Unlocking the Potential of Mass Customization Through Industry 4.0: Mapping Research Streams and Future Directions

Abstract

1. Introduction and Research Positioning

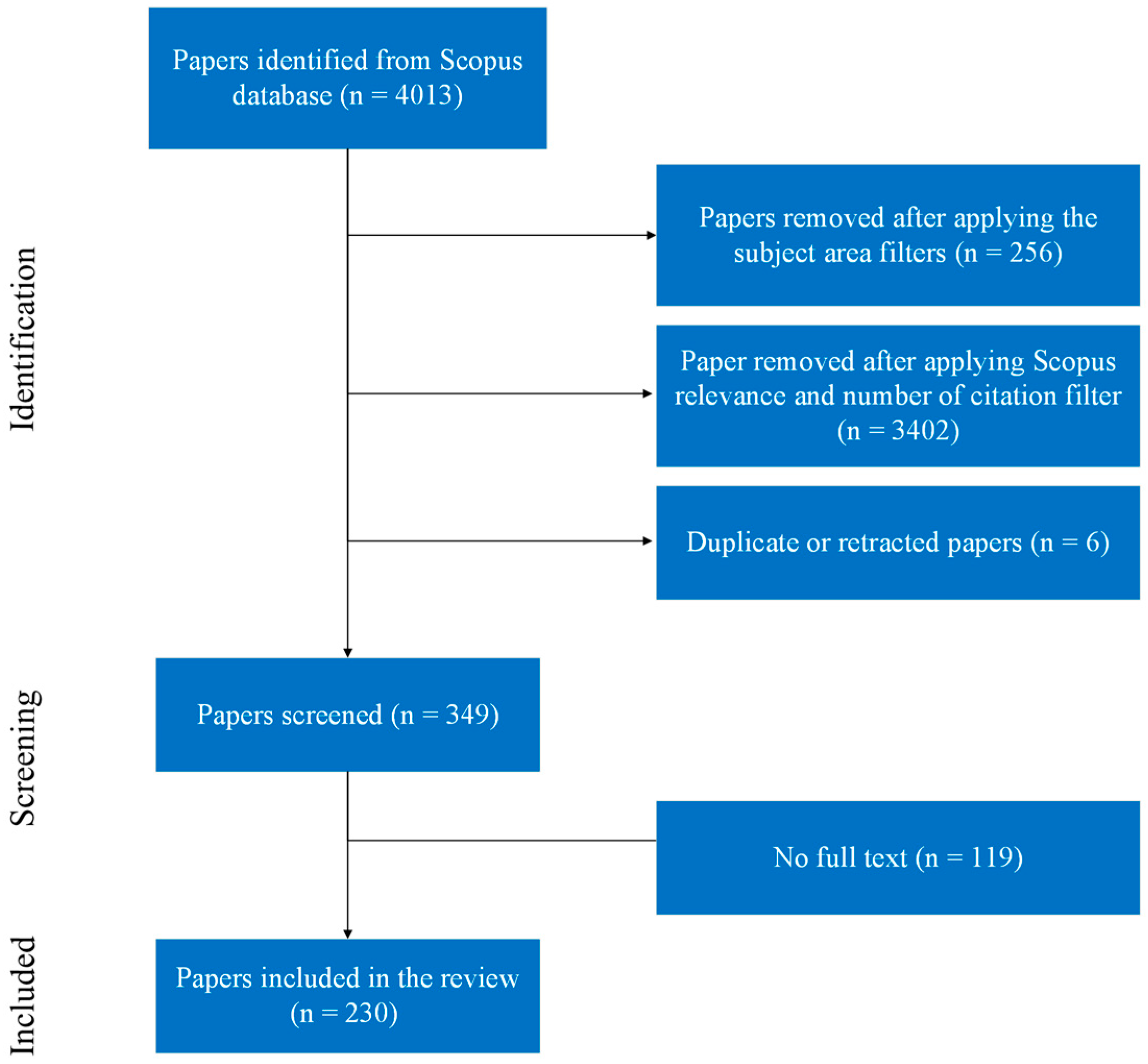

2. Research Methodology

- Peer-reviewed journal articles, conference papers, reviews, and book chapters;

- Documents published between 2011 and 2024;

- Documents written in English language, only;

- Documents focused on MC and related enabling technologies;

- Documents indexed in the Scopus database;

- Documents belonging to the following subject areas: Engineering, computer science, business management and accounting, decision sciences, mathematics, materials science, social sciences, and economics econometrics and finance.

- Editorials, commentaries, letters, and non-peer-reviewed material;

- Articles unrelated to MC or Industry 4.0;

- Duplicates or retracted papers;

- Papers without accessible full text.

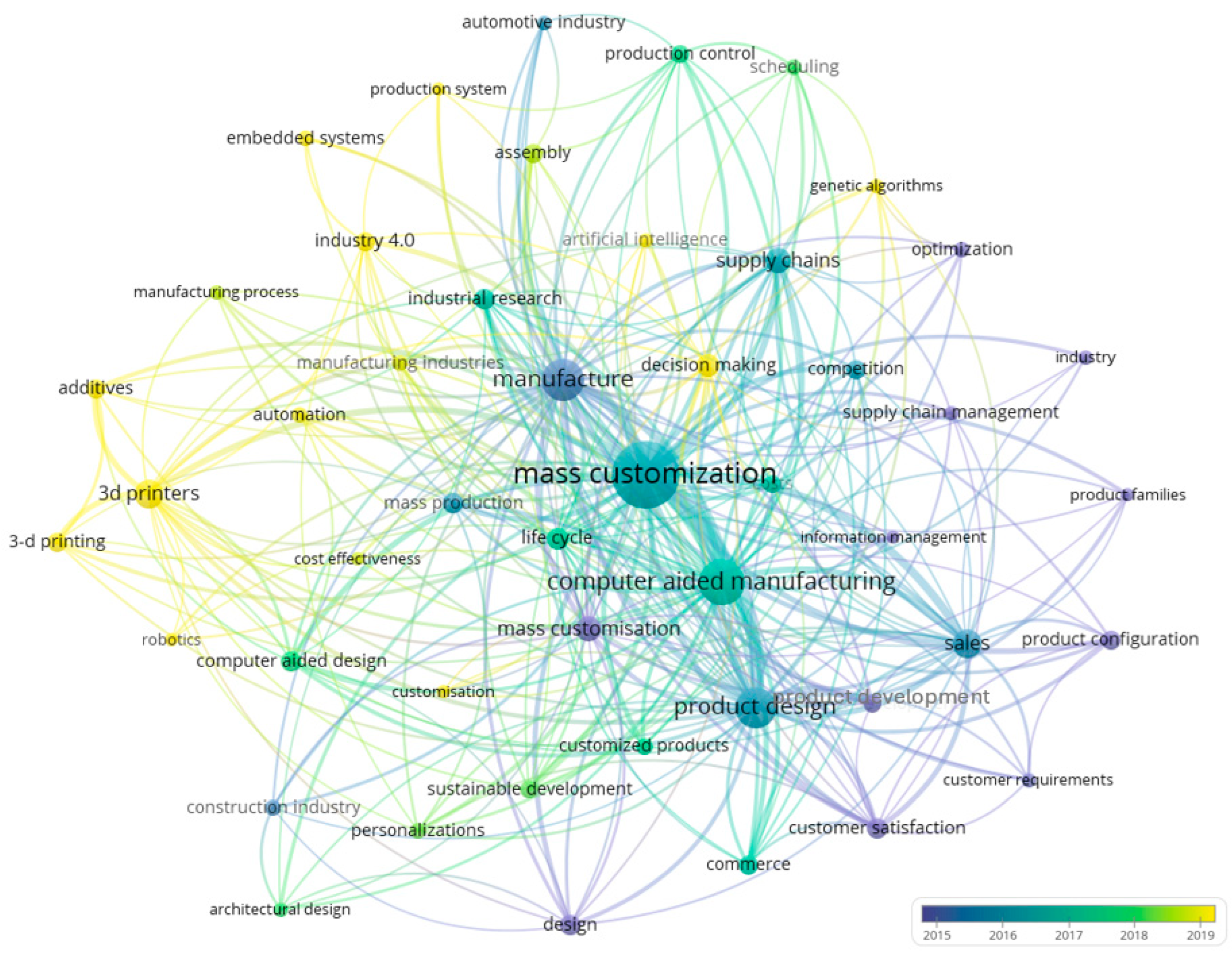

2.1. Bibliometric Mapping and Conceptual Clustering

2.2. Literature Classification and Thematic Coding

- RS1—MC general concepts and metrics: addressing foundational definitions, conceptual distinctions (e.g., customization vs. personalization), and performance evaluation models.

- RS2—MC technologies and methods: focusing on technological and methodological enablers of customization across the product lifecycle. Due to the high number of contributions within RS2, it was further divided into three sub-streams:

- ○

- RS2.1: customer–manufacturer interaction

- ○

- RS2.2: product design methodologies

- ○

- RS2.3: production architecture and manufacturing systems

- RS3—MC and supply chain management: analyzing how MC is implemented and supported within extended and reconfigurable supply chains.

3. Research Stream Analysis

3.1. RS1: MC General Concept and Metrics

- ✓

- solution space development, which involves identifying the dimensions along which customer needs vary;

- ✓

- robust process design, which focuses on reusing or recombining existing organizational and value chain resources to meet diverse customer needs efficiently;

- ✓

- choice navigation, which supports customers in selecting tailored solutions while minimizing complexity and decision fatigue.

3.2. RS2: MC Technologies and Methods

3.2.1. RS2.1: MC Technologies and Methods for Customer–Manufacturer Interaction

3.2.2. RS2.2: MC Technologies and Methods for Product Design

3.2.3. RS2.3: MC Technologies and Methods for Production Architecture

3.3. RS3: MC and Supply Chain Management

4. Key Outcomes and Discussion

- ✓

- Evolution and maturity of MC: MC has evolved from a niche concept to a mainstream production strategy, enabled by digitalization and I4.0. The convergence of customization with technologies such as CPS, IoT, and AI marks a shift from traditional modularity-based approaches to real-time, data-driven customization paradigms.

- ✓

- Three major research streams identified around three key domains:

- ○

- RS1—MC general concepts and metrics: focusing on MC definitions, strategic principles, and performance measurement, including sustainability metrics.

- ○

- RS2—MC technologies and methods: covering enablers such as product configurators, modular product design, and flexible production systems; structured into three sub-streams—customer interaction, product design, and production architecture.

- ○

- RS3—MC and supply chain management: emphasizing supply chain agility, integration, postponement strategies, and supplier collaboration as key to supporting MC systems.

- ✓

- Technological enablers and integration: enabling technologies such as product configurators, recommender systems, additive manufacturing, and digital twins play a pivotal role in making MC feasible and scalable. Their integration is essential to overcoming the operational complexity introduced by high product variety and dynamic customer preferences.

