Application of Fermented Wheat, Acorns, and Sorghum in Processing of Couscous: Effect on Culinary Quality, Pasting Properties, and Microstructure

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

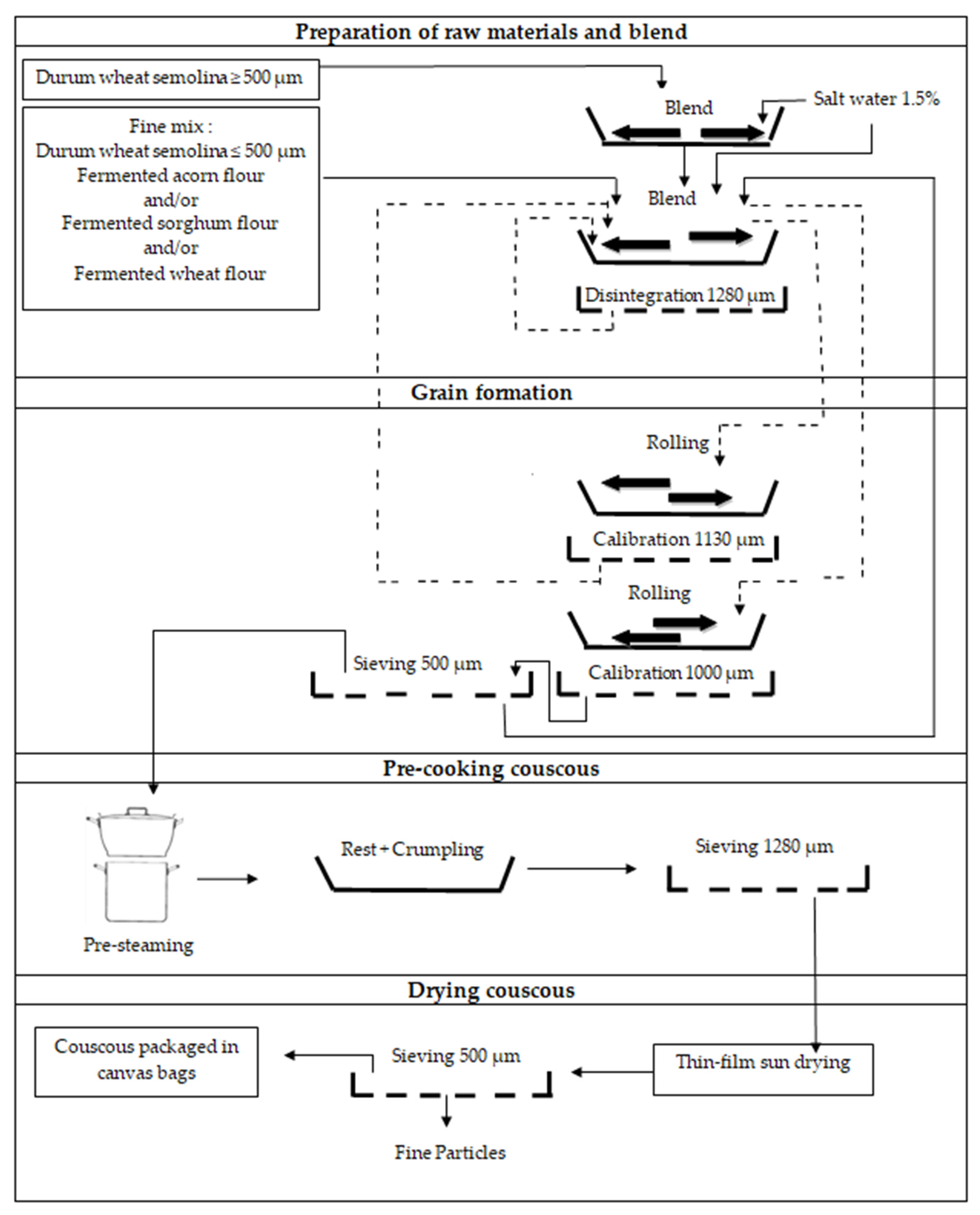

2.2. Investigation of the Couscous Production Diagram

2.2.1. Survey Area and Data Collection

2.2.2. Reproduction of Traditional Couscous Making

2.3. Characterization of the Produced Couscous

2.3.1. Color Determination

2.3.2. Culinary Quality Assessment

Swelling Index

Disintegration Degree

2.3.3. Pasting Properties

2.3.4. Microstructure

2.4. Data Analysis

3. Results and Discussion

3.1. Survey Results

3.1.1. Socio-Demographic Profile of Respondents

3.1.2. Main Stages of Traditional Couscous Production

Raw Materials Preparation

Humidification

Grain Formation (Rolling and Grading)

