1. Introduction

In the context of sustainable development and efficient waste management, incorporating recycled materials [

1,

2,

3] into cementitious compositions has gained significant attention. Among these, tire rubber waste is recognized for its potential to enhance toughness, energy absorption, and thermal properties, despite some reduction in compressive strength. The feasibility and challenges of using rubberized mortars have been demonstrated in previous studies [

4,

5]. On the other hand, Nuclear Magnetic Resonance (NMR) [

6] is an emerging tool in construction material analysis. Although NMR has been employed in cementitious material research for several decades, its recent applications benefit from enhanced precision and data interpretation capabilities. The capability of NMR techniques to reveal hydration dynamics, pore connectivity, and water mobility has been demonstrated in recent studies [

7,

8]. Despite these advances, the combined use of NMR to evaluate mortars modified with recycled tire rubber and organic additives [

9] such as casein or latex remains limited. This paper addresses this gap, applying NMR to explore microstructural evolution in eco-friendly mortars designed for animal housing applications, contributing both to sustainable construction and animal welfare.

Pertaining to current European and global environmental strategies promoting sustainable development in construction materials [

10], the integration of industrial waste materials as natural or synthetic polymers [

11,

12] into cementitious compositions represents an innovative research direction. Among environmentally detrimental waste materials [

13], end-of-life tires hold particular significance due to their substantial global annual accumulation and non-biodegradable nature [

14,

15]. NMR applications in cementitious materials have been reported for tracking cement hydration by Zhao et al. [

16] and for analyzing porosity, water distribution in fractured rocks, and predicting durability based on NMR parameters by Munsch et al. [

8].

The current study focuses on the relatively underexplored application of NMR in rubberized mortars, especially in the context of screed layers for livestock flooring [

17], where the balance between resilience and hygiene is crucial. This practical need in agricultural engineering motivated the development of durable, moderately elastic flooring [

18] solutions using recycled rubber components and investigating its hydration process [

19].

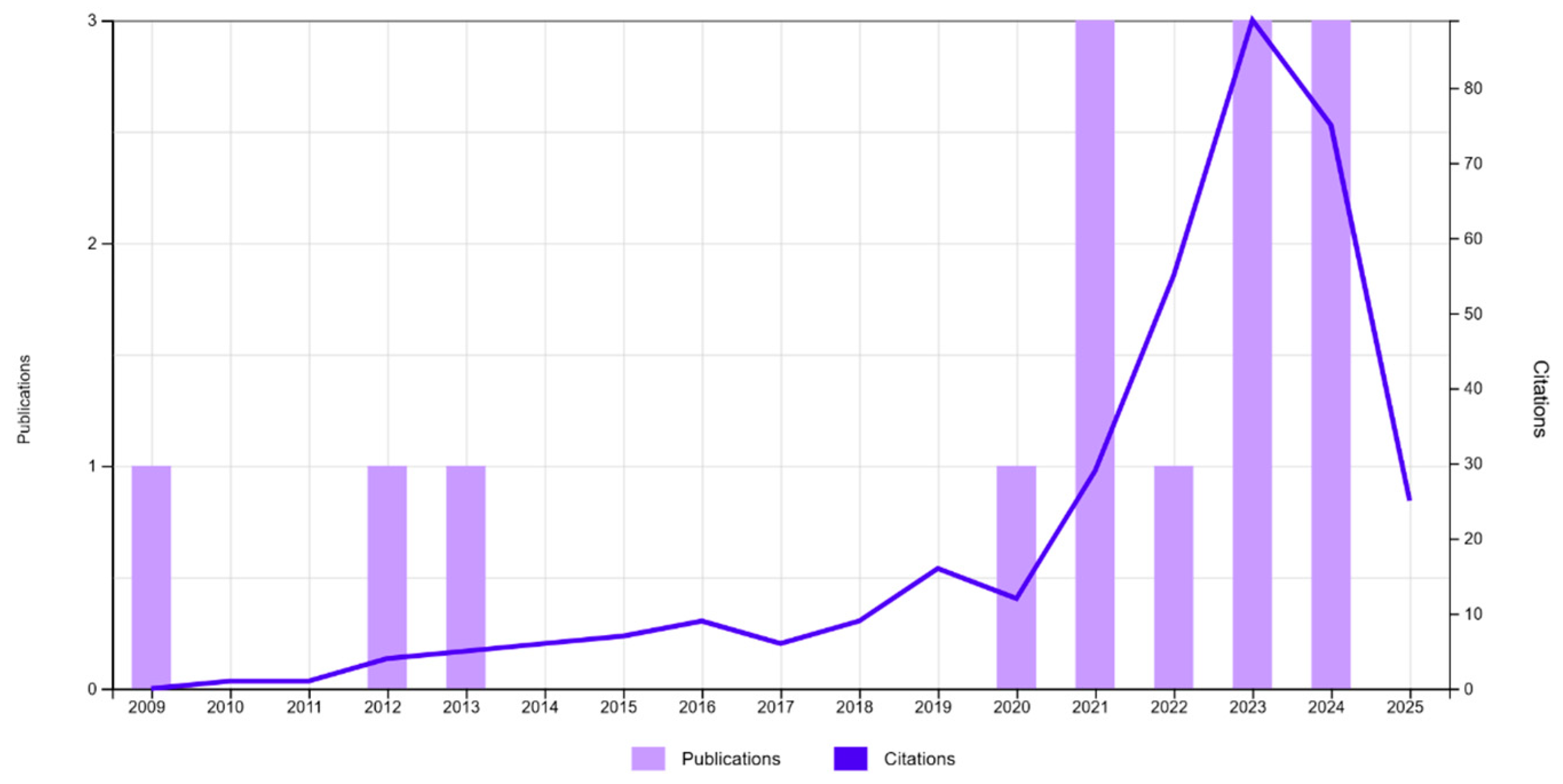

Recent specialized studies have extensively investigated the potential incorporation of waste tire rubber as aggregate in cementitious products such as mortars and plain concrete. A Web of Science (WOS) analysis of indexed publications reveals a marked increase in research activity focusing on rubberized mortars and concrete in recent years. As illustrated in

Figure 1, the keyword search “cement mortar with rubber granules” demonstrates particularly heightened research interest during 2021, 2023, and 2024 (with 2024 data currently undergoing updates).

For the integration of rubber tire waste into the cementitious matrix of mortars or concrete, the waste is processed into granules or flakes, which can provide benefits such as increased tensile strength through bending, superior impact resistance and improved thermal insulation [

20]. However, the incorporation of these rubber granules into the cementitious matrix can also lead to negative effects on mortars or concretes, such as a reduction in compressive strength [

21] and an increase in porosity, which may influence the long-term durability of construction elements.

In this regard, NMR (Nuclear Magnetic Resonance) has been used as an advanced and non-destructive technique for the analysis and characterization of cementitious materials. Through relaxometry and NMR spectroscopy, detailed information is obtained about the degree of hydration, the type and distribution of water within the structure and the pore size of the cementitious material, making it a valuable analysis for characterizing durability and physical-mechanical performance, as well as the long-term durability of the materials.