- ✓

- Customer involvement and co-design: a recurring theme in the literature is the centrality of customer involvement. Co-design, co-creation, and preference elicitation are key to ensuring that customized offerings deliver value. Tools such as AR, mobile interfaces, and interactive web platforms are widely used to support this involvement and reduce decision fatigue or “mass confusion”.

- ✓

- Barriers to adoption: despite its advantages, MC implementation is hindered by multiple challenges. These include high initial costs, lack of integration with legacy systems, difficulties in managing real-time data, and low digital readiness—particularly in SMEs. Moreover, aligning the customization strategy across product, process, and supply chain levels remains a complex endeavor.

- ✓

- Sustainability considerations: MC holds potential for environmental and economic sustainability through reduction in overproduction, minimized waste, and localized manufacturing. However, the operationalization of sustainability in MC environments is still in its infancy, with limited standardized metrics and few empirical validations.

- ✓

- Shift toward personalization: A growing body of literature suggests that MC is transitioning toward “mass personalization,” where AI-driven systems and real-time customer data are used to anticipate needs and deliver one-to-one tailored experiences. This paradigm shift implies a more granular, flexible, and intelligent MC framework aligned with the principles of I4.0.

4.1. Enablers and Barriers in the Implementation of Mass Customization

- ✓

- Product modularity and platform strategies: modular product architectures and shared platforms support the creation of product variants without excessive complexity. These design strategies enable flexibility and scale economies.

- ✓

- Advanced manufacturing technologies: technologies such as additive manufacturing, flexible manufacturing systems (FMS), reconfigurable manufacturing systems (RMS), and CPS enable agile production of customized products with minimal downtime and reconfiguration costs.

- ✓

- Customer integration tools: co-design platforms, web configurators, and recommender systems facilitate active customer participation, helping translate individual preferences into feasible product configurations.

- ✓

- Postponement and process modularity: delayed product differentiation (DPD) and modular production lines allow final customization to occur at later production stages, reducing inventory and operational uncertainty.

- ✓

- Supply chain reconfigurability: agile supply chains enabled by real-time data exchange and collaborative planning allow rapid adaptation to customer orders and enhance service levels.

- ✓

- Sustainability-oriented design: modular design and localized production reduce environmental impact. MC aligns well with circular economy principles by enabling repairability, reuse, and resource optimization.

- ✓

- High initial costs and investment risks: developing modular architectures, acquiring new manufacturing technologies, and integrating ICT systems often require significant capital and organizational transformation.

- ✓

- Data and IT integration challenges: many companies struggle with poor interoperability between systems, fragmented customer data, and cybersecurity concerns. These issues limit the capacity to automate and personalize effectively.

- ✓

- Organizational complexity and resistance: MC demands cross-functional integration and cultural change, which may be resisted by staff and management. Legacy processes and siloed departments can obstruct implementation.

- ✓

- Customer-related constraints: despite technological tools, many customers find customization processes confusing or time consuming. Poorly designed interfaces can reduce engagement and lead to suboptimal configurations.

- ✓

- Rigid supply chains: traditional supply chains may not accommodate high-variety, low-volume production. Without flexibility in procurement, manufacturing, and distribution, the benefits of MC are diluted.

- ✓

- Lack of standardized evaluation metrics: the absence of commonly accepted KPIs makes it difficult to assess MC success consistently across industries or compare alternative approaches.

4.2. Limitations of the Analysis

5. Summary and Future Research

- ✓

- Empirical testing and industrial validation: while conceptual models and frameworks are abundant, empirical studies demonstrating real-world MC implementation across diverse sectors, especially SMEs, are still limited. Future research should prioritize case-based and longitudinal studies to validate MC effectiveness.

- ✓

- Integration with digital twin and predictive analytics: the application of digital twins and AI-based predictive tools in MC environments offers promising avenues for real-time customization and operational optimization. Research should explore how these technologies can close the gap between customer intent and production reality.

- ✓

- Sustainability-oriented MC models: the dual pursuit of customization and sustainability calls for novel frameworks that quantify trade-offs and synergies across the product lifecycle. Metrics assessing environmental, economic, and social impacts of MC should be further developed and standardized.

- ✓

- Human-centered MC: as automation increases, the human factor remains critical—particularly in co-design, configuration interface usability, and decision-making support. Interdisciplinary studies that blend design thinking, cognitive ergonomics, and MC technology are needed to enhance user experience and system adoption.

- ✓

- Supply chain reconfigurability: the dynamic nature of personalized production requires agile and reconfigurable supply chains. Research should delve into decentralized and platform-based supply networks that can adapt rapidly to fluctuating demand without compromising efficiency or cost-effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- MacCarthy, B.L. An analysis of order fulfilment approaches for delivering variety and customisation. Int. J. Prod. Res. 2013, 51, 7329–7344. [Google Scholar] [CrossRef]

- Broda, C.; Weinstein, D.E. Globalization and the Gains from Variety. Q. J. Econ. 2006, 121, 541–585. Available online: http://www.jstor.org/stable/25098800 (accessed on 20 February 2025). [CrossRef]

- Huang, S.; Wang, G.; Nie, S.; Wang, B.; Yan, Y. Part family formation method for delayed reconfigurable manufacturing system based on machine learning. J. Intell. Manuf. 2022, 34, 2849–2863. [Google Scholar] [CrossRef]

- Daaboul, J.; Bernard, A.; Laroche, F. Extended value network modelling and simulation for mass customization implementation. J. Intell. Manuf. 2012, 23, 2427–2439. [Google Scholar] [CrossRef]

- Galizia, F.G.; ElMaraghy, H.; Bortolini, M.; Mora, C. Product platforms design, selection and customisation in high-variety manufacturing. Int. J. Prod. Res. 2020, 58, 893–911. [Google Scholar] [CrossRef]

- Davis, S. From future perfect: Mass customizing. Plan. Rev. 1989, 17, 16–21. [Google Scholar] [CrossRef]

- Pine, B.J. Mass Customization: The New Frontier in Business Competition; Harvard Business School Press: Boston, MA, USA, 1993. [Google Scholar]

- Da Silveira, G.J.C.; Fogliatto, F.S.; Fendyur, A. Demographics of mass customization: A global study of manufacturing plants. Production 2015, 26, 1–11. [Google Scholar] [CrossRef]

- Kumar, A. From mass customization to mass personalization: A strategic transformation. Int. J. Flex. Manuf. Syst. 2007, 19, 533–547. [Google Scholar] [CrossRef]

- Salvador, F.; de Holan, P.M.; Piller, F. Cracking the code of mass customization. MIT Sloan Manag. Rev. 2009, 50, 71–78. [Google Scholar]

- Fogliatto, F.S.; Da Silveira, G.J.C.; Borenstein, D. The mass customization decade: An updated review of the literature. Int. J. Prod. Econ. 2012, 138, 14–25. [Google Scholar] [CrossRef]

- Simpson, T.W.; Marion, T.; de Weck, O.; Holtta-Otto, K.; Kokkolaras, M.; Shooter, S.B. Platform-based design and development: Current trends and needs in industry. In Proceedings of the ASME 2006 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Philadelphia, PA, USA, 10–13 September 2006. [Google Scholar]

- Piller, F. Mass customization: Reflections on the state of the concept. Int. J. Flex. Manuf. Syst. 2004, 16, 313–334. [Google Scholar] [CrossRef]

- Zawadzki, P.; Żywicki, K. Smart Product Design and Production Control for Effective Mass Customization in the Industry 4.0 Concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Ninan, J.A.; Siddique, Z. Internet-based framework to support integration of customer in the design of customizable products. Concurr. Eng. 2006, 14, 245–256. [Google Scholar] [CrossRef]

- Nielsen, K.J.; Cox, J.J. Implementation of biomechanical mating conditions in CAD. Comput.-Aided Des. Appl. 2008, 5, 338–353. [Google Scholar] [CrossRef]

- Chandra, C.; Kamrani, A. Mass Customization: A Supply Chain Approach; Kluwer Academic Press: New York, NY, USA, 2004. [Google Scholar]

- Yao, J.; Liu, L. Optimization analysis of supply chain scheduling in mass customization. Int. J. Prod. Econ. 2009, 117, 197–211. [Google Scholar] [CrossRef]

- Dietrich, A.J.; Kirn, S.; Sugumaran, V. A service-oriented architecture for mass customization: A shoe industry case study. IEEE Trans. Eng. Manag. 2007, 54, 190–204. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, Y.; Jiao, R.J. Affective and cognitive design for mass personalization: Status and prospect. J. Intell. Manuf. 2013, 24, 1047–1069. [Google Scholar] [CrossRef]

- Karnik, N.; Bora, U.; Bhadri, K.; Kadambi, P.; Dhatrak, P. A Comprehensive study on Current and Future Trends towards the Characteristics and Enablers of Industry 4.0. J. Ind. Inf. Integr. 2021, 27, 100294. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review. 2015. Available online: https://www.researchgate.net/publication/307864150_Design_Principles_for_Industrie_40_Scenarios_A_Literature_Review?channel=doi&linkId=57cfd2fb08aed6789701cbeb&showFulltext=true (accessed on 15 September 2024).

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Galizia, F.G.; Bortolini, M.; Calabrese, F. A cross-sectorial review of industrial best practices and case histories on Industry 4.0 technologies. Syst. Eng. 2023, 26, 908–924. [Google Scholar] [CrossRef]

- Schmidt, R.; Möhring, M.; Härting, R.; Reichstein, C.; Neumaier, P.; Jozinović, P. Industry 4.0—Potentials for Creating Smart Products: Empirical Research Results. In Business Information Systems; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Da Silveira, G.; Borenstein, D.; Fogliatto, F.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar] [CrossRef]

- Ferguson, S.M.; Olewnik, A.T.; Cormier, P. A review of mass customization across marketing, engineering and distribution domains toward development of a process framework. Res. Eng. Des. 2014, 25, 11–30. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n 71. [Google Scholar] [CrossRef]

- Duray, R. Process Typology of Mass Customizers. In Mass Customization; Fogliatto, F.S., Da Silveira, G.J.C., Eds.; Springer Series in Advanced Manufacturing; Springer: London, UK, 2011; pp. 29–43. [Google Scholar] [CrossRef]

- Salvador, F.; Forza, C. Configuring Products to Address the Customization-Responsiveness Squeeze: A Survey of Management Issues and Opportunities. Int. J. Prod. Econ. 2005, 91, 273–291. [Google Scholar] [CrossRef]

- Jiao, R.J. Prospect of Design for Mass Customization and Personalization. In Proceedings of the 37th Design Automation Conference, Parts A and B, Presented at the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASMEDC, Washington, DC, USA, 28–31 August 2011; ASME: New York, NY, USA, 2011; Volume 5, pp. 625–632. [Google Scholar] [CrossRef]

