1. Introduction

Alluvial fan scree deposits (AFSDs) represent fan-shaped sedimentary formations developed at piedmont zones through episodic accumulation of fluvial-transported detritus in arid/semi-arid regions [

1,

2,

3,

4]. These colluvial systems form through unconfined sheet flooding processes when torrential discharges debouch from catchment outlets, losing channel constraints and depositing poorly sorted sediments [

5,

6,

7,

8]. The resultant depositional regime produces texturally immature clastic assemblages with subangular lithologies and weak stratigraphic differentiation. These proximal fan deposits exhibit enhanced hydraulic conductivity and matrix-supported fabric, characteristics that predispose surface erosion during pluvial events [

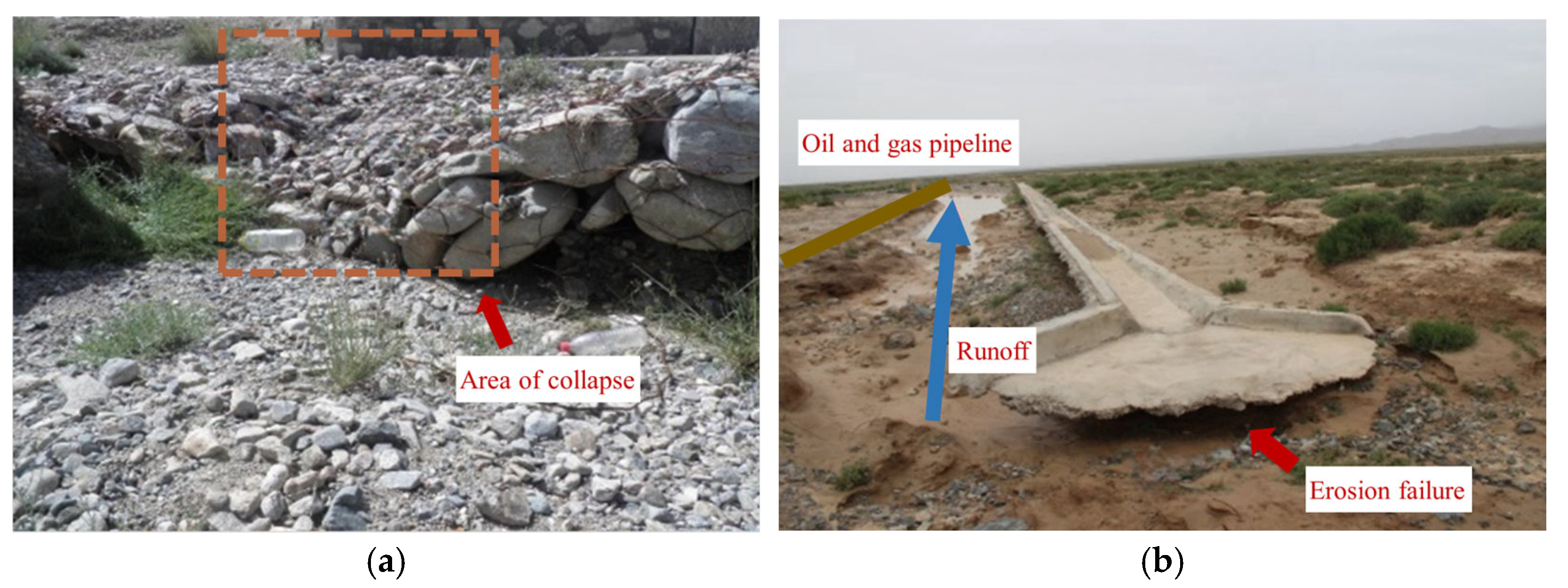

6]. This erosional susceptibility poses significant geohazards to buried infrastructure, particularly hydrocarbon pipelines. Pipeline failures not only compromise public safety but also require cost-intensive rehabilitation due to deep burial conditions and sediment mobility [

9,

10] (

Figure 1).

Contemporary soil conservation research predominantly focuses on pedogenic processes in loessic and lateritic terrains [

11,

12,

13,

14,

15,

16], with limited attention to AFSDs erosion dynamics. Conventional mitigation approaches emphasize infiltration suppression to preserve geomechanical properties, though this strategy adversely impacts xerophytic vegetation in northwest China’s water-limited ecosystems [

17,

18,

19,

20,

21]. Alternative chemical stabilization techniques demonstrate enhanced efficacy through matrix cementation and shear strength augmentation [

22,

23,

24,

25], notably improving hydro-structural stability and erosion resistance [

26,

27]. Additionally, in arid and semi-arid regions of northwest China, the establishment conditions for different AFSDs oil and gas pipeline layouts and prevention areas mainly consider geographical, geological, topographical, geomorphic (including micro-topography), climatic, hydrological, soil, and vegetation conditions [

28,

29,

30]. Based on contemporary soil conservation research, it is concluded that adopting environmentally friendly chemical methods to solidify AFSDs is a priority consideration.

This study systematically evaluates three stabilization strategies: SH polymer membranes, bioengineered AFSDs with native grass integration, and surface-applied SH composites. Experimental methodologies included membrane durability assessments, controlled rainfall simulations, and ecotoxicological profiling. This research quantifies long-term performance in erosion mitigation while assessing environmental sustainability.

2. Theoretical Inquiry

2.1. Rainfall Erosion Theory

The erosion of AFSDs is primarily categorized into three types caused by water flow: rainfall erosion, snowmelt erosion, and artificial irrigation-induced erosion. Rainfall erosion comprises two distinct mechanisms: raindrop splash erosion and sheet flow erosion. Raindrop splash erosion refers to the dispersion and detachment of soil particles caused by the direct impact of raindrops on the soil surface. This process initiates soil displacement and is a critical driver of erosion dynamics [

31]. Concurrently, raindrop impact compacts the soil surface, reducing infiltration capacity and accelerating surface runoff generation [

32]. Sheet flow erosion involves the detachment and transport of soil particles by thin, unconfined runoff. The mechanisms include the following: 1. Infiltration-induced weakening: Water infiltration softens slope interiors, increases soil moisture content, reduces matric suction, and diminishes shear strength [

33]. 2. Hydraulic scouring: Runoff applies shear stress to surface particles, causing particle detachment, sediment transport, and deposition [

34]. The spatiotemporal variability of sheet flow erosion poses significant risks to buried oil and gas infrastructure in AFSD environments. This necessitates innovative mitigation technologies to reduce rainfall erosion impacts on AFSDs.

2.2. Field-Based Hazard Assessment

A comprehensive field study was carried out to examine scree soil formations across multiple regions in Northwest China. The investigation focused on fan-shaped scree soil deposits in Shandan and Gaotai (Gansu Province), and Turpan and Dabancheng (Xinjiang Province), as well as Chaka and Wulan (Qinghai Province).

The analysis of 189 erosion sites, distributed across Gansu (39 sites), Xinjiang (86 sites), and Qinghai (64 sites), revealed that all observed hazards were associated with rill erosion on scree soils. This phenomenon arises from prolonged surface runoff erosion, which gradually shapes the soil structure. These erosion features predominantly occur in geologically unstable zones prone to severe degradation. Given these findings, there is an urgent need for effective mitigation measures to control erosion and prevent further extensive damage.

2.3. SH Polymer Material

Soil chemical stabilization technology, a subdiscipline of geotechnical engineering, focuses on enhancing soil properties through additive treatments. Since its emergence in the 1950s, over 50 reinforcement materials have been developed globally [

35,

36,

37,

38,

39,

40,

41,

42,

43]. However, few have achieved widespread field application, with most remaining experimental. SH polymer material, a liquid polymer derived from industrial by-products, is among the rare exceptions with practical implementations.

