A Review of the Methods Used in the Study of Creep Behavior of Fiber-Reinforced Composites and Future Developments

Featured Application

Abstract

1. Introduction

- Complex constitutive models are necessary because of the profound heterogeneity of the composite materials, where the phases (fiber and matrix) have very different mechanical and physical properties, with complex interactions and parameters varying in time. The distribution of the materials in composites can be non-uniform, and the materials can be nonlinear and can exhibit both elastic and plastic deformation over time. As a consequence, it is necessary to use anisotropic and viscoelastic/viscoplastic models to obtain an accurate creep prediction.

- Interfacial behavior plays an important role in creep behavior. The creep performance is greatly impacted by delamination or microcracking, which can result from a weak or weakly bonded surface. The stress transfer between fibers and matrix can be strongly influenced by the nature and quality of these interactions.

- Damage behavior remains one of the problems that arise in the study of creep evolution, which includes microcracking and delamination (microscopic cracks and delamination in the materials can accelerate the creep process). To the extent that the two phenomena (creep and microcracking/delamination) are mutually reinforcing, this represents a very important aspect. The failure mechanisms, as a consequence, must be studied in order to offer an accurate lifetime prediction.

- Scale effects, how microstructural phenomena influence macroscopic creep, are difficult to understand and model. Creep behavior can be greatly influenced by the size, shape, and lay-up arrangement of the composite material, and these effects are frequently hard to generalize across many composite systems.

- For the creep phenomenon, environmental factors become important. Fiber-reinforced composites’ creep behavior can be altered over time by moisture, UV radiation, or harsh chemicals that weaken the matrix or degrade the fibers. Composite sites may simultaneously experience cyclic loading (fatigue) and continuous loading (creep) in real-world applications. In this sense, the image shown to us is intricate and requires meticulous research and modeling.

- Extensive experimental data and sophisticated computational techniques are required for prediction models, which integrate several elements, including material qualities, loading conditions, and environmental parameters, into a single model.

- To fully understand the creep behavior of these materials, testing under a range of loading scenarios and orientations is necessary. Because creep behavior is intrinsically time-dependent, it necessitates extensive testing, which can take months or even years. Because of this, collecting enough experimental data for different loading circumstances, temperatures, and habitats is difficult and costly.

2. Fiber-Reinforced Plastics

2.1. Linear Viscoelastic Behavior

- (a)

- Homogeneity

- (b)

- Superpositions

2.2. The Rheological Model for Creep

2.3. Nonlinear Viscoelastic Behavior

2.4. The Method of Multiple Integrals

2.5. Findley Approach to Nonlinear Viscoelasticity

2.6. Method of Nonlinearity Factors

2.7. General Conclusions

- The main hypothesis used in most of the calculus of plastic composites is that these materials exhibit linear viscoelastic properties. Two conditions must be satisfied to have this: homogeneity (proportionality) and the superposition principle. Many materials may appear linear but are not; superposition must be tested to confirm linear behavior. Very clearly, Boltzmann’s superposition principle is valid only within the linear range.

- The nonlinear viscoelastic behavior may occur at low stress levels over long timescales. Boltzmann’s principle fails for nonlinear behavior. Nonlinear constitutive models must consider the stress–strain magnitude. A modified superposition (Leaderman) can be used. The method of multiple integrals (Green and Rivlin) represents a highly general framework using multiple integrals to capture any degree of nonlinearity and can model complex dependencies (stress, moisture, and temperature). Higher-order terms represent deviations from linear behavior.

- Findley’s Approach is an empirical model for nonlinear creep based on a power law with nonlinear coefficients and is widely used for its simplicity and practical applicability.

- The method of nonlinearity factors (Shapery) is derived from thermodynamic principles, is easier to implement experimentally than multiple integrals, and uses stress-dependent nonlinearity and time-shift factors to model material behavior.

3. Micromechanical Analysis

3.1. Basic Considerations

3.2. Micromechanical Methods

3.2.1. Model

- -

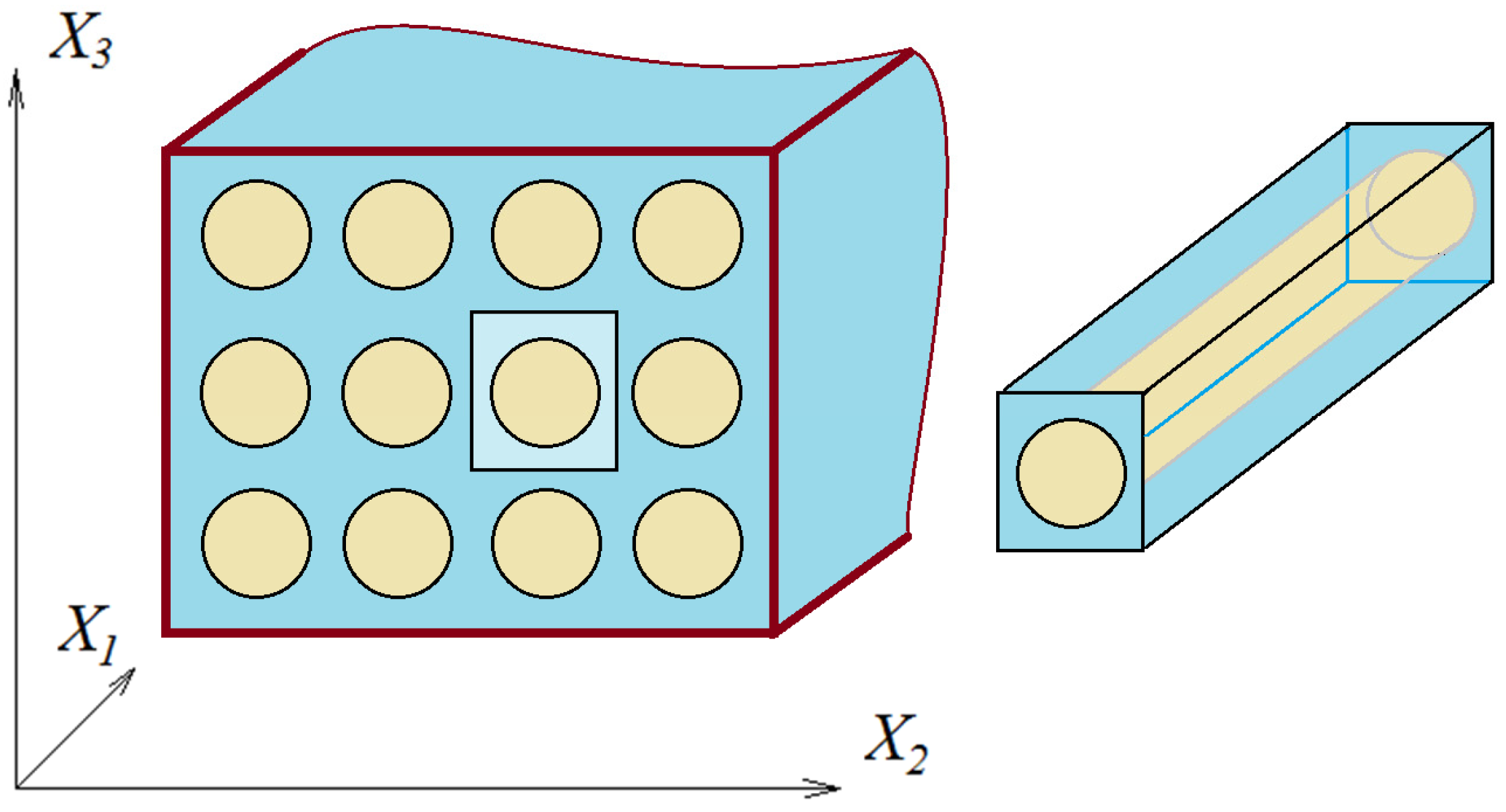

- The X2–X3 plane has a rectangular array of fibers that are expanded in the X1 direction. According to our presentation, the polymeric matrix is nonlinearly viscoelastic but isotropic, and the fibers are linearly elastic and anisotropic. Indeed, these presumptions may be changed in the case of the nonlinear material.

- -

- Under load, no cracks or holes may form since the interaction between the fibers and matrix is only mechanical.

- -

- The problem’s size and complexity are decreased by the aforementioned regular and periodic packing, which enables the study of a representative cell. Note that one of the recurring units of the periodical pattern depicted in Figure 1 is displayed in Figure 2a. The fiber is thought to have a transversal section that is circular. As seen in Figure 2b, the representative unit cell (RUC) (or representative volume element—RVE) can therefore be made up of two subcells, each representing a quarter of a fiber and the corresponding matrix material. In addition, the unit cells are thought to be tiny in relation to the composite’s overall dimensions.

3.2.2. Average Stresses in RUC

3.2.3. Continuity Conditions

3.2.4. Average Strains in RUC

3.3. Results and Real World Applications

3.4. Future Developments

- A combined approach of micromechanical models with different physical conditions can be considered. For example, thermal, mechanical, and environmental effects can be integrated. Additionally, behavior in high temperatures or corrosive environments can be considered. Thermal and chemical–mechanical coupling in the development of models can be an area of interest. Also, investigating the effect of residual thermal stresses on creep is a way forward.

- The complexity of engineering systems requires the incorporation of models of time-dependent interface behavior that explicitly account for interfacial creep and debonding mechanisms under long-term loading and consider the effect of interface strength degradation and damage evolution over time.

- It is also necessary to consider, for a better description of creep phenomena, the microstructural heterogeneity, including statistical distributions of different parameters defining the RUC as fiber orientation, volume fraction, and fiber–matrix geometry, and develop stochastic micromechanical models.

- The study of systems using multiscale approaches is a constant in current research in all engineering fields. It can be beneficial to use finite element-based micromechanics with continuum-level models to enable the accurate life predictions of composite components and use hierarchical modeling to bridge scales from a nano (e.g., fiber–matrix interface) to macro (component) level.

- Coupling micromechanical creep models with damage mechanics offers a better prediction in the initiation and growth of microcracks, fiber breaks, or matrix cavitation. At the same time, the simulation of creep rupture processes helps researchers to predict the time to failure under various stress levels.

