Presumptions for the Integration of Green Hydrogen and Biomethane Production in Wastewater Treatment Plants

Abstract

1. Introduction

1.1. EU Regulatory Environment

1.2. Biomethane and Green Hydrogen in WWTPs: Situation Overview

1.3. Aims and Objectives

- What are the main presumptions for the successful integration of green hydrogen and biomethane technologies?

- What is the relationship between the electrolyser capacity and the oxygen, hydrogen, and heat demand in a WWTP?

- What is the relationship between the electrolyser capacity and the availability of green electricity?

- What degree of energy neutrality can be achieved by integrating green hydrogen production into WWTP, and what other measures are needed to achieve complete energy neutrality of a WWTP?

- In which external systems and in what way can the excess energy produced in WWTP be consumed?

2. Methodology

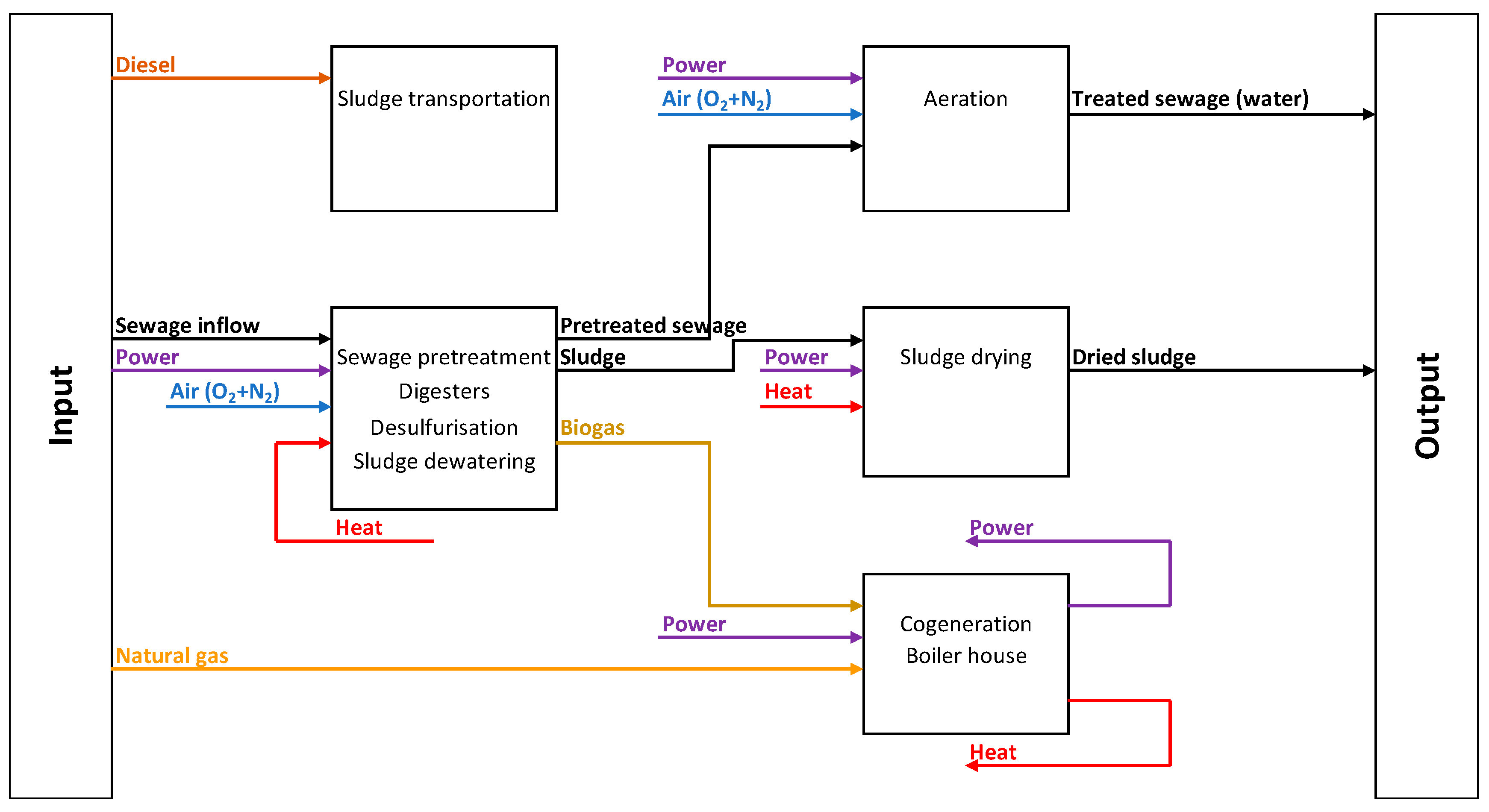

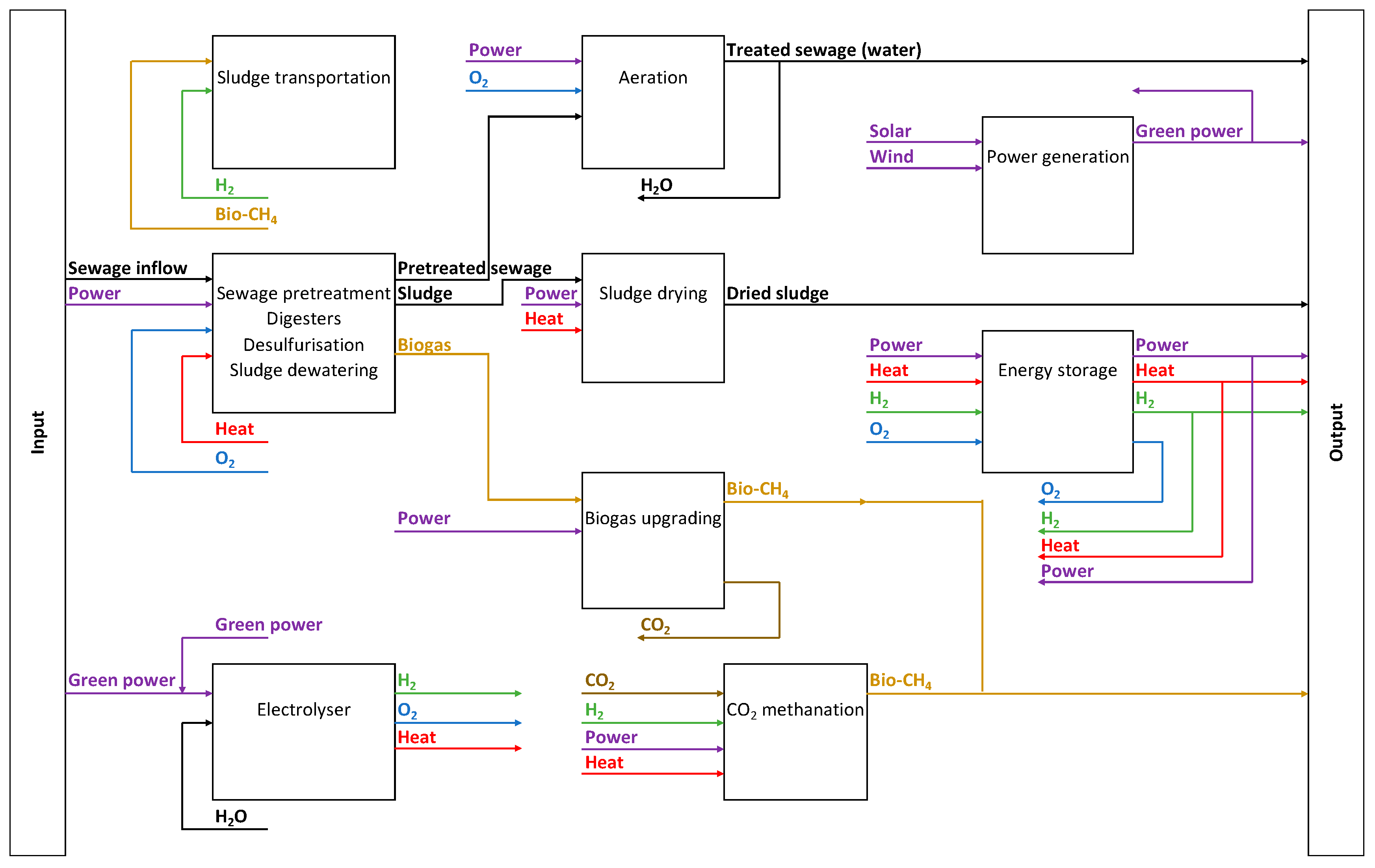

2.1. Wastewater Treatment Plant as an Integrated Energy System

2.2. Principles of Electrolyzer Power Selection

2.3. Presumptions for the Successful Integration of Green Hydrogen and Biomethane Production Processes

- Utilization possibility of all products from electrolysis in WWTP;