- Haapala, K.R.; Zhao, F.; Camelio, J.; Sutherland, J.W.; Skerlos, S.J.; Dornfeld, D.A.; Jawahir, I.S.; Zhang, H.C.; Clarens, A.F. A Review of Engineering Research in Sustainable Manufacturing. In Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference, Corvallis, OR, USA, 13–17 June 2011; Volume 44311, pp. 599–619. [Google Scholar] [CrossRef]

- Stojanova, T.; Suzic, N.; Orcik, A. Implementation of Mass Customization Tools in Small and Medium Enterprises. Int. J. Ind. Eng. Manag. 2012, 3, 253–260. [Google Scholar] [CrossRef]

- Medini, K.; Cunha, C.D.; Bernard, A. Sustainable Mass Customized Enterprise: Key Concepts, Enablers and Assessment Techniques. IFAC Proc. Vol. 2012, 45, 522–527. [Google Scholar] [CrossRef]

- Medini, K.; Da Cunha, C.; Bernard, A. A Sustainability and Mass Customization Assessment Framework. In Advanced Composite Materials and Processing; Robotics; Information Management and PLM; Design Engineering, Presented at the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, American Society of Mechanical Engineers, Nantes, France, 2–4 July 2012; ASME: New York, NY, USA, 2012; Volume 3, pp. 795–800. [Google Scholar] [CrossRef]

- Bettoni, A.; Corti, D.; Fontana, A.; Zebardast, M.; Pedrazzoli, P. Sustainable Mass Customization Assessment. In Intelligent Non-hierarchical Manufacturing Networks; Poler, R., Carneiro, L.M., Jasinski, T., Zolghadri, M., Pedrazzoli, P., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 249–276. [Google Scholar] [CrossRef]

- Sunikka, A.; Bragge, J. Applying text-mining to personalization and customization research literature—Who, what and where? Expert Syst. Appl. 2012, 39, 10049–10058. [Google Scholar] [CrossRef]

- Golay, L.; Church, A. Mass customization: The bane of OD or the cure to what ails it? Leadersh. Organ. Dev. J. 2013, 34, 661–679. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Boër, C.; Pedrazzoli, P.; Bettoni, A.; Sorlini, M. Mass Customization and Sustainability: An Assessment Framework and Industrial Implementation; Springer: London, UK, 2013; ISBN 978-1-4471-5115-9. [Google Scholar]

- Jaaron, A.A.M.; Backhouse, C.J. Systems Thinking for Service Delivery Design: A Real Time Mass Customisation Model. IFAC Proc. Vol. 2013, 46, 228–233. [Google Scholar] [CrossRef]

- Brunø, T.D.; Nielsen, K.; Taps, S.B.; Jørgensen, K.A. Sustainability Evaluation of Mass Customization. In Advances in Production Management Systems. Sustainable Production and Service Supply Chains; Prabhu, V., Taisch, M., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 175–182. [Google Scholar] [CrossRef]

- Nielsen, K.; Brunø, T.D. Assessment of Process Robustness for Mass Customization. In Advances in Production Management Systems. Sustainable Production and Service Supply Chains; Prabhu, V., Taisch, M., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 191–198. [Google Scholar] [CrossRef]

- Storbjerg, S.H.; Nielsen, K.; Brunoe, T.D. Choice Navigation: Towards a Methodology for Performance Assessment. In Proceedings of the Configuration Workshop, Vienna, Austria, 29–30 August 2013; pp. 87–94. [Google Scholar]

- Nielsen, K.; Brunø, T.D. Mass Customisation Assessment and Measurement Framework. In Enabling Manufacturing Competitiveness and Economic Sustainability; Zaeh, M.F., Ed.; Springer International Publishing: Cham, Switzerland, 2014; pp. 165–170. [Google Scholar] [CrossRef]

- Osorio, J.; Romero, D.; Betancur, M.; Molina, A. Design for sustainable mass-customization: Design guidelines for sustainable mass-customized products. In Proceedings of the 2014 International Conference on Engineering, Technology and Innovation (ICE), Bergamo, Italy, 23–25 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–9. [Google Scholar] [CrossRef]

- Pourabdollahian, G.; Taisch, M.; Piller, F.T. Is Sustainable Mass Customization an Oxymoron? An Empirical Study to Analyze the Environmental Impacts of a MC Business Model. In Proceedings of the 7th World Conference on Mass Customization, Personalization, and Co-Creation (MCPC 2014), Aalborg, Denmark, 4–7 February 2014; Brunoe, T.D., Nielsen, K., Joergensen, K.A., Taps, S.B., Eds.; Lecture Notes in Production Engineering. Springer International Publishing: Cham, Switzerland, 2014; pp. 301–310. [Google Scholar] [CrossRef]

- Pourabdollahian, G.; Steiner, F. Environmental and Social Impacts of Mass Customization: An Analysis of Beginning-of-Life Phases. In Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications; Bayro-Corrochano, E., Hancock, E., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2014; pp. 526–532. [Google Scholar] [CrossRef]

- Hsiao, W.-P.; Chiu, M.-C. A Mass Personalization Methodology Based on Co-creation. In Moving Integrated Product Development to Service Clouds in the Global Economy; IOS Press: Amsterdam, The Netherlands, 2014; pp. 698–705. [Google Scholar]

- Nielsen, K.; Brunø, T.D.; Joergensen, K.A.; Taps, S.B. Mass Customization Measurements Metrics. In Proceedings of the 7th World Conference on Mass Customization, Personalization, and Co-Creation (MCPC 2014), Aalborg, Denmark, 4–7 February 2014; Brunoe, T.D., Nielsen, K., Joergensen, K.A., Taps, S.B., Eds.; Lecture Notes in Production Engineering. Springer International Publishing: Cham, Switzerland, 2014; pp. 359–375. [Google Scholar] [CrossRef]

- An, W.; Yang, W.; Guo, W.; Zhu, D. Research on enterprise customization diagnosis for mass customization. Int. J. Adv. Manuf. Technol. 2015, 76, 669–674. [Google Scholar] [CrossRef]

- Gembarski, P.C.; Lachmayer, R. Degrees of Customization and Sales Support Systems-Enablers to Sustainibility in Mass Customization. In Proceedings of the 20th International Conference on Engineering Design (ICED15), Milan, Italy, 27–30 July 2015. [Google Scholar]

- Medini, K.; Da Cunha, C.; Bernard, A. Tailoring performance evaluation to specific industrial contexts—Application to sustainable mass customisation enterprises. Int. J. Prod. Res. 2015, 53, 2439–2456. [Google Scholar] [CrossRef]

- Hankammer, S.; Steiner, F. Leveraging the Sustainability Potential of Mass Customization through Product Service Systems in the Consumer Electronics Industry. Procedia CIRP 2015, 30, 504–509. [Google Scholar] [CrossRef]

- Hsiao, W.B.; Chiu, M.C.; Chu, C.Y.; Chen, W.F. A systematic service design methodology to achieve mass personalisation. Int. J. Agil. Syst. Manag. 2015, 8, 243. [Google Scholar] [CrossRef]

- Vidor, G.; Medeiros, J.F.D.; Fogliatto, F.S.; Tseng, M.M. Critical characteristics for the implementation of mass-customized services. Eur. Bus. Rev. 2015, 27, 513–534. [Google Scholar] [CrossRef]

- Arndt, H.-K. Mass Customization: Sustainability of a Computer-Based Manufacturing System. In Information Technology in Environmental Engineering; Marx Gómez, J., Scholtz, B., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2016; pp. 151–163. [Google Scholar] [CrossRef]

- Hora, M.; Hankammer, S.; Canetta, L.; Sel, S.K.; Gomez, S.; Gahrens, S. Designing Business Models for Sustainable Mass Customization: A Framework Proposal. Int. J. Ind. Eng. Manag. 2016, 7, 143–152. [Google Scholar] [CrossRef]

- Brunø, T.D.; Nielsen, K.; Joergensen, K.A.; Taps, S.B. Metrics for Assessing Product Variety Utilization. In Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications; Bayro-Corrochano, E., Hancock, E., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2014; pp. 328–335. [Google Scholar] [CrossRef]

- Mourtzis, D.; Fotia, S.; Boli, N. Metrics definition for the product-service system complexity within mass customization and industry 4.0 environment. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC), Funchal, Madeira, Portugal, 27–29 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1166–1172. [Google Scholar] [CrossRef]

- Taps, S.B.; Ditlev, T.; Nielsen, K. Mass Customization in SMEs: Literature Review and Research Directions. In Managing Complexity; Bellemare, J., Carrier, S., Nielsen, K., Piller, F.T., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2017; pp. 195–203. [Google Scholar] [CrossRef]

- Thomassen, M.K.; Alfnes, E. Mass Customization Challenges of Engineer-to-Order Manufacturing. In Managing Complexity; Bellemare, J., Carrier, S., Nielsen, K., Piller, F.T., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2017; pp. 27–39. [Google Scholar] [CrossRef]

- Tiihonen, J.; Felfernig, A. An introduction to personalization and mass customization. J. Intell. Inf. Syst. 2017, 49, 1–7. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Van Landeghem, V.H.; Aghezzaf, E. Complexity Issues in Mass Customized Manufacturing. In Mass Customized Manufacturing, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Modrak, V.; Bednar, S. Variety-induced complexity metrics. In Mass Customized Manufacturing; CRC Press: Boca Raton, FL, USA, 2017; pp. 131–160. [Google Scholar] [CrossRef]

- Zhang, M.; Qi, Y.; Guo, H. Impacts of intellectual capital on process innovation and mass customisation capability: Direct and mediating effects. Int. J. Prod. Res. 2017, 55, 6971–6983. [Google Scholar] [CrossRef]

- Mourtzis, D.; Fotia, S.; Boli, N.; Pittaro, P. Product-service system (PSS) complexity metrics within mass customization and Industry 4.0 environment. Int. J. Adv. Manuf. Technol. 2018, 97, 91–103. [Google Scholar] [CrossRef]

- Nielsen, K.; Brunø, T.D.; Simeonov, S.D. Validation of Metrics for Mass Customization: A Pre-study of Validation Methods. In Customization 4.0; Hankammer, S., Nielsen, K., Piller, F.T., Schuh, G., Wang, N., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2018; pp. 595–601. [Google Scholar] [CrossRef]

- Raza, A.; Haouari, L.; Pero, M.; Absi, N. Impacts of Industry 4.0 on the Specific Case of Mass Customization Through Modeling and Simulation Approach. In Customization 4.0; Hankammer, S., Nielsen, K., Piller, F.T., Schuh, G., Wang, N., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2018; pp. 217–234. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, R.R.K. Personality of leaders of mass customization firms. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Paris, France, 26–27 July 2018. [Google Scholar]

- Baranauskas, G. Mass personalization vs. mass customization: Finding variance in semantical meaning and practical implementation between sectors. In Social Transformations in Contemporary Society (STICS 2019): Proceedings of the An Annual International Conference for Young Researchers, Tokyo, Japan, 29–30 November 2019; Mykolas Romeris University: Vilnius, Lithuania, 2019; no. 7. [Google Scholar]