- Using the specific properties and conditions of a material can provide information that helps develop more accurate models or provide results in a shorter time. This can be used to analyze applications such as turbine blades (ceramic matrix composites), automotive heat shields (metal matrix composites), and aerospace panels (polymer matrix composites).

- As in all fields, the use of machine learning is starting to become important in the field as well. It is possible to combine machine learning algorithms with micromechanical simulations to accelerate creep property predictions, use surrogate models trained on high-fidelity micromechanical simulations to explore large design spaces, or apply physics-informed neural networks (PINNs) to incorporate constitutive creep laws into ML models with physical constraints.

4. Analytical Methods

4.1. Estimation of Bound

4.2. Mori–Tanaka Approach

4.3. Results and Applications (Mori-Tanaka Theory)

4.4. Future Development

- Using machine learning (ML) models to integrate the Mori–Tanaka formalism to predict effective properties from microstructural data more efficiently is one of the directions. In this way, ML can help to approximate the results of computationally expensive simulations for real-time design.

- Multiscale and multi-physics modeling represents an important future direction of development. This means a coupling between FEA and micromechanics to develop extended models for composites subjected to coupled physical fields (e.g., piezoelectric fibrous composites, magnetoactive polymers).

- Time-dependent and nonlinear behavior represent important aspects that must be incorporated into the models. Extended models must be developed to account for time-dependent responses in polymer matrix composites. Another aspect is the damage and failure modelling: combining Mori–Tanaka with continuum damage mechanics or phase-field models for progressive failure predictions.

- The bounded model remains important in design due to its simplicity. Enhanced bounding methods can be used for complex microstructures tailored to composites with more irregular, graded, or hierarchical structures.

- Bioinspired and smart composites with bioinspired fiber architectures or self-healing composites using modified homogenization schemes have a large field of application. More nuanced field interaction will be used in modeling smart composites.

- Another direction is represented by experimental validation and digital twins, combining homogenization methods with digital materials testing (e.g., X-ray CT + FEM) for real-time feedback and validation.

5. Homogenized Viscoelastic Coefficients

5.1. General Considerations in Homogenization

5.2. The Homogenized Method

- Using the local equations, the strain and stress field, and the averages are determined, obtaining the homogenized coefficients after averaging;

- Using the variational formulation and determining a special function wkh that can also help us determine the homogenized coefficients.

5.3. Results and Applications

5.4. Future Developments in Homogeniuzation

- A multiscale or multi-physics modeling approach, a widely used type of analysis, can be considered due to its existing computational possibilities. Currently, directions necessary in current engineering applications are being pursued, such as developing homogenization frameworks (for coupled phenomena, such as thermomechanical, viscoelastic/viscoplastic interactions or damage); coupling creep with oxidation, thermal gradients, and phase transformation; embedding microstructural evolution during creep (grain growth, void formation); or capturing interface behavior and its evolution (e.g., fiber–matrix debonding).

- Further development of numerical calculation methods includes FE2 (finite element squared), applying reduced order modeling (ROM) to reduce high computational costs, incorporating time-dependent behavior (creep laws) into microscale FE models and using adaptive methods to reduce the number of representative volume elements and therefore the dimension of the system [189,190,191,192,193,194].

- ML and AI can be used to accelerate the homogenization process using ML-based constitutive models that can evolve with damage and time. This results in a real-time prediction of creep properties from microstructure descriptors. ML can replace or accelerate homogenization processes. Instead of solving the RVE repeatedly, an ML model is trained on pre-computed data to instantly predict effective creep properties.

- Existing homogenization methods should be developed to adapt to creep strain evolution and introduce new internal variables such as creep strain, damage, and history-dependent responses.

- Recognizing the fact that the microstructure of composites is often non-deterministic, stochastic homogenization can be introduced in analysis to quantify uncertainty in creep life prediction. Spectral or Monte Carlo methods can be used to simulate the variability in the distribution of phases in a composite.

- High-resolution experimental data (micro-CT, SEM) can be directly integrated into homogenization. So, using digital volume correlation (DVC), it is possible to validate the creep strain field at different scales, and through direct 3D scans, it is possible to build RVEs directly and introduce them in numerical analysis.

- One important direction of study is the micro-damage evolution (cracking and fiber breakage) within homogenization schemes.

6. Finite Element Method

6.1. FEM Used to Determine the Field of Strain and Stress in a RUC

6.2. Results and Applications

6.3. Future Developments of FEM

7. Testing Methods

- Test specimens are loaded with a constant tensile or compressive load.

- Deformation (strain) is measured at different time intervals to monitor how it changes over time.

- Testing is carried out at various temperatures and environmental conditions. So, it is possible to study the composite’s behavior under different operating conditions.

- Constant strain (or stress relaxation) tests are performed when the material is strained to a fixed level, and the decay in stress is measured over time. So, it is possible to study the viscoelastic behavior of polymer matrix composites (PMCs). The results obtained are stress vs. time and relaxation modulus.

- A creep rupture test is very similar to that performed under constant load, but the focus is on time to failure under a constant stress and temperature. So, it is possible to obtain the durability/lifetime of a composite under long-term loads. It yields time to rupture vs. applied stress.

- Accelerated creep testing represents a class of tests conducted at higher-than-service temperatures or stresses to accelerate failure. To interpret the results, the time–temperature superposition and time–stress superposition principles are used.

- Dynamic mechanical analysis (DMA) is performed using oscillating stress to measure viscoelastic properties. This method is used mainly when short-term creep compliance and modulus measurements should be obtained.

- A bending creep test (flexural creep) in a three-point or four-point setup is used to study the real-world loading in structures composed of beams or panels.

- Thermal cycling tests are used for the study of composites under varying thermal conditions (expansion and contraction) to simulate real-world conditions experienced in aerospace, automotive, and other industries. In these tests, the specimens are exposed to high and low temperatures for a certain number of cycles, and thermal expansion, dimensional stability, and residual stresses are determined. Thermal expansion can lead to residual stresses, which may cause microcracking or delamination over time and matrix degradation, fiber–matrix debonding, or interlaminar shear failure.

- Impact resistance tests determine the ability of fiber-reinforced composites to withstand sudden and high-intensity forces. The energy absorbed during fracture is measured. Impact can cause delamination or fiber fracture, especially if the bonding between the matrix and fibers is weak.

- Moisture absorption tests measure how the fiber-reinforced composite absorbs moisture, which can affect its mechanical properties. Usually, the specimens are immersed in water at room temperature or elevated temperatures, and their mass change is measured over time. Moisture likely causes a reduction in tensile strength and modulus.

- X-ray or Micro-CT scanning is performed following the internal damage assessment (microcracks, delamination, or voids within the composite). These methods can reveal defects that may not be detectable through traditional methods.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ansari, M.N.M.; Shanks, R.A. Cellulose Fiber and Nano-Fiber Composites based on Castor Oil-Polyurethane Matrix. In Proceedings of the NSTI Nanotechnology Conference and Expo: Bio Sensors, Instruments, Medical, Environment and Energy, Boston, MA, USA, 13–16 June 2011; Volume 3, pp. 179–182. [Google Scholar]

- Babu, J.S.S.; Nair, K.P.; Kang, C.G. Hybrid preform for metal matrix composites: Processing and characterization. In Proceedings of the 9th International Conference on Semi-Solid Processing of Alloys and Composites, Busan, Republic of Korea, 11–13 September 2006; Volume 116–117, pp. 421–424. [Google Scholar]

- Mesa, M.C.; Oliete, P.B.; Larrea, A.; Orera, V.M. Directionally Solidified Al2O3-Er3Al5O12-ZrO2 Eutectic Ceramics with Interpenetrating or Nanofibrillar Microstructure: Residual Stress Analysis. J. Am. Ceram. Soc. 2012, 95, 1138–1146. [Google Scholar] [CrossRef]

- Khabaz-Aghdam, A.; Behjat, B.; da Silva, L.F.M.; Marques, E.A.S. A new theoretical creep model of an epoxy-graphene composite based on experimental investigation: Effect of graphene content. J. Compos. Mater. 2002, 54, 2461–2472. [Google Scholar] [CrossRef]

- Xue, C.; Gao, H.Y.; Hu, Y.C.; Hu, G.X. Experimental test and curve fitting of creep recovery characteristics of modified graphene oxide natural rubber and its relationship with temperature. Polym. Test. 2022, 87, 106509. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K. Evaluating the effective creep properties of graphene-reinforced polymer nanocomposites by a homogenization approach. Compos. Sci. Technol. 2021, 209, 108791. [Google Scholar] [CrossRef]

- Lin, C.M.; He, G.S.; Liu, J.H.; Huang, Z.; Pan, L.P.; Zhang, J.H.; Liu, S.J. Enhanced non-linear viscoelastic properties of TATB-based polymer bonded explosives filled with hybrid graphene/multiwalled carbon nanotubes. RSC Adv. 2005, 5, 94759–94767. [Google Scholar] [CrossRef]

- Maksimov, R.D.; Plume, E. Long-term creep of hybrid aramid/glass-fiber-reinforced plastics. Mech. Compos. Mater. 2001, 37, 271–280. [Google Scholar] [CrossRef]

- Su, X.L.; Wu, Y.; Jia, M.K.; Yao, L.Q.; Xu, W.X. Creep evaluation for fiber-reinforced composites with hybrid fibers: From quantifying fiber anchorage effect to homogenization model. J. Build. Eng. 2024, 98, 111204. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Z.; Jin, Y.; Shaw, W.J.D. Creep-Behavior of a Hybrid Fiber (Glass/Carbon) Reinforced Composite and its Application. Compos. Sci. Technol. 1994, 50, 431–439. [Google Scholar] [CrossRef]

- Skandani, A.A.; Al-Haik, M. Viscoplastic characterization and modeling of hybrid carbon fiber/carbon nanotubes reinforced composites. Compos. Part B-Eng. 2016, 99, 63–74. [Google Scholar] [CrossRef]

- Svoboda, M.; Pahutova, M.; Kucharova, K.; Sklenicka, V.; Kainer, K.U. Microstructure and creep behaviour of magnesium hybrid composites. Mater. Sci. Eng. A—Struct. Mater. Prop. Microstruct. Process. 2007, 462, 220–224. [Google Scholar] [CrossRef]

