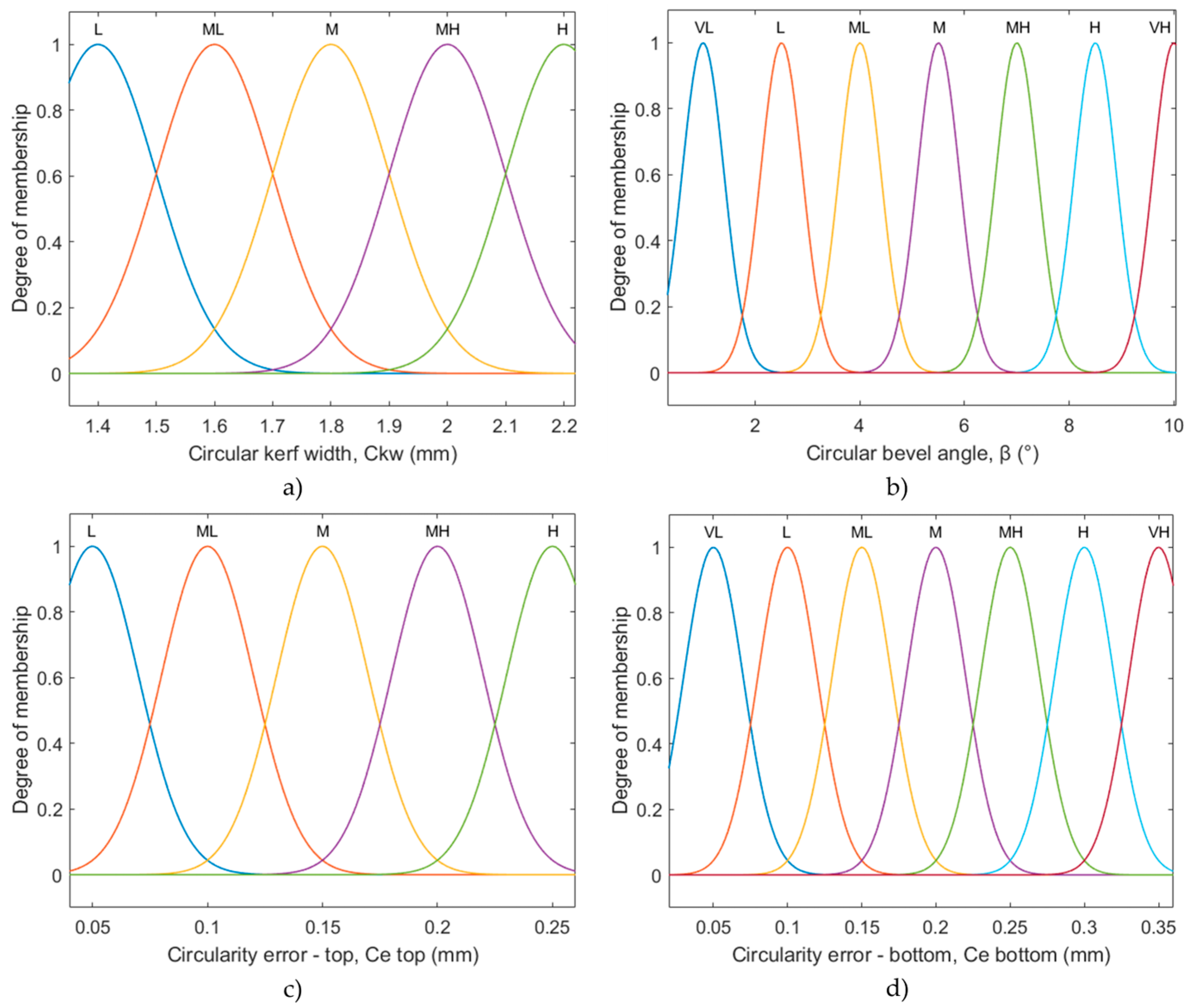

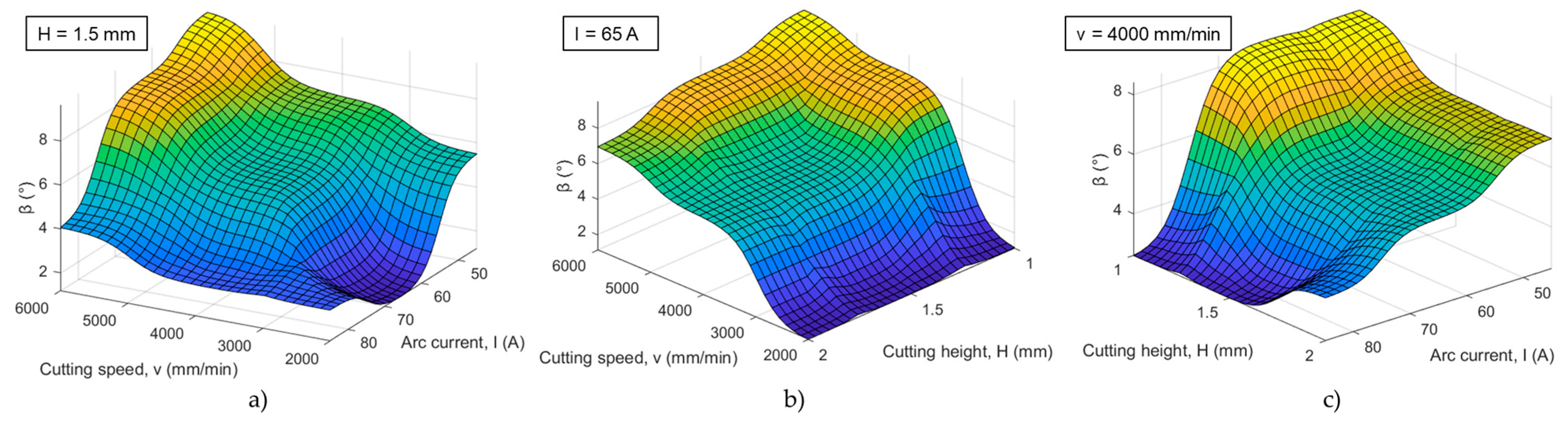

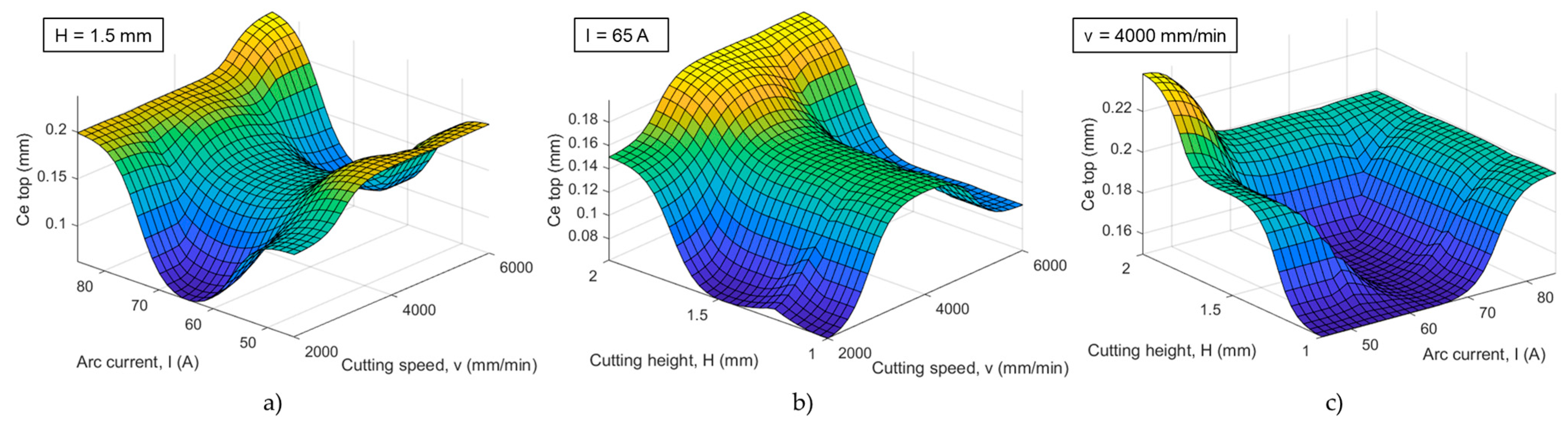

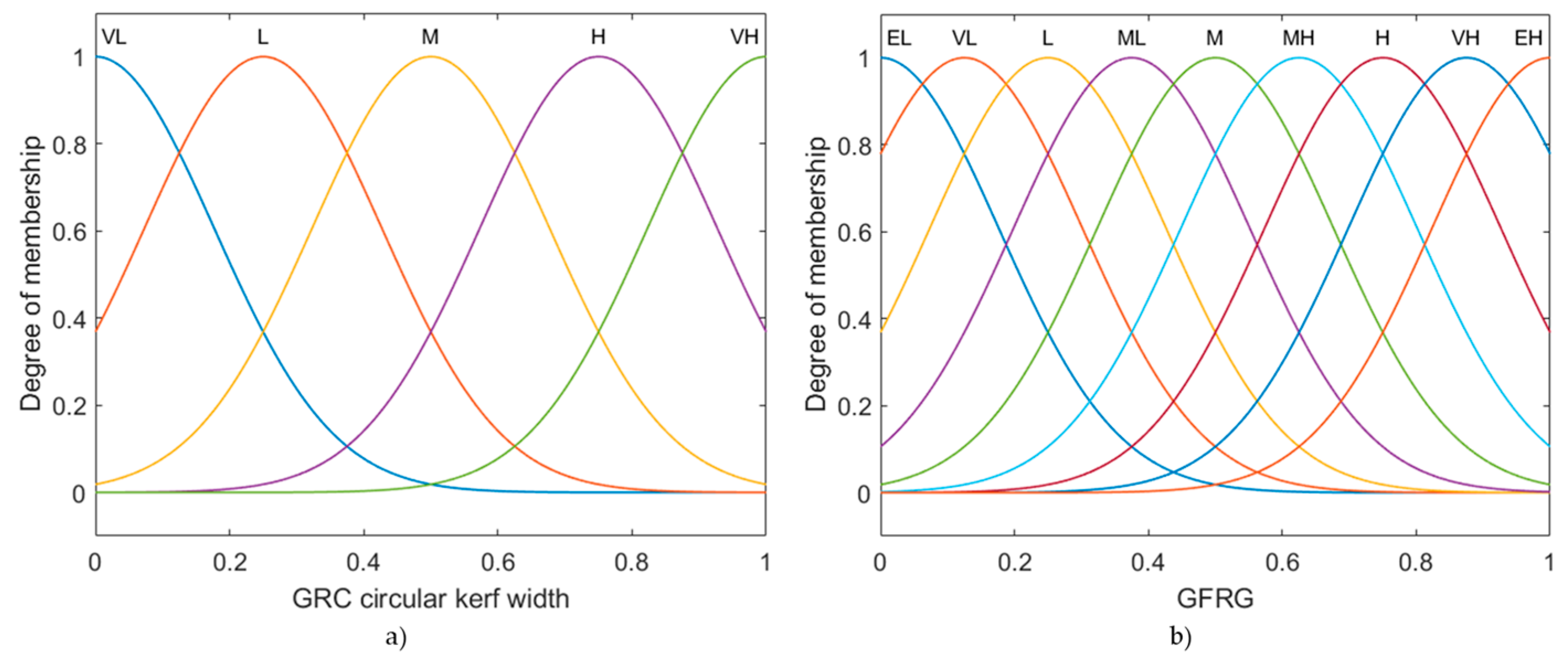

3. Modeling of Circular Quality Responses

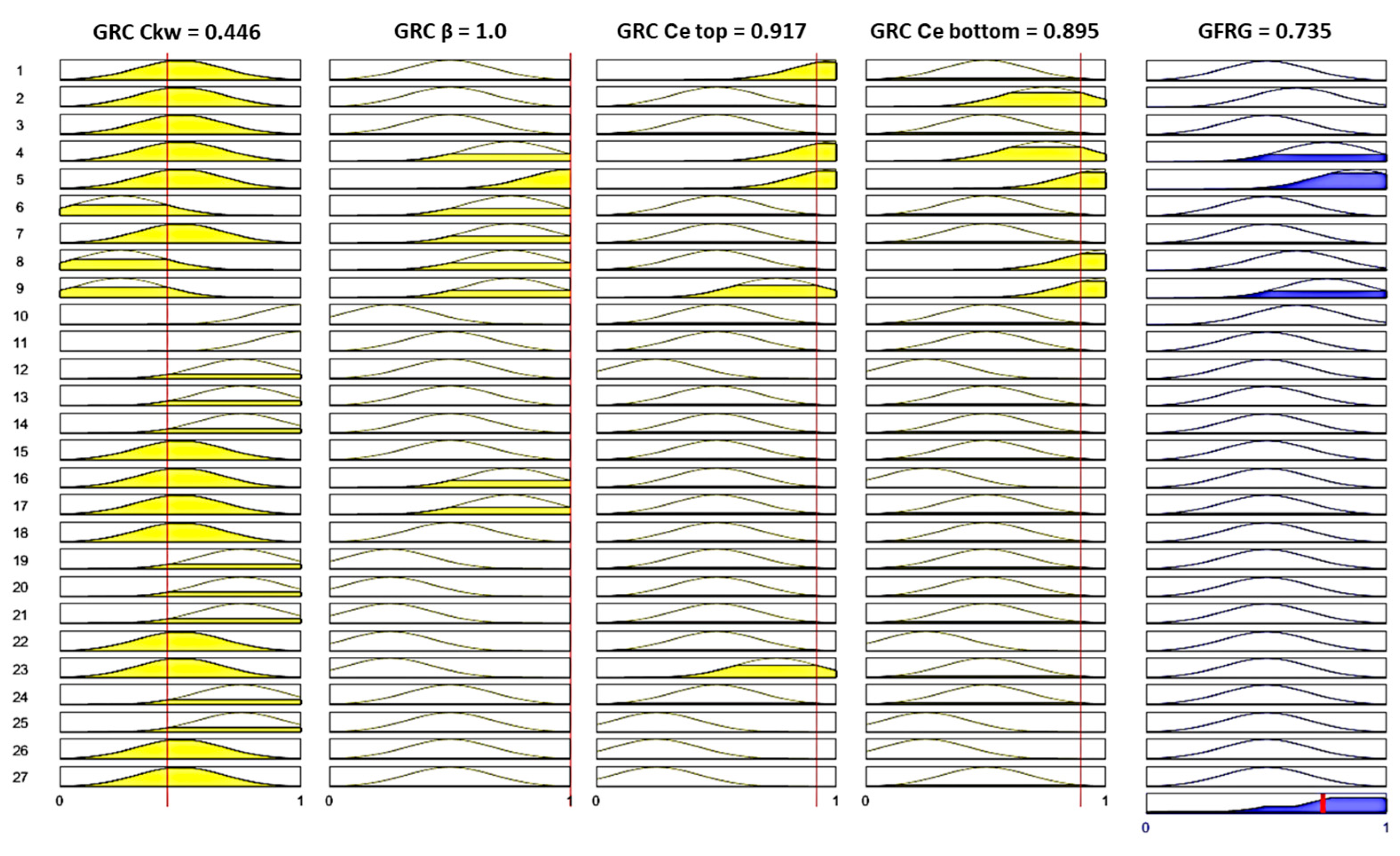

4. Multi-Response Optimization

5. Conclusions

- -

- Experimental investigations according to the Taguchi L27 orthogonal array served as a solid foundation for examining the impact of the cutting speed, arc current, and cutting height on the circular cut quality responses: the circular kerf width, circular bevel angle, circularity error—top, and circularity error—bottom.