Although NMR is widely used in fields such as medicine or chemical material characterization, its application in the analysis of mortars containing rubber granules [

5] in their composition is still limited, particularly in the design of screed compositions for use in livestock farms.

The aim of this article is to highlight the applicability of the NMR method [

8,

22] in the characterization of mortars containing rubber granules [

23] derived from tire recycling, focusing on the influence of various additives (casein, natural hydraulic lime, latex) on the hydration mechanism, porosity and water distribution within the cementitious matrix. By analyzing the relaxation times T

1 and T

2 at different curing ages of mortar samples, this article seeks to highlight the microstructural evolution of these materials and provide a scientific basis for the optimized use of these mortars in the construction of durable structures [

7].

This research aims to contribute to the development of the circular economy in the construction industry by offering new perspectives on the reuse of processed waste tires [

24] in the form of granules for the creation of flooring used in agricultural farms, with a beneficial impact on animal welfare [

25].

2. Materials and Methods

The mortar mixtures were prepared using CEM I 42.5 R cement, natural hydraulic lime (NHL 3.5 or NHL 5) (EN 459-1) [

26], standardized silica sand (EN 196-1) [

27], potable tap water, food-grade casein powder, commercial latex emulsion (SBR type), and recycled SBR rubber flakes [

28,

29,

30,

31], (1–3 mm, no surface pretreatment). Mix proportions were expressed as percentages relative to the cement mass, and a w/b ratio of 0.50 was maintained. Samples were cast in 40 mm × 40 mm × 160 mm molds, demolded after 24 h, and cured in a humidity chamber (20 °C, RH > 95%). Mechanical tests followed EN 196-1 and EN 1015 series standards [

32]. For NMR analysis, samples were broken into 5–8 mm fragments to fit into 18 mm diameter tubes, with approximately 10 g of material per sample. Samples were conditioned at room temperature (20 ± 2 °C) for 24 h prior to analysis. NMR tests used a Bruker Minispec MQ20 (Bruker, Billerica, MA, USA) at 20 MHz with CPMG sequence (100 μs echo time, 1024 echoes, 64 averages). T

2 relaxation times were determined using CONTIN 3.0 with regularization parameter λ = 0.01. To reduce noise interference, thresholding was applied based on a 5% signal-to-noise ratio. Measurements were performed on three samples per formulation, and average values were reported. The persistent T

2 peak around 30–40 ms observed at 28 days is attributed to contributions from

1H nuclei in organic compounds such as casein and rubber additives, which do not fully integrate into the cement matrix.

Additionally, the experimental program also incorporated more advanced research methods, which we aim to highlight in this article. Specifically, Nuclear Magnetic Resonance (NMR) tests were conducted. Exceptional samples and results obtained from the construction materials laboratory were subjected to further advanced testing to explain the time-dependent behavior of the newly developed materials and their performance compared to the reference mixture.

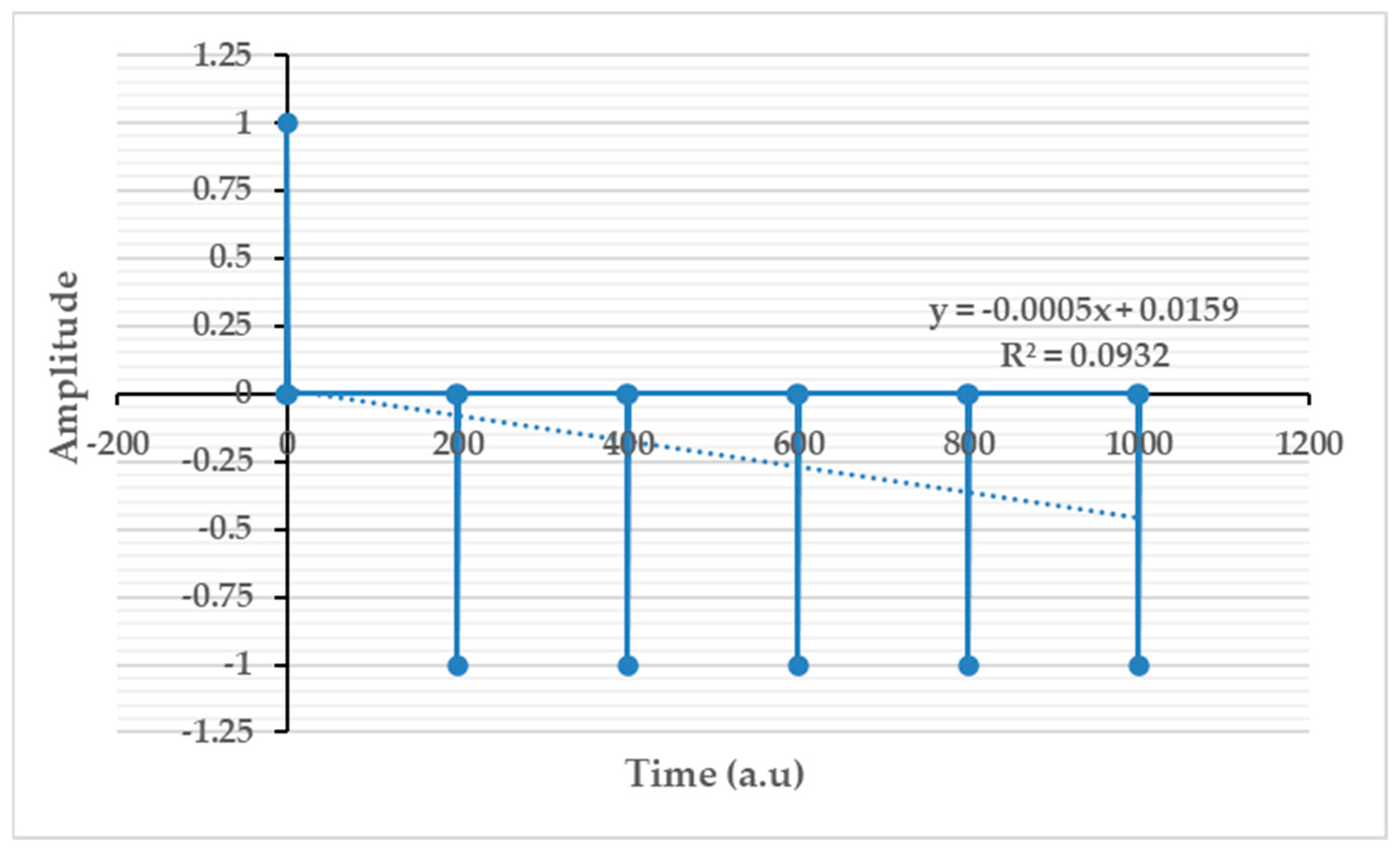

Also, the transverse relaxation measurements were conducted using the widely recognized Carr–Purcell–Meiboom–Gill (CPMG) method. The below figure illustrates the radiofrequency pulse sequence, and the corresponding echo train obtained during the experiment. A key benefit of this multiple-echo approach is its rapid acquisition, enabling repeated signal averaging—a crucial factor in enhancing detection sensitivity, particularly in low-field experiments. When the CPMG decay curve (

Figure 2) follows a mono-exponential trend and diffusion effects are negligible over the intervals *s*, the transverse relaxation time (T

2) of the sample can be determined by fitting the data to the Equation (1):

where

An is the amplitude of the

n-th echo,

A0 is a constant depending on magnetization and filling factor,

is the time between echoes, and

T2 is the transverse relaxation time. To assess potential diffusion effects on echo decay, experiments with varying echo times can be performed. However, if the relaxation time varies across the sample due to heterogeneity or differences in surface relaxivity—as often occurs in liquids confined within porous mortars—the CPMG decay curve is expected to exhibit a multi-exponential behavior.