- Skandani, A.A.; Boroujeni, A.Y.; Al-Haik, M. Viscoelastic behavior of epoxy/carbon fiber/Zno nano-rods hybrid composites. Polym. Compos. 2015, 36, 1967–1972. [Google Scholar] [CrossRef]

- Haj-Ali, R.M.; Muliana, A.H. A multi-scale constitutive formulation for the nonlinear viscoelastic analysis of laminated composite materials and structures. Int. J. Solids Struct. 2004, 41, 3461–3490. [Google Scholar] [CrossRef]

- Terada, K.; Hirayama, N.; Yamamoto, K.; Kato, J.; Kyoya, T.; Matsubara, S.; Arakawa, Y.; Ueno, Y.; Miyanaga, N. Applicability of micro-macro decoupling scheme to two-scale analysis of fiber-reinforced plastics. Adv. Compos. Mater. 2014, 23, 421–450. [Google Scholar] [CrossRef]

- Muliana, A.H.; Haj-Ali, R. A multi-scale framework for layered composites with thermo-rheologically complex behaviors. Int. J. Solids Struct. 2008, 45, 2937–2963. [Google Scholar] [CrossRef]

- Wang, S.; Stratford, T.; Reynolds, T.P.S. Linear creep of bonded FRP-strengthened metallic structures at warm service temperatures. Constr. Build. Mater. 2021, 283, 122699. [Google Scholar] [CrossRef]

- Arruda, M.R.T.; Garrido, M.; Correia, J.R. Numerical modelling of the creep behaviour of GFRP sandwich panels using the Carrera Unified Formulation and Composite Creep Modelling. Compos. Struct. 2018, 183, 103–113. [Google Scholar] [CrossRef]

- Upadhyaya, P.; Singh, S.; Roy, S. A mechanism-based multi-scale model for predicting thermo-oxidative degradation in high temperature polymer matrix composites. Compos. Sci. Technol. 2011, 71, 1309–1315. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Marin, M.; Scutaru, M.L. Modeling Study of the Creep Behavior of Carbon-Fiber-Reinforced Composites: A Review. Polymers 2023, 15, 194. [Google Scholar] [CrossRef]

- Chen, K.F.; Yang, H.; Wang, A.; Tang, L.S.; Zha, X.; Iita, N.S.; Zhang, H.; Li, Z.X.; Wang, X.Y.; Yang, W.; et al. Smart Driving Hardware Augmentation by Flexible Piezoresistive Sensor Matrices with Grafted-on Anticreep Composites. Adv. Sci. 2024, 12, e2408313. [Google Scholar] [CrossRef]

- Song, T.Y.; Xu, M.X.; Weng, Y.J.; Zhang, W.; Shi, Y.Q.; Li, X.; Zhang, Q.; Song, T.Y.; Xu, M.X. Silkworm-Shaped MoS2 Growing on Graphene Foam for Highly Sensitive and Flexible Strain Sensor with Full-Scale Human Motion Detection Ability. Adv. Mater. Technol. 2024, 10, 2401621. [Google Scholar] [CrossRef]

- Zhang, B.; Shi, D.Q.; Liu, C.Q.; Hao, W.Q.; Yang, X.G. Physics-informed machine learning with high-throughput design module for evaluating rupture life and guiding design of oxide/oxide ceramic matrix composites. Ceram. Int. 2023, 49, 34945–34957. [Google Scholar] [CrossRef]

- Kubo, A.; Umeno, Y. Machine-Learning-Based Atomistic Model Analysis on High-Temperature Compressive Creep Properties of Amorphous Silicon Carbide. Materials 2021, 14, 1597. [Google Scholar] [CrossRef] [PubMed]

- Yang, E.T.; Pressly, J.F.; Natarajan, B.; Colby, R.; Winey, K.I.; Riggleman, R.A. Understanding creep suppression mechanisms in polymer nanocomposites through machine learning. Soft Matter 2023, 19, 7580–7590. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Tewari, R.P.; Rawat, A. Tribological evolution of ultra-high molecular weight polyethylene and its composites for hip and knee replacement implants: A review. J. Tribol. 2024, 42, 161–197. [Google Scholar]

- Yang, J.Y.; Kang, G.Z.; Liu, Y.J.; Chen, K.J.; Kan, Q.H. Life prediction for rate-dependent low-cycle fatigue of PA6 polymer considering ratchetting: Semi-empirical model and neural network based approach. Int. J. Fatigue 2020, 136, 105619. [Google Scholar] [CrossRef]

- Guedes, R.M. Cumulative creep damage for unidirectional composites under step loading. Mech. Time-Depend. Mater. 2012, 16, 381–396. [Google Scholar] [CrossRef]

- Murakami, S.; Liu, Y. Local approach of fracture based on continuum damage mechanics and the related problems. Mater. Sci. Res. Int. 1996, 2, 131–142. [Google Scholar] [CrossRef][Green Version]

- Ogi, K.; Yoshikawa, S.; Okabe, T.; Onodera, S. Prediction of viscoelastic effective creep compliances in cracked cross-ply composite laminates. Mech. Mater. 2024, 197, 105085. [Google Scholar] [CrossRef]

- Mahadevan, S.; Mao, H.Y. Probabilistic fatigue-creep life prediction of composites. J. Reinf. Plast. Compos. 2004, 23, 361–371. [Google Scholar] [CrossRef]

- Guedes, R.M. Time-dependent failure criteria for polymer matrix composites: A review. J. Reinf. Plast. Compos. 2010, 29, 3041–3047. [Google Scholar] [CrossRef]

- Evans, A.G.; Zok, F.W. The physics and mechanics of brittle matrix composites. Solid State Phys.—Adv. Res. Appl. 1996, 47, 177–286. [Google Scholar]

- Pulngern, T.; Kaewkalya, P.; Rosarpitak, V.; Sombatsompop, N. Experimental and Computational Investigations of Creep Responses of Wood/PVC Composite Members. Int. Polym. Process. 2014, 29, 307–316. [Google Scholar] [CrossRef]

- Li, B.; Liu, Z.D.; Wang, S. An Experimental Study on Creep Damage of In-Situ TIC-Based Composites. Adv. Sci. Lett. 2011, 4, 1244–1248. [Google Scholar] [CrossRef]

- Wang, G.Y.; Li, H.L.; Li, Y.Q. Experimental research on creep properties of composite geomembrane. Rock Soil Mech. 2009, 30, 1599–1603. [Google Scholar]

- Kondo, K.; Kubo, T.; Masuyama, M. Creep-Behavior of Unidirectional Composites. Comput. Mech. 1994, 14, 16–27. [Google Scholar] [CrossRef]

- Berardi, V.P.; Perrella, M.; Armentani, E.; Cricrì, G. Experimental investigation and numerical modeling of creep response of glass fiber reinforced polymer composites. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1085–1095. [Google Scholar] [CrossRef]

- Pang, F.; Wang, C.H. Creep rupture failure of woven composites. J. Reinf. Plast. Compos. 2020, 19, 1201–1216. [Google Scholar]

- Takemura, K.; Miyamoto, S.; Katogi, H. Effect of Surface Treatment on Creep Property of Jute Fiber Reinforced Green Composite under Environmental Temperature. Key Eng. Mater. 2012, 525–526, 53–56. [Google Scholar] [CrossRef]

- Miller, S.A. Natural fiber textile reinforced bio-based composites: Mechanical properties, creep, and environmental impacts. J. Clean. Prod. 2018, 198, 612–623. [Google Scholar] [CrossRef]

- Xu, B.W.; van den Hurk, B.; Teuffel, P. Effect of environmental humidity on the creep behavior of flax fiber-reinforced polymer composites. Polymer 2023, 44, 6108–6121. [Google Scholar] [CrossRef]

- Morscher, G.N. Stress-Environmental Effects on Fiber-Reinforced SiC-Based Composites. In Ceramic Matrix Composites: Materials, Modeling and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 334–352. [Google Scholar]

- Ruggles-Wrenn, M.B. Environmental Effects on Oxide/Oxide Composites. In Ceramic Matrix Composites: Materials, Modeling and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 295–333. [Google Scholar]

- Raji, M.; Zari, N.; Bouhfid, R.; Qaiss, A.E. Durability of composite materials during hydrothermal and environmental aging. In Durability and Life Prediction in Biocomposites, Fiber-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2019; pp. 83–119. [Google Scholar]

- Ruggles-Wrenn, M.B.; Szymczak, N.R. Effects of steam environment on compressive creep behavior of Nextel™720/Alumina ceramic composite at 1200 °C. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1829–1837. [Google Scholar] [CrossRef]

- Barreira-Pinto, R.; Carneiro, R.; Miranda, M.; Guedes, R.M. Polymer-Matrix Composites: Characterising the Impact of Environmental Factors on Their Lifetime. Materials 2023, 16, 3913. [Google Scholar] [CrossRef] [PubMed]

- Miller, S.A.; Lepech, M.D.; Billington, S.L. Evaluation of Functional Units Including Time-Dependent Properties for Environmental Impact Modeling of Biobased Composites. J. Biobased Mater. Bioenergy 2013, 7, 588–599. [Google Scholar] [CrossRef]

- Seemüller, C.; Heilmaier, M.; Haenschke, T.; Bei, H.; Dlouhy, A.; George, E.P. Influence of fiber alignment on creep in directionally solidified NiAl-10Mo in-situ composites. Intermetallics 2013, 35, 110–115. [Google Scholar] [CrossRef]

- Chen, Y.F.; Setiawan, L.; Chou, S.R.; Hu, X.; Wang, R. Identification of safe and stable operation conditions for pressure retarded osmosis with high performance hollow fiber membrane. J. Membr. Sci. 2016, 503, 90–100. [Google Scholar] [CrossRef]

- Manu, K.M.S.; Raag, L.A.; Rajan, T.P.D.; Gupta, M.; Pai, B.C. Liquid Metal Infiltration Processing of Metallic Composites: A Critical Review. Metall. Mater. Trans. B-Process Metall. Mater. Process. Sci. 2016, 47, 2799–2819. [Google Scholar] [CrossRef]