- -

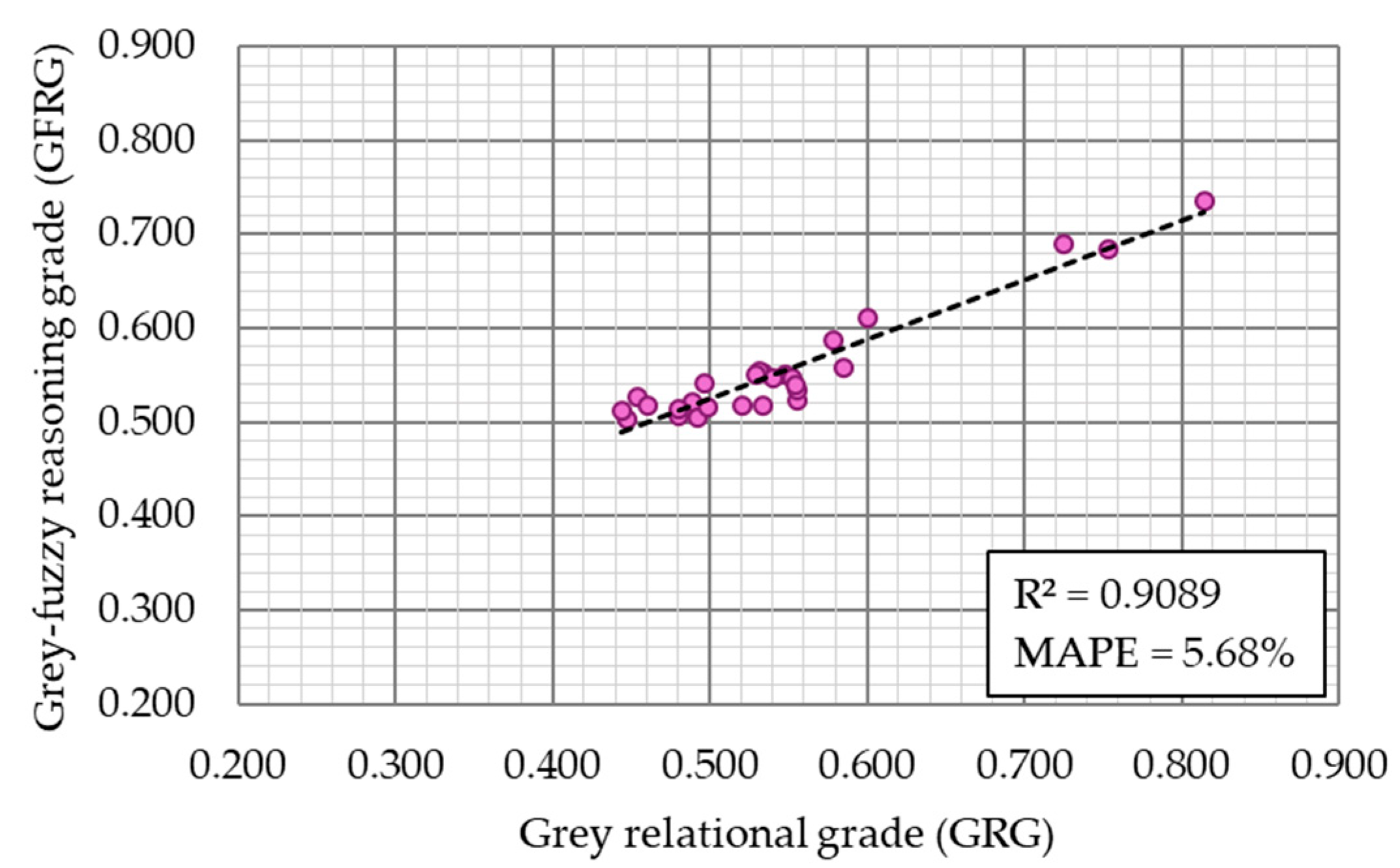

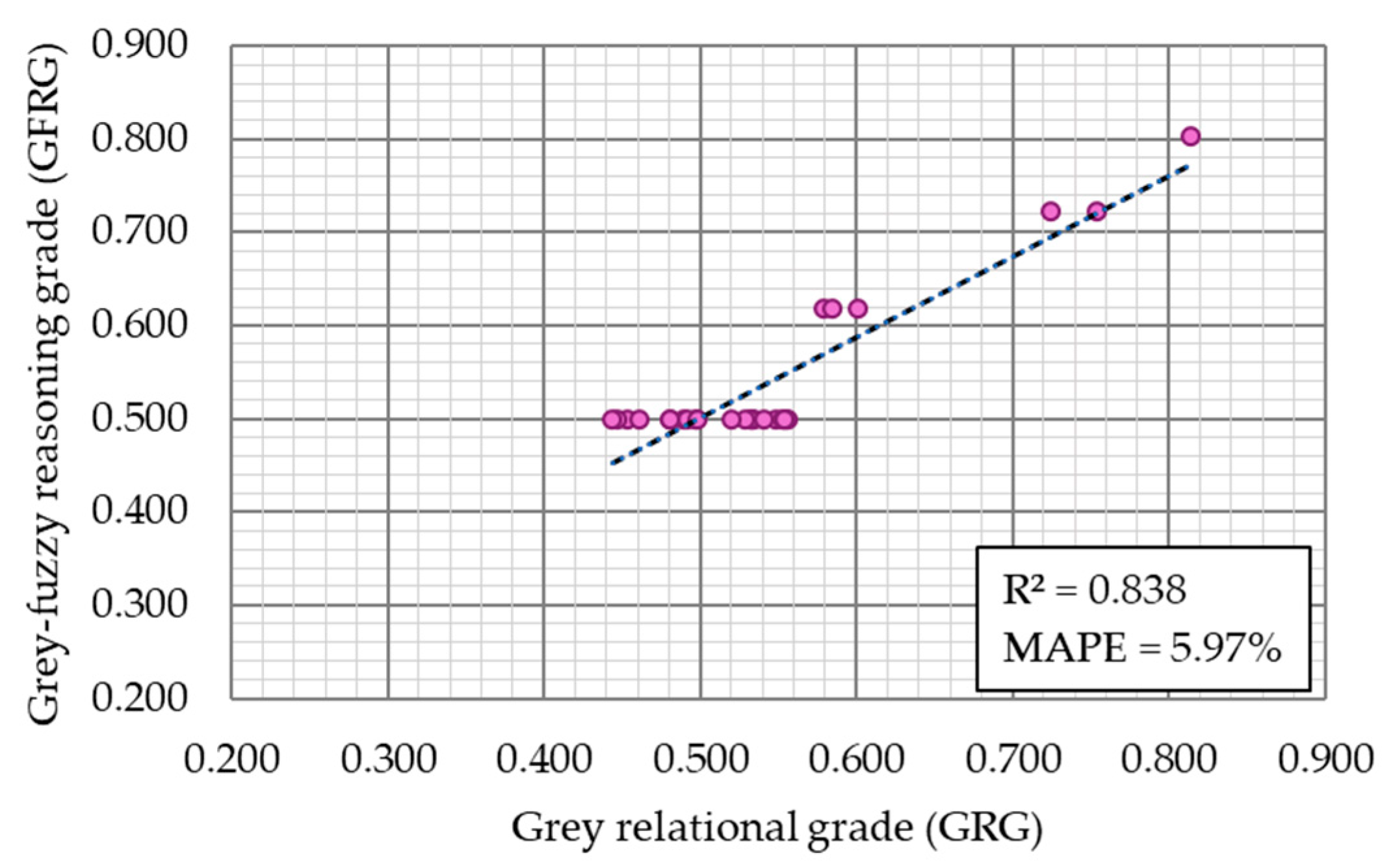

- Artificial intelligence fuzzy logic technique combined with ANOVA proved as a good tool to define functional relations between process parameters and analyzed responses, as well as to discuss the effects of the parameters and their interactions with response variations. This confirmed high values of validation metrics such as the coefficient of determination and the mean absolute percentage error between the experimental and predicted response values. In this case, one of the confirmed benefits of the fuzzy logic technique is its ability to model complex manufacturing processes, such as plasma jet cutting, where imprecise and vague data sets are possible.