Here’s the graph of the CPMG (

Figure 3) pulse sequence showing the initial 90° pulse in the blue spike, followed by a series of 180° pulses, illustrated in the red dashed spikes, appearing at regular intervals, decreasing in amplitude to mimic T

2 relaxation.

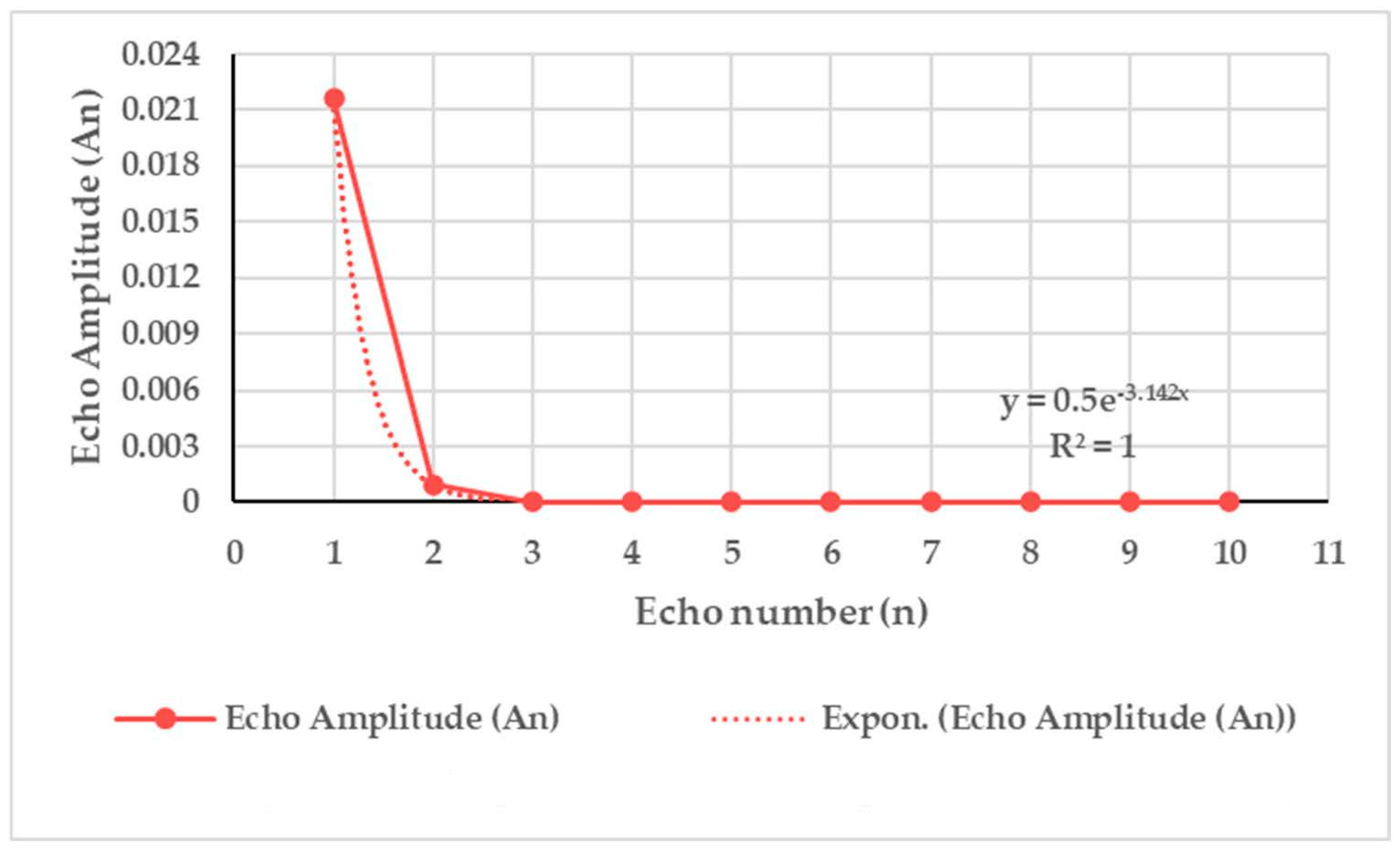

Here’s the graph of echo amplitude decay based on Equation (1).

Table 1 presents the measured echo amplitudes corresponding to different echo numbers.

Assuming the sample contains a continuous distribution of relaxation times, the amplitude of the

n-th echo in the echo train is given by the following expression:

where:

- -

represents the NMR signal measured at t;

- -

is the initial amplitude of the signal;

- -

is the probability density distribution of relaxation times T2;

- -

exp(−2n/T2) is the exponential decay function associated with each component T2.

In the framework of NMR applied to the mortar, the signal obtained as a function of time can be described by a superposition of exponential components, each associated with a transverse relaxation constant T2.

This Equation (2) allows information related to the distribution of porosity and moisture from the mortar structure to be extracted. Each value T2 is influenced by the size and connectivity of the pores, as well as the interactions between water molecules and the solid matrix. By inverting this transformation (usually by numerical methods), a distribution is obtained P(T2), which directly reflects the microstructural characteristics of the mortar under study.

This expression indicates that analyzing the experimental data using a Laplace inversion algorithm can reveal the distribution of relaxation times within the sample. One well-established and widely used algorithm for this purpose is CONTIN, which was also involved in our study. However, it is important to note that numerical Laplace inversion is an ill-posed problem. For a given CPMG decay curve, multiple combinations of characteristic relaxation times may produce equally good fits. This ambiguity becomes particularly significant in measurements affected by noise, potentially leading to large distortions in the inferred relaxation time distributions. As a result, inverse Laplace transforms must be applied with caution when interpreting experimental data.

Nuclear Magnetic Resonance, hereinafter referred to as NMR, is one of the most inherent techniques for investigating matter. The NMR technique is widely renowned for its applicability in medicine, but it is also successfully used in engineering for the study of liquids, solids, and gases, apart from plasma.