- Hiroshima, N.; Hatta, H.; Nagura, Y.; Koyama, M.; Sakai, T.; Kogo, Y. Spin test of three-dimensional composite rotor using polymer ring as a connection device for high-speed flywheel. Mech. Eng. J. 2016, 3, 16–00261. [Google Scholar] [CrossRef][Green Version]

- Tanks, J.D.; Rader, K.E.; Sharp, S.R. Accelerated Creep Testing of CFRP with the Stepped Isostress Method Annual Conference and Exposition of the Society-for-Experimental-Mechanics on Experimental and Applied Mechanics. Mech. Compos. Multifunct. Mater. 2016, 7, 397–403. [Google Scholar]

- Tanks, J.; Rader, K.; Sharp, S.; Sakai, T. Accelerated creep and creep-rupture testing of transverse unidirectional carbon/epoxy lamina based on the stepped isostress method. Compos. Struct. 2017, 159, 455–462. [Google Scholar] [CrossRef]

- Dasappa, P.; Lee-Sullivan, P.; Xiao, X.R. Development of viscoplastic strains during creep in continuous fiber GMT composites. Compos. Part B-Eng. 2010, 41, 48–57. [Google Scholar] [CrossRef]

- Yang, T.C.; Wu, T.L.; Hung, K.C.; Chen, Y.L.; Wu, J.H. Mechanical properties and extended creep behavior of bamboo fiber reinforced recycled poly(lactic acid) composites using the time-temperature superposition principle. Constr. Build. Mater. 2015, 93, 558–563. [Google Scholar] [CrossRef]

- Bozorg-Haddad, A.; Iskander, M. Comparison of Accelerated Compressive Creep Behavior of Virgin HDPE Using Thermal and Energy Approaches. J. Mater. Eng. Perform. 2011, 20, 1219–1229. [Google Scholar] [CrossRef]

- Scott, D.W.; Lai, J.S.; Zureick, A.H. Creep-Behavior of Fiber-Reinforced Polymeric Composites—A Review of the Technical Literature. J. Reinf. Plast. Compos. 1995, 14, 588–617. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Zaoutsos, S.P. Viscoelastic constitutive modeling of creep and stress relaxation in polymers and polymer matrix composites. In Creep and Fatigue in Polymer Matrix Composites; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–47. [Google Scholar]

- Akshantala, N.V.; Brinson, L.C. A damage evolution model for viscoelastic composite laminates. J. Compos. Technol. Res. 2001, 23, 3–14. [Google Scholar]

- Liu, X.; Tang, T.; Pipes, R.B. Multiscale modeling of viscoelastic behaviors of textile composites. Int. J. Eng. Sci. 2018, 130, 175–186. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, P.P.; Busso, E.P. A micromechanics-based constitutive model for linear viscoelastic particle-reinforced composites. Mech. Mater. 2020, 140, 103228. [Google Scholar] [CrossRef]

- Middendorf, P. Characterization of linear viscoelastic behavior of composites. Z. Angew. Math. Mech. 2001, 81, S835–S836. [Google Scholar]

- Zhang, Z.Z.; Liu, X.L.; Zhang, B. A rheological constitutive model for damaged zone evolution of a tunnel considering strain hardening and softening. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 56. [Google Scholar] [CrossRef]

- Toric, N.; Glavinic, I.U.; Burgess, I.W. Development of a rheological model for creep strain evolution in steel and aluminium at high temperature. Fire Mater. 2018, 42, 879–888. [Google Scholar] [CrossRef]

- Ma, C.; Hu, B.; Wang, X.G. Triaxial Rheological Mechanism and Creep Model of Mudstone under Complex Stress. ELECTRONIC J. Geotech. Eng. 2016, 21, 2127–2142. [Google Scholar]

- Yang, W.D.; Zhang, Q.Y.; Wang, G. Program implementation of nonlinear rheological model based on yield approach index piecewise function. Rock Soil Mech. 2013, 34, 2629–2637. [Google Scholar]

- Kränkel, T.; Lowke, D.; Gehlen, C. Prediction of the creep behaviour of bonded anchors until failure—A rheological approach. Constr. Build. Mater. 2015, 75, 458–464. [Google Scholar] [CrossRef]

- Hiel, C.C.; Cardon, A.H.; Brinson, R. Viscoelastic Modeling of Epoxy-Resins for Adhesive and Composite Applications. In Proceedings of the 5th International Congress on Experimental Mechanics, Montreal, QC, Canada, 10–14 June 1984; p. 263. [Google Scholar]

- Laederman, H. Elastic and Creep Properties of Filamentous Materials and Other High Polymers; The Textile Foundation: Washington, DC, USA, 1943. [Google Scholar]

- Yi, Z.P.; Wang, L.H.; Zhao, Y.Y. Nonlinear dynamic behaviors of viscoelastic shallow arches. Appl. Math. Mech. 2009, 30, 771–777. [Google Scholar] [CrossRef]

- Fan, L.F.; Wong, L.N.Y.; Ma, G.W. Experimental investigation and modeling of viscoelastic behavior of concrete. Constr. Build. Mater. 2013, 48, 814–821. [Google Scholar] [CrossRef]

- Lévesque, M.; Derrien, K.; Gilchrist, M.D. A micromechanical model for nonlinear viscoelastic particle reinforced polymeric composite materials: Undamaged state 1st International Conference on Composites Testing and Model Identification. Compos. Part A Appl. Sci. Manuf. 2004, 35, 905–913. [Google Scholar] [CrossRef]

- Stanciu, A.; Teodorescu-Draghicescu, H.; Calin, M.R. Mechanical behavior of CSM450 and RT800 laminates subjected to four-point bend tests. Optoelectron. Adv. Mater.-Rapid Commun. 2012, 6, 495–497. [Google Scholar]

- Walrath, D.E. Viscoelastic Response of A Unidirectional Composite Containing 2 Viscoelastic Constituents. Exp. Mech. 1991, 31, 111–117. [Google Scholar] [CrossRef]

- Green, A.E.; Rivlin, R.S. The Mechanics of Nonlinear Materials with Memory, Part I. Arch. Ration. Mech. Anal. 1957, 1, 1–21. [Google Scholar] [CrossRef]

- Green, A.E.; Rivlin, R.S.; Spencer, A.J.M. The Mechanics of Nonlinear Materials with Memory, Part II. Arch. Ration. Mech. Anal. 1959, 3, 82–90. [Google Scholar] [CrossRef]

- Findley, W.N.; Adams, C.H.; Worley, W.J. The Effect of Temperature on the Creep of Two Laminated Plastics as interpreted by the Hyperbolic Sine Law and Activation Energy Theory. ASTM Proc. 1948, 48, 1217–1239. [Google Scholar]

- Findley, W.N.; Khosla, G. Application of the Superposition Principle and Theories of Mechanical Equation of State and Time Hardening to Creep of Plastics under Changing Loads. J. Appl. Phys. 1955, 26, 821–832. [Google Scholar] [CrossRef]

- Schapery, R.A. On the Characterization of a Nonlinear Viscoelastic Materials. Polym. Eng. Sci. 1969, 9, 295–310. [Google Scholar] [CrossRef]

- Schapery, R.A. Further Development of a Thermodynamic Constitutive Stress Formulation; Report No. 69-2; Purdue University: Lafayett, IN, USA, 1969. [Google Scholar]

- Brueller, O.S.; Steiner, H. Creep-Based Characterization of Nonlinear Relaxation Behavior of Plastics. Polym. Eng.Sci. 1993, 33, 1400–1403. [Google Scholar] [CrossRef]

- Aboudi, J. Finite Strain Micromechanical Modeling of Multiphase Composites. Int. J. Multiscale Comput. Eng. 2008, 6, 411–434. [Google Scholar] [CrossRef]

- De Joardar, S.; Neog, A.; Banerjee, S. Micromechanics Based Finite Element Analysis of Effective Elastic Properties of Natural Fiber Reinforced Composites. J. Nat. Fibers 2022, 19, 15790–15807. [Google Scholar] [CrossRef]

- Kim, B.R.; Lee, H.K. An RVE-based micromechanical analysis of fiber-reinforced composites considering fiber size dependency. Compos. Struct. 2009, 90, 418–427. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Xia, Z.H.; Ellyin, F. Nonlinear viscoelastic micromechanical analysis of fibre-reinforced polymer laminates with damage evolution. Int. J. Solids Struct. 2005, 42, 591–604. [Google Scholar] [CrossRef]

- Li, S.G. On the unit cell for micromechanical analysis of fibre-reinforced composites. Proc. R. Soc. A Math. Phys. Eng. Sci. 1999, 455, 815–838. [Google Scholar] [CrossRef]

- Lim, T.C. Micromechanical Models for Auxetic Materials. In Auxetic Materials and Structures; Springer: Singapore, 2015; pp. 45–105. [Google Scholar]

- Ouardi, A.; Boukamel, A.; Damil, N. Towards a macro-chain polymer model using a micromechanical approach. In Proceedings of the 12th European Conference on Constitutive Models For Rubber (Eccmr), Constitutive Models For Rubber Xii, ECCMR 2022, Milano, Italy, 7–9 September 2022; pp. 112–117. [Google Scholar]

- Xu, Z.C.; Shao, X.R.; Huang, Q.B. A micromechanical model of multi-scale nano-reinforced composites. Polym. Test. 2023, 125, 108121. [Google Scholar] [CrossRef]

- Ivancevic, D.; Smojver, I. Explicit multiscale modelling of impact damage on laminated composites—Part I: Validation of the micromechanical model. Compos. Struct. 2016, 145, 248–258. [Google Scholar] [CrossRef]

- Xia, Z.H.; Zhang, Y.F.; Ellyin, F. A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 2003, 40, 1907–1921. [Google Scholar] [CrossRef]

- Massarwa, E.; Aboudi, J.; Haj-Ali, R. A multiscale progressive damage analysis for laminated composite structures using the parametric HFGMC micromechanics. Compos. Struct. 2018, 188, 159–172. [Google Scholar] [CrossRef]