- -

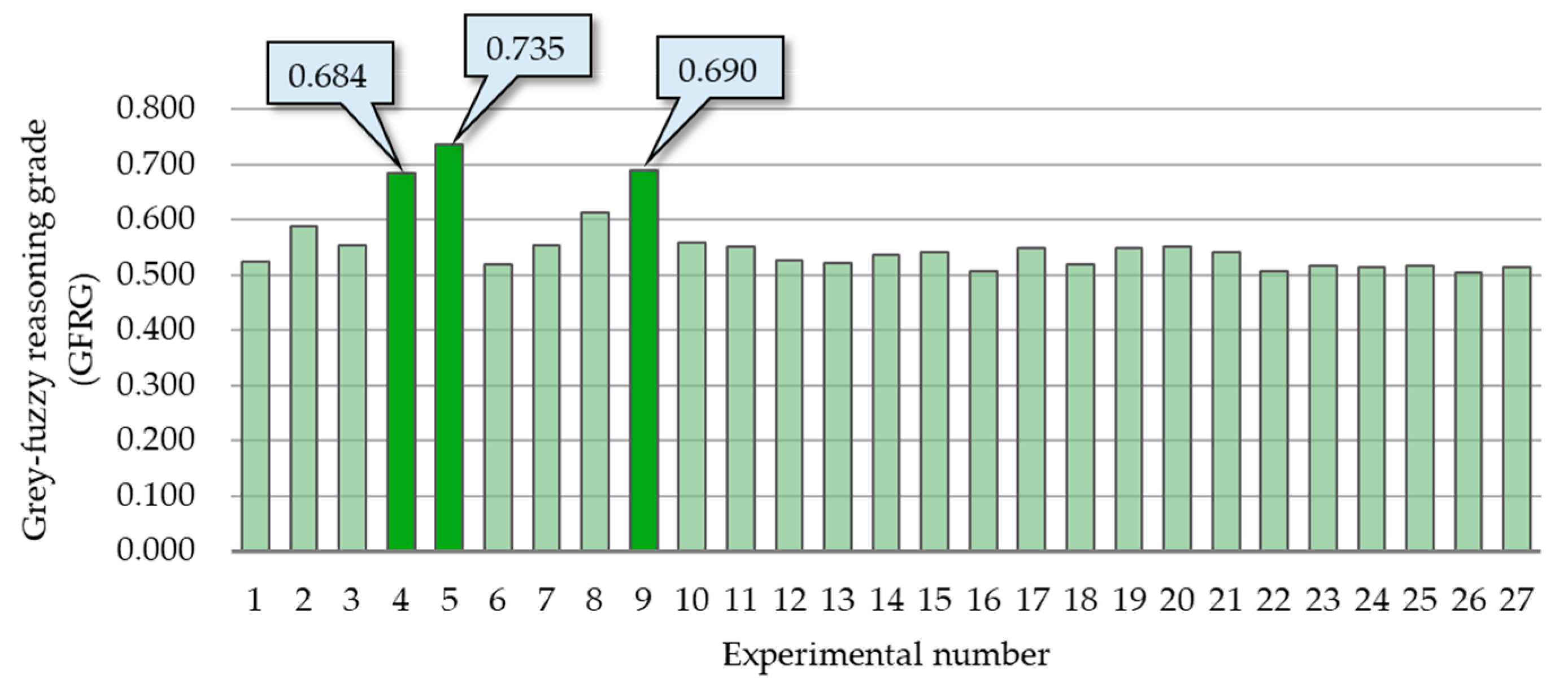

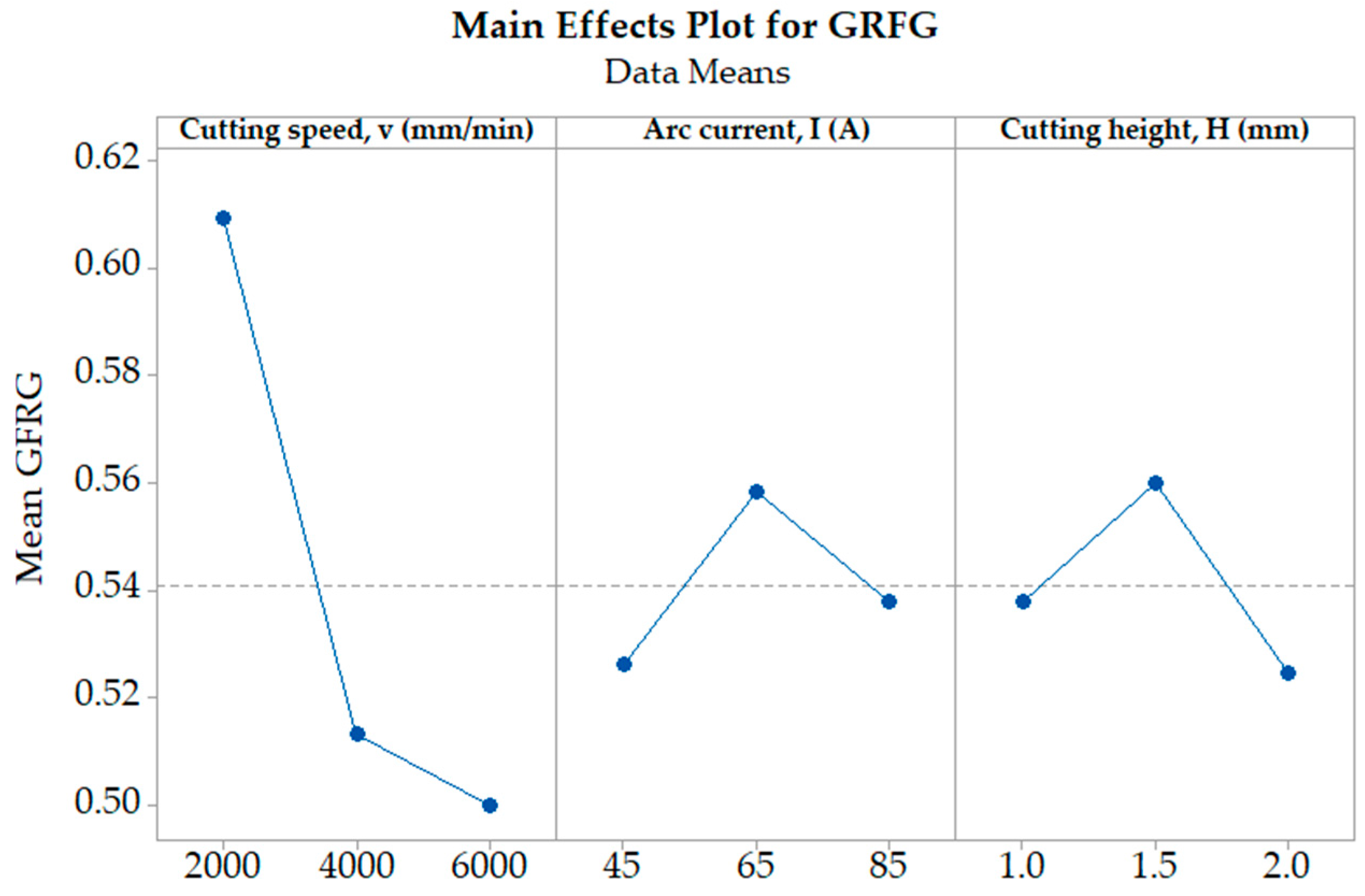

- The novel hybrid grey–fuzzy approach for solving multiple circular quality response optimization problems was presented. By using it, optimal process parameter settings that result in minimal response objective functions were determined: v = 2000 mm/min, I = 65 A, H = 1.5 mm.