- Availability of green electricity for the production of green hydrogen in terms of quantity and time;

- Availability of external infrastructure;

- Energy and products storage requirements and possibilities of various types of energy;

- Use of renewable energy carriers produced in WWTP for WWTP needs;

- Sufficiency of incoming waste streams for the efficient functioning of WWTP as an energy system;

- Technology readiness level of key processes.

2.3.1. Utilization Possibility of All Products from Electrolysis in WWTP

Oxygen Demand at the Wastewater Treatment Plant

Heat Demand at the Wastewater Treatment Plant

Hydrogen Demand at the Wastewater Treatment Plant

2.3.2. Availability of Green Electricity for the Production of Green Hydrogen in Terms of Quantity and Time

2.3.3. Availability of External Infrastructure

Natural Gas Network

District Heating Network

Power Grid

Transport Refuelling Infrastructure

2.3.4. Energy and Products Storage Requirements and Possibilities of Various Types of Energy

2.3.5. Use of Renewable Energy Carriers Produced in WWTP for WWTP Needs

Use of Biomethane and Hydrogen in Transport

Use of Biomethane (Biogas) and Hydrogen for Electricity and Heat Production

2.3.6. Sufficiency of Incoming Waste Streams for the Efficient Functioning of WWTP as an Energy System

2.3.7. Technology Readiness Level of Key Processes

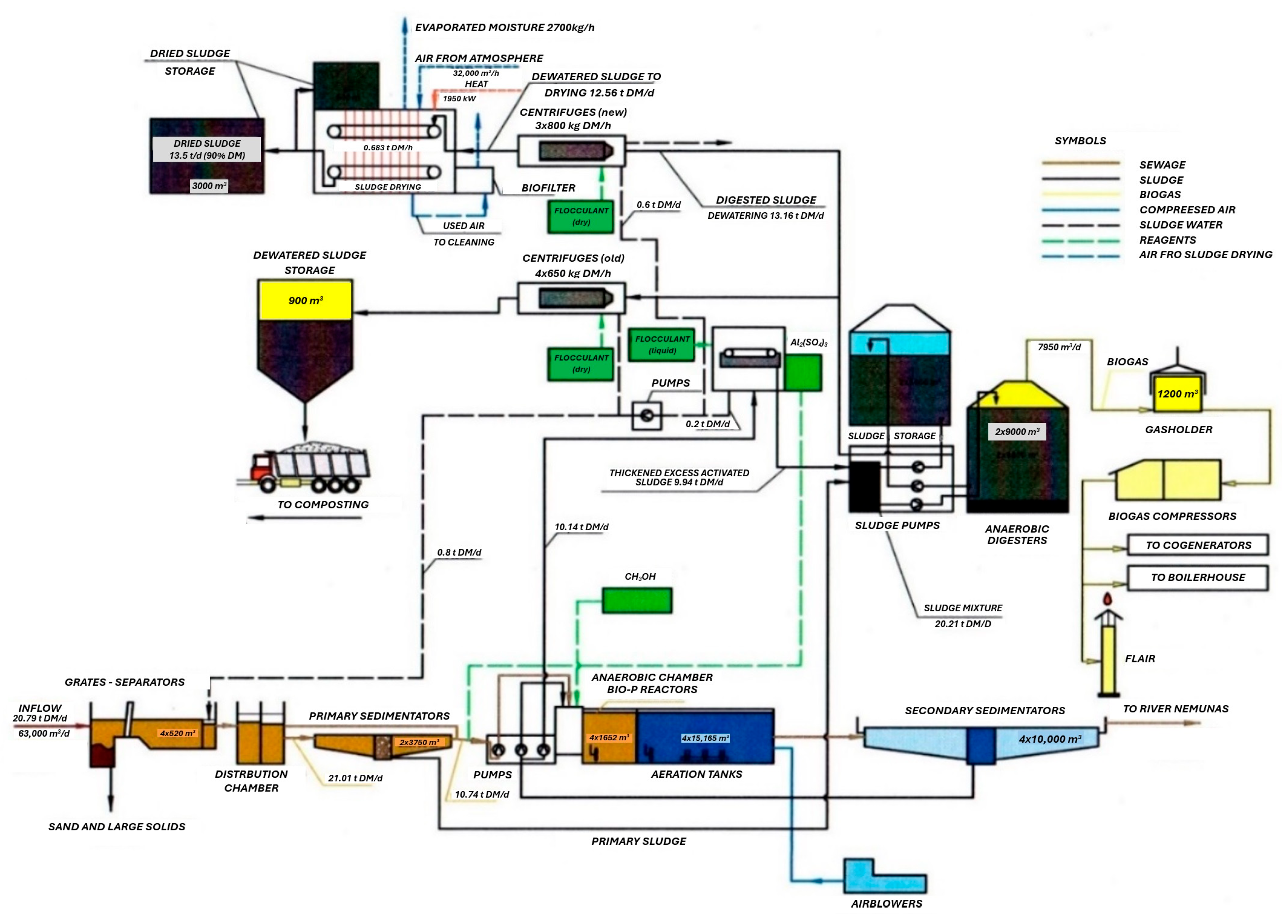

3. Analysis of Kaunas WWTP Case

4. Results and Discussion

4.1. Energy Balance Before Integration of the Electrolyzer

4.2. Selecting the Power of the Electrolyzer

4.3. Energy Balance After Integration of the Electrolyzer

5. Conclusions

- The task of energy neutrality of the WWTP should be divided into two stages. In the first stage, it should be achieved that the energy balance of the WWTP becomes positive—that is, the amount of all types of useful energy produced in the WWTP exceeds the consumption of all kinds of energy in the WWTP. In the second stage, it should be sought that all renewable electricity used for green hydrogen production is generated at WWTP as is required by the EU Regulations [9].

- The analyzed case of Kaunas WWPT showed that installing an electrolyzer in a WWTP can significantly improve the energy balance of the WWTP.

- To effectively utilize all electrolysis products and achieve the highest energy efficiency of the WWTP, the electrolyzer selection should be conducted by assessing the possibilities of using oxygen, hydrogen, heat and the availability of green electricity. For this, detailed technical and economic modeling of the WWTP should be carried out. This is the goal of the following research by the authors of this article. In this article, the electrolyzer was selected for analysis based on the oxygen demand.

- The main problem in ensuring that all hydrogen produced by WWTP is green usually is the unavailability of renewable electricity sources installed onsite of WWTP. The potential for solar and wind electricity production in the WWTP territory is often limited due to the size of the free WWTP territory and the immediate vicinity of the living areas. Therefore, in the case of Kaunas WWTP, the most realistic source of green electricity could be the construction of remote solar and wind parks, once the appropriate economic or political conditions are in place.