- Arabatti, T.; Parambil, N.K.; Gururaja, S. Micromechanical modeling of damage development in polymer composites. Adv. Compos. Lett. 2016, 25, 56–62. [Google Scholar] [CrossRef]

- Kim, M.J.; Park, J.S. Mechanical Properties Prediction by Geometric Modeling of Plain Weave Composites. J. Korean Soc. Aeronaut. Space Sci. 2016, 44, 941–948. [Google Scholar][Green Version]

- Hosseini, N.; Javid, S.; Karami, G. Micromechanical Viscoelastic Analysis of Flax Fiber Reinforced Bio-Based Polyurethane Composites. J. Renew. Mater. 2015, 3, 205–215. [Google Scholar] [CrossRef]

- Naik, A.; Abolfathi, N.; Ziejewski, M. Micromechanical viscoelastic characterization of fibrous composites. J. Compos. Mater. 2008, 42, 1179–1204. [Google Scholar] [CrossRef]

- Aboudi, J. Micromechanical characterization of the non-linear viscoelastic behavior of resin matrix composites. Compos. Sci. Technol. 1990, 38, 371–386. [Google Scholar] [CrossRef]

- Aboudi, J. Mechanics of Composite Materials—A Unified Micromechanical Approach; Elsevier: Amsterdam, The Netherlands, 1991. [Google Scholar]

- Lin, C.H. Effective properties of 0–3, 1–3, and 2–2 composites based on unified unit-cell micromechanics model. Mech. Res. Commun. 2022, 119, 103807. [Google Scholar] [CrossRef]

- Rao, M.V.P.; Harursampath, D.; Murthy, M.V.V.S. Closed-form asymptotic micromechanics model of fiber reinforced polymer and metal matrix composites. Forces Mech. 2023, 11, 100188. [Google Scholar]

- Yin, S.Z.; He, Z.L.; Pindera, M.J. A new hybrid homogenization theory for periodic composites with random fiber distributions. Compos. Struct. 2021, 269, 113997. [Google Scholar] [CrossRef]

- Bayat, M.; Aghdam, M.M. A micromechanics-based analysis of effects of square and hexagonal fiber arrays in fibrous composites using dqem. Eur. J. Mech. A Solids 2012, 32, 32–40. [Google Scholar] [CrossRef]

- Escarpini, R.D.; Marques, S.P.C. A Model for Homogenization of Linear Viscoelastic Periodic Composite Materials with Imperfect Interface. Lat. Am. J. Solids Struct. 2016, 13, 2406–2435. [Google Scholar] [CrossRef]

- Khafagy, K.H.; Sorini, C.; Chattopadhyay, A. Modeling creep behavior in ceramic matrix composites. Ceram. Int. 2021, 47, 12651–12660. [Google Scholar] [CrossRef]

- Goldberg, R.K.; Almansour, A.S.; Sullivan, R.M. Analytical simulation of the effects of local mechanisms and microstructure on the creep response of unidirectional ceramic matrix composites. J. Eur. Ceram. Soc. 2024, 44, 116710. [Google Scholar] [CrossRef]

- Santhosh, U.; Ahmad, J. Damage in ceramic matrix composites. J. Compos. Mater. 2013, 47, 1257–1272. [Google Scholar] [CrossRef]

- Xu, B.B.; Xu, W.X.; Guo, F.L. Creep behavior due to interface diffusion in unidirectional fiber-reinforced metal matrix composites under general loading conditions: A micromechanics analysis. Acta Mech. 2020, 231, 1321–1335. [Google Scholar] [CrossRef]

- Behzadpoor, H.; Masoumi, S.; Salehi, M. Micromechanical Analysis of Nonlinear Viscoelastic Unidirectional Fiber-Reinforced Composites. Appl. Mech. Mater. 2011, 110–116, 1166–1170. [Google Scholar] [CrossRef]

- Megnis, M.; Varna, J. Micromechanics based modeling of nonlinear viscoplastic response of unidirectional composite. Compos. Sci. Technol. 2003, 63, 19–31. [Google Scholar] [CrossRef]

- Mahmoodi, M.J.; Hassanzadeh-Aghdam, M.K.; Safi, M. Effects of nano-sized silica particles on the off-axis creep performance of unidirectional fiber-reinforced polymer hybrid composites. J. Compos. Mater. 2020, 55, 1575–1589. [Google Scholar] [CrossRef]

- Xu, B.B.; Guo, F.L. A micromechanics method for transverse creep behavior induced by interface diffusion in unidirectional fiber-reinforced metal matrix composites. Int. J. Solids Struct. 2019, 159, 126–134. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Marin, M. Elastic moduli for a rectangular fibers array arrangement in a two phases composite. J. Comput. Appl. Mech. 2024, 55, 538–551. [Google Scholar]

- Kamau-Devers, K.; Miller, S.A. Using a micromechanical viscoelastic creep model to capture multi-phase deterioration in bio-based wood polymer composites exposed to moisture. Constr. Build. Mater. 2022, 314, 125252. [Google Scholar] [CrossRef]

- Salazar, M.A.H. Viscoelastic Performance of Biocomposites. In Composites from Renewable and Sustainable Materials; IntechOpen: London, UK, 2016; pp. 303–331. [Google Scholar]

- Bednarcyk, B.A.; Arnold, S.M. Micromechanics-based deformation and failure prediction for longitudinally reinforced titanium composites. Compos. Sci. Technol. 2001, 61, 705–729. [Google Scholar] [CrossRef]

- Durodola, J.F.; Ruiz, C.; Derby, B. Atrix Composites. Compos. Eng. 1994, 4, 1241–1255. [Google Scholar] [CrossRef]

- Kazanci, M. Carbon fiber reinforced microcomposites in two different epoxies. Polym. Test. 2004, 23, 747–753. [Google Scholar] [CrossRef]

- Xu, B.B.; Lei, T.; Guo, F.L. A Micromechanics Analysis for Creep of Powder Metallurgy Aluminum Alloys with Continuous Precipitation. Int. J. Appl. Mech. 2021, 13, 2150031. [Google Scholar] [CrossRef]

- You, H.; Lim, H.J.; Yun, G.J. A micromechanics-based time-domain viscoelastic constitutive model for particulate composites: Theory and experimental validation. Adv. Aircr. Spacecr. Sci. 2022, 9, 217–242. [Google Scholar]

- Wen, Y.F.; Gibson, R.F.; Sullivan, J.L. Prediction of momentary transverse creep behavior of thermoplastic polymer matrix composites using micromechanical models. J. Compos. Mater. 1997, 31, 2124–2145. [Google Scholar] [CrossRef]

- Chen, C.H.; Chang, Y.H.; Cheng, C.H. Micromechanics and Creep-Behavior of Fiber-Reinforced Polyether-Ether-Ketone Composites. J. Compos. Mater. 1995, 29, 359–371. [Google Scholar] [CrossRef]

- Xu, B.N.; Wei, A.N.; Ye, J.Y.; Sha, W.H.; Guo, F.L. Transverse creep induced by interfacial diffusion in fiber-reinforced composites: A micromechanics model and computational validation. Int. J. Mech. Sci. 1992, 213, 106877. [Google Scholar] [CrossRef]

- Ha, S.K.; Wang, Q.L.; Chang, F.K. Modeling the Viscoplastic Behavior of Fiber-Reinforced Thermoplastic Matrix Composites at Elevated-Temperatures. J. Compos. Mater. 1991, 25, 334–374. [Google Scholar] [CrossRef]

- Dutra, V.F.P.; Maghous, S.; Campos, A.; Pacheco, A.R. A micromechanical approach to elastic and viscoelastic properties of fiber reinforced concrete. Cem. Concr. Res. 2010, 40, 460–472. [Google Scholar] [CrossRef]

- Shajari, A.R.; Ghajar, R.; Shokrieh, M.M. Multiscale modeling of the viscoelastic properties of CNT/polymer nanocomposites, using complex and time-dependent homogenizations. Comput. Mater. Sci. 2018, 142, 395–409. [Google Scholar] [CrossRef]

- Hamza, M.H.; Chattopadhyay, A. Multi deep learning-based stochastic microstructure reconstruction and high-fidelity micromechanics simulation of time-dependent ceramic matrix composite response. Compos. Struct. 2024, 345, 118360. [Google Scholar] [CrossRef]

- Phoenix, S.L. Modeling the statistical lifetime of glass fiber/polymer matrix composites in tension. Compos. Struct. 2000, 48, 19–29. [Google Scholar] [CrossRef]

- Falahatgar, S.R.; Salehi, M.; Aghdam, M.M. Nonlinear Viscoelastic Response of Unidirectional Fiber-Reinforced Composites in Off-Axis Loading. J. Reinf. Plast. Compos. 2009, 28, 1793–1811. [Google Scholar] [CrossRef]

- Scutaru, M.L.; Teodorescu-Draghicescu, H.; Vlase, S.; Marin, M. Advanced HDPE with increased stiffness used for water supply networks. J. Optoelectron. Adv. Mater. 2015, 17, 484–488. [Google Scholar]

- Teodorescu-Draghicescu, H.; Vlase, S.; Calin, M.R. Hysteresis effect in a three-phase polymer matrix composite subjected to static cyclic loadings. Optoelectron. Adv. Mater.-Rapid Commun. 2011, 5, 273–277. [Google Scholar]

- Pintelon, R.; Guillaume, P.; Vanlanduit, S.; De Belder, K.; Rolain, Y. Identification of Young’s modulus from broadband modal analysis experiments. Mech. Syst. Signal Process. 2004, 18, 699–726. [Google Scholar] [CrossRef]

- Hill, R. Theory of Mechanical Properties of Fiber-strengthened Materials: I Elastic Behavior. J. Mech. Phys. Solids 1964, 12, 199–212. [Google Scholar] [CrossRef]

- Hashin, Z. On Elastic Behavior of Fibre Reinforced Materials of Arbitrary Transverse Phase Geometry. J. Mech. Phys. Solids 1965, 13, 119–134. [Google Scholar] [CrossRef]

- Isaac, M.D. Engineering Mechanics of Composite Materials; Oxord Engineering Press: London, UK, 2004. [Google Scholar]