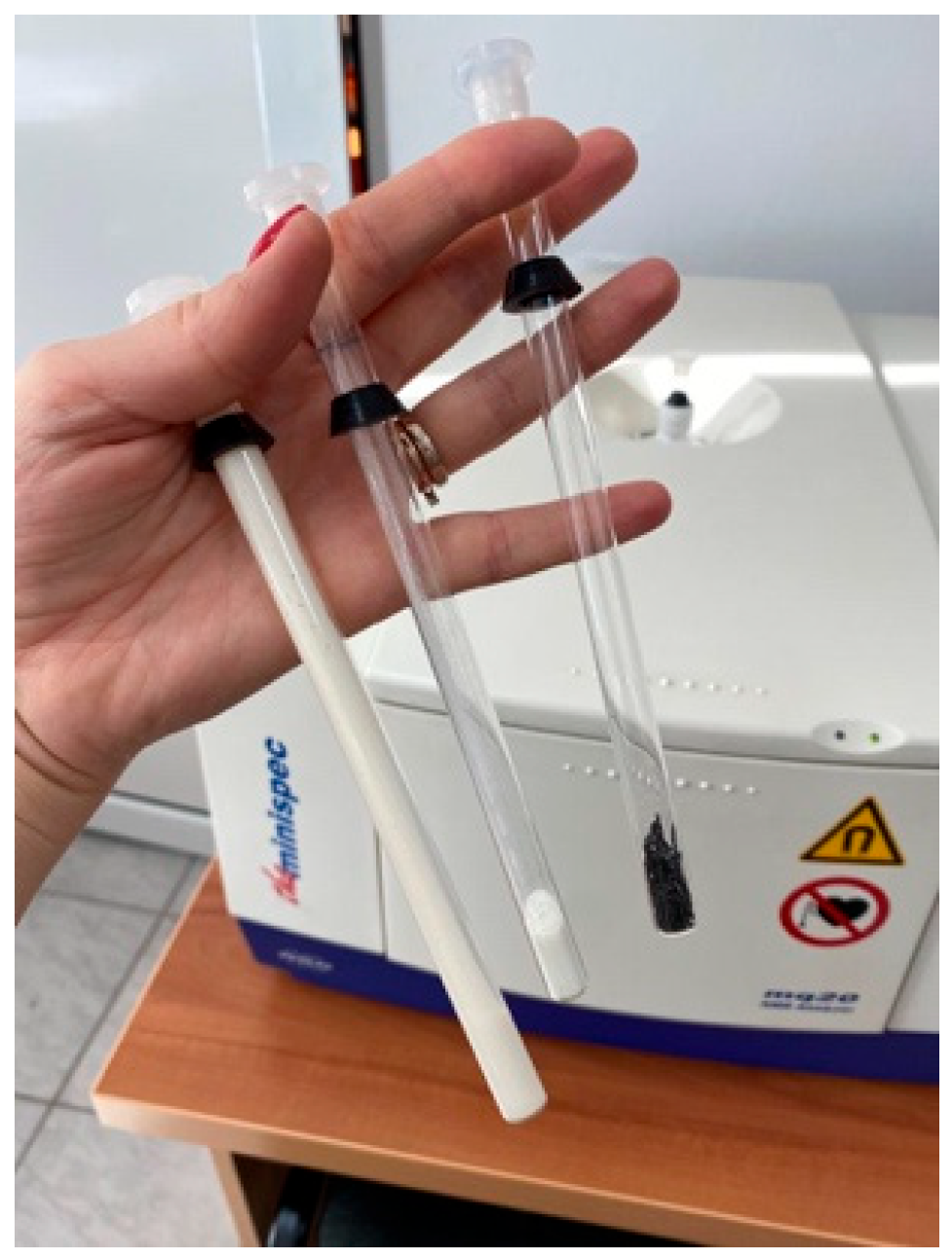

A very important and defining factor in the study of matter investigation techniques and in the choice of the research method, is the fact that the Nuclear Magnetic Resonance technique does not destroy the samples. Thus, this innovative technique is non-destructive and completely non-invasive. The most well-known application of Nuclear Magnetic Resonance is undoubtedly in medicine, where it is known. This method is widely used for detecting various forms of cancer or identifying atypical formations that could cause health problems. We will analyze how we quantify relaxation times and diffusion coefficients using the NMR method. This study will indicate the migration and dynamics of matter molecules and the interaction between the pores of the material under study. When discussing relaxation time, identified as T

2, and refer to the pore distribution in the material placed in the test tube, 1H NMR indicates the level of fluid content in the sample. To determine these characteristics, the Bruker Minispec spectrometer was used, which operates on the principle of relaxometry in low fields. Thus, the pore size in the studied material is indicated by the relaxation time T

2, corresponding to the longitudinal and transverse NMR relaxation times. The samples were prepared for analysis by breaking them into smaller pieces than the diameter of the test tubes, so they could be inserted into the tubes and subsequently into the Bruker Minispec (

Figure 4) device. The differences in color reflect the varying compositions of the mortar samples (

Figure 5 and

Figure 6). For instance, formulations containing latex (MV5F5%L5%) display lighter coloration, while those with casein or no latex appear darker due to organic content differences (

Figure 7 and

Figure 8). These variations are consistent with material differences and do not affect the comparability of the NMR analyses.

To address these needs, the process of developing optimized and improved mortar screed formulations was initiated: a mortar screed that is durable and as environmentally friendly as possible [

33,

34].

The formulations investigated, as noted in

Table 2, are coded as follows: MC2%F2%, MV3F5% and MV5F5%L5%.

3. Results and Discussion

By analyzing the distribution of transverse relaxation times T2, valuable information can be obtained about pore structure, pore size distribution, and fluid dynamics within the material.