SH polymer material is a non-toxic polymeric solution with a molecular weight of ~20,000 Da. The key properties include the following: 1. Dry density: 1.68 g/cm

3. 2. Curing behavior: forms a 0.2–0.5 mm flexible hydrogel film upon ambient-temperature curing for 72 h. 3. Hydrophilicity: exhibits unlimited water miscibility. This cost-effective, room-temperature-curable material has demonstrated efficacy in aeolian erosion control [

44], loess stabilization [

45,

46,

47] and coastal saline-alkali soil remediation [

48].

When applied to AFSDs, SH polymer membranes enhance rainfall erosion resistance. However, the weak interparticle bonds characteristic of AFSDs raise concerns about treatment efficacy. Critical unresolved questions include the following: 1. Longevity: Can SH polymer membranes maintain protective effects under cyclic wet-dry conditions? 2. Structural integrity: Will treated AFSDs resist disaggregation during intense rainfall events? 3. Hydrological compatibility: Do the SH polymer membranes balance water retention and permeability to support vegetation?

3. SH Polymer Membranes

3.1. Experimental Preparation

To evaluate the long-term protective capacity of SH polymer materials (

Figure 2) in AFSDs, we conducted a controlled immersion-tension test series.

SH polymer membranes were synthesized by spray-coating polymer solutions onto rectangular PTFE molds, generating specimens with thickness gradients (0.16–0.56 mm;

Table 1) to simulate field-scale polymer curing on AFSD slopes. All specimens underwent full immersion in deionized water under static conditions. The two maximum-thickness variants (0.36 mm and 0.56 mm) underwent tensile testing following immersion periods of 0, 3, 7, 14, 21, and 28 days, while dissolution resistance was quantitatively monitored through mass measurements at 3, 7, 14, and 19 days of immersion.

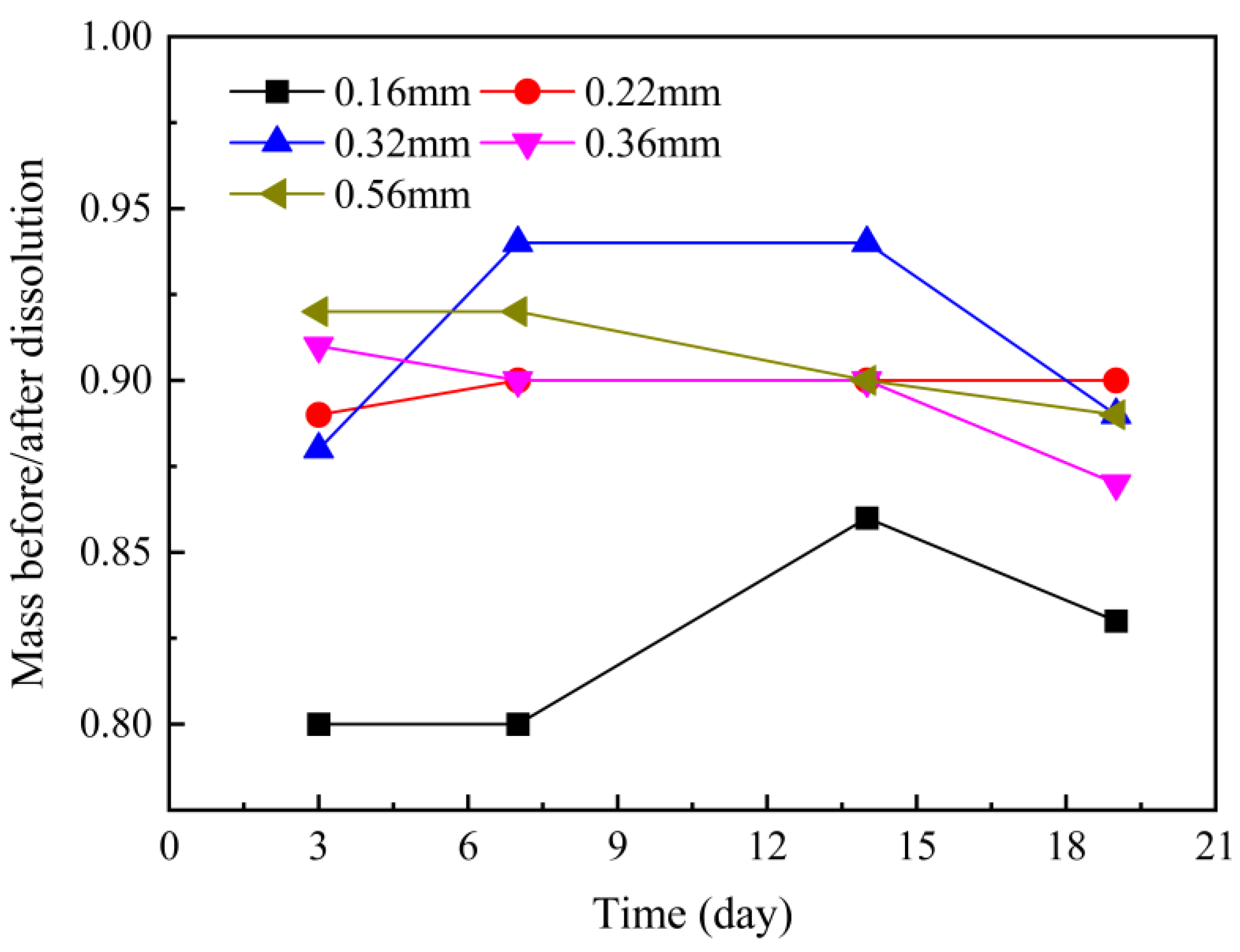

3.2. Dissolution Resistance

Immersion testing demonstrates mass retention ratios exceeding 0.8 for films ≥ 0.16 mm thickness after 19-day immersion, confirming critical thickness thresholds for long-term structural integrity (

Figure 3).

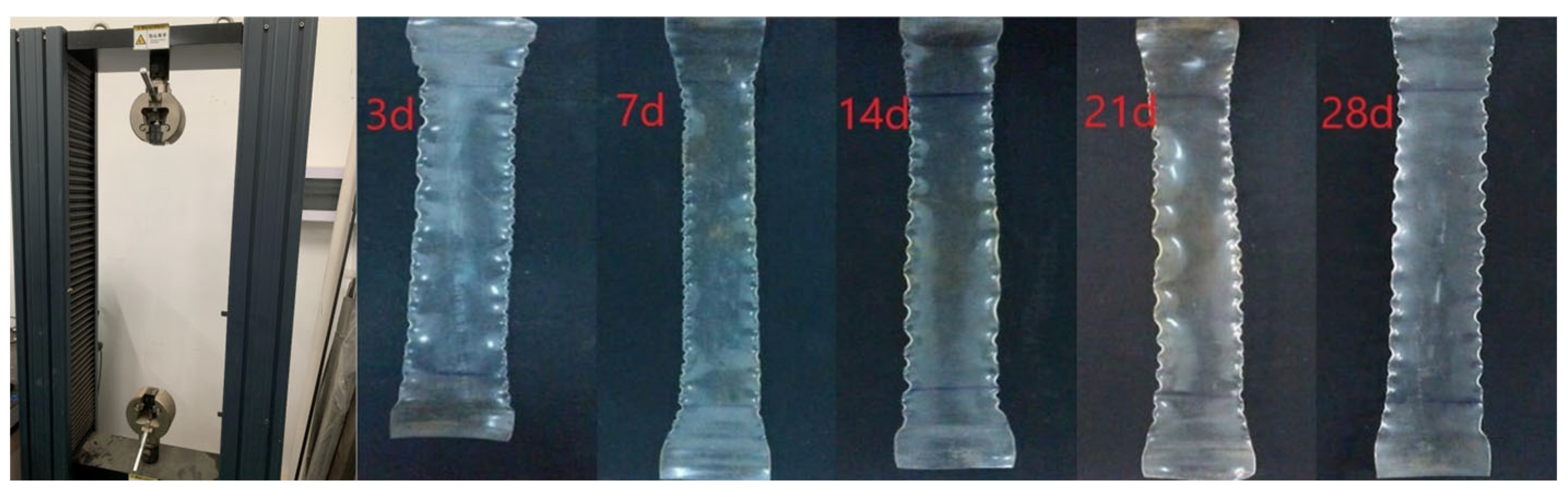

3.3. Deformation Characteristics

SH polymer membranes with thicknesses of 0.36 mm and 0.56 mm were subjected to tensile tests at different soaking times (

Figure 4).