- Hill, R. Continuum Micro-Mechanics of Elastoplastic Polycrystals. J. Mech. Phys. Solids 1965, 13, 89–101. [Google Scholar] [CrossRef]

- Hashin, Z.; Rosen, W.B. The Elastic Moduli of Fiber-Reinforced Materials. J. Appl. Mech. 1964, 31, 223–232. [Google Scholar] [CrossRef]

- Katouzian, M. On the Effect of Temperature on Creep Behavior of Neat and Carbon Fiber Reinorced PEEK and Epoxy- A Micromechanical Approach. Ph.D. Thesis, University of Muenchen, Munich, Germany, 1995. [Google Scholar]

- Hashin, Z.; Shtrikman, S. A Variational Approach to the Theory of the Elastic Behavior of Multiphase Materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Bourmaud, A.; Baley, C. Rigidity analysis of polypropylene/vegetal fibre composites after recycling. Polym. Degrad. Stab. 2009, 94, 297–305. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Marin, M.; Pop, N. Temperature Influence on the Creep Behavior of a Carbon Fiber/Polyetheretherketone Composite. J. Appl. Comput. Mech. 2025, 15, 4206. [Google Scholar] [CrossRef]

- Pham, D.C. Estimations for the overall properties of some locally-ordered composites. Acta Mech. 1997, 121, 177–190. [Google Scholar] [CrossRef]

- Liu, B.; Feng, X.; Zhang, S.M. The effective Young’s modulus of composites beyond the Voigt estimation due to the Poisson effect. Compos. Sci. Technol. 2009, 69, 2198–2204. [Google Scholar] [CrossRef]

- Tokarzewski, S.; Telega, J.J.; Gilewicz, J. A note on total bounds on complex transport moduli of parametric two-phase media. Z. Angew. Math. Phys. 2003, 54, 713–726. [Google Scholar] [CrossRef]

- Sadeghian, E.; Toosi, S. Reliability analysis of a composite laminate using estimation theory. J. Cent. South Univ. 2019, 26, 665–672. [Google Scholar] [CrossRef]

- Engström, C. Bounds on the effective tensor and the structural parameters for anisotropic two-phase composite material. J. Phys. D-Appl. Phys. 2005, 38, 3695–3702. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average Stress in the Matrix and Average Elastic Energy of Materials with Misfitting Inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R Soc. Lond. Ser. A Math. Phys. Sci. 1957, 241, 376–396. [Google Scholar]

- Zhao, Y.H.; Weng, G.J. Effective Elastic Moduli of Ribbon-Reinforced Composites. J. Appl. Mech. 1990, 57, 158–167. [Google Scholar] [CrossRef]

- Lou, Y.C.; Schapery, R.A. Viscoelastic Characterization of a Nonlinear Fiber-Reinforced Plastic. J. Compos. Mater. 1971, 5, 208–234. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Calin, R. Experimental procedures to determine the viscoelastic parameters of laminated composites. J. Optoelectron. Adv. Mater. 2011, 13, 1185–1188. [Google Scholar]

- Chiang, C.R. Bounds on the Transverse Effective Conductivity of a Fiber Reinforced Composite. Int. J. Fract. 2009, 159, 93–100. [Google Scholar] [CrossRef]

- Zhang, Y.; Sikarskie, D.L. Strength prediction of random fiber composite beams using a phenomenological-mechanistic model. J. Compos. Mater. 1999, 33, 1882–1896. [Google Scholar] [CrossRef]

- Liu, X.Y.; Wu, W.; Liang, N.G. Regularity of strain distribution in short-fiber/whisker reinforced composites. Mater. Sci. Res. Int. 2002, 8, 219–224. [Google Scholar] [CrossRef]

- Rossoll, A.; Moser, B.; Mortensen, A. Longitudinal deformation of fibre reinforced metals: Influence of fibre distribution on stiffness and flow stress. Mech. Mater. 2005, 37, 1–17. [Google Scholar] [CrossRef]

- Dong, K.; Liu, K.; Sun, B.Z. Experimental and numerical analyses on the thermal conductive behaviors of carbon fiber/epoxy plain woven composites. Int. J. Heat Mass Transf. 2016, 102, 501–517. [Google Scholar] [CrossRef]

- Tian, W.L.; Qi, L.H.; Zhou, J.M. Numerical evaluation on mechanical properties of short-fiber-reinforced metal matrix composites: Two-step mean-field homogenization procedure. Compos. Struct. 2016, 139, 96–103. [Google Scholar] [CrossRef]

- Thomas, M.P. Creep rupture of [90]8 Sigma fiber reinforced titanium matrix composite. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2001, 303, 30–36. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, H.H.; Yan, Z.G.; Ju, J.W.; Jiang, Z.W.; Wang, Y.Q. A multiphase micromechanical model for hybrid fiber reinforced concrete considering the aggregate and ITZ effects. Constr. Build. Mater. 2016, 114, 839–850. [Google Scholar] [CrossRef]

- Wada, A.; Fukuda, H. Approximate upper and lower bounds for the strength of unidirectional composites. Compos. Sci. Technol. 1999, 59, 89–95. [Google Scholar] [CrossRef]

- Wan, L.; Ismail, Y.; Zhu, C.; Zhu, P.; Sheng, Y.; Liu, J.; Yang, D.M. Computational micromechanics-based prediction of the failure of unidirectional composite lamina subjected to transverse and in-plane shear stress states. J. Compos. Mater. 2020, 54, 3637–3654. [Google Scholar] [CrossRef]

- Hara, E.; Yokozeki, T.; Hatta, H.; Iwahori, Y.; Ishikawa, T. Comparison of out-of-plane tensile moduli of CFRP laminates obtained by 3-point bending and direct loading tests. Compos. Part A Appl. Sci. Manuf. 2014, 67, 77–85. [Google Scholar] [CrossRef]

- Lavergne, F.; Sab, K.; Sanahuja, J.; Bomert, M.; Toulemonde, C. Estimation of creep strain and creep failure of a glass reinforced plastic by semi-analytical methods and 3D numerical simulations. Mech. Mater. 2015, 89, 130–150. [Google Scholar] [CrossRef]

- Schjodt-Thomsen, J.; Pyrz, R. Overall creep modelling of short fibre reinforced composites with weakened interfaces and complex fibre orientation distributions. Mech. Mater. 2000, 32, 349–359. [Google Scholar] [CrossRef]

- Valentová, S.; Sejnoha, M.; Vorel, J. Comparing Mori-Tanaka Method and First-Order Homogenization Scheme in the Viscoelastic Modeling of Unidirectional Fibrous Composites. Acta Polytech. CTU Proc. 2020, 26, 133–138. [Google Scholar] [CrossRef]

- Nguyen, B.N.; Kunc, V.; Bapanapalli, S.K. Creep Modeling for Injection-Molded Long-Fiber Thermoplastics. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, IMECE 2008: Mechanics Of Solids, Structures And Fluids, Boston, MA, USA, 31 October–6 November 2008; Volume 12, pp. 511–516. [Google Scholar]

- Wang, Y.M.; Weng, G.J. The Influence of Inclusion Shape on the Overall Viscoelastic Behavior o Composites. J. Appl. Mech.-Trans. ASME 1992, 59, 510–518. [Google Scholar] [CrossRef]

- Sakaue, K.; Ochiai, M.; Endo, S.; Takaoka, H. Viscoelastic characteristics of short fiber reinforced polybutylene terephthalate. Mech. Time-Depend. Mater. 2020, 24, 317–328. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S. Mori-Tanaka Formalism-Based Method Used to Estimate the Viscoelastic Parameters of Laminated Composites. Polymers 2020, 12, 2481. [Google Scholar] [CrossRef] [PubMed]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos. Part A-Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Li, D.; Hu, G.K. Effective viscoelastic behavior of particulate polymer composites at finite concentration. Appl. Math. Mech.-Engl. Ed. 2007, 28, 297–307. [Google Scholar] [CrossRef]

- Kalamkarov, A.L.; Andrianov, I.V.; Danishevs’kyy, V.V. Asymptotic Homogenization of Composite Materials and Structures. Appl. Mech. Rev. 2009, 62, 030802. [Google Scholar] [CrossRef]

- Schjodt-Thomsen, J.; Pyrz, R. Elastic and creep behaviour of short-fibre composites with weakened interfaces. Key Eng. Mater. 2001, 221–222, 267–280. [Google Scholar] [CrossRef]

- He, L.H.; Lim, C.W. Time-dependent interfacial sliding in fiber composites under longitudinal shear. Compos. Sci. Technol. 2001, 61, 579–584. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials; Taylor & Francis: Boca Raton, FL, USA, 1998. [Google Scholar]

- Wang, Y.M.; Weng, G.J. Transient Creep Strain of a Fiber-Reinforced Metal-Matrix Composite Under Transverse Loading. J. Eng. Mater. Technol.-Trans. ASME 1992, 114, 237–244. [Google Scholar] [CrossRef]

- Wongsto, A.; Li, S. Micromechanical FE analysis of UD fibre-reinforced composites with fibres distributed at random over the transverse cross-section. Compos. Part A-Appl. Sci. Manuf. 2005, 36, 1246–1266. [Google Scholar] [CrossRef]

- Pan, Y.H.; Zhong, Z. Micromechanical modeling of the wood cell wall considering moisture absorption. Compos. Part B-Eng. 2016, 91, 27–35. [Google Scholar] [CrossRef]

- Spilker, K.; Lebensohn, R.A.; Jacobsen, G.; Capolungo, L. A mean field homogenization model for the mechanical response of ceramic matrix composites. Compos. Struct. 2025, 352, 118630. [Google Scholar] [CrossRef]

- Mercier, S.; Molinari, A.; Berbenni, S.; Berveiller, M. Comparison of different homogenization approaches for elastic-viscoplastic materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 024004. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, G.N.; Chen, X.F.; Geng, J. Finite-volume homogenization of elastic/viscoelastic periodic materials. Compos. Struct. 2017, 182, 457–470. [Google Scholar] [CrossRef]

- Wang, X. Nonuniform Interfacial Slip in Fibrous Composites. J. Mech. Mater. Struct. 2009, 4, 107–119. [Google Scholar] [CrossRef]