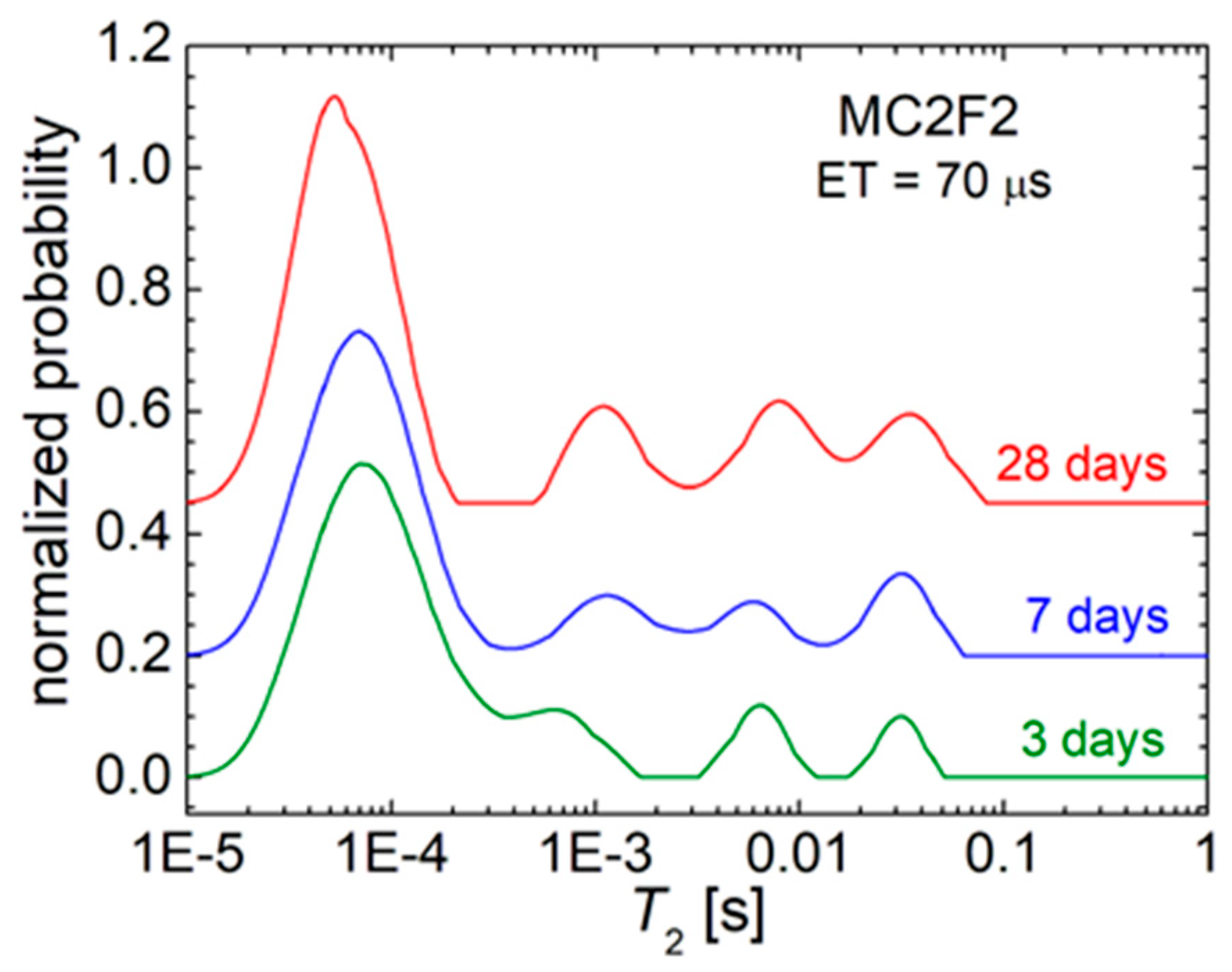

The T

2 relaxation time distributions for the casein-modified [

35] (2%) and rubber-flake-containing (2%) screed mortar (with partial cement replacement) are presented in

Figure 9.

The distributions were measured at 3, 7, and 28 days, as shown in

Figure 10. Four distinct peaks are observed, which can be associated with water bound to cement components.

The peaks with larger integrated areas are located at T2 values below 100 μs. Additionally, at all three testing ages, smaller peaks appear at approximately 1 ms, 7 ms, and 30–40 ms. These correspond to: the smallest peak (~1 ms) representing water in very small pores, the 7–8 ms peak indicating medium-sized pores, and the 20–30 ms peak corresponding to medium-to-large pores. The T2 distributions for this 2% casein/2% rubber flake mortar sample remain relatively similar across curing times, suggesting the mortar structure becomes well-established in as early as 3 days. Minor evolution is observed at 7 and 28 days, with a noticeable shift of the T2 maximum: from 600–700 μs at 3 days to 400–500 μs at later ages. This shift indicates sample hardening. At 3 days, the bound water and small pore water peaks overlap, revealing expected sample heterogeneity at early ages. By 28 days, all peaks become well-resolved, demonstrating: hydration water incorporation into rigid components, distinct formation and separation of small and medium-to-large pores and most of the water existing as hydration water.

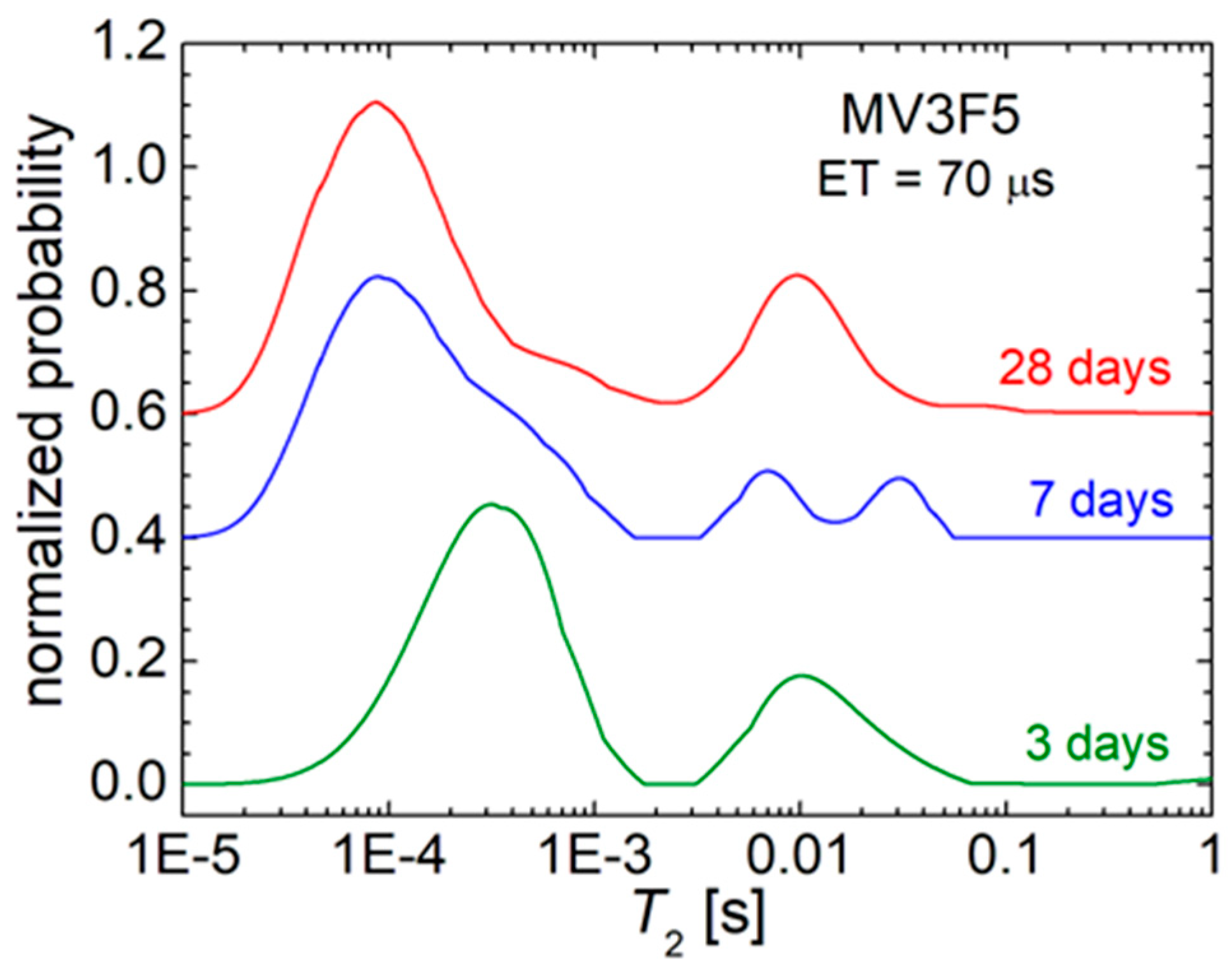

The distributions of measured relaxation times for the lime mortar sample with 3% and 5% rubber flakes are presented in