- -

- By analyzing 3D surface plots that show the influence of two process parameter variations on the GFRG values, a Pareto front of optimal solutions can be derived. This front corresponds to compromise solutions for the simultaneous optimization of circular quality responses. This front covers the next processing area: v = 2000 mm/min, I = 65 A, H = 1–1.5 mm/v = 2000 mm/min, I = 85 A, H = 2 mm.

- -

- ANOVA presented that the cutting speed has the largest influence on the GFRG, followed by the cutting height and arc current.

- -

- The validation experimental test confirmed the prediction and generalization capability of the developed circular quality responses as well as the GFRG fuzzy logic models. This was verified by calculating the mean absolute percentage errors between the newly received experimental and model-predicted data.

- -

- The optimal solutions presented in this paper, along with the novel hybrid grey–fuzzy approach, hold significant industrial relevance. Their practical application can enhance the process control and management, while also reducing manufacturing costs by minimizing post-processing procedures.

- -

- Future research in this area will focus on expanding the experimental domain and incorporating additional response variables into the analysis. Further investigations will explore the use of advanced artificial intelligence techniques, such as artificial neural networks for modeling, as well as evolutionary-based metaheuristic algorithms for multi-response optimization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maity, K.P.; Kumar Bagal, D. Effect of process parameters on cut quality of stainless steel of plasma arc cutting using hybrid approach. Int. J. Adv. Manuf. Technol. 2015, 78, 161–175. [Google Scholar] [CrossRef]

- Pawar, S.S.; Inamdar, K.H. Experimental Analysis of Plasma Arc Cutting Process for SS 316L Plates. IOSR J. Mech. Civ. Eng. 2017, 5, 75–80. [Google Scholar] [CrossRef]

- Adalarasan, R.; Santhanakumar, M.; Rajmohan, M. Application of Grey Taguchi-based response surface methodology (GT-RSM) for optimizing the plasma arc cutting parameters of 304L stainless steel. Int. J. Adv. Manuf. Technol. 2015, 78, 1161–1170. [Google Scholar] [CrossRef]

- Radovanovic, M.; Madic, M. Modeling the plasma arc cutting process using ANN. Nonconv. Technol. Rev. 2011, 4, 43–48. [Google Scholar]

- Sandeep, R.; Sudhakara, D.; Sreenivasulu, B. Multi objective optimization of process parameters in plasma arc cutting of SS 420 using Grey-Taguchi analysis. Int. J. Adv. Eng. Res. Sci. 2015, 2, 46–52. [Google Scholar]

- Lazarević, A. Experimental research of the plasma arc cutting process. J. Appl. Eng. Sci. 2014, 12, 291–296. [Google Scholar] [CrossRef]

- Ilii, S.M.; Coteata, M.; Munteanu, A. Experimental results concerning the variation of surface roughness parameter (Ra) at plasma arc cutting of stainless-steel workpiece. Int. J. Mod. Manuf. Technol. 2010, 2, 31–36. [Google Scholar]

- Kumar Das, M.; Kumar, K.; Barman, K.T.; Sahu, P. Optimization of process parameters in plasma arc cutting of EN31 steel based on MRR and multiple roughness characteristics using grey relational analysis. Procedia Mater. Sci. 2014, 5, 1550–1559. [Google Scholar]

- Tsiolikas, A.; Kechagias, J.; Salonitis, K.; Mastorakis, N. Optimization of cut surface quality during CNC Plasma Arc Cutting process. Int. J. Syst. Appl. Eng. Dev. 2016, 10, 305–308. [Google Scholar]

- Srinivasa Raju, S.V.S.S.; Kodanda Ram, K.; Satyanarayana, D.V.S.S.; Sai Nishood Goud, M. Optimization of Process Parameters of Plasma Arc Cutting Using Taguchi’s Robust Design Methodology. IOSR J. Mech. Civ. Eng. 2016, 3, 124–128. [Google Scholar] [CrossRef]

- Bini, R.; Colosimo, B.M.; Kutlu, A.E.; Monno, M. Experimental study of the features of the kerf generated by a 200A high tolerance plasma arc cutting system. J. Mater. Process. Technol. 2008, 196, 345–355. [Google Scholar] [CrossRef]

- Chamarthi, S.; Sinivasa Reddy, S.; Kumar Elipey, M.; Ramana Reddy, D.V. Investigation Analysis of Plasma arc cutting Parameters on the Unevenness surface of Hardox-400 material. Procedia Eng. 2013, 64, 854–861. [Google Scholar] [CrossRef]

- Peko, I.; Marić, D.; Nedić, B.; Samardžić, I. Modeling and Optimization of Cut Quality Responses in Plasma Jet Cutting of Aluminium Alloy EN AW-5083. Materials 2021, 14, 5559. [Google Scholar] [CrossRef]

- Peko, I.; Nedić, B.; Đorđević, A.; Veža, I. Modelling of Kerf Width in Plasma Jet Metal Cutting Process using ANN Approach. Tech. Gaz. 2018, 25, 401–406. [Google Scholar]

- Peko, I.; Nedić, B.; Dunđer, M.; Samardžić, I. Modelling of Dross Height in Plasma Jet Cutting Process of Aluminium Alloy 5083 Using Fuzzy Logic Technique. Tech. Gaz. 2020, 27, 1767–1773. [Google Scholar]

- Kadirgama, K.; Noor, M.M.; Harun, W.S.W.; Aboue-El-Hossein, K.A. Optimisation of heat affected zone by partial swarm optimisation in air plasma cutting operation. J. Sci. Ind. Res. 2010, 69, 439–443. [Google Scholar]

- Hamid, A.; Novareza, O.; DwiWidodo, T. Optimization of process parameters and quality results using plasma arc cutting in aluminium alloy. J. Eng. Manag. Ind. Syst. 2019, 7, 7–14. [Google Scholar]

- Patel, S.B.; Vyas, T.K. Parametric Investigation of Plasma Arc Cutting on Aluminium Alloy 6082. In Proceedings of the International Conference on Ideas, Impact and Innovation in Mechanical Engineering, Pune, India, 1–2 June 2017; pp. 87–93. [Google Scholar]

- Kechagias, J.; Pappas, M.; Karagiannis, S.; Petropoulos, G. An ANN approach on the optimization of the cutting parameters during CNC plasma arc cutting. In Proceedings of the 10th Biennial Conference on Engineering Systems Design and Analysis, Istanbul, Turkey, 12–14 July 2010; pp. 643–649. [Google Scholar]

- Asiabanpour, B.; Vejandla, D.T.; Jimenez, J.; Novoa, C. Optimising the automated plasma cutting process by design of experiments. Int. J. Rapid Manuf. 2009, 1, 19–40. [Google Scholar] [CrossRef]

- Chen, J.C.; Li, Y.; Cox, R.A. Taguchi-based Six Sigma approach to optimize plasma cutting process: An industrial case study. Int. J. Adv. Manuf. Technol. 2009, 41, 760–769. [Google Scholar] [CrossRef]

- Kechagias, J.; Billis, M. A parameter design of CNC plasma-arc cutting of carbon steel plates using robust design. Int. J. Exp. Des. Process Optim. 2010, 1, 315–326. [Google Scholar] [CrossRef]

- Hussein, W.; Abdullah Al-Shammari, M. Fatigue and Fracture Behaviours of FSW and FSP Joints of AA5083-H111 Aluminium Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 012055. [Google Scholar] [CrossRef]