- Sanchez-Palencia, E. Homogenization method for the study of composite media. In Asymptotic Analysis II Lecture Notes in Mathematics; Verhulst, F., Ed.; Springer: Berlin/Heidelberg, Germany, 1983; Volume 985. [Google Scholar]

- Bugaru, M.; Vasile, O. Modeling and Analysis of FBV Movements for Automotive Driveshafts in the PPR Region. Appl. Sci. 2022, 12, 3237. [Google Scholar] [CrossRef]

- Xu, W.; Nobutada, O. A Homogenization Theory for Time-Dependent Deformation of Composites with Periodic Internal Structures. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 1998, 41, 309–317. [Google Scholar][Green Version]

- Duvaut, G. Homogénéisation des plaques à structure périodique en théorie non linéaire de Von Karman. Lect. Notes Math. 1977, 665, 56–69. [Google Scholar]

- Caillerie, D. Homogénisation d’un corps élastique renforcé par des fibres minces de grande rigidité et réparties périodiquement. Compt. Rend. Acad. Sci. Paris Sér. 1981, 292, 477–480. [Google Scholar]

- Bensoussan, A.; Lions, J.L.; Papanicolaou, G. Asymptotic Analysis for Periodic Structures; American Mathematical Soc.: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Kondo, K.; Takiguchi, R. Finite element analysis of creep in unidirectional composites based on homogenization theory. Adv. Compos. Mater. 2002, 11, 31–39. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S. Creep Response of Carbon-Fiber-Reinforced Composite Using Homogenization Method. Polymers 2021, 13, 867. [Google Scholar] [CrossRef] [PubMed]

- Matsuda, T.; Ohno, N. Predicting the elastic-viscoplastic and creep behaviour of polymer matrix composites using the homogenization theory. In Creep and Fatigue in Polymer Matrix Composites; Woodhead Publishing: Cambridge, UK, 2011; pp. 113–148. [Google Scholar]

- Kim, J.; Muliana, A. Time-dependent and inelastic behaviors of fiber- and particle hybrid composites. Struct. Eng. Mech. 2010, 34, 525–539. [Google Scholar] [CrossRef]

- Lavergne, F.; Sab, K.; Sanahuja, J.; Bornert, M.; Toulemonde, C. An approximate multiscale model for aging viscoelastic materials exhibiting time-dependent Poisson’s ratio. Cem. Cincrete Res. 2016, 86, 42–54. [Google Scholar] [CrossRef]

- Feldman, E.; Aboudi, J. Buckling analysis of functionally graded plates subjected to uniaxial loading. Compos. Struct. 1997, 38, 29–36. [Google Scholar] [CrossRef]

- Bernasconi, A.; Kulin, R.M. Effect of Frequency Upon Fatigue Strength of a Short Glass Fiber Reinforced Polyamide 6: A Superposition Method Based on Cyclic Creep Parameters. Polym.Compos. 2009, 30, 154–161. [Google Scholar] [CrossRef]

- Pedoto, G.; Grandidier, J.C.; Gigliotti, M.; Vinet, A. Assessment and simulation of the thermomechanical tensile and creep behavior of C/PEKK composites for aircraft applications above the glass transition temperature. Compos. Struct. 2023, 318, 117069. [Google Scholar] [CrossRef]

- Marr, J.; Zartmann, L.; Reinel-Bitzer, D.; Andrä, H.; Müller, R. Multiscale optimization of the viscoelastic behavior of short fiber reinforced composites. Int. J. Mech. Mater. Des. 2023, 19, 501–519. [Google Scholar] [CrossRef]

- Kumar, R.; Zafar, S.; Pathak, H.; Subramani, M.; Li, C.; Huang, S.J. Effect of Stress Ratio and Loading Inclination on the Fatigue Life of Carbon-Fiber-Reinforced Polymer Composites: Multiscale Analysis Approach. J. Compos. Sci. 2023, 7, 406. [Google Scholar] [CrossRef]

- Cruz-González, O.L.; Ramirez-Torres, A.; Rodríguez-Ramos, R.; Otero, J.A.; Penta, R.; Lebon, F. Effective behavior of long and short fiber-reinforced viscoelastic composites. Appl. Eng. Sci. 2021, 6, 100037. [Google Scholar] [CrossRef]

- Courtois, A.; Marcin, L.; Benavente, M.; Ruiz, E.; Lévesque, M. Numerical multiscale homogenization approach for linearly viscoelastic 3D interlock woven composites. Int. J. Solids Struct. 2019, 163, 61–74. [Google Scholar] [CrossRef]

- Navrátil, L.; Leveuf, L.; Le Saux, V.; Marco, Y.; Olhagaray, J.; Leclercq, S.; Moyne, S.; Le Saux, M. A model to describe the cyclic anisotropic mechanical behavior of short fiber-reinforced thermoplastics. Mech. Time-Depend. Mater. 2020, 24, 481–503. [Google Scholar] [CrossRef]

- Wang, Y.C.; Huang, Z.M. Analytical Micromechanics Models for Elastoplastic Behavior of Long Fibrous Composites: A Critical Review and Comparative Study. Materials 2018, 11, 1919. [Google Scholar] [CrossRef] [PubMed]

- Carrere, N.; Valle, R.; Bretheau, T.; Chaboche, J.L. Multiscale analysis of the transverse properties of Ti-based matrix composites reinforced by SiC fibres: From the grain scale to the macroscopic scale. Int. J. Plast. 2004, 20, 783–810. [Google Scholar] [CrossRef]

- Rodríguez-Ramos, R.; Otero, J.A.; Cruz-González, O.L.; Guinovart-Díaz, R.; Bravo-Castillero, J.; Sabina, F.J.; Padilla, P.; Lebon, F.; Sevostianov, I. Computation of the relaxation effective moduli for fibrous viscoelastic composites using the asymptotic homogenization method. Int. J. Solids Struct. 2020, 190, 281–290. [Google Scholar] [CrossRef]

- Seidel, G.D.; Lagoudas, D.C. Micromechanical analysis of the effective elastic properties of carbon nanotube reinforced composites. Mech. Mater. 2006, 38, 884–907. [Google Scholar] [CrossRef]

- Ishfaq, K.; Asad, M.; Muhammad Harris, M.; Alfaify, A.; Saqib, A.; Luciano Lamberti, L.; Scutaru, M.L. EDM of Ti-6Al-4V under Nano-Graphene Mixed Dielectric: A Detailed Investigation on Axial and Radial Dimensional Overcuts. Nanomaterials 2022, 12, 432. [Google Scholar] [CrossRef]

- Cheng, C.; Aravas, N. Creep of metal-matrix composites with elastic fibers—1. Continuous aligned fibers. Int. J. Solids Struct. 1997, 34, 4147–4171. [Google Scholar] [CrossRef]

- Sosa-Rey, F.; Lingua, A.; Piccirelli, N.; Therriault, D.; Lévesque, M. Thermo-viscoelastic multiscale homogenization of additively manufactured short fiber reinforced polymers from direct microstructure characterization. Int. J. If Solids Struct. 2023, 281, 112421. [Google Scholar] [CrossRef]

- Otero, J.A.; Rodríguez-Ramos, R.; Guinovart-Díaz, R.; Cruz-González, O.L.; Sabina, F.J.; Berger, H.; Böhlke, T. Asymptotic and numerical homogenization methods applied to fibrous viscoelastic composites using Prony’s series. Acta Mech. 2020, 231, 2761–2771. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Marin, M.; Scutaru, M.L. Calculation of Homogenized Mechanical Coefficients of Fiber-Reinforced Composite Using Finite Element Method. Materials 2024, 17, 1334. [Google Scholar] [CrossRef]

- Gheorghe, V.; Scutaru, M.L.; Ungureanu, V.; Chircan, E.; Ulea, M. New Design of Composite Structures Used in Automotive Engineering. Symmetry 2021, 13, 383. [Google Scholar] [CrossRef]

- Köbler, J.; Schneider, M.; Ospald, F.; Andrä, H.; Müller, R. Fiber orientation interpolation for the multiscale analysis of short fiber reinforced composite parts. Comput. Mech. 2018, 61, 729–750. [Google Scholar] [CrossRef]

- Available online: https://www.ensingerplastics.com/en/shapes/pa66-tecamid-66-natural (accessed on 19 June 2025).

- Reinaldo, A.; Javier, M.; Pablo, S. Multiscale formulation for saturated porous media preserving the representative volume element size objectivity. Int. J. Numer. Methods Eng. 2024, 125, e7381. [Google Scholar] [CrossRef]

- Khoei, A.R.; Saeedmonir, S. Computational homogenization of fully coupled multiphase flow in deformable porous media. Comput. Methods Appl. Mech. Eng. 2021, 376, 113660. [Google Scholar] [CrossRef]

- Saeedmonir, S.; Khoei, A.R. Multiscale modeling of coupled thermo-hydro-mechanical analysis of heterogeneous porous media. Comput. Methods Appl. Mech. Eng. 2022, 391, 114518. [Google Scholar] [CrossRef]

- Pei, Q.X.; Li, F.; Fei, Z.H.; Lian, H.J.; Yuan, X.H. A DFE2-SPCE Method for Multiscale Parametric Analysis of Heterogenous Piezoelectric Materials and Structures. CMC-Comput. Mater. Contin. 2025, 83, 79–96. [Google Scholar]

- Dey, A.P.; Welschinger, F.; Schneider, M.; Gajek, S.; Böhlke, T. Rapid inverse calibration of a multiscale model for the viscoplastic and creep behavior of short fiber-reinforced thermoplastics based on Deep Material Networks. Int. J. Plast. 2023, 160, 103484. [Google Scholar] [CrossRef]

- Bourgogne, Q.C.P.; Bouchart, V.; Chevrier, P.; Dinzart, F. On the thermo-visco-elastic behavior of neat and aged PPS composites. Int. J. Mech. Sci. 2024, 284, 109761. [Google Scholar] [CrossRef]

- Aboudi, J. Micromechanics-based thermoviscoelastic constitutive equations for rubber-like matrix composites at finite strains. Int. J. Solids Struct. 2024, 41, 5611–5629. [Google Scholar] [CrossRef]