- In the analyzed case of Kaunas WWTP, there is good access to all types of infrastructure—natural gas, electricity, heating networks, and transport refueling. In this way, the injection of the produced biomethane into the natural gas network, the mixing of hydrogen into biomethane, the use of waste electrolysis excess heat, the direct use of biomethane and hydrogen for filling transport fuel tanks and the supply of electricity to the electrolyzer can be ensured.

- By completely replacing the air in the aeration with oxygen generated during electrolysis, the performance, and thus electricity consumption of blowers in Kaunas WWTP could be reduced by 5.5 times, from 4382 MWh to 797 MWh. The electricity consumption for wastewater treatment processes in the WWTP would be reduced by 38.3%.

- An essential factor is the availability of electricity to the electrolyzer. Although replacing air with oxygen significantly reduces electricity demand for wastewater treatment processes in Kaunas WWTP, but due to the installation of an electrolyzer, the total electricity demand of the WWTP can increase by up to 7 times if the electrolyzer power is selected according to the oxygen demand.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| BHM | Biological hydrogen methanation |

| Bio-P | Biological phosphorus removal |

| BOD | Biological oxygen demand |

| CBG | Compressed biomethane gas |

| CH4 | Methane |

| CHG | Compressed hydrogen gas |

| CO2 | Carbon dioxide |

| COD | Chemical oxygen demand |

| COP | Coefficient of performance |

| CSTRs | Continuously Stirred Tank Reactors |

| DH | District heating |

| DIET | Direct interspecies electron transfer |

| EC | European Commission |

| EFW | Edible food waste |

| EU | European Union |

| FSFs | Fine sieved fractions |

| FW | Food waste |

| GHG | Greenhouse gas |

| H2 | Hydrogen |

| H2S | Hydrogen sulphide |

| HGV | Heavy goods vehicle |

| IFW | Inedible food waste |

| LCA | Life cycle assessment |

| MER | Methane evolution rate |

| N/DN | Nitrification-denitrification |

| N2O | Nitrous oxide |

| O2 | Oxygen |

| OFMSW | Organic fraction of municipal solid waste |

| PE | Population equivalent |

| PEM | Proton exchange membrane |

| PoS | Proof of Sustainability |

| PSA | Pressure Swing Adsorption |

| Qcap | Capacity of wastewater heat pump |

| Qrec | Theorical potential of waste heat recovery |

| SOEC | Solid oxide olectrolyzer cell |

| TRL | Technology readiness level |

| VS | Volatile solids |

| WWTP | Wastewater treatment plant |

References

- European Commission. Questions and Answers on the New EU Rules on Treating Urban Wastewater. 2022. Available online: https://ec.europa.eu/commission/presscorner/detail/en/qanda_22_6281 (accessed on 8 May 2025).

- Lu, L.; Guest, J.S.; Peters, C.A.; Zhu, X.; Rau, G.H.; Ren, Z.J. Wastewater treatment for carbon capture and utilization. Nat. Sustain. 2018, 1, 750–758. [Google Scholar] [CrossRef]

- Maktabifard, M.; Al-Hazmi, H.E.; Szulc, P.; Mousavizadegan, M.; Xu, X.; Zaborowska, E.; Li, X.; Mąkinia, J. Net-zero carbon condition in wastewater treatment plants: A systematic review of mitigation strategies and challenges. Renew. Sustain. Energy Rev. 2023, 185, 113638. [Google Scholar] [CrossRef]

- Zaborowska, E.; Czerwionka, K.; Mąkinia, J. Integrated plant-wide modelling for evaluation of the energy balance and greenhouse gas footprint in large wastewater treatment plants. Appl. Energy 2021, 282 Pt A, 116126. [Google Scholar] [CrossRef]

- European Union. Directive (EU) 2024/3019 of the European Parliament and of the Council of 27 November 2024 Concerning Urban Wastewater Treatment (Recast). Available online: https://eur-lex.europa.eu/eli/dir/2024/3019/oj/eng (accessed on 8 May 2025).

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Consolidated Text: 2024-07-16. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02018L2001-20240716 (accessed on 8 May 2025).

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: REPowerEU Plan (COM/2022/230 Final). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52022DC0230 (accessed on 8 May 2025).

- European Union. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/eli/dir/2018/844/oj/eng (accessed on 8 May 2025).

- European Commission. Commission Delegated Regulation (EU)/… Supplementing Directive (EU) 2018/2001 of the European Parliament and of the Council by Establishing a Union Methodology Setting Out Detailed rules for the Production of Renewable Liquid and Gaseous Transport Fuels of Non-Biological Origin (C/2023/1087 Final). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=pi_com%3AC%282023%291087 (accessed on 8 May 2025).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Hydrogen Strategy for a Climate-Neutral Europe (COM/2020/301 Final). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0301 (accessed on 8 May 2025).

- Gruber-Glatzl, W.; Brunner, C.; Meitz, S.; Schnitzer, H. From the Wastewater Treatment Plant to the Turnstiles of Urban Water and District Heating Networks. Front. Sustain. Cities 2020, 2, 523698. [Google Scholar] [CrossRef]

- Drewnowski, J.; Remiszewska-Skwarek, A.; Duda, S.; Łagód, G. Aeration Process in Bioreactors as the Main Energy Consumer in a Wastewater Treatment Plant. Review of Solutions and Methods of Process Optimization. Processes 2019, 7, 311. [Google Scholar] [CrossRef]

- Rusmanis, D.; Yang, Y.; Lin, R.; Wall, D.M.; Murphy, J.D. Operation of a circular economy, energy, environmental system at a wastewater treatment plant. Adv. Appl. Energy 2022, 8, 100109. [Google Scholar] [CrossRef]

- Michailos, S.; Walker, M.; Moody, A.; Poggio, D.; Pourkashanian, M. Biomethane production using an integrated anaerobic digestion, gasification and CO2 biomethanation process in a real waste water treatment plant: A techno-economic assessment. Energy Convers. Manag. 2020, 209, 112663. [Google Scholar] [CrossRef]

- Müller, G.; Kullmann, F.; Linssen, J.; Stolten, D. The costs of future energy technologies: A comprehensive review of power-to-X processes. J. CO2 Util. 2025, 92, 103019. [Google Scholar] [CrossRef]

- Sterner, M.; Specht, M. Power-to-Gas and Power-to-X—The History and Results of Developing a New Storage Concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Zhang, L.; Song, Y.; Shi, J.; Shen, Q.; Hu, D.; Gao, Q.; Chen, W.; Kow, K.-W.; Pang, C.; Sun, N.; et al. Frontiers of CO2 Capture and Utilization (CCU) towards Carbon Neutrality. Adv. Atmos. Sci. 2022, 39, 1252–1270. [Google Scholar] [CrossRef]

- Zhang, B.; Yan, K.; Lyu, Y.; Qian, Y.; Gao, H.; Tian, J.; Zheng, W.; Chen, L. A “water and carbon” near-zero emission WWTP system: Model development and techno-economic-environmental benefits assessment. Appl. Energy 2024, 371, 123727. [Google Scholar] [CrossRef]

- Donald, R.; Boulaire, F.; Love, J.G. Contribution to net zero emissions of integrating hydrogen production in wastewater treatment plants. J. Environ. Manag. 2023, 344, 118485. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Xu, J.; Skov, I.R.; Østergaard, P.A. Hydrogen production from treated wastewater powered by solar–wind energy: Feasibility analysis and optimal planning. Int. J. Hydrogen Energy 2024, 89, 293–309. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, F.; Xu, J.; Tan, C.; Østergaard, P.A. Optimal planning and operation for a grid-connected solar–wind–hydro energy system in wastewater treatment plants. Renew. Energy 2024, 230, 120791. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, C.; Wang, F.; Yang, G. Industrial decarbonisation oriented distributed renewable generation towards wastewater treatment sector: Case from the Yangtze River Delta region in China. Energy 2022, 256, 124562. [Google Scholar] [CrossRef]