- De Bellis, E.; Hildebrand, C.; Ito, K.; Herrmann, A.; Schmitt, B. Personalizing the Customization Experience: A Matching Theory of Mass Customization Interfaces and Cultural Information Processing. J. Mark. Res. 2019, 56, 1050–1065. [Google Scholar] [CrossRef]

- Stehling, M.P.; Ruschel, R.C. A sustainable process for mass customization in the woodworking industry. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 15–17 July 2019; pp. 352–363. [Google Scholar] [CrossRef]

- Aheleroff, S.; Philip, R.; Zhong, R.Y.; Xu, X. The Degree of Mass Personalisation under Industry 4.0. Procedia CIRP 2019, 81, 1394–1399. [Google Scholar] [CrossRef]

- Trentin, A.; Somià, T.; Sandrin, E.; Forza, C. Operations managers’ individual competencies for mass customization. Int. J. Oper. Prod. Manag. 2019, 39, 1025–1052. [Google Scholar] [CrossRef]

- Sharma, M.; Purohit, D.J.K. Achieving Sustainable Mass Customization Capabilities—A Review. UGC CARE 2020, 10, 299–304. [Google Scholar]

- Becker, J.A. The Relationship of Factors on the Implementation of Mass Customized/Personalized Products. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Cannas, V.G.; Masi, A.; Pero, M.; Brunø, T.D. Implementing configurators to enable mass customization in the Engineer-to-Order industry: A multiple case study research. Prod. Plan. Control 2020, 33, 974–994. [Google Scholar] [CrossRef]

- Fathi, M.; Ghobakhloo, M. Enabling Mass Customization and Manufacturing Sustainability in Industry 4.0 Context: A Novel Heuristic Algorithm for in-Plant Material Supply Optimization. Sustainability 2020, 12, 6669. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. An Entropy-Based Formulation for Assessing the Complexity Level of a Mass Customization Industry 4.0 Environment. Math. Probl. Eng. 2020, 2020, 6376010. [Google Scholar] [CrossRef]

- Kang, M.; Kang, T.; Wang, X. The Effect of Intellectual Leadership on Mass Customization: Moderated Mediation Effect of Customer Market Knowledge. IEEE Access 2021, 9, 164589–164596. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. The role of manufacturing efficiency in the achievement of sustainable mass customization 4.0. Prod. Manuf. Res. 2022, 10, 132–159. [Google Scholar] [CrossRef]

- Barata, J.; Cardoso, J.; Rupino da Cunha, P. Mass customization and mass personalization meet at the crossroads of Industry 4.0: A case of augmented digital engineering. Syst. Eng. 2023, 26, 715–727. [Google Scholar] [CrossRef]

- Naldi, L.D.; Galizia, F.G.; Bortolini, M. Is Mass Customisation Sustainable? A Literature-Based Analysis. In Production Processes and Product Evolution in the Age of Disruption; Galizia, F.G., Bortolini, M., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023; pp. 15–23. [Google Scholar] [CrossRef]

- Renbin, X. Massive personalized customization: New development of mass personalization. Comput. Integr. Manuf. Syst. 2023, 29, 4215. [Google Scholar]

- Hui, G.; Al Mamun, A.; Masukujjaman, M.; Makhbul, Z.K.M.; Ali, M.H. The relationship between mass customization and sustainable performance: The role of firm size and global E-commerce. Heliyon 2024, 10, e27726. [Google Scholar] [CrossRef] [PubMed]

- Su, C.-J.; Chuang, H.-C. Toward Mass Customized Product Deployment in E-Commerce: The Modularization Function and Postponement Strategy. J. Organ. Comput. Electron. Commer. 2011, 21, 24–49. [Google Scholar] [CrossRef]

- Gillain, J.; Faulkner, S.; Heymans, P.; Jureta, I.; Snoeck, M. Product portfolio scope optimization based on features and goals. In Proceedings of the 16th International Software Product Line Conference, Salvador, Brazil, 2–7 September 2012; Volume 1, pp. 161–170. [Google Scholar] [CrossRef]

- Mavridou, E.; Kehagias, D.D.; Tzovaras, D.; Hassapis, G. Mining affective needs of automotive industry customers for building a mass-customization recommender system. J. Intell. Manuf. 2013, 24, 251–265. [Google Scholar] [CrossRef]

- Zhang, Y.H.; He, Y.J. Research on the Customer Requirement Processing for Mass Customization. Adv. Mater. Res. 2013, 744, 579–584. [Google Scholar] [CrossRef]

- Smith, S.; Smith, G.C.; Jiao, R.; Chu, C.-H. Mass customization in the product life cycle. J. Intell. Manuf. 2013, 24, 877–885. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, J.; Bernard, A. Knowledge Management in E-commerce Mass Customization. In Product Lifecycle Management for Society, Proceedings of the 10th IFIP WG 5.1 International Conference, PLM 2013, Nantes, France, 6–10 July 2013; Proceedings 10; Springer: Berlin/Heidelberg, Germany, 2013; pp. 259–267. [Google Scholar]

- Aichner, T.; Coletti, P. Customers’ online shopping preferences in mass customization. J. Direct Data Digit. Mark. Pract. 2013, 15, 20–35. [Google Scholar] [CrossRef][Green Version]

- Ma, J.; Liu, Y.; Xu, W.; Wang, C. An optimal method on automobile mass customization delivery period based on customer behavior prediction. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Psarommatis, F.; Giannoulis, C.; Michalos, G. A web-based platform for mass customisation and personalisation. CIRP J. Manuf. Sci. Technol. 2014, 7, 112–128. [Google Scholar] [CrossRef]

- Saldivar, A.A.F.; Goh, C.; Li, Y.; Chen, Y.; Yu, H. Identifying smart design attributes for Industry 4.0 customization using a clustering Genetic Algorithm. In Proceedings of the 2016 22nd International Conference on Automation and Computing (ICAC), Colchester, UK, 7–8 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 408–414. [Google Scholar] [CrossRef]

- Yoo, J.; Park, M. The effects of e-mass customization on consumer perceived value, satisfaction, and loyalty toward luxury brands. J. Bus. Res. 2016, 69, 5775–5784. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Vandera, C. Smart mobile apps for supporting product design and decision-making in the era of mass customisation. Int. J. Comput. Integr. Manuf. 2017, 30, 690–707. [Google Scholar] [CrossRef]

- Loef, J.; Pine Ii, B.J.; Robben, H. Co-creating customization: Collaborating with customers to deliver individualized value. Strategy Leadersh. 2017, 45, 10–15. [Google Scholar] [CrossRef]

- Tangchaiburana, S.; Techametheekul, K.W. Development model of web design element for clothing e-commerce based on the concept of mass customization. Kasetsart J. Soc. Sci. 2017, 38, 242–250. [Google Scholar] [CrossRef]

- Suzić, N.; Forza, C.; Trentin, A.; Anišić, Z. Implementation guidelines for mass customization: Current characteristics and suggestions for improvement. Prod. Plan. Control 2018, 29, 856–871. [Google Scholar] [CrossRef]

- Castiglione, C.; Alfieri, A.; Pastore, E. Decision Support System to balance inventory in customer-driven demand. IFAC-PapersOnLine 2018, 51, 1499–1504. [Google Scholar] [CrossRef]

- Jost, P.-J.; Süsser, T. Company-customer interaction in mass customization. Int. J. Prod. Econ. 2020, 220, 107454. [Google Scholar] [CrossRef]

- Yan, Y.; Gupta, S.; Schoefer, K.; Licsandru, T. A Review of E-mass Customization as a Branding Strategy. Corp. Reput. Rev. 2020, 23, 215–223. [Google Scholar] [CrossRef]

- Alfieri, A.; Castiglione, C.; Pastore, E. A multi-objective tabu search algorithm for product portfolio selection: A case study in the automotive industry. Comput. Ind. Eng. 2020, 142, 106382. [Google Scholar] [CrossRef]

- Pallant, J.L.; Sands, S.; Karpen, I.O. The 4Cs of mass customization in service industries: A customer lens. J. Serv. Mark. 2020, 34, 499–511. [Google Scholar] [CrossRef]

- Ciccarelli, M.; Papetti, A.; Senesi, P.; Lonzi, B.; Germani, M. User-Centered Design of Co-design Experience Based on X-Reality and Virtual Simulation. In Proceedings of the International Conference of the Italian Association of Design Methods and Tools for Industrial Engineering, Palermo, Italy, 11–13 September 2024; Springer Nature: Cham, Switzerland, 2023; pp. 538–545. [Google Scholar]

- Powell, C.; Yang, S. Decision support tools for product customisation: An in-depth review. Int. J. Manuf. Res. 2024, 19, 62–97. [Google Scholar] [CrossRef]

- Qu, T.; Bin, S.; Huang, G.Q.; Yang, H.D. Two-stage product platform development for mass customisation. Int. J. Prod. Res. 2011, 49, 2197–2219. [Google Scholar] [CrossRef]

- Yetis, H.; Karakose, M. A Data-Driven Method for Decision Support Systems in Mass Production and Mass Customization. In Proceedings of the 2018 International Conference on Artificial Intelligence and Data Processing (IDAP), Malatya, Turkey, 28–30 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Anzanello, M.J.; Fogliatto, F.S. Selecting the best clustering variables for grouping mass-customized products involving workers’ learning. Int. J. Prod. Econ. 2011, 130, 268–276. [Google Scholar] [CrossRef]

- Chowdhury, S.; Messac, A.; Khire, R.A. Comprehensive Product Platform Planning (CP3) Framework. J. Mech. Des. 2011, 133, 101004. [Google Scholar] [CrossRef]

- Daaboul, J.; Da Cunha, C.; Bernard, A.; Laroche, F. Design for mass customization: Product variety vs. process variety. CIRP Ann. 2011, 60, 169–174. [Google Scholar] [CrossRef]

- Rojas Arciniegas, A.J.; Kim, H.M. Optimal component sharing in a product family by simultaneous consideration of minimum description length and impact metric. Eng. Optim. 2011, 43, 175–192. [Google Scholar] [CrossRef]

- Sköld, M.; Karlsson, C. Product platform replacements: Challenges to managers. Int. J. Oper. Prod. Manag. 2012, 32, 746–766. [Google Scholar] [CrossRef]

- AlGeddawy, T.; ElMaraghy, H. Reactive design methodology for product family platforms, modularity and parts integration. CIRP J. Manuf. Sci. Technol. 2013, 6, 34–43. [Google Scholar] [CrossRef]

- Liao, K.; Deng, X.; Marsillac, E. Factors that influence Chinese automotive suppliers’ mass customization capabilities. Int. J. Prod. Econ. 2013, 146, 25–36. [Google Scholar] [CrossRef]

- Agrawal, T.; Sao, A.; Fernandes, K.J.; Tiwari, M.K.; Kim, D.Y. A hybrid model of component sharing and platform modularity for optimal product family design. Int. J. Prod. Res. 2013, 51, 614–625. [Google Scholar] [CrossRef]