Figure 11. In this case, a dramatic evolution is observed for the samples measured at 3, 7, and 28 days. Thus, at 3 days after preparation, the appearance of two peaks is quite clearly observed: one containing the largest amount of hydrogen, which exists as hydration water but in much more mobile components than in the previous mortar sample with 2% casein and 2% rubber flakes. Additionally, there is only one type of pore that might cover the range from medium to large pores, though not very well defined. At 7 days after the preparation of the mortar sample with 3% and 5% rubber flakes, the appearance of two types of pores is observed, indicated by two peaks located at approximately 7–8 ms and around 30 ms. There is also a broader peak centered at approximately 90–100 μs, which also features a shoulder at higher T

2 values, potentially indicating the formation of small pores in this case.

Thus, the addition of lime has a dramatic effect on the mortar. At 28 days after preparation, another dramatic change in the pore distribution is observed. There is a quantity of large, medium-to-large pores in which water is present in very small amounts, as indicated by a low-amplitude peak located at approximately 70–80 ms. The distribution of medium and medium-to-large pores is no longer as well resolved or differentiated compared to medium or medium-to-large pores, and a relatively small number of small pores is also observed. However, the hydration water retains its characteristics with a high degree of approximation to the hydration water found in the sample measured at 7 days.

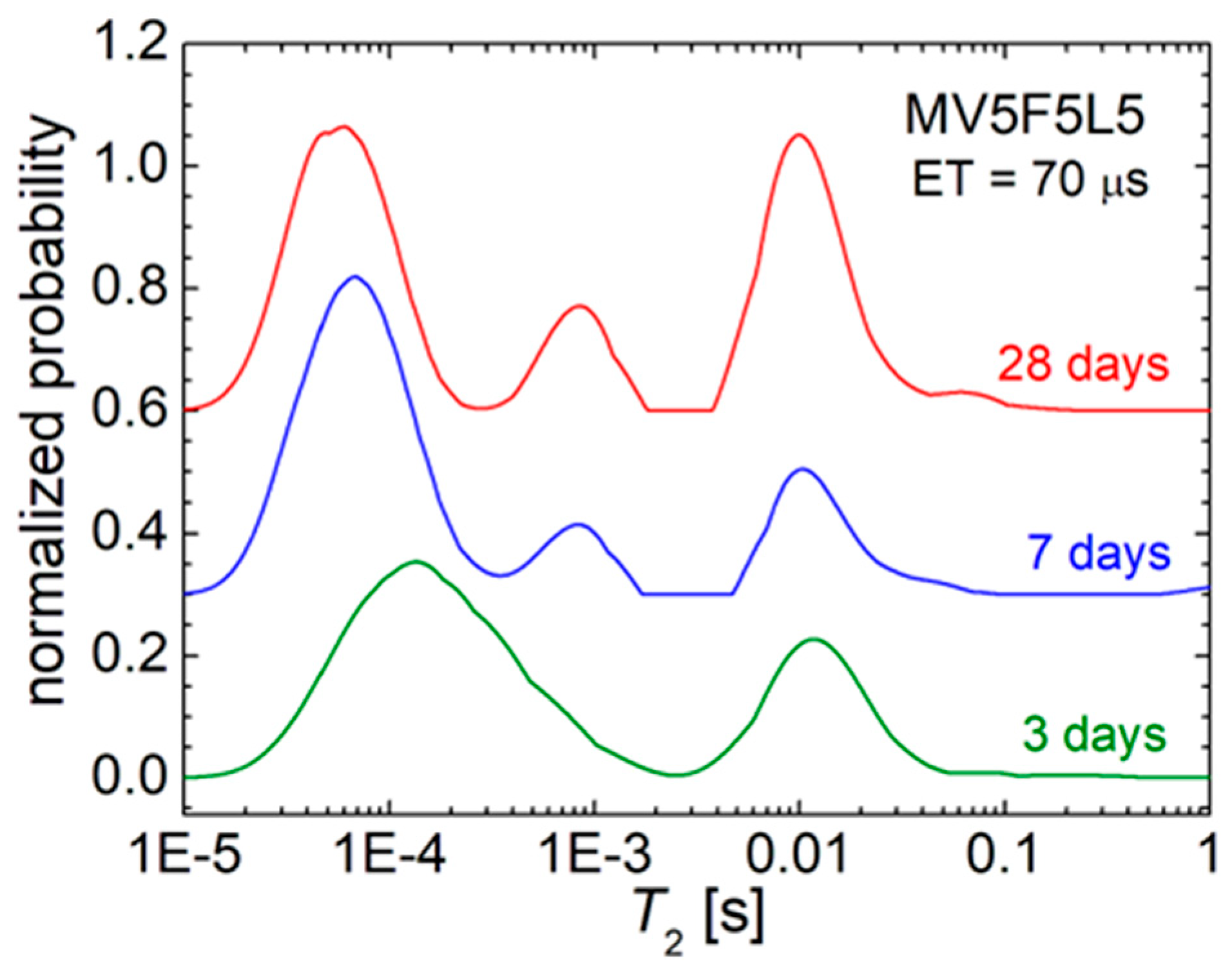

When lime NHL 5 was used instead of lime NHL3, with the addition of 5% latex [

36] and 5% rubber flakes [

37] (relative to the cement quantity), the evolution from 3 to 7 and 28 days is not as dramatic as in the case of the mortar sample with NHL 3 lime and 5% rubber flakes. However, it is still more evident than in the case of the mortar sample with 2% casein and 2% rubber flakes. Thus, for this sample, whose T

2 distributions are presented in

Figure 11, a two-peak distribution is observed at 3 days. This time, the peak with the largest amount of hydrogen, or associated with the largest hydrogen content, is positioned at approximately 150 μs, indicating that the hydrogen is found in relatively rigid components.

A very small peak can be distinguished, suggesting the formation of small pores. A relatively large amount of hydrogen is likely present in water within medium or medium-to-large pores. At 7 days after preparation, the formation of small pores is clearly observed through the appearance of a low-amplitude peak located at approximately one millisecond, which this time is well distinguished from the hydration water found in rigid components. There is a quantity of hydrogen, most likely in water located in medium-to-large pores, and a small-volume appearance of some medium-to-large pores is also observed, as indicated by a so-called shoulder located at approximately 40–50 ms. At 28 days after preparation, the transverse T2 relaxation time distribution does not evolve significantly. The hydration water shows a slight shift toward slightly lower T2 values, indicating a slight increase in sample rigidity.