- Llácer-Iglesias, R.M.; López-Jiménez, P.A.; Pérez-Sánchez, M. Exploring options for energy recovery from wastewater: Evaluation of hydropower potential in a sustainability framework. Sustain. Cities Soc. 2023, 95, 104576. [Google Scholar] [CrossRef]

- Tomczyk, P.; Mastalerek, K.; Wiatkowski, M.; Kuriqi, A.; Jurasz, J. Assessment of a Francis Micro Hydro Turbine Performance Installed in a Wastewater Treatment Plant. Energies 2023, 16, 7214. [Google Scholar] [CrossRef]

- Punys, P.; Jurevičius, L. Assessment of Hydropower Potential in Wastewater Systems and Application in a Lowland Country, Lithuania. Energies 2022, 15, 5173. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Hydrogen Review 2024. Available online: https://iea.blob.core.windows.net/assets/89c1e382-dc59-46ca-aa47-9f7d41531ab5/GlobalHydrogenReview2024.pdf (accessed on 8 May 2025).

- Jacobs, Yarra Valley Water. Towards a Zero Carbon Future. 2020. Available online: https://www.jacobs.com/sites/default/files/2022-03/jacobs-yarra-valley-water-towards-a-zero-carbon-future.pdf (accessed on 8 May 2025).

- Silva, J.; Gonçalves, J.C.; Rocha, C.; Vilaça, J.; Madeira, L.M. Biomethane production from biogas obtained in wastewater treatment plants: Process optimization and economic analysis. Renew. Energy 2024, 220, 119469. [Google Scholar] [CrossRef]

- Burrin, D.; Roy, S.; Roskilly, A.P.; Smallbone, A. A combined heat and green hydrogen (CHH) generator integrated with a heat network. Energy Convers. Manag. 2021, 246, 114686. [Google Scholar] [CrossRef]

- Pilz, F.; Svardal, K.; Kreuzinger, N.; Krampe, J. Model-based dynamic simulation study to boost the WWTP performance in winter tourism regions. J. Water Process Eng. 2024, 61, 105266. [Google Scholar] [CrossRef]

- Gabrielli, M.; Compagni, R.D.; Gusmaroli, L.; Malpei, F.; Polesel, F.; Buttiglieri, G.; Antonelli, M.; Turolla, A. Modelling and prediction of the effect of operational parameters on the fate of contaminants of emerging concern in WWTPs. Sci. Total Environ. 2023, 856, 159200. [Google Scholar] [CrossRef] [PubMed]

- Hallas, J.F.; Mackowiak, C.L.; Wilkie, A.C. Mitigating rural WWTP impacts: System dynamics modeling of downstream nutrient outputs. Sci. Total Environ. 2020, 744, 140809. [Google Scholar] [CrossRef]

- Struk-Sokołowska, J.; Miodoński, S.; Muszyński-Huhajło, M.; Janiak, K.; Ofman, P.; Mielcarek, A.; Rodziewicz, J. Impact of differences in speciation of organic compounds in wastewater from large WWTPs on technological parameters, economic efficiency and modelling of chemically assisted primary sedimentation process. J. Environ. Chem. Eng. 2020, 8, 104405. [Google Scholar] [CrossRef]

- Yu, W.; Liu, R.; Zhu, K.; Hao, X. Variable emission factors of CH4 and N2O from WWTPs: A model-based analysis on available data. Environ. Res. 2025, 264, 120380. [Google Scholar] [CrossRef]

- Shukuru, B.N.; Politaeva, N.A. Mitigating CH4 and N2O emissions from domestic and industrial wastewater. Renew. Sustain. Energy Rev. 2025, 210, 115203. [Google Scholar] [CrossRef]

- Zhang, Z.; Qi, F.; Liu, Y.; Asif, M.B.; Ikhlaq, A.; Wang, Z.; Chen, C.; Li, C.; Chang, J.; Li, Q.; et al. Comprehensive assessment, intelligent prediction, and precise mitigation strategies for greenhouse gas emissions in full-scale wastewater treatment plants. Environ. Res. 2025, 270, 121052. [Google Scholar] [CrossRef]

- Lancioni, N.; Szelag, B.; Sgroi, M.; Barbusiński, K.; Fatone, F.; Eusebi, A.L. Novel extended hybrid tool for real time control and practically support decisions to reduce GHG emissions in full scale wastewater treatment plants. J. Environ. Manag. 2024, 365, 121502. [Google Scholar] [CrossRef]

- Alrbai, M.; Al-Dahidi, S.; Al-Ghussain, L.; Alahmer, A.; Hayajneh, H. Minimizing grid energy consumption in wastewater treatment plants: Towards green energy solutions, water sustainability, and cleaner environment. Sci. Total Environ. 2024, 926, 172139. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Stazi, V.; Tomei, M.C. Dissolved methane in anaerobic effluents: A review on sustainable strategies for optimization of energy recovery or internal process reuse. J. Clean. Prod. 2021, 317, 128359. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, G.; An, C.; Chen, X.; Zhang, P.; Xin, X.; Shen, J.; Agnew, J. Anaerobic digestion of livestock manure in cold regions: Technological advancements and global impacts. Renew. Sustain. Energy Rev. 2020, 119, 109494. [Google Scholar] [CrossRef]

- Swedish Environmental Protection Agency (SEPA). Biogas ur Gödsel, Avfall och Restprodukter—Goda Svenska Exempel; SEPA: Stockholm, Sweden, 2012; pp. 1–116. Available online: https://www.diva-portal.org/smash/get/diva2:1614170/FULLTEXT01.pdf (accessed on 8 May 2025).

- Xiong, Y.-T.; Zhang, J.; Chen, Y.-P.; Guo, J.-S.; Fang, F.; Yan, P. Geographic distribution of net-zero energy wastewater treatment in China. Renew. Sustain. Energy Rev. 2021, 150, 111462. [Google Scholar] [CrossRef]

- Renfrew, D.; Vasilaki, V.; Katsou, E. Indicator based multi-criteria decision support systems for wastewater treatment plants. Sci. Total Environ. 2024, 915, 169903. [Google Scholar] [CrossRef] [PubMed]

- Pascuzzi, S.; Anifantis, A.S.; Blanco, I.; Scarascia Mugnozza, G. Electrolyzer Performance Analysis of an Integrated Hydrogen Power System for Greenhouse Heating. A Case Study. Sustainability 2016, 8, 629. [Google Scholar] [CrossRef]

- Lagoeiro, H.; Maidment, G.; Ziemele, J. Potential of treated wastewater as an energy source for district heating: Incorporating social elements into a multi-factorial comparative assessment for cities. Energy 2024, 304, 132190. [Google Scholar] [CrossRef]

- Saravanakumar, A.; Sudha, M.R.; Chen, W.H.; Pradeshwaran, V. Hydrogen and biomethane pathways to achieve sustainable transportation in circular economic concept: A review. Int. J. Hydrogen Energy 2025, 143, 403–419. [Google Scholar] [CrossRef]

- European Hydrogen Observatory. Hydrogen Production. Available online: https://observatory.clean-hydrogen.europa.eu/hydrogen-landscape/production-trade-and-cost/hydrogen-production (accessed on 8 May 2025).

- Nord Pool. Prices. Available online: https://data.nordpoolgroup.com/auction/day-ahead/prices?deliveryDate=latest¤cy=EUR&aggregation=YearlyAggregate&deliveryAreas=GER (accessed on 8 May 2025).