- Peko, I.; Ljumović, P.; Nedić, B.; Dunđer, M. Analysis of the heat affected zone in plasma jet cutting process of the aluminium alloy EN AW5083. Zaštita Mater. 2019, 60, 174–181. [Google Scholar]

- Vrsalović, L.; Čatipović, N.; Gudić, S.; Kožuh, S. Beneficial effect of Cu content and austempering parameters on the hardness and corrosion properties of austempered ductile iron (ADI). Facta Univ. Ser. Mech. Eng. 2025, 23, 33–47. [Google Scholar] [CrossRef]

- Čatipović, N.; Peko, I.; Grgić, K.; Periša, K. Multi Response Modelling and Optimisation of Copper Content and Heat Treatment Parameters of ADI Alloys by Combined Regression Grey-Fuzzy Approach. Metals 2024, 14, 735. [Google Scholar] [CrossRef]

- Kusumoto, K.; Wang, J.; Nezu, K. A Study on the Cut Surface Quality of Mild Steel Plate by Oxygen Plasma Arc Cutting. Q. J. Jpn. Weld. Soc. 1999, 17, 201–208. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, Z.; He, C.; Yang, F. Effect of dual swirling plasma arc cutting parameters on kerf characteristics. Int. J. Mater. Form. 2011, 4, 39–43. [Google Scholar] [CrossRef]

- Lukic, D.; Cep, R.; Milosevic, M.; Antic, A.; Zivkovic, A.; Todic, V.; Rodic, D. A Grey Fuzzy Approach to the Selection of Cutting Process from the Aspect of Technological Parameters. Appl. Sci. 2022, 12, 12589. [Google Scholar] [CrossRef]

- Dragičević, M.; Begović, E.; Ekinović, S.; Peko, I. Multi-Response Optimization in MQLC Machining Process of Steel St50-2 Using Grey-Fuzzy Technique. Tech. Gaz. 2023, 30, 248–255. [Google Scholar]

- Babu, J.; Madarapu, A.; Paul, L.; Ahmed, A.N.K.; Davim, J.P. Multi-Response Optimization during the High-Speed Drilling of Composite Laminate Using the Grey Entropy Fuzzy Method (GEF). Processes 2022, 10, 1865. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, V.; Babbar, A.; Dhawan, V.; Kotecha, K.; Prakash, C. Experimental Investigation and Optimization of Electric Discharge Machining Process Parameters Using Grey-Fuzzy-Based Hybrid Techniques. Materials 2021, 14, 5820. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Sudha, J.; Muthukumar, V. A grey-fuzzy approach for optimizing machining parameters and the approach angle in turning AISI 1045 steel. Adv. Prod. Eng. Manag. 2015, 10, 195–208. [Google Scholar] [CrossRef]

- Horng, J.T.; Chiang, K.T. A grey and fuzzy algorithms integrated approach to the optimization of turning Hadfield steel with Al2O3/TiC mixed ceramic tool. J. Mater. Process. Technol. 2008, 207, 89–97. [Google Scholar] [CrossRef]

- Soepangkat, B.O.P.; Soesanti, A.; Pramujati, B. The use of Taguchi-grey-fuzzy to optimize performance characteristics in turning of AISI D2. Appl. Mech. Mater. 2013, 315, 211–215. [Google Scholar] [CrossRef]

| Producer | Arpel Automation |

|---|---|

| Model | FlameCut 2513 |

| Overall sizes (mm) | 3720 × 2500 × 1850 |

| Weight (kg) | 1300 |

| Tool travels (X, Y, Z) | 3000 mm × 1500 mm × 200 mm |

| Maximum tool speed | 20,000 mm/min |

| Supply | 400 V/50 Hz |

| Drive | AC Servo |

| X, Y, Z drive | Ball screw |

| Accuracy | 0.1 mm/m |

| Plasma type | User defined |

| Chemical Composition | |||||||||||||||||

| Al | Ti | Cr | Zn | Si | Mg | Cu | Fe | Mn | |||||||||

| Balance | 0.15 | 0.05–0.25 | 0.25 | 0.40 | 4–4.90 | 0.10 | 0.40 | 0.40–1 | |||||||||

| Physical Properties | |||||||||||||||||

| Density | Melting point | Thermal expansion | Modulus of elasticity | Thermal conductivity | Electrical resistivity | ||||||||||||

| 2.65 g/cm3 | 570 °C | 25 × 10–6/K | 72 GPa | 121 W/m·K | 0.058 × 10–6 Ω·m | ||||||||||||

| Mechanical Properties | |||||||||||||||||

| Proof stress | Tensile strength | Elongation | Shear strength | Vickers Hardness | |||||||||||||

| 145 MPa | 300 MPa | 23% | 175 MPa | 75 HV | |||||||||||||

| Exp. Trial | Process Parameters | Circular Quality Responses | |||||

|---|---|---|---|---|---|---|---|

| v (mm/min) | I (A) | H (mm) | Ckw (mm) | β (°) | Ce Top (mm) | Ce Bottom (mm) | |

| 1 | 2000 | 45 | 1 | 1.94 | 6.62 | 0.05 | 0.23 |

| 2 | 2000 | 45 | 1.5 | 1.68 | 4.89 | 0.17 | 0.07 |

| 3 | 2000 | 45 | 2 | 1.76 | 5.96 | 0.13 | 0.13 |

| 4 | 2000 | 65 | 1 | 1.84 | 1.08 | 0.04 | 0.10 |

| 5 | 2000 | 65 | 1.5 | 1.89 | 0.32 | 0.05 | 0.04 |

| 6 | 2000 | 65 | 2 | 2.11 | 1.37 | 0.15 | 0.23 |

| 7 | 2000 | 85 | 1 | 1.99 | 3.08 | 0.16 | 0.13 |

| 8 | 2000 | 85 | 1.5 | 2.12 | 2.23 | 0.22 | 0.03 |

| 9 | 2000 | 85 | 2 | 2.22 | 1.69 | 0.07 | 0.02 |

| 10 | 4000 | 45 | 1 | 1.35 | 8.66 | 0.14 | 0.23 |

| 11 | 4000 | 45 | 1.5 | 1.37 | 7.09 | 0.18 | 0.30 |

| 12 | 4000 | 45 | 2 | 1.52 | 7.38 | 0.24 | 0.36 |

| 13 | 4000 | 65 | 1 | 1.61 | 8.13 | 0.15 | 0.23 |

| 14 | 4000 | 65 | 1.5 | 1.52 | 5.43 | 0.15 | 0.18 |

| 15 | 4000 | 65 | 2 | 1.63 | 5.87 | 0.22 | 0.17 |

| 16 | 4000 | 85 | 1 | 1.66 | 3.18 | 0.21 | 0.32 |

| 17 | 4000 | 85 | 1.5 | 1.75 | 3.12 | 0.18 | 0.15 |

| 18 | 4000 | 85 | 2 | 1.94 | 4.42 | 0.18 | 0.24 |

| 19 | 6000 | 45 | 1 | 1.44 | 10.05 | 0.15 | 0.16 |

| 20 | 6000 | 45 | 1.5 | 1.43 | 9.43 | 0.21 | 0.17 |

| 21 | 6000 | 45 | 2 | 1.47 | 9.62 | 0.14 | 0.15 |

| 22 | 6000 | 65 | 1 | 1.62 | 9.80 | 0.11 | 0.33 |

| 23 | 6000 | 65 | 1.5 | 1.64 | 8.62 | 0.09 | 0.25 |

| 24 | 6000 | 65 | 2 | 1.57 | 7.56 | 0.18 | 0.26 |

| 25 | 6000 | 85 | 1 | 1.55 | 3.78 | 0.24 | 0.31 |

| 26 | 6000 | 85 | 1.5 | 1.72 | 3.91 | 0.26 | 0.35 |

| 27 | 6000 | 85 | 2 | 1.83 | 4.67 | 0.23 | 0.27 |

| 1. rule: | If (cutting speed is L) and (arc current is L) and (cutting height is L) then (Ckw is MH) (β is MH) (Ce top is L) (Ce bottom is MH) | 15. rule: | If (cutting speed is M) and (arc current is M) and (cutting height is H) then (Ckw is ML) (β is M) (Ce top is MH) (Ce bottom is ML) |