Finishing

Pre-Cooking Couscous

Drying

3.2. Characteristics of Manufactured Couscous

3.2.1. Color Parameters Results

3.2.2. Culinary Quality Results

Swelling Index Results

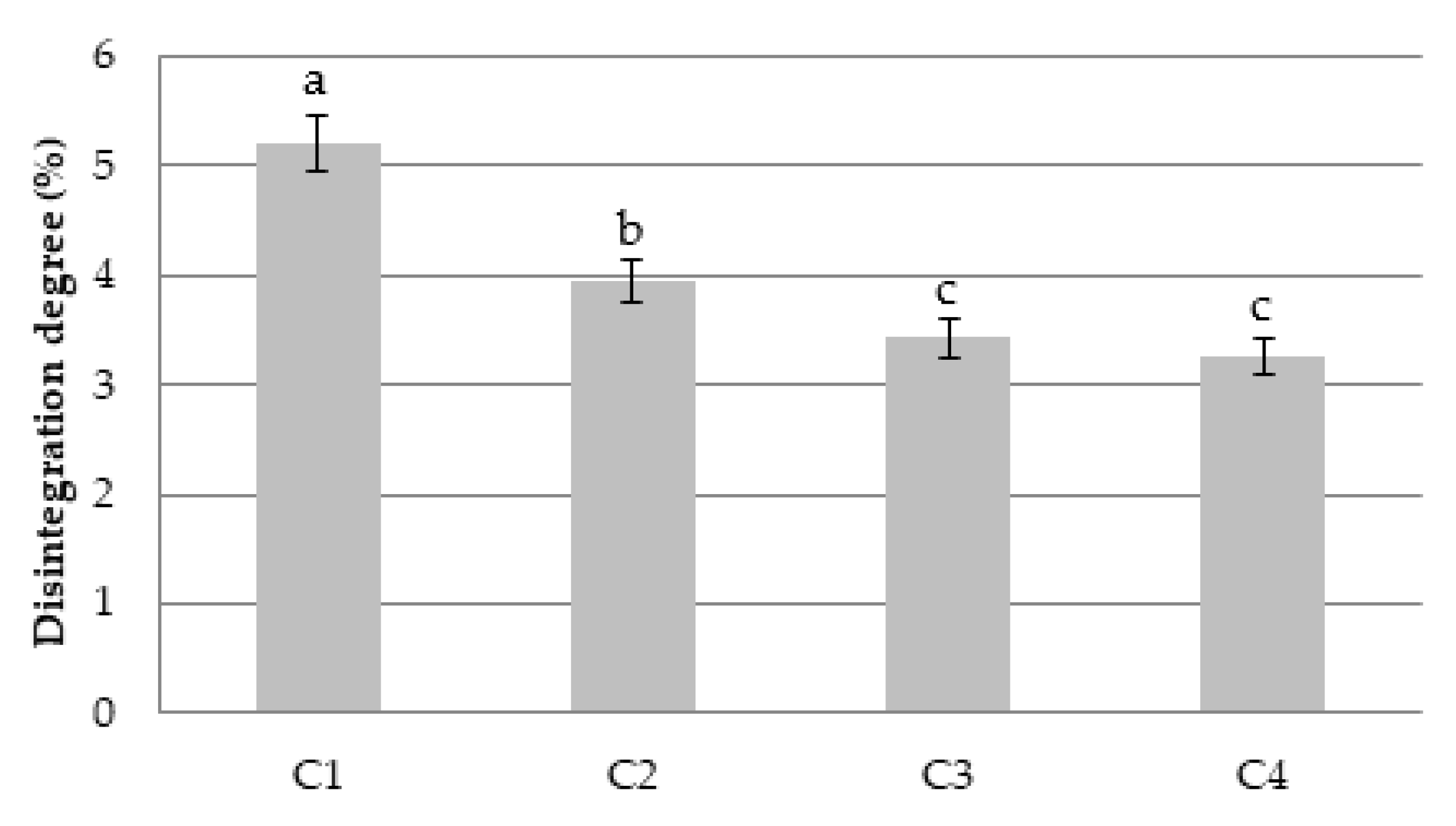

Disintegration Degree Results

3.2.3. Pasting Properties Results

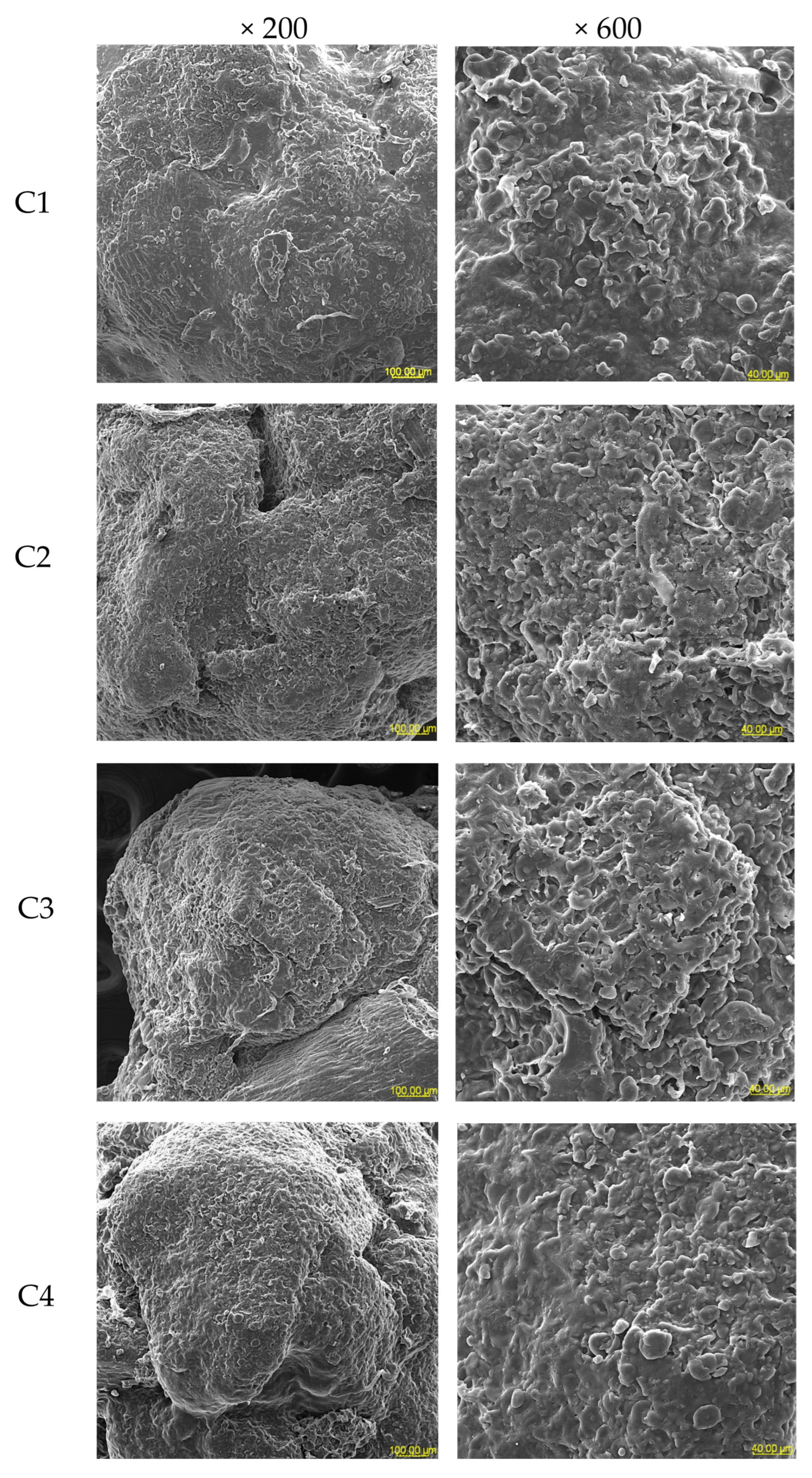

3.2.4. Microstructure of Couscous

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hammani, O.; El-Otmani, N.; Lenda, O.B.; El Azhari, H.; Rfaki, A.; Lahlouhi, N.; Mourad, Y.; Abdallaoui, A. Exploratory analysis of potential toxic elements in Moroccan couscous and health risk evaluation utilizing ICP-OES. J. Trace Elem. Miner. 2025, 11, 100207. [Google Scholar] [CrossRef]