- Fan, Y.; Lei, Z.; Guo, Z.; Huang, W.; Wang, D.; Wang, X.; Zhang, Z.; Shimizu, K. Enhanced solubilization of solid organics and methane production by anaerobic digestion of swine manure under nano-bubble water addition. Bioresour. Technol. 2020, 299, 122512. [Google Scholar] [CrossRef] [PubMed]

- Mohammadpour, H.; Cord-Ruwisch, R.; Pivrikas, A.; Ho, G. Utilisation of oxygen from water electrolysis—Assessment for wastewater treatment and aquaculture. Chem. Eng. Sci. 2021, 246, 117008. [Google Scholar] [CrossRef]

- Environmental Protection Agency Ireland (EPA Ireland). Waste Water Treatment Manuals. Primary, Secondary and Tertiary Treatment. Available online: https://www.susana.org/_resources/documents/default/3-3017-7-1520420240.pdf (accessed on 8 May 2025).

- Pera, L.; Gandiglio, M.; Marocco, P.; Pumiglia, D.; Santarelli, M. Trace contaminants in biogas: Biomass sources, variability and implications for technology applications. J. Environ. Chem. Eng. 2024, 12, 114478. [Google Scholar] [CrossRef]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas upgrading technologies—Recent advances in membrane-based processes. Int. J. Hydrogen Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Dada, O.I.; Yu, L.; Neibergs, S.; Chen, S. Biodesulfurization: Effective and sustainable technologies for biogas hydrogen sulfide removal. Renew. Sustain. Energy Rev. 2025, 209, 115144. [Google Scholar] [CrossRef]

- Haosagul, S.; Prommeenate, P.; Hobbs, G.; Pisutpaisal, N. Sulfur-oxidizing bacteria in full-scale biogas cleanup system of ethanol industry. Renew. Energy 2020, 150, 965–972. [Google Scholar] [CrossRef]

- European Biogas Association (EBA). Statistical Report 2022: Tracking Biogas and Biomethane Deployment Across Europe; EBA: Brussels, Belgium, 2022; pp. 1–162. Available online: https://www.europeanbiogas.eu/__trashed-3/ (accessed on 8 May 2025).

- Macor, A.; Benato, A. Regulated Emissions of Biogas Engines—On Site Experimental Measurements and Damage Assessment on Human Health. Energies 2020, 13, 1044. [Google Scholar] [CrossRef]

- Ghimire, A.; Gyawali, R.; Lens, P.N.L.; Lohani, S.P. Chapter 11—Technologies for removal of hydrogen sulfide (H2S) from biogas. In Emerging Technologies and Biological Systems for Biogas Upgrading; Aryal, N., Ottosen, L.D.M., Kofoed, M.V.W., Pant, D., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 295–320. [Google Scholar] [CrossRef]

- Wasajja, H.; Lindeboom, R.E.F.; van Lier, J.B.; Aravind, P.V. Techno-economic review of biogas cleaning technologies for small scale off-grid solid oxide fuel cell applications. Fuel Process. Technol. 2020, 197, 106215. [Google Scholar] [CrossRef]

- Cano, P.I.; Colón, J.; Ramírez, M.; Lafuente, J.; Gabriel, D.; Cantero, D. Life cycle assessment of different physical-chemical and biological technologies for biogas desulfurization in sewage treatment plants. J. Clean. Prod. 2018, 181, 663–674. [Google Scholar] [CrossRef]

- Corey, K.; Zappa, L. Global Environmental Solutions, Inc. Odor Control “ABC’s”. How to Compare and Evaluate Odor Control Technologies. 2018. Available online: http://gesodorcontrol.com/abcs.pdf (accessed on 8 May 2025).

- Barbusiński, K.; Urbaniec, K.; Kasperczyk, D.; Thomas, M. Chapter 2—Biofilters versus bioscrubbers and biotrickling filters: State-of-the-art biological air treatment. In From Biofiltration to Promising Options in Gaseous Fluxes Biotreatment; Soreanu, G., Dumont, É., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 29–51. [Google Scholar] [CrossRef]

- Wang, J.; Wen, J.; Wang, J.; Yang, B.; Jiang, L. Water electrolyzer operation scheduling for green hydrogen production: A review. Renew. Sustain. Energy Rev. 2024, 203, 114779. [Google Scholar] [CrossRef]

- Ravina, M.; Castellana, C.; Panepinto, D.; Zanetti, M.C. MCBioCH4: A computational model for biogas and biomethane evaluation. J. Clean. Prod. 2019, 227, 739–747. [Google Scholar] [CrossRef]

- Rusmanis, D.; O’Shea, R.; Wall, D.M.; Murphy, J.D. Biological hydrogen methanation systems—An overview of design and efficiency. Bioengineered 2019, 10, 604–634. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Xia, A.; Wall, D.M.; Murphy, J.D. Use of surplus wind electricity in Ireland to produce compressed renewable gaseous transport fuel through biological power to gas systems. Renew. Energy 2017, 105, 495–504. [Google Scholar] [CrossRef]

- Guilera, J.; Andreu, T.; Basset, N.; Boeltken, T.; Timm, F.; Mallol, I.; Morante, J.R. Synthetic natural gas production from biogas in a waste water treatment plant. Renew. Energy 2020, 146, 1301–1308. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; Koch, A.M.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Voelklein, M.A.; Rusmanis, D.; Murphy, J.D. Biological methanation: Strategies for in-situ and ex-situ upgrading in anaerobic digestion. Appl. Energy 2019, 235, 1061–1071. [Google Scholar] [CrossRef]

- Lecker, B.; Illi, L.; Lemmer, A.; Oechsner, H. Biological hydrogen methanation—A review. Bioresour. Technol. 2017, 245 Pt A, 1220–1228. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Kougias, P.G.; Treu, L.; Benavente, D.P.; Boe, K.; Campanaro, S.; Angelidaki, I. Ex-situ biogas upgrading and enhancement in different reactor systems. Bioresour. Technol. 2017, 225, 429–437. [Google Scholar] [CrossRef]

- Kougias, P.G.; Tsapekos, P.; Treu, L.; Kostoula, M.; Campanaro, S.; Lyberatos, G.; Angelidaki, I. Biological CO2 fixation in up-flow reactors via exogenous H2 addition. J. Biotechnol. 2020, 319, 1–7. [Google Scholar] [CrossRef]

- Wu, L.; Wei, W.; Song, L.; Woźniak-Karczewska, M.; Chrzanowski, Ł.; Ni, B.-J. Upgrading biogas produced in anaerobic digestion: Biological removal and bioconversion of CO2 in biogas. Renew. Sustain. Energy Rev. 2021, 150, 111448. [Google Scholar] [CrossRef]

- Luo, G.; Angelidaki, I. Hollow fiber membrane based H2 diffusion for efficient in situ biogas upgrading in an anaerobic reactor. Appl. Microbiol. Biotechnol. 2013, 97, 3739–3744. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Wall, D.M.; Ring, D.; Rajendran, K.; Murphy, J.D. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation. Appl. Energy 2018, 212, 1191–1202. [Google Scholar] [CrossRef]

- Ericsson, K. Biogenic Carbon Dioxide as Feedstock for Production of Chemicals and Fuels: A Technoeconomic Assessment with a European Perspective; Miljö- och Energisystem, LTH, Lunds Universitet: Lund, Sweden, 2017; pp. 1–48. Available online: https://lucris.lub.lu.se/ws/portalfiles/portal/31711760/Biogenic_carbon_dioxide_as_feedstock_for_production_of_chemicals_and_fuels_IMES_report_103.pdf (accessed on 8 May 2025).