- Magnusson, M.; Pasche, M. A Contingency-Based Approach to the Use of Product Platforms and Modules in New Product Development. J. Prod. Innov. Manag. 2014, 31, 434–450. [Google Scholar] [CrossRef]

- Simpson, T.W.; Jiao, R.J.; Siddique, Z.; Hölttä-Otto, K. Product Family and Product Platform Design: Looking Forward. In Advances in Product Family and Product Platform Design; Springer: New York, NY, USA, 2014; pp. 777–787. [Google Scholar]

- Kim, S.H. Postponement for designing mass-customized supply chains: Categorization and framework for strategic decision making. Int. J. Supply Chain. Manag. 2014, 3, 1–11. [Google Scholar]

- Gawer, A.; Cusumano, M.A. Industry Platforms and Ecosystem Innovation. J. Prod. Innov. Manag. 2014, 31, 417–433. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, K.D. Product Form Design for Mass Customization. Adv. Mater. Res. 2014, 971–973, 1416–1419. [Google Scholar] [CrossRef]

- Fan, B.; Qi, G.; Hu, X.; Yu, T. A network methodology for structure-oriented modular product platform planning. J. Intell. Manuf. 2015, 26, 553–570. [Google Scholar] [CrossRef]

- Hanafy, M.; ElMaraghy, H. A modular product multi-platform configuration model. Int. J. Comput. Integr. Manuf. 2015, 28, 999–1014. [Google Scholar] [CrossRef]

- Hanafy, M.; ElMaraghy, H. Developing assembly line layout for delayed product differentiation using phylogenetic networks. Int. J. Prod. Res. 2015, 53, 2633–2651. [Google Scholar] [CrossRef]

- Levandowski, C.E.; Jiao, J.R.; Johannesson, H. A two-stage model of adaptable product platform for engineering-to-order configuration design. J. Eng. Des. 2015, 26, 220–235. [Google Scholar] [CrossRef]

- Shaik, A.M.; Rao, V.V.S.K.; Rao, C.S. Development of modular manufacturing systems—A review. Int. J. Adv. Manuf. Technol. 2015, 76, 789–802. [Google Scholar] [CrossRef]

- Van Den Broeke, M.; Boute, R.; Samii, B. Evaluation of product-platform decisions based on total supply chain costs. Int. J. Prod. Res. 2015, 53, 5545–5563. [Google Scholar] [CrossRef]

- Ang, J.H.; Goh, C.; Li, Y. Smart design for ships in a smart product through-life and industry 4.0 environment. In Proceedings of the 2016 IEEE Congress on Evolutionary Computation (CEC), Vancouver, BC, Canada, 24–29 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 5301–5308. [Google Scholar] [CrossRef]

- Bonvoisin, J.; Halstenberg, F.; Buchert, T.; Stark, R. A systematic literature review on modular product design. J. Eng. Des. 2016, 27, 488–514. [Google Scholar] [CrossRef]

- Facin, A.L.F.; De Vasconcelos Gomes, L.A.; De Mesquita Spinola, M.; Salerno, M.S. The Evolution of the Platform Concept: A Systematic Review. IEEE Trans. Eng. Manag. 2016, 63, 475–488. [Google Scholar] [CrossRef]

- Hanafy, M.; ElMaraghy, H. Modular product platform configuration and co-planning of assembly lines using assembly and disassembly. J. Manuf. Syst. 2017, 42, 289–305. [Google Scholar] [CrossRef]

- Johannesson, H.; Landahl, J.; Levandowski, C.; Raudberget, D. Development of product platforms: Theory and methodology. Concurr. Eng. 2017, 25, 195–211. [Google Scholar] [CrossRef]

- Srinivasan, R.; Giannikas, V.; McFarlane, D.; Ahmed, M. Customisation in Manufacturing: The Use of 3D Printing. In Service Orientation in Holonic and Multi-Agent Manufacturing, Studies in Computational Intelligence; Borangiu, T., Trentesaux, D., Thomas, A., Leitão, P., Oliveira, J.B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 215–223. [Google Scholar] [CrossRef]

- Moussa, M.; ElMaraghy, H. Multiple platforms design and product family process planning for combined additive and subtractive manufacturing. J. Manuf. Syst. 2021, 61, 509–529. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Kumar Mahla, S.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Yuan, P.F.; Beh, H.S.; Yang, X.; Zhang, L.; Gao, T. Feasibility study of large-scale mass customization 3D printing framework system with a case study on Nanjing Happy Valley East Gate. Front. Archit. Res. 2022, 11, 670–680. [Google Scholar] [CrossRef]

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.L.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and application of machine learning for additive manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Bortolini, M.; Calabrese, F.; Galizia, F.G.; Regattieri, A. A two-step methodology for product platform design and assessment in high-variety manufacturing. Int. J. Adv. Manuf. Technol. 2023, 126, 3923–3948. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Naldi, L.D. A Preliminary Model for Delayed Product Differentiation Towards Mass Customization. In Sustainable Design and Manufacturing, Smart Innovation, Systems and Technologies; Scholz, S.G., Howlett, R.J., Setchi, R., Eds.; Springer: Singapore, 2023; pp. 322–330. [Google Scholar] [CrossRef]

- Siiskonen, M.; Govender, R.; Malmqvist, J.; Folestad, S. Modelling the cost-benefit impact of integrated product modularisation and postponement in the supply chain for pharmaceutical mass customisation. J. Eng. Des. 2023, 34, 865–896. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Naldi, L.D.; Regattieri, A. Managing Mass Customization through Delayed Product Differentiation: A bi-objective model for product platforms design. Procedia CIRP 2024, 130, 1250–1255. [Google Scholar] [CrossRef]

- Bortolini, M.; Cafarella, C.; Galizia, F.G.; Gamberi, M.; Naldi, L.D. A Clustering-Based Algorithm for Product Platform Design in the Mass Customization Era. In Sustainable Design and Manufacturing 2023. SDM 2023; Scholz, S.G., Howlett, R.J., Setchi, R., Eds.; Smart Innovation, Systems and Technologies; Springer: Singapore, 2024; Volume 377. [Google Scholar] [CrossRef]

- Louth, H.D.; Fragachan, C.; Bhooshan, V.; Bhooshan, S. Configurator: A Platform for Multifamily Residential Design and Customisation. In Architecture and Design for Industry 4.0; Barberio, M., Colella, M., Figliola, A., Battisti, A., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, L. Modular design of new products and remanufacturing of used products under mass customization. RAIRO-Oper. Res. 2023, 58, 103–128. [Google Scholar] [CrossRef]

- Meyer, M.; Lehnerd, A.P. The Power of Product Platform—Building Value and Cost Leadship; Free Press: New York, NY, USA, 1997. [Google Scholar]

- Haddou Benderbal, H.; Dahane, M.; Benyoucef, L. Modularity assessment in reconfigurable manufacturing system (RMS) design: An Archived Multi-Objective Simulated Annealing-based approach. Int. J. Adv. Manuf. Technol. 2018, 94, 729–749. [Google Scholar] [CrossRef]

- Baheti, R.; Gill, H. Cyber-physical systems. Impact Control Technol. 2011, 12, 161–166. [Google Scholar]

- Hu, S.J.; Ko, J.; Weyand, L.; ElMaraghy, H.A.; Lien, T.K.; Koren, Y.; Bley, H.; Chryssolouris, G.; Nasr, N.; Shpitalni, M. Assembly system design and operations for product variety. CIRP Ann. 2011, 60, 715–733. [Google Scholar] [CrossRef]

- Xia, F.; Yang, L.T.; Wang, L.; Vinel, A. Internet of Things. Int. J. Commun. Syst. 2012, 25, 1101–1102. [Google Scholar] [CrossRef]

- Lenart, B.; Grzybowska, K.; Cimer, M. Adaptive Inventory Control in Production Systems, Hybrid Artificial Intelligent Systems. In Hybrid Artificial Intelligent Systems; Corchado, E., Snášel, V., Abraham, A., Woźniak, M., Graña, M., Cho, S.B., Eds.; Part II; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7209, pp. 222–228. [Google Scholar]

- Müller, R.; Esser, M.; Vette, M. Reconfigurable handling systems as an enabler for large components in mass customized production. J. Intell. Manuf. 2013, 24, 977–990. [Google Scholar] [CrossRef]

- Bryan, A.; Wang, H.; Abell, J. Concurrent Design of Product Families and Reconfigurable Assembly Systems. J. Mech. Des. 2013, 135, 051001. [Google Scholar] [CrossRef]

- Greschke, P.; Schönemann, M.; Thiede, S.; Herrmann, C. Matrix Structures for High Volumes and Flexibility in Production Systems. Procedia CIRP 2014, 17, 160–165. [Google Scholar] [CrossRef]

- Taphorn, C. Factors for a decentralized production and sequence planning from the perspective of products and resources. In Proceedings of the 24th International Conference on Flexible Automation & Intelligent Manufacturing, San Antonio, TX, USA, 20–23 May 2014; DEStech Publications, Inc.: Lancaster, PA, USA, 2014; pp. 1057–1063. [Google Scholar] [CrossRef]

- Shi, Y. The Planning System Based on the Postponement Manufacturing Theory. Appl. Mech. Mater. 2014, 571–572, 1195–1201. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, L.; Zhao, X.; Zhou, W. Modularity in building mass customization capability: The mediating effects of customization knowledge utilization and business process improvement. Technovation 2014, 34, 678–687. [Google Scholar] [CrossRef]

- Durkop, L.; Trsek, H.; Otto, J.; Jasperneite, J. A field level architecture for reconfigurable real-time automation systems. In Proceedings of the 2014 10th IEEE Workshop on Factory Communication Systems (WFCS 2014), Toulouse, France, 5–7 May 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–10. [Google Scholar] [CrossRef]

- Yu, C.; Xu, X.; Lu, Y. Computer-Integrated Manufacturing, Cyber-Physical Systems and Cloud Manufacturing—Concepts and relationships. Manuf. Lett. 2015, 6, 5–9. [Google Scholar] [CrossRef]

- Fatemi Moghaddam, F.; Ahmadi, M.; Sarvari, S.; Eslami, M.; Golkar, A. Cloud computing challenges and opportunities: A survey. In Proceedings of the 1st International Conference on Telematics and Future-Generation Networks (TAFGEN), Kuala Lumpur, Malaysia, 26–28 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 34–38. [Google Scholar] [CrossRef]

- Pedersen, M.R.; Nalpantidis, L.; Andersen, R.S.; Schou, C.; Bøgh, S.; Krüger, V.; Madsen, O. Robot skills for manufacturing: From concept to industrial deployment. Robot. Comput.-Integr. Manuf. 2016, 37, 282–291. [Google Scholar] [CrossRef]

- Mesa, J.; Maury, H.; Arrieta, R.; Bula, A.; Riba, C. Characterization of modular architecture principles towards reconfiguration: A first approach in its selection process. Int. J. Adv. Manuf. Technol. 2015, 80, 221–232. [Google Scholar] [CrossRef]