- Chemache, L.; Kehal, F.; Namoune, H.; Chaalal, M.; Gagaoua, M. Couscous: Ethnic making and consumption patterns in the Northeast of Algeria. J. Ethn. Foods 2018, 5, 211–219. [Google Scholar] [CrossRef]

- Becila, F.Z.; Bouasla, A.; Turchiuli, C.; Almeida, G.; Moulin, G.; Bekhouche, F. Fermentation effects on physical, microstructural, cooking and sensory characteristics of a traditional Algerian couscous based on fermented wheat Lemzeïet. Food Biosci. 2023, 53, 102505. [Google Scholar] [CrossRef]

- Abecassis, J.; Cuq, B.; Boggini, G.; Namoune, H. Other traditional durum-derived products. In Durum Wheat: Chemistry and Technology, 2nd ed.; Sissons, M., Abecassis, J., Marchylo, B., Carcea, M., Eds.; AACC International: St. Paul, MN, USA, 2012; pp. 177–199. [Google Scholar]

- Hammami, R.; Barbar, R.; Laurent, M.; Cuq, B. Durum wheat couscous grains: An ethnic Mediterranean food at the interface of traditional domestic preparation and industrial manufacturing. Foods 2022, 11, 902. [Google Scholar] [CrossRef]

- Hammami, R.; Sissons, M. Durum wheat products, couscous. In Wheat Quality for Improving Processing and Human Health; Igrejas, G., Ikeda, T.M., Guzmán, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 347–367. [Google Scholar] [CrossRef]

- Sara, M.; Mouna, T.; Djamel, S.; Omar, K. Traditional Algerian fermented food: First data on nutritional characteristics of wheat (Triticum durum) fermented in underground silos Matmor (Mascara, Algeria) compared to unfermented wheat. Adv. Biol. Earth Sci. 2020, 5, 176–192. [Google Scholar]

- Bellocq, B. Approche Multi-Echelles Pour la Maîtrise Technologique de la Transformation de la Semoule de blé dur en Couscous. Ph.D. Thesis, University Montpellier SupAgro, Montpellier, France, 2017. [Google Scholar]

- Galiba, M.; Rooney, L.; Waniska, R.; Miller, F. The preparation of sorghum and millet couscous in West Africa. Cereal Foods World 1987, 32, 878–884. [Google Scholar]

- Kaup, S.; Walker, C. Couscous in North-Africa. Cereal Foods World 1986, 31, 179–182. [Google Scholar]

- Zannou, O.; Agossou, D.J.; Miassi, Y.; Agani, O.B.; Aisso, M.D.; Chabi, I.B.; Kpoclou, Y.E.; Azokpota, P.; Koca, I. Traditional fermented foods and beverages: Indigenous practices of food processing in Benin Republic. Int. J. Gastron. Food Sci. 2022, 27, 100450. [Google Scholar] [CrossRef]

- Anyogu, A.; Olukorede, A.; Anumudu, C.; Onyeaka, H.; Areo, E.; Adewale, O.; Odimba, J.N.; Nwaiwu, O. Microorganisms and food safety risks associated with indigenous fermented foods from Africa. Food Control 2021, 129, 108227. [Google Scholar] [CrossRef]

- Belmouloud, R.; Bourekoua, H.; Wójtowicz, A.; Mahroug, H.; Ayad, R.; Krajewska, M.; Różyło, R. Physicochemical, functional, antioxidant, pasting and FT-IR spectroscopic properties of fermented acorns and sorghum using traditional Algerian processes. Processes 2024, 12, 1647. [Google Scholar] [CrossRef]