- Launay, A.; Maitournam, M.H.; Marco, Y.; Raoult, I. Multiaxial fatigue models for short glass fiber reinforced polyamide—Part I: Nonlinear anisotropic constitutive behavior for cyclic response. Int. J. Fatigue 2013, 47, 382–389. [Google Scholar] [CrossRef]

- Klasztorny, M.; Niezgoda, T. Viscoelastic Modeling of Regular Cross-Ply Laminates. Compos. Theory Pract. 2009, 9, 223–227. [Google Scholar]

- Fanara, A.; Courard, L.; Collin, F. Numerical FE2 study of chloride ingress in unsaturated recycled aggregates concrete. Cem. Concr. Res. 2024, 186, 107703. [Google Scholar] [CrossRef]

- Marinelli, F.; van den Eijnden, A.P.; Collin, F. Modeling of granular solids with computational homogenization: Comparison with Biot’s theory. Finite Elem. Anal. Des. 2016, 119, 45–62. [Google Scholar] [CrossRef]

- Omprakasam, S.; Karthick, N.; Althaf, M. Numerical and Experimental Evaluation and Investigation on Banana Fibre Reinforced Epoxy Composites; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2025. [Google Scholar] [CrossRef]

- Marin, M.; Chirila, A.; Öchsner, A.; Vlase, S. About finite energy solutions in thermoelasticity of micropolar bodies with voids. Bound. Value Probl. 2019, 2019, 89. [Google Scholar] [CrossRef]

- Brinson, L.C.; Knauss, W.G. Finite Element Analysis of Multiphase Viscoelastic Solids. J. Appl. Mech. 1992, 59, 730–737. [Google Scholar] [CrossRef]

- Öchsner, A.; Merkel, M. One-Dimensional Finite Elements—An Introduction to the FE Method; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Schaffer, B.G.; Adams, D.F. Nonlinear Viscoelastic Behavior of a Composite Material Using a Finite Element Micrimechanical Analysis; Defense Technical Information Center: Ft. Belvoir, VA, USA, 1980. [Google Scholar]

- Chandra, R.; Singh, S.P.; Gupta, K. Damping studies in fiber-reinforced composites—A review. Compos.Struct. 1999, 46, 41–51. [Google Scholar] [CrossRef]

- Moser, K. Fase-Kunststoff-Verbund, Entwurfs- und Berechnungsgrundlagen, VDI-Verlag; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Teodorescu-Draghicescu, H; Stanciu, A; Vlase, S; Scutaru, M.L.; Calin, M.R.; Serbina, L. Finite element method analysis of some fibre-reinforced composite laminates. Optoelectron. Adv. Mater. RapidCommun. 2011, 5, 782–785.

- Purcarea, R.; Motoc, D.L.; Scutaru, M.L. Mechanical behavior of a thin nonwoven polyester mat subjected to three-point bend tests. Optoelectron. Adv. Mater. RapidCommun. 2012, 6, 214–217. [Google Scholar]

- Safaei, B.; Fattahi, A.M.; Chu, F.L. Finite element study on elastic transition in platelet reinforced composites. Microsyst. Technol.-Micro-Nanosyst.-Inf. Storage Process. Syst. 2018, 24, 2663–2671. [Google Scholar] [CrossRef]

- Yazdchi, K.; Srivastava, S.; Luding, S. Micro-macro relations for flow through random arrays of cylinder. Compos. Part A Appl. Sci. Manuacturing 2012, 43, 2007–2020. [Google Scholar] [CrossRef]

- Katouzian, M.; Vlase, S.; Scutaru, M.L. Finite Element Method-Based Simulation Creep Behavior of Viscoelastic Carbon-Fiber Composite. Polymers 2021, 13, 1017. [Google Scholar] [CrossRef] [PubMed]

- Mondali, M.; Abedian, A.; Ghavami, A. A new analytical shear-lag based model for prediction of the steady state creep deformations of some short fiber composites. Mater. Des. 2009, 30, 1075–1084. [Google Scholar] [CrossRef]

- Mondali, M.; Abedian, A.; Adibnazari, S. FEM study of the second stage creep behavior of Al6061/SiC metal matrix composite. Comput. Mater. Sci. 2005, 34, 140–150. [Google Scholar] [CrossRef]

- Monfared, V.; Mondali, M. Semi-analytically presenting the creep strain rate and quasi shear-lag model as well as finite element method prediction of creep debonding in short fiber composites. Mater. Des. 2014, 54, 368–374. [Google Scholar] [CrossRef]

- Gao, X.P.; Wang, L.P. Finite Element Modelling for Tensile Behaviour of Thermally Bonded Nonwoven Fabri. Autex Res. J. 2015, 15, 48–53. [Google Scholar] [CrossRef]

- Abedian, A.; Szyszkowski, W.; Yannacopoulos, S. Analysis of creep effects on the residual stress in SCS-6/Ti-6Al-4V composites using FEM. J. Therm. Stress. 2001, 24, 1–17. [Google Scholar]

- Jianmin, H.; Cao, Z.; Zhang, Y.; Hu, Y. Designing Bouligand-inspired reinforcement for creating wood fibre-reinforced composites with excellent bending properties. Polym. Compos. 2025; ahead of print. [Google Scholar] [CrossRef]

- Yahyaei-Moayyed, M.; Taheri, F. Creep response of glued-laminated beam reinforced with pre-stressed sub-laminated composite. Constr. Build. Mater. 2011, 25, 2495–2506. [Google Scholar] [CrossRef]

- Ganguly, P.; Poole, W.J. In situ measurement of reinforcement stress in an aluminum-alumina metal matrix composite under compressive loading. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 352, 46–54. [Google Scholar] [CrossRef]

- Teodorescu-Draghicescu, H.; Scutaru, M.L.; Rosu, D.; Calin, M.R.; Grigore, P. New Advanced Sandwich Composite with twill weave carbon and EPS. J. Optoelectron. Adv.Mater. 2013, 15, 199–203. [Google Scholar]

- Smirnov, A.S.; Smirnova, E.O.; Vichuzhanin, D.I.; Khudorozhkova, Y.V.; Spirina, I.A.; Kanakin, V.; Muizemnek, O.Y. Determining the Elastic Constants and Thickness of the Interphase in Fibreglass Plastic Composites from Micromechanical and Macromechanical Tests. J. Compos. Sci. 2025, 9, 54. [Google Scholar] [CrossRef]

- Morcous, G.; Cho, Y.; El-Safty, A.; Chen, G.M. Structural behavior of FRP sandwich panels for bridge decks. KSCE J. Civ. Eng. 2010, 14, 879–888. [Google Scholar] [CrossRef]

- Zhang, L.; Ernst, L.J.; Brouwer, H.R. Transverse behaviour of a unidirectional composite (glass fibre reinforced unsaturated polyester) Part I. Influence of fibre packing geometry. Mech. Mater. 1998, 27, 13–36. [Google Scholar] [CrossRef]

- Joo, J.-H.; Kim, S.-H.; Yim, Y.-J.; Bae, J.-S.; Seo, M.-K. Interfacial Interlocking of Carbon Fibre-Reinforced Polymer Composites: A Short Review. Polymers 2025, 17, 267. [Google Scholar] [CrossRef] [PubMed]

- Monfared, V.; Daneshmand, S.; Reddy, J.N. Rate dependent plastic deformation analysis of creeping short fiber composites using the virtual fiber method in the non-reinforced regions. J. Comput. Sci. 2015, 10, 26–35. [Google Scholar] [CrossRef]

- Yue, Z.F.; Lu, Z.Z. A numerical determination of the fiber/matrix interlayer creep properties from the indentation creep testing in fiber reinforced composites. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 352, 266–272. [Google Scholar] [CrossRef]

- Xu, D.; Schmauder, S.; Soppa, E. Influence of geometry factors on the mechanical behavior of particle- and fiber-reinforced composites. Comput. Mater. Sci. 1999, 15, 295–301. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modeling of short fiber reinforced polymer composites: A literature review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- Mondali, M.; Monfared, V.; Abedian, A. Non-linear creep modeling of short-fiber composites using Hermite polynomials, hyperbolic trigonometric functions and power series. Comptes Rendus Mec. 2013, 341, 592–604. [Google Scholar] [CrossRef]

- Monfared, V. A displacement based model to determine the steady state creep strain rate of short fiber composites. Compos. Sci. Technol. 2015, 107, 18–28. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A.; Yang, X. Short- and long-term properties of glass fiber reinforced asphalt mixtures. Int. J. Pavement Eng. 2021, 22, 64–76. [Google Scholar] [CrossRef]

- Hinterhoelzl, R.M. Coupling the theory of viscoelasticity and continuum damage mechanics to model the time dependent behavior of fiber reinforced plastics and particulate composites. 6th ISSAT International Conference on Reliability and Quality in Design. Int. J. Mater. Prod. Technol. 2002, 17, 121–133. [Google Scholar] [CrossRef]

- Kaleel, I.; Pineda, E.J.; Bednarcyk, B.A. Micromechanical modeling of discontinuous long fibre reinforced composites. Mech. Adv. Mater. Struct. 2024, 32, 596–604. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katouzian, M.; Vlase, S. A Review of the Methods Used in the Study of Creep Behavior of Fiber-Reinforced Composites and Future Developments. Appl. Sci. 2025, 15, 7265. https://doi.org/10.3390/app15137265

Katouzian M, Vlase S. A Review of the Methods Used in the Study of Creep Behavior of Fiber-Reinforced Composites and Future Developments. Applied Sciences. 2025; 15(13):7265. https://doi.org/10.3390/app15137265

Chicago/Turabian StyleKatouzian, Mostafa, and Sorin Vlase. 2025. "A Review of the Methods Used in the Study of Creep Behavior of Fiber-Reinforced Composites and Future Developments" Applied Sciences 15, no. 13: 7265. https://doi.org/10.3390/app15137265

APA StyleKatouzian, M., & Vlase, S. (2025). A Review of the Methods Used in the Study of Creep Behavior of Fiber-Reinforced Composites and Future Developments. Applied Sciences, 15(13), 7265. https://doi.org/10.3390/app15137265