| 2. rule: | If (cutting speed is L) and (arc current is L) and (cutting height is M) then (Ckw is ML) (β is M) (Ce top is M) (Ce bottom is VL) | 16. rule: | If (cutting speed is M) and (arc current is H) and (cutting height is L) then (Ckw is ML) (β is L) (Ce top is MH) (Ce bottom is H) |

| 3. rule: | If (cutting speed is L) and (arc current is L) and (cutting height is H) then (Ckw is M) (β is M) (Ce top is M)(Ce bottom is ML) | 17. rule: | If (cutting speed is M) and (arc current is H) and (cutting height is M) then (Ckw is M) (β is L) (Ce top is MH) (Ce bottom is ML) |

| 4. rule: | If (cutting speed is L) and (arc current is M) and (cutting height is L) then (Ckw is M) (β is VL) (Ce top is L) (Ce bottom is L) | 18. rule: | If (cutting speed is M) and (arc current is H) and (cutting height is H) then (Ckw is MH) (β is ML) (Ce top is MH) (Ce bottom is MH) |

| 5. rule: | If (cutting speed is L) and (arc current is M) and (cutting height is M) then (Ckw is M) (β is VL) (Ce top is L) (Ce bottom is VL) | 19. rule: | If (cutting speed is H) and (arc current is L) and (cutting height is L) then (Ckw is L) (β is VH) (Ce top is M) (Ce bottom is ML) |

| 6. rule: | If (cutting speed is L) and (arc current is M) and (cutting height is H) then (Ckw is H) (β is VL) (Ce top is M) (Ce bottom is MH) | 20. rule: | If (cutting speed is H) and (arc current is L) and (cutting height is M) then (Ckw is L) (β is VH) (Ce top is MH) (Ce bottom is ML) |

| 7. rule: | If (cutting speed is L) and (arc current is H) and (cutting height is L) then (Ckw is MH) (β is L) (Ce top is M) (Ce bottom is ML) | 21. rule: | If (cutting speed is H) and (arc current is L) and (cutting height is H) then (Ckw is L) (β is VH) (Ce top is M) (Ce bottom is ML) |

| 8. rule: | If (cutting speed is L) and (arc current is H) and (cutting height is M) then (Ckw is H) (β is L) (Ce top is MH) (Ce bottom is VL) | 22. rule: | If (cutting speed is H) and (arc current is M) and (cutting height is L) then (Ckw is ML) (β is VH) (Ce top is ML) (Ce bottom is VH) |

| 9. rule: | If (cutting speed is L) and (arc current is H) and (cutting height is H) then (Ckw is H) (β is VL) (Ce top is L) (Ce bottom is VL) | 23. rule: | If (cutting speed is H) and (arc current is M) and (cutting height is M) then (Ckw is ML) (β is H) (Ce top is ML) (Ce bottom is MH) |

| 10. rule: | If (cutting speed is M) and (arc current is L) and (cutting height is L) then (Ckw is L) (β is H) (Ce top is M) (Ce bottom is MH) | 24. rule: | If (cutting speed is H) and (arc current is M) and (cutting height is H) then (Ckw is ML) (β is MH) (Ce top is MH) (Ce bottom is MH) |

| 11. rule: | If (cutting speed is M) and (arc current is L) and (cutting height is M) then (Ckw is L) (β is MH) (Ce top is MH) (Ce bottom is H) | 25. rule: | If (cutting speed is H) and (arc current is H) and (cutting height is L) then (Ckw is ML) (β is ML) (Ce top is H) (Ce bottom is H) |

| 12. rule: | If (cutting speed is M) and (arc current is L) and (cutting height is H) then (Ckw is ML) (β is MH) (Ce top is H) (Ce bottom is VH) | 26 rule: | If (cutting speed is H) and (arc current is H) and (cutting height is M) then (Ckw is M) (β is ML) (Ce top is H) (Ce bottom is VH) |

| 13. rule: | If (cutting speed is M) and (arc current is M) and (cutting height is L) then (Ckw is ML) (β is H) (Ce top is M) (Ce bottom is MH) | 27. rule: | If (cutting speed is H) and (arc current is H) and (cutting height is H) then (Ckw is M) (β is ML) (Ce top is H) (Ce bottom is MH) |

| 14. rule: | If (cutting speed is M) and (arc current is M) and (cutting height is M) then (Ckw is ML) (β is M) (Ce top is M) (Ce bottom is M) |

| Circular Kerf Width | Circular Bevel Angle | |||||||||

| Source | DF | SS | MS | F-Value | p-Value | DF | SS | MS | F-Value | p-Value |

| v | 2 | 0.77796 | 0.388978 | 49.27 | 0.000 | 2 | 92.394 | 46.1968 | 75.91 | 0.000 |

| I | 2 | 0.44207 | 0.221033 | 28.00 | 0.000 | 2 | 87.425 | 43.7123 | 71.83 | 0.000 |

| H | 2 | 0.07340 | 0.036700 | 4.65 | 0.046 | 2 | 4.948 | 2.4739 | 4.06 | 0.061 |

| v∙I | 4 | 0.01298 | 0.003244 | 0.41 | 0.796 | 4 | 30.646 | 7.6614 | 12.59 | 0.002 |

| v∙H | 4 | 0.01538 | 0.003844 | 0.49 | 0.746 | 4 | 0.705 | 0.1763 | 0.29 | 0.877 |

| I∙H | 4 | 0.05967 | 0.014917 | 1.89 | 0.206 | 4 | 2.418 | 0.6045 | 0.99 | 0.464 |

| Error | 8 | 0.06316 | 0.007894 | - | - | 8 | 4.869 | 0.6086 | - | - |

| Total | 26 | 1.44460 | - | - | - | 26 | 223.404 | - | - | - |

| Circularity Error—Top | Circularity Error—Bottom | |||||||||

| Source | DF | SS | MS | F-Value | p-Value | DF | SS | MS | F-Value | p-Value |

| v | 2 | 0.025874 | 0.012937 | 11.78 | 0.004 | 2 | 0.113252 | 0.056626 | 11.88 | 0.004 |

| I | 2 | 0.020763 | 0.010381 | 9.45 | 0.008 | 2 | 0.000052 | 0.000026 | 0.01 | 0.995 |

| H | 2 | 0.005652 | 0.002826 | 2.57 | 0.137 | 2 | 0.014007 | 0.007004 | 1.47 | 0.286 |

| v∙I | 4 | 0.008148 | 0.002037 | 1.85 | 0.212 | 4 | 0.065259 | 0.016315 | 3.42 | 0.065 |

| v∙H | 4 | 0.005126 | 0.001281 | 1.17 | 0.393 | 4 | 0.011770 | 0.002943 | 0.62 | 0.662 |

| I∙H | 4 | 0.023437 | 0.005859 | 5.34 | 0.022 | 4 | 0.007637 | 0.001909 | 0.40 | 0.803 |

| Error | 8 | 0.008785 | 0.001098 | - | - | 8 | 0.038119 | 0.004765 | - | - |

| Total | 26 | 0.097785 | - | - | - | 26 | 0.250096 | - | - | - |

| Exp. No. | Normalization Results | GRC | GRG | Rank | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ckw (mm) | β (°) | Ce Top (mm) | Ce Bottom (mm) | Ckw (mm) | β (°) | Ce Top (mm) | Ce Bottom (mm) | |||