Tensile deformation illustrates time-dependent viscoelastic responses:

All specimens achieved ≥250 mm elongation without fracture, showing only minor mid-span microcracking in 3-day immersed samples.

Waveform deformation patterns exhibited progressive amplitude increases (3–28 days), correlating with reduced material softening over time.

Lateral strain uniformity confirmed homogeneous stress distribution, enabling continuous strain accommodation for optimal material utilization.

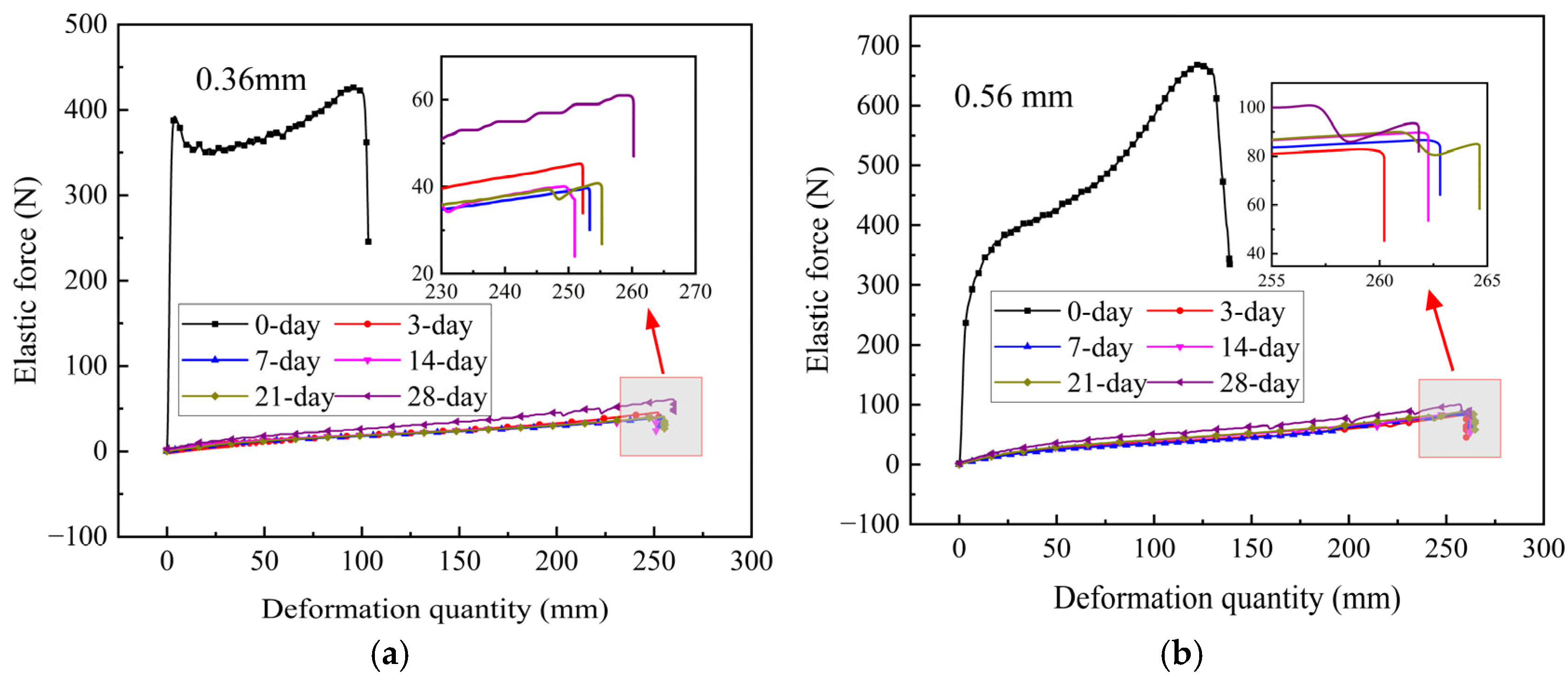

3.4. Tensile Behavior

In tensile tests at different soaking times, the relationship between deformation and elastic force is illustrated in

Figure 5.

In the tensile tests of SH polymer membranes, both 0.36 mm and 0.56 mm thick films exhibited strong tensile strength without soaking. At a deformation of 0.56mm, both films generated elastic forces of nearly 400 N. The 0.36 mm thick film underwent plastic deformation of up to 100 mm under the peak elastic force, while the 0.56 mm thick film, with continuous stretching, eventually reached an elastic force of nearly 700 N. This indicates that, without soaking, SH polymer membranes have excellent tensile strength and ductility.

After immersing the SH polymer membranes for 3 days, 7 days, 14 days, 21 days, and 28 days, although the maximum tensile strength for both 0.36 mm and 0.56 mm thickness decreased from the original 430 N and 680 N to around 40 N and 90 N, respectively, the films maintained their maximum elastic force when stretched to approximately 250 mm. The films exhibited enhanced ductility after immersion, and the softening degree of the films reached its peak after 3 days of immersion, with subsequent immersion having minimal impact on strength. This allows the films to excel in long-term surface erosion in the terrain of AFSDs. Moreover, the exceptional ductility of the films enhances the overall soil performance, proving beneficial soil in resisting raindrop erosion.

3.5. Summary

The tensile tests substantiate that SH polymer membranes:

Maintain ≥80% mass retention at critical thicknesses (≥0.16 mm).

Dry-state performance: Non-immersed 0.36 mm and 0.56 mm films exhibited ultimate tensile strengths of 430 N and 680 N, respectively, at 0.56 mm displacement.

Post-immersion degradation: After 28-day immersion, strength reduced to 40 N (90.7% loss) and 90 N (86.8% loss).

Preserve functional ductility (250 mm strain capacity) despite strength degradation.

The tensile testing of SH polymer membranes has demonstrated their exceptional capacity for surface integrity preservation and stress redistribution. This material system provides robust erosion protection for AFSDs during rainy seasons, maintaining soil structural stability while thereby improving resistance against both raindrop impact and surface flow erosion.

4. Anti-Rainfall Erosion Test

4.1. Rainfall Simulation System Configuration

The NJJY-10 artificial rainfall simulator (

Figure 6) was employed to replicate natural rainfall erosion processes. This system integrates an automated monitoring/data acquisition module, a hydraulic power unit, water storage reservoirs, sediment collection basins, and a modular rainfall generation assembly utilizing three nozzle types (The FULLJET series nozzles (models 1/8, 2/8, and 3/8) were supplied by Spraying Systems (Shanghai) Co., Ltd., China.) to achieve variable droplet spectra. Critical operational parameters are summarized in

Table 2.