- Bekhouche, F.; Merabti, R.; Bailly, J. Lemzeiet traditional couscous manufacture from fermented wheat (Algeria): Investigation of the process and estimation of the technological and nutritional quality. Afr. J. Sci. Technol. 2013, 4, 167e75. [Google Scholar] [CrossRef]

- Merabti, R. Blé dur Fermenté Lemzeïet: Étude du Nouveau Procédé de Fermentation à l’Exterieur du Matmor et Caractérisation de l’Ecosystème (Interactions du Microbiote Avec la Matrice). Ph.D. Thesis, University Frères Mentouri-Constantine 1, Constantine, Algeria, 2015. [Google Scholar]

- AACC. Approved Methods of the AACC; American Association of Cereal Chemists: St. Paul, MN, USA, 2010. [Google Scholar]

- Chemache, L.; Kehal, F.; Namoune, H. Wet agglomeration of barley flour-wheat semolina blends into couscous: Effects on rheological culinary sensory properties. Int. J. Gastron. Food Sci. 2021, 26, 100412. [Google Scholar] [CrossRef]

- Bouasla, A. Pastification Sans Gluten par Cuisson-Extrusion. Ph.D. Thesis, University Frères Mentouri-Constantine 1, Constantine, Algeria, 2018. [Google Scholar]

- Agrahar-Murugkar, D.; Dixit-Bajpai, P. Physicochemical, textural, color, nutritional, scanning electron microscopy and sensorial characterization of calcium-rich breads fortified with sesame, malted finger millet, cumin and moringa leaves. Nutr. Food Sci. 2020, 50, 47–60. [Google Scholar] [CrossRef]

- Benatallah, L.; Agli, A.; Zidoune, M.N. Gluten-free couscous preparation: Traditional procedure description and technological feasibility for three rice-leguminous supplemented formulae. J. Food Agric. Environ. 2008, 6, 105. [Google Scholar]

- Zohra, B.-B.F. Enquête sur le Couscous Lemzeïet et Effets de la Fermentation sur les Caractéristiques Microbiologiques et Biochimiques du blé dur et sur les Propriétés Technologiques, Culinaires, Microstructurales et Sensorielles du Couscous Lemzeïet. Ph.D. Thesis, University Frères Mentouri-Constantine 1, Constantine, Algeria, 2024. [Google Scholar]

- Chemache, L. Enquête sur le Couscous et Effets de Quelques Paramètres sur sa Qualité et sur le Phénomène D’agglomération Humide de la Semoule de blé dur, de la Farine d’orge et de Farines Sans Gluten (Maïs, Sarrasin, Quinoa, Amarante et Manioc). Ph.D. Thesis, University Frères Mentouri-Constantine 1, Constantine, Algeria, 2020. [Google Scholar]

- Lefkir, S.; Karima, K.; Yesli, A.; Ounane, G. Hydration rate influence on the couscous quality. J. Food Agric. Environ. 2017, 15, 5–11. [Google Scholar]

- Benatallah, L. Couscous et Pain Sans Gluten Pour Malades Cœliaques: Aptitude Technologique de Formules à Base de Riz et de Légumes Secs. Ph.D. Thesis, University Frères Mentouri-Constantine 1, Constantine, Algeria, 2009. [Google Scholar]

- Barkouti, A. Agglomération Humide de Poudres à Réactivité de Surface-Approche Mécanistique de la Morphogenèse de Structures Alimentaires Agglomérées. Ph.D. Thesis, University Montpellier II-Sciences et Techniques du Languedoc, Montpellier, France, 2012. [Google Scholar]

- Benayad, A.; Taghouti, M.; Benali, A.; Benbrahim, N.; Aboussaleh, Y. Development and nutritional, technological, microbiological, cooking and sensory characterization of durum wheat couscous partially enriched with lentil semolina. Food Biosci. 2021, 42, 101062. [Google Scholar] [CrossRef]

- Nani, M.; Krishnaswamy, K. Physical and functional properties of ancient grains and flours and their potential contribution to sustainable food processing. Int. J. Food. Prop. 2021, 24, 1529–1547. [Google Scholar] [CrossRef]