- Burkhardt, M.; Koschack, T.; Busch, G. Biocatalytic methanation of hydrogen and carbon dioxide in an anaerobic three-phase system. Bioresour. Technol. 2015, 178, 330–333. [Google Scholar] [CrossRef]

- Ministry of Energy of the Republic of Lithuania. Frequently Asked Questions About Electricity Generating Consumers. Available online: https://enmin.lrv.lt/lt/veiklos-sritys-3/atsinaujinantys-energijos-istekliai/elektros-energija-gaminantys-vartotojai/dazniausiai-uzduodami-klausimai-apie-elektra-gaminancius-vartotojus/ (accessed on 8 May 2025).

- Seimas of the Republic of Lithuania. Law of the Republic of Lithuania on Renewable Energy Resources Nr. XI-1375. Consolidated Text: 2025-01-23. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/TAIS.398874/asr (accessed on 8 May 2025).

- Lithuanian Wind Power Association (LVEA). Wind Energy in Lithuania 2022. Available online: https://lvea.lt/en/lithuanian-statistics/ (accessed on 8 May 2025).

- Chae, K.-J.; Kim, I.-S.; Ren, X.; Cheon, K.-H. Reliable energy recovery in an existing municipal wastewater treatment plant with a flow-variable micro-hydropower system. Energy Convers. Manag. 2015, 101, 681–688. [Google Scholar] [CrossRef]

- Mérida García, A.; Rodríguez Díaz, J.A.; García Morillo, J.; McNabola, A. Energy Recovery Potential in Industrial and Municipal Wastewater Networks Using Micro-Hydropower in Spain. Water 2021, 13, 691. [Google Scholar] [CrossRef]

- Ehalt Macedo, H.; Lehner, B.; Nicell, J.; Grill, G.; Li, J.; Limtong, A.; Shakya, R. Distribution and characteristics of wastewater treatment plants within the global river network. Earth Syst. Sci. Data 2022, 14, 559–577. [Google Scholar] [CrossRef]

- European Small Hydropower Association (ESHA). Guide on How to Develop a Small Hydropower Plant, 2nd ed.; ESHA: Brussels, Belgium, 2004; pp. 1–296. Available online: https://energycommunityplatform.eu/wp-content/uploads/2022/06/Merged-Guide-Develop-a-Small-Hydropower-Plant.pdf (accessed on 8 May 2025).

- Zhou, D.; Deng, Z.D. Ultra-low-head hydroelectric technology: A review. Renew. Sustain. Energy Rev. 2017, 78, 23–30. [Google Scholar] [CrossRef]

- Munaaim, M.A.C.; Razali, N.; Ayob, A.; Hamidin, N.; Mydin, M.A.O. Potential of Micro Hydroelectric Generator Embedded at 30,000 PE Effluent Discharge of Sewerage Treatment Plant. E3S Web. Conf. 2018, 34, 2037. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Greenhouse Gas Emission Intensity of Electricity Generation, Country Level. Chart (Interactive), Published 25 October 2024, Modified 15 April 2025. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1/greenhouse-gas-emission-intensity-of-electricity-generation-country-level (accessed on 8 May 2025).

- European Hydrogen Backbone (EHB). European Hydrogen Infrastructure Map. Available online: https://ehb.eu/page/h2-infrastructure-map (accessed on 8 May 2025).

- International Energy Agency (IEA). IEA Bioenergy Task 37—Country Reports Summaries 2019. 2020. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/03/IEA-Task-37-Country-Report-Summaries-2019-1.pdf (accessed on 8 May 2025).

- Cristello, J.B.; Yang, J.M.; Hugo, R.; Lee, Y.; Park, S.S. Feasibility analysis of blending hydrogen into natural gas networks. Int. J. Hydrogen Energy 2023, 48, 17605–17629. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, H.; Yang, M.; Jia, W.; Qiu, Y.; Lan, L. From the perspective of new technology of blending hydrogen into natural gas pipelines transmission: Mechanism, experimental study, and suggestions for further work of hydrogen embrittlement in high-strength pipeline steels. Int. J. Hydrogen Energy 2022, 47, 8071–8090. [Google Scholar] [CrossRef]

- Erdener, B.C.; Sergi, B.; Guerra, O.J.; Chueca, A.L.; Pambour, K.; Brancucci, C.; Hodge, B.-M. A review of technical and regulatory limits for hydrogen blending in natural gas pipelines. Int. J. Hydrogen Energy 2023, 48, 5595–5617. [Google Scholar] [CrossRef]

- Minister of Energy of the Republic of Lithuania. Order on Approval of Natural Gas Quality Requirements Nr. 1-194. Consolidated Text: 2024-12-10. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/TAIS.457419/asr (accessed on 8 May 2025).

- Mahajan, D.; Tan, K.; Venkatesh, T.; Kileti, P.; Clayton, C.R. Hydrogen Blending in Gas Pipeline Networks—A Review. Energies 2022, 15, 3582. [Google Scholar] [CrossRef]

- Munćan, V.; Mujan, I.; Macura, D.; Anđelković, A.S. The state of district heating and cooling in Europe—A literature-based assessment. Energy 2024, 304, 132191. [Google Scholar] [CrossRef]

- The Association for Decentralised Energy (ADE). Market Report: Heat Networks in the UK. 2018. Available online: https://www.theade.co.uk/media/qh2npmkg/heat-networks-in-the-uk_v5-web-single-pages.pdf (accessed on 8 May 2025).

- Tiktak, J. Heat Management of PEM Electrolysis: A Study on the Potential of Excess Heat from Medium-to Large-Scale PEM Electrolysis and the Performance Analysis of a Dedicated Cooling System. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. Available online: https://scispace.com/pdf/heat-management-of-pem-electrolysis-a-study-on-the-potential-13l7kpv6y9.pdf (accessed on 7 May 2025).

- Li, J.; Lin, J.; Song, Y.; Xing, X.; Fu, C. Operation optimization of power to hydrogen and heat (P2HH) in ADN coordinated with the district heating network. IEEE Trans. Sustain. Energy 2019, 10, 1672–1683. Available online: https://ieeexplore.ieee.org/document/8454770 (accessed on 3 June 2025). [CrossRef]

- Ministry of Energy of the Republic of Lithuania. Lithuania’s National Energy Independence Strategy. Available online: https://enmin.lrv.lt/public/canonical/1731396595/5432/NENS%202024-2.12.pdf (accessed on 8 May 2025).

- Ember Energy. Data on the EU Electricity Sector in 2023. Power Sector CO2 Emissions. Available online: https://ember-energy.org/latest-insights/european-electricity-review-2024/eu-electricity-trends/#power-sector-co2-emissions (accessed on 8 May 2025).

- Schäfer, M.; Gretzschel, O.; Schmitt, T.G.; Knerr, H. Wastewater Treatment Plants as System Service Provider for Renewable Energy Storage and Control Energy in Virtual Power Plants—A Potential Analysis. Energy Procedia 2015, 73, 87–93. [Google Scholar] [CrossRef]

- European Biogass Association (EBA). 22 bcm of Biogases were Produced in Europe in 2023, According to a New Report Released Today. Available online: https://www.europeanbiogas.eu/22-bcm-of-biogases-were-produced-in-europe-in-2023according-to-a-new-report-released-today/ (accessed on 8 May 2025).