4.2. Experimental Protocol

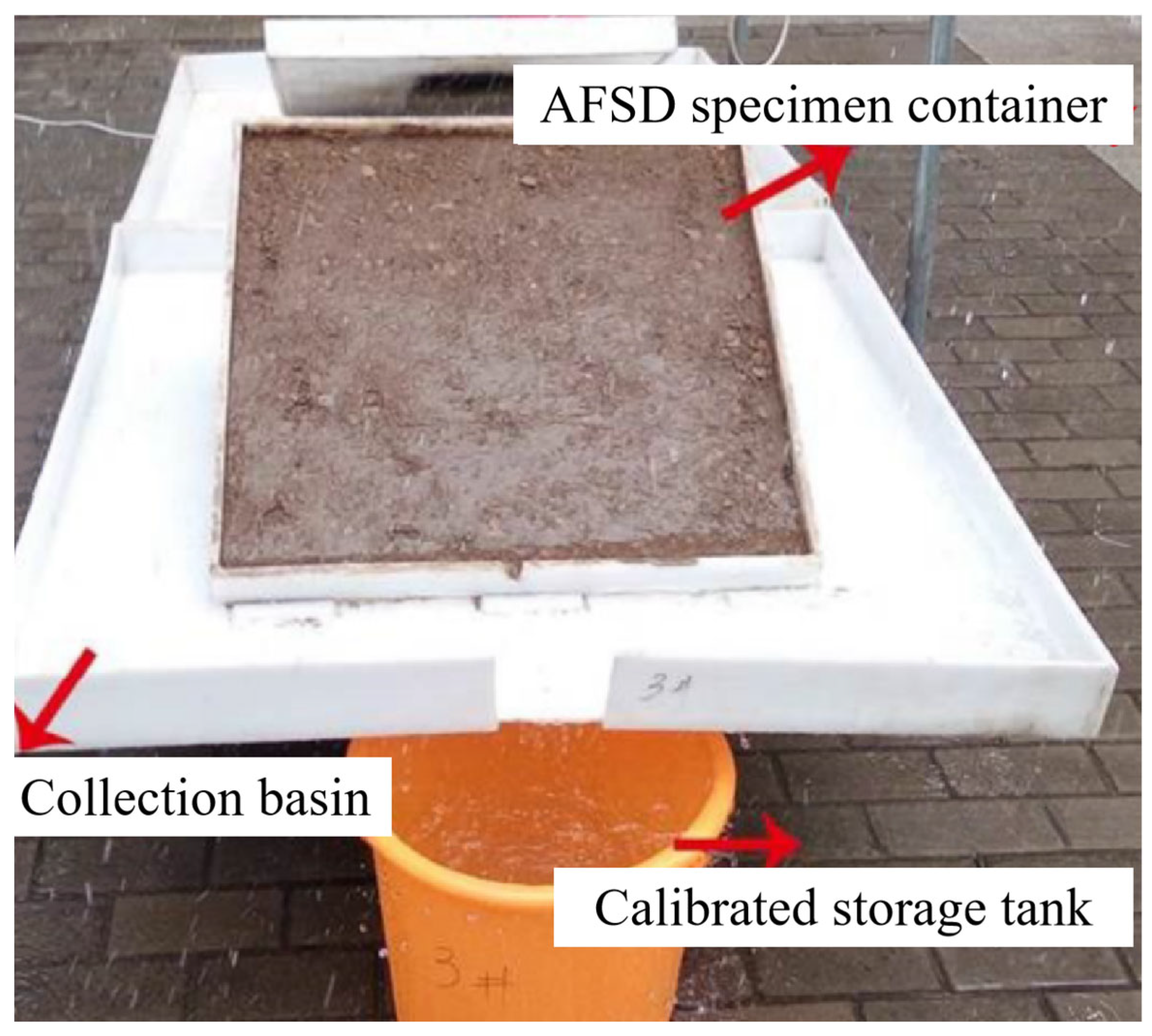

(1) Specimen Preparation: The AFSD specimen container (60 cm × 60 cm × 6 cm) was nested within a larger collection basin (100 cm × 100 cm × 10 cm), positioned centrally within the simulator’s rainfall zone. The nested design facilitated complete retention of both splash-dispersed particles (via basal overflow ports) and sheetwash-transported sediments (through lateral collection channels), with final deposition in a calibrated storage tank (

Figure 7).

(2) Hydraulic Parameters: A constant nozzle pressure (0.1 MPa) ensured consistent droplet size distribution across trials. Rainfall intensity was maintained at 200 mm/h for 60 min to simulate extreme precipitation events.

(3) Post-Test Analysis: Surface morphology documentation preceded quantitative erosion measurement. Sediment-laden runoff was decanted after 24 h of quiescent settling, followed by oven-drying (105 °C, 24 h) and precision mass measurement (±0.01 g) of retained particles.

4.3. Variable-Spray Comparative Testing (Test Series 1)

This test series evaluated SH polymer material application rates (1.0, 1.5, 2.0 kg/m

2) on erosion resistance using identical curing duration (3 days) and soil parameters (

Table 3).

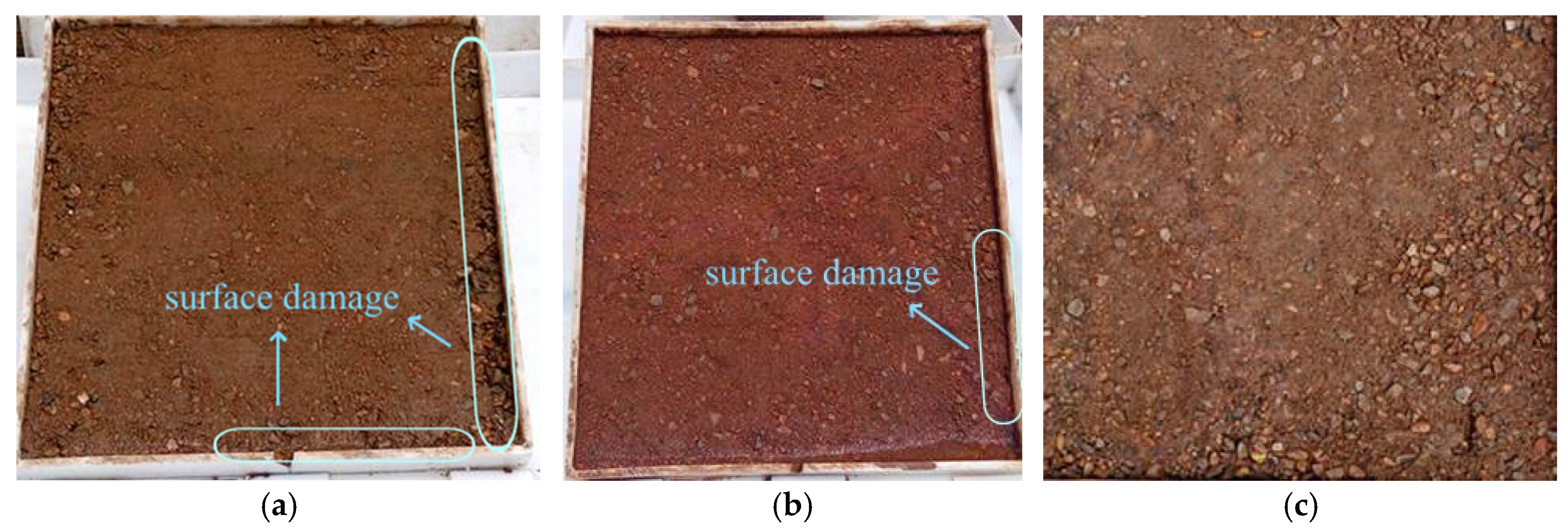

In the variable-spray comparative testing, the spraying quantity of SH polymer material serves as the influencing factor. Under a rainfall intensity of 200 mm/h, the resistance of soil to erosion was measured using the mass of eroded soil particles as the benchmark. The erosion damage patterns of AFSD under varying SH polymer material spraying quantities can be observed in

Figure 8.

When the SH polymer material was sprayed at a rate of 1.0 kg/m2, the AFSD remained largely intact. However, there was some damage observed at the lower right side due to rainfall erosion, accompanied by a few minor holes, resulting in an overall soil erosion amount of 9.69 g. The application of 1.5 kg/m2 of the SH polymer material resulted in noticeable improvements, with only minor damages observed at the right corner of the sample and a predominantly intact surface. The total amount of soil erosion was measured to be 6.01 g. Upon spraying the SH polymer material at a rate of 2.0 kg/m2, there were no significant signs of erosion on the soil surface, and the overall soil erosion amount decreased dramatically to 1.03 g. It can be concluded that all three application rates of the SH polymer material exhibited excellent efficacy in preserving the integrity of the AFSD against erosion from rainfall. This effectively prevented extensive damage to the soil during rainfall erosion. Additionally, the experimental findings revealed that elevating SH polymer concentration in soil systematically reduces rainfall erosion impacts. This dose-responsive attenuation of surface degradation confirms concentration-dependent activation of pore-filling optimization and interparticle bonding reinforcement mechanisms.