| 1 | 0.322 | 0.353 | 0.955 | 0.382 | 0.424 | 0.436 | 0.917 | 0.447 | 0.556 | 7 |

| 2 | 0.621 | 0.530 | 0.409 | 0.853 | 0.569 | 0.516 | 0.458 | 0.773 | 0.579 | 6 |

| 3 | 0.529 | 0.420 | 0.591 | 0.676 | 0.515 | 0.463 | 0.550 | 0.607 | 0.534 | 13 |

| 4 | 0.437 | 0.922 | 1.000 | 0.765 | 0.470 | 0.865 | 1.000 | 0.680 | 0.754 | 2 |

| 5 | 0.379 | 1.000 | 0.955 | 0.941 | 0.446 | 1.000 | 0.917 | 0.895 | 0.814 | 1 |

| 6 | 0.126 | 0.892 | 0.500 | 0.382 | 0.364 | 0.822 | 0.500 | 0.447 | 0.533 | 14 |

| 7 | 0.264 | 0.716 | 0.455 | 0.676 | 0.405 | 0.638 | 0.478 | 0.607 | 0.532 | 15 |

| 8 | 0.115 | 0.804 | 0.182 | 0.971 | 0.361 | 0.718 | 0.379 | 0.944 | 0.601 | 4 |

| 9 | 0.000 | 0.859 | 0.864 | 1.000 | 0.333 | 0.780 | 0.786 | 1.000 | 0.725 | 3 |

| 10 | 1.000 | 0.143 | 0.545 | 0.382 | 1.000 | 0.368 | 0.524 | 0.447 | 0.585 | 5 |

| 11 | 0.977 | 0.304 | 0.364 | 0.176 | 0.956 | 0.418 | 0.440 | 0.378 | 0.548 | 11 |

| 12 | 0.805 | 0.274 | 0.091 | 0.000 | 0.719 | 0.408 | 0.355 | 0.333 | 0.454 | 25 |

| 13 | 0.701 | 0.197 | 0.500 | 0.382 | 0.626 | 0.384 | 0.500 | 0.447 | 0.489 | 21 |

| 14 | 0.805 | 0.475 | 0.500 | 0.529 | 0.719 | 0.488 | 0.500 | 0.515 | 0.555 | 8 |

| 15 | 0.678 | 0.430 | 0.182 | 0.559 | 0.608 | 0.467 | 0.379 | 0.531 | 0.497 | 19 |

| 16 | 0.644 | 0.706 | 0.227 | 0.118 | 0.584 | 0.630 | 0.393 | 0.362 | 0.492 | 20 |

| 17 | 0.540 | 0.712 | 0.364 | 0.618 | 0.521 | 0.635 | 0.440 | 0.567 | 0.541 | 12 |

| 18 | 0.322 | 0.579 | 0.364 | 0.353 | 0.424 | 0.543 | 0.440 | 0.436 | 0.461 | 24 |

| 19 | 0.897 | 0.000 | 0.500 | 0.588 | 0.829 | 0.333 | 0.500 | 0.548 | 0.553 | 10 |

| 20 | 0.908 | 0.064 | 0.227 | 0.559 | 0.845 | 0.348 | 0.393 | 0.531 | 0.529 | 16 |

| 21 | 0.862 | 0.044 | 0.545 | 0.618 | 0.784 | 0.343 | 0.524 | 0.567 | 0.554 | 9 |

| 22 | 0.690 | 0.026 | 0.682 | 0.088 | 0.617 | 0.339 | 0.611 | 0.354 | 0.480 | 22 |

| 23 | 0.667 | 0.147 | 0.773 | 0.324 | 0.600 | 0.370 | 0.688 | 0.425 | 0.521 | 17 |

| 24 | 0.747 | 0.256 | 0.364 | 0.294 | 0.664 | 0.402 | 0.440 | 0.415 | 0.480 | 23 |

| 25 | 0.770 | 0.644 | 0.091 | 0.147 | 0.685 | 0.584 | 0.355 | 0.370 | 0.498 | 18 |

| 26 | 0.575 | 0.631 | 0.000 | 0.029 | 0.540 | 0.575 | 0.333 | 0.340 | 0.447 | 26 |

| 27 | 0.448 | 0.553 | 0.136 | 0.265 | 0.475 | 0.528 | 0.367 | 0.405 | 0.444 | 27 |

| Process Parameters | Operating Level | Max–Min | Rank | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Cutting speed, v (mm/min) | 0.6093 | 0.5131 | 0.5000 | 0.1093 | 1 |

| Arc current, I (A) | 0.5262 | 0.5584 | 0.5378 | 0.0322 | 3 |

| Cutting height, H (mm) | 0.5378 | 0.5599 | 0.5247 | 0.0352 | 2 |

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| v | 2 | 0.064090 | 0.032045 | 5.68 | 0.011 |

| I | 2 | 0.004780 | 0.002390 | 0.42 | 0.661 |

| H | 2 | 0.005690 | 0.002845 | 0.50 | 0.612 |

| Error | 20 | 0.112916 | 0.005646 | - | - |

| Total | 26 | 0.187476 | - | - | - |

| Process Parameters | Circular Quality Responses | Experimental | Predicted | MAPE (%) | GRG | GFRG | MAPE (%) |

|---|---|---|---|---|---|---|---|

| v = 2000 mm/min I = 65 A H = 1 mm | Ckw (mm) β (°) Ce top (mm) Ce bottom (mm) | 1.91 | 1.79 | 5.76 | 0.756 | 0.722 | 4.46 |

| 1.29 | 1.17 | 8.58 | |||||

| 0.059 | 0.061 | 4.40 | |||||

| 0.095 | 0.102 | 7.68 | |||||

| v = 2000 mm/min I = 65 A H = 1.5 mm | Ckw (mm) β (°) Ce top (mm) Ce bottom (mm) | 1.87 | 1.79 | 3.75 | 0.787 | 0.803 | 2.05 |

| 1.21 | 1.18 | 2.39 | |||||

| 0.065 | 0.061 | 5.23 | |||||

| 0.059 | 0.056 | 5.08 | |||||

| v = 2000 mm/min I = 85 A H = 2 mm | Ckw (mm) β (°) Ce top (mm) Ce bottom (mm) | 2.15 | 2.12 | 1.01 | 0.759 | 0.722 | 4.84 |

| 1.15 | 1.09 | 4.69 | |||||

| 0.067 | 0.061 | 8.05 | |||||

| 0.061 | 0.055 | 9.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peko, I.; Crnokić, B.; Čulić-Viskota, J.; Matić, T. Hybrid Grey–Fuzzy Approach for Optimizing Circular Quality Responses in Plasma Jet Manufacturing of Aluminum Alloy. Appl. Sci. 2025, 15, 7447. https://doi.org/10.3390/app15137447

Peko I, Crnokić B, Čulić-Viskota J, Matić T. Hybrid Grey–Fuzzy Approach for Optimizing Circular Quality Responses in Plasma Jet Manufacturing of Aluminum Alloy. Applied Sciences. 2025; 15(13):7447. https://doi.org/10.3390/app15137447

Chicago/Turabian StylePeko, Ivan, Boris Crnokić, Jelena Čulić-Viskota, and Tomislav Matić. 2025. "Hybrid Grey–Fuzzy Approach for Optimizing Circular Quality Responses in Plasma Jet Manufacturing of Aluminum Alloy" Applied Sciences 15, no. 13: 7447. https://doi.org/10.3390/app15137447

APA StylePeko, I., Crnokić, B., Čulić-Viskota, J., & Matić, T. (2025). Hybrid Grey–Fuzzy Approach for Optimizing Circular Quality Responses in Plasma Jet Manufacturing of Aluminum Alloy. Applied Sciences, 15(13), 7447. https://doi.org/10.3390/app15137447