There is a less prominent presence of small pores, marked by a resolved peak located at approximately 800–900 μs. A relatively large, or the largest, amount of hydrogen is likely present in water within small-to-medium pores, along with the appearance of a peak at higher T2 values (around 70–80 ms), indicating the formation of large-sized pores.

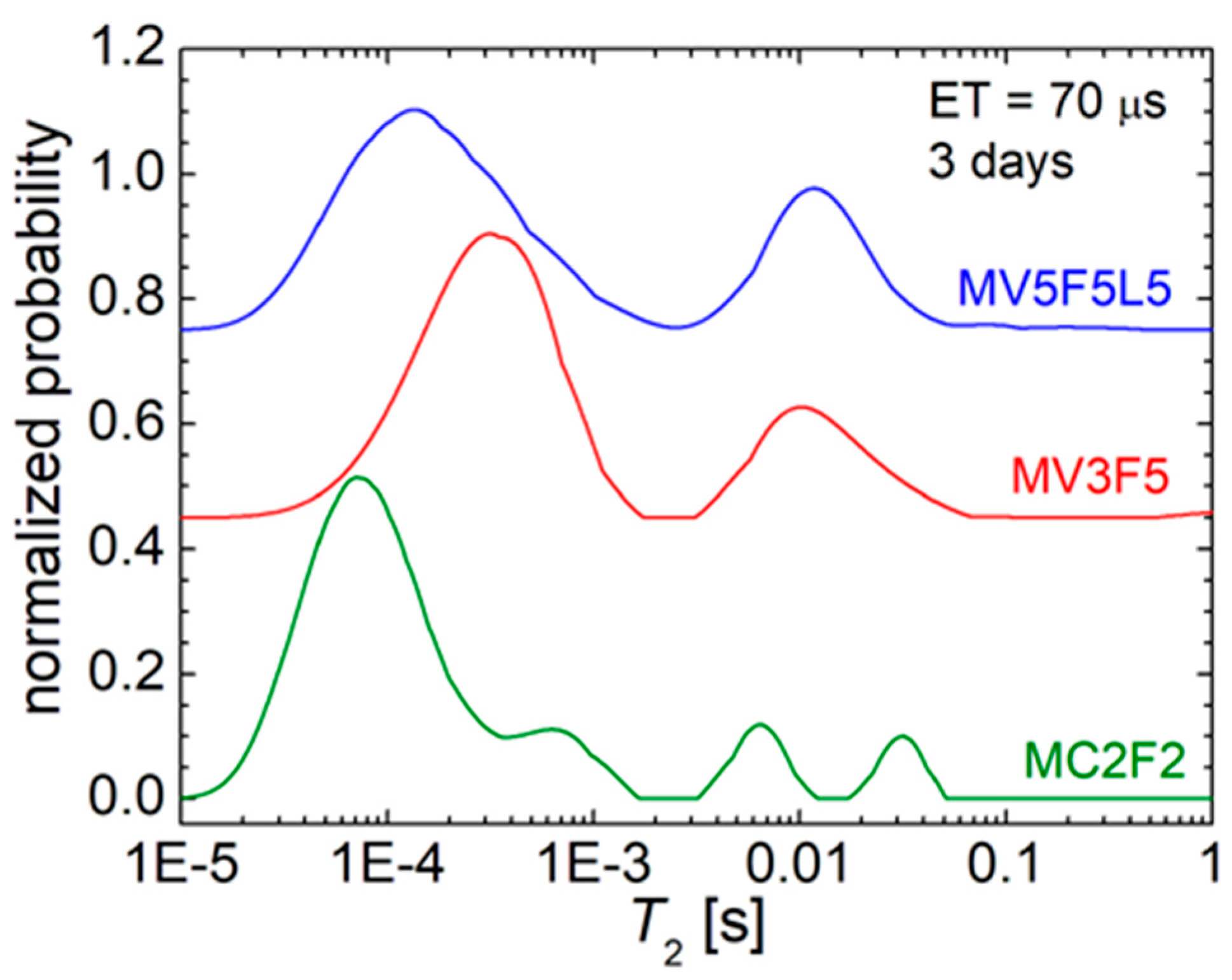

To evaluate the effect of each recipe modification, namely, the type of lime, the amount of rubber flakes [

38], casein, and latex, the relaxation time distributions are presented comparatively for 3 days, 7 days, and 28 days in

Figure 12. The use of natural hydraulic lime (NHL) impacts porosity through additional pozzolanic reactions and micro-filler effects, leading to denser CSH formation in early stages and varied pore size distribution. This explains the difference in microstructural evolution across NHL 3.5 and NHL 5 formulations. Regarding water state classification, we used a widely accepted T

2-based scheme: T

2 < 1 ms corresponds to strongly bound water, T

2 between 1–10 ms indicates capillary/loosely bound water, and T

2 > 10 ms reflects free water in larger pores. This basis aligns with studies on hardened cement pastes and porous materials analyzed via relaxometry.

Thus, in

Figure 12, the transverse T

2 relaxation time distributions are shown for the three mortar samples with 2% casein and 2% rubber flakes. For the mortar sample with 3% lime and 5% rubber flakes (relative to the cement quantity) and the mortar sample with 5% lime, 5% rubber flakes, and 5% latex (relative to the cement quantity), it is observed that all three distributions are different. For the simpler recipe with 2% casein and 2% rubber flakes, the T

2 distribution shows four peaks. The hydration water is clearly observed, which this time is found in rigid components, and the formation of small, medium, and medium-to-large pores is already evident. In the case of the mortar samples with 3% lime and 5% lime, the relaxation time distributions at 3 days show only approximately two peaks. Thus, the effect of lime appears to prevent the formation of a well-defined pore structure during the early hydration stages.

Furthermore, when the sample contains 3% or 5% lime and 5% rubber flakes without latex, it is observed that at 3 days after preparation, the T2 distribution shows a broad peak containing the largest amount of hydrogen, but at relatively high T2 values, centered at approximately 300 μs. This indicates that these more rigid components are still found in a relatively mobile environment compared to the hydrogen that participates in the hydration water, which likely binds to cement and 5% lime components but in a much more rigid environment, as indicated by the broad peak centered at approximately 150 μs.