4.4. Slope Morphology Impact Assessment (Test Series 2)

Test series 2 considered slope morphology as the influencing factor, with the mass of eroded soil particles as the indicator. Four slope configurations (planar smooth/rough, curved smooth/rough) were tested under optimal SH dosage (2.0 kg/m

2) to isolate topographic effects. Specific experimental parameters are outlined in

Table 4.

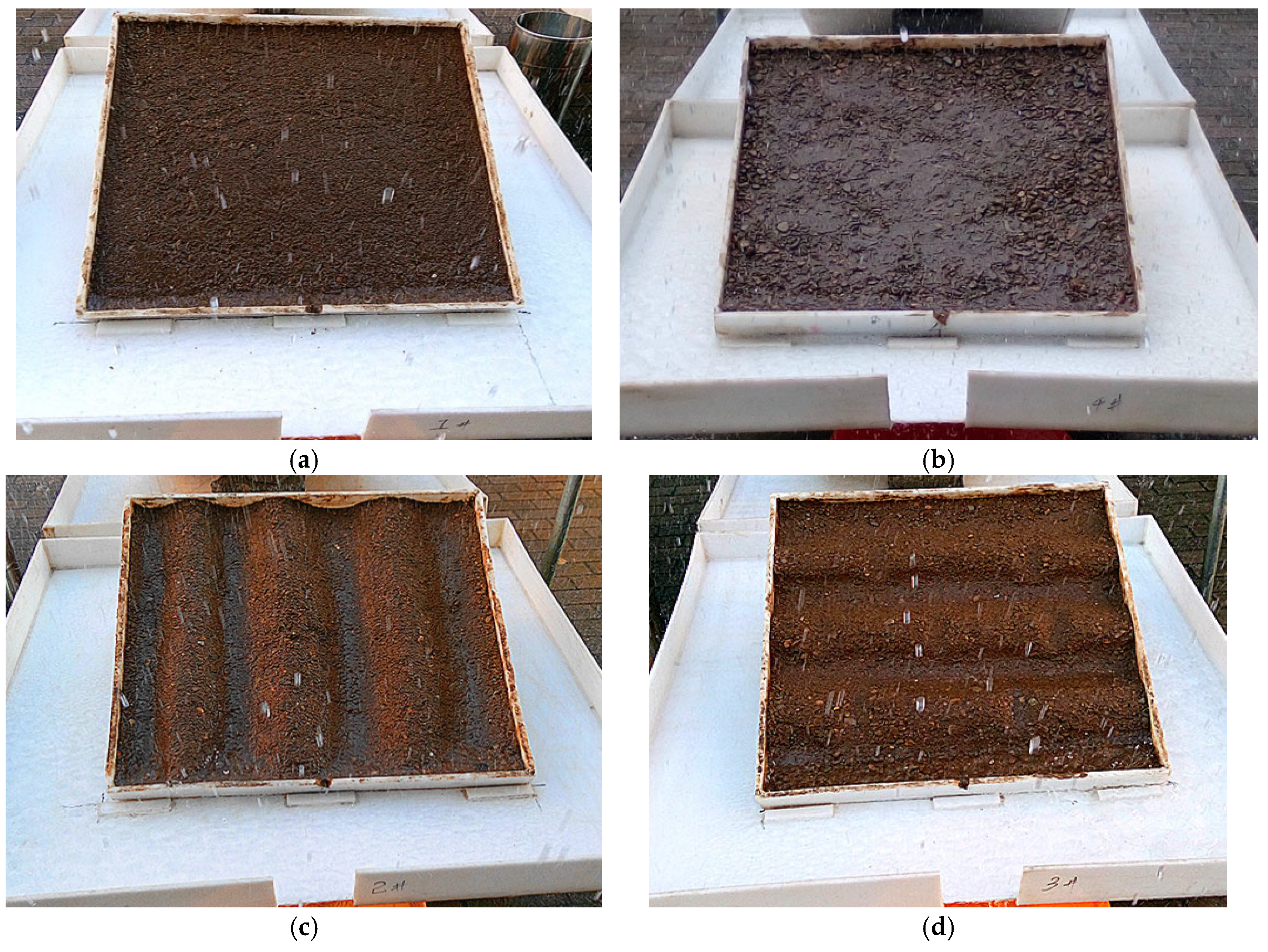

Rainfall erosion test No. 2 explores the impact of four slope surface forms—planar smooth, planar rough, curved smooth, and curved rough—on the mass of eroded soil particles. The erosional damage patterns of AFSDs under the four slope surface forms are shown in

Figure 9.

Under rainfall intensity of 200 mm/h, the soil samples sprayed with 2.0 kg/m2 of SH polymer material perform well for all four slope surface forms. The slope surfaces remain intact without significant damage, and the erosion amounts are quite low. Specifically, the erosion amounts are 1.66 g for planar smooth, 1.17 g for planar rough, 1.22 g for curved smooth, and 1.16 g for curved rough. This indicates that the 2.0 kg/m2 SH polymer material is effective under various slope surface forms, demonstrating strong adaptability to different terrains. Based on these findings, our experiments conclusively demonstrate that the effectiveness of the SH polymer material remains largely unaffected by varying terrains. It helps maintain the integrity of reinforced soil during rainfall erosion.

5. Environmental Friendliness Assessment of SH Polymer Material

5.1. Experimental Design

A controlled pot experiment was conducted to systematically evaluate the eco-compatibility of the SH polymer material. The investigation focused on two critical application scenarios: (1) surface vegetation pre-establishment and (2) bare soil conditions prior to polymer application.

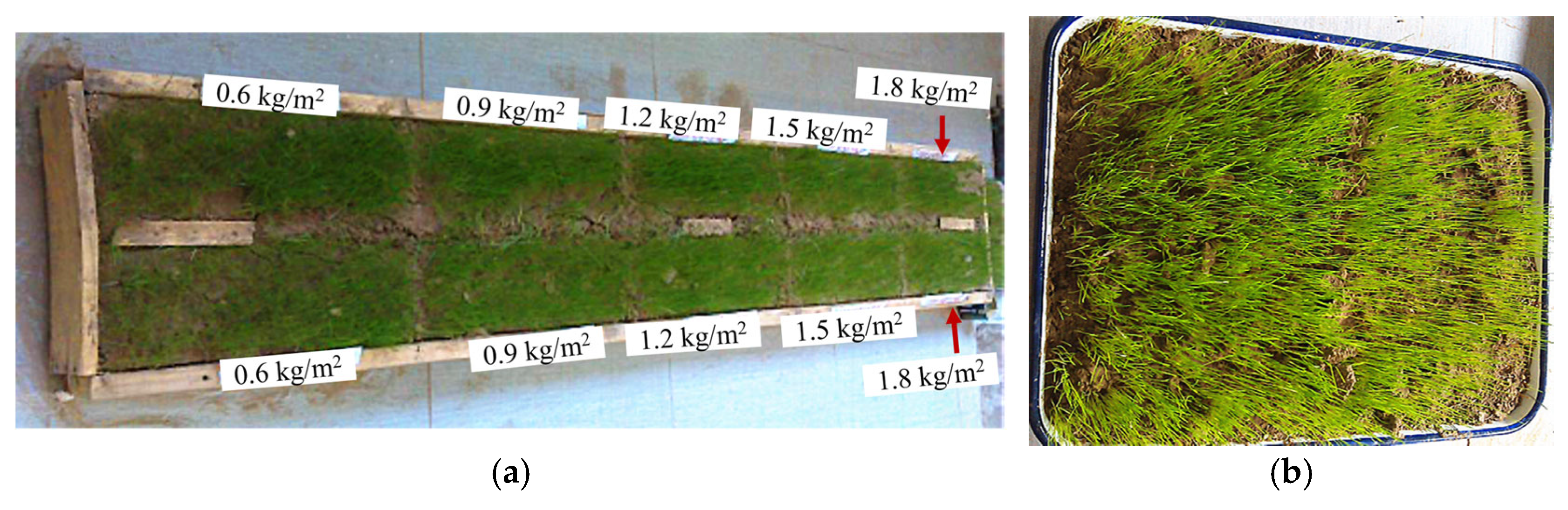

Ten randomized blocks were established in standardized wooden cultivation containers (240 cm × 42 cm) to examine five gradient application rates (0.6, 0.9, 1.2, 1.5, and 2.0 kg/m

2) under dual application protocols (

Table 5). Tall fescue (

Festuca arundinacea Schreb.), a stress-tolerant perennial grass species with demonstrated adaptability to nutrient-deficient AFSDs, was selected as the bioindicator due to its ① exceptional drought resistance, ② acid tolerance, and ③ phytoremediation potential in degraded ecosystems.