- Kumar, R.; Haleem, A.; Garg, S.K.; Singh, R.K. Automated guided vehicle configurations in flexible manufacturing systems: A comparative study. Int. J. Ind. Syst. Eng. 2015, 21, 207. [Google Scholar] [CrossRef]

- Michniewicz, J.; Reinhart, G.; Boschert, S. CAD-Based Automated Assembly Planning for Variable Products in Modular Production Systems. Procedia CIRP 2016, 44, 44–49. [Google Scholar] [CrossRef]

- Müller, R.; Vette, M.; Scholer, M. Robot Workmate: A Trustworthy Coworker for the Continuous Automotive Assembly Line and its Implementation. Procedia CIRP 2016, 44, 263–268. [Google Scholar] [CrossRef]

- Brettel, M.; Klein, M.; Friederichsen, N. The Relevance of Manufacturing Flexibility in the Context of Industrie 4.0. Procedia CIRP 2016, 41, 105–110. [Google Scholar] [CrossRef]

- Scholer, M.; Müller, R. Modular configuration and control concept for the implementation of human-robot-cooperation in the automotive assembly line. IFAC-PapersOnLine 2017, 50, 5694–5699. [Google Scholar] [CrossRef]

- Brunoe, T.D.; Andersen, A.-L.; Nielsen, K. Reconfigurable Manufacturing Systems in Small and Medium Enterprises. In Managing Complexity; Bellemare, J., Carrier, S., Nielsen, K., Piller, F.T., Eds.; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2017; pp. 205–213. [Google Scholar] [CrossRef]

- Farid, A.M. Measures of reconfigurability and its key characteristics in intelligent manufacturing systems. J. Intell. Manuf. 2017, 28, 353–369. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Kokuryo, D.; Kaihara, T.; Kuik, S.S.; Suginouchi, S.; Hirai, K. Graduate school of System Informatics, Kobe University, Value Co-Creative Manufacturing with IoT-Based Smart Factory for Mass Customization. Int. J. Automation Technol. 2017, 11, 509–518. [Google Scholar] [CrossRef]

- Sun, H.; Fan, S. Car sequencing for mixed-model assembly lines with consideration of changeover complexity. J. Manuf. Syst. 2018, 46, 93–102. [Google Scholar] [CrossRef]

- Gania, I.P.; Stachowiak, A.; Oleśków-Szłapka, J. Flexible manufacturing systems: Industry 4.0 solution. Idea 2018, 10, 7–11. [Google Scholar] [CrossRef]

- Mishra, A.; Sainul, I.A.; Bhuyan, S.; Deb, S.; Sen, D.; Deb, A.K. Development of a Flexible Assembly System Using Industrial Robot with Machine Vision Guidance and Dexterous Multi-finger Gripper. In Precision Product-Process Design and Optimization; Pande, S.S., Dixit, U.S., Eds.; Lecture Notes on Multidisciplinary Industrial Engineering; Springer: Singapore, 2018; pp. 31–71. [Google Scholar] [CrossRef]

- Bihi, T.; Luwes, N.; Kusakana, K. Innovative Quality Management System for Flexible Manufacturing Systems. In Proceedings of the 2018 Open Innovations Conference (OI), Johannesburg, South Africa, 3–5 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 40–46. [Google Scholar] [CrossRef]

- Mourtzis, D.; Zogopoulos, V.; Xanthi, F. Augmented reality application to support the assembly of highly customized products and to adapt to production re-scheduling. Int. J. Adv. Manuf. Technol. 2019, 105, 3899–3910. [Google Scholar] [CrossRef]

- Thramboulidis, K.; Vachtsevanou, D.C.; Kontou, I. CPuS-IoT: A cyber-physical microservice and IoT-based framework for manufacturing assembly systems. Annu. Rev. Control 2019, 47, 237–248. [Google Scholar] [CrossRef]

- Díaz-Reza, J.R.; Mendoza-Fong, J.R.; Blanco-Fernández, J.; Marmolejo-Saucedo, J.A.; García-Alcaraz, J.L. The Role of Advanced Manufacturing Technologies in Production Process Performance: A Causal Model. Appl. Sci. 2019, 9, 3741. [Google Scholar] [CrossRef]

- Outón, J.L.; Villaverde, I.; Herrero, H.; Esnaola, U.; Sierra, B. Innovative Mobile Manipulator Solution for Modern Flexible Manufacturing Processes. Sensors 2019, 19, 5414. [Google Scholar] [CrossRef]

- Van De Ginste, L.V.; Goos, J.; Schamp, M.; Claeys, A.; Hoedt, S.; Bauters, K.; Biondi, A.; Aghezzaf, E.-H.; Cottyn, J. Defining Flexibility of Assembly Workstations Through the Underlying Dimensions and Impacting Drivers. Procedia Manuf. 2019, 39, 974–982. [Google Scholar] [CrossRef]

- Cohen, Y.; Naseraldin, H.; Chaudhuri, A.; Pilati, F. Assembly systems in Industry 4.0 era: A road map to understand Assembly 4.0. Int. J. Adv. Manuf. Technol. 2019, 105, 4037–4054. [Google Scholar] [CrossRef]

- Bortolini, M.; Botti, L.; Galizia, F.G.; Mora, C. Safety, Ergonomics and Human Factors in Reconfigurable Manufacturing Systems. In Reconfigurable Manufacturing Systems: From Design to Implementation; Benyoucef, L., Ed.; Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2020; pp. 123–138. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, X.; Xu, Y.; Chen, Y. A flexible planning methodology for product family assembly line based on improved NSGA_II. Assem. Autom. 2020, 40, 625–639. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Park, J.-W.; Baek, S.; Park, K.-B.; Kim, H.-R.; Park, J.-I.; Kim, H.-S.; Kim, B.-B.; Oh, H.-Y.; Namgung, K.; et al. A modular factory testbed for the rapid reconfiguration of manufacturing systems. J. Intell. Manuf. 2020, 31, 661–680. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Lu, Y.; Aristizabal, M.; Pablo Velásquez, J.; Joa, B.; Valencia, Y. IoT-enabled smart appliances under industry 4.0: A case study. Adv. Eng. Inform. 2020, 43, 101043. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Campos Sabioni, R.; Daaboul, J.; Le Duigou, J. An integrated approach to optimize the configuration of mass-customized products and reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2021, 115, 141–163. [Google Scholar] [CrossRef]

- Ronzoni, M.; Accorsi, R.; Botti, L.; Manzini, R. A support-design framework for Cooperative Robots systems in labor-intensive manufacturing processes. J. Manuf. Syst. 2021, 61, 646–657. [Google Scholar] [CrossRef]

- He, Y.; Smith, M. FMS Scheduling Integration for Mass Customization. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Dolgui, A., Bernard, A., Lemoine, D., Von Cieminski, G., Romero, D., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2021; pp. 507–515. [Google Scholar] [CrossRef]

- Martinez, S.; Mariño, A.; Sanchez, S.; Montes, A.M.; Triana, J.M.; Barbieri, G.; Abolghasem, S.; Vera, J.; Guevara, M. A Digital Twin Demonstrator to enable flexible manufacturing with robotics: A process supervision case study. Prod. Manuf. Res. 2021, 9, 140–156. [Google Scholar] [CrossRef]

- Gao, S.; Daaboul, J.; Le Duigou, J. Process Planning, Scheduling, and Layout Optimization for Multi-Unit Mass-Customized Products in Sustainable Reconfigurable Manufacturing System. Sustainability 2021, 13, 13323. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 smart reconfigurable manufacturing machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Campos Sabioni, R.; Daaboul, J.; Le Duigou, J. Joint optimization of product configuration and process planning in Reconfigurable Manufacturing Systems. Int. J. Ind. Eng. Manag. 2022, 13, 58–75. [Google Scholar] [CrossRef]

- Campos Sabioni, R.; Daaboul, J.; Le Duigou, J. Concurrent optimisation of modular product and Reconfigurable Manufacturing System configuration: A customer-oriented offer for mass customisation. Int. J. Prod. Res. 2022, 60, 2275–2291. [Google Scholar] [CrossRef]

- Dolgui, A.; Sgarbossa, F.; Simonetto, M. Design and management of assembly systems 4.0: Systematic literature review and research agenda. Int. J. Prod. Res. 2022, 60, 184–210. [Google Scholar] [CrossRef]

- Raffik, R.; Sathya, R.R.; Vaishali, V.; Balavedhaa, S. Industry 5.0: Enhancing human-robot collaboration through collaborative robots–A review. In Proceedings of the 2023 2nd International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 16–17 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Yaqub, M.Z.; Alsabban, A. Industry-4.0-enabled digital transformation: Prospects, instruments, challenges, and implications for business strategies. Sustainability 2023, 15, 8553. [Google Scholar] [CrossRef]

- Emiliani, F.; Costa, D.; Palmieri, G.; Polucci, D.; Bajrami, A.; Leoni, C. Collaborative robots in industrial manufacturing: A case study of tolerated assembly. In Proceedings of the 2024 20th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Genova, Italy, 2–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar]

- Patalas-Maliszewska, J.; Kowalczewska, K.; Rehm, M.; Schlegel, H.; Pajak, G. Managing Production for Mass Customized Manufacturing—Case Studies. In Intelligent Systems in Production Engineering and Maintenance III. ISPEM 2023; Burduk, A., Batako, A.D.L., Machado, J., Wyczółkowski, R., Dostatni, E., Rojek, I., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Krot, K.; Mazgajczyk, E.; Rusińska, M.; Woźna, A. Strategy of improving skills of innovation managers in the area of advanced manufacturing technologies. In Proceedings of the Intelligent Systems in Production Engineering and Maintenance, Wrocław, Poland, 17–18 September 2019; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Yang, Q.; Geng, R.; Feng, T.; Li, T. Impacts of supply chain integration on product- and service- oriented mass customisation capability: The role of customer need. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 354–377. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D. A literature review of decision-making models and approaches for partner selection in agile supply chains. J. Purch. Supply Manag. 2011, 17, 256–274. [Google Scholar] [CrossRef]

- Liu, G.; Deitz, G.D. Linking supply chain management with mass customization capability. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 668–683. [Google Scholar] [CrossRef]

- Trentin, A.; Forza, C.; Perin, E. Organisation design strategies for mass customisation: An information-processing-view perspective. Int. J. Prod. Res. 2012, 50, 3860–3877. [Google Scholar] [CrossRef]

- Baud-Lavigne, B.; Agard, B.; Penz, B. Mutual impacts of product standardization and supply chain design. Int. J. Prod. Econ. 2012, 135, 50–60. [Google Scholar] [CrossRef]

- Lai, F.; Zhang, M.; Lee, D.M.S.; Zhao, X. The Impact of Supply Chain Integration on Mass Customization Capability: An Extended Resource-Based View. IEEE Trans. Eng. Manag. 2012, 59, 443–456. [Google Scholar] [CrossRef]