- Spirito, G.; Dénarié, A.; Cirillo, V.F.; Casella, F.; Famiglietti, J.; Motta, M. Energy mapping and district heating as effective tools to decarbonize a city: Analysis of a case study in Northern Italy. Energy Rep. 2021, 7, 254–262. [Google Scholar] [CrossRef]

- Miranzadeh, M.B.; Jafarsalehi, M.; Akram, J.; Ebrahimi, M.; Mazaheri, A.; Mashayekh, M. Boosting biogas production in the wastewater treatment plants: A narrative review on co-digestion of sewage sludge with internal and external organic waste. Bioresour. Technol. Rep. 2024, 26, 101856. [Google Scholar] [CrossRef]

- Snieška, D. Gas powered heavy duty trucks—Solutions from Scania. In Proceedings of the European Innovation Partnership (EIP) Project Conference “Use of Innovative Biogas Production Technologies and Biomethane in Agriculture and Heavy Transport”, Kaunas, Lithuania, 7 March 2024. [Google Scholar]

- Xia, A.; Cheng, J.; Song, W.; Su, H.; Ding, L.; Lin, R.; Lu, H.; Liu, J.; Zhou, J.; Cen, K. Fermentative hydrogen production using algal biomass as feedstock. Renew. Sustain. Energy Rev. 2015, 51, 209–230. [Google Scholar] [CrossRef]

- Sayer, M.; Ajanovic, A.; Haas, R. On the economics of a hydrogen bus fleet powered by a wind park—A case study for Austria. Int. J. Hydrogen Energy 2022, 47, 33153–33166. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Task 37: Energy from Biogas. Available online: http://task37.ieabioenergy.com/ (accessed on 8 May 2025).

- Swedish Environmental Protection Agency (SEPA). Wastewater Treatment in Sweden 2018; SEPA: Stockholm, Sweden, 2020; pp. 1–36. Available online: https://www.naturvardsverket.se/4a4387/globalassets/media/publikationer-pdf/8800/978-91-620-8867-5.pdf (accessed on 8 May 2025).

- Masłoń, A.; Czarnota, J.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies 2020, 13, 6056. [Google Scholar] [CrossRef]

- Fernando-Foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies 2021, 14, 3411. [Google Scholar] [CrossRef]

- Budych-Gorzna, M.; Smoczynski, M.; Oleskowicz-Popiel, P. Enhancement of biogas production at the municipal wastewater treatment plant by co-digestion with poultry industry waste. Appl. Energy 2016, 161, 387–394. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Kyriakou, A.; Lasaridi, K.; Manios, T. Boosting biogas production from sewage sludge by adding small amount of agro-industrial by-products and food waste residues. Waste Manag. 2018, 71, 605–611. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Schoene, R.P.; Snyder, S.W. Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn stover biochar with in-situ CO2 removal. Appl. Energy 2015, 158, 300–309. [Google Scholar] [CrossRef]

- Sillero, L.; Solera, R.; Perez, M. Improvement of the anaerobic digestion of sewage sludge by co-digestion with wine vinasse and poultry manure: Effect of different hydraulic retention times. Fuel 2022, 321, 124104. [Google Scholar] [CrossRef]

- Cavinato, C.; Bolzonella, D.; Pavan, P.; Fatone, F.; Cecchi, F. Mesophilic and thermophilic anaerobic co-digestion of waste activated sludge and source sorted biowaste in pilot- and full-scale reactors. Renew. Energy 2013, 55, 260–265. [Google Scholar] [CrossRef]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Waste Framework Directive). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 8 May 2025).

- Mayanti, B. Life cycle assessment and waste reduction optimisation of household food waste in Finland. Sci. Total Environ. 2024, 957, 177438. [Google Scholar] [CrossRef]

- Silvennoinen, K.; Nisonen, S.; Katajajuuri, J.-M. Food waste amount, type, and climate impact in urban and suburban regions in Finnish households. J. Clean. Prod. 2022, 378, 134430. [Google Scholar] [CrossRef]

- Stenmarck, Å.; Jensen, C.; Quested, T.; Moates, G. ResearchGate. Estimates of European Food Waste Levels. 2016. Available online: https://www.researchgate.net/publication/301216380_Estimates_of_European_food_waste_levels (accessed on 8 May 2025).

- De Laurentiis, V.; Caldeira, C.; Serenella, S.; Barco Cobalea, H. Review of Studies on Food Waste Accounting at Member State Level; Publications Office of the European Union: Luxembourg, 2019; pp. 1–66. Available online: https://data.europa.eu/doi/10.2760/340637 (accessed on 8 May 2025).

- Zhang, J.; Hu, Q.; Qu, Y.; Dai, Y.; He, Y.; Wang, C.-H.; Tong, Y.W. Integrating food waste sorting system with anaerobic digestion and gasification for hydrogen and methane co-production. Appl. Energy 2020, 257, 113988. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; González, R.; Gómez, X. Feasibility of coupling hydrogen and methane production in WWTP: Simulation of sludge and food wastes co-digestion. Energy Nexus 2024, 14, 100285. [Google Scholar] [CrossRef]

- Shi, L.; Yang, Q.; Xu, Z.Z.; Yang, C. Technologies for in-situ H2S control in wastewater treatment plants: A review. J. Water Process Eng. 2024, 65, 105716. [Google Scholar] [CrossRef]

- Striūgas, N.; Valinčius, V.; Pedišius, N.; Poškas, R.; Zakarauskas, K. Investigation of sewage sludge treatment using air plasma assisted gasification. Waste Manag. 2017, 64, 149–160. [Google Scholar] [CrossRef] [PubMed]

- AB Kauno Energija. City Heat. Available online: https://www.miestosiluma.lt/ (accessed on 8 May 2025).

- Cipolla, S.S.; Maglionico, M. Heat recovery from urban wastewater: Analysis of the variability of flow rate and temperature. Energy Build. 2014, 69, 122–130. [Google Scholar] [CrossRef]

- Lagoeiro, H.; Davies, G.; Revesz, A.; Maidment, G. Heat recovery opportunities from wastewater treatment plants. In Proceedings of the American Society of Heating, Refrigerating and Airconditioning Engineers (ASHRAE) Conference, Atlanta, GA, USA, 4–8 February 2023; Available online: https://openresearch.lsbu.ac.uk/item/958z4 (accessed on 8 May 2025).

- Alytus Regional Waste Management Center. Company Activity Report for 2023. Available online: https://www.aratc.lt/uploads/Veiklos%20ataskaitos/ARATC%20ataskaita%202023.pdf (accessed on 8 May 2025).

- Biogas Vienna. From Food Waste to Biogas. Available online: https://www.wien.gv.at/umwelt/ma48/service/publikationen/pdf/infoblatt-biogas-wien-en.pdf (accessed on 8 May 2025).

| Process Name | The Temporal Nature of the Process | Main Type of Energy | |||

|---|---|---|---|---|---|

| Continuous | Intermittent | Volatile | Electricity | Heat | |

| Energy-consuming processes | |||||

| Anaerobic digestion | X | X | |||

| Biogas cleaning | X | X | |||

| Biogas upgrading | X | X | |||

| Sludge management | X | X | X | X | |

| Aeration | X | X | X | ||

| Methanation | X | X | |||

| Electrolysis | X | X | X | ||

| Energy-generating processes | |||||

| Solar power production | X | X | |||

| Wind power production | X | X | |||

| Cogeneration | X | X | X | X | |

| Hydropower production | X | X | |||

| Electrolysis | X | X | X | ||

| Technology Name | Technology Readiness Level | Application in WWTP | ||||

|---|---|---|---|---|---|---|

| Laboratory Scale | Pilot Scale | Industrial Scale | Demo Cases | Industrial Cases | Wide Use | |

| Biogas production | X | X | ||||

| Biogas upgrading | X | X | ||||

| Biogas cogeneration | X | X | ||||

| Biological removal of H2S with oxygen aeration | X | X | ||||

| Oxygen aeration | X | X | ||||

| Co-digestion | X | X | X | |||

| Electrolysis | X | X | ||||

| Biological CO2 methanation in situ | X | X | ||||

| Biological CO2 methanation ex situ | X | X | ||||

| Chemical (catalytic) CO2 methanation | X | X | ||||

| Hydrogen cogeneration | X | X | X | |||

| Sludge gasification | X | X | X | |||

| Sludge incineration | X | X | ||||

| Heat pumps | X | X | ||||

| Solar power plants | X | X | X | |||

| Wind power plants | X | X | ||||

| Electricity storage (batteries) | X | X | ||||

| Hydro power plants | X | X | ||||

| Biomethane-powered transport | X | X | ||||

| Hydrogen-powered transport | X | X | ||||

| Biogas boiler exhaust gas CO2 methanation | X | X | X | |||

| Parameter Name | Value | Units | Parameter Name | Value | Units |

|---|---|---|---|---|---|

| Wastewater treatment plant | Power | ||||

| Total territory of WWTP | 19.3 | ha | Total power demand of WWTP | 9350 | MWh/a |