5.2. Methodology

The experimental protocol comprised three operational phases:

Substrate preparation: A thin layer of soil was applied to the wooden cultivation pots, followed by the burial of tall fescue seeds in a grid pattern within the soil.

Vegetation pre-establishment: Two spraying methods were employed: one involved covering the soil surface with dry soil after burying the seeds, and then spraying SH polymer material, simulating a scenario where vegetation was already present on the soil surface before the application of SH polymer material. In this case, there was a layer of soil between the seeds and the SH polymer material.

Bare soil conditions: The second method included spraying SH polymer material after burying the seeds and then covering with dry soil, simulating a situation where vegetation was not initially present on the soil surface. In this case, the contact between seeds and the SH polymer material was more direct.

SH polymer material was then sprayed, with application rates of 0.6, 0.9, 1.2, 1.5, and 2.0 kg/m

2. The detailed experimental process is illustrated in

Figure 10 and

Table 6. The experiment involved observing the growth of grass samples in the test area, evaluating the water retention and permeability of the SH polymer material to assess its environmental friendliness. A control group with no application of SH polymer material was also included.

Under the five application rates of SH polymer material and two application methods (covering soil before or after spraying), tall fescue grass successfully emerged and exhibited robust growth. The impact of different methods on tall fescue grass was minimal, indicating that the SH polymer material had good permeability and water retention compatible with the AFSDs. The experiment demonstrated that applying SH polymer material in this soil type does not negatively affect plant growth, highlighting its environmentally friendly nature and potential application in practical engineering.

6. Conclusions

The study establishes laboratory applications with a well-defined methodological sequence for using a specific polymer to evaluate sediment loss control. It employs soil loss assessment methods, including film characterization, rainfall erosion simulation, and environmental compatibility assessment, to analyze material loss in various forms of SH polymer application for soil protection. This research aims to present the behavior of the polymer in relation to water, its degradation when submerged in water, and in relation to rain erosion.

- (1)

Film durability and mechanical performance. The SH polymer membranes (0.16–0.56 mm thickness) demonstrated exceptional anti-dissolution properties, retaining over 80% of their mass after prolonged immersion. Tensile tests revealed superior ductility, with elongation exceeding 250 mm after 3 days of immersion, while subsequent strength degradation stabilized, ensuring long-term structural integrity. This durability enables effective resistance against continuous surface runoff and raindrop impact, significantly enhancing AFSD stability during intense rainfall events.

- (2)

Rainfall erosion mitigation efficacy. This study builds upon previous work by incorporating laboratory evaluations of SH polymer in controlling soil loss caused by rainfall erosion. Under simulated extreme rainfall (200 mm/h), SH polymer application at 1.0 kg/m2 reduced surface erosion, while dosages ≥ 1.5 kg/m2 preserved near-complete slope integrity. The optimal application rate of (2.0 kg/m2) minimized soil loss (<1.2 g) across all tests, whereas field observations revealed that most erosion was extremely severe, further confirming the polymer’s robustness in erosion control.

- (3)

Terrain adaptability. The SH polymer exhibited consistent performance across diverse slope morphologies (planar/curved, smooth/rough), demonstrating universal applicability in AFSD environments. Even under a 200 mm/h rainfall for 60 min, treated slopes maintained structural stability with minimal erosion, highlighting the polymer’s adaptability to varying field conditions.

- (4)

Environmental compatibility. Ecological assessments, conducted through comparative experiments with various SH polymer concentrations, confirmed that SH polymer films do not hinder vegetation growth, demonstrating excellent water permeability and retention. Tall fescue thrived in treated soils regardless of the application method (pre- or post-vegetation), highlighting the material’s eco-friendly properties.

- (5)

Limitations and future research directions. While demonstrating the SH polymer’s effectiveness for AFSD stabilization, this study has limitations. Laboratory simulations may not fully replicate natural hydrologic-geomorphic interactions, necessitating field validation. Although immersion tests showed good durability, longer-term monitoring of wet-dry cycling performance is needed. While tall fescue growth was unaffected, long-term impacts on soil microbiota and nutrient cycling remain unassessed. The economic feasibility of large-scale implementation also requires investigation. Future work should prioritize field trials, extended performance monitoring, ecological impact assessments, and application technique optimization to enhance real-world applicability without compromising the technology’s environmental compatibility.

The research aims to investigate the behavior of the polymer in relation to water, its degradation when submerged, and its performance under rain erosion. It validates SH polymer as a sustainable, high-performance solution for stabilizing AFSDs, combining mechanical resilience, terrain versatility, and environmental safety. Its application is recommended for protecting critical infrastructure in arid and semi-arid regions while also supporting ecosystem health.

Author Contributions

Writing—original draft preparation, W.L., Q.L. and F.J.; writing—review and editing, W.L. and X.Y.; funding acquisition, F.J. and Z.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Guangxi Science and Technology Achievements Transfer and Transformation Projects (Nos. ZY24212029), Research on Key Technologies of Modified Titanium Gypsum Solidification and Road Application Demonstration (Project No.: JH-ZX-2024-016) and the Shenzhen Metro Scientific Research Consulting Project (Project No.: STJS-DT416-KY001/2020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Xi Yu was employed by the companies Central-South Architectural Design Institute Co., Ltd. and Hangzhou Venture Investment Film and Television Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ben-Hur, M. Using synthetic polymers as soil conditioners to control runoff and soil loss in arid and semi-arid regions—A review. Aust. J. Soil Res. 2006, 44, 191–204. [Google Scholar] [CrossRef]

- Chen, T.; Jiao, J.; Zhang, Z.; Lin, H.; Zhao, C.; Wang, H. Soil quality evaluation of the alluvial fan in the Lhasa River Basin, Qinghai-Tibet Plateau. Catena 2022, 209, 105829. [Google Scholar] [CrossRef]

- Cheng, A.; Cheng, Y.; Liu, W.; Li, H.; Li, X. Study on the Solidification/Stabilization Mechanisms of Heavy Metals Composite Contaminated Soils by New Curing Agent. Environ. Sci. Technol. 2021, 44, 83–88. [Google Scholar]

- Cheng, J.; Wang, Y.; Miao, S.; Wang, H. Property Study of Solidified Loess Under Wet-dry Cycles. J. Eng. Geol. 2014, 22, 226–232. [Google Scholar]

- Ding, X.; Zhang, X.; Dou, J.; Hao, Z. Effects of EN-1 Solidifying Agent on Saturated Hydraulic Conductivity of Four Soils. Bull. Soil Water Conserv. 2012, 32, 132–134. [Google Scholar]

- Du, Y.; Zhu, J. Impact on soil solidifying agent to different soil characteristics. Agric. Res. Arid Areas 2004, 22, 229–231. [Google Scholar]

- Ellison, W.D. Soil Erosion by Rainstorms. Science 1950, 111, 245–249. [Google Scholar] [CrossRef]

- Falcon-Lang, H.J. Vegetation ecology of Early Pennsylvanian alluvial fan and piedmont environments in southern New Brunswick, Canada. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2006, 233, 34–50. [Google Scholar] [CrossRef]