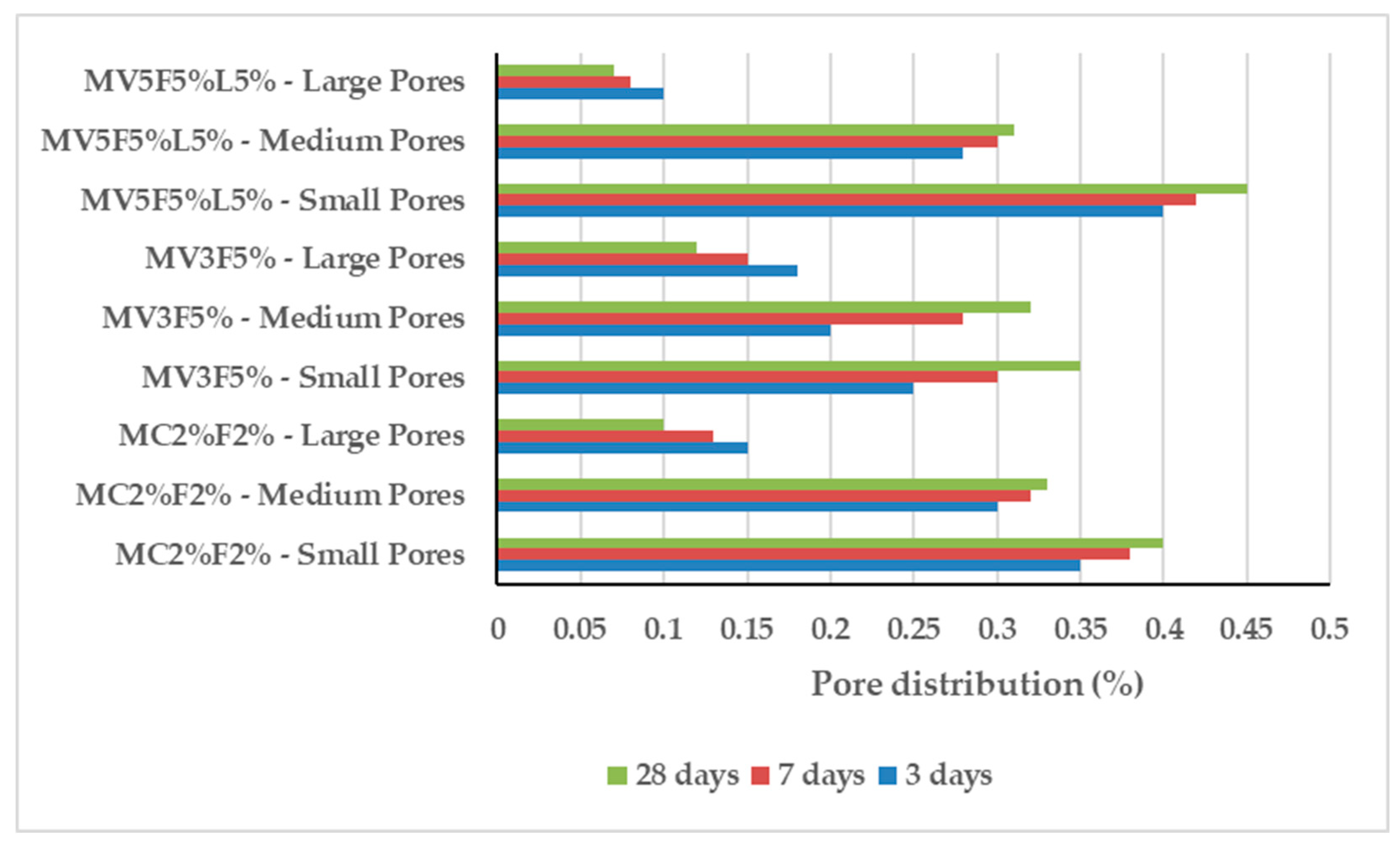

The proportional distribution of small, medium, and large pores derived from the T

2 distributions is plotted in

Figure 13. This plot highlights how the porous structure evolves over time for the three formulations tested: MC2%F2%, MV3F5% and MV5F5%L5%. The values represent the relative proportion of each pore category, deduced by integrating the areas under the T

2 curves obtained from the NMR data.

On the other hand, concerning the porous structure of both samples containing lime, a broad peak appears in a position where medium and medium-to-large pores are likely to form later.

In terms of accuracy, all measurements were repeated on three samples per formulation, and averaged values are reported. Measurement error was maintained below 5% through calibration and repeatability control. Each result is compared to a standard mortar formulation, serving as the reference benchmark.

Concurrently with the NMR characterization, standard physical and mechanical tests were performed in accordance with EN 196-1 and EN 1015-11. The findings demonstrated that the MV3F5% sample attained a 28-day compressive strength of 11.2 MPa, which surpassed the 9.5 MPa strength of the MV5F5%L5% sample and the 7.3 MPa strength of the MC2%F2% sample. The bulk density of the formulations ranged from 1850–1980 kg/m3, with corresponding water absorption values of 12.6%, 15.2%, and 17.8%, respectively. These data confirm that formulations incorporating higher natural hydraulic lime content and exhibiting optimized porosity (as identified through NMR) consistently demonstrate enhanced mechanical performance and reduced capillary absorption.

4. Conclusions

This study demonstrated the potential of low-field NMR as an effective, non-destructive method to analyze the microstructural evolution of mortars containing recycled rubber and various additives. The optimal composition identified—3.5% NHL and 5% rubber flakes—achieved a balanced performance in terms of water retention and stability. Quantitative analysis of T2 relaxation time distributions enabled the differentiation between bound water, capillary water, and free water across pore sizes, supporting precise pore structure evaluation. These insights help guide the design of functional, eco-friendly mortars suitable for specialized applications like animal housing floors.

During the analysis, it was found that the MV3F5% formulation, comprising 3.5% natural hydraulic lime and 5% rubber flakes, exhibited optimal performance in terms of water retention and internal structure stability over time. Even though NHL 3.5 lime exhibits a reduced degree of mechanical strength in comparison to NHL 5, it is distinguished by a more organized pore structure and a less aggressive pore evolution, factors which collectively contribute to an enhancement in durability under moderate service conditions.

The results also revealed that the addition of NHL 5 lime in combination with latex and rubber, leads to faster and more evident microstructural changes, indicating a possible long-term structural vulnerability despite the increased mechanical strength. This observation is of particular importance in applications where flexibility and stability over time are more valuable than initial stiffness. Furthermore, the study emphasizes that T2 distributions can be used as a diagnosis tool to ascertain the nature of water (free, loosely or strongly bound) and pore size, which is imperative information in optimizing mortar recipes. The application of the CONTIN algorithm for the inversion of the Laplace transform enabled the identification of continuous relaxation time distributions; however, it was also noted that the algorithm was highly sensitive to noise, which necessitates caution when interpreting the data.

The incorporation of waste rubber into mortar compositions is a practice that aligns with the principles of a circular economy, whilst concurrently facilitating the development of functional materials that are customized to meet the requirements of sustainable construction. Consequently, optimized formulations derived from NMR results can deliver sustainable solutions for flooring utilized in the context of animal husbandry, exhibiting both structural and animal welfare benefits.

Future studies will explore the mechanical performance under real farm conditions to validate the microstructural predictions obtained through NMR.

In conclusion, the NMR method has been demonstrated to be a valuable tool for research and quality control in the field of construction materials, contributing to a deep understanding of hydration mechanisms and to the design of efficient, sustainable and environmentally friendly recipes.