- Doukani, K. Etude comparative entre le couscous industriel et le couscous à base de glands. Nat. Technol. B Sci. Agron. Biol. 2015, 13, 2–11. [Google Scholar]

- Becila, F.Z.; Bouasla, A.; Turchiuli, C.; Boussekine, R.; Bekhouche, F.; Wójtowicz, A. Biochemical and microbiological changes associated with fermentation of durum wheat for Lemzeïet processing, a traditional Algerian fermented food. Processes 2022, 10, 2347. [Google Scholar] [CrossRef]

- Hama-Ba, F.; Silga, P.; Diawara, B. Evaluation de la qualité et de l’acceptabilité de couscous à base de trois formulations de farines composites enrichies au soja (Glycine max) et au moringa (Moringa oleifera). Int. J. Biol. Chem. Sci. 2016, 10, 2497–2510. [Google Scholar] [CrossRef]

- Khemiri, S.; Nunes, M.C.; Bessa, R.J.; Alves, S.P.; Smaali, I.; Raymundo, A. Technological feasibility of couscous-algae-supplemented formulae: Process description, nutritional properties and in vitro digestibility. Foods 2021, 10, 3159. [Google Scholar] [CrossRef] [PubMed]

- Iwe, M.; Onyeukwu, U.; Agiriga, A. Proximate, functional and pasting properties of FARO 44 rice, African yam bean and brown cowpea seeds composite flour. Cogent. Food Agric. 2016, 2, 1142409. [Google Scholar] [CrossRef]

- Kim, W.; Yoo, B. Rheological and thermal effects of galactomannan addition to acorn starch paste. LWT-Food Sci. Technol. 2011, 44, 759–764. [Google Scholar] [CrossRef]

- Chandra, S. Assessment of functional properties of different flours. Afr. J. Agric. Res. 2013, 38, 4849–4852. [Google Scholar]

- Taib, M.; Bouyazza, L. Composition, physicochemical properties, and uses of Acorn starch. J. Chem. 2021, 2021, 9988570. [Google Scholar] [CrossRef]

- Zhong, F.; Li, Y.; Ibáñez, A.M.; Oh, M.H.; McKenzie, K.S.; Shoemaker, C. The effect of rice variety and starch isolation method on the pasting and rheological properties of rice starch pastes. Food Hydrocoll. 2009, 23, 406–414. [Google Scholar] [CrossRef]

- Kim, J.-M.; Shin, M. Effects of particle size distributions of rice flour on the quality of gluten-free rice cupcakes. LWT-Food Sci. Technol. 2014, 59, 526–532. [Google Scholar] [CrossRef]

- Hayes, A.M.; Swackhamer, C.; Mennah-Govela, Y.A.; Martinez, M.M.; Diatta, A.; Bornhorst, G.M.; Hamaker, B.R. Pearl millet (Pennisetum glaucum) couscous breaks down faster than wheat couscous in the Human Gastric Simulator, though has slower starch hydrolysis. Food Funct. 2020, 11, 111–122. [Google Scholar] [CrossRef]

- Jingyi, Y.; Reddy, C.K.; Fan, Z.; Xu, B. Physicochemical and structural properties of starches from non-traditional sources in China. Food Sci. Hum. Wellness 2023, 12, 416–423. [Google Scholar] [CrossRef]

- Hamid, M.G.; Elkhatim, K.A.S.; Idris, Y.M.; Elsafy, M.; Rahmatov, M.; Abdelhalim, T.; Muneer, F. Impact of fermentation time on the in vitro enzymatic digestibility of traditionally extracted pearl millet starch. LWT-Food Sci. Technol. 2025, 218, 117523. [Google Scholar] [CrossRef]

- Yang, C.; Wang, J.; Wu, Y.; Shi, Y.; Wang, Z.; Guo, Y.; Gilbert, R.G.; Lv, P.; Li, E. How sorghum starch structural properties affect its resistance to cooking in baijiu brewing. Food Hydrocoll. 2025, 160, 110837. [Google Scholar] [CrossRef]