- Gao, Z.; Shi, Y.; Feng, J.; Zhou, C.; Zhai, Y.; Fan, X. Sedimentary Evolution of Alluvial Fan Under Combined Action of Drainage System and Structure: A Case of Huangshuigou Alluvial Fan in Piedmont of Southern Tianshan Mountains. Xinjiang Pet. Geol. 2019, 40, 638–648. [Google Scholar]

- Girmay, G.; Singh, B.R.; Nyssen, J.; Borrosen, T. Runoff and sediment-associated nutrient losses under different land uses in Tigray, Northern Ethiopia. J. Hydrol. 2009, 376, 70–80. [Google Scholar] [CrossRef]

- Guo, S.; Xu, P.; Zhang, P.; Wang, S. Numerical Investigation of the Anti-infiltration and Anti-Erosion Performance of Composite Layers Mixed With Polyacrylamide and Basalt Fibre for the Protection of Silt Subgrade Slopes. Front. Earth Sci. 2022, 10, 815602. [Google Scholar] [CrossRef]

- Huang, J.; Wu, P.; Zhao, X. Effects of rainfall intensity, underlying surface and slope gradient on soil infiltration under simulated rainfall experiments. Catena 2013, 104, 93–102. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, D.; Zhao, Z.; Liu, Y.; Meng, H.; Zou, S.; Ma, B.; Feng, Q. Determining hydrogeological and anthropogenic controls on N pollution in groundwater beneath piedmont alluvial fans using multi-isotope data. J. Geochem. Explor. 2021, 229, 106844. [Google Scholar] [CrossRef]

- Jiang, L.; Xing, Z.; LU, S. Test on Road Performance of Soil-Solidified Agent of Condensate EN-1. J. North-East For. Univ. 2009, 37, 51–53. [Google Scholar]

- Jiao, N.; Wang, Z.; Liu, J. Regulating Effect of Jag C162 Application on Infiltration on Loess Slope. Bull. Soil Water Conserv. 2014, 34, 25–30. [Google Scholar] [CrossRef]

- Kumar, S.S.; Midha, V.K. Influence of slope angle and rainfall intensity on the runoff erosion control performance of woven geomesh. J. Nat. Fibers 2019, 16, 153–162. [Google Scholar] [CrossRef]

- Li, S.; Li, B.; Zhang, J. Soil Erosion Characteristics under Different Precipitation Conditions in Loess Plateau. J. Agro-Environ. Sci. 2005, 24, 94–97. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Liu, J.; Jiao, N.; Zhang, J. Effect of Spraying Jag S on Rain Water Infiltration on Loess Slope. Acta Pedol. Sin. 2017, 54, 844–853. [Google Scholar]

- Liu, F.; Cui, J.; CHEN, L.; Zhao, Y.; Qin, Y.; Wu, C. A View on Geomorphologic Zonalization of North China Plain. Geogr. Geo-Inf. Sci. 2009, 25, 100–103. [Google Scholar]

- Lyu, Q.; Wang, Q.; Wang, S.; Zhao, B. GIS and AHP based slope erosion analysis for the oil and gas pipeline across alluvial fan. Chin. J. Geol. Hazard Control 2018, 29, 119–124. [Google Scholar]

- Mather, A.E.; Stokes, M.; Whitfield, E. River terraces and alluvial fans: The case for an integrated Quaternary fluvial archive. Quat. Sci. Rev. 2017, 166, 74–90. [Google Scholar] [CrossRef]

- Montenegro, A.A.A.; Abrantes, J.R.C.B.; de Lima, J.L.M.P.; Singh, V.P.; Santos, T.E.M. Impact of mulching on soil and water dynamics under intermittent simulated rainfall. Catena 2013, 109, 139–149. [Google Scholar] [CrossRef]

- Qiao, X.; Li, X.; Guo, Y.; Ma, S. In-situ experimental research on water scouring of loess slopes. Environ. Earth Sci. 2018, 77, 417. [Google Scholar] [CrossRef]

- Shen, J.; Xu, Y.; Chen, J.; Wang, Y. Study on the Stabilization of a New Type of Waste Solidifying Agent for Soft Soil. Materials 2019, 12, 826. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Li, P.; Jing, P.; Liu, Y.; Feng, R.; Liu, X. Experiment and Mechanism Analysis on the Solidification of Saline Dredger Fill with Composite Slag Solidifying Agent: A Case Study in Caofeidian, China. Appl. Sci. 2022, 12, 1849. [Google Scholar] [CrossRef]

- Shi, Z.; Wen, A.; Zhang, X.; Yan, D. Comparison of the soil losses from 7Be measurements and the monitoring data by erosion pins and runoff plots in the Three Gorges Reservoir region, China. Appl. Radiat. Isot. 2011, 69, 1343–1348. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, Y.; Lei, P. Mass Exchange of Water and Soil on the Soil Surface in the Rainfall Splash Erosion. Front. Earth Sci. 2021, 9, 739804. [Google Scholar] [CrossRef]

- Tang, T.; Hao, M.; Shan, F. Effects of Straw Mulch Application on Water Loss and Soil Erosion Under Simulated Rainfall. Res. Soil Water Conserv. 2008, 15, 9–11, 40. [Google Scholar]

- Wang, P.; Wang, X.; Chai, S. Solidifying methods for inshore saline soil and its deviator stress-strain. Rock Soil Mech. 2010, 31, 3939–3944. [Google Scholar]

- Wang, Q.; Gao, H.; Liang, Z.; Yang, J.; Yao, W.; Xiao, P. Effect of a Novel Hydrophilic Polyurethane on Increasing Pisha Sandstone Resistance to Rainfall Erosion. J. Soil Water Conserv. 2016, 30, 29–32, 114. [Google Scholar]

- Wang, Q.; Wang, P.; Wang, Z.; Pan, S.; Li, C. Analysis of Disaster Factors of Slope Erosion for Oil and Gas Pipelines Crossing Alluvial Fans. J. Southwest Pet. Univ. Sci. Technol. Ed. 2018, 40, 157–164. [Google Scholar] [CrossRef]

- Wang, Y.; Chai, S.; Li, M. Rain Erosion Resistance of Debris Flow Fan Sprayed by SH Agent in Surface. J. Eng. Geol. 2018, 26, 334–339. [Google Scholar]

- Wei, L.; Chai, S. Evaluation of Solidifying Effect of SH Agent on Inshore Saline Soils. J. Eng. Geol. 2018, 26, 407–415. [Google Scholar]

- Wu, S.; Feng, W.; Yin, S.; Yu, C.; Zhang, K. Research advances in alluvial fan depositional architecture. J. Palaeogeogr. 2016, 18, 497–512. [Google Scholar]

- Xiao, P.; Yang, E.; Li, L. Research Progress on Soil Erosion Process of slope-Gully System on the Loess Plateau of China. In Advances in Environmental Technologies, Advanced Materials Research, Proceedings of the 2nd International Conference on Energy and Environmental Protection (ICEEP 2013), Guilin, China, 19–21 April 2013; Zhao, J., Iranpour, R., Li, X., Jin, B., Eds.; Trans Tech Publications Ltd.: Bäch, Switzerland, 2013; pp. 3747–3750. [Google Scholar] [CrossRef]

- Xiao, P.; Yao, W. Progress of Studying Soil Erosion Process on the Loess Plateau of China. In Proceedings of the 2nd International Yellow River Forum on Keeping Healthy Life of the River, Zhengzhou, China, 6 October 2005; Shang, H., Ed.; Yellow River Water Conservancy Press: Zhengzhou, China; Volume II, pp. 158–163. [Google Scholar]

- Xu, P.; Li, Z.; Wang, Y.; Dong, Y. Impact of Freeze-Thaw Cycles on Mechanical Properties of Loess Solidified with New Polymer Curing Agent SH. J. Yangtze River Sci. Res. Inst. 2021, 38, 137–141. [Google Scholar]