- Nepal, B.; Monplaisir, L.; Famuyiwa, O. Matching product architecture with supply chain design. Eur. J. Oper. Res. 2012, 216, 312–325. [Google Scholar] [CrossRef]

- Shahzad, K.M.; Hadj-Hamou, K. Integrated supply chain and product family architecture under highly customized demand. J. Intell. Manuf. 2013, 24, 1005–1018. [Google Scholar] [CrossRef]

- Shao, X.-F. Integrated Product and Channel Decision in Mass Customization. IEEE Trans. Eng. Manag. 2013, 60, 30–45. [Google Scholar] [CrossRef]

- Vickery, S.K.; Koufteros, X.; Droge, C. Does Product Platform Strategy Mediate the Effects of Supply Chain Integration on Performance? A Dynamic Capabilities Perspective. IEEE Trans. Eng. Manag. 2013, 60, 750–762. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Psarommatis, F. Design and operation of manufacturing networks for mass customisation. CIRP Ann. 2013, 62, 467–470. [Google Scholar] [CrossRef]

- Nielsen, K.; Brunø, T.D. Closed Loop Supply Chains for Sustainable Mass Customization. In Advances in Production Management Systems. Sustainable Production and Service Supply Chains; Prabhu, V., Taisch, M., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 425–432. [Google Scholar] [CrossRef]

- Boysen, N.; Emde, S.; Hoeck, M.; Kauderer, M. Part logistics in the automotive industry: Decision problems, literature review and research agenda. Eur. J. Oper. Res. 2015, 242, 107–120. [Google Scholar] [CrossRef]

- Doukas, M.; Psarommatis, F.; Mourtzis, D. Planning of manufacturing networks using an intelligent probabilistic approach for mass customised products. Int. J. Adv. Manuf. Technol. 2014, 74, 1747–1758. [Google Scholar] [CrossRef]

- Laurent Lim, L.; Alpan, G.; Penz, B. Reconciling sales and operations management with distant suppliers in the automotive industry: A simulation approach. Int. J. Prod. Econ. 2014, 151, 20–36. [Google Scholar] [CrossRef]

- Yinan, Q.; Tang, M.; Zhang, M. Mass Customization in Flat Organization: The Mediating Role of Supply Chain Planning and Corporation Coordination. J. Appl. Res. Technol. 2014, 12, 171–181. [Google Scholar] [CrossRef]

- Saghiri, S.; Hill, A. Supplier relationship impacts on postponement strategies. Int. J. Prod. Res. 2014, 52, 2134–2153. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Psarommatis, F. Design of manufacturing networks for mass customisation using an intelligent search method. Int. J. Comput. Integr. Manuf. 2015, 28, 679–700. [Google Scholar] [CrossRef]

- Huo, B.; Qi, Y.; Wang, Z.; Zhao, X. The impact of supply chain integration on firm performance: The moderating role of competitive strategy. Supply Chain. Manag. Int. J. 2014, 19, 369–384. [Google Scholar] [CrossRef]

- Pashaei, S.; Olhager, J. Product architecture and supply chain design: A systematic review and research agenda. Supply Chain. Manag. Int. J. 2015, 20, 98–112. [Google Scholar] [CrossRef]

- Gaber, Y.H.; Abdelsalam, H.M. A multi-objective optimization algorithm for the integrated product line selection and supply chain configuration problem with quality considerations. In Proceedings of the 2015 IEEE International Conference on Service Operations And Logistics, And Informatics (SOLI), Yasmine Hammamet, Tunisia, 15–17 November 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 165–170. [Google Scholar]

- Hussien, R.R.; Abdelsalam, H.M. Joint Supplier Selection and Product Family Optimization in Supply Chain Design: A Literature Review. Int. J. Comput. Sci. Issues 2015, 12, 200. [Google Scholar]

- Khan, A.; Haasis, H.-D. Producer–buyer interaction under mass customization: Analysis through automotive industry. Logist. Res. 2016, 9, 17. [Google Scholar] [CrossRef][Green Version]

- Simão, L.E.; Gonçalves, M.B.; Taboada Rodriguez, C.M. An approach to assess logistics and ecological supply chain performance using postponement strategies. Ecol. Indic. 2016, 63, 398–408. [Google Scholar] [CrossRef]

- Shou, Y.; Li, Y.; Park, Y.W.; Kang, M. The impact of product complexity and variety on supply chain integration. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 297–317. [Google Scholar] [CrossRef]

- Xiong, Y.; Du, G.; Jiao, R.J. Modular product platforming with supply chain postponement decisions by leader-follower interactive optimization. Int. J. Prod. Econ. 2018, 205, 272–286. [Google Scholar] [CrossRef]

- Yu, Y.; Huo, B. Supply chain quality integration: Relational antecedents and operational consequences. Supply Chain. Manag. 2018, 23, 188–206. [Google Scholar] [CrossRef]

- Guo, S.; Choi, T.-M.; Shen, B.; Jung, S. Inventory Management in Mass Customization Operations: A Review. IEEE Trans. Eng. Manag. 2019, 66, 412–428. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, H.; Huo, B.; Zhao, X.; Huang, J. Linking supply chain quality integration with mass customization and product modularity. Int. J. Prod. Econ. 2019, 207, 227–235. [Google Scholar] [CrossRef]

- Budiman, S.D.; Rau, H. A mixed-integer model for the implementation of postponement strategies in the globalized green supply chain network. Comput. Ind. Eng. 2019, 137, 106054. [Google Scholar] [CrossRef]

- Weskamp, C.; Koberstein, A.; Schwartz, F.; Suhl, L.; Voß, S. A two-stage stochastic programming approach for identifying optimal postponement strategies in supply chains with uncertain demand. Omega 2019, 83, 123–138. [Google Scholar] [CrossRef]

- Aeknarajindawat, N.; Chancharoen, S. Product Modularity, Mass Customization Supply Chain Quality Integration and the Competitive Performance of Textile and Appraisal Sector of Indonesia: The Role of Open Book Accounting. Int. J. Supply Chain. Manag. 2019, 8, 467–478. [Google Scholar]

- Issa, M.; Elgholmy, S.; Sheta, A.; Fors, M.N. A System Dynamics Model of Apparel Supply Chain Under Mass Customization. In Proceedings of the 4th North American International Conference on Industrial Engineering and Operations Management, Toronto, ON, Canada, 25–27 October 2019. [Google Scholar]

- He, Y.; Smith, M.L. Investigation of scheduling integration of flexible manufacturing systems for mass customisation. Int. J. Prod. Res. 2024, 62, 2060–2082. [Google Scholar] [CrossRef]

- Van Hoek, R.I. The rediscovery of postponement a literature review and directions for research. J. Oper. Manag. 2001, 19, 161–184. [Google Scholar] [CrossRef]

- Li, S.; Ragu-Nathan, B.; Ragu-Nathan, T.S.; Rao, S.S. The impact of supply chain management practices on competitive advantage and organizational performance. Omega 2006, 34, 107–124. [Google Scholar] [CrossRef]

| Author(s) | Year | Personalization Approach | Implementation Context | Performance Evaluation Metrics | Sustainability-Oriented MC |

|---|---|---|---|---|---|

| [29] | 2011 | ✓ | |||

| [31] | 2011 | ✓ | |||

| [32] | 2011 | ✓ | |||

| [11] | 2012 | ✓ | |||

| [33] | 2012 | ✓ | |||

| [34] | 2012a | ✓ | |||

| [35] | 2012b | ✓ | |||

| [36] | 2012 | ✓ | |||

| [37] | 2012 | ✓ | |||

| [38] | 2013 | ✓ | |||

| [39] | 2013 | ✓ | |||

| [1] | 2013 | ✓ | |||

| [20] | 2013 | ✓ | |||

| [40] | 2013 | ✓ | |||

| [41] | 2013 | ✓ | |||

| [42] | 2013 | ✓ | |||

| [43] | 2013a | ✓ | |||

| [44] | 2013 | ✓ | |||

| [27] | 2014 | ✓ | |||

| [45] | 2014 | ✓ | |||

| [46] | 2014 | ✓ | |||

| [47] | 2014 | ✓ | |||

| [48] | 2014 | ✓ | |||

| [49] | 2014 | ✓ | |||

| [50] | 2014 | ✓ | |||

| [51] | 2015 | ✓ | |||

| [52] | 2015 | ✓ | |||

| [53] | 2015 | ✓ | ✓ | ||

| [54] | 2015 | ✓ | |||

| [55] | 2015 | ✓ | |||

| [56] | 2015 | ✓ | |||

| [57] | 2016 | ✓ | |||

| [8] | 2015 | ✓ | |||

| [58] | 2016 | ✓ | |||

| [59] | 2016 | ✓ | |||

| [60] | 2017a | ✓ | |||

| [61] | 2017 | ✓ | |||

| [62] | 2017 | ✓ | |||

| [63] | 2017 | ✓ | |||

| [64] | 2017 | ✓ | |||

| [65] | 2017 | ✓ | |||

| [66] | 2017 | ✓ | |||

| [67] | 2017 | ✓ | |||

| [68] | 2018 | ✓ | |||

| [69] | 2018 | ✓ | |||

| [70] | 2018 | ✓ | |||

| [71] | 2018 | ✓ | |||

| [72] | 2019 | ✓ | |||

| [73] | 2019 | ✓ | |||

| [74] | 2019 | ✓ | ✓ | ||

| [75] | 2019 | ✓ | |||

| [76] | 2019 | ✓ | |||

| [77] | 2020 | ✓ | |||

| [78] | 2020 | ✓ | |||

| [79] | 2020 | ✓ | |||

| [80] | 2020 | ✓ | |||

| [81] | 2020 | ✓ | |||

| [82] | 2021 | ✓ | |||

| [83] | 2022 | ✓ | |||

| [84] | 2023 | ✓ | |||

| [85] | 2023 | ✓ | |||

| [86] | 2023 | ✓ | |||

| [87] | 2024 | ✓ | ✓ | ||

| 63 | 15 | 14 | 17 | 20 |

| Author(s) | Year | Customer Co-Design Mechanism | Decision Support Tools for Customers | I4.0 Technologies for Interaction | Customer Preference Prediction Models |