- Xu, X.; Bean, S.; Wu, X.; Shi, Y.-C. Effects of protein digestion on in vitro digestibility of starch in sorghum differing in endosperm hardness and flour particle size. Food Chem. 2022, 383, 132635. [Google Scholar] [CrossRef]

| Population Surveyed | Number (Percentage%) |

|---|---|

| Age group | |

| 21–39 | 19 (9.50%) |

| 40–59 | 162 (81.00%) |

| 60–83 | 19 (9.50%) |

| Education level | |

| Lettered | 54 (27.00%) |

| Primary/secondary | 111 (55.50%) |

| University | 35 (17.50%) |

| Activity | |

| Active | 42 (21.00%) |

| Not active | 158 (79.00%) |

| Origin (province) | |

| Jijel | 174 (87.00%) |

| Skikda | 17 (8.50%) |

| Bejaïa | 9 (4.50%) |

| Source of knowledge | |

| Mother | 159 (79.50%) |

| Grandmother | 15 (7.50%) |

| Mother in law | 26 (13.00%) |

| Couscous | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| Respondents (%) | 48.81 | 25.60 | 13.69 | 10.71 |

| Fermented materials incorporation rates | ||||

| FA (%) | 8 | 8 | 6 | 4 |

| FS (%) | 4 | 0 | 0.8 | 0 |

| FW (%) | 4 | 0 | 0 | 4 |

| Total incorporation rates (%) | 16 | 8 | 6.8 | 8 |

| Wheat semolina incorporation rate | ||||

| Wheat semolina (%) | 84 | 92 | 93.2 | 92 |

| Total formulation (%) | 100 | 100 | 100 | 100 |

| Couscous | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| Color Parameters | ||||

| L* | 60.66 ± 0.90 c | 63.12 ± 0.89 b | 70.36 ± 1.49 a | 63.55 ± 0.67 b |

| a* | 5.80 ± 0.13 a | 5.25 ± 0.06 b | 4.86 ± 0.17 c | 5.68 ± 0.10 a |

| b* | 10.42 ± 0.35 d | 10.84 ± 0.43 c | 16.03 ± 0.36 a | 11.86 ± 0.28 b |

| BI | 39.34 a | 36.88 b | 29.64 d | 36.45 c |

| Couscous | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| Initial Viscosity (mPas) | 15.60 ± 0.32 d | 24.00 ± 0.50 c | 25.00 ± 0.00 b | 27.00 ± 0.00 a |

| Maximum Viscosity (mPas) | 24.20 ± 0.39 d | 26.00 ± 1.50 c | 31.00 ± 0.50 a | 30.00 ± 1.86 b |

| Final Viscosity (mPas) | 37.00 ± 1.60 d | 40.00 ± 0.00 c | 49.00 ± 1.20 a | 46.00 ± 3.00 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belmouloud, R.; Bourekoua, H.; Chemache, L.; Mitrus, M.; Benatallah, L.; Różyło, R.; Wójtowicz, A. Application of Fermented Wheat, Acorns, and Sorghum in Processing of Couscous: Effect on Culinary Quality, Pasting Properties, and Microstructure. Appl. Sci. 2025, 15, 7418. https://doi.org/10.3390/app15137418

Belmouloud R, Bourekoua H, Chemache L, Mitrus M, Benatallah L, Różyło R, Wójtowicz A. Application of Fermented Wheat, Acorns, and Sorghum in Processing of Couscous: Effect on Culinary Quality, Pasting Properties, and Microstructure. Applied Sciences. 2025; 15(13):7418. https://doi.org/10.3390/app15137418

Chicago/Turabian StyleBelmouloud, Rayene, Hayat Bourekoua, Loucif Chemache, Marcin Mitrus, Leila Benatallah, Renata Różyło, and Agnieszka Wójtowicz. 2025. "Application of Fermented Wheat, Acorns, and Sorghum in Processing of Couscous: Effect on Culinary Quality, Pasting Properties, and Microstructure" Applied Sciences 15, no. 13: 7418. https://doi.org/10.3390/app15137418

APA StyleBelmouloud, R., Bourekoua, H., Chemache, L., Mitrus, M., Benatallah, L., Różyło, R., & Wójtowicz, A. (2025). Application of Fermented Wheat, Acorns, and Sorghum in Processing of Couscous: Effect on Culinary Quality, Pasting Properties, and Microstructure. Applied Sciences, 15(13), 7418. https://doi.org/10.3390/app15137418