- Yao, W.; Xiao, P. Research direction of the study of soil erosion in the Loess Plateau. Adv. Sci. Technol. Water Resour. 2012, 32, 73–78. [Google Scholar]

- Yin, S.; Liu, Z.; Chen, Y.; Wu, X. Research Progress and Sedimentation Experiment Simulation about Alluvial Fan: A case study on alluvial fan controlled by debris flow and braided river. Acta Sedimentol. Sin. 2017, 35, 10–23. [Google Scholar]

- Young, R.; Wiersma, J. Role of Rainfall Impact in Soil Detachment and Transport. Water Resour. Res. 1973, 9, 1629–1636. [Google Scholar] [CrossRef]

- Yu, G.; Li, Z.; Pei, L.; Li, P. Difference of Runoff-Erosion-Sediment Yield Under Different Vegetation Type. J. Soil Water Conserv. 2012, 26, 1–5, 11. [Google Scholar] [CrossRef]

- Yuan, J.; Ye, C.; Pei, X.; Pei, Z.; Xie, Z.; Luo, L.; Yu, B. Runoff and soil loss characteristics on sandy soil slope with new chemical sand-fixing agent under simulated rainfall. Environ. Earth Sci. 2023, 82, 266. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, G.Q.; Li, Z.B.; Li, P. Experimental Study on Slope Runoff, Erosion and Sediment under Different Vegetation Types. Water Resour. Manag. 2014, 28, 2415–2433. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Z. Research progress on mechanism of grassland vegetation regulating soil erosion in Loess Plateau. Pratacultural Sci. 2015, 32, 64–70. [Google Scholar]

- Zhang, Z.; Omine, K.; Flemmy, S.O. Evaluation of the improvement effect of cement-stabilized clays with different solidifying agent addition and water content. J. Mater. Cycles Waste Manag. 2022, 24, 2291–2302. [Google Scholar] [CrossRef]

- Zhao, L.; Hou, R.; Wu, F.; Keesstra, S. Effect of soil surface roughness on infiltration water, ponding and runoff on tilled soils under rainfall simulation experiments. Soil Tillage Res. 2018, 179, 47–53. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, H.; Wang, Y.; Miao, S. Effects of soil parameters on deformation of improved loess slope. South-North Water Transf. Water Sci. Technol. 2016, 14, 167–172. [Google Scholar]

- Zhu, Z.; Hao, J.; Zhao, L. Analysis of stable effect of silty subgrade by solidifying agent with high performance. J. Hefei Univ. Technol. Nat. Sci. 2009, 32, 1599–1601+1611. [Google Scholar]

Figure 1.

Failure of engineering measures to prevent geological hazards of pipeline erosion. (a) Collapse damage to the lead-wire gabion fender; (b) excavation erosion damage at the bottom of the drainage channel.

Figure 1.

Failure of engineering measures to prevent geological hazards of pipeline erosion. (a) Collapse damage to the lead-wire gabion fender; (b) excavation erosion damage at the bottom of the drainage channel.

Figure 2.

Immersion testing for SH polymer membranes.

Figure 2.

Immersion testing for SH polymer membranes.

Figure 3.

Mass retention of SH polymer membranes during immersion testing.

Figure 3.

Mass retention of SH polymer membranes during immersion testing.

Figure 4.

Tensile deformation of SH polymer membranes under varying immersion durations.

Figure 4.

Tensile deformation of SH polymer membranes under varying immersion durations.

Figure 5.

Tensile stress–strain relationships for (a) 0.36 mm and (b) 0.56 mm SH polymer membranes.

Figure 5.

Tensile stress–strain relationships for (a) 0.36 mm and (b) 0.56 mm SH polymer membranes.

Figure 6.

Structural diagram of NJJY-10 artificial rainfall simulator.

Figure 6.

Structural diagram of NJJY-10 artificial rainfall simulator.

Figure 7.

Detailed diagram of the rainfall erosion test apparatus.

Figure 7.

Detailed diagram of the rainfall erosion test apparatus.

Figure 8.

Erosion and damage morphology of AFSDs under different SH polymer material spraying quantities. (a) 1.0 kg/m2: Localized scouring (9.69 g loss) at lower quadrant with incipient piping. (b) 1.5 kg/m2: Marginal corner erosion (6.01 g loss), stabilized matrix. (c) 2.0 kg/m2: Negligible detachment (1.03 g loss), intact surficial crust.

Figure 8.

Erosion and damage morphology of AFSDs under different SH polymer material spraying quantities. (a) 1.0 kg/m2: Localized scouring (9.69 g loss) at lower quadrant with incipient piping. (b) 1.5 kg/m2: Marginal corner erosion (6.01 g loss), stabilized matrix. (c) 2.0 kg/m2: Negligible detachment (1.03 g loss), intact surficial crust.

Figure 9.

Erosion response of SH-treated AFSDs under varying slope morphologies. (a) Planar smooth: 1.66 g—Uniform surficial runoff with isolated particle detachment. (b) Planar rough: 1.17 g—Microtopography-induced turbulence reducing erosive shear stress. (c) Curved smooth: 1.22 g—Curvature-driven flow concentration causing lateral scouring. (d) Curved rough: 1.16 g—Synergistic roughness-curvature effects inhibiting sediment mobilization.

Figure 9.

Erosion response of SH-treated AFSDs under varying slope morphologies. (a) Planar smooth: 1.66 g—Uniform surficial runoff with isolated particle detachment. (b) Planar rough: 1.17 g—Microtopography-induced turbulence reducing erosive shear stress. (c) Curved smooth: 1.22 g—Curvature-driven flow concentration causing lateral scouring. (d) Curved rough: 1.16 g—Synergistic roughness-curvature effects inhibiting sediment mobilization.

Figure 10.

The overall growth state of tall fescue. (a) Experimental group and (b) control group (0 kg/m2).

Figure 10.

The overall growth state of tall fescue. (a) Experimental group and (b) control group (0 kg/m2).

Table 1.

SH polymer membranes parameter.

Table 1.

SH polymer membranes parameter.

| Parameter Type | SH Polymer Membranes | Unit |

|---|

| thickness | 0.16 | 0.22 | 0.32 | 0.36 | 0.56 | mm |

Table 2.

Technical specifications of NJJY-10 rainfall simulator.

Table 2.

Technical specifications of NJJY-10 rainfall simulator.

| Parameter | Value Range | Unit |

|---|

| Rainfall height | 2~4 | m |

| Effective rainfall area | 2.7 × 2.7 | m2 |

| Range of rainfall intensity variation | 60~320 | mm/h |

| Rainfall uniformity coefficient | >0.86 | − |

| Raindrop diameter size | 0.5, 2.0, 4.5 | mm |

| Rainfall regulation accuracy | ±7 | mm/h |

Table 3.

Test series 1 parameters.

Table 3.

Test series 1 parameters.

| SH Dosage (kg/m2) | Curing Time | Soil Properties |

|---|

| 1.0–2.0 | 3 days | Dry density: 1.65 g/cm3 |

| Slope: 30° longitudinal, 0° cross |

| Dimensions: 60 × 60 × 3 cm |

| Surface: Planar smooth |

Table 4.

Test series 2 parameters.

Table 4.

Test series 2 parameters.

| Slope Configurations | SH Dosage (kg/m2) | Curing Time | Soil Properties |

|---|

| Planar smooth | 2.0 | 3-day | Dry density: 1.65 g/cm3 |

| Planar rough | Slope: 30° longitudinal, 0° cross |

| Curved smooth | Dimensions: 60 × 60 × 3 cm |

| Curved rough | Surface: Planar smooth |

Table 5.

Experimental matrix.

Table 5.

Experimental matrix.

| Treatment Sequence | Application Rates (kg/m2) |

|---|

| Soil coverage prior to spraying | 0.6, 0.9, 1.2, 1.5, 2.0 |

| Spraying prior to soil coverage | 0.6, 0.9, 1.2, 1.5, 2.0 |

Table 6.

The growth status of tall fescue in each area.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).