|---|---|---|---|---|---|

| [88] | 2011 | ✓ | |||

| [89] | 2012 | ✓ | |||

| [90] | 2013 | ✓ | ✓ | ||

| [91] | 2013 | ✓ | |||

| [92] | 2013 | ✓ | |||

| [93] | 2013 | ✓ | |||

| [94] | 2013 | ✓ | ✓ | ||

| [49] | 2014 | ✓ | |||

| [95] | 2014 | ✓ | |||

| [96] | 2014 | ✓ | |||

| [97] | 2016 | ✓ | ✓ | ||

| [98] | 2016 | ✓ | |||

| [57] | 2016 | ✓ | |||

| [99] | 2017b | ✓ | |||

| [100] | 2017 | ✓ | |||

| [101] | 2017 | ✓ | |||

| [63] | 2017 | ✓ | |||

| [102] | 2018 | ✓ | |||

| [103] | 2018 | ✓ | |||

| [104] | 2020 | ✓ | |||

| [105] | 2020 | ✓ | ✓ | ||

| [106] | 2020 | ✓ | |||

| [107] | 2020 | ✓ | |||

| [84] | 2023 | ✓ | |||

| [108] | 2024 | ✓ | ✓ | ||

| [109] | 2024 | ✓ | |||

| 26 | 9 | 5 | 11 | 6 |

| Author(s) | Year | Design of Product Platforms | Use of Modularity in Product Design | Product Family Architecture | Postponement Strategies in Design | Virtual Prototyping | Rapid Prototyping |

|---|---|---|---|---|---|---|---|

| [112] | 2011 | ✓ | ✓ | ||||

| [113] | 2011 | ✓ | ✓ | ✓ | |||

| [114] | 2011 | ✓ | ✓ | ✓ | |||

| [110] | 2011 | ✓ | ✓ | ✓ | |||

| [115] | 2011 | ✓ | ✓ | ✓ | |||

| [116] | 2012 | ✓ | |||||

| [88] | 2011 | ✓ | ✓ | ||||

| [117] | 2013 | ✓ | ✓ | ✓ | |||

| [118] | 2013 | ✓ | |||||

| [119] | 2013 | ✓ | ✓ | ✓ | |||

| [92] | 2013 | ✓ | ✓ | ||||

| [120] | 2014 | ✓ | ✓ | ||||

| [121] | 2014 | ✓ | ✓ | ✓ | |||

| [122] | 2014 | ✓ | |||||

| [123] | 2014 | ✓ | ✓ | ✓ | |||

| [124] | 2014 | ✓ | ✓ | ||||

| [125] | 2015 | ✓ | ✓ | ✓ | |||

| [126] | 2015a | ✓ | ✓ | ✓ | |||

| [127] | 2015b | ✓ | ✓ | ✓ | ✓ | ||

| [128] | 2015 | ✓ | ✓ | ||||

| [129] | 2015 | ✓ | |||||

| [130] | 2015 | ✓ | |||||

| [131] | 2016 | ✓ | |||||

| [132] | 2016 | ✓ | |||||

| [133] | 2016 | ✓ | |||||

| [14] | 2016 | ✓ | ✓ | ||||

| [134] | 2017 | ✓ | ✓ | ✓ | |||

| [135] | 2017 | ✓ | ✓ | ✓ | |||

| [136] | 2017 | ✓ | ✓ | ||||

| [102] | 2018 | ✓ | ✓ | ✓ | |||

| [111] | 2018 | ✓ | |||||

| [5] | 2020 | ✓ | ✓ | ✓ | |||

| [137] | 2021 | ✓ | ✓ | ||||

| [138] | 2021 | ✓ | |||||

| [139] | 2022 | ✓ | |||||

| [140] | 2022 | ✓ | |||||

| [141] | 2023a | ✓ | ✓ | ✓ | |||

| [142] | 2023b | ✓ | ✓ | ✓ | |||

| [143] | 2023 | ✓ | ✓ | ✓ | |||

| [144] | 2024a | ✓ | ✓ | ✓ | |||

| [145] | 2024b | ✓ | ✓ | ✓ | |||

| [108] | 2024 | ✓ | |||||

| [146] | 2024 | ✓ | ✓ | ✓ | |||

| [147] | 2024 | ✓ | ✓ | ||||

| 45 | 28 | 28 | 22 | 9 | 5 | 5 |

| Author(s) | Year | Process-Level Postponement Design | Manufacturing Modularity Practices | Advanced Manufacturing Technologies | Production Planning and Scheduling | Smart Technology (I4.0 Enablers) | Human-Robot Collaboration and Interface |

|---|---|---|---|---|---|---|---|

| [114] | 2011 | ✓ | |||||

| [88] | 2011 | ✓ | |||||

| [150] | 2011 | ✓ | |||||

| [151] | 2011 | ✓ | |||||

| [152] | 2012 | ✓ | |||||

| [153] | 2012 | ✓ | |||||

| [154] | 2013 | ✓ | |||||

| [118] | 2013 | ✓ | ✓ | ||||

| [155] | 2013 | ✓ | |||||

| [92] | 2013 | ✓ | |||||

| [156] | 2014 | ✓ | ✓ | ||||

| [157] | 2014 | ✓ | ✓ | ||||

| [122] | 2014 | ✓ | |||||

| [158] | 2014 | ✓ | |||||

| [159] | 2014 | ✓ | |||||

| [160] | 2014 | ✓ | |||||

| [129] | 2015 | ✓ | |||||

| [161] | 2015 | ✓ | ✓ | ||||

| [162] | 2015 | ✓ | |||||

| [163] | 2016 | ✓ | |||||

| [164] | 2015 | ✓ | |||||

| [165] | 2015 | ✓ | |||||

| [97] | 2016 | ✓ | |||||

| [14] | 2016 | ✓ | ✓ | ||||

| [166] | 2016 | ✓ | ✓ | ✓ | |||

| [167] | 2016 | ✓ | |||||

| [168] | 2016 | ✓ | |||||

| [134] | 2017 | ✓ | |||||

| [169] | 2017 | ✓ | |||||

| [23] | 2017 | ✓ | ✓ | ||||

| [149] | 2018 | ✓ | |||||

| [170] | 2017 | ✓ | |||||

| [171] | 2017 | ✓ | |||||

| [172] | 2017 | ✓ | |||||

| [173] | 2017 | ✓ | |||||

| [174] | 2018 | ✓ | |||||

| [102] | 2018 | ✓ | |||||

| [175] | 2018 | ✓ | |||||

| [176] | 2018 | ✓ | ✓ | ✓ | |||

| [177] | 2018 | ✓ | |||||

| [178] | 2019 | ✓ | ✓ | ||||

| [179] | 2019 | ✓ | ✓ | ||||

| [180] | 2019 | ✓ | |||||

| [181] | 2019 | ✓ | |||||

| [182] | 2019 | ✓ | ✓ | ||||

| [183] | 2019 | ✓ | |||||

| [184] | 2020 | ✓ | |||||

| [185] | 2020 | ✓ | |||||

| [186] | 2020 | ✓ | |||||

| [187] | 2020 | ✓ | |||||

| [188] | 2020 | ✓ | |||||

| [189] | 2021a | ✓ | |||||

| [190] | 2021 | ✓ | |||||

| [191] | 2021 | ✓ | |||||

| [192] | 2021 | ✓ | ✓ | ✓ | |||

| [193] | 2021 | ✓ | |||||

| [138] | 2021 | ✓ | |||||

| [194] | 2021 | ✓ | ✓ | ||||

| [195] | 2022 | ✓ | |||||

| [196] | 2022b | ✓ | |||||

| [197] | 2022 | ✓ | |||||

| [198] | 2023 | ✓ | ✓ | ✓ | |||

| [143] | 2023 | ✓ | ✓ | ||||

| [199] | 2023 | ✓ | |||||

| [200] | 2024 | ✓ | ✓ | ✓ | |||

| [201] | 2024 | ✓ | ✓ | ||||

| 66 | 6 | 6 | 30 | 16 | 18 | 12 |

| Author(s) | Year | Link Between Product Architecture and Supply chain | Supply Chain Postponement Strategies | Supplier Integration and Collaboration | End-to-End Process Integration | Supply Network Structure and Reconfigurability |

|---|---|---|---|---|---|---|

| [88] | 2011 | ✓ | ||||

| [204] | 2011 | ✓ | ||||

| [205] | 2011 | ✓ | ✓ | |||

| [206] | 2012 | ✓ | ✓ | |||

| [207] | 2012 | ✓ | ||||

| [208] | 2012 | ✓ | ✓ | |||

| [209] | 2012 | ✓ | ||||

| [118] | 2013 | ✓ | ✓ | |||

| [210] | 2013 | ✓ | ||||

| [211] | 2013 | ✓ | ||||

| [92] | 2013 | ✓ | ||||

| [212] | 2013 | ✓ | ✓ | ✓ | ||

| [213] | 2013 | ✓ | ||||

| [214] | 2013 | ✓ | ||||

| [215] | 2015 | ✓ | ||||

| [216] | 2014 | ✓ | ||||

| [217] | 2014 | ✓ | ||||

| [122] | 2014 | ✓ | ||||

| [158] | 2014 | ✓ | ||||

| [218] | 2014 | ✓ | ||||

| [219] | 2014 | ✓ | ✓ | |||

| [220] | 2015 | ✓ | ||||

| [221] | 2014 | ✓ | ||||

| [222] | 2015 | ✓ | ||||

| [130] | 2015 | ✓ | ||||

| [223] | 2015 | ✓ | ✓ | |||

| [224] | 2015 | ✓ | ||||

| [225] | 2016 | ✓ | ||||

| [226] | 2016 | ✓ | ||||

| [227] | 2017 | ✓ | ✓ | |||

| [228] | 2018 | ✓ | ✓ | |||

| [229] | 2018 | ✓ | ||||

| [230] | 2019 | ✓ | ||||

| [231] | 2019 | ✓ | ✓ | |||

| [232] | 2019 | ✓ | ||||

| [233] | 2019 | ✓ | ✓ | |||

| [234] | 2019 | ✓ | ||||

| [235] | 2019 | ✓ | ||||

| [203] | 2023 | ✓ | ||||

| [143] | 2023 | ✓ | ✓ | ✓ | ||

| [236] | 2024 | ✓ | ✓ | |||

| 41 | 9 | 10 | 13 | 11 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naldi, L.D.; Galizia, F.G.; Bortolini, M.; Gabellini, M.; Ferrari, E. Unlocking the Potential of Mass Customization Through Industry 4.0: Mapping Research Streams and Future Directions. Appl. Sci. 2025, 15, 7160. https://doi.org/10.3390/app15137160

Naldi LD, Galizia FG, Bortolini M, Gabellini M, Ferrari E. Unlocking the Potential of Mass Customization Through Industry 4.0: Mapping Research Streams and Future Directions. Applied Sciences. 2025; 15(13):7160. https://doi.org/10.3390/app15137160

Chicago/Turabian StyleNaldi, Ludovica Diletta, Francesco Gabriele Galizia, Marco Bortolini, Matteo Gabellini, and Emilio Ferrari. 2025. "Unlocking the Potential of Mass Customization Through Industry 4.0: Mapping Research Streams and Future Directions" Applied Sciences 15, no. 13: 7160. https://doi.org/10.3390/app15137160

APA StyleNaldi, L. D., Galizia, F. G., Bortolini, M., Gabellini, M., & Ferrari, E. (2025). Unlocking the Potential of Mass Customization Through Industry 4.0: Mapping Research Streams and Future Directions. Applied Sciences, 15(13), 7160. https://doi.org/10.3390/app15137160