| Free territory of WWTP | 7.8 | ha | Power demand for basic tech. processes, MWh/a: | ||

| Wastewater inflow | -sludge management; | 4115 | MWh/a | ||

| Number of inhabitants in Kaunas | 302,875 | vnt | -biological treatment of wastewater; | 4382 | MWh/a |

| Wastewater inflow into WWTP | 25,501,000 | m3/a | -other processes and administrative premises. | 854 | MWh/a |

| Wastewater amount in popul. equivalent (PE) | 392,413 | PE | Power demand for basic tech. processes, %: | ||

| Wastewater biological oxygen demand (BOD) | 337 | mg O2/L | -sludge management; | 44.0% | % |

| Sludge | -biological treatment of wastewater; | 46.9% | % | ||

| Dewatered sludge (dry mass) | 7175 | t DM/a | -other processes and administrative premises. | 9.1% | % |

| Dewatered sludge (wet mass) | 31,367 | t/a | Power production from biogas in cogenerators | 1627 | MWh/a |

| Humidity of dewatered sludge | 77.1% | % | Power from the grid | 7533 | MWh/a |

| Dried sludge (dry mass) | 3533 | t DM/a | Power production in a solar power plant | 190 | MWh/a |

| Dried sludge (wet mass) | 3926 | t/a | Total power prod. in WWTP from RES, MWh/a | 1817 | MWh/a |

| Humidity of dried sludge | 10.0% | % | Total power production in WWTP from RES, % | 19.4% | % |

| Moisture evaporated during sludge drying | 11,519 | t/a | Installed power of solar power plant | 200 | kW |

| Sludge drying temperature | 85 | °C | Natural gas | ||

| Installed power of the sludge dryer | 1.95 | MW | Natural gas consumption, nm3/a | 37,215 | nm3/a |

| Heat consumption for sludge drying | 7320 | MWh/a | Natural gas consumption, MWh/a | 395 | MWh/a |

| Energy value of dewatered sludge | 38,315 | MWh/a | Biogas | ||

| Aeration | Biogas production, nm3/a | 3,814,800 | nm3/a | ||

| Power consumption for aeration | 4382 | MWh/a | Biogas production, MWh/a | 27,161 | MWh/a |

| Oxygen amount for aeration | 5,823,558 | m3/a | Biogas energy value | 7.12 | kWh/m3 |

| Heat | Biogas storage volume | 1200 | m3 | ||

| Total heat demand of WWTP | 16,129 | MWh/a | Biogas cons. for heat production in boilerhouse | 2,711,456 | m3/a |

| Heat demand for basic tech. processes, MWh/a: | Biogas cons. for power prod. in cogenerators | 924,813 | m3/a | ||

| -heating of anaerobic digesters; | 4633 | MWh/a | Biogas utilization in the flare | 178,531 | m3/a |

| -sludge drying; | 7320 | MWh/a | Transport | ||

| -other processes and administrative premises. | 4176 | MWh/a | Diesel consumption in WWTP transport | 100 | MWh/a |

| Heat demand for basic tech. processes, %: | Diesel consumption for sludge transportation | 355 | MWh/a | ||

| -heating of anaerobic digesters; | 28.7% | % | Hydro energy | ||

| -sludge drying; | 45.4% | % | Hydro power production from wastewater | 0 | MWh/a |

| -other processes and administrative premises. | 25.9% | % | Hydro power potential from wastewater | 654 | MWh/a |

| Heat production from natural gas | 301 | MWh/a | |||

| Heat production from biogas in the boiler house | 14,692 | MWh/a | |||

| Heat production from biogas in cogenerators | 1137 | MWh/a | |||

| Total heat prod. in WWTP from RES, MWh/a | 15,829 | MWh/a | |||

| Total heat production in WWTP from RES, % | 98.1% | % |

| Levels of Electrolyzer Capacity | Based on O2 Demand | Based on H2 Demand | Based on Heat Demand | Based on Electricity Availability | ||

|---|---|---|---|---|---|---|

| Case * | V1 and V2 | V1 | V2 | V1 and V2 | V1 | V2 |

| Electrical power of electrolyzer, MW | 8.3 | 4.1 | 5.2 | 6.8 | 1.4 | 2.3 |

| Electricity consumption, MWh/a | 58,302 | 28,442 | 36,271 | 47,440 | 9991 | 15,976 |

| Hydrogen production, mln m3/a | 11.6 | 5.7 | 7.2 | 9.5 | 2.0 | 3.2 |

| Oxygen production, m3/a | 5.8 | 2.8 | 3.6 | 4.7 | 1.0 | 1.6 |

| Heat production, MWh/a | 19,823 | 9670 | 12,332 | 16,129 | 3397 | 5432 |

| Energy Form | Existing Situation | Case V1 * | Case V2 * |

|---|---|---|---|

| Energy consumption | MWh/a | MWh/a | MWh/a |

| Electricity consumption | 9350 | 64,067 | 64,067 |

| Heat consumption (produced from biogas) | 15,829 | ||

| Heat consumption (produced in electrolyzer) | 16,129 | 16,129 | |

| Natural gas consumption for heat production | 395 | ||

| Hydrogen consumption | 17,046 | 21,738 | |

| Consumption of diesel as a transport fuel | 455 | ||

| Consumption of biomethane as a transport fuel | 455 | 455 | |

| Total net energy consumption: | 26,029 | 97,697 | 102,389 |

| Energy production | MWh/a | MWh/a | MWh/a |

| Heat production from biogas | 15,829 | ||

| Power production from biogas | 1627 | ||

| Power production in the existing solar power plant | 190 | 190 | 190 |

| Biomethane production | 39,674 | 48,022 | |

| Hydrogen production | 34,941 | 34,941 | |

| Useful heat production in the electrolyzer | 19,823 | 19,823 | |

| Solar power production, additional potential | 3268 | ||

| Hydropower production | 654 | ||

| Total useful energy production: | 17 645 | 94,628 | 106,898 |

| Energy balance | |||

| Energy balance, MWh/a | −8383 | −3069 | 4508 |

| Energy balance, % | −32.2% | −3.1% | 4.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukoševičius, R.; Rimkevičius, S.; Pabarčius, R. Presumptions for the Integration of Green Hydrogen and Biomethane Production in Wastewater Treatment Plants. Appl. Sci. 2025, 15, 7417. https://doi.org/10.3390/app15137417

Lukoševičius R, Rimkevičius S, Pabarčius R. Presumptions for the Integration of Green Hydrogen and Biomethane Production in Wastewater Treatment Plants. Applied Sciences. 2025; 15(13):7417. https://doi.org/10.3390/app15137417

Chicago/Turabian StyleLukoševičius, Ralfas, Sigitas Rimkevičius, and Raimondas Pabarčius. 2025. "Presumptions for the Integration of Green Hydrogen and Biomethane Production in Wastewater Treatment Plants" Applied Sciences 15, no. 13: 7417. https://doi.org/10.3390/app15137417

APA StyleLukoševičius, R., Rimkevičius, S., & Pabarčius, R. (2025). Presumptions for the Integration of Green Hydrogen and Biomethane Production in Wastewater Treatment Plants. Applied Sciences, 15(13), 7417. https://doi.org/10.3390/app15137417